Abstract

The Hardening Soil model, an elasto-plastic second-order hyperbolic isotropic hardening model, in Plaxis has seen many applications in finite element analysis of various earth structures. This technical note presents a protocol for determination of the model parameters of the Hardening Soil model from a set of triaxial compression tests. The technical note also describes details about how to determine the Mohr-Coulomb strength parameters c and ϕ for well-compacted fills (with and without cohesion), of which the failure envelopes are typically curved. The motivation for preparing this technical note came from a study on analysis of field-scale soil–geosynthetic composites in which the soil model and model parameters deduced from triaxial tests were able to predict with very good accuracy “all” measured results of five field-scale soil–geosynthetic composites under increasing applied vertical loads up to 1000 kPa (approximately five times the load level commonly used in design of reinforced soil bridge abutments). The model parameters were determined by a well-defined protocol. The protocol should be of value to researchers and engineers who use the soil model for sophisticated finite element analysis and design of earth structures.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Determination of model parameters in a soil model is usually a critical component when performing stress-deformation analysis of earth structures by the finite element methods. The Hardening Soil (HS) model, an elasto-plastic second-order hyperbolic isotropic hardening model, in Plaxis (2002) has seen many applications in sophisticated finite element analysis of different earth structures (e.g., Morrison et al. 2006; Obrzud 2010; Surarak et al. 2012; Ruiz 2015; Gaur and Sahay 2017; Skels and Bondars 2017). This technical note describes a protocol for determination of the model parameters of the Hardening Soil model based on a set of triaxial compression tests. The technical note also describes details about how to determine the Mohr-Coulomb strength parameters c and ϕ for well-compacted fills, of which the failure envelopes are typically curved.

The motivation for preparing this technical note came from a study on the behavior of soil-geosynthetic composites (Wu et al. 2018). The soil model and model parameters successfully predicted, with very good accuracy, “all” measured results of five field-scale soil–geosynthetic composites under increasing applied vertical loads up to 1000 kPa (approximately five times the load level commonly used in design of reinforced soil bridge abutments). The model parameters were determined by a well-defined protocol. The protocol should be of value to researchers and engineers who use the HS model for sophisticated finite element analysis and design of earth structures.

2 The Hardening Soil Model and Model Parameters

Plaxis is a finite element computer program coded for analysis of stresses and deformation of geotechnical engineering problems (Plaxis 2002). Plaxis is equipped with various features to accommodate many important aspects of complex geotechnical structures. The features include higher-order elements for improved computational accuracy, automatic generation of finite element meshes with options for global and local mesh refinement, tension-only structural elements for simulation of geosynthetics, joint elements to simulated interface behavior between dissimilar materials, multiple soil models to simulate stress–deformation characteristics of soils of different levels of sophistication, updated Lagrangian analysis to account for large deformation and displacements, staged-construction algorithm to simulate sequential construction operation, and a convenient post-processor to facilitate interpretation of load–displacement relationships, stress and strain paths, stress–strain diagrams, and time–settlement relationships.

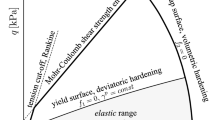

The Hardening Soil (HS) model is among a handful of soil models available in Plaxis. It is an elasto-plastic second-order hyperbolic isotropic hardening model developed by Schanz et al. (1999). The model computes deformation as the sum of elastic strain and plastic strain. It is capable of simulating key characteristics of soils, except hysteretic or cyclic mobility. The Hardening Soil model comprises a set of mathematical equations to describe the constitutive law of soils. The constitutive equations have been presented in detail in the Plaxis Material Models Manual (Plaxis 2002). Experiences gained by the users have indicated that the Hardening Soil model is capable of simulating soil behavior very accurately under complicated stress paths. The model parameters needed for the Hardening Soil model can be determined by a set of the conventional triaxial compression tests performed on the soil. Table 1 shows a summary of all the parameters of the Hardening Soil model. A brief description of each parameter and the laboratory tests needed to determine each parameter are also given in the table.

3 Protocol for Determining Model Parameters of the Hardening Soil Model

Wu et al. (2018) have shown that the finite element analysis performed by using the Hardening Soil model in Plaxis is capable of giving excellent simulation of five field-scale experiments of soil–geosynthetic composites. The experiments were conducted under well-controlled conditions at the Turner-Fairbank Highway Research Center of the Federal Highway Administration (Wu et al. 2013). The angular gravelly soil employed in the experiments is used an example in this technical note. The model parameters for the Hardening Soil model were determined from stress–strain and volume change relationships obtained from a set of drained triaxial compression tests, shown in Fig. 1.

The protocol presented below describes how exactly to determine the key parameters of the Hardening Soil model, including (a) plastic soil stiffness parameters \( {E}_{50}^{\mathrm{ref}} \) and \( {E}_{\mathrm{ur}}^{\mathrm{ref}} \), (b) elastic soil stiffness parameter \( {E}_{\mathrm{oed}}^{\mathrm{ref}} \), (c) angle of dilation ψ and elastic unloading-reloading Poisson’s ratio νur, and (d) Mohr-Coulomb strength parameters c and ϕ (especially for well-compacted soils). In the following sub-sections, these key parameters are described. For two other soil parameters in Table 1, namely, the stress-dependency power parameter (m) and failure ratio (Rf), use of default values suggested by Plaxis is recommended for well-compacted granular fills. For the elastic soil stiffness parameter (\( {E}_{\mathrm{oed}}^{\mathrm{ref}} \)) and elastic unloading-reloading Poisson’s ratio νur, either the procedure described below or the default values suggested by Plaxis can be used.

3.1 Plastic Soil Stiffness Parameters \( {E}_{50}^{\mathrm{ref}} \) and \( {E}_{\mathrm{ur}}^{\mathrm{ref}} \)

Plastic soil stiffness parameters \( {E}_{50}^{\mathrm{ref}} \) and \( {E}_{\mathrm{ur}}^{\mathrm{ref}} \), also referred to as E50 and Eur for simplicity, at a selected confining pressure can be determined from triaxial compression test results, as presented in Fig. 2. Using the triaxial compression test results shown Fig. 1, for a reference pressure of 100 kPa, the plastic soil stiffness parameters E50 and Eur at σ3 = 35 kPa (5 psi) and 210 kPa (30 psi) are determined by the procedure seen in Table 2. Considering confining pressures of 0 to 210 kPa (0 to 30 psi) as a prevailing range of design loads for the given soil–geosynthetic composites, the average values of model parameters at σ3 = 35 kPa, 105 kPa, and 210 kPa (5 psi, 15 psi, and 30 psi, respectively) were selected for determination of the model parameters. The average values are determined as \( {E}_{50}^{\mathrm{ref}}=63,400\;\mathrm{kPa} \) and \( {E}_{\mathrm{ur}}^{\mathrm{ref}}=476,000\;\mathrm{kPa} \).

Determination of soil model parameters E50 and Eur from triaxial compression test results (modified after Plaxis (2002))

3.2 Elastic Soil Stiffness Parameter \( {E}_{\mathrm{oed}}^{\mathrm{ref}} \)

Figure 3 illustrates how to determine soil stiffness parameter \( {E}_{\mathrm{oed}}^{\mathrm{ref}} \) from results of an oedometer test. In the absence of oedometer test of the soil, Plaxis suggests using a simple correlation for determination of \( {E}_{\mathrm{oed}}^{\mathrm{ref}},\mathrm{namely}, \)\( {E}_{\mathrm{oed}}^{\mathrm{ref}}\approx {E}_{50}^{\mathrm{ref}} \).

Determination of soil model parameter \( {E}_{\mathrm{oed}}^{\mathrm{ref}} \) at a selected reference pressure from oedometer test results (modified after Plaxis (2002))

3.3 Angle of Dilation ψ and Elastic Poisson’s Ratio νur

The angle of dilation ψ (with a “dilation cut-off”) can be determined from the volume change curve obtained from drained triaxial tests, as shown in Fig. 4. The elastic Poisson’s ratio νur, on the other hand, can be estimated by the initial part of the volume change curve, see Fig. 4.

The average values of the model parameters ψ and νur at σ3 = 35 kPa (5 psi) and 210 kPa (30 psi) using the volume change curves shown Fig. 1 can be taken as the input model parameters. The detail calculations of νurfrom the drained triaxial test result at σ3 = 35 kPa (5 psi) and 210 kPa (30 psi) are shown in Table 3. The average values of ψ and vur were determined to be ψ = 19o and vur = 0.375. Three different values of vur were examined: 0.1, 0.2, and 0.375. It was found that the vur values had little effect on the volume change curve. However, the stress–strain curve associated with vur = 0.2 (default value in Plaxis) was somewhat “smoother” than those of the other two vur values. It is recommended that the model parameter vur be determined by (a) comparing simulated volume change curves with the measured curves by using values of vur ranging from 0.1 to 0.4 to determine the best vur value, or (b) adopting the default value of vur = 0.2.

3.4 Mohr-Coulomb Strength Parameters c and ϕ

The Mohr-Coulomb strength parameters c and ϕ are, respectively, the intercept and the angle of the Mohr-Coulomb failure envelope. For loose sands and normally consolidated clay (i.e., non-prestressed clay), the Mohr-Coulomb failure envelope can usually be approximated by a straight line, and the values of strength parameters c and ϕ can be determined rather easily from the failure envelope. Alternatively, the c and ϕ values can be determined by using a p–q diagram as shown in Fig. 5. The p–q diagram approach usually gives a more consistent c-ϕ values as it is less dependent on individual judgments.

Mohr-Coulomb failure envelopes for heavily compacted soils are typically a concave downward curve (i.e., the tangent slope decreases with increasing normal stress). The denser the soil, the more curved the failure envelope tends to be. Figure 6 shows the Mohr-Coulomb failure envelope of the soil under consideration at confining pressures ranging from 35 kPa (5 psi) to 760 kPa (110 psi). Note that the failure envelope in Fig. 6 was constructed by assuming c = 0. A rule-of-thumb in basic soil mechanics is pertinent here: when the ϕ-value is large, a small c-value goes a long way! In this case, ϕ is very large (well over 40°); therefore, it is very important to determine if the assumption of c = 0 is appropriate. To that end, there is no substitute to physically feel the soil sample. If the soil is cohesive (i.e., sticky when wet) and the fines content (percent passing the 75-μm sieve) is significant (say, less than 5% to 10% by weight), c ≠ 0 should be used. Otherwise, the assumption that c = 0 as depicted in Fig. 6 is deemed acceptable.

If a soil possesses nonzero cohesion (c ≠ 0), the value of “c” can be determined by the Mohr circles at small confining pressures. When making a selection of confining pressures for triaxial testing for soils that are suspected of nonzero cohesion, at least two low values of confining pressure should be used (say, 35 kPa and 70 kPa, or 5 psi and 10 psi). From the Mohr failure circles at the low confining pressures, the c-value can be determined by sketching a straight line failure envelope tangent to the failure circles.

Once the value of “c” is determined, the value of “ϕ” can be determined as described below. Let us start by considering the case of c = 0. A curved failure envelope over the range of relevant stress would indicate that the ϕ-value is not a constant and would vary with the normal stress. Since nearly all finite element computer codes require that the value of ϕ be a constant, an average value of ϕ over the applicable range of stress is needed. A simple yet accurate average value of ϕ is the secant method. The method is described below.

It can be shown mathematically that “the average rate of change of a curve is equal to the slope of the secant line.” In other words, to determine the average tangent slopes between any two points on a curve, one only needs to determine the slope of the secant line connecting the two points. The secant method can be used to determine the average ϕ-value of a curved Mohr-Coulomb failure envelope, as shown in Figs. 7 and 8, for c = 0 soil and c ≠ 0 soil, respectively. The procedure for determination of the secant ϕ-value can be described in steps as:

- i.

construct a smooth failure envelope that is tangent to all the failure Mohr circles considered reliable

- ii.

estimate the largest value of σ3 (or σ1) for the problem under consideration

- iii.

sketch a failure circle that is tangent to the failure envelope for the estimated largest value of σ3 or ϕ1 (i.e., see Figs. 7 and 8);

- iv.

determine the point of tangency of the failure circle determined in step (iii) on the failure envelope and

- v.

determine the secant ϕ-value, which is equal to the slope of a straight line connecting the origin (for c = 0) or the c-intercept (for c ≠ 0) with the point of tangency determined in step (iv)

For the soil under consideration, the procedure for the determination of c and ϕ is depicted in Fig. 9. The c-value for the soil was determined by plotting the p–q diagram for σ3 = 35 kPa (5 psi) and 105 kPa (15 psi), as shown in Fig. 10, and represented by the dashed line in Fig. 9. The c-value was determined to be 70.3 kPa (or 10.2 psi). Using the procedure shown in Fig. 8, the secant ϕ-value was determined as 48° (see Fig. 9). The soil model parameters determined as the average value at σ3 = 35 kPa (5 psi), 105 kPa (15 psi), and 210 kPa (30 psi) for the example soil are summarized in Table 4.

4 Validation of the Soil Model Parameters

With the soil model parameter values shown in Table 4, finite element analyses were conducted to simulate stress–strain–volume change relationships of the soil in drained triaxial compression tests at confining pressures of 35 kPa, 70 kPa, and 105 kPa (5 psi, 15 psi, and 30 psi). The simulated results were compared with measured values. Figs. 11, 12, and 13 show the comparisons at σ3 = 35 kPa (5 psi), 105 kPa (15 psi), and 210 kPa (30 psi), respectively. Excellent agreement between simulated and measured values is seen. This suggests that the soil model parameters deduced from results of triaxial tests by following the protocol described in this technical note are indeed capable of simulating the behavior of soil under triaxial compression testing conditions.

The soil model parameters were subsequently used to simulated the load–deformation behavior in five 2.0 m (height) by 1.4 m (length) soil–geosynthetic composite experiments in a plane strain condition. The five experiments varied in reinforcement stiffness and strength, confining pressure, and reinforcement spacing, and were subject to increasing vertical loads until failure occurred. The analysis results and comparisons with measured results have been presented elsewhere (Wu et al. 2018). The simulation was found to be in very good to excellent agreement with “all” measured data, including applied load vs. vertical displacements relationships, applied load vs. lateral movement relationships, and internal displacement fields up to an applied load of 1000 kPa (five times the typical design load) for all five field-scale experiments.

5 Concluding Remarks

This technical note describes a protocol for determination of the parameters for the Hardening Soil model of an angular gravelly soil. It should be noted that the technical note is presented to share the authors’ experience and should not be considered an endorsement of the Hardening Soil model or Plaxis code. The protocol for determination of Mohr-Coulomb strength parameters c and ϕ for well-compacted soils, of which the failure envelopes are curved, is also described in detail. The soil model parameters determined by the protocol were shown to give very good to excellent simulation of “all” measured data of triaxial tests and five field-scale experiments under applied loads up to 1000 kPa. The protocol is believed to be of value to researchers and design engineers who employ the soil model to perform stress-deformation analysis of earth structures.

References

Gaur, A., Sahay, A.: Comparison of different soil models for excavation using retaining walls. SSRG International Journal of Civil Engineering. 4(3), 43–48 (2017)

Morrison, K.F., Harrison, F.E., Collin, J.G., Dodds, A., Arndt, B.: "Shored mechanically stabilized earth (SMSE) wall systems design guidelines." Report FHWA-CFL/TD-06-001. Federal Highway Administration, Lakewood (2006) 210 p

Obrzud, R.: On the use of the hardening soil small strain model in geotechnical practice. In: Zimmermann, Truty, Podles (eds.) Numerics in Geotechnics and Structures 2010. Elmepress, International (2010)

Plaxis, B.V.: Plaxis Version 8 Material Models Manual. Balkema, Rotterdam (2002)

Ruiz, J.F.: Application of an advanced soil constitutive model to the study of railway vibrations in tunnels through 2D numerical models (in Madrid, Spain). Journal of Construction. 14(3), 55–62 (2015)

Schanz, T., Vermeer, P.A., Bonnier, P.G.: Formulation and Verification of the Hardening Soil Model. In: Brinkgreve (ed.) Beyond 2000 in Computational Geotechnics, pp. 281–290. Balkema, Rotterdam (1999)

Skels, P., Bondars, K.: Applicability of small strain stiffness parameters for pile settlement calculation. Procedia Eng. 172, 999–1006 (2017)

Surarak, C., Likitlersuang, S., Wanatowski, D., Balasubramaniam, A., Oh, E., Guan, H.: Stiffness and strength parameters for hardening soil model of soft and stiff Bangkok clays. Soils Found. 52(4), 682–697 (2012)

Wu, J.T.H., Pham, T.Q., Adams, M.T.: “Composite Behavior of Geosynthetic Reinforced Soil Mass.” Report No. FHWA-HRT-10-077. Turner-Fairbank Highway Research Center, FHWA, McLean (2013) 211 p

Wu, J.T.H., Tung, C.-Y., Adams, M.T., Nicks, J.E.: Analysis of stress-deformation behavior of soil-geosynthetic composites in plane strain condition. Transportation Infrastructure Geotechnology. 5(3), 210–230 (2018). https://doi.org/10.1007/s40515-018-0057-y

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wu, J.T.H., Tung, S.CY. Determination of Model Parameters for the Hardening Soil Model. Transp. Infrastruct. Geotech. 7, 55–68 (2020). https://doi.org/10.1007/s40515-019-00085-8

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40515-019-00085-8