Abstract

The term “biomaterial” refers to any material that is well-suited to biological environments. It has several properties that vary depending on the application; areas where properties such as loading and strength are important are dominated by metal-based biomaterials, while others where shear properties of the material are important are dominated by ceramic-based materials. Magnesium (Mg) is a lightweight metal that can be found in nature as salt. Because of their bioactivity and biocompatibility, Mg and Mg-based alloys have found application in biological environments in recent years, making them suitable for vascular and orthopedic applications. During the late 1800s, Mg metal was used to develop medical device but this was promptly halted because of the corrosion rate observed in Mg-based medical devices in a biological environment. As development in metal alloying processes, coating techniques, and surface treatment have advanced in the twentieth century, the option to revisit Mg as a suitable option for medical application has opened up. This article discusses how various authors use Mg and its alloys for biomedical applications. It also discusses how various authors aim to improve the compatibility of medical implants containing Mg. Polylactic acid, hydroxyapatite nanoparticles, polycaprolactone, bredigite (Ca7MgSi4O16), calcium, and other materials are used as reinforcement or matrix for Mg-containing medical devices.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Magnesium (Mg) metal is a major mineral in the human anatomy, it is estimated that about 50–65% of the bone tissue comprises of magnesium, magnesium is the second prevalent intracellular mineral and makes up 1% of the extracellular fluid [1, 2]. The commercialization of magnesium in the mid-nineteenth century paved the way for its application for medical devices. The first occurrence of magnesium in the medical device was as a wire ligature, Edward C. Huse used this device to impede bleeding during surgical applications in 1878 [3]. This opens the door for magnesium and its alloys to be applied for orthopedic, vascular, and general surgery. Erwin Payr stands out of the early pioneers, this was because of the numerous investigations into the application of magnesium as a biomaterial at the turn of the twentieth century [4]. Erwin developed materials such as thin tubes for anastomosis, plates for joint arthroplasty, pins, and nails for fracture fixation, pegs for intramedullary stabilization of long bones, plates and sheets for suturing organs after partial resection, and arrow-shaped implants for the treatment of hemangiomas, Erwin encountered varying levels of success of this device [4]. Nonorthopedic application of magnesium devices where arguably the most successful of all the devices Erwin created whereas, the treatment of hemangioma and the suturing of organs where less successful [4].

Tubes and ring plates, clips for vessel anastomosis [4], clips for gastrointestinal anastomosis [3], and tubes for ureterorectostomy [5] are other surgical application of magnesium which were recorded as successful. Note that the application of magnesium as the material of choice was suited for its properties where quick degradation time, the development of hydrogen gas bi-product would not influence the development of tissues negatively and the deteriorating mechanical properties would not be an issue. Whereas its application in the area of orthopedics as met with mixed reviews. The use of magnesium and another metal was recorded in the early twentieth century by Albin Lambotte. Lambotte attempted to fix a bone fracture (tibia and fibula) of a 17-year-old boy. Lambotte accomplished this by combining magnesium plate with steel screws; however, after the material was implanted, Lambotte discovered that it corroded due to the use of different metals [6]. With this discovery, Lambotte conducted additional experiments, this time with animals, and discovered that magnesium as a standalone implant corrodes gradually after 3 months and completely after 7 to 10 months [7]. Recognizing this, Lambotte conducted supplementary experiments on human subjects, this time using only Mg-based nails and studs to repair supracondylar humeral fractures in various children. This time, the implants performed well in biological environments, and the bone healed one year after surgery [4]. Albin Lambotte is widely regarded as the most successful researcher in the field of musculoskeletal applications of magnesium and its alloy [7]. Jean Verbrugge, Albin Lambotte assistant, continued his research into the effects of magnesium implants on both animals and humans. Verbrugge reported that the material was successfully used, with no adverse reactions other than small amounts of harmless gas [4].

A contrary opinion was provided by Ernest Hey Groves, who investigated Mg implants on animals also in the early twentieth century (1913). Ernest Hey Groves attempts were not successful, the rapid rate of corrosion of the medical implant and excessive callus formation this was before adequate healing could be achieved [3, 8]. Nevertheless, his negative reviews were not a deterrent for other physicians who applied magnesium for orthopedic applications. Earl McBride, during the late 1930s, employed the use of an Mg alloy which contained aluminum (Al) and manganese (Mn) for the development of screws and nails which were used for repairing fractures in humans [9].

Earl McBride discovered that magnesium as a standalone material did not contain the necessary strength required compared to magnesium alloys, suggesting that magnesium-based implants should not be used in areas of the body where there is need for high mechanical loading [9]. Earl McBride identified that Mg alloy plates as intraosseous implants did not corrode as fast as intramedullary pegs [4]. On the lack of tissue reaction from Mg-based implants, Earl McBride advocated that it should not be a deterrent for the use of magnesium [10]. However, Earl McBride distinguished the application of Mg for areas where the influence of the corrosion properties of the material would not affect the surrounding tissues [9].

Maier and Troitskii are other authors who successfully applied magnesium and its alloys for orthopedic implants applications in the 1940s. These were for humeral fracture fixations and pseudarthrosis using Mg-cadmium (Cd) alloy plates and screws, respectively [4]. After this period there was a decline in the research of magnesium as a viable material for biological environments. Walker et al. [5] hypothesized that the waning interest in magnesium and its alloys in the application in biological environments are based on the above-stated issues of degradation over time, its inability to be applied where load beating is a major factor. Walker et al., also suggested, that the inability of authors of physicians in the early twentieth century to consider coating as a means to reduce corrosion also had its negative impact on the widespread adoption of the material.

The application of Mg-based biomedical devices is different from its earlier application (early twentieth century). The application of magnesium-based alloys is championed for orthopedic and vascular applications. The application of Mg alloys for vascular application is touted as the more successful of the two mentioned. Mg alloys were tested as suitable implants first on animals [11] after success was attained in large animals [9], it was then applied on a preterm baby to correct a ligation defect of the left pulmonary artery the Mg alloy was used as a stent, and success was recorded when reperfusion of the lung was observed [12]. Literature is littered with the success of Mg alloy-based stents for both babies and adults, with a 100% corrosion of implant recorded after 4 months [13,14,15,16].

Orthopedic applications for Mg-based material are still lagging compared to vascular applications. The majority of research is still carried out in vitro with little in vivo studies being carried out. Mg-based implants are a rear occurrence in relevant clinical implants, the investigations Mg-based implants for orthopedic application majority have developed screw implants for long bones of rabbits, Erdmann et al. [17], Wang et al. [18] and Duygulu et al. [19] who studied screw implants into sheep pelvis. In a case reported by Erdmann et al. [17] mechanical performance of the implant was well-assessed. However, general reports about tissue and implant behavior have been rudimentary [18, 19]. In those research, no surgical trauma was applied to the bone before implant therefore the implants were not assessed in a functional sense. The case of low reporting of Mg-based implant investigation by authors can be associated with issues hypothesized by Walker et al. [5].

Nevertheless, once an understanding of the behavior of magnesium metal in the biological environment is achieved, it would correlate with an expansion of the application of the material, Mg and Mg alloys would not only be applicable just for the development of screws but would include wires and plates when fixing fractures, it would also prove advantageous in the development of scaffolds [20,21,22,23,24,25,26,27]. This article discusses how various authors use magnesium and its alloys for biomedical applications. It also discusses how various authors aim to improve the compatibility of medical implants containing magnesium. Polylactic acid (PLA), hydroxyapatite nanoparticles (HA), polycaprolactone (PCL), bredigite (Ca7MgSi4O16), calcium, and other materials are used as reinforcement or matrix for magnesium-containing medical devices.

2 Hydroxyapatite

Hydroxyapatite (Ca10(PO4)6(OH)2) (Fig. 1) (HA) is the primary constituent of the mineral bone [28, 29], and as a member of the calcium phosphate ceramic family and can be applied in the area of bone-substitution. Tricalcium phosphates and bioglass ceramics are also members of the calcium phosphate family. The structural and functional similarities of HA to the mineral composition in teeth and bones give it the advantage over other calcium phosphates. The natural bioactivity and biocompatibility and relative ease of fabrication and production make it an easy choice for implant material [30,31,32]. There is the synthetic and natural mode of producing HA [33, 34]. Producing HA synthetically involves the combination of calcium and phosphate-based oxide and acids as an example in a pH-controlled processing technique [35, 36]. The material resulting from this processing technique has structural similarities with natural bone and teeth, nevertheless, the cost of manufacturing this material proves too high [35, 37]. To solve the problem of cost for decades HA has been produced using animal bones which are termed as Xenograft bones. Animal bone is applied in affected areas to rapidly increase the production of HA and bone regeneration. There are concerns over cross-contamination of diseases from animals to humans researchers are dissuaded this notion by developing multistage processing techniques that identify and destroy existing organic matter and pathogens when present [37]. The fabrication of HA can take different forms, when crushed into nanomaterials HA can improve bone mineralization, HA can also be used as material scaffolds with pores which aids cell migration and improve bone regeneration, HA can also be used as protective coating for metals. Though the osteogenic and osteoconductive properties of HA makes it suitable for application in biological environments, HA is also a brittle material which increases the difficult in attempts to fabricate it into different shapes and sizes [38].

Molecular structure of hydroxyapatite [39]

To improve the degradation properties of magnesium alloy in biological environments authors have studied how to produce a magnesium matrix composite with the best possible properties. Ma et al. [40] studied different production routs to proffer solutions to this problem. Ma et al. considered two production methods for magnesium matrix nanocomposite with HA has reinforcement which is; friction stir process (FSP) and two state nano-processing (which was finished with ultrasonic processing and laser surface melting (LSM)). The microstructure of the two samples was analyzed and the difference in particle reinforcement dispersion was observed. In samples that underwent FSP and TSnP, the HA nanoparticles were dispersed and inculpated into the Mg matrix, in TSnP samples the nanoparticles where inculpated at the liquid state whereas in samples that underwent FSP the nanoparticles where inculpated in solid-state.

It was observed that the grains of MgHA composite were refined as a result of FSP, and the inclusion of LSM to the surface of the samples which were produced from TSnP improved the surface roughness of the material this was not required for FSP. The effects of these two processes on the resulting composite resulted in improved corrosion resistance of the resulting composite compared to Mg as a standalone material. Comparing both material composite the corrosion current in samples developed using TSnP decreased by 71% compared to samples developed using FSP whose corrosion rate was 52%. It was also recorded that a further decrease of 30% occurred once the LSM was performed on the surface of the material. It is logical to assume controlling grain refinement of material, dispersion of reinforcement, surface roughness and percentage of reinforcement would greatly improve the corrosion behavior of a material.

Magnesium matrix composite reinforced with nano-hydroxyapatite was developed through the processing rout of FSP by some authors Ratna Sunil et al. [41]. They expanded on the ideas of Ma et al. who hypothesized that grain size influences the corrosion rate of the material. The authors investigated this and also studied the biocompatibility of the magnesium matrix composite in vitro. They discovered that the grain structure of the composite influenced the wettability of the composite and corrosion capability of the resulting composite. In turn, the material was found to be bioactive because of the grain structure which allowed the formation of protective mineral phases on the surfaces of the Mg–nHA composite. Ratna Sunil et al. [41, 42] also discovered that the composite was when introduced to a simulated biological environment.

Ratna Sunil et al. [43] attempted another processing variation of Mg–nHA composite using powder metallurgy route. Powdered forms of Mg metal and nHA were milled for twenty hours followed with the sintering of the derived powdered material. The sample derived varied in Wight percentage of nHA with 8, 10, and 15 percent weight of nHA. The structure of the magnesium metal was studied under the microscope and it had what was described as a lamellar structure. Ratna Sunil et al. [43] discovered that the different weight percentage of HA affected the mechanical properties and corrosion resistance of the material. The hardness value and Young’s modulus of the resulting composite were less compared to pure milled magnesium, except for fracture toughness which was higher in 8%HA composite compared to pure magnesium and other derived composites. Whereas, 10%HA had the best corrosion resistance compared to other derived composites.

Coating of Mg is another method authors considered in solving the degradation time problem posed by introducing Mg in a biological environment. HA has been synthesized as a suitable coating material either as a part of a matrix polycaprolactone (PCL) [44] and polylactic glycolic acid (PLGA) [45] or as a standalone coating material [46]. Linsheng et al. [46] studied the effects of HA coating on the Mg substrate. The HA coating was applied to the treated Mg substrate using the electrophoretic deposition method and was studied in vivo [Sprague–Dawley (SD) rats]. The authors analyzed the corrosion behavior and biocompatibility of the material. They discovered that the coated Mg implant did not have any adverse effect in the biological environment and displayed excellent biocompatibility after 8 weeks. The Mg-coated substrate also displayed the ability to develop calcium deposits on its surface which improved the corrosion resistance of the material in a biological environment and maintained the mechanical properties of the Mg substrate.

Polycaprolactone composite coating and its influence of Mg alloy (AZ 31)-based implant were studied in vitro by Zomorodian et al. [44]. Zomorodian et al. varied the concentration of PCL to HA where four out of five samples had the PCLHA coating introduced and compared to the Mg alloy. The authors discovered that PCL as a stand-alone coating material improved the corrosion resistance of the Mg alloy but did not possess the cell proliferation effects implants containing HA composite coating. They also notice that implants containing equal parts PCL to HA performed poorly once corrosion tests were conducted out, this is because of the creation of more porous morphology. Johnson et al. [45] corroborated the influence of coating HA nanoparticles when introduced to a composite coating of PLGA.

Unlike other studies previously mentioned authors such as Hickey et al. and Kalantari et al. [47,48,49] have studied the influence materials like Magnesium Oxide (MgO) and monticellite (CaMgSiO4) have on HA matrix composite. MgO and CaMgSiO4 are classified as ceramics so when introduced into a HA matrix they present different properties. Hickey et al. reported improved bioactivity of HA composite because of the presence of Mg ions which improved bioactivity. The presence of Mg in monticellite also had similar effects in works done by Kalantari et al. [48, 49]. They all echoed the importance of further study in the application of this ceramic material containing Mg in biological environments. See Table 1 for further information.

3 Polylactic Acid

The thermoplastic, compostable, and bio-compatible polymer of the polylactic acid (PLA) (Fig. 2) is derived from sustainable resources including corn, sugar beets, and potato starch [50]. This is used in the field of biomedicine for wound closures, prosthesis implants, bone operation, and controlled release systems [51, 52]. PLA is also used in packaging materials with the help of emerging technology and large-scale development [53]. PLA degrades with backbone ester groups, and the degradation rate is determined by the PLA crystallinity, molecular weight, distribution of molecular weight, morphology, diffusion rates in the water to the polymer, and stereoisomeric content [53].

Molecular structure of polylactic acid [54]

Morawska-Chochół et al. [55] analysed three production methods in the creation of intramedullary nails which are biodegradable. The production method analysed includes injection molding, hot pressing and solution-based production method. The nails where reinforced with either carbon and alginate fibers or magnesium wires, with a matrix poly(l-lactide) (modified tricalcium phosphate and gentamicin sulfate). The influence of the production method on the degradation rate and mechanical properties the resulting composite was studied [55] identified peculiarities in the production methods, where uniform homogeneity was identified with samples produced using injection molding. This was compared with the high volume of fibers with improved impregnation in the matric material identified using hot pressing. Upon analysis Morawska-Chochół et al. [55] recommended production method should depend on the desired case (application) the resulting samples are to be applied.

Kang et al. [56] studied the effect of PLLA by-products, which acidify surrounding tissues during in vivo degradation, and consequently induces inflammatory response. To overcome this, magnesium hydroxide nanoparticles (nMH) was introduced to the PLLA matrix as a bioactive filler, they identified nMH as a material which can suppress inflammatory responses by neutralizing the acidified environment caused by the degradation of PLLA. The authors noted that the strong cohesion of the nMH nanoparticles towards each other would serve as a drawback in the production of a homogeneous polymer matrix material through thermal processing. Two types of surface-modified nMH were prepared with oligolactide (ODLLA) utilizing grafting to (GT) and grafting from (GF) strategies this was done to improve the mechanical and biological characteristics of the organic–inorganic hybrid composite. The researcher attested that the inclusion of surface-modified nMH was not limited to the enhancement of mechanical properties, like Young's modulus, but consequently improved homogeneity of magnesium hydroxide particles in the PLLA matrix due to the increase in interfacial interaction. Additionally, It discovered during hydrolytic degradation that the PLLA composites (with surface-modified nMH) exhibited reduced bulk erosion with lower cytotoxicity and immunogenicity. The authors recorded a lower influence of platelet activation and higher albumin fibrinogen ratio (AFR) of the PLLA composite (with nMH fillers) from the hemocompatibility tests. They concluded that a surface-modified nMH particle would positively influence the biological and physical characteristics of a polymer composite.

Ferrández-Montero et al. processed Mg reinforced PLA composite in the shape of films that would be suitable for tissue regeneration [57]. The Mg reinforced PLA films had an Mg content up to 50 wt%, the produced composite also had good thermal stability of the polymer. This was attained by adding a colloidal step, which was described as the inclusion of organic additives to Magnesium (Mg) particles for the modification of Mg particle surface, and also to improve a chemical stable suspension. The product of the colloidal suspension was used as a feed to create composite films through tape casting. It was discovered that the films show degradation, hydrogen release, and oxygen permeability in advantageous vitro behavior. Also, the author identified their compatibility with fibroblast cells (MEF) as a game changer in the field of bio-absorbable material for tissue engineering and wound dressing applications.

The degradation of a polylactic acid matrix composite reinforced with a 30% magnesium microparticle was studied by Zimmermann et al. [58] included titanium and polyether ether ketone (PEEK) as materials to improve the corrosion properties of the original composite. The authors achieved this by testing six dental implant samples, three containing titanium, and others with PEEK [58]. The samples were placed in a central perforation, then incubated for 30 days in a McCoy’s 5A modified medium at 37 °C. The resulting H2 was evaluated, the authors discovered that at day’s 7 and 16 the titanium samples evolve more H2 compared to the PEEK samples (3.1 ± 0.4 ml vs. 2.8 ± 0.4 ml). The authors continued and emphasized the difference in H2 evaluation becomes insignificant at day 30 (3.5 ± 0.7 ml/cm2 vs. 3.2 ± 0.8 ml/cm2). Zimmermann et al. concluded that it is possible to produce metal-free implants material through PEEK since they have similar corrosion behavior.

Yang et al. [59] successfully prepared a poly(l-lactide)-based composite and modified the MgO nanoparticles (m-MgO-NPs) by introducing a copolymer which contained the malic acid and low molecular weight poly(l-lactide)(poly(l-lactide-co-malice acid (PLMA)). Yang et al. [59] coated the MgO-NPs with the PLMA, then the MgO-NPs were distributed uniformly in the PLLA matrix to form a new material described as (PLLA/m-MgO-NPs) which had excellent interface bonding and uniform dispersion, compared to PLLA/MgO-NPs. Yang et al. observed that m-MgO-NPs shows better hydrophilicity, neutralization effect of acidic solution evolved from degradation compared to neat PLLA and PLLA/MgO-NPs films. The m-MgO-NPs, also had increased cell viability and reduction of toxicity to the cell during the degradation process of PLLA in vitro and hereby reducing the degradation rate of PLLA.

The production of a biodegradable polymer matrix composite of polylactic acid matrix and 10 wt% magnesium microparticle was studied by Cifuentes et al. [60]. In their work, they investigated the in vitro degradation of the composite for 28 days and the importance of the Mg reinforcement particle shape on the composite. The authors compared a spherical-shaped Mg reinforced particulate to an irregular shaped particle. Cifuentes et al. discovered a spherical-shaped Mg reinforced composite had a lower degradation rate compared to irregularly shaped Mg reinforced composite. The authors attributed this to the smaller surface area to volume ratio as the root cause of the spherical-shaped composite reinforcement had better degradation properties compared to the irregular which promoted the formation of cracks. Cifuentes et al. recorded that the spherical-shaped composite retained up to 90% of its mechanical properties after 7 days of immersion and greater than 60% after 28 days.

Magnesium substrate was coated applying PLLA/vaterite composite, Yamada et al. [61] studied the effect of the coatings on the degradation and biocompatibility of the composite coating on the magnesium substrate. They created two types of composite the first with 30 wt% and the other 60 wt% of vaterite to PLLA. The authors observed the composite coating with 30 wt% of vaterite had little pores on its surface and in turn suppressed initially the degradation of magnesium substrate. Whereas, the composite coating containing 60% vaterite did not stop the initial degradation of the magnesium substrate this is because of the presence of pores of 1.0–2.0 μm in diameter. After immersion in a culture medium, both samples responded differently, the sample containing 30 wt% developed pores whereas, the 60 wt% composite coating maintained a pH of 7.4–7.5 because of the vaterite particles dissolved in solution and PLLA degradation. Consequently, the authors observed improvement in murine osteoblast-like cells (MC3T3-E1) around the substrate with coatings of 60 wt%. Electrospinning was the method of choice of Zhou et al. [62] in the production of fibrous bionanocomposites consisting of amorphous magnesium phosphate (AMP) nanospheres and polylactic acid (PLA). Zhou et al. [62] argued that the production of magnesium and phosphate ions from the PLA matrix could be a game changer in cell responses.

4 Polycaprolactone

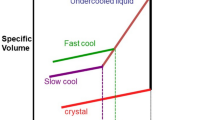

Polycaprolactone (Fig. 3) is an example of polyester biodegradable material [63, 64]. The polymerization of the ring-opening (caprolactone) leads to a hydrophobic polymer, semi-crystalline materials which has a glass-transition temperature and melting point of − 60 °C and 63 °C, respectively. The degradation speed of the polymer materials is improved by the synthesis of copolymers which has a faster bioabsorption process compared to homopolymer which degrade within a period of 2 years. Consequently, the flexibility and rate of degradation of caprolactone copolymers with dl-lactide is significantly better than that of polycaprolactone. Polycaprolactone finds application in the development of drug delivery systems because of its high permeability.

Molecular structure of polycaprolactone [65]

In a polycaprolactone (PCL) coating systems, Yang et al. [66] introduced copper containing bioactive glass nanoparticles (Cu-BGNs), the authors hypothesized that the introduction would greatly increase the bioactivity, antibacterial properties, and corrosion resistance of vulnerable magnesium matrices under physiological conditions. Yang et al. [66] investigated the influence of the differing amount of Cu-BGNs on the electrochemical properties, wettability, and antibacterial effects Escherichia coli and Staphylococcus carnosus, including cytocompatibility. It was observed that the Cu-BGNs where scattered randomly in the PCL coating. Consequently, they observed that altering the amount of Cu-BGNs affects the water contact angle and reduces the corrosion properties of Cu-BHN composite coating. Whereas, further increase of Cu-BGN content in coatings results in an increase in calcium phosphate formation on the surface. The observation was after immersion in a simulated body fluid after seven days, this was confirmed consequently using X-ray photoelectron spectroscopy and Fourier-transform infrared spectroscopy. It was further observed that the release of Cu2+ ions released from the Cu-BGN coating was inhibited the development of S. carnosus and E. coli. The authors continued by expanding on the influence of Cu-BGNs coating on MG-63 cells, they recorded higher activity after conducting indirect and direct cyto-compatibility experiments compared to pure magnesium. However, they cautioned that a further increase in Cu-BGN would reduce slightly cell activity and cell proliferation.

The influence introducing magnesium oxide (MgO) nanoparticles to polycaprolactone (PCL)/Hap composite were investigated by Roh et al. [67] through the creation of a 3D scaffold of PCL/HAp/MgO using a three-dimensional bioextruder. The PCL/HAp/MgO scaffolds were then treated with oxygen and nitrogen plasma, this was to improve the bioactivity of the scaffold. Their hypothesis was confirmed by testing the 3D scaffold using X-ray photoelectron spectroscopy, scanning electron microscopy, and atomic force microscopy. The study attested that the addition of plasma treatment to the MgO/HAp nanoparticles enhanced the adhesion, differentiation, and proliferation of MC3T3-E1 cells in the PCL scaffolds. The authors concluded the effect of plasma treatment on the 3D scaffold could affect the behavior of MC3T3-E1 cells because of the corresponding change in surface chemical properties and physical surface morphology.

For tissue engineering applications, Liu et al. [68] developed a conductive and biodegradable composite consisting of polycaprolactone (PPy-PCL), poly(lactic-co-glycolic acid) (PLGA) and magnesium (Mg). The process of producing the composite. First, the PPy-PCL is used as a coating for the Mg particles to improve the corrosion resistance through a UV-induced photopolymerization method. Then the biodegradability of the composite is improved when coated magnesium particles are added to the PPLGA matrix. The authors developed composites of varying composition. The authors discovered that the 293FT-GFP cells during in vitro experiments reacted positively to cell growth and culture. Furthermore, Liu et al. [68] indicated that the addition of PLGA matrix increased the degradation time of the resulting composite (greater than eight weeks). They identified this as an advantage for tissue formation compared to composites or alloys of Mg.

The bioresorbable composite containing phosphate glass fiber of around 20% was introduced in a polycaprolactone (PCL) matrix by Liu et al. [69]. The varied the experiment by coating some glass fiber samples with Mg leaving other samples without the magnesium coating. The coating was achieved through the magnetron sputtering technique and was done to improve fiber-matrix interfacial properties. The inhibition of media influx for samples containing Mg-coating glass fiber as reinforcement was observed after samples of coated Mg and non-coated where subjected to phosphate-buffered saline (PBS) for 28 days at a temperature of 37C and water, this was done to derive values for water uptake, mass loss properties, and ion release profile. The authors recorded high retention of mechanical properties after the 28 day degradation period of the Mg-coated composite.

Liu et al. [70] investigated the influence magnesium coating has on manufacture and characterization of a random chopped fiber reinforces polycaprolactone composite. The short chopped strand non-woven phosphate glass fiber mats were sputter-coated with degradable magnesium to manufacture phosphate glass fiber/polycaprolactone composites. The degradation behavior of the composite as well as pure polycaprolactone was investigated in PBS. The results of the degradation behavior of the resulting composites indicated that the composite had less mass loss and water uptake compared to the control substance (polycaprolactone). The authors also indicated that the cations released of Mg-coated composite was also lesser compared to the control substance. The authors continued that the tensile strength and modulus was higher in the Mg-coated composite. Further investigation was done on the integrity of the mechanical properties of the Mg-coated composite after immersing it in PBS for 10 days at a fixed temperature and discovered the composite retained its properties. No difference in the cytocompatibility of both materials on osteosarcoma cells in humans.

Kharaziha et al. [71], investigated the effects of modifying the surface of forsterite nanoparticles. To achieve this they developed samples of nanofibrous PCL/(Mg2SiO4) scaffolds, using the electrospinning technique, surface esterified forsterite nanoparticles was used. They discovered that the toughness and tensile strength of scaffolds were greatly influenced by surface modification of nanoparticles compared to unmodified nanoparticle samples. Kharaziha et al. indicated that the bioactivity and cellular attachment where modified because of the hydrolytic treatment of scaffolds. Whereas, proliferation was attributed to the improved hydrophilicity of forsterite nanoparticles compared to surface-modified samples [71]. The authors concluded that the hydrolytic treatment and surface modification of the developed scaffolds and forsterite nanopowder, were efficient methods in the formation of bioactive composite scaffolds, which have the ideal structural and mechanical properties relevant in tissue engineering and bone formation.

PCL was employed by Dai et al. [72] as coating composite (Mg–6%Zn–10%Ca3(PO4)2) developed through powder metallurgy. The effect the PCL coating had on the corrosion, surface morphology and Cytotoxicity of the resulting composite was studied. It was discovered that using PCL as a coating improved the corrosion resistance with low pH value in simulated body fluid at 37 °C during immersion test, this is when compared to uncoated composite specimen. Consequently, PCL coating indicated better growth rate compared to specimens which did not have it as coating. Also, PCL coating is nontoxic in biological environments.

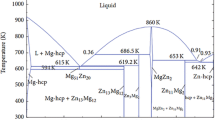

5 Bredigite

Bredigite which has a chemical formula (Ca7MgSi4O16) is a calcium bioceramic [73, 74]. Bredigite is a biodegradable, bioactive material with mechanical properties similar to cortical bone in the human body. So if bredigite particles are introduced into magnesium matrixes, a chemical reaction between the two materials occurs, resulting in the formation of a Mg-bredigite layer from the reaction of Si–O with Mg. Optimizing the production method of the composite would have a lasting effect on the resulting material [75]. In this section the works from Dezfuli and coworkers [76,77,78] who produced Mg–bredigite composite from powder metallurgy route. This production method is best to optimize the distribution of the reinforcement of the material in the metal matrix.

Dezfuli et al. [76], successfully developed Mg–bredigite biocomposite using powder metallurgy. The authors were able to optimize the reactivity between the matrix and reinforcement using powder metallurgy as they observed the formation of the Mg–bredigite interface in the composite material. In vitro analysis was done on the material composite, and the authors observed the rate of corrosion was reduced compared to pure magnesium. Dezfuli et al. also noted that the production process also encouraged amalgamation between the Mg matrix and the composite powder. Additionally, when the resulting composite was thermally treated, it was observed that there was an improvement in the mechanical behavior if the composite [78].

Dezfuli et al. continued their study where they compared a 40% bredigite reinforced composite to a 20% reinforced composite [77]. The authors discovered that the material with 40% reinforcement had a lighter bulk density compared to that of 20% reinforcement. They also discovered that sintering time and temperature improved the bulk density, and its similarities to the cortical bone in terms of mechanical properties. Dezfuli et al., cautioned that the corrosion rate of composite reinforced with 40% of bredigite corroded faster compared to 20%. Nevertheless, the mechanical properties after 12 days where similar [77].

6 Beta-Tricalcium Phosphate (β-TCP)

Beta-tricalcium phosphate (β-TCP) is a form of calcium phosphate ceramic [79, 80]. β-TCP like HA find biomedical application because of the similarities they have in structure with natural bone, this influence their area of application in bone grafting. β-TCP can be produced either through chemical precipitation as described by Rakovsky et al. [81, 82] or calcination as described by Tang et al. [83]. β-TCP is classified as a ceramic so it cannot be applied in parts of the body where properties such as ductility and toughness would be tested. Compared to HA, β-TCP is readily reabsorbed by the human body.

β-TCP particles were used as a reinforcement for a composite comprising Mg alloy (Zn as an alloying element) matrix. Tang et al. [83] and Huang et al. [84] aimed at improving the properties of the composite with different processing techniques. Tang et al. developed their composite (Mg–3%Zn–5%β-TCP) using powder metallurgy. Whereas, Huang et al. [84] developed their composite (Mg–2%Zn–0.5%Ca–1%β-TCP) using high shear solidification (HSS) along with equal channel extrusion (ECAE). These techniques improved the homogeneity of the resulting composite and grain refinement of the magnesium. It was observed that the rate of degradation compared to the matrix was greatly improved and the cytocompatibility of the material was hugely improved compared to its alloy matrix.

β-TCP was used as a matrix material for the development of a biocomposite for biomedical applications by authors Swain et al. [85]. The β-TCP matrix made up to 70% matrix whereas the reinforcement which was 30% contained Fe and Mg in equal portions and another set with an 80:20 ratio of Fe to Mg, the samples were produced using powder metallurgy. The authors noticed the development of a hierarchical nanocomposite structure and an improvement in the overall mechanical properties of the resulting composite. Both samples supported the formation of cells on their surfaces as a reason for the degradation which occurred in the materials when tested in vitro, and there was an improvement in bioactivity.

7 Others

Other notable experiments on magnesium have been conducted in order to improve its service life in biological environments. A study was carried out by Yang et al. [86] on the influence of mesoporous silica (MS) reinforcement on Mg matrix composite. MS was the material reinforcement of choice because of its large surface area and frequency of pour formation, which is why it is a form of silica (mesoporous). The MS reinforcement was introduced into the matrix and samples were fabricated using a selective laser melt (SLM). The introduction of MS reinforcement improved the corrosion properties of the material compared to pure MS.

Similarly, Meifeng et al. [87] studied the influence of pearl powder on magnesium matrix composite using the powder metallurgy route. They also found that the rate of degradation in the composite created was reduced. Additionally, they attested that the bioactivity and biocompatibility of the materials were greatly improved compared to pure magnesium. Collagen was added to bioglass/magnesium matrix composite using low-level laser therapy. A corroborated study was also done by Gabbai-Armelin et al. [88] and observed that the biological and mechanical properties of the resulting composite were observed, but the authors did not study the longevity of the composite material.

Researchers have also studied the introduction of Mg metal to a metal matrix to improve bioactivity and its role as a reinforcement particulate for composites [89]. Iron and Titanium matrix has been studied by Sikora-Jasinska et al. [90] and Jiang et al. [91] respectively. Iron (Fe) was the matrix of choice of Sikora-Jasinska et al. the authors noted that the low corrosion rate in Fe hindered its biocompatibility. Consequently, they opted for the addition of Mg2Si particles to improve the bioactivity of their composite implant. Jiang et al. introduced magnesium to porous titanium entangled wires to improve the bioactivity of the resulting composite. The superior properties of the resulting composite were identified to be similar to that of the cortical bone.

8 Summary

Due to the extreme rate at which magnesium metal degrades in the biological environment, it is unsuitable for use in medical implants. Cos of their superior mechanical and chemical properties, metals such as iron, titanium, and their corresponding alloys have been used. Notwithstanding, magnesium has suitable bioactivity properties in the biological environment when compared to other metals. Since the turn of the century, authors have aimed to develop smart materials that aid cell regeneration and increase the healing rate of tissues in affected areas. As a result, magnesium metal has been studied as either a suitable matrix material with reinforcement that reduces the rate of corrosion of the metal matrix in a biological environment or as particles reinforcement that, when added to other matrix materials, improves the biocompatibility, bioactivity, and cell regeneration of affected tissues in a biological environment without any adverse effects.

-

Hydroxyapatite is a suitable material for magnesium alloy reinforcement and can also be used as a matrix, either as a composite matrix containing Polycaprolactone or as a standalone matrix. The effectiveness of this material as a reinforcement is determined by the method of manufacture and the grain size of the reinforcement. HA composite coating matrix, on the other hand, is more effective at slowing the deterioration of magnesium alloys while improving cell regeneration and biocompatibility in vivo.

-

Controlling the rate of corrosion of magnesium-based medical devices has the potential to revolutionize medicine. Polymer-based coatings such as Polylactic acid and Polycaprolactone are recommended for coating magnesium substrates. These polymer-based coatings are appropriate due to their biocompatibility and inertness to other metals that can be introduced to form a type of composite coating.

-

Bredigite and beta-tricalcium phosphate on-the-other-hand are ceramic-based compounds which can be used as reinforcement or matrix for metal salt. The decision to use Bredigite or beta-tricalcium phosphate as matrix or reinforcement depends on the area of application. Bredigite and beta-tricalcium phosphate optimize the properties of the magnesium, reducing the rate of corrosion and improving the biocompatibility of the materials and cell formation.

-

Magnesium can also be used to reinforce other materials like perl powder or mesoporous silica which can be considered as ceramics. Another application of Magnesium in biological environment is as a reinforcement metal for metal matrix composite where Titanium and steel are matrixes.

Considering all this, there is still need for more research in of organic-based materials such as Egg shell, Periwinkle shell, Snail shell to name a few as possible reinforcement or matrix for magnesium in biological environment.

References

Li Y, Wen C, Mushahary D, Sravanthi R, Harishankar N, Pande G, Hodgson P (2012) Mg–Zr–Sr alloys as biodegradable implant materials. Acta Biomater 8(8):3177–3188

Laurencin D, Almora-Barrios N, de Leeuw NH, Gervais C, Bonhomme C, Mauri F et al (2011) Magnesium incorporation into hydroxyapatite. Biomaterials 32(7):1826–1837

Amerinatanzi A (2018) Magnesium-based biomedical implants: towards a mathematical model for degradation and design. University of Toledo, Toledo

Witte F (2010) The history of biodegradable magnesium implants: a review. Acta Biomater 6(5):1680–1692

Walker J, Shadanbaz S, Woodfield T, Staiger M, Dias G (2014) Magnesium biomaterials for orthopedic application: a review from a biological perspective. J Biomed Mater Res B Appl Biomater 102(6):1316–1331

Zhao D, Witte F, Lu F, Wang J, Li J, Qin L (2017) Current status on clinical applications of magnesium-based orthopaedic implants: a review from clinical translational perspective. Biomaterials 112:287–302

Poinern GEJ, Brundavanam S, Fawcett D (2012) Biomedical magnesium alloys: a review of material properties, surface modifications and potential as a biodegradable orthopaedic implant. Am J Biomed Eng 2(6):218–240

Witte F (2015) Reprint of: The history of biodegradable magnesium implants: a review. Acta Biomater 23:S28–S40

Zheng YF, Gu XN, Witte F (2014) Biodegradable metals. Mater Sci Eng R Rep 77:1–34

Xin Y, Hu T, Chu PK (2011) In vitro studies of biomedical magnesium alloys in a simulated physiological environment: a review. Acta Biomater 7(4):1452–1459

Zeng R, Dietzel W, Witte F, Hort N, Blawert C (2008) Progress and challenge for magnesium alloys as biomaterials. Adv Eng Mater 10(8):B3–B14

Chen Y, Xu Z, Smith C, Sankar J (2014) Recent advances on the development of magnesium alloys for biodegradable implants. Acta Biomater 10(11):4561–4573

Erbel R, Di Mario C, Bartunek J, Bonnier J, de Bruyne B, Eberli FR et al (2007) Temporary scaffolding of coronary arteries with bioabsorbable magnesium stents: a prospective, non-randomised multicentre trial. Lancet 369(9576):1869–1875

Barlis P, Tanigawa J, Di Mario C (2007) Coronary bioabsorbable magnesium stent: 15-month intravascular ultrasound and optical coherence tomography findings. Eur Heart J 28(19):2319

Schranz D, Zartner P, Michel-Behnke I, Akintürk H (2006) Bioabsorbable metal stents for percutaneous treatment of critical recoarctation of the aorta in a newborn. Catheter Cardiovasc Interv 67(5):671–673

Waksman R, Erbel R, Di Mario C, Bartunek J, de Bruyne B, Eberli FR et al (2009) Early-and long-term intravascular ultrasound and angiographic findings after bioabsorbable magnesium stent implantation in human coronary arteries. JACC Cardiovasc Interv 2(4):312–320

Erdmann N, Angrisani N, Reifenrath J, Lucas A, Thorey F, Bormann D, Meyer-Lindenberg A (2011) Biomechanical testing and degradation analysis of MgCa0.8 alloy screws: a comparative in vivo study in rabbits. Acta Biomater 7(3):1421–1428

Wang Q, Tan L, Xu W, Zhang B, Yang K (2011) Dynamic behaviors of a Ca–P coated AZ31B magnesium alloy during in vitro and in vivo degradations. Mater Sci Eng B 176(20):1718–1726

Duygulu O, Kaya RA, Oktay G, Kaya AA (2007) Investigation on the potential of magnesium alloy AZ31 as a bone implant. Mater Sci Forum 546:421–424

Barfield WR, Colbath G, DesJardins JD, An YH, Hartsock LA (2012) The potential of magnesium alloy use in orthopaedic surgery. Curr Orthop Pract 23(2):146–150

Bohner M (2010) Resorbable biomaterials as bone graft substitutes. Mater Today 13(1–2):24–30

Giannoudis PV, Dinopoulos H, Tsiridis E (2005) Bone substitutes: an update. Injury 36(3):S20–S27

Sen MK, Miclau T (2007) Autologous iliac crest bone graft: should it still be the gold standard for treating nonunions? Injury 38(1):S75–S80

Staiger MP, Kolbeinsson I, Kirkland NT, Nguyen T, Dias G, Woodfield TBF (2010) Synthesis of topologically-ordered open-cell porous magnesium. Mater Lett 64(23):2572–2574

Nguyen TL, Staiger MP, Dias GJ, Woodfield TBF (2011) A novel manufacturing route for fabrication of topologically-ordered porous magnesium scaffolds. Adv Eng Mater 13(9):872–881

Zhuang H, Han Y, Feng A (2008) Preparation, mechanical properties and in vitro biodegradation of porous magnesium scaffolds. Mater Sci Eng C 28(8):1462–1466

Gu XN, Zhou WR, Zheng YF, Liu Y, Li YX (2010) Degradation and cytotoxicity of lotus-type porous pure magnesium as potential tissue engineering scaffold material. Mater Lett 64(17):1871–1874

Dutta SR, Passi D, Singh P, Bhuibhar A (2015) Ceramic and non-ceramic hydroxyapatite as a bone graft material: a brief review. Irish J Med Sci 184(1):101–106

Brickley MB, Ives R (2010) The bioarchaeology of metabolic bone disease. Elsevier, New York

Ferraz M, Monteiro F, Manuel C (2003) Hydroxyapatite nanoparticles: a review of preparation methodologies. J Appl Biomater Biomech 2:74–80

Dorozhkin SV (2010) Bioceramics of calcium orthophosphates. Biomaterials 31(7):1465–1485

Dorozhkin SV (2010) Calcium orthophosphates as bioceramics: state of the art. J Funct Biomater 1(1):22–107

Fathi MH, Hanifi A, Mortazavi V (2008) Preparation and bioactivity evaluation of bone-like hydroxyapatite nanopowder. J Mater Process Technol 202(1–3):536–542

Hu J, Russell J, Ben-Nissan B, Vago R (2001) Production and analysis of hydroxyapatite from Australian corals via hydrothermal process. J Mater Sci Lett 20(1):85–87

Xuechu C, Hainan K, Deyi WU, Xinze W, Yongyong LIN (2009) Phosphate removal and recovery through crystallization of hydroxyapatite using xonotlite as seed crystal. J Environ Sci 21(5):575–580

Tripathi G, Basu B (2012) A porous hydroxyapatite scaffold for bone tissue engineering: physico-mechanical and biological evaluations. Ceram Int 38(1):341–349

Akram M, Ahmed R, Shakir I, Ibrahim WAW, Hussain R (2014) Extracting hydroxyapatite and its precursors from natural resources. J Mater Sci 49(4):1461–1475

Anderson JM, Shive MS (2012) Biodegradation and biocompatibility of PLA and PLGA microspheres. Adv Drug Deliv Rev 64:72–82

Šupová M (2014) Isolation and preparation of nanoscale bioapatites from natural sources: a review. J Nanosci Nanotechnol 14:546–563

Ma C, Chen L, Xu J, Fehrenbacher A, Li Y, Pfefferkorn FE, Duffie NA, Zheng J, Li X (2013) Effect of fabrication and processing technology on the biodegradability of magnesium nanocomposites. J Biomed Mater Res Part B Appl Biomater 101B(5):870–877

Ratna Sunil B, Sampath Kumar TS, Chakkingal U, Nandakumar V, Doble M (2014) Friction stir processing of magnesium-nanohydroxyapatite composites with controlled in vitro degradation behavior. Mater Sci Eng C 39(1):315–324

Ratna Sunil B, Sampath Kumar TS, Chakkingal U, Nandakumar V, Doble M (2014) Nano-hydroxyapatite reinforced AZ31 magnesium alloy by friction stir processing: A solid state processing for biodegradable metal matrix composites. J Mater Sci Mater Med 25(4):975–988

Ratna Sunil B, Ganapathy C, Sampath Kumar TS, Chakkingal U (2014) Processing and mechanical behavior of lamellar structured degradable magnesium-hydroxyapatite implants. J Mech Behav Biomed Mater 40:178–189

Zomorodian A, Garcia MP, Moura E Silva T, Fernandes JCS, Fernandes MH, Montemor MF (2015) Biofunctional composite coating architectures based on polycaprolactone and nanohydroxyapatite for controlled corrosion activity and enhanced biocompatibility of magnesium AZ31 alloy. Mater Sci Eng C 48:434–443

Johnson I, Akari K, Liu H (2013) Nanostructured hydroxyapatite/poly(lactic-co-glycolic acid) composite coating for controlling magnesium degradation in simulated body fluid. Nanotechnology 24(37):375103

Linsheng L, Guoxiang L, Lihui L (2016) Research on the preparation, biocompatibility and bioactivity of magnesium matrix hydroxyapatite composite material. Biomed Mater Eng 27(2–3):251–258

Hickey DJ, Ercan B, Sun L, Webster TJ (2015) Adding MgO nanoparticles to hydroxyapatite-PLLA nanocomposites for improved bone tissue engineering applications. Acta Biomater 14:175–184

Kalantari E, Naghib SM (2019) A comparative study on biological properties of novel nanostructured monticellite-based composites with hydroxyapatite bioceramic. Mater Sci Eng C 98:1087–1096

Kalantari E, Naghib SM, Iravani NJ, Esmaeili R, Naimi-Jamal MR, Mozafari M (2019) Biocomposites based on hydroxyapatite matrix reinforced with nanostructured monticellite (CaMgSiO4) for biomedical application: Synthesis, characterization, and biological studies. Mater Sci Eng C 105:109912

Rasal RM, Janorkar AV, Hirt DE (2010) Poly (lactic acid) modifications. Prog Polym Sci 35(3):338–356

Saeidlou S, Huneault MA, Li H, Park CB (2012) Poly (lactic acid) crystallization. Prog Polym Sci 37(12):1657–1677

Cifuentes SC, Bensiamar F, Gallardo-Moreno AM, Osswald TA, González-Carrasco JL, Benavente R, González-Martín ML, García-Rey E, Vilaboa N, Saldaña L (2016) Incorporation of Mg particles into PDLLA regulates mesenchymal stem cell and macrophage responses. J Biomed Mater Res Part A 104(4):866–878

Jamshidian M, Tehrany EA, Imran M, Jacquot M, Desobry S (2010) Poly-Lactic Acid: production, applications, nanocomposites, and release studies. Compr Rev Food Sci Food Saf 9(5):552–571

Li L, Cui L-Y, Zeng R, Li S, Zheng Y, Mathan BK (2018) Advances in functionalized polymer coatings on biodegradable magnesium alloys—a review. Acta Biomater 79:23–36

Morawska-Chochół A, Chłopek J, Szaraniec B, Domalik-Pyzik P, Balacha E, Boguń M, Kucharski R (2015) Influence of the intramedullary nail preparation method on nail’s mechanical properties and degradation rate. Mater Sci Eng C 51:99–106

Kang EY, Park SB, Choi B, Baek SW, Ko KW, Rhim WK, Park W, Kim IH, Han DK (2020) Enhanced mechanical and biological characteristics of PLLA composites through surface grafting of oligolactide on magnesium hydroxide nanoparticles. Biomater Sci 8(7):2018–2030

Ferrández-Montero A, Lieblich M, González-Carrasco JL, Benavente R, Lorenzo V, Detsch R, Boccaccini AR, Ferrari B (2019) Development of biocompatible and fully bioabsorbable PLA/Mg films for tissue regeneration applications. Acta Biomater 98:114–124

Zimmermann T, Ferrandez-Montero A, Lieblich M, Ferrari B, González-Carrasco JL, Müller WD, Schwitalla AD (2018) In vitro degradation of a biodegradable polylactic acid/magnesium composite as potential bone augmentation material in the presence of titanium and PEEK dental implants. Dent Mater 34(10):1492–1500

Yang J, Cao X, Zhao Y, Wang L, Liu B, Jia J, Liang H, Chen M (2017) Enhanced pH stability, cell viability and reduced degradation rate of poly(L-lactide)-based composite in vitro: effect of modified magnesium oxide nanoparticles. J Biomater Sci Polym Ed 28(5):486–503

Cifuentes SC, Gavilán R, Lieblich M, Benavente R, González-Carrasco JL (2016) In vitro degradation of biodegradable polylactic acid/magnesium composites: relevance of Mg particle shape. Acta Biomater 32:348–357

Yamada S, Yamamoto A, Kasuga T (2014) Poly(l-lactic acid)/vaterite composite coatings on metallic magnesium. J Mater Sci Mater Med 25(12):2639–2647

Zhou H, Nabiyouni M, Lin B, Bhaduri SB (2013) Fabrication of novel poly(lactic acid)/amorphous magnesium phosphate bionanocomposite fibers for tissue engineering applications via electrospinning. Mater Sci Eng C 33(4):2302–2310

Chen Q, Thouas GA (2015) Metallic implant biomaterials. Mater Sci Eng R Rep 87:1–57

Nuss KMR, von Rechenberg B (2008) Biocompatibility issues with modern implants in bone-a review for clinical orthopedics. Open Orthop J 2:66

Ramesh N, Moratti S, Dias G (2017) Hydroxyapatite-polymer biocomposites for bone regeneration: a review of current trends. J Biomed Mater Res B Appl Biomater 106(5):2046–2057

Yang Y, Zheng K, Liang R, Mainka A, Taccardi N, Roether JA, Detsch R, Goldmann WH, Virtanen S, Boccaccini AR (2018) Cu-releasing bioactive glass/polycaprolactone coating on Mg with antibacterial and anticorrosive properties for bone tissue engineering. Biomed Mater 13(1):15001

Roh HS, Lee CM, Hwang YH, Kook MS, Yang SW, Lee D, Kim BH (2017) Addition of MgO nanoparticles and plasma surface treatment of three-dimensional printed polycaprolactone/hydroxyapatite scaffolds for improving bone regeneration. Mater Sci Eng C 74:525–535

Liu H, Wang R, Chu HK, Sun D (2015) Design and characterization of a conductive nanostructured polypyrrole-polycaprolactone coated magnesium/PLGA composite for tissue engineering scaffolds. J Biomed Mater Res Part A 103(9):2966–2973

Liu X, Grant DM, Palmer G, Parsons AJ, Rudd CD, Ahmed I (2015) Magnesium coated phosphate glass fibers for unidirectional reinforcement of polycaprolactone composites. J Biomed Mater Res Part B Appl Biomater 103(7):1424–1432

Liu X, Hasan MS, Grant DM, Harper LT, Parsons AJ, Palmer G, Rudd CD, Ahmed I (2014) Mechanical, degradation and cytocompatibility properties of magnesium coated phosphate glass fibre reinforced polycaprolactone composites. J Biomater Appl 29(5):675–687

Kharaziha M, Fathi MH, Edris H (2013) Effects of surface modification on the mechanical and structural properties of nanofibrous poly(ε-caprolactone)/forsterite scaffold for tissue engineering applications. Mater Sci Eng C 33(8):4512–4519

Dai Y, Lu Y, Li D, Yu K, Jiang D, Yan Y, Chen L, Xiao T (2017) Effects of polycaprolactone coating on the biodegradable behavior and cytotoxicity of Mg-6%Zn-10%Ca3(PO4)2 composite in simulated body fluid. Mater Lett 198:118–120

Yi D, Wu C, Ma B, Ji H, Zheng X, Chang J (2014) Bioactive bredigite coating with improved bonding strength, rapid apatite mineralization and excellent cytocompatibility. J Biomater Appl 28(9):1343–1353

Su J, Teng J, Xu Z, Li Y (2020) Biodegradable magnesium–matrix composites: a review. Int J Miner Metall Mater 27(6):724–744

Naqvi RB, Joya YF, Karim MRA (2018) Next-generation biomaterials for bone-tissue regeneration: Mg-alloys on the move. Key Eng Mater 778:306–315

NaddafDezfuli S, Brouwer JC, Mol JMC, van der Helm FCT, Zhou J (2018) Biodegradation and mechanical behavior of an advanced bioceramic-containing Mg matrix composite synthesized through in-situ solid-state oxidation. J Mech Behav Biomed Mater 80:209–221

Dezfuli SN, Huan Z, Mol A, Leeflang S, Chang J, Zhou J (2017) Advanced bredigite-containing magnesium-matrix composites for biodegradable bone implant applications. Mater Sci Eng C 79:647–660

Dezfuli SN, Leeflang S, Huan Z, Chang J, Zhou J (2017) Fabrication of novel magnesium–matrix composites and their mechanical properties prior to and during in vitro degradation. J Mech Behav Biomed Mater 67:74–86

Horch H-H, Sader R, Pautke C, Neff A, Deppe H, Kolk A (2006) Synthetic, pure-phase beta-tricalcium phosphate ceramic granules (Cerasorb®) for bone regeneration in the reconstructive surgery of the jaws. Int J Oral Maxillofac Surg 35(8):708–713

Akira O, Kondo N, Umezu H, Hotta T, Kawashima H, Tokunaga K, Ito T, Kudo N, Hoshino M, Gu W et al (2006) Histological assessment in grafts of highly purified beta-tricalcium phosphate (OSferion®) in human bones. Biomaterials 27(8):1542–1549

Rakovsky A, Gutmanas EY, Gotman I (2010) Ca-deficient hydroxyapatite/polylactide nanocomposites with chemically modified interfaces by high pressure consolidation at room temperature. J Mater Sci 45(23):6339–6344

Rakovsky A, Gotman I, Rabkin E, Gutmanas EY (2013) Strong bioresorbable Ca phosphate-PLA nanocomposites with uniform phase distribution by attrition milling and high pressure consolidation. J Mech Behav Biomed Mater 18:37–46

Tang M, Yan Y, OuYang J, Yu K, Liu C, Zhou X, Wang Z, Deng Y, Shuai C (2019) Research on corrosion behavior and biocompatibility of a porous Mg-3%Zn/5%β-Ca3(PO4)2 composite scaffold for bone tissue engineering. J Appl Biomater Funct Mater 17(2):2280800019857064

Huang Y, Liu D, Anguilano L, You C, Chen M (2015) Fabrication and characterization of a biodegradable Mg-2Zn-0.5Ca/1β-TCP composite. Mater Sci Eng C 54:120–132

Swain SK, Gotman I, Unger R, Kirkpatrick CJ, Gutmanas EY (2016) Microstructure, mechanical characteristics and cell compatibility of β-tricalcium phosphate reinforced with biodegradable Fe-Mg metal phase. J Mech Behav Biomed Mater 53:434–444

Yang Y, Guo X, He C, Gao C, Shuai C (2018) Regulating degradation behavior by incorporating mesoporous silica for Mg bone implants. ACS Biomater Sci Eng 4(3):1046–1054

Meifeng H, Xianyang H, Xue F, Deng P (2016) In vitro corrosion behavior and biocompatibility of biodegradable magnesium-pearl powder metal matrix composite. J Alloys Compd 663:156–165

Gabbai-Armelin PR et al (2018) Association of bioglass/collagen/magnesium composites and low level irradiation: effects on bone healing in a model of tibial defect in rats. Laser Ther 27(4):271–282

Joseph OO, Babaremu KO (2019) Agricultural waste as a reinforcement particulate for aluminum metal matrix composite (AMMCs): a review. Fibers 7(4):33

Sikora-Jasinska M, Paternoster C, Mostaed E, Tolouei R, Casati R, Vedani M, Mantovani D (2017) Synthesis, mechanical properties and corrosion behavior of powder metallurgy processed Fe/Mg2Si composites for biodegradable implant applications. Mater Sci Eng C 81:511–521

Jiang G, Wang C, Li Q, Dong J, He G (2015) Porous titanium with entangled structure filled with biodegradable magnesium for potential biomedical applications. Mater Sci Eng C 47:142–149

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors named K.O Babaremu, M. E. John U. Mfoh, E.T Akinlabi, I.P Okokpujie of the article titled “Behavioural Characteristics of Magnesium as a Biomaterial for Surface Engineering Application; A Review” do not have any conflict of interest as regarding this manuscript. Hence, have decided to publish this article in your prestigious journal.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Babaremu, K.O., John, M.E., Mfoh, U. et al. Behavioral Characteristics of Magnesium as a Biomaterial for Surface Engineering Application. J Bio Tribo Corros 7, 142 (2021). https://doi.org/10.1007/s40735-021-00579-4

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40735-021-00579-4