Abstract

In the competitive world of today, each organization has a desire to sustain in the marketplace with the implementation of their healthier and flexible supply chain performance measurement (SCPM) system. For the successful implementation, needs to know the significant set of enablers. This study identifies a set of important enablers based on literature review and discussion with field experts of automobile manufacturing industries located in the National Capital Region of India. The vagueness and impreciseness of field expert’s judgements has been reduced using fuzzy decision making trial and evaluation laboratory (fuzzy DEMATEL) approach and analyzed the enablers in order to implement a flexible SCPM system. The findings of this research advocate that enabler ‘higher customer satisfaction’ comes in picture with highest value of ‘Prominence’ (6.4272) and ‘Relation’ (1.0354), therefore seems as a most significant and influencing enabler, while on other side the enabler ‘proper capacity utilization’ is considered as ample influencing enabler, because it has lowest Prominence’ (4.4735) and ‘Relation’ (minus 0.9680) values. This research discussed the categorization into the cause and effect group, degree of interaction and inter-relationship of considered enablers. The outcomes of this study may provide an aid to the managers to implement an effective and flexible SCPM system through which overall profitability of an organization may be improved.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Since 1980s, it has been seen that supply chain management (SCM) is working as a base pillar in enhancing the overall performance of organizations. Womack and Jones (2005) found that SCM works as a key component to make the organization more effective and efficient under the competitive environment. According to Bowersox et al. (2010), aim of SCM should be to maximize the supply chain outcomes, by providing appropriate service level to the end users. Without proper understanding of SCM, it is not thinkable to construct a seamless supply chain. Therefore, there is a need to optimize the supply chain performance in order to provide the products and services at faster rate with lowest possible cost (Gunasekaran et al. 2001). That’s why; to make supply chain more effective and efficient; most of the companies are inserting additional efforts towards implementation of flexible supply chain performance measurement (SCPM) system, today.

In this paper, our focus is to provide the key enablers to mangers in aspect of implementing and improving their SCPM system through incorporating proper flexibility to enhance the overall performance of an organization. In broad aspect, performance measurement can be defined as a manner of enumerating the efficacy and proficiency of activities (Neely et al. 1995). Waggoner et al. (1999) says that ample performance measurement provides a path to identify the area that required more attention and also helpful in improving the communications level among the supply chain associates. Simatupang and Sridharan (2002) stated that a continual improvement for supply chain members, end customers and outside stakeholders could be achieved easily through an effective performance measurement system. Charan et al. (2008) says that higher effectiveness of SCPM system provides more improvement in the supply chain performance. In the previous studies many performance based frameworks were developed, for example: Qureshi et al. (2008) developed an integrated framework using interpretive structural modeling (ISM) and fuzzy MICMAC analysis to examine the key criteria of 3PLs providers in order to enhance the effectiveness of SCM. Thakkar et al. (2009) proposed an integrated SCPM framework for small and medium scale enterprises (SMEs) using a set of qualitative and quantitative insights. Mangla et al. (2014) analyzed a sustainable supply chain performance based framework. Sidola et al. (2012) analyzed the impact of information technology (IT) capabilities on an organization’s performance using system dynamics concept. Tyagi et al. (2014) developed and analyzed the IT enabled supply chain performance model for Indian automobile industry located at Delhi region.

During the competitive environment, customer not only oriented towards high product quality with lower pricing but also expects customized products with short delivery time. To meet such type of expectations, flexible systems management may be helpful (Kumar and Deshmukh 2006). Wadhwa et al. (2007) developed the various flexibility based performance models related to product recovery programs and visualized the importance of flexible system in decision making process. Hu et al. (2013) examined the performance of centralized supply chain by incorporating the flexible ordering policies. Thome et al. (2014) discussed the key effects of supply chain flexibility capabilities at multi-tiers level that required in delivering the products from point of origin to the point of consumptions. Sushil (2012) stated that the flexible systems management is quite valuable in gaining and improving the performance of supply chain operations as a whole.

From last two decades, Indian automobile sector is attracting the automobile manufacturers like: Maruti Suzuki, Hyundai, Honda, Toyota, Nissan etc. to set up manufacturing bases at different locations in India. It have amplified the competition among the manufacturers and encouraging them to make a product at low cost with better quality in order to fulfill the customer’s demand. To sustain in this competitive environment, most of the automobile manufacturers are trying to improve their SCPM system in order to build a seamless supply chain to fulfill the customer’s requirements. Many previous studies have discussion on supply chain performance measurement in the various sectors; however, there is an absence of analysis of performance matrices or barriers/enablers (Gunasekaran et al. 2004). Saad and Patel (2006) found that there is a limited research that concentrates on the supply chain performance system of an Indian automobile manufacturing company. By keeping above themes in the mind, automobile manufacturing companies located at NCR of India have been chosen for this research.

This study aims to identify a set of enablers based on literature review and field expert’s opinions, and to analyze their mutual importance using fuzzy decision making trial and evaluation laboratory (fuzzy DEMATEL), a multi-criteria decision making approach. This study discussed the cause and effect behavior and inter-relationship mapping of considered enablers and addresses the following research queries:

-

What is the list of significant enablers related to flexible SCPM system?

-

How to address the internal consistency of identified enablers with general perspectives of an organization?

-

What are the behaviour, importance ranking and interaction level of considered enablers?

-

Why are ranking and interaction level of these enablers valuable for SCPM system implementation?

-

How are these enablers useful for managers to improve and implement a flexible SCPM system?

Enabler’s Identification: Literature Review

For a company, customer satisfaction is very essential element to improve their supply chain performance and overall profit. To make a positive customer voice, higher level of customer satisfaction is required that in turn also increases the market share/value. Moreover, it may be expected that, increase in the market share will provide a higher growth in the market place. As an outcome of this, it is easy for the company to provide its products at a minimum price with better quality and will also improve the overall performance of a company (Anderson et al. 1994).

There are many aspects to improve the production performance; out of them proper capacity utilization can be selected as a significant measure to enhance the supply chain performance. The capacity utilization has a direct impact on lead time, flexibility and delivery system and also affects the customer demand by enhancing the speed of response (Slack et al. 1995). According to Christopher (1998), the company can achieve a competitive advantage on the basis of proper focusing towards their service and cost leadership. For this, it is required to build a flexible and appropriate performance measurement of supply chain to promote the better understanding among the supply chain stages (Fawcett and Cooper 1998; Dreyer 2000).

Today’s most of the organizations are trying to enhance the use of Information Technologies (IT) in their SCM system, to make it more efficient and effective. It indicates that IT works as a supply chain enabler and helps to the managers in developing information systems and in providing more flexibility among the work related tasks. IT provides a seamless flow of entities among the existing stages of supply chain and also built the organization functions more efficient throughout the whole supply chain (Handfield and Nichols 1999). Finally, information technology can be considered as a key enabler/driver in implementing a flexible SCPM system (Koh et al. 2006). Tompkins and Ang (1999) stated that effectively and timely use of information among the supply chain stages works as a key enabler/driver for this competitive market place. According to Lin and Tseng (2006) appropriate level of information sharing among the supply chain partners provides the reduction in total cost, improvement in order fulfillment and reduction in order cycle time, thus as a result improving the overall supply chain performance.

Ragatz et al. (1997) say that effective integration among the suppliers and manufacturers plays a very important role in improving the product value or supply chain performance to remain competitive in the market place. The various existing theories suggested that if degree of integration among the supply chain stages is higher, then it is necessary that firm performance will also be better (Anderson and Katz 1998; Narasimhan and Jayaram 1998; Johnson 1999; Frohlich and Westbrook 2001). Barut et al. (2002) found that the inter-company integration and coordination can be achieved by proper information sharing and works as a significant success factor to improve the supply chain performance. Turner (1993) says that supply chain integration helps to make an effective communication and flexibility among the all supply chain stages. With this continuation, it has been seen that level of information sharing and information suitability are important to achieve the customer responsiveness. Daugherty et al. (1995) support the above statement and says that information availability and customer responsiveness are positively related to each other in order to improve the supply chain performance of an organization.

Green and Inman (2005) noticed that alignment of systems in all supply chain stages ranging from point of origin to the point of consumption will help to enhance the organizational performance. To obtain competitive advantage at the supply chain phase, marketing strategies should be appropriately implemented and executed with a higher level of integration and coordination, to concentrate more towards the end consumer (Mavi et al. 2013). To achieve the competitive advantage, supply chain performance also depends on its partner’s talent under dynamic environment (Vanderhaeghe and de Treville 2003).

Gunasekaran and Kobu (2007) say that open and transparent communication between people builds a better co-operative and supportive work environment. It also facilitates to develop an appropriate set of performance measures in order to make a SCPM system more flexible and efficient, by which organizational performance will improve very rapidly. During this competitive and changing behavior of market, it is required to focus towards the new product design and development. As an advancement of manufacturing technologies and innovations throughout the prominent organizations, product development can be seen as a significant source of competitive advantage. Therefore, it is mandatory to reduce the new product development (NPD) cycle time in order to make an improvement in market share and profit, and to remain stable in this competitive environment (Cooper and Kleinschmidt 1995; Griffin 1997; Ittner and Larcker 1997). An organization can also improve its performance by adopting the modern manufacturing practices such as quality management, just-in-time and information technology (Flynn and Flynn 2005; Green and Inman 2005). Little et al. (1995) noticed that effectiveness of scheduling techniques directly affects the production system and also helps in improving the supply chain performance.

According to Heizer and Render (2006) an effective SCM should have the ability to sustain long-term strategic relationships with their supply chain associates. Because, the quality of supply chain relationships have direct impact on the supply chain performance (Fynes et al. 2004). Kohli and Jaworski (1990) found that improvement in organizational performance can also be achieved by adopting the market orientation. Hence, adoption of market orientation will play a crucial role in improving the supply chain performance.

Research Methodology

The objective of this research is to evaluate the importance level of considered enablers to implement a flexible SCPM system. To achieve the objective, a set of significant enablers which affects the flexible SCPM system of an organization, was identified based on literature review and discussion with field experts, chosen from automobile industry located at national capital region (NCR) of India. For the discussion purpose, extensive brainstorming sessions (with five industrial and two academic experts) were fixed to strengthen and improve the literature inputs.

As a pre-testing part, a questionnaire has been formulated on five point Likert scale (1 for least important…..5 for absolutely most important) and send to the 150 field experts to collect their opinions in order to know the importance level and to test the feasibility of enablers. For this purpose, a reliability analysis has been performed. After that the consistency (post-testing) of considered enablers has been checked using Kappa statistics. To derive this statistics, the opinion of twenty five experts (fifteen from industry and ten from academia) were collected using a questionnaire study, regarding the existence of fifteen enablers under the four perspectives (managerial, information, integration and production). Based on collected opinions, Kappa index value has been calculated, which gives the evidence about the internal consistency of enablers under these perspectives. In this case, Kappa index value comes under the significant range as interpreted in Tables 4 and 5. Hence, the identified set of enablers as shown in Table 1 is consistent and ready for further analysis.

After finding the consistency evidence, the set of enablers has been analyzed using fuzzy DEMATEL approach. To derive the fuzzy DEMATEL analysis, a questionnaire has been structured on linguistic terms (no influence… very high influence) and discussed with the nineteen field experts to collect their individual opinions regarding importance level of considered enablers. Then, step by step procedure of fuzzy DEMATEL approach has been adopted to meet the specified objective of present research.

Data Collection and Analysis

Reliability Analysis

With the purpose of pre-testing the feasibility of considered enablers, a questionnaire was structured and sent to the 150 professionals, out of them 57 responses were received. The response rate was found 38 % which is sufficient to drive analysis (Malhotra and Grover 1998). To check the reliability of collected data, Cronbach’s alpha coefficient (α) has been computed using SPSS-16, which comes as 0.785 and is given in Table 2, i.e. under the recommended range (0.7 < α > 0.95). The mean and standard deviation are also calculated as shown in Table 3. In a mode of supply chain performance improvement, this table gives an initial picture about the importance level of enablers based on their mean value. For example, enablers such as higher customer satisfaction, quality of the supply chain, relationships, and alignment of systems throughout the supply chain have higher mean values in comparison to the other enablers. Hence, it is an indication that these enablers have more importance in edifice of better and flexible supply chain performance system.

Check for Internal Consistency: Kappa Statistics

The kappa statistics developed by Cohen (1968) has been applied to check the consistency (post-testing part) of considered enablers under the four categories namely as: C 1 = managerial perspective; C 2 = information perspective; C 3 = integration perspective and C 4 = production perspective. As a broad aspect, the identified enablers can be assumed under the above four perspectives of an organization, thus to know the nature of consistency of each enabler under the corresponding perspective, kappa statistics has been used in this study.

The kappa index (k) is known for true and actual consensus assessment and defined as the ratio of difference of observed theoretical and chance agreement to the beyond by chance agreement. It is a quantitatively rated contract rather than predicted by chance and is given as:

where

The assignments percentage P j under the jth category and degree of involvement (P i ) of raters/experts for the ith enabler are calculated by using the Eqs. 4 and 5, as given below:

The notations used in the Eqs. 2–5 are described as:

u = Total number of identified enablers = \( \mathop \sum \nolimits A_{m } ,\,(m = 1, \ldots .15) \)

v = Total number of categories = \( \mathop \sum \nolimits C_{n} , ({\text{n}} = 1, \ldots .4) \)

W = Total number of considered experts = 25

w ij = Ratings of ith enabler with respect to jth category, \( (i = 1, \ldots .u) \), \( (j = 1, \ldots .v) \)

Table 4 has been prepared and the filled value in each cell represents the number of experts involved for the existence of enablers in corresponding category.

The value of kappa (k) is calculated as:

The interpretation scale proposed by Landis and Koch (1977) of kappa value is given as in Table 5.

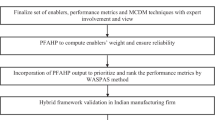

Analyzing ‘k’, it is observed that it comes in the showing fair consideration of all enablers in their category. Further analysis has been done using fuzzy DEMATEL approach as given in flow chart of the work (Fig. 1).

Fuzzy Set Theory and Triangular Fuzzy Numbers

For decision making problems related to complex system, most of the organizations have formulated a questionnaire based on linguistic terms instead of crisp values and send to the field experts to gather their opinions regarding enablers. The states of each linguistic variable are represented by linguistic terms. The linguistic terms used are: very small, small, medium, large, and very large. The judgements of decision makers in terms of linguistic expressions have some degree of vagueness or fuzziness. Fuzzy set theory propose by Zadeh (1965), has been used to reduce the fuzziness associated with the human judgements, which deals with the linguistic variables to resolve the real world problems. A fuzzy set gives a degree of belongingness by incorporating the membership function between 0 and 1, while crisp set by binary logic 0 or 1 only, i.e. fuzzy set is advantageous over the crisp set to reduce the uncertainty.

Let X be a universe of discourse, \( X = \left\{ {x_{1} ,x_{2} , \ldots ,x_{n} } \right\} \), A fuzzy set \( \tilde{a} \) of X is a set of order pairs like \( \left\{ {\left( {x_{1} ,\mu_{{\tilde{a}}} \left( {x_{1} } \right)} \right), \left( {x_{2} ,\mu_{{\tilde{a}}} \left( {x_{2} } \right)} \right), \ldots ,\left( {x_{n} ,\mu_{{\tilde{a}}} \left( {x_{n} } \right)} \right)} \right\} \), where \( \mu_{{\tilde{a}}} :X \to \left[ {0, 1} \right] \) is the membership function of \( \tilde{a} \) and \( \mu_{{\tilde{a}}} \left( {x_{i} } \right) \) terms a membership degree of \( x_{i} \) in \( \tilde{a} \). If \( \tilde{a} \to 1, \) then the grade of membership of \( x_{i} \) in \( \tilde{a} \) will be higher (Kaufmann and Gupta 1991). Then in the universe of discourse ‘X’, a fuzzy set \( \tilde{a} \) is denoted as:

(When X is discrete and finite).

(When X is continuous and infinite).

To maximize the real world applications and ease in computation, triangular fuzzy number (TFN) has been used (Yeh and Deng 2004). Its membership function \( \mu_{{\tilde{a}}} (x) \) has been as:

where in the Eq. 9, the symbols used are:

Triangular fuzzy number, \( \tilde{a} \) = triplet (a 1 , a 2 , a 3 )

a 1 = lower value of triplet, a 2 = middle value triplet and a 3 = upper value triplet.

The two TFN’s (Fig. 2) \( \tilde{a} = \left( {a_{1} ,a_{2} ,a_{3} } \right) \) and \( \tilde{b} = \left( {b_{1} ,b_{2} ,b_{3} } \right) \) have their usual operation law and used in the analysis.

In the study, the opinions of field experts with certain degree of uncertainty have been tabulated, aggregated and searched the crisp values using CFCS (Converting Fuzzy data into Crisp Scores) defuzzification method (Opricovic and Tzeng 2003).

Fuzzy DEMATEL Approach

The DEMATEL method (Gabus and Fontela 1973) analyze the mutual interaction among the complex set of criteria/factors on the basis of graph theory (Chen and Chen 2010) and the contextual relationship among the existing criteria, based on cause and effect behavior (Charan et al. 2008; Li and Tzeng 2009). In recent years, DEMATEL method has been applied by various scholars in different–different fields to solve the critical problems. Out of them some important applications are as follows: Hsu et al. (2007) have used a combination of fuzzy DEMATEL approach with fuzzy multi-criteria decision making to find the significant criteria in order to frame the relations of an ideal customer’s choice behavior. Shieh et al. (2010) have used DEMATEL method in the hospital management to analyze the key success factors of hospital service quality. Chang et al. (2011) have applied fuzzy DEMATEL method to find significant criteria for the selection of supply chain management suppliers. Lin et al. (2011) have applied DEMATEL method to analyze the interrelationship among the core competences of IC design Service Company. Mavi et al. (2013) have applied fuzzy DEMATEL method to evaluate the logistical criteria for the selection of green supplier. Lin (2013) has applied fuzzy DEMATEL method to evaluate the green supply chain management practices.

By applying this method, both direct and indirect influences can be taken into account very easily. Furthermore, it has been seen that human perceptions or opinions on considered factors are subjective. In most of the cases, human judgements have uncertainty and vagueness in their preferences. To cover the uncertainty and vagueness of judgements, it is required to involve the fuzzy logic/concept at the stage of data collection from field experts. The criteria/factors in the questionnaire have been structured using fuzzy scale as shown in Table 2, and the opinions of field experts have been gathered.

Algorithm of fuzzy DEMATEL approach is given in five steps as:

-

(1)

Construction of average direct-relation matrix.

-

(2)

Normalization of direct relation matrix

-

(3)

Determination of total-relation matrix

-

(4)

Formation of a causal diagram

-

(5)

Calculate threshold value

Construction of Average Direct-Relation Matrix

To collect the opinions of field expert’s and find out the direct influence of i \( \to \) jth element, fuzzy linguistic scale has been used as shown in Table 6. Then assign the corresponding triangular fuzzy numbers and aggregate the fuzzy numbers. Fuzzy aggregation process in this paper has been done using Converting Fuzzy data into Crisp Scores (CFCS) defuzzification method. The fuzzy maximum and minimum fuzzy number range have been determined and crisp score is obtained in the form of weighted average value (Opricovic and Tzeng 2003; Wu and Lee 2007). Let, \( \tilde{A}_{ij}^{n} = \left( {a_{ij}^{n} , b_{ij}^{n} , c_{ij}^{n} } \right), \) and influence matrix is calculated as:

where m = number of criteria and h = number of respondents.

The CFCS method in five steps is given below:

Normalization:

Compute right (rs) and left (ls) normalized values:

Compute total normalized crisp values:

Compute crisp values:

Integrate crisp values:

The average direct-relation matrix is written as:

Normalization of Direct Relation Matrix

Normalized direct relation matrix ‘X’ can be obtained by using the following equation:

where

Determination of Total-Relation Matrix

It is written as:

where ‘I’ is the identity matrix.

In the total relation matrix, the sum of rows (R) and columns (C) are calculated as:

Then, add the corresponding values of ‘R’ and ‘C’, to obtain the value of Prominence (R + C) and Relation (R − C).

Formation of a Causal Diagram

The casual diagram is prepared by mapping Prominence and Relation data, marked horizontally and vertically in the graph. Then categorization of enablers into cause and effect group is done. If (R − C) value is positive, enablers comes in the cause group and if (R − C) value is negative then comes in the category of effect group (Tzeng et al. 2007; Yang et al. 2008; Lee et al. 2009).

Calculate Threshold Value (α)

The threshold value (α) is calculated by taking the average of the elements in total relation matrix T, as in Eq. 25, and inter-relationship diagram (Fig. 4) is obtained.

where N is the total number of elements in the matrix T.

Numerical Illustration

After performing reliability and consistency analysis of enablers, a questionnaire has been structured on fuzzy linguistic scale shown in Table 6, and discussed with nineteen field experts for seeking their opinion regarding enabler’s importance. Then, linguistic tables are prepared; Table 9 is the example of such a table from one of the experts. This table explains the influencing nature of considered enablers over each other, for example the enabler A1 has no influence on enabler A12, low influence on enablers A6, A7, A9, A10, A11 and high influence over the enablers A2, A4, A5, A8, and very high influence on enabler A3. After that linguistic scale direct-relation matrix (Table 9 in Appendix) has been converted into the corresponding triangular fuzzy numbers and then applied CFCS defuzzification method (Eqs. 11–17) to aggregate the fuzzy inputs. The defuzzified direct-relation matrix is shown in Table 10 in Appendix. By using Eq. 18, aggregate the defuzzified/crisp direct-relation matrices of all experts and average direct-relation matrix is computed as given in Table 11 in Appendix.

Further, normalization of average direct-relation matrix has been done by using Eq. 20, as shown in Table 12 in Appendix. Then, total relation matrix as given in Table 13 in Appendix, is attained using Eq. 21. Using Eqs. 22–24, computed the sum of rows (R) and sum of columns (C) of the total inter-relation matrix to find the ‘prominence’ and ‘relation’ value of enablers and are given in Table 7. By mapping (R + C) and (R − C) values, cause and effect diagram is constructed as shown in Fig. 3 and threshold value (α = 0.1847) by Eq. 25 has also been computed. The interaction matrix is constructed based on computed threshold value, to give a mutual degree of interaction among the considered enablers as shown in Table 8. Then an inter-relationship diagram is developed based on interaction matrix and shown in Fig. 4.

Results and Discussion

Table 7 and Fig. 5 show the importance ratings of all enablers based on their (R + C) values and noticed that the enabler A1 has greater importance rating than others. The importance rating order of all enablers comes as: A1 > A6 > A15 > A8 > A4 > A12 > A13 > A7 > A10 > A14 > A3 > A5 > A9 > A11 > A2. Thus, the primary focus of a company should be to fulfill the customer requirements to achieve better customer satisfaction. It is the role of enabler, ‘higher degree of integration across supply chain (A6)′.

Also visualizing the (R − C) values, where enablers are categorized into their cause and effect group. The enablers namely higher customer satisfaction (A1), making proper performance measurement (A3), information sharing (A4), higher degree of integration across the supply chain (A6), alignment of systems throughout the supply chain (A8) and adoption of a market orientation (A15) have ‘positive’ (R − C) values and comes under the category of cause group. While the others such as: proper capacity utilization (A2), effective integration of suppliers (A5), information availability and customer responsiveness (A7), open and transparent communication (A9), reduction of new product development cycle time (A10), adoption of modern manufacturing practices (A11), effectiveness of scheduling techniques (A12), long-term, strategic relationships (A13), and quality of the supply chain relationships (A14) have ‘negative’ (R − C) values and comes under the category of effect group. The enablers of cause group have an influence over the effect group enablers, which is shown by casual diagram (Fig. 3). Various thoughtful decisions may be made through Table 7 and by analyzing the casual diagram i.e. A1 seems to be more significant as it has highest (R + C) and (R − C) values i.e. 6.4272 and 1.0354 and also called precise influencing enabler, while the other enabler A2 is considered as ample influencing enabler because it has lowest (R + C) and (R − C) values [4.4735 and minus 0.9680].

Table 8 and Fig. 4, show the mutual interaction or influencing behaviour of enablers over each other. In the inter-relationship diagram as shown in Fig. 4, six types of lines are used to represent an influencing nature of one enabler over another enabler based on their cause and effect group categorization as: thin regular orange line indicates the influence of one cause group enabler over the effect group enabler, thin dotted orange line indicates the influence of one cause group enabler over the other cause group enabler, thick dotted orange lines indicates the influence of two cause group enablers over each other, thick regular red line indicates the influence of one cause group enabler and one effect group enabler over each other, thin dotted black line indicates the influence of one effect group enabler over the other effect group enabler and thick dotted black line indicates the influence of two effect group enablers over each other. After visualizing Fig. 4, it is noticed that cause group enablers (A1, A3, A4, A6, A8, and A15) have higher degree of interaction and influencing nature over the effect group enablers (A2, A5, A7, A9, A10, A11, A12, A13, and A14). Furthermore for better understanding can be says that enablers A1, A6, A8, and A15 have highest degree of interaction and other enablers A2, A9, A10 and A11 have least degree of interaction, while the remaining enablers A3, A4, A5, A7, A12, A13 and A14 have moderate degree of interaction.

Conclusions

To meet the specified research objective, a set of fifteen critical enablers is identified and analyzed using fuzzy DEMATEL approach. The proposed approach is an extension of DEMATEL method with use of linguistic terms and fuzzy aggregation method, in order to avoid the vagueness and impreciseness of the judgments. This study uses the CFCS (Converting Fuzzy data into Crisp Scores) method for fuzzy input aggregation. In order to reduce the complexity of problem and make precise decision, fuzzy DEMATEL categorizes a set of enablers into cause and effect groups.

The analysis reveals that the cause group enablers (A1, A3, A4, A6, A8 and A15) have more impact over the specified goal due to their higher degree of interaction. That’s why; they cannot be moved easily and remunerated more attention. Based on research findings it is observed that, the higher customer satisfaction (A1) is a very influencing enabler and can be achieved through adopting the market orientation (A15). For this, a company should be focused towards higher degree of integration across the supply chain (A6) in order to build an alignment of the systems throughout the supply chain (A8). Hence, it is clear that enablers (A1, A6, A8 and A15) have higher degree of interaction through maintaining an appropriate level of information sharing (A4) and proper performance measurement (A3). On the other flank, the effect group enablers (A2, A5, A7, A9, A10, A11, A12, A13 and A14) are influenced easily by the cause group enablers and can be moved easily, hence, needs to be improved. Therefore, it is concluded that to improve or implement an effective and flexible SCPM system, an organization should emphasize more to maintain higher customer satisfaction level and higher degree of integration across their supply chain functions.

The concluding trail of the present research could be supported by the outcomes of previous studies. Some significant outcomes out of them are as: the higher level of customer satisfaction is an essential factor to enhance the market share value of an organization. The increase in the market share will provide a higher growth in the market place and improve the overall performance of a company (Anderson et al. 1994; Gunasekaran et al. 2001). Frohlich and Westbrook (2001) stated that if degree of integration among the supply chain stages is higher, then it is necessary that firm performance will also be better. Hence, it is easy to conclude that higher customer satisfaction and higher degree of integration across supply chain functions work as the key enablers for flexible SCPM system implementation.

The present study delivers an empirical analysis of considered enablers and highlights their categorization into cause and effect groups and degree of interaction. The outcomes of this study may provide an aid to the managers to implement an effective and flexible SCPM system through which overall profitability of an organization may be improved.

Limitations and Future Scope

During this study, respondents were selected from Indian automobile manufacturing industries located at National Capital Region, while the automobile industries are spread in a very large area of India at various locations with different requirements. Therefore; results of the present study cannot be generalized for automobile industries all over the country. This limitation generates future scope for this study as: first the data can be collected from other locations of India and compare the results. Second, other multi-criteria decision making techniques can also be applied in order to validate the results of this study.

References

Anderson, E. W., Fornell, C., & Lehmann, D. R. (1994). Customer satisfaction, market share, and profitability: Findings from Sweden. Journal of Marketing, 58(7), 53–66.

Anderson, M. F., & Katz, P. B. (1998). Strategic sourcing. International Journal of Logistics Management, 9(1), 1–13.

Aviv, Y. (2007). On the benefits of collaborative forecasting partnerships between retailers and manufacturers. Management Science, 53(5), 777–794.

Barut, M., Faisst, W., & Kanet, J. J. (2002). Measuring supply chain coupling: an information system perspective. European Journal of Purchasing & Supply Management, 8(3), 161–171.

Beamon, B. M. (1999). Measuring supply chain performance. International Journal of Operations and Production Management, 19(3), 275–292.

Bhagwat, R., & Sharma, M. K. (2007). Performance measurement of supply chain management: A balanced scorecard approach. Computers & Industrial Engineering, 53(1), 43–62.

Bowersox, D., Closs, D., & Cooper, M. (2010). Supply chain logistics management (Int ed.). New York: McGraw-Hill.

Brown, S., Squire, B., & Blackmon, K. (2007). The contribution of manufacturing strategy involvement and alignment to world-class manufacturing performance. International Journal of Operations and Production Management, 27(3), 282–302.

Chan, F. T. S., Nayak, A., Raj, R., Chong, A. Y. L., & Tiwari, M. (2014). An innovative supply chain performance measurement system incorporating research and development (R&D) and marketing policy. Computers & Industrial Engineering, 69, 64–70.

Chang, B., Chang, C. W., & Wu, C. H. (2011). Fuzzy DEMATEL method for developing supplier selection criteria. Expert Systems with Applications, 38(3), 1850–1858.

Charan, P., Shankar, R., & Baisya, R. K. (2008). Analysis of interactions among the variables of supply chain performance measurement system implementation. Business Process Management Journal, 14(4), 512–529.

Chen, J. K., & Chen, S. (2010). Using a novel conjunctive MCDM approach based on DEMATEL, fuzzy ANP, and TOPSIS as an innovation support system for Taiwanese higher education. Expert Systems with Applications, 37(3), 1981–1990.

Chiadamrong, N., & Prasertwattana, K. (2006). A comparative study of supply chain models under the traditional centralized and coordinating policies with incentive schemes. Computers & Industrial Engineering, 50(4), 367.

Cho, D. W., Lee, Y. H., Ahn, S. H., & Hwang, M. K. (2012). A framework for measuring the performance of service supply chain management. Computers & Industrial Engineering, 62(3), 801–818.

Christopher, M. (1998). Logistics and supply chain management: Strategies for reducing costs and improving services. Financial times (2nd ed.). London: Pitman Publishing.

Cohen, J. (1968). Weighted kappa: Nominal scale agreement with provision for scaled disagreement or partial credit. Psychological Bulletin, 70(4), 213–220.

Cooper, R. G., & Kleinschmidt, E. J. (1995). Benchmarking the firm’s critical success factors in new project development. Journal of Product Innovation Management, 12(5), 374–391.

Cousins, P. D. (2005). The alignment of appropriate firm and supply strategies for competitive advantage. International Journal of Operations & Production Management, 25(5), 403–428.

Das, A., Narasimhan, R., & Talluri, S. (2006). Supplier integration: Finding an optimal configuration. Journal of Operations Management, 24(5), 563–582.

Daugherty, P. J., Ellinger, A. E., & Rogers, D. S. (1995). Information accessibility: Customer responsiveness and enhanced performance. International Journal of Physical Distribution and Logistics Management, 25(1), 4–17.

Dawes, J. (1999). The relationship between subjective and objective company performance measures in market orientation research: Further empirical evidence. Marketing Bulletin, 10, 65–75.

Demirbag, M., Koh, S. C. L., Tatoglu, E., & Zaim, S. (2006). TQM and market orientation’s impact on SMEs’ performance. Industrial Management & Data Systems, 106(8), 1206–1228.

Dreyer, D. E. (2000). Performance measurement: A practitioner’s perspective. Supply Chain Management Review, 4(4), 30–36.

Fawcett, S. E., & Cooper, M. B. (1998). Logistics performance measurement and customer success. Industrial Marketing Management, 27(4), 341–357.

Fawcett, S. E., & Myers, M. B. (2001). Product and employee development in advanced manufacturing: Implementation and impact. International Journal of Production Research, 39(1), 65–79.

Flynn, B. B., & Flynn, E. J. (2005). Synergies between supply chain management and quality management: Emerging implications. International Journal of Production Research, 43(16), 3421–3436.

Frohlich, M. T., & Westbrook, R. (2001). Arcs of integration: an international study of supply chain strategies. Journal of Operations Management, 19(2), 185–200.

Fynes, B., de Búrca, S., & Marshall, D. (2004). Environmental uncertainty, supply chain relationship quality and performance. Journal of Purchasing and Supply Management, 10(4/5), 179–190.

Gabus, A., & Fontela, E. (1973). Perceptions of the world problematique: Communication procedure, communicating with those bearing collective responsibility. Geneva: Battelle Geneva Research Center. (DEMATEL Report No. 1).

Giannakis, M. (2011). Management of service supply chains with a service oriented reference model: The case of management consulting source. Supply Chain Management, 16(5), 346–361.

Graham, T. S., Dougherty, P. J., & Dudley, W. N. (1994). The long term strategic impact of purchasing partnerships. International Journal of Purchasing and Materials Management, 30(4), 13–18.

Green, K. W, Jr., & Inman, R. A. (2005). Using a just-in-time selling strategy to strengthen supply chain linkages. International Journal of Production Research, 43(16), 3437–3453.

Green, K. W., Jr., Inman, R. A., Brown, G., & Willis, T. H. (2005). Market orientation: Relation to structure and performance. Journal of Business & Industrial Marketing, 20(6), 276–284.

Griffin, A. (1997). PDMA research on new product development practices: Updating trends and benchmarking best practices. Journal of Product Innovation Management, 14(6), 429–458.

Gunasekaran, A., & Kobu, B. (2007). Performance measures and metrics in logistics and supply chain management: A review of recent literature (1995–2004) for research and applications. International Journal of Production Research, 45(12), 2819–2840.

Gunasekaran, A., & Ngai, E. W. T. (2008). Adoption of e-procurement in Hong Kong: An empirical research. International Journal of Production Economics, 113(1), 159–175.

Gunasekaran, A., Patel, C., & McGaughey, R. E. (2004). A Framework for supply chain performance measurement. International Journal of Production Economics, 87(3), 333–347.

Gunasekaran, A., Patel, C., & Tirtiroglu, E. (2001). Performance measures and metrics in a supply chain environment. International Journal of Operations & Production Management, 21(1/2), 71–87.

Gupta, A. K., & Govindarajan, V. (2000). Knowledge flows within multinational corporations. Strategic Management Journal, 21(4), 473–496.

Handfield, R. B., & Nichols, E. L, Jr. (1999). Introduction to supply chain management. Prentice-Hall: Upper Saddle River.

Harrtman, R. V., & Bengtsson, L. (2009). Manufacturing competence: A key to success-full supplier integration. International Journal of Manufacturing Technology and Management, 16(3), 283–299.

Heizer, J., & Render, B. (2006). Operations management (8th ed.). Pearson Education New Jersey: Upper Saddle River.

Hofmann, E., & Locker, A. (2009). Value-based performance measurement in supply chains: A case study from the packaging industry. Production Planning and Control, 20(1), 68–81.

Holweg, M., Disney, S., Holmstrom, J., & Smaros, J. (2005). Supply chain collaboration: Making sense of the strategy continuum. European Management Journal, 23(2), 170–181.

Hsu, C. Y., Chen, Y. H., & Tzeng, G. H. (2007). FMCDM with Fuzzy DEMATEL Approach for customers’ choice behavior model. International Journal of Fuzzy Systems, 9(4), 236–246.

Hu, F., Lim, C. C., & Lu, Z. (2013). Coordination of supply chains with a flexible ordering policy under yield and demand uncertainty. International Journal of Production Economics, 146, 686–693.

Hurley, R. F., & Hult, G. T. M. (1998). Innovation, market orientation, and organisational learning: An integration and empirical examination. Journal of Marketing, 62, 42–54.

Ittner, C. D., & Larcker, D. F. (1997). Product development cycle time and organizational performance. Journal of Marketing Research, 34(1), 13–23.

Jakhar, S. K., & Barua, M. K. (2014). An integrated model of supply chain performance evaluation and decision-making using structural equation modelling and fuzzy AHP. Production Planning and Control, 25(11), 938–957.

Johnson, J. L. (1999). Strategic integration in distribution channels: Managing the inter-firm relationship as a strategic asset. Academy of Marketing Science Journal, 27(1), 4–18.

Kaufmann, A., & Gupta, M. M. (1991). Introduction to fuzzy arithmetic: theory and application. New York: Van Nostrand Reinhold.

Kaynak, H. (2003). The relationship between total quality management practices and their effects on firm performance. Journal of Operations Management, 21(4), 405–435.

Ketokivi, M. A., & Schroeder, R. G. (2004). Strategic, structural contingency and institutional explanations in the adoption of manufacturing practices. Journal of Operations Management, 22(1), 63–89.

Klein, S., & Roth, V. J. (1993). Satisfaction with international marketing channels. Journal of the Academy of Marketing Science, 21(1), 39–44.

Koh, S. C. L., Saad, S. M., & Arunachalam, S. (2006). Competing in the 21st century supply chain through supply chain management and enterprise resource planning integration. International Journal of Physical Distribution and Logistics Management, 36(6), 455–465.

Kohli, A. K., & Jaworski, B. J. (1990). Market orientation: The construct, research propositions, and managerial implications. Journal of Marketing, 54(2), 1–18.

Kumar, P., & Deshmukh, S. G. (2006). A model for flexible supply chain through flexible manufacturing. Global Journal of Flexible Systems Management, 7(3), 17–24.

Kwon, I.-W. G., & Suh, T. (2004). Factors affecting the level of trust and commitment in supply chain relationships. Journal of Supply Chain Management, 40(2), 4–14.

Labahn, D. W., Ali, A., & Krapfel, R. (1997). New product development cycle time: The influence of project and process factors in small manufacturing companies. Journal of Business Research, 36(2), 179–188.

Lalonde, B. J. (1998). Building a supply chain relationship. Supply Chain Management Review, 2(2), 7–8.

Landis, J. R., & Koch, G. G. (1977). A one-way component of variance model for categorical data. Biometrics, 33(4), 671–679.

Lawson, B., & Potter, A. (2012). Determinants of knowledge transfer in inter-firm new product development projects. International Journal of Operations & Production Management, 32(10), 1228–1247.

Lee, H. I., Kang, H. Y., Hsu, C. F., & Hung, H. C. (2009). A green supplier selection model for high-tech industry. Expert System Application, 36(4), 7917–7927.

Li, C. W., & Tzeng, G. H. (2009). Identification of a threshold value for the DEMATEL method using the maximum mean de-entropy algorithm to find critical services provided by a semiconductor intellectual property mall. Expert Systems with Applications, 8(1), 9891–9898.

Lin, R. J. (2013). Using fuzzy DEMATEL to evaluate the green supply chain management practices. Journal of Cleaner Production, 40, 32–39.

Lin, H. T., & Chang, W. L. (2008). Order selection and pricing methods using flexible quantity and fuzzy approach for buyer evaluation. European Journal of Operational Research, 187(2), 415–428.

Lin, C., & Tseng, H. (2006). Identifying the pivotal role of participation strategies and information technology application for supply chain excellence. Industrial Management & Data Systems, 106(5), 739–756.

Lin, Y. T., Yang, Y. H., Kang, J. S., & Yu, H. C. (2011). Using DEMATEL method to explore the core competences and causal effect of the IC design service company: An empirical case study. Expert Systems with Applications, 38(5), 6262–6268.

Lings, I. (2004). Internal market orientation construct and consequences. Journal of Business Research, 57(4), 405–413.

Little, D., Kenworthy, J., Jarvis, P., & Porter, K. (1995). Scheduling across the supply chain. Logistics Information Management, 8(1), 42–48.

Lockstrom, M., Schadel, J., Harrison, N., Moser, R., & Malhotra, M. K. (2010). Antecedents to supplier integration in the automotive, industry: A multiple-case study of foreign subsidiaries in China. Journal of Operations Management, 28(3), 240–256.

Malhotra, M. K., & Grover, V. (1998). An assessment of survey research in POM: From constructs to theory. Journal of Operations Management, 16(4), 407–425.

Mangla, S. K., Kumar, P., & Barua, M. K. (2014). Flexible decision approach for analyzing performance of sustainable supply chains under risks/uncertainty. Global Journal of Flexible Systems Management, 15(2), 113–130.

Mavi, R. K., Kazemi, S., Najafabadi, A. F., & Mousaabadi, H. B. (2013). Identification and assessment of logistical factors to evaluate a green supplier using the fuzzy logic DEMATEL method. Polish journal of environmental studies, 22(2), 445–455.

Mishra, A. A., & Shah, R. (2009). In union lies strength: Collaborative competence in new product development and its performance effects. Journal of Operations Management, 27(4), 324–338.

Morgan, J., & Monczka, R. M. (1996). Supplier integration: A new level of supply chain management. Purchasing, 120, 110–113.

Narasimhan, R., & Jayaram, J. (1998). Causal linkages in supply chain management: an exploratory study of North American manufacturing firms. Decision Sciences, 29(3), 579–605.

Neely, A., Gregory, M. J., & Platts, K. (1995). Performance measurement system design, a literature review and research agenda. International Journal of Operations and Production Management, 15(4), 80–116.

Nyaga, G., Whipple, J., & Lynch, D. (2010). Examining supply chain relationships: Do buyer and supplier perspectives on collaborative relationships differ? Journal of Operations Management, 28(2), 101–114.

Oke, A., Prajogo, D. I., & Jayaram, J. (2013). Strengthening the innovation chain: The role of internal innovation climate and strategic relationships with supply chain partners. Journal of Supply Chain Management, 49(4), 43–58.

Opricovic, S., & Tzeng, G. H. (2003). Defuzzification within a multi-criteria decision model. International Journal of Uncertainty, Fuzziness and Knowledge-Based Systems, 11(5), 635–652.

Paulraj, A., Lado, A. A., & Chen, J. J. (2008). Inter-organizational communication as a relational competency: Antecedents and performance outcomes in collaborative buyer-supplier relationships. Journal of Operations Management, 26(1), 45–64.

Petersen, K., Handfield, R., & Ragatz, G. (2005). Supplier integration into new product development: coordinating product, process, and supply chain design. Journal of Operations Management, 23(3–4), 371–388.

Qureshi, M. N., Kumar, D., & Kumar, P. (2008). An integrated model to identify and classify the key criteria and their role in the assessment of 3PL services providers. Asia Pacific Journal of Marketing and Logistics, 20(2), 227–249.

Rabelo, L., Eskandari, H., Shaalan, T., & Helal, M. (2007). Value chain analysis using hybrid simulation and AHP. International Journal of Production Economics, 105, 536–547.

Ragatz, G. L., Handfield, R. B., & Scannell, T. V. (1997). Success factors for integrating suppliers into new product development. Journal of Product Innovation Management, 14(3), 190–202.

Ravi, V., Shankar, R., & Tiwari, M. K. (2005). Analyzing alternatives in reverse logistics for end-of-life computers: ANP and balanced scorecard approach. Computers & Industrial Engineering, 48(2), 327–356.

Saad, M., & Patel, B. (2006). An investigation of supply chain performance measurement in Indian automotive sector. Benchmarking, 13(1/2), 36–53.

Shieh, J. I., Wu, H. H., & Huang, K. K. (2010). A DEMATEL method in identifying key success factors of hospital service quality. Knowledge-Based Systems, 23(3), 277–282.

Sidola, A., Kumar, P., & Kumar, D. (2012). System dynamics investigation of information technology in small and medium enterprise supply chain. Journal of Advances in Management Research, 9(2), 199–207.

Simatupang, T. M., & Sridharan, R. (2002). The collaborative supply chain. International Journal of Logistics Management, 13(1), 15–30.

Slack, N., Chambers, S., Harland, C., Harrison, A., & Johnston, R. (1995). Operations management. London: Pitman Publishing.

Sushil. (2012). Multiple perspectives of flexible systems management. Global Journal of Flexible Systems Management, 13(1), 1–2.

Thakkar, J., Kanda, A., & Deshmukh, S. G. (2009). Supply chain performance measurement framework for small and medium scale enterprises. Benchmarking, 16(5), 702–723.

Thome, A. M. T., Scavarda, L. F., Pires, S. R. I., Ceryno, P., & Klingebiel, K. (2014). A multi-tier study on supply chain flexibility in the automotive industry. International Journal of Production Economics, 158, 91–105.

Tompkins, J., & Ang, D. (1999). What are your greatest challenges related to supply chain performance measurement? IIE Solutions, 31(6), 66.

Turner, J. R. (1993). Integrated supply chain management: What’s wrong with this picture? Industrial Engineering, 25(12), 52–55.

Tyagi, M., Kumar, P., & Kumar, D. (2014). Selecting alternatives for improvement in IT enabled supply chain performance. International Journal of Procurement Management, 7(2), 168–182.

Tzeng, G. H., Chiang, C. H., & Li, C. W. (2007). Evaluating intertwined effects in e-learning programs: a novel hybrid MCDM model based on factor analysis and DEMATEL. Expert Systems with Applications, 32(4), 1028–1044.

Ulaga, W., & Chacour, S. (2001). Measuring customer-perceived value in business markets. Industrial Marketing Management, 30(6), 525–540.

Van der Vorst, J. G. A. J., & Beulens, A. J. M. (2002). Identifying sources of uncertainty to generate supply chain redesign strategies. International Journal of Physical Distribution & Logistics Management, 32(6), 409–430.

Vanderhaeghe, A., & de Treville, S. (2003). How to fail at flexibility. Supply Chain Forum, 4(1), 64–67.

Wadhwa, S., Madaan, J., & Avneet, S. (2007). Need for flexibility and innovation in healthcare management systems. Global Journal of Flexible Systems Management, 8(1–2), 45–54.

Waggoner, D., Neely, A., & Kennerley, M. (1999). The forces that shape organizational performance measurement systems: An interdisciplinary review. International Journal of Production Economics, 60–61, 53–60.

Womack, J. P., & Jones, D. T. (2005). Lean solutions: How companies and customers can create wealth together. New York: Simon & Schuster.

Wu, W. W., & Lee, Y. T. (2007). Developing global managers’ competencies using the fuzzy DEMATEL method. Expert Systems with Applications, 32(2), 499–507.

Yang, Y. P., Shieh, H. M., Leu, J. D., & Tzeng, G. H. (2008). A novel hybrid MCDM model combined with DEMATEL and ANP with applications. International Journal Operational Research, 5(3), 160–168.

Yeh, C. H., & Deng, H. (2004). A practical approach to fuzzy utilities comparison in fuzzy multi-criteria analysis. International Journal of Approximate Reasoning, 35(2), 179–194.

Zadeh, L. A. (1965). Fuzzy Set. Information and Control, 8(3), 338–353.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tyagi, M., Kumar, P. & Kumar, D. Assessment of Critical Enablers for Flexible Supply Chain Performance Measurement System Using Fuzzy DEMATEL Approach. Glob J Flex Syst Manag 16, 115–132 (2015). https://doi.org/10.1007/s40171-014-0085-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40171-014-0085-6