Abstract

The inhibitive action of an examined expired Ambroxol (AB) drug on the corrosion of mild steel in 1 M hydrochloric acid medium has been studied by both weight loss and electrochemical techniques. The weight loss techniques result was discussed. The inhibition efficiency increases with increasing the concentration of the AB inhibitor. Electrochemical studies data support that examined expired AB drug is an efficient inhibitor for mild steel in 1 M hydrochloric acid medium. The adsorption of the examined drug obeys Langmuir’s and Temkin adsorption isotherm. Polarization studies indicate that this inhibitor acts as a mixed mode of inhibition. The various thermodynamic parameters were calculated and discussed. The protective film formed on the surface was confirmed by FTIR, SEM and EDS. The quantum-chemical calculation also supports the inhibitive effect of the inhibitors. The data collected from the studied techniques are in good agreement to confirm the ability of using expired Ambroxol (AB) drug as corrosion inhibitor for mild steel in 1 M hydrochloric acid medium.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Corrosion is the primary means by which metals deteriorate [1]. Corrosion introduces itself into many parts of our lives. The great majority of us have personal feeling for the importance of corrosion [2]. Far too many have cringed at the emergence of rust holes in the body panels of relatively new automobiles [3]. The outdoor rusting of steel, household, and garden appliances is a common fact of our life. All have seen the strains on cooking utensils from hot foods or experienced the metallic taste in acid foods stored too long on open cans. That these effects are caused by corrosion is well known [4, 5]. However, corrosion is just as common in other material classes such as ceramics, plastics, and rubber. Since, practically all environments are corrosive to some degree and are major contributing causes of material failure and also are a large economic cost to the society [6]. Known to people as rust, corrosion is undesirable phenomenons which destroys the luster and beauty of the materials and lessens their life [7,8,9,10]. There is no single figure for loss to the nation due to corrosion. It can be a minimum of 3.5% of the nation’s GDP. Losses due to corrosion could be around Rs. 2.0 lakh crores per annum in India. Corrosion costs manifest in the form of premature deterioration or failure necessitating maintenance, repairs and replacement of damaged parts [11].

Corrosion has a huge economic and environmental impact on all facets of national infrastructure; from highways, bridges, buildings, oil and gas, chemical processing, water and waste water treatment, and virtually on all metallic objects in use. Other than material loss, corrosion interferes with human safety, disrupts industrial operations and poses danger to environment. Awareness to corrosion and adaptation of timely and appropriate control measures hold the key in the abatement of corrosion failures [12, 13].

The consequences of corrosion are many and varied, the effects of these on the safe, reliable and efficient operation of equipment or structures are often more serious than the simple loss of a mass of metal. Failures of various kinds and the need for expensive replacements may occur even though the amount of metal destroyed is quite small. Some of the major harmful effects of corrosion are nuclear plant shutdown due to failure e.g., nuclear reactor during decontamination process, replacement of corroded equipment resulting in heavy expenditure, high cost preventive maintenance such as painting, loss of efficiency, loss of product from a corroded container etc.,

Metals are opaque, lustrous elements that are good conductors, malleable, and ductile. In Chemistry, metals may be defined as elements that readily form cations (positive ions) and form metallic bonds with other metal atoms and ionic bonds with non-metals. Metals may also be described as a lattice of positive ions surrounded by a cloud of localized electrons. The metallurgist considers metals as elements that have overlapping conduction bands and valence bands in their electronic structure [14,15,16,17,18].

Metals are obtained from their ore by the expenditure of large amounts of energy. Metals store heat as potential energy during the smelting and refining process and release this energy during the corrosion process after reacting with the environment. These metals can therefore be regarded as being in a metastable state and will tend to lose their energy by reverting to compounds more or less similar to their original states, for example, the starting material for iron and steel making and the corrosion product rust has the same chemical composition (Fe2O3). The energy stored during melting and released during corrosion supplies the driving potential for the corrosion process to take place [19]. Since most metallic compounds, and especially corrosion products, have little mechanical strength, a severely corroded piece of metal is quite useless for its original purpose. Metals such as Mg, Al, Zn, and Fe which require larger amount of energy for refining are more susceptible to corrosion than metals which require lesser amount for refining such as gold, silver, and platinum [20].

Hydrochloric acid is the medium generally being used for pickling of mild steel in various industries. The using corrosion inhibitors are one of the most effective and economical methods to protect metal from corrosion in acidic medium. Recently, many expired drugs have been reported to be very effective corrosion inhibitors for the protection of mild steel in acidic media to promote eco-friendly environment [21]. In this study, the inhibitive effect of expired Ambroxol drug on the corrosion of mild steel was investigated using weight loss and electrochemical method. The literature report on the studies of corrosion inhibition effect on Ambroxol on mild steel in acidic media was reported in our earlier paper in sulfuric acid medium [22]. Hence, attempts are made to utilize the expired Ambroxol drug acts as anticorrosion agent on mild steel in hydrochloric acid medium.

2 Materials and Methods

Solution of 1 M concentration of hydrochloric acid was prepared from analar grade. The composition of mild steel has been analyzed using vacuum emission spectrometer. The composition of mild steel has found to be 0.03% carbon, 0.25% manganese, 0.015% silicon, 0.003% phosphorus, and the remaining iron. The commercially available cold rolled mild steel sheets were machined into strips of rectangular size 5 × 1 × 0.2 cm3 containing a hole at one end of the coupons for easy hooking. These specimens were polished with different grades of emery paper, degreased with acetone, washed with double-distilled water and properly dried and stored in desiccator.

2.1 Analytical Methods

2.1.1 Weight Loss Method

The pre-treated specimen’s initial weights were noted accurately and were fully immersed in 100 ml of the experimental solution (in triplicate) of 1 M hydrochloric acid with and without different concentrations [1.0–11.0% (v/v)] of the AB inhibitor with the help of glass hooks at different time intervals (0.5, 2, 4, 6, 8, and 24 h) and temperature (303, 313, 333, and 343 K). After the exposed period, the specimen was removed, dried, and weighed. From the weight loss, the inhibition efficiency (IE), surface coverage (θ), and corrosion rate (mpy) were calculated using the formula given in our earlier papers [23,24,25,26,27,28].

2.1.2 Electrochemical Method

The electrochemical measurements were carried out in a conventional three-electrode cell assembly consisting platinum electrode as an auxiliary electrode, saturated calomel electrode as reference electrode and mild steel as working electrode. A time interval of 30 min was given for each experiment to attain the steady-state open-circuit potential. The three-electrode set-up was immersed in hydrochloric acid solutions in the absence and presence of AB inhibitor at room temperature. For the measurements of impendence, the cell used was same as that used for potentiodynamic polarization. An AC potential of 10 mV was super imposed on the study of open-circuit potential. Nyquist plots were obtained from the results of these experiments. The charge transfer resistance (Rct) values were obtained from the plots of Z′ versus Z″ and the double-layer capacitance Cdl values were obtained from the following Eq. (1),

where, Cdl is the double-layer capacitance; Rct is the charge transfer resistance; fmax is the frequency at Z″ value maximum.

Besides, the above method, the inhibition efficiencies were obtained from Rp and Rct values as follows:

where Rp(i) and Rp are the charge transfer resistance in the presence and absence of AB inhibitor.

2.1.3 Surface Examination Studies

The surface morphology of corrosion product on mild steel sample in 1 M hydrochloric acid in the absence and presence of 9.0% (v/v) of examined expired Ambroxol (AB) at 4 h was studied. After the immersion period, sample was dried and analyzed by a scanning electron microscope with SEM Hitachi model S-4500 field emission. SEM with a Quartz X-One EDX system at magnification from 500 to 3000 operated at an accelerating voltage of 20 kV.

2.1.4 Theoretical Calculations

The Quantum-chemical calculations were done using semi-empirical method—Parameterized Model 3 (PM 3). This method is suitable for analyzing closely resembling molecules that are subject of our correlation studies. The output of MOPAC program reports values such as ionization potential, Eigen values, dipole moment etc. The quantum-chemical parameters were generated to evaluate the theoretical inhibition efficiency of the inhibitor molecule.

3 Results and Discussion

3.1 By Weight Loss Method

3.1.1 Effect of Immersion Time on Corrosion Rate (CR) and Inhibition Efficiency (IE)

The variation of inhibition efficiency showed in Table 1 and corrosion rate mentioned in Table 2 with change in concentration of the inhibitors are presented. It is obvious from the data that there is decrease in the corrosion rate with increase in the examined AB inhibitor from 1.0 to 11.0% v/v concentration for all immersion periods. The decrease in corrosion rate and increase in inhibitor efficiency is usually attributed to the adsorption of inhibitor constituents on the surface of mild steel which makes a barrier for mass and charge transfers and protects further attack by the acid [29,30,31,32,33]. The maximum inhibition efficiency was noticed at a concentration 9.0% of the inhibitor are 94.03% for examined AB inhibitor in 1 M hydrochloric acid medium. The inhibitor efficiency increases with an increase in immersion time, since more adsorption takes place on the metal surface which is mentioned in Table 1. From the Table 2, we can clearly see about the corrosion rate of the AB inhibitor in 1 M hydrochloric acid medium. Optimum inhibition efficiency is reached at 4 h (Fig. 1).

3.1.2 Effect of Temperature on CR and IE of AB Inhibitor on Mild Steel in 1 M HCl

The effect of temperature on inhibition reaction of inhibited acid metal surface is highly complex, because many changes may occur on the metal surface, such as rapid etching, rupture, desorption of the inhibitor, and the decomposition and/or rearrangement of the inhibitor [34,35,36,37,38]. Temperature has a great effect on the rate of metal electrochemical corrosion. In case of corrosion in an acid medium, the corrosion rate increases with temperature increase because the hydrogen evolution over potential decreases [39]. It is generally assumed that in the acid corrosion the inhibitors adsorb on the metal surface, resulting in a structural change of the double-layer and reduced rate of the electrochemical partial reaction [40]. In industrial processes like pickling and acid cleaning, the choice of optimum temperature is of particular importance as temperature modifies the interaction between the mild steel surface and the acid media in the absence and presence of inhibitor.

In the presence of inhibitor which is of adsorptive type the temperature variation affects the metal dissolution as well as the degree of metal surface coverage by inhibitor at a constant value of its bulk concentration. To test the stability of the AB inhibitor at higher temperature, experiments were performed at different temperature in the range of 303–343 K in 1 M hydrochloric acid medium [41]. The obtained corrosion rate (CR) and inhibition efficiency (IE%) result are listed in the Table 3. A remarkable decrease in mild steel corrosion was noticed with the addition of increasing amounts of AB inhibitor used at each temperature. The maximum efficiency was found to be 93.35% at 333 K for 9.0 v/v% concentration of the inhibitor. This increase in efficiency with increase in temperature (Fig. 2) suggests the chemical adsorptions of the inhibitor over the corroding surface.

3.1.3 Thermodynamic Parameters of Adsorption of the AB Inhibitor in 1 M HCl

Thermodynamic parameters play an important role in understanding the inhibitive mechanism. The increase of temperature increases the rate of all electrochemical processes and influences adsorption equilibrium and kinetics as well. Temperature investigations allow the determination of activation energy in the absence and in the presence of inhibitor. The obtained results can elucidate the mechanism of corrosion inhibition [42]. The adsorption mechanism is offered by considering the apparent activation energies (Ea) for the mild steel dissolution in hydrochloric acid solutions in the absence and presence of different concentrations of the tested inhibitors. The energy of activation (Ea), for mild steel dissolution in the blank hydrochloric acid as well as hydrochloric acid with different concentrations of the AB inhibitor at temperatures range of 303–343 K. Energy of activation (Ea) has been calculated from the Arrhenius equation. The Arrhenius plots (Fig. 3) for the AB inhibitor in 1 M hydrochloric acid medium is shown. It is observed that the apparent activation energy (Ea) value decreases in the presence of the inhibitor [43]. Activation energy (Ea) value for blank is 60.98 kJ/mol and 41.42 kJ/mol for 9.0% concentration of the AB inhibitor listed in the Table 4. The decrease in activation energy in the presence of the inhibitor and increase in inhibition efficiency with temperature are suggestive of chemisorption of inhibitor on the metal surface. The negative value of free energy of adsorption (∆Gads) indicates the spontaneous adsorption of the inhibitor [44]. The positive values of entropy and negative values of enthalpy of adsorption indicates that the strong interaction of the inhibitor with the metal surface. An endothermic reaction suggesting that a high temperature favors the complexation process and it is in good agreement with the increase in stability with the temperature. This also supports the assumption of chemical adsorption [45]. Also the above mentioned factors support the assumption of chemical adsorption.

3.1.4 Adsorption Isotherm

Inhibition of metal dissolution in acidic media involves adsorption of organic molecules at the metal–electrolytes interface. Corrosion inhibition is generally believed to be due to the formation and maintenance of a protective film on the metal surface. Adsorptions isotherm are very important in determining the mechanism of organo-electrochemical reactions, the most frequently used are those of Langmuir, Frumkin, Parsons, Temkin, Flory–Huggins, and Bockris–Swinkels. The data were tested graphically by fitting to various isotherms. Temkin adsorption isotherm (Fig. 4) was applied to explain the nature of the adsorption of the inhibitor. This explains the relationship between log Ѳ/(1 − Ѳ) and concentration of the three inhibitors at various temperatures. A starlight line is obtained on plotting log Ѳ/(1 − Ѳ) versus log C suggesting that adsorption of the compound on the surface of mild steel follows Langmuir’s adsorption isotherm (Fig. 5). These results depicted that all the slopes are close to unity, which indicates that the adsorption of all the inhibitor follows Langmuir adsorption isotherm [46]. This isotherm is applicable for the chemisorptions of species to form a monolayer on the surface.

3.2 Electrochemical Methods

3.2.1 Potentiodynamic Polarization (Tafel) Studies in 1 M HCl

Electrochemical measurements were carried out to study the nature of inhibitor, mode of action, and mechanism of reaction. The effect of the acid dissolution of the inhibitors on the electrochemical behavior of mild steel in 1 M hydrochloric acid solutions in the absence and presence of inhibitor was studied and the electrochemical parameters such as corrosion potential (Ecorr), corrosion current density (Icorr), anodic and cathodic Tafel slopes (ba and bc), resistance polarization (Rp), and percentage inhibition efficiency based on Tafel fit and linear polarization fit are listed in the Table 5.

The results revealed the strong inhibiting effect of the AB inhibitor. Ecorr values are centered and the addition of inhibitors in 1 M hydrochloric acid solution did not show much significant change in Ecorr in all the three expired drugs suggesting that the acid dissolution control the corrosion by controlling both anodic and cathodic reactions. This indicates that the inhibition of corrosion of mild steel in 1 M hydrochloric acid for the acid dissolution is under mixed control [47]. The Ecorr values are also shifted to the more negative side with an increase in the inhibitor concentration. These shifts can be attributed to the decrease in the rate of metal dissolution process. Icorr values of the inhibited acids are lower than that of the uninhibited acid, which indicates that increase in corrosion inhibition property is due to increase in blocked fraction by adsorption of inhibitor molecules on the electrode surface. Thus as the concentration increases, there is a regular decrease in Icorr, showing that AB inhibitor in 1 M hydrochloric acid acts as a very good inhibitor for mild steel. Lower Icorr values without causing any significant changes in the corrosion potential. Ecorr suggests that the AB inhibitor is a mixed-type inhibitor [48].

Even though ba and bc values change with an increase in inhibitor concentrations, a higher bc values indicates that the cathodic reaction is retarded to a higher extent than the anodic reaction. It can also be stated as due to formation of oxides on the metal surface in the presence of the inhibitor which is confirmed by the presence of metal oxygen bond observed on the surface of mild steel through FTIR technique. This observation suggests that the inhibitor consists of various organic compounds like phenols, amino acids, all of which might act by specific mechanism and the overall effect may be a mixed mode of inhibition [49]. Inhibition efficiency has been calculated by both Tafel method and linear polarization method. The IE values were found to increase with increase in the concentration of the acid dissolution.

The maximum linear inhibition efficiency at an optimum concentration of 9.0% v/v of AB in 1 M hydrochloric acid was found to be 60.52%. The polarization curves for mild steel in 1 M hydrochloric acid solution in the absence and presence of AB inhibitor is shown (Fig. 6). From the figures, it can be interpreted that the addition of the inhibitor to corrosive media changes the anodic and cathodic Tafel slopes [50]. The changes in slopes showed the influence of the inhibitor both the cathodic and anodic reaction. However, the influence is more pronounced in the cathodic polarization plots compared to that in the anodic polarization plots. Compared with the blank solution, a marked shift of about one order of magnitude decrease in the cathodic current is seen at higher concentration of the inhibitor. Polarization plots reveal that the presence of the inhibitor shifts the anodic curves towards the more positive potential direction and the cathodic curves towards the negative direction. The shapes of Tafel plots also indicate that the electrodic reactions are kinetically controlled [51].

3.3 Electrochemical Impedance Spectroscopy (EIS)

3.3.1 Impedance Studies of Mild Steel in 1 M HCl

The EIS method is very useful in characterizing electrode behavior. The EIS technique is based on the response of an equivalent Randles circuit (Fig. 7) for an electrode-solution interface [52]. The equivalent circuit consists of double-layer capacitance (Cdl) in parallel with charge transfer resistance (Rct) which is in series with solution resistance (Rs). Values of these components and inhibition efficiencies are derived from EIS measurements.

The corrosion behavior of mild steel in 1 M hydrochloric acid solution in presence of AB was investigated by EIS method at room temperature. The various parameters such as charge transfer resistance (Rct), double-layer capacitance (Cdl) and the corresponding inhibition efficiency were calculated and given in the Table 6. The charge transfer resistance (Rct) is calculated from difference in impedance at lower and higher frequencies.

The increase in Rct values with an increase in inhibitor concentration is the result of an increase in the surface coverage by the inhibitor molecules. The increased surface coverage led to an increase in inhibitor efficiency. From the data it is clear that Cdl values decrease with the increase in inhibitor concentrations due to the adsorption of the chemical constituents of the acid dissolution of the expired drugs replacing water at the metal-solution interface that led to the decrease in local dielectric constant and/or an increase in the thickness of the electrical double-layer and also decrease the roughness of the mild steel surface [53].

The Nyquist plots for various concentrations of the inhibitor are given. The impedance diagram for AB in 1 M hydrochloric shows (Fig. 8) that the diameters of the Nyquist plot which is semicircular in appearance. There was a gradual increase in the diameter of each semicircle of the Nyquist plot due to increase in the number of inhibitive molecules in the dissolution when the concentration was raised from 2.0, 5.0 and 9.0% v/v. This suggested that the formed inhibitive film was strengthened by addition of inhibitor. The increase in diameters clearly reflected that the Rct values also increased from 46.61 to 67.47 ohm cm2 for AB inhibitor as moving from 2.0% o the highest concentration of 9.0% v/v. This may be due to formation and gradual improvement of the barrier layer of the inhibitive molecules (IE) and as a result the acid corrosion rate of mild steel gradually decreased [54]. Thus, it may be inferred that the inhibitor could be adsorbed in specific places on the mild steel surface. According to this mechanism the inhibitor could be adsorbed at active points thus causing the corrosion rate to drop. The difference in corrosion rate is attributed to the frequency dispersion, due to roughness and in-homogeneity of the solid surface.

3.4 Surface Examination Studies

The results pertaining to the comparison of corrosion inhibition efficiency of some expired drugs such as Ambroxol in 1 M hydrochloric acid medium on mild steel are supported by the Scanning electron microscopy (SEM) micrographs, Energy dispersive X-ray (EDX) and Fourier transform infrared (FTIR) spectroscopy. The surface morphological characteristics of the uninhibited mild steel in 1 M hydrochloric acid medium and the inhibited mild steel using AB in 1 M hydrochloric acid medium was analyzed under SEM Hitachi model S-4500 field emission SEM with a Quartz X-One EDX system at magnification from 500 to 3000 operated at an accelerating voltage of 20 kV.

3.4.1 Scanning Electron Microscopy (SEM) Analysis

SEM photographs of the polished mild steel specimen and mild steel specimens after immersion in 1 M hydrochloric acid medium without (Fig. 9a) and with (Fig. 9b) the inhibitor containing optimum concentration of (9.0% v/v) inhibitor are presented. In the SEM photograph of polished mild steel (Fig. 9), no pits or cracks were observed except polishing lines. Inspection of figures revealed that (Fig. 9a) the specimens immersed were rough and extremely damaged in the presence of 1 M hydrochloric acid medium. The depth of surface corroded due to exposure of mild steel to acid is well visible with shallow pits, pores and cracks [55]. The SEM photographs of mild steel exposed to acids containing AB inhibitor (Fig. 9b) show that there is less damage on the mild steel surface which clearly confirms the inhibition action due to the formation of protective film by the chemical components present in the inhibitor on the mild steel surface resulting in a decrease in the contact between the metal and the aggressive medium and effectively exhibit excellent inhibition effect. It was also noticed that the corrosion products formed are found to deposit as separate layers in cluster.

3.4.2 Energy Dispersive X-ray Spectroscopy (EDX) Studies

EDX spectra employed to investigate the composition of the corrosion scales in the case of mild steel immersed for 4 h in 1 M hydrochloric acid without and with the inhibitor containing 9.0% v/v concentration. The percentage atomic content of Fe for mild steel immersed in 1 M hydrochloric acid is 59% (Fig. 9c). And those for mild steel dipped in an optimum concentration of the inhibitor AB is 79.85 (Fig. 9d). From the figures, the spectra of inhibited samples show that the Fe peaks are considerably suppressed, when compared with uninhibited mild steel samples [56]. This suppression of Fe lines is due to the inhibitory film formed on the metal surface. EDX analysis is good agreement with the results of electrochemical studies, which suggest that the surface film inhibits the metal dissolution.

3.4.3 Fourier Transforms Infrared Spectroscopy (FTIR) Studies

The FTIR spectra may be taken for inhibitor in an automatic recording FTIR spectrophotometer. The region in the FTIR spectrum shows spectral bands or peaks due to the vibrations of individual bonds or functional groups. The fact that many functional groups can be identified by their characteristic vibration frequencies makes the spectrum, the simplest and often the most reliable method of assigning a compound to its class. In spite of this, FTIR spectroscopy is most frequently used in chemical studies as a ‘fingerprint’ device, for comparing natural samples. The complexity of the spectrum lends itself particularly well to this purpose and such comparisons are very important in the complete identification of many types of chemical constituent. The spectroscopy can also usefully contribute to structural elucidation, when new compounds are encountered. FTIR spectra were taken for raw inhibitor in hydrochloric acid dissolution. The results of FTIR peak values and functional groups are represented in Table 7. The FTIR spectrum AB inhibitor profile is illustrated (Fig. 10 a, b, c). The FTIR spectrum confirmed the presence of alcohols, amides, alkenes, and para substituted acid aromatic compounds, carboxylic acids, ethers, esters, amines, halogens, and aromatics in different inhibitor. FTIR spectroscopy is a powerful tool that can be used to determine the type of functional groups and bonding for organic inhibitors adsorbed on the metal surface. FTIR spectra of adsorption layer formed on the mild steel surface after immersion of 1 M hydrochloric acid (Fig. 10c) and with AB inhibitor (Fig. 10b) shows the presence of OH, NH, C=O group of amide and aromatic rings. The inhibition active dissolution of the metal is due to the adsorption of inhibitor molecules on the metal surface forming protective film. The inhibitor molecules can be adsorbed onto the metal surface through electron transfer from the adsorbed species to the vacant electron orbital of low energy in the metal to form co-ordinate type complex with the metal through the functional groups and π electrons of aromatic ring [57].

3.5 Mechanism of Inhibition

The mechanism of the inhibition process of the corrosion inhibitors under consideration is mainly due to the adsorption. The phenomenon of adsorption is influenced by the nature and surface charge of the metal and by chemical structure of inhibitors. The surface charge of the metal is due to the electrical field which emerges at the interface on immersion in the electrolyte. Weight loss, potentiodynamic polarization, and EIS measurement clearly depict that corrosion of mild steel in 1 M hydrochloric acid was retarded in the presence of the inhibitor. The results clearly showed that the inhibition mechanism (Fig. 11) involves blocking of mild steel surface by inhibitor molecules by adsorption.

The inhibition efficiency values of the investigated inhibitors were found to vary in the different acid media. The differences in inhibition efficiency may be referred to the molecular structure effect, and the rigidity of pi-delocalized system of the inhibitor that may cause the increasing or decreasing of the electron density on center of adsorption, and leading to an easier electron transfer from the functional groups to the metal, producing greater co-ordinate bonding. Besides the physical adsorption, the inhibitor may be adsorbed on the metal surface via the chemical adsorption mechanism, involving the co-ordinate bonds that may be formed between the lone electrons of N atom and the empty p-orbital of Fe atoms which enhanced the combination intension between the inhibitor molecule and electrode surface. The adsorption of the inhibitor molecules on the mild steel surface can be explained on the basis of the four methods. They are

-

(i)

Electrostatic attraction between charged molecules and the charged metals.

-

(ii)

Interaction of unshared electron pairs in the molecule with the metal.

-

(iii)

Interaction of π electron with the metal

-

(iv)

A combination of all the above.

The inhibition mechanism can be explained by the formation of Fe-(Inh) ads intermediates:

This Fe-(Inh)ads is the intermediate of inhibitor adsorption. The adsorption layer acts as a hindrance to the aggressive solution and enhances the protection of the metal surface. Initially there is insufficient Fe-(Inh)ads to cover the metal surface, because the inhibitor concentration is low or because the adsorption rate is slow, the metal dissolution takes place at sites on mild steel surface where Fe-(Inh)ads is not available. To further elucidate the mechanism of inhibitor adsorption, it is necessary to establish the adsorption modes of the inhibiting species. The predominant adsorption mode depends upon factors such as the extract composition, type of acid anion as well as chemical changes to the acid dissolution of the inhibitors. The isolated inhibitors undergo protonation easily in hydrochloric acid medium. The protonated species can get adsorbed on cathodic sites of the mild steel surface and reduce hydrogen gas evolution.

Besides the physical adsorption, inhibitor may be adsorbed on the metal surface via the chemisorption mechanism, involving the co-ordinate bonds that may be formed between the lone pair of the un-protonated N atoms and the empty orbital of Fe atom which enhanced the condensation intension between the inhibitor molecule and electrode surface. Inhibition efficiency also depends on the number of adsorption sites, their charge density, molecular size, and heat of hydrogenation, mode of interaction with metal surface, and formation of metallic complex. Physical adsorption requires the presence of electrically charged metal surface, charged species in the solution, presence of metal with vacant low-energy electron orbital and inhibitor molecules with lone pair of electrons. Structural and electronic parameters like type of functional group, steric and electronic effects are also responsible for the inhibition efficiency of any inhibitor. Since the compound has to block the active corrosion sites present on the metal surface, the adsorption occurs by free electrons of the inhibitor linking with the metals. The inhibitors normally have organic compounds containing:

-

1.

Heteroatoms (N, S, P, O) with lone pair of electrons

-

2.

Molecules with π-electrons which are most effective but harmful to the environment

-

3.

Cyano groups with triple bonds and

-

4.

Heterocyclic compounds like phenolic compounds, etc.

Most of these organic compounds possess heteroatoms such as O- and N- which strengthen their adsorptive property over metal surface and hence the anti-corrosive behavior. It was reported that N-containing compounds are relatively ineffective in prevention of corrosion of iron and steel in sulfuric acid solutions unless certain anions, especially halide and pseudo-halide ions, are present. This long known synergistic effect is widely used in inhibitor formulation as a rule of thumb; N- containing compounds exert their best efficiencies in hydrochloric solutions. Thus it can be suggested that the high inhibition efficiency of AB may be due to the active organic constituents containing –O and –N. The inhibiting influence of these molecules can be attributed to their adsorption through the NH, C=O, OH, COOH groups and also may be due to the presence of more π electrons in the rings.

It can be suggested that they may act together for their better protective performance towards acid corrosion of mild steel. These organic molecules get chemisorbed on the metal surface forming a protective film. The adsorbed organic molecules may interact with each other as well as with the electrode surface [58]. In present case the inhibitors consisted of -O and- N containing groups which orient themselves over the metal surface (Fig. 12) so as to cover it horizontally via weak bonding.

The inhibitors inhibit the dissolution reaction by adsorption at the metal surface in two different ways. First, the inhibitor may compete with Cl− or SO42− of ions for sites at the water covered anodic surface. The protonated inhibitor then loses its associated protons in entering the double-layer and chemisorbs by donating electrons to the metal. In addition, the protonated inhibitor electrostatically adsorbs onto the anion covered surface, through its cation form [59]. Since chemisorption plays a main role, competitive adsorption of the green inhibitor which involves the donation of electron pair to the metal surface appears too predominant.

Moreover, the expired drugs show good inhibition efficiency in sulfuric acid medium than in hydrochloric acid media. This may be due to the availability of more sites on the metal surface in sulfuric acid medium because of lesser adsorption of the sulfate ions on the steel surface [60]. This results in high IE even at relatively low concentration of the extract. This also explains the observation that increases in concentration of the inhibitor above 9.0% v/v does not show significant change in the inhibition efficiency.

3.6 Quantum-Chemical Calculations

Quantum-chemical methods have a strong impact towards the design and development of corrosion inhibitors. Density functional theory has been used to precisely calculate information regarding molecular geometries and electron distributions. Due to its accuracy and smaller time requirement for the computational methods; it’s widely used to analyze the inhibition efficiency and inhibitors surface interactions [61]. The chemical reactivity of an organic inhibitor with metal surfaces has been widely reported to depend on a set of quantum-chemical parameters such as the energy of the higher occupied molecular orbital (EHOMO), the energy of the lowest unoccupied molecular orbital (ELUMO), energy gap (∆E = EHOMO − ELUMO), the dipole moment (µ), and atomic charges of reactive atoms.

According to the frontier molecular orbital theory, the formation of a transition state is due to an interaction between the highest occupied molecular orbital (HOMO) and the lowest unoccupied molecular orbital (LUMO) of the reactants. It is found that, high EHOMO values of the molecules leads to higher electron donating ability to appropriate acceptor molecules with low-energy empty molecular orbital. A low ELUMO values suggests that the molecule accepts electrons easily from donor molecules. The difference (∆E = ELUMO − EHOMO) is the energy required to move an electron from HOMO to LUMO. The energy gap (ΔE) between the HOMO and LUMO provides information about the overall reactivity of a molecule. As ΔE decreases, the reactivity of the molecule increases leading to increase in the inhibition efficiency of the molecule [62]. Low values of the ΔE gap will render good inhibition efficiencies since the energy to remove an electron from the last occupied orbital will be minimized. A molecule with a low energy gap is more polarizable and is generally associated with the high chemical activity and low kinetic stability and is termed soft molecule [63].

Low value of the dipole moment (µ) will favors the accumulation of inhibitor molecules on the metallic surface. From the values of Mulliken charge we can observe the presence of excess of negative charge on nitrogen, oxygen, and sulfur atoms which can be adsorbed on the metal surface using these active centers leading to the corrosion inhibition action. High ionization energy indicates high stability and chemical inertness and small ionization energy indicates high reactivity of the atoms and molecules. The low ionization energy (eV) indicates the high inhibition efficiency. A hard molecule has a large energy gap and a soft molecule has a small energy gap [64].

Normally, the inhibitor with the least value of global hardness [Chemical hardness (η)] (hence the highest value of global softness) is expected to have the highest inhibition efficiency. For the simplest transfer of electron, adsorption could occur at the part of the molecule where softness(S), which is a local property, has a highest value [65].

3.6.1 Quantum Studies for the Inhibitor AB

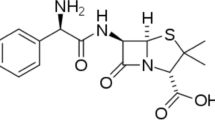

The AB inhibitor contains two chemical constituents namely, Ambroxol hydrochloride and Salbutamol sulfate, its optimized geometry (Fig. 13a, b), HOMO and LUMO (Figs. 14a, b, 15a, b) are shown. The related quantum-chemical parameters are given in the Table 8. In analysis, the trend for the ΔE values follows the order Ambroxol hydrochloride > Salbutamol sulfate, which suggests that AB inhibitor’s constituents Ambroxol hydrochloride has the highest reactivity in comparison to the salbutamol sulfate.

4 Evaluation of Inhibition Efficiency of the Inhibitor Obtained from Different Techniques

The inhibition efficiency obtained by the weight loss measurements, polarization, and electrochemical impedance techniques are given in the Table 9. The inhibition efficiency of the AB drug studied by various techniques is almost similar. Hence the expired drug AB can be effectively used as an inhibitor for static and dynamic conditions. Corrosion is a natural process which reduces the binding energy in metals. The end result of corrosion involves a metal atom being oxidized, whereby it loses one or more electrons. The corrosion manifests itself as a break-up of bulk metal to metal powder. Corrosion degrades the useful properties of materials. Based on the above investigations, the following conclusions were drawn. The weight loss measurements were carried out for mild steel in 1 M hydrochloric acid medium in the absence and presence of various concentrations of the AB inhibitor at different immersion period and different temperature range (303–343 K). The weight loss, electrochemical methods, SEM, EDX, FTIR, and quantum-chemical calculations were employed in the present investigation.

5 Conclusion

-

The expired Ambroxol drug acts as good and efficient corrosion inhibitor for the corrosion of mild steel in 1 M HCl medium by weight loss method and electrochemical methods

-

The inhibition efficiencies (IE) of inhibitor is found to increase with increase of concentration and exposure time.

-

The inhibitor is found to obey Temkin and Langmuir adsorption isotherm.

-

Polarization studies indicate that the inhibitor act as a mixed-type inhibitor.

-

The FTIR results indicate the presence of a uniform film over the metal surface, which effectively protects from the corrosion.

-

The SEM and EDX morphology of the adsorbed thin film on the mild steel surface has shown high performance of inhibitive effect of the inhibitors. SEM reveals the formation of a smooth uniform surface on mild steel in the presence of the inhibitor which indicates the formation of a good protective layer on the metal surface.

-

Quantum-chemical calculation also supports the inhibitive effect of the inhibitor.

-

Data obtained from the conventional weight loss method and electrochemical measurements have shown that the compound has excellent inhibiting properties for mild steel in acid solution and was also found to follow the similar trend.

References

Abdallah M, Jahdaly AL (2015) Gentamicin, Kanamycin and Amikacin Drugs as Non toxic inhibitors for corrosion of aluminum in 1.0 M hydrochloric acid. Int J Electrochem Sci 10:9808–9823

Abdallah M, Zaafarany I, Al-Karanee SO, Abd El-Fattah AA (2012) Antihypertensive drugs as an inhibitors for corrosion of aluminum and aluminum silicon alloys in aqueous solutions. AraJ Chem 5:225–234

Abdel Hameed RS, AlShafey HI, Abu-Nawwas SH (2014) 2-(2,6-Dichloranilino) phenylacetic acid drugs as ecofriendly corrosion inhibitors for mild steel in 1 M HCl. Int J ElecChem Sci 9:6006–6019

Abdel Hameed RS (2011) Ranitidine drugs as non-toxic corrosion inhibitors for mild steel in hydrochloric acid medium. Port ElecChimActa 29:273–285

Singh AK et al (2013) Cephamycin-A novel corrosion inhibitor for mild steel corrosion in HCl acid solution. Int J ElecChem Sci 8:9442–9448

Singh AK, Ebenso EE (2013) Cefotatan; a new corrosion inhibitor for corrosion of mild steel in hydrochloric acid solution. Int J ElecChem Sci 8:10903–10909

Ahama I, Khan S, Ansari KR, Quraishi MA (2011) Primaquine: a pharmaceutically active compound as corrosion inhibitor for mild steel in hydrochloric acid solution. J Chem Pharm Res 3(2):703–717

Ahmad A, Alamiery AA, Kadhum H (2013) Synthesis and characterization of a novel eco-friendly corrosion inhibition for mild steel in 1 M hydrochloric acid. Sci Rep, 6:1420–1431

Akpan IA (2014) Amodiaquine drug as a corrosion inhibitor for mild steel in 0.1 M HCl solution. Chem Met Alloys 7:149–153

Singh A, Singh AK, Quraishi MA (2010) Dapsone-a novel corrosion inhibitor for mild steel in acid media. Open Elec Chem J 2:43–51

Ansari KR, Quraishi MA, Ebenso EE (2013) Electrochemical and thermodynamic investigation of diclofenac sodium drug as a potential corrosion inhibitor for mild steel in hydrochloric acid. Int J ElecChem Sci 8:12860–12873

Verma CB, Quraishi MA, Ambrish Singh (2015) Corrosion inhibition of mild steel in hydrochloric acid by some pyridine derivatives: An experimental and quantum chemical study. J Taiwan Ins Chem Engg 25:89–98

Chadrasekaran K, Jayasree AC, Bangaru SA, Ravichandran R (2014) Protective effect of N-[(benzylidene hydrazino)-propyl]-benzotriazole and N-[(4-oxo-2-phenyl-1,3-thiazolidineimino)-propyl]-benzotriazole for the control of corrosion of Cu-Ni (90/10) alloy in Sea water. Elixir Cor 16:22941–22946

Anal Jha K, Kamal Prasad (2016) Green synthesis and antimicrobial activity of silver nanoparticles onto cotton fabric: an amenable option for textile industries. Adv Mater Lett 7(1):42–46

Anal Jha K, Kamal Prasad (2012) Synthesis of nanomaterials using expired medicines: an eco-friendly option. Nano Tech 2(7):36–39

Ebenso EE, Arslan T, Kandemirli F (2010) Theoretical studies of some sulphonamides as corrosion inhibitors for mild steel in acidic medium. Int J Quantum Chem 10:2614–2636

Fouda AS, Mohamed M, Farahat Abdallah M (2014) Cephalosporin antibiotics as new corrosion inhibitors for nickel in HCl solution. Res Chem Intermed 40:1249–1266

Geethamani P, Kasthuri PK (2016) The inhibitory action of expired asthalin drug on the corrosion of mild steel in acidic media: a comparative study. J Taiwan Ins ChemEngn 63(4):490–499

Hari Kumar S, Karthikeyan S (2012) Inhibition of mild steel corrosion in hydrochloric acid solution by cloxacillin drug. J Mat Environ Sci 3(5):925–934

Hari Kumar S, Karthikeyan S (2013) Amoxicillin as an efficient green corrosion inhibitor for mild steel in 1 M sulphuric acid. J Mat Environ Sci 4:675–984

Karthik G, Sundaravadivelu M (2013) Inhibition of mild steel corrosion in sulphuric acid using esomeprazole and the effect of iodide ion addition. ISRN ElecChem 23:1–10

Kasthuri PK, Arulanantham A (2010) Ecofriendly extract of euphorbiahirta as corrosion inhibitor on mild steel in sulphuric acid medium. Asian J Chem 22(1):430–436

Obi-Egbedi NO, Obot IB, Eseola AO (2014) Synthesis, characterization and corrosion inhibition efficiency of 2-(6-methylpyridin-2-yl)-1Himidazo[4,5-f][1,10] phenanthroline on mild steel in sulphuric acid. Arb J Chem 7:197–207

Obi-Egbedi NO, Obot IB, El-Khaiary MI, Umoren SA, Ebenso EE (2011) Quantum chemical studies on the inhibition potentials of thiophene derivatives for the corrosion inhibitors of carbon steel. Int J Ele Chem Sci 6:5649–5675

Obot IB, Obi-Egbedi NO, Eseola AO (2011) Anticorrosion potential of 2-Mesityl-1H-imidazo[4,5-f][1,10] phenanthroline on mild steel in sulfuric acid solution: experimental and theoretical study. IndEnggChemRes 50(4):2098–2110

Nataraja SE, Venkatesha TV, Tandon HC (2012) Computational and experimental evaluation of the acid corrosion inhibition of steel by tacrine. CorrSci 60:214–223

Odozi NW, Babalola JO, Ituen EB, Eseola AO (2015) Imidazole derivative as novel effective inhibitor of mild steel corrosion in aqueous sulphuric acid Nnenna. Am J Phys Chem 4(1):142–155

Hazazi OA, Abdallah M (2013) Prazole compounds as inhibitors for corrosion of aluminum in hydrochloric acid. Int J ElecChem Sci 8:8138–8152

Pavithra MK, Venkatesha TV, Punith Kumar MK (2013) Inhibiting effects of rabeprazole sulfide on the corrosion of mild steel in acidic chloride solution. Int J Elec Chem 1:1–9

Geethamani P, Kasthuri PK, Aejitha S (2015) Corrosion inhibition of mild steel in sulphuric acid medium by Ambroxol drug. IntJ App Chem Sci 3(4):151–157

Geethamani P, Kasthuri PK, Aejitha S (2014) Mitigation of mild steel corrosion in 1 M sulphuric acid medium by Croton sparciflorus—A green inhibitor. Che Sci Rev Lett 2(6):507–516

Geethamani P, Kasthuri PK, Aejitha S (2014) A new pharmaceutically expired drug acts as corrosion inhibitor for mild steel in acidic medium. Elixir Corrosion Dye 76:28406–28410

Geethamani P, Kasthuri PK (2015) Adsorption and corrosion inhibition of mild steel in acidic media by expired pharmaceutical drug. Cogent Chem 1:1091558

Obi-Egbedi NO, Obot IB, El-Khaiary MI, Umoren SA, Ebenso EE (2011) Computational simulation and statistical analysis on the relationship between corrosion inhibition efficiency and molecular structure of some phenanthroline derivatives on mild steel surface. Int J Elec Chem Sci 6:5649–5675

Singh P, Quaraishi MA (2012) Study of amine as vapour phase corrosion inhibitors for mild steel under different aggressive atmospheric conditions at high temperature. Ind J Life Sci 7:12270–12282

Ghulamullah khan et al (2015) Application of natural product extracts as green corrosion inhibitors for metals and alloys in acid pickling processes—a review. Int J Electrochem Sci 10:6120–6134

Quraishi MA, Sudheer (2011) Effect of pharmaceutically active compound Omeprazole, on the corrosion of mild steel in hydrochloric acid solution. J Chem Pharm Res 3:82–92

Rastogi RB, Singh MM, Singh K, Yadav M (2011) Organotin dithiobiurets as corrosion inhibitors for mild steel-dimethyl sulfoxide containing HCl. Afr J Pure App Chem 5:19–33

Akpan IA, Offiong NO (2013) Effects of ethanolamine and ethylamine on the entropy content of the corrosion of mild steel in 1 mol/l HCl solution. Indian J Phys Chem 8(3):112–117

Sachin H, Moinuddin Khan MH, Bhujangaiah NS (2009) Surface modification of mild steel by orthophenylenediamine and its corrosion study. Int J Elec Chem Sci 4:134–143

Kumar SH, Karthikeyan S (2013) Torsemide and Furosemide as green inhibitors for the corrosion of mild steel in hydrochloric acid medium. Ind Eng Chem Res 52:7457–7469

Shyamala M, Kasthuri PK (2011) A comparative study of the inhibitory effect of the extracts of Ocimum sanctum, Aegle marmelos, and Solanum trilobatum on the corrosion of mild steel in hydrochloric acid medium. Int J Corr 10:352–364

Shyamala M, Kasthuri PK (2012) The inhibitory action of the extracts of Adathoda vasica, Eclipta alba, and Centella asiatica on the corrosion of mild steel in hydrochloric acid medium: a comparative study. Int J Corr 9:827–839

Singh AK, Quraishi MA (2010) Effect of fruit extracts of some environmentally benign green corrosion inhibitors on corrosion of mild steel in hydrochloric acid solution. J Mat Environ Sci 1:163–174

Khaled KF, El-mghraby A, Ibrahim OB, Elhabib OA, Magdy AM, Ibrahim J (2010) Inhibitive effect of thio semicarbazone derivative on corrosion of mild steel in hydrochloric acid solution. Mater Environ Sci 1:139–150

Singh AK, Quraishi MA (2010) Piroxicam; a novel corrosion inhibitor for mild steel corrosion in HCl acid solution. J Mater Environ Sci 1:101–110

Geethamani P, Kasthuri PK, Aejitha S (2015) An expired non-toxic drug acts as corrosion inhibitor for mild steel in hydrochloric acid medium. IJCPS 3(1):1442–1448

Subbaian Aejitha PK, Kasthuri P, Geethamani P (2014) Inhibitory action of acalypha indica extract on corrosion of mild steel in hydrochloric acid medium. Che Sci Rev Lett 2(7):566–573

Majidi L, Faska Z, Znini M, Kharchouf S, Bouyanzer A, Hammouti B (2010) Synthesis and anticorrosive effects of epoxy-allylpulegols on steel in molar hydrochloric acid. J Mater Environ Sci 1:219–226

Aejitha S, Kasthuri PK, Geethamani P (2016) comparative study of corrosion inhibition of Commiphora caudata and Digera muricata for mild steel in 1 M HCl Solutio. Asian J of Chemistry 28(2):307–311

Aejitha S, Kasthuri PK, Geethamani P (2015) Corrosion studies with antigonon leptopus in 1 M HCl. Int J Chem Sci 13(1):38–52

Singh AK, Ebenso EE, Quraishi MA (2012) Adsorption behaviour of Cefapirin on mild steel in hydrochloric acid solution. Int J Electrochem Sci 7:2320–2333

Aejitha S, Kasthuri PK, Geethamani P (2015) Comparison of the corrosion inhibition efficiencies of mild steel in different acidic mediums using commiphora caudata plant extract Int. J Adv Tech Engg Sci 3(5):25–30

Obot IB, Obi-Egbedi NB, Umoren SA, Ebenso EE (2010) Synergistic and antagonistic effects of anions and ipomoea invulcrata as green corrosion inhibitor for aluminium dissolution in acidic medium. Int J Electrochem Sci 5:994–1007

Obot IB, Macdonald DD, Gasem ZM (2015) Density functional theory (DFT) as a powerful tool for designing new organic corrosion inhibitors. Part 1: an overview. Corr Sci 99:1–30

Johnsirani V et al (2015) Corrosion inhibition by dyes from plants. Int J Nano Corr Sci Eng 2(3):22–28

Salghi R et al (2016) Pyridazinium-based ionic liquids as corrosion inhibitors for copper in phosphoric acid containing chloride: electrochemical, surface and quantum chemical comparatives studies. Der Pharma Chemica 8(2):67–83

Obi-Egbedi et al (2011) Inhibitive properties, thermodynamic and quantum chemical studies of alloxazine on mild steel corrosion in H2SO4. J Corr Sci 53(1):263–275

Obi-Egbedi et al (2008) Fluconazole as an inhibitor for aluminium corrosion in 0.1 M HCl. J Coll Surf, 330(2–3):207–212

Umoren SA et al (2014) Performance evaluation of pectin as ecofriendly corrosion inhibitor for X60 pipeline steel in acid medium: experimental and theoretical approaches. Carbohydr Polym 25(124):280–291

Olasunkanmi LO, Obot IB, Kabanda MM, Ebenso EE (2015) Some quinoxalin-6-yl derivatives as corrosion inhibitors for mild steel in hydrochloric acid: experimental and theoretical studies. J Phy Chem C 119(28):16004–16019

Umoren SA (2009) Raphia hookeri gum as a potential eco-friendly inhibitor for mild steel in sulfuric acid. Mater Sci 44:274–279

Tappa Vinod K et al (2016) Computational studies for inhibitory action of 2-mercapto-1-methylimidazole tautomers on steel using of density functional theory method (DFT). Int J Comp Theo Chem 4(1):1–6

Prathibha BS, Kotieswaren P (2013) Study on the inhibition of mild steel corrosion by Quaternary Ammonium compound in H2SO4 medium. ResJ Recent Sci 2013, 2:1

Prathibha BS et al (2017) Inhibiting effect of quaternary ammonium compound on the corrosion of mild steel in 1 M hydrochloric acid solution, its adsorption and kinetic characteristics. Mat Today: Proce 4(11):12245–12254

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Geethamani, P., Narmatha, M., Dhanalakshmi, R. et al. Corrosion Inhibition and Adsorption Properties of Mild Steel in 1 M Hydrochloric Acid Medium by Expired Ambroxol Drug. J Bio Tribo Corros 5, 16 (2019). https://doi.org/10.1007/s40735-018-0205-5

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40735-018-0205-5