Abstract

Application of series compensation in extra high voltage (EHV) transmission line makes the protection job difficult for engineers, due to alteration in system parameters and measurements. The problem amplifies with inclusion of electronically controlled compensation like thyristor controlled series compensation (TCSC) as it produce harmonics and rapid change in system parameters during fault associated with TCSC control. This paper presents a pattern recognition based fault type identification approach with support vector machine. The scheme uses only half cycle post fault data of three phase currents to accomplish the task. The change in current signal features during fault has been considered as discriminatory measure. The developed scheme in this paper is tested over a large set of fault data with variation in system and fault parameters. These fault cases have been generated with PSCAD/EMTDC on a 400 kV, 300 km transmission line model. The developed algorithm has proved better for implementation on TCSC compensated line with its improved accuracy and speed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The continuously increasing power market demands increase in power transmission capacity. This force the power engineers to transmit maximum possible power through transmission lines (up to thermal limits). This leads power sector for installation of series compensation in transmission lines. With increase in power transfer capacity, the series compensation facilitates control of power flow and improves transient and steady state stability also. Two main types of series compensators are found in practice, fixed series compensator and controllable series compensator [1], each with its own advantages and disadvantages. The controllable compensator utilizes power electronics control to regulate power flow by changing the conduction of the power electronic devices. Thyristor controlled series compensation (TCSC) is one of the main controllable compensation techniques.

Besides the advantages gained by series compensation, it makes the protection requirement altered from regular non-compensated transmission line protection. This is due to non-linear changes introduced in system with implementation of TCSC. The TCSC produce harmonics, rapid changes associated to TCSC control actions in primary system parameters such as line impedances and load currents. In the event of fault, quick changes would be registered by TCSC’s control system for protective measures. To reduce the fault current, the firing angle will be change to take TCSC into inductive mode. The normal practice is to provide an over-voltage protection to the capacitor in the TCSC circuit with help of MOV and a circuit breaker. The conduction of the MOV depends on severity of the fault current, this leads towards two different impedances during fault according to the MOV conduction. All these changes make the protection of the TCSC implemented transmission line complicated. The conventionally used series compensated transmission line protective algorithm uses impedance measurement approach. This is used for identification of the phases involved in the fault and position of fault with respect to the compensator. This paper describes a newly designed fault type identification system for TCSC compensated transmission line.

Many efforts are registered for series compensated and controllable compensated transmission line protections in literature. Digital signal processing has emerged as a potential tool for protection relaying. The use of wavelet transform (WT) [2], discrete wavelet transform (DWT) [3], S-transform [4] can be seen in literature.

Many of reported methods employs DSP tool as a spectrum analyzer with the Artificial Intelligence (AI) technique. The application of Fourier transform (FT) with artificial neural network (ANN) for controllable compensated transmission line has been demonstrated in [5]. However, the input requirement of more than one cycle post fault data makes it slow. The application of versatile processing tool Wavelet Transform with Extreme Learning Machine has been shown in [6] and with Neuro-Fuzzy system in [7]. However, two step methods require cascaded implementation of DSP and AI technique. This makes the system slow in consideration of digital protection system.

One of the better solutions for fast processing protective requirement is implementation of AI technique as a pattern recognition tool for protection relaying. The ANN finds its implementation for pattern recognition in an article proposed by authors of [8]. However, authors fail to prove efficacy of the method in the absence of sufficient testing for varying system conditions. Authors of [9] presented ANN based scheme for fault classification with the delta-bar-delta algorithm based training. However, the algorithm is developed for end-line compensation configuration. The algorithm developed for end-line compensation can suffer when used with mid-line configuration as need to adapt to two dissimilar conditions of impedances. In the absence of neural design governing mechanism, the ANN involves higher designing efforts and heavier network size. Moreover, ANN require an extensive training, for which it requires a large training data set and time. The ANN is also sensitive to power system parameter variation like frequency. These limitations of ANN, leads to Support Vector Machine (SVM), that render its own structure during training. The SVM is a classifier that expands its input into higher dimension plane to generate better classification boundary. The SVM is a potential classifier for protection requirements; therefore, it has been studied for fault classification and its performance has been compared with traditional ANN for same training and testing fault cases.

As discussed earlier, the DSP based scheme requires numbers of filters for relaying applications that makes it slow for practical implementation. The two-staged DSP and AI based scheme require additional implementation of AI classifier after DSP. In this scenario, the AI based pattern recognition techniques held an edge for development. The algorithm proposed in this paper uses Support Vector Machine (SVM) as a pattern recognition tool for fault classification of the transmission line equipped with TCSC. The proposed algorithm utilizes only half cycle post fault data at relaying end to conclude on fault type. This makes the algorithm fast and practical. The developed algorithm has been tested for a large fault data set encircling various system conditions. These faults have been generated in bulk by the real time power system simulation software PSCAD/EMTDC [10]. The SVM has been implemented with LibSVM [11] software on windows platform.

Support Vector Machine

SVMs have emerged as a very powerful AI technique for classification and regression. It is a binary classifier based on statistical theory of generalization and Kernel expansion [12]. For classification problems, the SVMs try to find out a hyper-plane to separate the data points according to their classes such that the separation between the classes is maximum. In that case, the hyper-plane is said to be the optimal hyper-plane. The SVM expands its input into a higher dimensional dot product space for classification. This process makes SVM a classifier that can handle many classification features simultaneously to obtain optimal hyper-lane for classification.

Considering a two-class training data set {x i ,y i } N i=1 consisted of N data points. xi is ith real valued input vector and yi is the corresponding class of xi with value of either +1 or −1. A hyper-plane, separating these points according to their classes, can be given by equation: w T x i + b = 0 as shown in Fig. 1. The ‘w’ and ‘b’ represents weight vector and bias term respectively and determine the position of the separating hyperplane. The training is performed to find out the value of w and b such that the separation between the classes is maximum. It can be shown that the separation margin (m) is given by [13]:

For better separation, maximum value of ‘m’ should be increased with training with, reducing value of ‖w‖ to its minimum value. Hence, for linearly separable data, the SVM can be constructed by minimizing v(w) where

The non-linear classification problem can also be dealt with SVMs. This can be done by mapping of classified data onto a high-dimensional feature space where the linear classification is possible using nonlinear vector function,

By expanding the non-linear function, the non-linear function can become separable. In practice, the nonlinear data transformation is accomplished indirectly by using so called kernel functions [14], which is defined by

This expansion generates a higher dimensional space; the SVM can be trained to find out maximum margin between the classes by Eq. (2). However, there is a possibility that, the expanded data is still not linearly separable. In that case it will be impossible to separate out the data and satisfy condition in Eq. (3). Hence, instead function v(w) a new function v(w, ɛ) can be used, and given by:

Subject to,

where ɛ i = 1, 2, …, N are slack variables. C > 0 and known as regularization parameter. The vectors v(w, ɛ) are known as support vectors and are used to determine decision surface of the classifier. The classification accuracy largely depends on selection of Kernel function and value of C for classification.

Fault Case Studies

Figure 2 shows a two area system considered for study in this research. The system consists of a 300 km, 50 Hz, 3-phase, 400 kV EHV transmission line connected with two generators on either end. The generators (G1 and G2) represent two areas of a power system, the variation in system areas are simulated with variation in generator impedances. The transmission line is equipped with an advanced series compensator TCSC at the middle of the line. The TCSC is aided with a series compensator (SCf1). The TCSC and the fixed series compensator are protected against over voltage by Metal Oxide Varistor (MOV) as shown in Fig. 2. The transmission line parameters used for this simulation are provided in Table 1.

The fixed series compensator is providing 30 % compensation to the total line length. The TCSC provides a variable compensation of 0–15 % with variation of the firing angle (α) from 180° to 144°. The MOV used with TCSC and fixed compensator is set to conduct at 2.5 times the normal operating current. The generators are working with following impedance values: positive sequence resistance = 1.31 Ω; zero sequence resistance = 2.33 Ω; positive sequence reactance = 15.0 Ω; zero sequence reactance = 26.6 Ω.

Considering these values as unit values ZG1 and ZG2, system variations are considered with variation in ZG1 and ZG2 in a combination of (ZG1-ZG2), (0.75ZG1-ZG2), (1.25ZG1-ZG2), (ZG1-0.75ZG2) and (ZG1-1.25ZG2).

To examine the accuracy of the proposed algorithm, it has been evaluated with a large fault data set with a wide variation of system and fault parameters. To generate data in bulk, all system components are dynamically simulated using PSCAD/EMTDC, an established simulator for power system studies. The transmission line is modeled with the distributed parameter model in PSCAD/EMTDC. To encircle maximum fault conditions fault are created under wide variation in system parameters. These variations are created by varying system parameters like source impedance (given above), TCSC firing angle (α) and generator loading angle (δ) as given in Table 2.

Combination of these variations creates 45-various system conditions. Faults are created under these system conditions with variation in fault parameters like:

-

(a)

Fault Inception Angle (FIA): 0°, 45°, 115°.

-

(b)

Fault Resistance (Rf): 0 Ω, 5 Ω, 25 Ω, 50 Ω.

-

(c)

Fault Length: 20, 40, 49, 51, 60, 80 % of the total line length.

-

(d)

Type of Faults: L–g, L–L–g, L–L, L–L–L (all ten types of faults).

For a specific system condition, combination of these fault parameters creates 720 distinct fault cases. Therefore, for 45 system conditions a sum total of 32,400 fault cases have been generated with PSCAD.

The SVM used for fault type identification demands training. For this purpose, a set of 2400 fault patterns are separated out for training of the SVM as given in Table 3. It is worth to note here that, only few of the parameters are used for training case generation. All the cases separated out are a small bunch of fault patterns from 144° of the TCSC firing angle, other are used exclusively for testing.

The remaining 30,000 fault patterns are used for testing of the algorithm. It can be easily seen from the above discussion that, the each test fault patterns carries different system and fault conditions than every training pattern.

Fault Classification

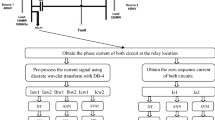

The magnitude and spectra of the measured current changed with inception of fault in the transmission line. These changes are because of a sudden change in impedance at the time of fault and also due to inclusion of transient frequencies and TCSC control related harmonics. The proposed algorithm is based on recognition of these changes with SVM as the pattern recognition tool. The algorithm has been developed with measurements at relaying end (bus-A) of the considered system shown in Fig. 2. The three-phase currents measured at this end are considered for pattern recognition with a cluster of four Support Vector Machines (SVMs).

Figure 3 shows current waveforms for all three phase for a A-G fault at 180 km fault distance with 5 Ω fault resistance and 45° fault inception angle. The fault has been simulated with line loading angle of 20° with TCSC operating at firing angle (α) = 160°. Figure 4 shows A–B–G fault with same system and fault conditions for fault in Fig. 3.

The three-phase currents measured at the relaying end are sampled with suggested sampling frequency of 4 kHz in this research. A half cycle post fault data (40 samples) from each phase is supplied to three SVMs identifying involvement of each phase in the event of fault. These make a classification vector (Vphase) for each phase classifier SVMs of 120 samples as shown in Fig. 5.

where, CA, CB, CC are sample vector of the respective phase. To recognize the involvement of ground in fault the fourth SVM has been supplied with a ground vector (Vground) representing summation of all three current samples (40 samples).

The input vectors are cycled through the SVMs to give output ‘+1’, if the respective phase/ground is involved in fault, otherwise ‘−1’. The LibSVM 3.11 software has been used for implementation of SVMs [11, 15]. The training of each SVM has been performed with same data set of 2400 cases depicted in Table 2. The Gaussian Kernel has found suitable for all four SVMs in this work. The literature reveals that in absence of classification parameters (cost function ‘C’ and ‘γ’) governing mechanism, they are supposed to be finely adjusted for each SVM separately for appropriate classification. In this work, common values of these parameters are determined from implementation experiences for all four SVMs for fault type classification. The value of C = 10,000 and γ = 0.0000042 are chosen for all four SVMs and used successfully. The trained SVM with these variables and Gaussian Kernel carries [10, 47, 39, and 09] support vectors for Phase-A, Phase-B, Phase-C and ground respectively, with training accomplished in [100, 412, 549, and 47] iteration for respective SVMs.

To demonstrate the ability of the proposed SVM based system, it has been compared with implementation with a cluster of four ANNs. A typical feed-forward neural network with a single hidden layer has been considered for this evaluation. The numbers of hidden layer neurons, in the absence of the decisive algorithm for the architecture, are chosen based on application performance. After checking performance with different architecture of neural nets, a structure of [(40-14-1) for A-Phase ANN, (40-18-1) for B-Phase ANN, (40-20-1) got C-Phase ANN and (40-4-1) for Ground ANN have been chosen for their better performance accuracy.

The same classification vectors of Vphase and Vground generated in (7) and (8) are used for classification with ANNs. The set of all four ANNs are trained with same training set of Table 3, which is used for training of the SVMs. The detailed results of this comparison are given in following section.

Results and Discussion

The algorithm has been tested with a large data set of 30,000 fault cases with all of the system and fault data variations discussed in the section of fault case studies. These variations included are different TCSC firing angles, fault inception angles, fault resistances, and system loading angles with different system conditions of the fault group set with all ten types of faults. Fault type identification accuracy for SVM and ANN based schemes are given in Tables 4 and 5. As can be seen in Tables 4 and 5, accuracy of the both proposed methods are quite satisfactory at various levels of compensation with different firing angles. The performance of SVM with proposed method for different firing angles can be seen in Table 4.

The accuracy of the proposed method with SVM is consistent for different firing angles (level of compensations). The SVM is trained to take intuitive shape in the multi-dimensional classification plane to give same level of accuracy for various TCSC firing angles; however it has been trained with TCSC angle of 160° only. The highest accuracy level obtained at TCSC firing angle of 160° and a bit inferior for 144° due to higher percentage changes in spectral components. This is the potential of the SVM to handle large feature spaces for classification. The training of SVM is carried out so that the dimension of classified vectors does not have distinct influence on the performance of SVM. This makes SVM efficient in large classification problems. The fault waveforms carries number of features that can be used for fault classification, and use of SVM in this case becomes advantageous.

It can be observed form Table 5 that, the accuracy of the ANN based scheme is comparable with SVM based scheme for firing angle of 160°, for which its training had been performed. However, a decline in accuracy is observed with change in TCSC firing angle. This hints over fitting of the ANN to training. This limitation of the ANN can be overcome by inclusion of fault cases with different firing angle; however, this option has not been used in this work.

From this discussion, it can easily be noticed that, non-linear capability of the SVM is higher than ANN and this hints advantage of SVM over the ANN for fault type classification.

Table 6 shows level of accuracies for all possible fault types on transmission line. The results establish SVM as a better trained classifier and is able to produce same level of accuracy for various types of faults for different fault conditions. This owes to the better generalization capacity of SVM compare to conventional ANN.

The overall accuracies obtained in this method (99.91 %) shows improvement in performance compare to fault classification problems depicted with accuracies of 99.11 % in [6] and 99.30 % in [7].

The performance of the ANN and SVM based scheme at various fault distance is shown in Fig. 6. Further, breakup of these accuracies at various fault distances for different TCSC firing angles have been shown in Table 7. It is observed from the table that, the fault classification accuracy of SVM is consistent for all the fault lengths.

It is worth to notice here that, the fault lengths of 147 km (49 % of total line length) and 153 km (51 % of total line length) are in most critical region for transmission line fault analysis with TCSC at the middle of the line. No fault cases around this line zone are included in the training cases. However, SVM produce same level of accuracy for this region also. This proves adaptability of the SVM training for better classification.

An advancement gained by SVM over ANN in fault classification problem for TCSC compensated transmission line can be seen in Fig. 7 in graphical format.

Critical Comparison Between ANN and SVM

In case of non-linear classification, both SVMs and ANNs apply non-linear projection into higher-dimensional space. These projections are achieved by introduction of additional hidden layer neuron in case of ANN. These hidden layer neurons are defined by the user with implementation experimentation. On other side, the SVM uses a Kernel function to the same effect with automatically defining support vector during training.

Moreover, the ANN training is based on minimization of the mean square error, while SVM trained with minimization of both training errors and ‘hypothesis complexity’ simultaneously. This leads the SVM towards more global and unique solutions compare to ANN which suffers from problem of local minima.

Another parameter to be watched for is memory requirement. With addition of the hidden layer the ANN produces (40 × 14 × 1=) 560 interconnections for Phase-A and 720, 800 and 160 for Phase-B, C and ground respectively. The SVM marks 10, 47, 39, and 09 support vector for implementation. Moreover, with increased structure size, ANN require higher computation during training and require more time and epochs compare to SVM. The SVM uses kernel based expansion to transform inputs into multi-dimensional space; the training procedure is comparatively easy and quick. The final vector structures (support vector) are very less compared to ANN and within very less number of epochs. This improves response time in real time and makes SVM a better classifier for implementation. The performance of the proposed method in comparison to the recent methods is given in Table 8.

Conclusion

This paper establishes a new fault type identification scheme for TCSC compensated transmission line protection. The scheme has been developed with application of Artificial Intelligence (AI) method of Support Vector Machine (SVM) as a pattern recognition tool. With comparison to ANN based scheme, the SVM has proved a better classifier for protection system. Requirement of only half cycle post fault data for proper identification of the fault types makes the scheme faster. As the classification has performed with three phase currents data only, it eliminates voltage measurements and related computations. Moreover, the need for setting of classification parameters of each SVM separately has been negated by establishing their value usable equally for each SVM in this algorithm.

The performance of the scheme has been examined with a large data set of 30,000 fault patterns with wide variation of system and fault parameter variations. The results indicate improvement in classification accuracy compare to many established methods.

References

N.G. Hingorani, L. Gyugyi, Understanding FACTS, First Indian edn. (IEEE Press, Piscataway, 2001)

Y. Liao, S. Elangovan, Fault noise based approach to phase selection using wavelets based feature extraction. Electr Mach Power Syst 27, 389–398 (1999)

P.K. Dash, S.R. Samantray, Phase selection and fault section identification in thyristor controlled series compensated line using discrete wavelet transform. Int J Electr Power Amp Energy Syst 26, 725–732 (2004)

S. Samantaray, P. Dash, Pattern recognition based digital relaying for advanced series compensated line. Int J Electr Power Energy Syst 30, 102–112 (2008)

Y. Song, A. Johns, Q. Xuan, Artificial Neural-Network-Based Protection Scheme for Controllable Series-Compensated EHV Transmission Lines, IEE Proceedings on Generation, Transmission and Distribution, vol. 143, Issue 6 (1996), pp. 535–540

V. Malathi, N.S. Marimuthu, S. Baskar, K. Ramar, Application of extreme learning machine for series compensated transmission line protection. Eng. Appl. Artif. Intell. 24, 880–887 (2011)

H. Eristi, Fault diagnosis system for series compensated transmission line based on wavelet transform and adaptive neuro-fuzzy inference system. Measurement 46, 393–401 (2013)

H.Khorashadi-Zadeh, Artificial neural network approach to fault classification for double circuit transmission lines, in Transmission and Distribution Conference and Exposition: Latin America, IEEE/PES (2004), pp. 859–862

Q.Y. Xuan, Y.H. Song, A.T. Johns, R. Morgan, D. Williams, Performance of an adaptive protection scheme for series compensated EHV transmission systems using neural networks. Electr. Power Syst. Res. 36, 57–66 (1996)

User’s Guide on the use of PSCAD: Manitoba HVDC Research Centre, 2010

C.C. Chang, C.J. Lin, LIBSVM: A library for support vector machines. ACM Trans Intell Syst Technol (TIST) 2, 27 (2011)

N. Cristianini, J. Shawe-Taylor, An introduction to support vector machines and other kernel-based learning methods (Cambridge University Press, Cambridge, 2000)

S. Haykin, Neural Networks: A Comprehensive Foundation, 2nd edn. (Prentice Hall, NJ) (1998)

U.B. Parikh, B. Das, R.P. Maheshwari, Combined wavelet-SVM technique for fault zone detection in a series compensated transmission line. IEEE Trans. Power Deliv. 23, 1789–1794 (2008)

C.W. Hsu, C.C. Chang, C.J. Lin, A Practical Guide to Support Vector Classification, Ed, 2003

S.R. Samantaray, Decision tree-based fault zone identification and fault classification in flexible AC transmissions-based transmission line. IET-Gener. Transm. Distrib. 3, 425–436 (2009)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yashvantrai Vyas, B., Maheshwari, R.P. & Das, B. Pattern Recognition Application of Support Vector Machine for Fault Classification of Thyristor Controlled Series Compensated Transmission Lines. J. Inst. Eng. India Ser. B 97, 175–183 (2016). https://doi.org/10.1007/s40031-015-0210-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40031-015-0210-8