Abstract

In today’s competitive market of globalization, supply chain flexibility (SCF) has emerged as a potential weapon to address various uncertainties and associated risks. Offering sales promotional schemes (SPSs) is one of the obvious and inevitable features in the present competitive commercial environment, affecting demand uncertainty severely. This paper models the SCF of automobile industry under SPS environment. Supply chain professionals from two automobile OEMs are involved in the process of identifying 14 SCF strategies that are relevant to the present study. Personal interviews have been conducted with about 15 field managers from these industries and the causal relationships between these flexibility strategies have been established using a structured Fuzzy DEMATEL questionnaire. Using Fuzzy DEMATEL methodology, the identified strategies are ranked based on their degree of influence and classified into cause/effect groups. Based on the analysis, four strategies, viz. volume flexibility, manufacturing flexibility, supplier collaboration flexibility and supplier flexibility, have been recognized to play a decisive role in firm’s performance. The systematic elucidation of the model offers modest bunch bits of knowledge to practicing field experts to ken the utmost essential approaches influencing the performance of the firm in terms of their impelling strength. This helps them in crucial decision-making during SPS. Also, the present investigation will help in spanning the SCF with sales promotions, an unexplored gap in the earlier studies.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Supply chain literature offers flexibility as a potential weapon to address various uncertainties, mitigates the associated risks and improves the business performance (Das 2011; Seebacher and Winkler 2013; Singh and Acharya 2013; Kazemian and Aref 2016; Shibin et al. 2016). Though issues related to both the flexibility and agility are topics of interest in the literature for being responsive to customer demand especially when the supply chain is subjected to various uncertainties and disruptions (Chiang et al. 2012; Um 2017), the relationship between flexibility and agility is considered competence–capability relationship (Swafford et al. 2008). That is to say, without the competence, i.e., flexibility, it is not possible to be agile, i.e., to cope and survive through all the unexpected challenges. Hence, flexibility being the fundamental aspect to face any challenge, this study accentuates the analysis of SCF in Indian automobile industry in tending to the sudden rise in demand under the environment of sales promotions. An inevitable marvel and a conspicuous highlight in today’s market condition is contending to draw the consumer attention through innovative SPS. In spite of the fact that SPS returns high benefits (Donnell et al. 2009), forecasts become erratic (Manders et al. 2016) and make the supply chain prone to a sudden rise in demand. Thus, analogous to circumstances mass customization, swift introduction of new products and fast reply to consumer requirements (Lummus et al. 2005; Gong 2008), SPS calls for highly flexible supply chains. This has been substantiated by Manders et al. (2016) that sales promotions require highly flexible supply chains. Nonetheless, the SCF studies in the context of SPS have not been tended to in the earlier works. Hence, the research questions can be posed as what are the flexibilities required in a supply chain to take care of the demand uncertainty under SPS and what is the relationship between these flexibilities? Addressing these questions, the research objectives fulfilled in this study are proposed as follows.

-

To identify the SCF strategies required during SPS.

-

To model the SCF strategies for their cause and effect relationships, thus identifying the most important strategies contributing to the firm’s performance during SPS.

In today’s global market, the automobile industry is of economic importance to many nations (Kannegiesser et al. 2014; Asadi et al. 2015). With about 20,000 components required to make a single model, an automobile industry involves many companies in its supply chain. Managing the complicated interactions and collaborative relationships between these participant companies (Oh et al. 2010), it gives considerable attention to the high degree of flexibility in its supply chain management (SCM). Also according to Sánchez and Pérez (2005), an automobile industry experiences a better firm performance by exhibiting higher flexibility capabilities and hence offers the potential to study different dimensions of SCF. Being well-established and a hub for studying supply chain practices in an emerging economy, India (Thomé et al. 2014; Chandra et al. 2016), it will be a perfect case to study. Discussion with a senior supply chain expert from a leading automobile OEM revealed that the automobile supply chain should be highly flexible to meet the uncertain demand during SPS. Though all the OEMs are well prepared to meet this uncertainty in demand with built-up inventories because of the unpredictable market dynamics, they should be fully equipped with all types of flexibilities to overcome any risk in delivering the product on time.

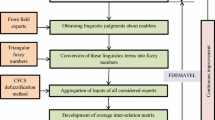

In this paper, flexibility strategies in a supply chain important to be embraced by an automobile industry in the midst of SPS have been recognized. In order to rank them based on their degree of influence over each other and to classify them under cause and effect groups, decision-making trial and evaluation laboratory (DEMATEL) method under fuzzy atmosphere has been applied. The developed model offers profound bits of knowledge to the supply chain managers in decision-making and helps focus on the most influencing SCF strategies in confronting the rise in demand amid SPS adequately.

This paper is organized as takes after. Section 2—review of flexibility literature. Section 3—explanation of Fuzzy DEMATEL approach and CFCS defuzzification method. Section 4—data collection; data analysis using Fuzzy DEMATEL methodology and classification of SCF strategies into cause/effect groups. Section 5—outcomes and discussion alongside managerial inferences. Section 6—conclusions with limitations and scope for future work.

Literature Review

As per Wadhwa et al. (2008), flexibility is the extensively deliberated theme in the manufacturing and supply chain areas. Despite the fact that the theme of flexibility was originally considered in manufacturing area because of the increasing levels of uncertainty and associated risks, taking the total systems approach, it is now being considered at the broader level of supply chain systems (Vickery et al. 1999; Duclos et al. 2003; Pujawan 2004; Sánchez and Pérez 2005; Sushil. 2012, 2016). Thus, the research on flexibility extended from intra-firm level to inter-firm level (Wang 2008). To respond effectively to changing market requirements, increasing the flexibility level of supply chains has become the way for many companies (Merschmann and Thonemann 2011). As described by Manders et al. (2016), flexibility is the way of life and is one of the strategic goals of many organizations (Gong 2008). Also, in the work of Yi et al. (2011), it is stated that low cost and price are not the sources of competitive advantage, but adding flexibility to operating systems and organizations is so.

Beginning with the work of Vickery et al. (1999), a significant number of theoretical conceptualizations and methods of assessment were contributed for establishing the concept of SCF thoroughly as a way to enhance business performance. However, studies conducted in specific situations are of high practical relevance and offer handy solutions to the supply chain managers. As an effort in this direction, this analysis is led under the presence of sales promotions. Examining the SPS literature, it is for the most part limited to the design of sales promotions for the ideal cost, deal period and deal recurrence (Abad 2003; Kurata and Liu 2007; Zhu and Cetinkaya 2015). In any case, designing the SPS alone isn’t adequate. Properly implementing the supply chain processes with numerous adaptable managerial techniques is necessary for realizing the advantages of SPS. Improving the SCF of 3PLs, Choy et al. (2008) alluded to five actual instances of the letdown of supply chain tasks because of flexibility needs. However, this feature has not been tended to in the earlier works on SPS and subsequently the topic of discussion in this study. The following paragraph summarizes the earlier works on SCF.

Authors like Yi et al. (2011), Gosling et al. (2013) and Fayezi et al. (2014) explored various uncertainties and the SCF strategies adopted by the firms. While Merschmann and Thonemann (2011) and Luo and Yu (2016) examined the fits/misfits among various SCF types and uncertainties, Garavelli (2003) and Aprile et al. (2005, 2006) studied the effect of flexibility configurations on firm performance, and the authors like Pujawan (2004), Gong (2008), Chuu (2011), Moon et al. (2012), Sokri (2014) and Xiao (2015) have contributed to the assessment/measuring of supply chain flexibility. Apart from these studies, the SCF has been proposed as a risk mitigation strategy by some of the authors like Tang and Tomlin (2008), Das (2011), Skipper and Hanna (2012), Sahay and Ierapetritou (2015), Mishra et al. (2016) and Sreedevi and Saranga (2017). Adding to all this, Srinivasan and Swink (2017) investigated the complementary role of flexibility in enhancing the analytics capability of the supply chain.

Research Gaps

Based on the literature review, the research gaps identified are presented as follows.

-

According to Manders et al. (2016), the forecasts during SPS fall far behind compared to the actual order, thus demanding high flexibility in supply chains. Be that as it may, the study of SCF under sales promotional environment has not been seen in the earlier works.

-

Research on SPS is generally bound to design of sales promotions. Be that as it may, properly implementing the supply chain processes with numerous adaptable managerial techniques is necessary for realizing the advantages of SPS, which is at present not addressed in the SPS literature.

Attempting to fill these gaps according to the research objectives stated in Sect. 1, various SCF strategies identified under SPS environment have been introduced.

Identified SCF Strategies and Business Functions

SCF is a multi-dimensional and context-oriented idea (More and Babu 2008). Although various flexibility strategies were deliberated in the earlier works under diverse contexts, the applicable strategies necessary amid SPS are exceptional and industry-particular to be investigated.

SCM incorporates an extensive variety of functions starting from procuring the raw material to the conveyance of finished item to the final customer alongside the information systems monitoring of these functions. Subsequently, SCF ought to incorporate all the flexibility strategies embraced at distinctive functions by the supply chain members to effectively take care of the demand (Yi et al. 2011). Adopting the way, Lummus et al. (2005), Yi et al. (2011) and Manders et al. (2016) have grouped different flexibility strategies; the strategies applicable for the present context of SPS (shown in Table 1) are extracted based on literature survey and opinion of industry experts. These strategies are grouped under different functions, viz. information system, logistics, organization, operations system and procurement. Thus, the present study offers a unique contribution to the SCM literature by spanning SCF with SPS which are two different research streams. The explanation of flexibility strategies distinguished for this analysis is given below.

Supplier collaboration flexibility means flexibility in collaboration by the manufacturers with the suppliers when there is a sudden change in demand during SPS (Duclos et al. 2003). It helps in improving the response to the delivery by adjusting the present relationship (Jin et al. 2014). Supplier flexibility indicates responses by the suppliers for the initiative taken by the manufacturer on a short notice (Kumar et al. 2008; Jin et al. 2014; Manders et al. 2016). Sourcing flexibility is to maintain a strategic distance from any kind of inconsistencies from the supplier’s end in providing the request beneath sudden rise in demand. In such a case, it is basic to have numerous sources of suppliers (Sánchez and Pérez 2005; Tang and Tomlin 2008; Yi et al. 2011).

Organizational environment flexibility means the flexibility in work for the workers, i.e., organization should provide a conducive environment at the workplace to increase the morale, motivation and sustainability to the workers (Duclos et al. 2003). Labor flexibility is the flexibility of hiring the additional workforce during the peak period of demand (Gong 2008). Inter-organizational relationship flexibility is to develop inter-cooperative relations among different members of the chain with the goal of adapting to the changing circumstances (Skipper and Hanna 2012).

The facility to rapidly modify the capacity with the specific goal of altering the production rate w.r.t the demand fluctuations is called as the volume flexibility. According to Sánchez and Pérez (2005), volume flexibility specifically influences customers’ discernments by evading out-of-stock circumstances for highly sought after products. Manufacturing flexibility is the capacity to alter the assets and utilize the alternate sources for manufacturing or assembling the products (Coronado and Lyons 2007; Yi et al. 2011; Mishra et al. 2017). Sub-contracting flexibility indicates adopting sub-contractors in the situations either the firm is not able to fulfill the demand on time or the firm wants to improve the defined tasks (Yi et al. 2011).

Storage flexibility is defined as the capacity to accommodate storage for the sudden rise in demand (Duclos et al. 2003 and Manders et al. 2016). Utilization of substitute transportation means to suit the surge in demand over brief periods is defined as the alternative logistics flexibility (Coronado and Lyons 2007; Yu 2013). Trans-shipment flexibility is the capability to re-position stock concerning diverse areas which is vital amid crest times (Pujawan 2004; Sánchez and Pérez 2005). Flexible information system means an effective information system with the support of top management to do different tasks inside and over the firms in a supply chain (Moon et al. 2012). The adaptability to access the information, i.e., customer demand and inventory levels by every one of the individual firms within the supply chain network is defined as flexible information visibility which is required to react quickly to take care of the demand variations successfully (Duclos et al. 2003; Coronado and Lyons 2007).

The study directed for this analysis has been featured as takes after, which is explained in the subsequent sections.

-

Examining the concern with the field experts of the automobile industry and recognizing the key flexibility strategies to be executed.

-

Using the Fuzzy DEMATEL approach for identifying the causal relations among these strategies.

Research Methodology: Fuzzy DEMATEL

The objective of this study is linking the concept of supply chain flexibility with SPS by steering the analysis of flexibility under the condition of sales promotions. To accomplish the objective, the current examination endeavors setting up the causal relationships among the recognized strategies and rank them in view of their degree of influence over each other. For this reason, a well-known and demonstrated to be a fruitful technique (DEMATEL) that communicates the cause and effect relationships with ease has been used for examination and is elucidated as takes after.

The DEMATEL approach was first created by the Science and Human Affairs Program of Battelle Memorial Institute of Geneva, in the vicinity of 1972 and 1976, to investigate and resolve the muddled gathering of issues (Govindan et al. 2016). In order to better visualize the system of complicated relationships, it uses digraphs to classify the elements of the system into cause and effect groups (Tyagi et al. 2015; Luthra et al. 2016). The digraphs portray the causal relationships among these elements and their strength of influence over each other (Wu and Tsai 2012). Unlike AHP, which assumes the elements to be independent, DEMATEL establishes the inter-dependencies among the elements using structural modeling technique (Wu and Tsai 2012). Also, when compared to the well-established methodology ISM for developing the inter-relationships, DEMATEL yields more accurate results because of the degrees of influence being calculated by assigning the weights to the inter-relationships.

The application of DEMATEL in this study results in a causal diagram, inter-relationship diagram and the importance ratings of SCF strategies based on their strength of influence. Though DEMATEL has been proven a useful method for solving the complex decision-making problems (Lin et al. 2011) and has been applied in various diverse fields, its application in the SCF literature is limited to the works of Singh and Acharya (2014) and Asad et al. (2016). However, in this study, Fuzzy DEMATEL methodology has been applied that is explained as follows.

Fuzzy Set Theory

To manage the vagueness and uncertainty of the choice maker’s thoughts and to improve the accuracy of the human judgements’, Zadeh (1965) proposed the fuzzy set theory. In order to avoid the subjectivity and ambiguity faced by the group of decision-makers when assessing the relative influence of the SCF strategies over each other, the fuzzy set theory has been used in this work along with DEMATEL. Also, the triangular fuzzy number’s (TFN’s), commonly used for practical applications (Lin and Wu 2008), is used in this work. The membership function (\(\mu_{\text{M}} (x)\)), for any TFN (l, m, r), is expressed mathematically as shown in Eq. (1), where l, m, r (l < m < r) are lower, mean and upper boundaries of TFN.

Defuzzification Method: CFCS

As any fuzzy model has a defuzzification method to convert the inputs of human judgements with fuzzy linguistic variables, i.e., fuzzy numbers into crisp values, the Converting Fuzzy data into Crisp Scores (CFCS) method proposed by Opricovic and Tzeng (2003) has been adopted for the present study in developing the fuzzy DEMATEL model. This method has the advantage over other defuzzification methods in terms of providing better crisp values and in distinguishing two symmetrical TFN’s with the same mean. The procedure for this defuzzification method has been presented as follows.

Let \(N\) be the number of expert responses \(E_{n}\), \(n\, = \,1, \ldots ,N\). For a given response, suppose \(p\) alternatives are to be evaluated with respect to the \(i{\text{th}}\) element with the fuzzy numbers \(\tilde{f}_{ij}^{n}\), for the TFN’s \(\tilde{f}_{ij}^{n} \, = \,\left( {l_{ij}^{n} ,m_{ij}^{n} ,r_{ij}^{n} } \right),\,j = 1, \ldots ,p\), the crisp values of the \(i{\text{th}}\) element is determined through the following steps.

Step 1: Normalization

Compute for all \(p\) alternatives,

Step 2: Compute right (rs) and left (ls) normalized values for \(j = 1, \ldots ,p\)

Step 3: Compute total normalized crisp values for \(j = 1, \ldots ,p\)

Step 4: Compute crisp values for \(j = 1, \ldots ,p\)

Now, on carrying out the above four steps for all other elements, all the fuzzy values in a given expert response will be converted to crisp values.

By performing this entire procedure on all responses, the average scores in all expert responses are obtained by integrating their crisp values according to the equation given below.

Fuzzy DEMATEL Method

The analytical procedure of the DEMATEL method for group decision-making under fuzzy atmosphere is as follows (Wu and Tsai 2012).

(i) Average direct relation matrix: On applying the CFCS deffuzification method (as described in Sect. 3.2) on all the group expert responses and taking the average of their inputs using Eq. (7), the average direct relation matrix is written as follows.

(ii) Normalized direct relation matrix \(X\) is obtained using the following equation:

where \(\lambda \, = \,\hbox{min} \left[ {\frac{1}{{{}_{1 \le i \le p}^{\hbox{max} } \sum_{j = 1}^{p} |f_{ij} |}},\frac{1}{{{}_{1 \le j \le p}^{\hbox{max} } \sum_{i = 1}^{p} |f_{ij} |}}} \right]\), \(i,j\, = \,1,2, \ldots ,p\).

(iii) Total relation matrix \(T\) gives the comprehensive picture of all the direct and indirect influencing relationships between all the elements of the system (Wang and Lin 2014). It is obtained by using the following equation:

where \(I\) is the identity matrix.

The sum of rows and columns in total relation matrix, represented by \(R\) and \(C\), is calculated using the following equations.

For \(T\, = \,[t_{ij} ]_{p \times p}\) \(i,j\, = \,1,2, \ldots ,p\)

(iv) Causal diagram: From the total relation matrix, the R + C (prominence) values represent the influencing strength of each element and the R − C (relation) values classify the elements into cause/effect groups. The elements having the positive R − C values fall under the ‘cause’ category and the elements having the negative R − C values fall under the ‘effect’ category. By mapping the R + C and R − C datasets on horizontal and vertical axes, the causal diagram is developed. Causal diagram results in a simple visible structure from complicated causal relationships and assists the decision-maker to take right decisions by grasping the mutual influence/impact between different elements (Wang and Lin 2014).

(v) Threshold value (\(\alpha\)): By taking the average of all the elements in total relation matrix as shown in Eq. (13), the threshold value is calculated. The SCF strategies having influence strength more than \(\alpha\) are identified, and showing their intess0073r-relationships, an inter-relationship diagram is developed.

where N is the total number of elements in matrix T.

Data Collection and Analysis

On identifying the important SCF strategies in view of literature survey and thorough discourse with industry specialists, to study their causal relationships in affecting the firm’s performance, a structured questionnaire has been devised. Being tedious and time-consuming to fill the Fuzzy DEMATEL questionnaire, personal interview method is opted over e-mail survey, to get the questionnaire filled. Since the personal interviews help the respondents in completely understanding the subject under study, the replies are practically valid. To have more generalized and unbiased results, the data has been collected from supply chain managers of two leading OEMs in North India manufacturing four wheelers. The respondents' profile includes two general managers, five senior-level managers and eight managers, i.e., in total, the data have been analyzed from 15 responses using Excel 2010. Any queries raised during analysis are clarified through the telephone calls.

Adopting the fuzzy linguistic scale from Bakeshlou et al. (2017) as shown in Table 2, respondents are requested to give their inputs for relative influence of SCF strategies using linguistic terms, viz. ‘no influence (No),’ ‘very low influence (VL),’ ‘low influence (L),’ ‘high influence (H)’ and ‘very high influence (VH).’ To show the application of fuzzy DEMATEL process, the response of an expert (shown in Table 3) has been considered for analysis. On applying the CFCS defuzzification method, the crisp values obtained for this response are shown in Table 4. Thus, by taking the average of all 15 responses, average direct relation matrix (shown in Table 5) is obtained. Now, by going through the further steps of fuzzy DEMATEL, i.e., using Eqs. (9) and (10), the acquired total relation matrix is shown in Table 6. Using Eqs. (11) and (12), the R and C values are calculated from total relation matrix. Finally, Table 7 shows the influence/impact strengths of identified business functions, strategies within them and the classification of various strategies into cause and effect groups. The importance rating of a particular business function (BF) is obtained by taking the average of all the R + C values of the strategies within that BF. Similarly, the impact of a particular BF is obtained by taking the sum of all the R − C values of the strategies within that BF. By mapping the influence (R + C) and impact (R − C) values on horizontal and vertical axes, the causal diagrams for SCF strategies and business functions are shown in Figs. 1 and 2. The influence values of all the SCF strategies more than the threshold value are highlighted in Table 6, and their inter-relationships are shown in Fig. 3.

Discussion on Findings, Contributions, Limitations and Future Scope

As fuzzy DEMATEL analysis results in ranking the elements of the system based on their degree of influence over each other and grouping the elements into cause and effect categories; the findings of this study given in Tables 6 and 7 and presented in figures (Figs. 1, 2, 3, 4) form the basis of discussion. While the cause and effect analysis helps the decision-makers in understanding the inter-relationship dynamics between the elements of the system, ranking of elements based on their strength of influence helps them focus on those that most affect the performance of the firm. Hence, the strategies having high strength of influence should be emphasized more by the management.

From Table 7, the descending order of importance of SCF strategies is OS1, OS2, P1, P2, O3, IS1, OS3, P3, IS2, O1, O2, L2, L3 and L1. For managerial implications, this study has chosen four strategies, i.e., volume flexibility (OS1), manufacturing flexibility (OS2), supplier collaboration flexibility (P1), and supplier flexibility (P2) whose strength of influence (R + C) values is more than the mean (3.67) of all R + C values. Though all the identified flexibility strategies are essential to meet the change in volume during SPS, these four flexibilities are highly sensitive because of the high degree of influence they have on the remaining strategies and hence assume an unequivocal part in firm’s execution. Furthermore, among these four strategies, first two are from ‘operating systems’ function and the latter two are of ‘procurement’ function. This shows that the management should especially focus on these two business functions during SPS.

Also from Table 7, while IS1, IS2, O1, OS1, OS2, O3 and P1 in the descending order of their impact are grouped under ‘cause’ category, P3, OS3, P2, O2, L1, L3 and L2 are grouped under ‘effect’ category. The higher the positive R − C value, the higher the impact of particular strategy on other strategies. In other words, it is strongly causing the other strategies to happen. Similarly, the higher the negative R − C value, the more the particular strategy is being affected by others. Findings show that while IS1 and IS2 strongly cause other flexibilities, L2, L3 and L1 are strongly affected by others. Though IS1 and IS2 have a high impact on others, their level of importance in affecting the firm’s performance is not high. But, because implementing all the other strategies is strongly dependent on their implementation, they could be placed under the category of basic elements every firm should have. Similarly, though the strategies under logistics function (L1, L2 and L3) are majorly affected by others and placed in the last place in the order of their importance, they are mandatory for every firm, without which the produced demand cannot be supplied on time. Hence, these strategies also form the list of basic category.

The visual figures in the form of causal diagrams (Figs. 1 and 2) give the clear picture of causal relationships and influencing degrees of SCF strategies and business functions. These figures show that the strategies on the right side are more influential in affecting the firm’s performance and the strategies above the horizontal axis have more impact on others to happen.

Further, by calculating the threshold value (0.131) using Eq. (13), the influencing strengths of all the strategies more than this value are highlighted in Table 6, indicating the prominent influences. Now, illustrating only these prominent relationships, inter-relationship diagram is developed between the causes/effects as shown in Fig. 3. From Fig. 3, it is clear that the number of interactions between strategies in cause group is more than the effect group. Also, as shown by the importance ranks in Table 7, the strategies in cause group have more degree of influence. Hence, these strategies should be given more importance by the management, as they contribute more to the firm’s performance. In addition to all this, the digraphs shown in Fig. 4 benefit the experts in better understanding the prominent inter-relationships inside each function.

Contrasting the current study with prior works demonstrates that, modeling the SCF of an IT-based supply chain (Asad et al. 2016) underpins the results of this analysis to a decent grade by yielding high rank to the operating systems flexibility and lower ranks to the logistics/distribution flexibility and information flexibility. Also, the high impact strength of information flexibility and relatively low impact strength of distribution flexibility support the results of the present study. However, there are slight variations in the results w.r.t the sourcing flexibility. While it is assigned with the highest rank in the prior work, it has a medium strength of influence in the present study. This difference could be credited to the reality that the modeling of flexibility in ‘IT-based’ supply chain is not quite the same as the modeling of flexibility in an automobile industry in the presence of sales promotions. Though Singh and Acharya (2014) have evaluated the SCF in Indian FMCG sector since the types of flexibilities considered are largely different from that of the flexibilities in the present study, the scope for comparison is less. However, in both the studies, while the manufacturing and information system flexibilities are categorized under cause group, the sourcing and trans-shipment flexibilities are categorized under effect group.

Contribution to Theory

Though SPS calls for a great amount of flexibility in supply chain network which has also been substantiated by Manders et al. (2016), there is no SCF study conducted under SPS environment in the earlier works. Subsequently, this analysis adds to the flexibility literature, spanning over SCF with SPS and be a vital course outline for all the future works in this direction. Also, this study will prepare for flexibility literature to require up ponders in other particular circumstances demanding flexibility. With research on SPS being for the most part bound to planning the promotions in relation to order cost, sales rate of recurrence, deal period, etc., the emphasis on supply chain operations is limited. Henceforth, this analysis adds to the earlier works on SPS through the analysis of flexibility strategies in various supply chain operations for effectively meeting the demand fluctuation during SPS. Apart from these, this study extends the application of DEMATEL methodology to both the SPS and SCF literature, which is very limited at present.

Contribution to Practice/Managerial Implications

The proposed model using fuzzy DEMATEL methodology offers significant bits of knowledge to the supply chain experts and decision-makers in realizing the causal relationships among various flexibility strategies and the foremost critical strategies to center on in terms of their influencing strength. This study helps the managers be flexible enough in confronting the demand variations amid SPS successfully by being responsive and remain ahead in the aggressive market. Putting in a nutshell, various practical implications this study proposes to the practicing managers and decision-makers are presented as follows.

-

With volume flexibility, manufacturing flexibility, supplier collaboration flexibility, and supplier flexibility having a high degree of influence on, play a decisive role in firm’s performance, indicating that the management should especially focus on the operating system and procurement functions of the supply chain to take care of the surge in demand.

-

SCF strategies like flexible information system, flexible information visibility, alternative logistics flexibility, trans-shipment flexibility and storage flexibility, though not having high degree of influence on firm’s performance, being mandatory to every firm for successful running of all other supply chain operations and supplying the rise in demand on time, will form the basic list of essential category of flexibilities.

-

Strategies under the cause group having more inter-relationships and a high degree of influence when compared to the strategies under effect group indicates that the management should give more importance to these strategies as their contribution to the firm’s performance is large.

Limitations and Directions for Future Research

This analysis is particular to SPS situation; thus, the outcomes cannot be generalized to all circumstances. Additionally, this analysis being conducted in Indian scenario, a developing nation, in which the way the supply chains are configured are different from that of the developed nations, this study will be a reference for conducting the similar studies in developed nations and form a route map for taking up the studies in other developing nations. As the inputs in this analysis are collected only from OEM’s, contributions from others might be valuable for featuring a few other concerns. Whereas the present analysis concentrated on the automobile industry, future examinations may reach out to further industry divisions where sales promotions are predominant. Aside from these, future exploration is necessary to dissect different other inter-relationships between the identified SCF strategies using other multi-criteria decision-making methodologies like, analytical hierarchy process (AHP), analytical network process (ANP), interpretive structural modeling (ISM), total interpretive structural modeling (TISM), etc., and to study the relationship between the SCF strategies and various performance measures of a firm using interpretive ranking process (IRP) method. Further, the fuzzy set theory has limitations in dealing with fuzziness (Luthra et al. 2018). Hence, grey theory (which deals with fuzziness in a more effective way), will be applied in the future as a comparative study proving its superiority over the fuzzy set theory.

Conclusion

A large number of organizations have widely accepted SCF as the best approach to manage the developing number of uncertainties and accompanying risks of the present-day competitive market. This paper investigates SCF in automobile industry amid SPS, which is an inevitable marvel and one of the noticeable highlights in the present market condition to intensify the benefits, yet prone the supply chain to extreme demand upsurge. Fourteen flexibility strategies from five functional zones of the supply chain have been recognized in light of the literature survey and opinion taken from the field experts. Applying fuzzy DEMATEL, the strategies are ranked based on their strength of influence and various causal relationships among them are established. Findings show that the strategies like volume flexibility (OS1), manufacturing flexibility (OS2) in operating systems function and supplier collaboration flexibility (P1), supplier flexibility (P2) in procurement function have a high degree of influence and hence contribute more to the firm’s performance during SPS. Discussion on the positions possessed by the flexibility strategies within the causal diagrams and the relationships among various groups of causes and effects exhibited in the inter-relationship exhibit is of extraordinary advantage to field experts. Additionally, the digraphs displayed in Fig. 4 may offer assistance to the experts in having a rich depiction on the inter-relationships among strategies inside every business function. In this manner, the analysis of these strategies utilizing fuzzy DEMATEL helps show different bits of knowledge in the relationships which are generally hard to see. This analysis adds to the prior works on flexibility, by linking SCF to SPS and be a key course of outline for all the field specialists undertaking sales promotions. Finally, this study ends with the presentation of limitations and scope for the future work.

References

Abad, P. L. (2003). Optimal price and lot size when the supplier offers a temporary price reduction over an interval. Computers & Operations Research, 30(1), 63–74. https://doi.org/10.1016/S0305-0548(01)00081-8.

Aprile, D., Garavelli, A. C., & Giannoccaro, I. (2005). Operations planning and flexibility in a supply chain. Production Planning & Control, 16(1), 21–31. https://doi.org/10.1080/09537280412331313348.

Aprile, D., Garavelli, A. C., & Giannoccaro, I. (2006). A cost analysis of supply chain flexibility configurations. International Journal of Services, Technology and Management, 7(5/6), 535–551. https://doi.org/10.1504/IJSTM.2006.011285.

Asad, M. M., Mohammadi, V., & Shirani, M. (2016). Modeling flexibility capabilities of IT-based supply chain, using a grey-based DEMATEL method. Procedia Economics and Finance, 36, 220–231. https://doi.org/10.1016/S2212-5671(16)30033-8.

Asadi, N., Fundin, A., & Jackson, M. (2015). The essential constituents of flexible assembly systems: A case study in the heavy vehicle manufacturing industry. Global Journal of Flexible Systems Management, 16(3), 235–250.

Bakeshlou, E. A., Khamseh, A. A., Asl, M. A. G., Sadeghi, J., & Abbaszadeh, M. (2017). Evaluating a green supplier selection problem using a hybrid MODM algorithm. Journal of Intelligent Manufacturing, 28(4), 913–927. https://doi.org/10.1007/s10845-014-1028-y.

Chandra, S., Ghosh, D., & Srivastava, S. K. (2016). Outbound logistics management practices in the automotive industry: An emerging economy Perspective. DECISION, 43(2), 145–165. https://doi.org/10.1007/s40622-015-0122-0.

Chiang, C.-Y., Kocabasoglu-Hillmer, C., & Suresh, N. (2012). An empirical investigation of the impact of strategic sourcing and flexibility on firm’s supply chain agility. International Journal of Operations and Production Management, 32(1), 49–78. https://doi.org/10.1108/01443571211195736.

Choy, K. L., Chow, H. K. H., Tan, K. H., Chan, C. K., Mok, E. C. M., & Wang, Q. (2008). Leveraging the supply chain flexibility of third party logistics–hybrid knowledge-based system approach. Expert Systems with Applications, 35(4), 1998–2016. https://doi.org/10.1016/j.eswa.2007.08.084.

Chuu, S. (2011). Interactive group decision-making using a fuzzy linguistic approach for evaluating the flexibility in a supply chain. European Journal of Operational Research, 213(1), 279–289. https://doi.org/10.1016/j.ejor.2011.03.022.

Coronado, A. E., & Lyons, M. A. C. (2007). Evaluating operations flexibility in industrial supply chains to support build-to-order initiatives. Business Process Management Journal, 13(4), 572–587. https://doi.org/10.1108/14637150710763586.

Das, K. (2011). Integrating effective flexibility measures into a strategic supply chain planning model. European Journal of Operational Research, 211(1), 170–183. https://doi.org/10.1016/j.ejor.2010.12.006.

Donnell, T. O., Humphreys, P., Mcivor, R., & Maguire, L. (2009). Expert systems with applications reducing the negative effects of sales promotions in supply chains using genetic algorithms. Expert Systems with Applications, 36(4), 7827–7837. https://doi.org/10.1016/j.eswa.2008.11.034.

Duclos, L. K., Vokurka, R. J., & Lummus, R. R. (2003). A conceptual model of supply chain flexibility. Industrial Management & Data Systems, 103(6), 446–456. https://doi.org/10.1108/02635570310480015.

Fayezi, S. A., Zutshi, & O’Loughlin, A. (2014). Developing an analytical framework to assess the uncertainty and flexibility mismatches across the supply chain. Business Process Management Journal, 20(3), 362–391. https://doi.org/10.1108/BPMJ-10-2012-0111.

Garavelli, A. C. (2003). Flexibility configurations for the supply chain management. International Journal of Production Economics, 85, 141–153. https://doi.org/10.1016/S0925-5273(03)00106-3.

Gong, Z. (2008). An economic evaluation model of supply chain flexibility. European Journal of Operational Research, 184, 745–758. https://doi.org/10.1016/j.ejor.2006.11.013.

Gosling, J., Naim, M., & Towill, D. (2013). A supply chain flexibility framework for engineer-to-order systems. Production Planning & Control, 24(7), 552–566. https://doi.org/10.1080/09537287.2012.659843.

Govindan, K., Khodaverdi, R., & Vafadarnikjoo, A. (2016). A grey DEMATEL approach to develop third-party logistics provider selection criteria. Industrial Management & Data Systems, 116(4), 690–722. https://doi.org/10.1108/IMDS-05-2015-0180.

Jin, Y., Vonderembse, M., Ragu-nathan, T. S., & Smith, J. T. (2014). Exploring relationships among it-enabled sharing capability, supply chain flexibility and competitive performance. International Journal of Production Economics, 153, 24–34. https://doi.org/10.1016/j.ijpe.2014.03.016.

Kannegiesser, M., Günther, H. O., & Gylfason, Ó. (2014). Sustainable development of global supply chains—part 2: Investigation of the European automotive industry. Flexible Services and Manufacturing Journal, 26(1–2), 48–68. https://doi.org/10.1007/s10696-013-9177-4.

Kazemian, I., & Aref, S. (2016). Multi-echelon supply chain flexibility enhancement through detecting bottlenecks. Global Journal of Flexible Systems Management, 17(4), 357–372.

Kumar, P., Shankar, R., & Yadav, S. S. (2008). Flexibility in global supply chain: Modeling the enablers. Journal of Modelling in Management, 3(3), 277–297. https://doi.org/10.1108/17465660810920609.

Kurata, H., & Liu, J. J. (2007). Optimal promotion planning-depth and frequency for a two-stage supply chain under markov switching demand. European Journal of Operational Research, 177(2), 1026–1043. https://doi.org/10.1016/j.ejor.2006.01.009.

Lin, C. J., & Wu, W. W. (2008). A causal analytical method for group decision-making under fuzzy environment. Expert Systems with Applications, 34(1), 205–213. https://doi.org/10.1016/j.eswa.2006.08.012.

Lin, Y. T., Yang, Y. H., Kang, J. S., & Yu, H. C. (2011). Using DEMATEL method to explore the core competences and causal effect of the IC design service company: An empirical case study. Expert Systems with Applications, 38(5), 6262–6268. https://doi.org/10.1016/j.eswa.2010.11.092.

Lummus, R. R., Vokurka, R. J., & Duclos, L. K. (2005). Delphi study on supply chain flexibility. International Journal of Production Research, 43(13), 2687–2708. https://doi.org/10.1080/00207540500056102.

Luo, B. N., & Yu, K. (2016). Fits and misfits of supply chain flexibility to environmental uncertainty: Two types of asymmetric effects on performance. The International Journal of Logistics Management, 27(3), 862–885. https://doi.org/10.1108/IJLM-01-2015-0004.

Luthra, S., Govindal, K., Kharb, R. K., & Mangla, S. K. (2016). Evaluating the enablers in solar power developments in the current scenario using fuzzy DEMATEL: An Indian perspective. Renewable and Sustainable Energy Reviews, 63, 379–397. https://doi.org/10.1016/j.rser.2016.04.041.

Luthra, S., Mangla, S. K., Shankar, R., Garg, C. P., & Jakhar, S. (2018). Modelling critical success factors for sustainability initiatives in supply chains in Indian context using Grey-DEMATEL. Production Planning and Control. https://doi.org/10.1080/09537287.2018.1448126.

Manders, J. H. M., Caniëls, M. C. J., & Ghijsen, P W Th. (2016). Exploring supply chain flexibility in a FMCG food supply chain. Journal of Purchasing and Supply Management, 22(3), 181–195. https://doi.org/10.1016/j.pursup.2016.06.001.

Merschmann, U., & Thonemann, U. W. (2011). Supply chain flexibility, uncertainty and firm performance: An empirical analysis of german manufacturing firms. International Journal of Production Economics, 130(1), 43–53. https://doi.org/10.1016/j.ijpe.2010.10.013.

Mishra, D., Sharma, R. R. K., Kumar, S., & Dubey, R. (2016). Bridging and buffering: Strategies for mitigating supply risk and improving supply chain performance. International Journal of Production Economics, 180, 183–197. https://doi.org/10.1016/j.ijpe.2016.08.005.

Mishra, D., Sharma, R. R. K., Gunasekaran, A., Papadopoulos, T., & Dubey, R. (2017). Role of decoupling point in examining manufacturing flexibility: An empirical study for different business strategies. Total Quality Management & Business Excellence. https://doi.org/10.1080/14783363.2017.1359527.

Moon, K. K. L., Yi, C. Y., & Ngai, E. W. T. (2012). An instrument for measuring supply chain flexibility for the textile and clothing companies. European Journal of Operational Research, 222(2), 191–203. https://doi.org/10.1016/j.ejor.2012.04.027.

More, D., & Babu, A. S. (2008). Perspectives, practices and future of supply chain flexibility. International Journal of Business Excellence, 1(3), 302–336. https://doi.org/10.1504/IJBEX.2008.017885.

Oh, S., Ryu, K., Moon, I., Cho, H., & Jung, M. (2010). Collaborative fractal-based supply chain management based on a trust model for the automotive industry. Flexible Services And Manufacturing Journal, 22(3–4), 183–213. https://doi.org/10.1007/s10696-011-9082-7.

Opricovic, S., & Tzeng, G. H. (2003). Defuzzification within a multicriteria decision model. International Journal of Uncertainty, Fuzziness and Knowledge-Based Systems, 11(5), 635–652. https://doi.org/10.1142/S0218488503002387.

Pujawan, I. N. (2004). Assessing supply chain flexibility: A conceptual framework and case study. International Journal of Integrated Supply Management, 1(1), 79–97. https://doi.org/10.1504/IJISM.2004.004599.

Sahay, N., & Ierapetritou, M. (2015). Flexibility assessment and risk management in supply chains. AIChE Journal, 61(12), 4166–4178. https://doi.org/10.1002/aic.14971.

Sánchez, A. M., & Pérez, M. P. (2005). Supply chain flexibility and firm performance: A conceptual model and empirical study in the automotive industry. International Journal of Operations & Production Management, 25(7), 681–700. https://doi.org/10.1108/01443570510605090.

Seebacher, G., & Winkler, H. (2013). A citation analysis of the research on manufacturing and supply chain flexibility. International Journal of Production Research, 51(11), 3415–3427. https://doi.org/10.1080/00207543.2013.774483.

Shibin, K. T., Gunasekaran, A., Papadopoulos, T., Dubey, R., Singh, M., & Wamba, S. F. (2016). Enablers and barriers of flexible green supply chain management: A total interpretive structural modeling approach. Global Journal of Flexible Systems Management, 17(2), 171–188.

Singh, R. K., & Acharya, P. (2013). Supply chain flexibility: A frame work of research dimensions. Global Journal of Flexible Systems Management, 14(3), 157–166. https://doi.org/10.1007/s40171-013-0039-4.

Singh, R. K., & Acharya, P. (2014). Identification and evaluation of supply chain flexibilities in Indian FMCG sector using DEMATEL. Global Journal of Flexible Systems Management, 15(2), 91–100. https://doi.org/10.1007/s40171-013-0050-9.

Skipper, J. B., & Hanna, J. B. (2012). Minimizing supply chain disruption risk through enhanced flexibility. International Journal of Physical Distribution & Logistics Management, 39(5), 404–427. https://doi.org/10.1108/09600030910973742.

Sokri, A. (2014). Military supply chain flexibility measures. Journal of Modelling in Management, 9(1), 78–86. https://doi.org/10.1108/JM2-10-2011-0050.

Sreedevi, R., & Saranga, H. (2017). Uncertainty and supply chain risk: The moderating role of supply chain flexibility in risk mitigation. International Journal of Production Economics, 193, 332–342. https://doi.org/10.1016/j.ijpe.2017.07.024.

Srinivasan, R., & Swink, M. (2017). An investigation of visibility and flexibility as complements to supply chain analytics: An organizational information processing theory perspective. Production and Operations Management. https://doi.org/10.1111/poms.12746.

Sushil, (2012). Flexibility maturity model: Possibilities and directions. Global Journal of Flexible Systems Management, 13(2), 75–76. https://doi.org/10.1007/s40171-012-0011-8.

Sushil, (2016). Strategic flexibility in ecosystem. Global Journal of Flexible Systems Management, 17(3), 247–248.

Swafford, P. M., Ghosh, S., & Murthy, N. (2008). Achieving supply chain agility through IT integration and flexibility. International Journal of Production Economics, 116(1), 288–297. https://doi.org/10.1016/j.ijpe.2008.09.002.

Tang, C., & Tomlin, B. (2008). The power of flexibility for mitigating supply chain risks. International Journal of Production Economics, 116(1), 12–27. https://doi.org/10.1016/j.ijpe.2008.07.008.

Thomé, A. M. T., Scavarda, L. F., Pires, S. R. I., Ceryno, P., & Klingebiel, K. (2014). A multi-tier study on supply chain flexibility in the automotive industry. International Journal of Production Economics, 158, 91–105. https://doi.org/10.1016/j.ijpe.2014.07.024.

Tyagi, M., Kumar, P., & Kumar, D. (2015). Assessment of critical enablers for flexible supply chain performance measurement system using fuzzy DEMATEL approach. Global Journal of Flexible Systems Management, 16(2), 115–132. https://doi.org/10.1007/s40171-014-0085-6.

Um, J. (2017). Improving supply chain flexibility and agility through variety management. The International Journal of Logistics Management, 28(2), 464–487. https://doi.org/10.1108/IJLM-07-2015-0113.

Vickery, S., Calantone, R., & Dröge, C. (1999). Supply chain flexibility: An empirical study. Journal of Supply chain Management, 35(2), 16–24. https://doi.org/10.1111/j.1745-493X.1999.tb00058.x.

Wadhwa, S., Saxena, A., & Chan, F. T. S. (2008). Framework for flexibility in dynamic supply chain management. International Journal of Production Research, 46(6), 1373–1404. https://doi.org/10.1080/00207540600570432.

Wang, Y. C. (2008). Evaluating flexibility on order quantity and delivery lead time for a supply chain system. International Journal of Systems Science, 39(12), 1193–1202. https://doi.org/10.1080/00207720802298939.

Wang, R., & Lin, Y. (2014). Push–pull factors of E-Learning in the hotel industry. Industrial Management & Data Systems, 114(8), 1169–1185. https://doi.org/10.1108/IMDS-07-2014-0200.

Wu, H. H., & Tsai, Y. N. (2012). An integrated approach of AHP and DEMATEL methods in evaluating the criteria of auto spare parts industry. International Journal of Systems Science, 43(11), 2114–2124. https://doi.org/10.1080/00207721.2011.564674.

Xiao, Y. (2015). Flexibility measure analysis of supply chain. International Journal of Production Research, 53(10), 3161–3174. https://doi.org/10.1080/00207543.2014.975864.

Yi, C. Y., Ngai, E. W. T., & Moon, K.-L. (2011). Supply chain flexibility in an uncertain environment: Exploratory findings from five case studies. Supply Chain Management: An International Journal, 16(4), 271–283. https://doi.org/10.1108/13598541111139080.

Yu, K. 2013. The effects of objective and perceived environmental uncertainty on supply chain flexibility. In Paper presented in 10th international conference on service systems and service management (ICSSSM). (pp. 410–415). IEEE. https://doi.org/10.1109/icsssm.2013.6602647.

Zadeh, L. A. (1965). Fuzzy sets. Information and Control, 8(3), 338–353. https://doi.org/10.1016/S0019-9958(65)90241-X.

Zhu, X., & Cetinkaya, S. (2015). A stochastic inventory model for an immediate liquidation and price-promotion decision under price-dependent demand. International Journal of Production Research, 53(12), 3789–3809. https://doi.org/10.1080/00207543.2014.990233.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declared that they have no conflicts of interest.

Rights and permissions

About this article

Cite this article

Chirra, S., Kumar, D. Evaluation of Supply Chain Flexibility in Automobile Industry with Fuzzy DEMATEL Approach. Glob J Flex Syst Manag 19, 305–319 (2018). https://doi.org/10.1007/s40171-018-0195-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40171-018-0195-7