Abstract

Celecoxib is a non-steroidal, anti-inflammatory drug used in the treatment of pain and inflammation associated with rheumatoid arthritis, and several other inflammatory disorders. It is a class II compound according to the Biopharmaceutics Classification System owing to its low water solubility and high membrane permeability. The objective of this study was to improve the solubility and dissolution rate of celecoxib using solid surfactant technology that might be useful in developing solid dosage forms. Solid surfactant was developed by mixing and grinding together a liquid surfactant (Tween 80) with various inorganic carriers like Fujicalin® (Dibasic Calcium Phosphate Anhydrous), Pineflow® (Porous-structured Maltodextrin), Neusilin® (Magnesium Alumino metasilicate) and Aerosil® (Colloidal Silicon dioxide) in a mortar and pestle in different ratios of liquid surfactant and the carrier to obtain solid surfactants. The celecoxib tablets prepared with solid surfactants were then evaluated for their solubility and dissolution properties. Among the fillers used, Fujicalin showed the highest solubilization capacity for celecoxib. The dissolution behaviors of various tablets prepared with solidified surfactants were compared to those of conventional celecoxib tablets in a simulated gastric fluid. Celecoxib tablets prepared using solidified surfactants showed improved dissolution behaviors when compared to the conventional counterparts. Fujicalin solidified Tween 80 was further analyzed by powder X-ray diffraction analysis, differential scanning calorimetry thermographs and reverse phase high performance liquid chromatography.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Celecoxib, 4-[5-(4-methylphenyl)-3-trifluoromethyl-1Hpyrazole-1-yl] benzene sulfonamide, is a representative selective cyclooxygenase (COX)-2 inhibitor with no inhibition of COX-1 at therapeutic doses and mostly used to treat osteoarthritis, rheumatoid arthritis and acute pain (Clemett and Goa 2000). Celecoxib is hydrophobic (log P value of 3.5) and exists in polymorphic forms of which the stable crystalline form is practically insoluble in aqueous buffer at a range of physiological pH. However, celecoxib is categorized into Class II according to the BCS and is considered as a highly permeable compound (Amidon et al. 1995; Paulson et al. 2001). Therefore, both the rate and extent of drug absorption appear to be limited by intraluminal drug concentration in the gastrointestinal (GI) tract. Various approaches to improve solubility of celecoxib have been reported such as use of a salt form (Tawa et al. 2007), co-crystals (Remenar et al. 2007), new polymorphs (Lu et al. 2006), solid dispersion (Vasconcelos et al. 2007), cyclodextrin complex (Nagarsenker and Joshi 2005) and polymeric nanoparticles (Morgen et al. 2012). Although these techniques have shown enough promise in improving drug solubility, they have certain limitations such as high processing costs, requirement of sophisticated equipment (such as requirement of size reduction mills for production of nanoparticles and a melt extractor for melt extraction techniques) or processes and use of potentially harmful solvents.

Solidified Tween 80 (ST) is a new approach to enhance solubility of drug in an oral solid drug dosage form. It can be a simple, convenient and cost effective method of solubility enhancement of hydrophobic drugs since this approach can cut down the cost of expensive equipment and labor while minimizing the complications of the manufacturing process. Preparation of solidified surfactant is easy and can be used as a solubility and dissolution enhancing excipient in the preparation of various solid dosage forms.

Surfactants are one of the widely used excipients in pharmaceutical dosage forms to enhance solubility of the active pharmaceutical ingredients (APIs) (Savjani et al. 2012) but most of the surfactants are commercially available in liquid forms and are difficult to be used directly in solid drug dosage formulations. Therefore, this study was an attempt to develop a solid form of the surfactant by solidifying the liquid surfactant (Tween 80) with different inert inorganic materials. The objective of this study was to prepare solidified surfactants using various inert pharmaceutical fillers and to use them in the preparation of celecoxib tablets. The solubility properties and dissolution profiles of celecoxib from the test tablets were studied.

Materials and methods

Materials

Celecoxib was purchased from Dong Gwang Pharmaceuticals (Seoul, Republic of Korea). Fujicalin® (Dibasic Calcium Phosphate Anhydrous), Neusilin® (Magnesium Alumino metasilicate) and Pineflow® (Porous-structured Maltodextrin) were provided by Woo-Shin Medics (Seoul, Republic of Korea). Aerosil® (Colloidal silicon dioxide) was obtained from Evonic Industries (Germany). Tween 80 was purchased from Samchun Chemical Co. Ltd. (Pyeongtaek, Republic of Korea). HPLC-grade methanol was purchased from Burdick and Jackson (Muskegon, MI, USA). Distilled and deionized water was used for the preparation of all solutions and analytic procedures.

Preparation of solidified Tween 80

Solidified Tween 80 was prepared by grinding Tween 80 with an inorganic carrier (one of Fujicalin, Pineflow, Neusilin and Aerosil at a time) in mortar and pestle for 20 min at 30:70 ratios of Tween 80 and the carrier (Table 1). During mixing of Tween 80 and inorganic carriers, ingredients were thoroughly mixed to ensure that uniform powdered product was obtained. Since different carriers showed different adsorption behaviors with Tween 80, they produced powders of different textures and were either too sticky or not uniformly mixed. 30:70 ratios of Tween 80 and inert fillers were the most suitable composition to prepare stable powdered solidified surfactant. After the powders were obtained, they were passed through 200 μm sieves to obtain particles of uniform size.

Bulk and tapped density of the powders

The bulk density (Db) of a powder is the ratio of the mass of an untapped powder sample and its volume including the contribution of the inter-particulate void volume. Hence, the bulk density depends on both the density of powder particles and the spatial arrangement of particles in the powder bed (Jallo et al. 2012). Tapped density (Dt) can be measured after mechanically tapping cylinder containing a powder sample (Santomaso et al. 2003). The mechanical tapping was done by raising the cylinder and allowing it to drop under its own weight from a specified distance. The volumes before and after the mechanical tapping were measured and recorded to calculate the tap densities. The bulk and tapped densities were used to calculate Hausner’s ratio and Carr’s index (Eqs. 1, 2). Hausner’s ratio reflects the flow characteristics of the powder particles whereas Carr’s index is the indicator of relative flow rate, cohesiveness and particle size of the powders (Shah et al. 2008).

Scanning electron microscope (SEM) observation

The surface morphology of carriers and the prepared solidified Tween 80 was observed by scanning electron microscope (SEM) (LVSEM, S-3000N, Hitachi Co., Tokyo, Japan). The samples were fixed on a carbon fiber tape, and were coated twice by platinum–palladium, each for 100 s, under argon gas. The samples were then observed at 5.0 kV.

Phase solubility study

Excess amount of celecoxib was added to 1 mL of water in a glass vial. The mixture was shaken for 24 h at room temperature (25 ± 1 °C) in a magnetic shaker (Varomag, Erweka, Germany). Then the sample was centrifuged (Gyrogen 1580 MGR, Korea) at 4000 rpm for 5 min to separate undissolved celecoxib and the supernatant layer was filtered using a 0.45 μm syringe filter (Rawat and Jain 2004). The solubility of celecoxib in water was analyzed using a high performance liquid chromatography. The solubility values of celecoxib together with different solidified Tween 80 powders in an aqueous medium were also determined using the same procedures as above. The solubility experiments were carried out in triplicate.

Preparation of celecoxib tablets with solidified Tween 80

Celecoxib and Fujicalin solidified Tween 80 powders were mixed together at a ratio of 1:15. After the drug and solidified surfactant were thoroughly mixed, the mixture was transferred into a mortar and pestle. Then other excipients like Crospovidone (a disintegrant), Ludipress and Magnesium stearate were added slowly and gradually to prepare fine non-sticky powders. Then the powders were passed through 700 μm sieve and then prepared into tablets. All tablets were compressed by single punch IR tablet machine (Riken power, Riken Seiki Co. Ltd., Japan) with compression force of 200 kgf/cm2 and dwelling time of 60 s. The conventional celecoxib tablets were also prepared in the laboratory. The amounts of the ingredients of the tablets are shown in Table 2. The tablets were tested for size, hardness, disintegration, friability and the dissolution properties in vivo.

In vitro release test

Dissolution study was performed by USP dissolution Apparatus II (paddle method) with 900 mL of dissolution medium (simulated gastric juice pH 1.2 with 0.5 % SLS) at 37 ± 0.5 °C and the paddle rotation speed of 100 rpm using a dissolution tester (EDT-08LX, Electrolab Inc., India). Dissolution profiles of tablets formulated with Fujicalin solidified Tween 80 was compared to that of conventional celecoxib tablets (control group). 2 mL samples were withdrawn at 5, 10, 20, 30, 60, 90 and 120 min from the dissolution fluid, and were replaced with equal volumes of fresh dissolution medium each time. The samples were then filtered through 0.45 μm polyvinylidene difluoride (PVDF) membrane filter before 20 μL of the sample was injected into a reverse phase-high performance liquid chromatography (RP-HPLC) system to determine the celecoxib solubility. HPLC analysis was performed with YL-9100 HPLC system and YL-9150 auto sampler (YL Instrument Co. Ltd, Republic of Korea) using a reverse phase C18 column (250 × 4.6 mm, 5 μm particle size) and a 75 % v/v methanol as the mobile phase at flow rate of 1.25 mL/min. The detection wavelength of the system was 250 nm.

Crystallinity study

Powder X-ray diffraction (PXRD) analysis was performed to analyze the crystallinity of celecoxib, carriers and the prepared solid surfactant. The step size was 0.02°. The angle of PXRD analysis was from 3° to 40° at scan speed of 6°/min and 100 mA, 40 kV conditions.

Thermal analysis

Thermal analysis of the samples was performed by differential scanning calorimetry (DSC). 5 mg of each sample was analyzed by sealing in aluminum pans and heating at a rate of 10 °C/min over a temperature range from 0 to 350 °C.

Results and discussion

Powder flowability and compressibility

The flowability and compressibility indices of four types of solidified Tween 80 powders are presented in Table 3. The bulk density and tapped density values of four types of solidified Tween 80 (Fujicalin ST, Neusilin ST, Pineflow ST, Aerosil ST) are presented as the indicators of their physical properties.

The Hausner ratio values give indication about the flow properties of solidified Tween 80. According to the flowability scale described in USP 30, Hausner ratio less than 1.25 indicates better flowability whereas values more than 1.25 indicates relatively poor flowability. Among four solidified Tween 80 powders, Fujicalin ST, Pineflow ST and Aerosil ST showed good flowability where, Fujicalin ST showed the best flowability (Hausner ratio 1.10) whereas Neusilin ST showed poor flowability (Hausner ratio 1.30).

Similarly, compressibility index of four different solidified Tween 80 powders were explained on the basis of Carr’s index. Carr’s index values between 5 and 12 indicate excellent compressibility, the values between 12 and 16 indicate good compressibility, and the values between 18 and 21 indicate fair compressibility, while the values between 23 and 35 indicate poor compressibility. In this study, Fujicalin ST and Aerosil ST showed excellent compressibility index 9.20 and 10.54 respectively among all solidified Tween 80 powders. Pine flow ST also showed good flowability while Neusilin ST exhibited poor compressibility.

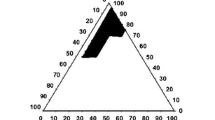

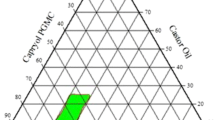

Solubility of celecoxib in solidified Tween 80

The solubility of celecoxib with four different solidified Tween 80 powders is explained based on phase solubility diagram (Fig. 1; Table 4). It was observed that the aqueous solubility of the drug was improved when it was complexed with solidified Tween 80. Celecoxib with Fujicalin solidified Tween 80 showed better improvement in solubility profiles when compared to other solidified Tween 80 powders. The result of the solubility study indicated that pure celecoxib possesses a very low solubility in water (0.002040 mg/mL). The saturation solubility of celecoxib plus Fujicalin ST was almost 74 times higher (0.1518 mg/ml) than that of pure celecoxib. Other solidified Tween 80 powders (Neusilin ST, Pineflow ST, Aerosil ST) were also able to enhance the solubility of celecoxib. Celecoxib was dispersed in molecular form and remained in intimate contact with the solidified Tween 80 powders. The better solubilization capacity of Fujicalin among other carriers can be attributed to its better release capacity and reduction in aggregation of drug particles due to improved humectation (Punitha et al. 2010). Celecoxib was uniformly mixed with Fujicalin ST and the particles were assumed to be uniformly adsorbed and remained in intimate contact with each other.

Due to its better solubilization capacity among all solidified surfactants, Fujicalin ST was selected for further experiments in the study. It was also observed that solubility of celecoxib was improved with the increase in amount of Fujicalin ST (Fig. 2; Table 5), where 100, 200 and 300 mg of Fujicalin ST improved the solubility of celecoxib to 0.1518, 0.3964 and 0.6115 mg/mL respectively. Higher the amount of Fujicalin ST, higher was the molecular interaction between celecoxib and the solid surfactant which was assumed to facilitate solubility enhancement (Savjani et al. 2012). The drug molecules can interact with the surfactant that is solidified with a carrier, to form soluble drug entities.

SEM observation

The SEM study was performed to study the surface morphology of the carriers and solidified Tween 80 powders (Fig. 3). The morphology of the carriers was found to be altered after surfactant was incorporated into them. It was understood that the surfactant in fact changed the morphology of the inert carrier. The size of Fujicalin ST was decreased compared to that of Fujicalin carrier alone which might be due to the grinding in a mortar and pestle during mixing of Fujicalin and Tween 80. Similar changes were observed in case of Pineflow, another inert carrier in the study. On the other hand, not much change in size was observed when Tween 80 was incorporated into aerosol and Neusilin. Aerosol and Neusilin have been reported to have higher specific surface areas of 590 and 300 m2/g respectively compared to only 35 m2/g of Fujicalin (Vadher et al. 2009). Due to the large specific surface area, aerosol and Neusilin could adsorb more Tween 80 molecules on their surfaces which might be the reason behind unchanged surface morphology of these two inert carriers. These observations support the idea that adsorption capacity of a material is dependent on its surface morphology.

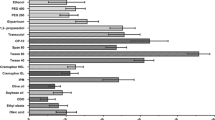

Release profiles of celecoxib

The release profile of celecoxib from solidified Tween 80 tablets is shown in Fig. 4. Dissolution test was performed in simulated gastric juice pH 1.2 with 0.5 % SLS and conventional celecoxib tablets were used as a control group. It was found that Fujicalin ST tablets displayed a dramatic increase in the rate and extent of dissolution in comparison to conventional celecoxib tablets especially during the initial stage (first 20 min). 35 % of drug was released from tablets prepared with Fujicalin ST within 20 min whereas only 5 % of the drug was released from conventional celecoxib tablets during the same time. The cumulative drug release was 78 % at 120 min for the tablets prepared with Fujicalin ST whereas that of conventional celecoxib tablets was 34 % at 120 min. Tablets prepared with Fujicalin ST exhibited higher dissolution rate and cumulative drug release than the conventional celecoxib tablets. The dissolution rate of drugs form a dosage form is often affected by the crystallinity, particle size and the amount of surfactant used (Balakrishnan et al. 2004). Enhancement of surfactant generally occurs due to modification in physicochemical properties which in turn increases the affinity with the surrounding solvent. The enhancement of dissolution in our study was probably due to the formation of an inclusion complex in the solid state and also due to the reduction of the crystallinity of the products, as confirmed by PXRD studies. The increase in the dissolution rate is also due to improved wetting and solubility by Tween 80 (Hu et al. 2011), the basic surfactant used in the study. Thus, it was confirmed that celecoxib tablets prepared with solidified Tween 80 shows improved dissolution properties than the conventional celecoxib tablets.

Crystallinity study

PXRD assay was performed to study the crystallinity of celecoxib, Fujicalin, Fujicalin ST, Crospovidone, and ground mixture of celecoxib, Crospovidone and Fujicalin ST (Fig. 5). Celecoxib appeared to have highest crystallinity among all the substances tested. In a PXRD study, a pure drug exhibits intense and long peaks (Gupta et al. 2007). Similarly, in our study, celecoxib showed highest peak whereas Fujicalin (Fig. 5b) and Fujicalin ST (Fig. 5c) both showed less intense peaks. Crospovidone (Fig. 5d) was found to be amorphous in nature because it did not show any crystallinity peak in the PXRD study (Barzegar-jalali et al. 2007). Thus, it was confirmed that the inert carriers used to solidify Tween 80 were amorphous in nature. Also, it was found that the crystallinity of celecoxib disappeared on grinding with Fujicalin ST powder (Fig. 5e). These results support the idea that celecoxib is well mixed and adsorbed with Fujicalin ST and the grinding of this mixture led to the changes in physicochemical properties and change of the crystalline nature to the amorphous state. The amorphous solids show better solubility properties than the crystalline substances and therefore can enhance the dissolution rate (Wong et al. 2006). Therefore in our study, the improvement in dissolution rates of celecoxib was due to the change of crystalline nature of the celecoxib to the amorphous state when prepared together with Fujicalin ST.

Thermal analysis

DSC study was conducted to confirm the melting points of crystalline celecoxib, Fujicalin, Fujicalin ST, Crospovidone and the ground mixture of celecoxib, Crospovidone and Fujicalin ST (Fig. 6). Celecoxib exhibited a characteristic endothermic fusion peak at 164.31 °C hence it was concluded that no polymorphs of celecoxib were present (Reddy et al. 2004). Fujicalin (Fig. 6b) did not show melting point between 0 and 450 °C. However, persistence of the exothermic peak at 192.8 °C was observed for Fujicalin ST (Fig. 6c). This observation supported that the crystallinity of Fujicalin was reduced by Tween 80 when compared to that of Fujicalin alone. Furthermore, the characteristic exothermic peak of the ground mixture of celecoxib, Crospovidone and Fujicalin ST (Fig. 6c) was slightly shifted to higher temperatures at 197.76 °C. It indicated that celecoxib had formed a complex with Fujicalin ST. This phenomenon indicated a stronger interaction between celecoxib and carrier in the solid state (Cabral et al. 1990). Overall, the DSC results showed that the crystallinity of celecoxib disappeared by grinding with solidified Tween 80.

Conclusion

The aim of this study was to improve the solubility and dissolution rate of celecoxib. Therefore, we prepared celecoxib tablets using Fujicalin ST as one of the excipients in the solid dosage form. Conventional celecoxib tablets were used as control. The aqueous solubility and dissolution rate of celecoxib was found to be improved by inclusion complexation with Fujicalin ST. Phase solubility profile indicated that the solubility of celecoxib was significantly increased in the presence of solidified Tween 80. The mixture of celecoxib with Fujicalin solidified Tween 80 was found to alter the crystalline properties of celecoxib, changing it to the more soluble, amorphous state. These results suggested that solidified Tween 80 was effective in altering the physicochemical properties as well as improving the solubility and dissolution properties of celecoxib. Thus, solidified surfactant technology can be used to improve the solubility and dissolution of poorly soluble drugs when formulated into solid dosage forms.

References

Amidon GL, Lennernas H, Shah VP (1995) A theoretical basis for a biopharmaceutics drug classification: the correlation of in vitro drug product dissolution and in vivo bioavailability. Pharm Res 12:413–420

Balakrishnan A, Rege BD, Amidon GL, Polli JE (2004) Surfactant-mediated dissolution: contributions of solubility enhancement and relatively low micelle diffusivity. J Pharm Sci 93:2064–2075

Barzegar-jalali M, Valizadeh H, Dastmalchi S (2007) Enhancing dissolution rate of carbamazepine via cogrinding with crospovidone and hydroxypropylmethylcellulose. Iran J Pharm Res 6:159–165

Cabral HM, Hadgraft J, Kellaway IW (1990) Studies of cyclodextrin inclusion complexes. I. The salbutamol-cyclodextrin complex as studied by phase solubility and DSC. Int J Pharm 63:259–266

Clemett D, Goa KL (2000) Celecoxib: a review of its use in osteoarthritis, rheumatoid arthritis and acute pain. Drugs 59:957–980

Gupta VR, Mutalik S, Patel MM, Jani GK (2007) Spherical crystals of celecoxib to improve solubility, dissolution rate and micromeritic properties. Acta pharm 57:173–184

Hu L, Zhang N, Yang G, Zhang J (2011) Effects of Tween-80 on the dissolution properties of Daidzein solid dispersion in vitro. Int J Chem 3:68–73

Jallo LJ, Ghoroi C, Gurumurthy L, Patel U, Davé RN (2012) Improvement of flow and bulk density of pharmaceutical powders using surface modification. Int J Pharm 423:213–225

Lu GW, Hawley M, Smith M, Geiger BM, Pfund W (2006) Characterization of a novel polymorphic form of celecoxib. J Pharm Sci 95:305–317

Morgen M, Bloom C, Beyerinck R, Bello A, Song W, Wilkinson K, Steenwyk R, Shamblin S (2012) Polymeric nanoparticles for increased oral bioavailability and rapid absorption using celecoxib as a model of a low-solubility, high-permeability drug. Pharm Res 29:427–440

Nagarsenker MS, Joshi MS (2005) Celecoxib-cyclodextrin systems: characterization and evaluation of in vitro and in vivo advantage. Drug Dev Ind Pharm 31:169–178

Paulson SK, Vaughn MB, Jessen SM, Lawal Y, Gresk CJ, Yan BO, Maziasz TJ, Cook CS, Karim A (2001) Pharmacokinetics of celecoxib after oral administration in dogs and humans : effect of food and site of absorption. J Pharmacol Exp Ther 297:638–645

Punitha S, Hari BN, Karthikeyan D (2010) Enhancement of celecoxib solubility by solid dispersion using mannitol. J Pharm Pharm Sci 2:4–6

Rawat S, Jain SK (2004) Solubility enhancement of celecoxib using beta-cyclodextrin inclusion complexes. Eur J Pharm Biopharm 57:263–267

Reddy MN, Rehana T, Ramakrishna S, Chowdhary KP, Diwan PV (2004) Beta-cyclodextrin complexes of celecoxib : molecular-modeling, characterization, and dissolution studies. AAPS PharmSci 6:1–9

Remenar JF, Peterson ML, Stephens PW, Zhang Z, Zimenkov Y, Hickey MB (2007) Celecoxib: Nicotinamide dissociation: using excipients to capture the cocrystal’s potential. Mol Pharm 4:386–400

Santomaso A, Lazzaro P, Canu P (2003) Powder flowability and density ratios: the impact of granules packing. Chem Eng Sci 58:2857–2874

Savjani KT, Gajjar AK, Savjani JK (2012) Drug solubility: importance and enhancement techniques. ISRN Pharm 2012:195727

Shah RB, Tawakkul MA, Khan MA (2008) Comparative evaluation of flow for pharmaceutical powders and granules. AAPS PharmSciTech 9:250–258

Tawa M, Zhang Z, Ratanabanangkoon P, Shaw P, Guzma CR, Gardner CR, Chen H, Moreau J (2007) Combined use of crystalline salt forms and precipitation inhibitors to improve oral absorption of celecoxib from solid oral formulations. J Pharm Sci 96:2686–2702

Vadher AH, Parikh JR, Parikh RH, Solanki AB (2009) Preparation and characterization of co-grinded mixtures of aceclofenac and neusilin US2 for dissolution enhancement of aceclofenac. AAPS PharmSciTech 10:606–614

Vasconcelos T, Sarmento B, Costa P (2007) Solid dispersions as strategy to improve oral bioavailability of poor water soluble drugs. Drug Discov Today 12:1068–1075

Wong SM, Kellaway IW, Murdan S (2006) Enhancement of the dissolution rate and oral absorption of a poorly water soluble drug by formation of surfactant-containing microparticles. Int J Pharm 317:61–68

Acknowledgments

This article does not contain any studies with human and animal subjects performed by any of the authors. And all authors (S Chakma, P Khadka, K Jo, H Kim, J Ro, K Park, S Karki, S Barua, and J Lee) declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chakma, S., Khadka, P., Jo, K. et al. Solubility enhancement of celecoxib using solidified Tween 80 for the formulation of tablet dosage forms. Journal of Pharmaceutical Investigation 45, 449–460 (2015). https://doi.org/10.1007/s40005-015-0192-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40005-015-0192-1