Abstract

Alkalophilic Paenibacillus polymyxa CKWX1, capable of producing xylanase was isolated from Dendrocalamus strictus decomposing wood samples. High level of xylanase produced by using easily available inexpensive agricultural waste residues as substrates such as wheat straw supported maximal xylanase activity, (1.41 IU/mL) followed by apple pomace, (1.22 IU/mL), Bombax ceiba wood dust, (0.64 IU/mL), Eucalyptus sp. wood dust (0.56 IU/mL) and Pinus roxburghii wood dust (0.33 IU/mL). The decomposing wood may provide excellent source for isolation of xylanolytic bacteria because of their varied physical and chemical conditions. The optimum pH and temperature for growth of this organism was 7.0–9.0 and 30–40 °C, respectively. On optimization of cultural conditions viz. 1.0 % inoculum size containing 80 × 108 colony forming unit (CFU)/mL, 1.0 % wheat straw, pH 7.0, temperature 35 °C, yeast extract 1.0 %, Tween 20 0.05 %, xylanase activity was increased by 2.6 folds. The novel alkaline xylanase was produced efficiently by alkalophilic P. polymyxa CKWX1. These results indicate the potential of P. polymyxa CKWX1 xylanase to be useful in pulp and paper industry.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The quest for generating renewable energy source has naturally focused on plant biomass and its effective utilization through advances in technology development. Cellulose and hemicellulose are the world’s largest renewable carbohydrates universally present in all agricultural and forest residues [1] and frequently constitute the waste disposal problem. It offers great promise as a substrate for variety of useful products. Various ways of realizing these potentials are being investigated. Xylanolytic enzymes are receiving increasing attention because of their potential applications in improving the digestibility of animal feed [2], pulp bleaching [3] and bioconversion of lignocelluloses into feedstocks and fuels [4].

Xylans are major hemicellulose components of lignocellulosic materials. They mostly occur as heteropolysaccharides consisting of a backbone of β, 1-4 linked xylose residues substituted by arabinose and uronic acids which are linked glycosidically to the backbone and acetic, ferulic, cinnamic acids which are attached by ester linkages [5]. It is located in the cell walls of higher plants, especially hard wood and grasses [6] and constitutes for as much as 30 % of the dry weight of higher plants [7].

Studies on the occurrence, coincidence and production of xylanase of bacteria isolated from soil [8], compost [9, 10], municipal waste [11] and agricultural waste [12] have been conducted. However, reports on such studies in case of bacteria isolated from decomposing wood are lacking. Xylan being the most abundant hemicellulosic component in wood [13], it is presumed that many bacteria involved in or associated with the decay of wood are able to degrade and assimilate this polysaccharide.

The decomposing wood may provide excellent source for isolation of xylanolytic bacteria because of their varied physical and chemical conditions. No attempts seem to have been made earlier to study occurrence and level of xylanases in bacteria isolated from these ecological niches.

Material and Methods

Culture and Growth Medium

Alkalophilic bacterium isolated from decomposed wood and identified as Paenibacillus polymyxa CKWX1 under the GenBank accession number JX534241 was studied for xylanase production in submerged fermentation (SmF). The isolate was grown and maintained on basal salt medium (BSM, pH 7.0) of following composition (g/L): Na2HPO4 6.0; KH2PO4 3.0; NaCl 0.5; NH4Cl 1.0. Separately sterilized solution of 1 M MgSO4 (2 mL) and 1 M CaCl2 (0.1 mL) were added into the sterilized medium. The bacterial culture was grown at 35 °C and maintained in liquid medium as well as in solid medium containing 0.5 % xylan and stored at 4º C.

Collection of Decomposing Wood Samples

The samples of decomposing wood of different trees were collected from the varied sites of Forest Research Institute, Dehradun, Uttarakhand. These wood samples had been decomposing since 1940′s. Wood samples were trees like Champ (Michelia champeae), Babool (Acacia arabica), Hopea (Hopea parviflora), Deodar (Cedrus deodara), Bamboo (Bambosa polymorpha), Bamboo (Dendrocalamus strictus), Silk Cotton tree (Salmalia malabariaca), Amoori (Amoora wallichii), Chir pine (Pinus roxburghiii), Jamun (Syzygium communis), Teak (Tectona grandis) and Sal (Shorea robusta).

Enumeration of Cellulolytic Microorganism in Decomposing Wood Samples

Enumeration was done by using a standard dilution technique in which three portions (each 10 g) of the wood dust of decomposing wood samples were shaken separately in 90 mL sterilized distilled water in 250 mL Erlenmeyer flasks. After keeping the flasks on rotary shaker at 120 rpm for 1 h, dilutions were made to give three replicate tenfold dilution series from 10−1 to 10−7, for each sample. Cellulolytic fungi, bacteria and actinomycetes were counted by plating 0.1 mL of each dilution on separate plates and incubated at temperature 28 ± 2 °C. Rose Bengal cellulose agar [14]; Hans medium [15] and Kenknight medium [15] were the selective media for the enumeration of fungi, bacteria and actinomycetes, respectively.

Isolation of Xylanolytic Bacteria From Decomposing Wood

Bacteria capable of degrading xylan were isolated from decomposing wood by enrichment and adaptation technique. Samples of decomposing wood material were macerated and passed through 106μ sieve. Wood dust samples of 10 g each were put into 90 mL BSM in 250 mL Erlenmeyer flask. The mixture was incubated at 35 °C on a rotary shaker at 120 rpm. After incubating for 10 days, an aliquot (5 mL) of this enriched culture was inoculated into fresh medium containing 0.5 % wood dust and incubated at 35 °C on a rotary shaker. After incubating for 5 days, an aliquot of this medium was inoculated into 50 mL of fresh medium with wood dust (0.5 %). Again the mixture was inoculated for 5 days and the process was repeated five times. Every transfer to the fresh culture was made when more than 100 colonies per 0.1 mL of suspension were obtained by plating on BSM. Finally xylanolytic bacteria were isolated by plating on BSM containing 0.5 % xylan.

The most predominant bacterial colonies capable of good growth on this medium were picked and purified. These isolates were again tested for their ability to grow and capacity to produce clear zones on BSM containing 0.5 % xylan by Congo red plate assay [16].

Xylanase Production

Erlenmeyer flasks each containing 50 mL of the Basal Salt Yeast Extract Medium (BSYEM) and containing all the ingredients of BSM supplemented with yeast extract (0.5 %) was used as media for production of xylanase. BSYEM was supplemented with different concentrations of a variety of substrates. The medium was autoclaved at 15 psi pressure for 20 min. The medium was inoculated with 1 % bacterial cell suspension (unless mentioned otherwise) containing 80 × 108 CFU/mL and incubated at 35 °C under shaken conditions (120 rpm) for 96 h. At the end of incubation period the contents were centrifuged at 8,000 rpm for 15 min at 4 °C. The culture supernatant was filter sterilized and used as crude xylanase preparation. Prior to centrifugation, the samples were withdrawn and used for the determination of cell density by measurement of cell survival by quantitative plating.

Selection of Best Substrate for Xylanase Production

The xylanase production by the best isolate in the presence of different substrates such as glucose, fructose, sucrose, galactose, wheat straw, P. roxburghii wood shavings dust, apple pomace, Eucalyptus sp. wood dust, Bombax ceiba wood dust and xylan (0.5 %) in BSYEM was studied. The substrate that induced the maximum xylanase production was used for further production studies.

Effect of Incubation Period on Xylanase Production

Effect of different incubation periods (0, 12, 24, 48, 72 and 96 h) on xylanase production was studied. The incubation period that gave the maximum xylanase production was selected for further studies.

Effect of Inoculum Size on Xylanase Production

0.5, 1.0, 1.5 and 2.0 % inoculum (v/v) was added to BSYEM and the production of xylanolytic activity was determined after incubating the flasks. The inoculum size showing the best xylanase activity was used for further production studies.

Effect of Substrate Concentration on Xylanase Production

Different substrate concentrations of the best substrate (0.25–2.0 %) were added to BSYEM. Substrate concentration giving the maximum activity was considered as optimum and used for further experiments.

Effect of Temperature on Xylanase Production

To find the optimum temperature for the maximum xylanse production, a range of temperature (25–50 °C) was used. The best temperature was maintained in further experiments.

Effect of pH on Xylanase Production

To find the optimum pH for the maximum xylanase production, a range of pH (5.0–10.0) was used. The best pH was selected and maintained in all further experiments.

Effect of Surfactants on Xylanase Production

Surfactants like Tween 20, Tween 40, Tween 80, Triton X100 and Triton X405 at the concentration of 0.025–0.1 % were used to study their effect on the production of xylanolytic activity. The experiment was carried out under all optimum conditions.

Xylanase Assay

Xylanase activity was assayed using 1 % oat spelt xylan (Sigma, St, Louis, MO, USA) in 0.2 M Tris–HCl buffer (pH 8.0) according to the calorimetric method of Miller [17]. The release of reducing sugars was determined using 3, 5-dinitrosalicylic acid (DNSA) against xylose as standard. The reaction mixture contained 0.5 mL of 1 % D-xylan in Tris–HCl buffer (0.2 M, pH 8.0) and 0.5 mL tenfold diluted enzyme. It was incubated at 50 °C for 5 min in a water bath with occasional shaking. After incubation, 3 mL DNSA reagent was added into the test tubes, which also stopped the enzymatic reaction. The tubes were immersed in boiling water bath and removed after 15 min color development. Tubes were cooled to room temperature. The contents were transferred to a 25 mL volumetric flask and final volume made up with distilled water. Optical density was measured at 540 nm in a Spectronic-20. One International unit (IU) of enzyme activity was defined as the amount of enzyme required to liberate 1 μ mol reducing sugar per minute under given assay condition.

Statistical Analysis

All the experiments were conducted in triplicates along with equal number of controls. The data obtained were subjected to analysis of variance technique using Completely Randomized Design [18].

The multiple linear regression planes were also worked out considering xylanase production as dependent variable and protein and viable count as independent variable.

Results

Enumeration of Cellulolytic Microbial Populations in Decomposing Wood Samples

The results (Table 1) showed maximum fungal population (4.40 × 104 CFU/g), bacterial population (32.01 × 106 CFU/g) and population of actinomycetes (2.05 × 105 CFU/g) in the decomposing wood samples of S. communis, D. strictus and A. wallichii, respectively.

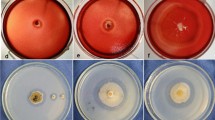

Screening of Isolates for the Production of Xylanolytic Activity

The xylanase activity of five isolates along with total sugars and the final pH of culture filtrate are presented in Table 2. The xylanase activity varied between 0.67 IU/mL for B5 to minimum 0.2 IU/mL for B1.

Phenotypic and Metabolic Characteristics of P. polymyxa CKWX1

The strain was characterized initially according to morphological, physiological and biochemical characteristics. The isolated colonies on basal salt yeast extract medium after 48 h of incubation were cream colored, irregular with a smooth surface, flat elevation, <1.0 mm in diameter and lobate margin. The morphological characteristics of the strain showed Gram positive cells, spore forming and motile rods, spores being oval and sub terminal without bulging.

The isolate tested positive for gelatin liquefaction. The strain was positive for citrate utilization, casein hydrolysis, phenylalanine deaminase, cytochrome oxidase and DNase and could utilize a wide array of carbohydrates including xylose, arabinose, cellobiose, dextrose, fructose, galactose, inositol, maltose, mannitol, mannose, raffinose, sorbitol and sucrose as carbon source (Data not shown).

Effect of Substrates on Xylanase Production

A variety of substrates (Fig. 1) were tested for the production of xylanase by P. polymyxa CKWX1 in SmF. It was observed that the presence of some of the lignocellulosic material in the growth medium increased the production of xylanolytic activity more than that produced in the growth medium containing (0.5 %) xylan. Of all the substrates, wheat straw supported maximal xylanase activity, (1.41 IU/mL) followed by apple pomace, (1.22 IU/mL), B. ceiba wood dust, (0.64 IU/mL), Eucalyptus sp. wood dust (0.56 IU/mL) and P. roxburghii wood shavings dust (0.33 IU/mL). Based on these results, wheat straw in combination with 0.5 % yeast extract was used as the inducer of xylanase activity in all subsequent experiments.

Effect of Incubation Period and Inoculum Size on Xylanase Production

Growth and production of xylanolytic activity was monitored for 96 h in BSYEM containing 0.5 % wheat straw. It was observed that xylanolytic activity was essentially present in the culture filtrate after 12 h (0.22 IU/mL) of growth. From this point the level of xylanolytic activity increased gradually over the next 48 h. A sharp decrease in the level of enzyme activity was observed after 48 h of incubation. Maximum xylanase production (1.41 IU/mL) was obtained at 48 h; further increase in incubation period decreased xylanase production (Fig. 2).

The effect of varying the bacterial concentration on the production of xylanolytic activity was studied (Fig. 3). The increase in initial number of viable cells added from 0.5 % i.e. 32 × 108 to 1.0 % i.e. 80 × 108 CFU/mL (v/v) increased the production of xylanolytic activity from 1.18 to 1.42 IU/mL at 48 h of incubation. Further increase in the size of inoculum to 2.0 % containing 134 × 108 CFU/mL decreased the enzyme activity but the differences were found to be statistically non-significant.

Effect of Substrate Concentration on Xylanase Production

The varying concentrations of the substrate i.e. wheat straw were added to BSYEM before autoclaving. The results (Fig. 4) revealed that increase in substrate concentration from 0.25 to 1.0 % increased the xylanolytic activity from 0.75 to 2.50 IU/mL after 48 h of incubation. Further increase in substrate concentration decreased the xylanolytic activity. Xylanase activity at all the substrate concentrations was recorded to be significantly different from each other.

Effect of pH and Temperature on Xylanase Production

Xylanase production was found to be highly dependent on pH and temperature. The production of enzyme activity initially increased with the increase in incubation temperature from 25 to 35 °C and decreased thereafter (Fig. 5). It attained a peak value of 2.50 IU/mL at temperature 35 °C, which was also optimum for the growth of the isolate. Statistically significant decrease in the enzyme activity was found at temperature 40 °C. A study of xylanase production was conducted at 35 °C using media with initial pH ranging from 5.0 to 10.0 (Fig. 6). The production of enzyme activity initially increased with the increase in pH of the medium up to pH 7.0 and decreased thereafter. On analysis, xylanase activity at pH 6.0 and 7.0 was recorded to be at par with each other while significantly different at all other pH.

Effect of Surfactant on Xylanase Production

Surfactants are known to increase extracellular enzyme production. The results presented in Fig. 7 revealed that production of xylanolytic activity by P. polymyxa CKWX1 was enhanced with increasing concentration of Tween 20 in the medium until, at the level of 0.05 %, and an increase of 1.32 fold in the enzyme yield was obtained (3.72 IU/mL). Thereafter, an increase in Tween 20 decreased the xylanase production. The enzyme activity at 0.025, 0.05 and 0.1 % concentration of Tween 20 was found to be at par with each other. Similar results were obtained with Triton X 405. The surfactants Tween 40 and Tween 80 also increased xylanase production over control but the difference in enzyme activity was statistically non-significant. Negligible enzyme activity was detected in the medium to which Triton X 100 was added.

Multiple Linear Regression Plane of Xylanase Production (Y) on Protein (X1) and Viable Count (X2)

The linear regression planes were developed assuming xylanase production as dependent variable on protein content and viable count (independent variables). The coefficient of determination calculated for each of the planes fitted indicated the contribution to dependent variable corresponding to one unit change in independent variable.

According to the coefficient of determination obtained for every parameter (Table 3), enzyme production was most sensitive to surfactants followed by substrate concentration, pH, inoculum size, incubation period and temperature.

The maximum contribution of protein content (X1) and viable count (X2) on xylanase production (99.12 %) was observed when surfactants were added to the culture medium. A change of 29.83 % in xylanase production was found to be caused by protein content (X1) and viable count (X2), when effect of temperature was studied on xylanase production. In this case, the effect of independent variables on xylanase production was found to be minimum. Rest of the contribution was from the factors which have not been considered.

The protein content and viable count were responsible for 99.02, 97.82, 95.82, 88.02 % changes in xylanase production when the effect of substrate concentration, pH, inoculum size and incubation period was studied on the production of xylanolytic activity, respectively.

Discussion

The cellulolytic fungi and bacteria play a very important role in degrading cellulose and hemicellulose of wood to simple acceptable forms needed for nutrition of microorganisms. The population of actinomycetes capable of growth on cellulose medium was not recorded for most of the wood samples. This may be attributed to their inability to degrade the more complex organic substrates including cellulose, hemicellulose and lignin. In general actinomycetes often appear relatively late in successions colonizing organic matter [19].

In vitro enrichment cultures with powdered wood dust mimic natural habitat, wherein xylan-containing plant material are normally presented to degradative microbial communities in insoluble particulate form. Such enrichment allows for selection of xylan degrading bacteria [20]. Xylan is normally complexed with, and secondary in abundance to cellulose of plant cell walls [1, 5]. Therefore, effective decomposition of xylan by this isolate in nature probably occurs involving microbial consortia in containing cellulolytic bacteria, because only five isolates out of total population of various bacteria were able to degrade xylan and all could grow well with pure and native cellulosic materials (Table 2).

The isolates which formed clear zones on xylan salt medium were selected to screen for xylanase production in liquid medium (Table 3). The organism which produced highest xylanase activity was picked up for identification. The isolated strain is an aerobic, spore forming, gram positive, motile, rod shaped bacterium. Preliminary biochemical characterization tentatively identified the potential isolate as Bacillus polymyxa [21]. However, 16S rRNA gene analysis has finally identified this isolate as P. polymyxa CKWX1 (GenBank accession no. JX534241) because of its 99 % homology with the P. polymyxa strain 1182-2 (GenBank accession no. EU982506.1).The characteristic feature of the bacterial isolate is that it grows well in alkaline media.

The effect of different substrates on extracellular xylanase production was investigated in shake flask culture of P. polymyxa CKWX1. Activity was highest when the organism was grown on wheat straw. The difference in enzyme yields with different substrates indicates that the yield of xylanase is not primarily determined by the lignin content and sugar compositions of these substrates [22, 23]. Reduced xylanase activity obtained with metabolizable sugars as compared to lignocellulosic compounds can be interpreted in terms of catabolite repression [24].

The increase in the production of xylanolytic activity with the increase in incubation period may be due to increase in the growth of the microorganism and its enzyme production pattern. The production of maximum xylanase activity at the end of exponential growth phase is in agreement with the results obtained by Archana and Satyanarayana [25] and Waino and Ingvorsen [26] while working with Bacillus licheniformis and Halorhabdus utahensis.Thus, the time required for enzyme production in case of bacteria was far less due to their faster doubling rate as compared to fungal cultures [27].

The relative yield of xylanase was markedly affected by the size of inoculum (Fig. 3). At low level of inoculum, the number of substrate molecules remain free in the medium, while an increase in the inoculum size reduces free substrate molecules till equilibrium is achieved resulting in maximum xylanase production. A further increase in inoculum above the optimum i.e. 1.0 % containing 80 × 108 CFU/mL results in a competition for substrate and the stable substrate-inoculum relationship necessary for enzyme production [28, 29].

The xylanase production was characterized by an initial rapid increase in activity followed by steady decline at higher substrate concentration (Fig. 4). An increase in the concentration of soluble sugars resulted in decreased xylanase production by P. polymyxa CKWX1 probably due to the catabolite repression. It is also supported by Battan et al. [30] while working with Bacillus sp. In contrast, Sindhu et al. [31] reported stimulation of xylanase production by xylose.

Xylanase activity has been found to be highly dependent on cultivation temperature and pH. This behaviour of the present bacterial strain is similar to the usual response of the mesophilic organisms when the metabolic activities get slowed down below and above the optimum and results in denaturation of certain essential enzymes involved in various metabolic pathways. The results are in accordance with several earlier reports including those of Beg et al. [32] and Battan et al. [30]. Xylanase production also depends upon the pH of cultivation medium. The production of xylanase at alkaline pH values have been reported for alkalotolerant Bacillus sp. [33]. Production of xylanase at other pH levels may be due to its adaptability to different pH of the culture medium.

The usefulness of surfactants such as Tween 20, Tween 80, Triton X100 and fatty acids such as oleic acid is well documented in cellulase, xylanase, β-glucosidase and lignase production [5, 34]. Xylanase yield has been shown to increase by 13, 20 and 21 % with paddy husk, wheat bran and rice straw, respectively, when medium was supplemented with 0.5 % Tween 80 [35]. Various additives have been reported to enhance enzyme production in Bacillus sp. [30, 36]. In the present study, it is worth noting that addition of surfactant resulted increase in the growth of the organism. These results are in contrast to those obtained with Streptomyces griseus [34] where there is no effect on the growth of the organism.

Production of xylanase by P. polymyxa CKWX1 is affected by various culture parameters and nature of nutrients studied (Table 3). The highest coefficient of determination (99.12 %) obtained for surfactants indicates that xylanase production increases with more growth and high levels of extracellular protein in the medium containing the surfactants. These results are in agreement with those reported in the literature for production of various extracellular products by microorganisms [34, 35, 37].

The novel alkaline xylanase was produced efficiently by alkalophilic P. polymyxa CKWX1. High pH optima are especially important in the treatment of alkaline pulp. These results indicate that the effectiveness of P. polymyxa CKWX1 xylanase could be useful in pulp and paper industry.

References

Christakopoulos PK, Marcis BJ, Claeyssens M, Bhat K (1996) Purification and characterisation of a major xylanase with cellulose and transferase activities from Fusarium oxysporium. Carbohydr Res 289:91–104

Selle PH, Ravindran V, Partridge GG (2009) Beneficial effects of xylanase and/or phytase inclusions on ileal amino acid digestibility, energy utilization, mineral retention and growth performance in wheat-based broiler diets. Anim Feed Sci Technol 153(3–4):303–313

Rifaat HM, Nagieb ZA, Ahmed YM (2005) Production of xylanases by Streptomyces species and their bleaching effect on rice straw pulp. Appl Ecol Environ Res 4:151–160

Kim JH, Kim SC, Nam SW (2000) Constitutive overexpression of the endoxylanase gene in Bacillus subtilis. J Microbiol Biotechnol 10:551–553

Biely P, Mislovicova D, Toman R (1985) Soluble chromogenic substrates for the assay of endo-1,4-β-xylanases and endo-1,4-β-glucanase. Anal Biochem 144:142–146

Collins T, Gerday C, Feller G (2005) Xylanase families and extremophilic xylanases. FEMS Microbiol Rev 29:3–23

Annamalai N, Thavasi R, Jayalakshmi S, Balasubramanian T (2009) Thermostable and alkaline tolerant xylanase production by Bacillus subtilis isolated from marine environment. IJBT 8:291–297

Pajni S, Dhillon N, Vadhera DV, Sharma P (1989) Carboxymethyl cellulose, β-glucosidase and xylanase production of Bacillus isolates from soil. Int Biodeter 25:1–5

Shandilya TR (1989) Paddy straw compost formulation for growing button mushroom and its comparison with traditionally made compost based on wheat straw and chicken manure. Mushroom Sci 12:333–344

Walia A, Mehta P, Chauhan A, Shirkot CK (2012) Optimization of cellulase-free xylanase production by alkalophilic Cellulosimicrobium sp. CKMX1 in solid-state fermentation of apple pomace using central composite design and response surface methodology. Ann Microbiol. doi:10.1007/s13213-012-0460-5

Murty MVS, Chandra TS (1997) Fermentability of hemicelluloses extracted from municipal waste and commercial xylans of Clostridium sp. Appl Microbiol Biotechnol 147:212–217

Biswas R, Sahai V, Mishra S, Bisaria V (2010) Bioprocess strategies for enhanced production of xylanase by Melanocarpus albomyces IITD3A on agro-residual extract. J Biosci Bioeng 110(6):702–708

Maheshwari R, Bhardwaj G, Bhat MK (2000) Thermophilic fungi: their physiology and enzymes. Microbiol Mol Biol Rev 64:461–488

Bose RG (1968) A modified cellulosic medium for the isolation of cellulolytic fungi from infected material and soil. Appl Microbiol 16(2):419–420

Subba Rao NS (1995) Biofertilizers in agriculture and forestry, 3rd edn. Oxford and IBH Publishing Co, New Delhi, p 223

Teather RM, Wood PJ (1982) Use of congo-red polysaccharide interactions on enumeration and characterization of cellulolytic bacteria from bovine rumen. Appl Environ Microbiol 43:777–780

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugars. Anal Chem 31:426–428

Gomez KA, Gomez AA (1976) Statistical procedures for agricultural research, 2nd edn. John Wiley and Sons, Singapore

Lacey J (1973) Actinomycetes in soils, composts and fodders. In: G Skyes, FA Skinner (eds) Actinomycetes: characteristics and practical importance. Society for Appl Bacteriol Symposium series No. 2, UK, Academic press, pp 231–251

Haack SK, Breznak JA (1993) Cytophaga xylanolytica sp. nov., a xylan-degrading, anaerobic gliding bacterium. Arch Microbiol 59:6–15

Claus D, Barkeley RCW (1986) Genus Bacillus cohn 1872, 174. In: Sneath PHA, Mair NS, Sharpe ME, Holt JG (eds) Bergey’s manual of systematic bacteriology, vol 2. Williams and Wilkins, Baltimore MD, pp 1105–1139

Gomes J, Purkarthofer H, Hayn M, Kapplmuller J, Sinner M, Steiner W (1993) Production of a high level of cellulase free xylanase by the thermophilic fungus Thermomyces lanuginosus in laboratory and pilot scale using lignocellulosic materials. Appl Microbiol Biotechnol 39:700–707

Da Silva R, Lago ES, Merheb CW, Macchione MM, Park YK, Gomes E (2005) Production of xylanase and CMCase on solid state fermentation in different residues by Thermoascus aurantiacus miehe. Braz J Microbiol 36(3):235–241

Berenger JF, Frixon C, Biglearde J, Creuzet N (1985) Production, purification and properties of thermostable xylanases of Clostridium stercorarium. Can J Microbiol 31:635–643

Archana A, Satyanarayana T (1997) Xylanase production by thermophilic Bacillus licheniformis A 99 in solid state fermentation. Enzyme Microb Technol 21:12–17

Waino M, Ingvorsen K (2003) Production of β-xylanase and β-xylosidase by the extremely halophilic archaeon Halorhabdus utahensis. Extremophiles 7:87–93

Topkas E, Katapodis P, Kekos D, Macris BJ, Christakopoulos P (2003) Production and partial characterization of xylanase by Sporotrichum thermophile under solid state fermentation. World J Microbiol Technol 19:195–198

Biely P, Vrsanska M, Kratky Z (1980) Xylan-degrading enzymes of the yeast Cryptococcus albidus: identification and cellular localization. Eur J Biochem 108:313–321

Bhatt AK, Bhalla TC, Agrawal HO, Sharma N (1994) Characterisation of xylanolytic activity of Flavobacterium sp. isolated from forest soil. Ind. J Microbiol 34(2):119–123

Battan B, Sharma J, Kuhad RC (2006) High-level xylanase production by alkaliphilic Bacillus pumilus ASH under solid state fermentation. World J Microbiol Biotechnol 22:1281–1287

Sindhu I, Chibber S, Caplash N, Sharma P (2006) Production of cellulase free xylanase from Bacillus megaterium by solid state fermentation for biobleaching of pulp. Curr Microbiol 53:167–172

Beg QK, Bhushan B, Kapoor M, Hoondal GS (2000) Enhanced production of a thermostable xylanase from Streptomyces sp. QG-11-3 and its application in biobleaching of eucalyptus craft pulp. Enzyme Microb Technol 27:459–466

Prakash S, Veeranagouda Y, Kyoung L, Sreeramulu K (2009) Xylanase production using inexpensive agricultural wastes and its partial characterization from a halophilic Chromohalobacter sp. TPSV 101. World J Microbiol Biotechnol 25:197–204

Bakshi A, Mehta V, Gupta JK (1991) Constitutive extracellular expression of β-glucosidase by Streptomyces griseus. Ind J Microbiol 31(2):201–203

Karni M, Deopurkar RL, Rale VB (1993) Β-xylanase production by Aureobasidium pullulans grown on sugars and agricultural residues. World J Microbiol Biotechnol 9:476–478

Gessesse A, Mamo G (1999) High-level xylanase production by an alkaliphilic Bacillus sp. by using solid state fermentation. Enzyme Microb Technol 25:68–72

Liu J, Yuan X, Zeng G, Shi J, Chen S (2006) Effect of biosurfactant on cellulase and xylanase production by Trichoderma viride in solid substrate fermentation. Process Biochem 41(11):2347–2351

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Walia, A., Mehta, P., Chauhan, A. et al. Production of Alkalophilic Xylanases by Paenibacillus polymyxa CKWX1 Isolated from Decomposing Wood. Proc. Natl. Acad. Sci., India, Sect. B Biol. Sci. 83, 215–223 (2013). https://doi.org/10.1007/s40011-012-0122-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40011-012-0122-1