Abstract

The study at hand presents for the first time the use of pyrophyllite as adsorbent for nitrate removal from soil and artificial fertilizers. A series of column and batch adsorption experiments were conducted to examine the effects of the adsorbent’s various parameters, the contact time, pH of the solution, the initial concentration of nitrate, concentration and adsorbent granulometry. Pyrophyllite fractions of 0.25, 0.50 and 1.00 mm had very similar pH values of aqueous suspensions and were in the weakly basic range. Nitrate adsorption capacity on pyrophyllite expressed by recovery factor values ranges from 93.14 to 99.77%. High recovery factor values from 90.44 to 97.45% for 1, 3, 5 and 8 mL min−1 flow rates were obtained using all pyrophyllite fractions. Nitrate removal was very effective by the contact time of 1 and 2 h, and the recovery factor values were in the range of 90.38–91.47% and 92.15–93.18% for a contact time of 1 h and 2 h, respectively. In addition, elution of nitrate from pyrophyllite was performed using the following solution with different pH values: 1.70 (synthetic gastric juice), 6.40 (rainwater), 7.70 (distilled water), 9.30 and 12.50 (NaOH solution). Elution was very low for all used solutions and was the highest at the pH 9.30. The results show that the use of pyrophyllite for removal of nitrate from artificial fertilizers and soil was an adequate approach because it has a high nitrate adsorption capacity, while the nitrate elution from the pyrophyllite was very low.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The collecting process of soluble substances from a solution on a suitable solid interface is called adsorption (Öztürk and Bektaş 2004). The technology of adsorption is notable in removing different types of inorganic anions, such as bromate, perchlorate, fluoride, nitrate (NO3−) from the environment by using different materials as adsorbents (Bhatnagar and Sillanpää 2011). Moreover, the rapid industrial development (Zhang et al. 2014) is causing the pollution of the environment by industries. Due to its high water solubility, nitrate is probably the most common groundwater pollutant in the world (Thomson 2001).

Anthropogenic effects on the global nitrogen (N) cycle have disrupted the involved biogeochemical processes (Gruber and Galloway 2008). Nitrogen can be released in available form as a plant essential nutrient during the mineralization of soil organic matter. Application of N fertilizer is usually required to maximize crop yields (Fan et al. 2010). And yet, improper use of N fertilizer can result in nitrate leaching below the zone of crop root, which may eventually contaminate groundwater (Strebel et al. 1989; Olgun et al. 2013). The great amount of artificial N released into the environment can lead to superfluous N in aquatic systems, and hence successively to N saturation state (Liu et al. 2020). Understanding leaching of N from fertilized agriculture is important for several reasons: (1) the largest components of N leachate, nitrite (NO2−) and nitrate (NO3−), can impact human health (Mansouri and Lurie 1993; Riley et al. 2001); (2) enhanced N loading can alter ecological processes and nutrient balances in rivers, lakes and estuaries, potentially leading to eutrophication, increased bottom water hypoxy and net phytoplankton productivity (Dinnes et al. 2002; Soaresa et al. 2011); (3) N leaching can represent a significant economic loss to the farmer, and (4) predicting other agriculture impacts requires an understanding of the factors which control N levels in soil (Riley et al. 2001). A major process for nitrate removal from soil is denitrification (Lin et al. 2007). Knowledge about the transformation rates of NH4+ –N and NO3− –N, as well as the NO2− –N accumulation, is very important since NO2− –N has a higher carcinogenicity than that of NO3− –N (Liu et al. 2020). Elevated nitrate content in table water can potentially cause human health problems such as blue-baby syndrome in infants and stomach cancer in adults (Battas et al. 2019). Consequently, different techniques are used for the removal of nitrates from water including biological denitrification, adsorption, ion exchange, chemical denitrification, electro dialysis and reverse osmosis and many others (Öztürk and Bektaş 2004; Bhatnagar and Sillanpää 2011; Giles et al. 2012).

According to numerous researches, the presence of other ions such as chloride, sulfate, phosphate and carbonate significantly reduces the efficiency of the nitrate removal from aqueous solutions (Dehghani et al. 2015). A study by Nabizadeh et al. (2014) showed that anions have a considerable effect on the removal of nitrate; for example, chloride affected the nitrate removal potential by an adsorbent up to 85%. In the mentioned study, the results showed that chloride is the greatest competitor for nitrate, followed by carbonate, sulfate and fluoride. It follows that the outer spherically sorbing anions (especially chloride, carbonate and sulfate) can significantly interfere with the nitrate adsorption at lower concentration where they compete for the limited amount of sorption sites on functionalized polyacrylonitrile coated with iron oxide nanoparticles.

In a research conducted by Bhatnagar and Sillanpää (2011), among others, activated carbon and zeolites were tested as adsorbents to remove nitrates from water. The results showed poor adsorption toward anions pollutants by using carbon as adsorbent. Only a few available studies are reporting the sorption of nitrate ion by activated carbon. Afkhami et al. (2007) studied the effects of functional groups on the adsorption of nitrate and nitrite ions by carbon cloth. The adsorption capacity of acid-treated carbon cloth for nitrate and nitrite was 2.03 and 1.01 mmol g−1, respectively. Arora et al. (2010) used chitosan-coated zeolite (Ch–Z) protonated with either sulfuric or hydrochloric acid and tested for its suitability to capture nitrate ion from water.

The adsorption ability of natural aluminosilicates is related to humans from the times of their existence till now. The use of clays in agriculture and industry is based on the characteristics of their surfaces to adsorb water, organic compounds and inorganic ions (Novikova and Belchinskaya 2016). Pyrophyllite, which belongs to the group of aluminosilicates with a balanced mineral structure (Das and Mohanty 2009) and a very small particle size, could be a very efficient ions adsorbent.

In this study, pyrophyllite was used as a nitrate adsorbent from artificial fertilizers and soil. According to Zhang et al. (2015), pyrophyllite, a 2:1 phyllosilicate mineral AlSi2O5OH, is comprised of an octahedral aluminum hydroxide sheet sandwiched between two tetrahedral silicon oxide sheets. The tetrahedral–octahedral–tetrahedral unit is electrically balanced as neutral on the basal plane, while the successive 2:1 layers are held together by Van der Waals forces (Zhang et al. 2015). No hydroxyl groups are found on the surface of silicon oxide, so dispersion forces dominate interlayer binding. Pyrophyllite consists of neutral layers and does not contain interlayer cations (Uygun and Solakoġlu 2002; Parmelee and Barrett 2006; Angelini et al. 2007). Liu and Bai (2017) stated that little attention has been paid to study the relationship between the chemical composition, surface property and flotation recovery of pyrophyllite. Pyrophyllite is widely used in the industry, especially in the manufacture of ceramics, glass and refractory materials (Zhang and Zhang 2020) due to its good physicochemical characteristics, such as low thermal and electrical conductivity, low expansion coefficient, low reversible thermal expansion and excellent reheating stability (Liu and Bai 2017).

To optimize the removal process, the adsorption characteristics of pyrophyllite have been examined in the presented study by testing the effect of contact time, pH, the effect of the sample’s flow rate, the amount of initial nitrate concentration, as well as the amount and the fraction of the adsorbent. The various parameters of pyrophyllite as moisture, ash content and acidity have also been determined. Nevertheless, there is very limited information, and there is a lack of studies about the adsorption capacity of nitrate from artificial fertilizers and soil on pyrophyllite. Bibliographic references most commonly describe the use of pyrophyllite for the removal of other anions such as cyanide (Saxena et al. 2001) and borate (Keren et al. 1994). Therefore, the main aim of this study was to present the first findings of adsorption capacity of nitrate from artificial fertilizers and soil on pyrophyllite obtained from Parsovići pyrophyllite deposit near Konjic, Bosnia and Herzegovina during the year of 2018.

Materials and methods

Materials

The pyrophyllite used for the nitrate adsorption experiments was obtained from the Parsovići pyrophyllite deposit near Konjic, Bosnia and Herzegovina. The particle size distribution was determined by sieving ground pyrophyllite through standard nylon sieves (Fritsch, Analysette, Germany) with openings of 16.00, 8.00, 4.00, 2.00, 1.00, 0.50, 0.25, 0.125, 0.063 and < 0.063 mm. All experiments were performed on 0.25, 0.50 and 1.00 mm pyrophyllite fractions.

Analytic grade KNO3 (Merck, Germany) was used in all the experiments. A stock solution of nitrate (1000 mg L−1) was prepared by dissolving the required amount of KNO3 in Milli-Q water. All the other reagents used in the experiments were reagent grade and purchased from Merck, Germany.

Determination of various parameters of pyrophyllite

Pyrophyllite moisture was determined as follows: About 2 g of the pyrophyllite sample were weighed for each 0.25, 0.5 and 1 mm fraction; then, the samples were dried at 105 °C for 45 min. The ash content was determined after the samples have been annealed at 550 °C and 800 °C for 1 h. The calibrated pH meter (Schott, CG 841, Germany) was used for pyrophyllite acidity determination. About 10 g of the pyrophyllite was transferred to a beaker and topped with 25 mL of distilled water. After 30 min, the pH was measured on the calibrated pH meter.

Adsorption studies

The batch and columns (percolation tubes) experiments were used for the study of nitrate ions adsorption on pyrophyllite. A glass column with an internal diameter of 0.8 cm and a length of 15 cm was used for column studies. To prevent losses, columns were sealed with glass wool and filled with 10 g of pyrophyllite. For batch experiments, the adsorbent and the KNO3 solution were placed in a volumetric flask (250 mL) and shaken at 140 rpm using a shaker (Heidolph Rotamax 120, Germany). Pyrophyllite fractions of 0.25, 0.5 and 1 mm and KNO3 solutions of 75, 150 and 250 mg L−1 were used for both experiments.

During the column and batch extractions, pyrophyllite samples were topped with 100 mL of 75, 150 and 250 mg L−1 concentrations of nitrate solutions. The nitrate content of the eluate was measured by calibrated UV–Vis spectrophotometer (Varian, Cary 50) according to the procedure specified in the international standard method ISO 7890–3:1988. The recovery factor was used to express the adsorption capacity.

The findings suggested that there was no significant difference in the nitrate adsorption capacity between the 0.25, 0.50 and 1.00 mm fractions, and therefore, a 0.50 mm fraction was selected for further experiments. In addition, a concentration of 75 mg L−1 was chosen as the optimal solution concentration.

The effect of sample flow rate and contact time

The quantitative retention of nitrates on pyrophyllite depends on the sample solution flow rate. Consequently, the sample’s flow rate effect on the retention of the nitrate on the adsorbent was investigated by passing 100 mL (75 mg L−1) of nitrate solution through the column and by adjusting the flow rate of 1, 3, 5 and 8 mL min−1. Moreover, in order to check the effect of the contact time of the KNO3 solution and pyrophyllite in a batch extraction, contact times of 1 and 2 h were examined.

The effect of pH solution on the nitrate elution from pyrophyllite

The effect of the pH solution on the nitrate elution from pyrophyllite was investigated by passing the following solutions: 1.70 (synthetic gastric juice), 6.40 (rainwater), 7.70 (distilled water), 9.30 and 12.50 (NaOH solution). The pH measurements were performed on the calibrated pH meter Schott, type CG 841 (Germany). Synthetic gastric juice was prepared as described by Žero et al. (2017). The pH value providing the maximum removal of nitrate was determined.

Determination of adsorption capacity of nitrate from fertilizers on pyrophyllite

To determine the adsorption capacity of nitrates from fertilizers, the content of total N in the fertilizer was first determined as follows: About 2.5 g of the fertilizer sample was ground and homogenized, dissolved in Milli-Q water and transferred to a 250-mL volumetric flask, and filled to the mark with Milli-Q water. Then, an aliquot of 25 mL was transferred to a distillation balloon, and 200 mL of distilled water was added, followed by 5 mL of 96% ethanol and 2 g of Devarda's alloy. A distillation funnel was placed on the distillation balloon into which 40 mL of 33% NaOH solution was poured. Predistilled ammonia was captured in 100 mL of 0.1 mol L−1 HCl solution. After completing the distillation, excess of HCl was titrated with 0.1 mol L−1 NaOH solution, with methyl orange as an indicator (Vatrenjak-Velagić 1997).

After the total N content of the fertilizer was determined, a fertilizer solution of 75 mg L−1 was prepared. The prepared solution was passed through the column (the same procedure was applied as for the study of the adsorption of nitrate ions onto pyrophyllite that was previously described) containing about 10 g of pyrophyllite of 0.50 mm fraction. The nitrate content was determined spectrophotometrically as described in the section adsorption studies of this paper.

In order to study the elution of nitrates from pyrophyllite, distilled water (pH = 7.70) and rainwater solution (pH = 6.40) were used.

Determination of adsorption capacity of nitrates from the soil on pyrophyllite

For the purpose of determining the adsorption capacity of nitrates from soil on pyrophyllite, three different soil samples were analyzed where total N was determined in the same manner as in the fertilizer sample. The adsorption capacity was determined using columns. About 10 g of all three soil samples were weighed in three columns. The soil samples were first topped with 100 mL of distilled water. Then, an aliquot of eluate (0.5 mL) was taken for nitrate analysis. Three new columns were used to weigh around 10 g of pyrophyllite (fraction 0.50 mm) and to pass the remaining 95.50 mL of the solution. An aliquot of 0.5 mL eluate was then taken for nitrate analysis.

In the end distilled water, rainwater and a solution of 2 mol L−1 KCl were passed through the columns so as to examine the possibility of eluting nitrates from pyrophyllite.

Results and discussion

Various parameters of the adsorbent and granulometry

In the present study, pyrophyllite was used as an adsorbent for nitrate removal from artificial fertilizers and soil by adsorption. Table 1 shows the granulometric composition of the pyrophyllite sample.

The highest percentage in the pyrophyllite sample has a fraction of 0.063 mm and a fraction of < 0.063 mm, while the lowest percentage has a fraction of 4.00 mm. Table 2 shows the moisture, ash content and acidity for the pyrophyllite fractions of 0.25, 0.50 and 1.00 mm.

All three pyrophyllite fractions had very similar pH values of aqueous suspensions and were in the weakly basic range. Through the pyrophyllite structure, it can be assumed that the poor basicity of pyrophyllite is probably due to the presence of OH− groups. Poor pyrophyllite basicity favors good plant growth and development while improving soil properties, and it also favorably affects soil fertility when using artificial fertilizers and optimizing fertilization.

Nitrate adsorption capacity

The efficiency of nitrate adsorption on pyrophyllite was expressed by recovery factor values and presented for extraction processes, column and batch. The results are shown in Table 3.

Similar recovery factor values were obtained for all pyrophyllite fractions and all concentrations of the KNO3 solution, from 93.14 to 99.77%. Likewise, by increasing the concentration of the KNO3 solution, the recovery factor also increased. The nitrate adsorption capacity in this study increased with increasing concentration. That might be due to an increase in the driving force of the concentration gradient as an increase in the initial concentration of the adsorbate. El Ouardi et al. (2015) concur that an increase in the initial concentration of the adsorbate could increase the driving force of the concentration gradient, causing an increase in adsorption capacity. Very similar findings were obtained in the study by Gulnaz et al. (2004) where an increase in the initial concentration of activated sludge increased the driving force of the concentration gradient, causing an increase in adsorption capacity of basic dyes from aqueous solution. There was no significant difference in the results when columns and batch extraction were used. High adsorption capacity of nitrate on pyrophyllite was confirmed.

Flow rate and contact time effect

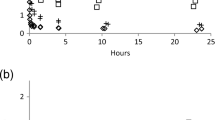

For three pyrophyllite fractions (0.25, 0.50 and 1.00 mm), the effect of the KNO3 solution flow rate (1, 3, 5 and 8 mL min−1) in the columns on the nitrate adsorption capacity was examined by passing the KNO3 solution of 75 mg L−1 through pyrophyllite. The effect of the flow rate, expressed by the recovery factor value, is given in Fig. 1.

For all pyrophyllite fractions at all flow rates, high recovery factor values (90.44–97.45%) were obtained. Highest values were obtained for a flow rate of 5 mL min−1, except for the 0.25 mm fraction where the highest recovery factor was determined for a flow of 8 mL min−1. The flow rate of 5 mL min−1 was selected for further experiments.

The effect of contact time of the KNO3 solution (75 mg L−1) and pyrophyllite in batch extraction (1 and 2 h) was also examined. The results are shown in Table 4.

Nitrate removal was very effective for both contact times (1 and 2 h); recovery factor values were in the range of 90.38% to 91.47% for a contact time of 1 h and in the range of 92.15% to 93.18% for a contact time of 2 h. The recovery factor value was slightly higher if the contact time of the KNO3 solution and pyrophyllite was longer. The conducted experiments showed that the recovery factor increases by increasing the contact time of the KNO3 solution and pyrophyllite. The adsorption process was accelerated at the beginning, followed by a phase of slow adsorption. Ion binding in two phases is a frequent occurrence since ions bind to free sites on the adsorbent in the first phase faster because of more available free sites on the adsorbent, while ion binding in the second phase is slower. The saturation of active sites reduces the speed of the process.

The effect of pH on nitrate elution from pyrophyllite

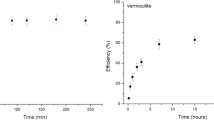

The effect of pH (1.70 (synthetic gastric juice), 6.40 (rainwater), 7.70 (distilled water), 9.30 and 12.50 (NaOH solution)) on the elution of nitrate from pyrophyllite is shown in Fig. 2.

Generally, the percentage of elution was low for all of the used solutions and was highest for solutions with higher pH values. It is observed that the percentage of elution has the highest value at the pH 9.30 and decreases as the solution pH becomes acidic or more alkaline. The influence of pH on anion exchange reaction was mainly due to the competition between anions and the hydroxyl ions (Battas et al. 2019). The pyrophyllite surface in water has a net negative surface charge, and the surface charges become more negative as the pH increases. Consequently, the adsorption of nitrate ion is hampered because negatively charged surface sites on the adsorbent do not favor nitrate due to the electrostatic repulsion (Battas et al. 2019). In the area of low pH, removal efficiency of nitrates decreases. This behavior of adsorbate-adsorbent system is explained by the fact that the active sites of the clay at the lower pH values become more protonated due to the adsorption of H+ ion; because of that, they are less available for nitrate adsorption. Moreover, by increasing the pH value of the solution, the active sites of the clay undergo a reaction of deprotonations and with electrostatic forces attract positively charged ions. That explains the higher efficiency of nitrate removal in the area of higher pH values. The pH of the aqueous medium affects the adsorbent surface charge, degree of ionization and analytes (Šabanović et al. 2016).

Capacity for nitrate adsorption from fertilizers on pyrophyllite

As noted above, it was found that there was no significant difference in the nitrate adsorption capacity between the three pyrophyllite fractions, 0.25, 0.50 and 1.00 mm. The experiments used to determine the adsorption capacity of nitrates from fertilizers were performed only on a 0.50 mm fraction. Also, a concentration of 75 mg L−1 was chosen as the optimum nitrate concentration. Three probes of the same sample were used, and the result was presented as the mean value ± standard deviation. The recovery factor was 99.35%, suggesting that pyrophyllite has a high capacity of nitrate adsorption from fertilizers containing N in the form of nitrate (NO3− –N).

After passing the fertilizer solution through pyrophyllite and in order to check the percentage of nitrate elution from the adsorbent, the pyrophyllite was topped with distilled water (pH = 7.70) and rainwater solution (pH = 6.40). The obtained results are expressed as the mean of the elution percentage ± standard deviation and are shown in Table 5.

The process of elution of nitrates from pyrophyllite with distilled water and rainwater did not lead to significant release of nitrate from pyrophyllite, and the elution percentage ranged from 1.60 to 2.07%. These data further support the selection of pyrophyllite for nitrate removal because it has a high nitrate adsorption capacity and the nitrate elution process from the adsorbent was very low.

Adsorption capacity of nitrates from the soil to pyrophyllite

Nitrogen can occur in soil in many forms: mineral (nitrate, nitrite, amide, ammonia) and organic (humus). It has been reported (Zhang et al. 2018) that the soil acidification of croplands happens very often due to agricultural activities and is mostly attributed to N fertilizers and deposition. The use of artificial N fertilizer has multiplied in the past years with the goal to have a higher crop yield for a large world population, leading to increased N saturation of the terrestrial ecosystem (Qiao et al. 2020). Plants from the soil adopt all forms of N but most often the nitrate form (NO3−), which reflects the importance of nitrates in the soil. Accordingly for the purpose of determining the adsorption capacity of nitrates from soil on pyrophyllite, the content of total N in three different soil samples was first determined, and the results obtained are shown in Table 6.

After determination of total N, soil samples were placed in columns and eluted with distilled water (pH = 7.70), rainwater (pH = 6.40) and a solution of 2 mol L−1 KCl (pH = 7.20). The elution results are shown in Table 7. After the eluate (0.5 mL) nitrate content determination, the remaining 95.50 mL of the solution was passed through pyrophyllite. The elution rate was checked with rainwater (pH = 6.40) and a solution of 2 mol L−1 KCl (pH = 7.20). Results are also presented in Table 7.

In general, low percentages of nitrate elution from pyrophyllite were obtained. Also, slightly higher percentages of nitrate elution from pyrophyllite compared to nitrate elution from soil were determined. It is interesting that after passing the solution through pyrophyllite, higher concentrations of nitrate have been obtained in the effluent, than by passing the solution through the soil. After passing the aqueous soil extract through the pyrophyllite, there was an increase in the nitrate concentration. Such results are probably due to the fact that pyrophyllite translated some of the N forms from the soil into nitrate form.

Conclusion

For the first time, the use of pyrophyllite as an adsorbent for nitrate removal from soil and artificial fertilizers was presented. Pyrophyllite, an environmentally friendly material, was shown to be suitable for the nitrate ions adsorption from artificial fertilizers and soil. High recovery factor values (90.44–97.45%) were obtained for all pyrophyllite fractions. The process of nitrate elution from pyrophyllite with different pH solutions showed that the nitrate elution process from the adsorbent was very low. Pyrophyllite may be used as an inexpensive and effective sorbent for the adsorption of nitrates ions from aqueous solutions. It is necessary to point out the study at hand could be used as a starting point for further research, which could be helpful for the design of an economically cheap treatment process using pyrophyllite for the removal of nitrate from artificial fertilizers and soil.

References

Afkhami A, Madrakian T, Karimi Z (2007) The effect of acid treatment of carbon cloth on the adsorption of nitrite and nitrate ions. J Hazard Mater 144(1,2):427–431. https://doi.org/10.1016/j.jhazmat.2006.10.062

Angelini MM, Garrard RJ, Rosen SJ, Hinrichs RZ (2007) Heterogeneous reactions of gaseous HNO3 and NO2 on the clay minerals kaolinite and pyrophyllite. J Phys Chem A 111:3326–3335. https://doi.org/10.1021/jp0672656

Arora M, Eddy KN, Mumford AK, Baba Y, Perera MJ, Stevens WG (2010) Surface modification of natural zeolite by chitosan and its use for nitrate removal in cold regions. Cold Reg Sci Technol 62(2,3):92–97. https://doi.org/10.1016/j.coldregions.2010.03.002

Battas A, Gaidoumi AE, Ksakas A, Kherbeche A (2019) Adsorption study for the removal of nitrate from water using local clay. Sci World J 2019:1–10. https://doi.org/10.1155/2019/9529618

Bhatnagar A, Sillanpää M (2011) A review of emerging adsorbents for nitrate removal from water. Chem Eng J 168(2):493–504. https://doi.org/10.1016/j.cej.2011.01.103

Das B, Mohanty JK (2009) Mineralogical characterization and benefication studies of pyrophyllite from Orissa, India. J Miner Mater Char Eng 8(4):329–338

Dehghani M, Haidari E, Shahsavani S, Shamsedini N (2015) Removal of nitrate in the aqueous phase using granular ferric hydroxide. Jundishapur J Health Sci 7(2):e26419. https://doi.org/10.5812/jjhs.7(2)2015.26419

Dinnes DL, Karlen DL, Jaynes DB, Kaspar TC, Hatfield JL, Colvin TS, Cambardella CA (2002) Nitrogen management strategies to reduce nitrate leaching in tile-drained midwestern soils. Agron J 94:153–171. https://doi.org/10.2134/agronj2002.1530

El Ouardi M, Qourzal S, Alahiane S, Assabbane A, Douch J (2015) Effective removal of nitrates ions from aqueous solution using new clay as potential low-cost adsorbent. J Encap Adsorpt Sci 5(4):178–190. https://doi.org/10.4236/jeas.2015.54015

Fan J, Hao M, Malh SS (2010) Accumulation of nitrate-N in the soil profile and it simplications for the environment under dry land agriculture in northern China: a review. Can J Soil Sci 90:429–440. https://doi.org/10.4141/CJSS09105

Giles M, Morley N, Baggs EM, Daniell TJ (2012) Soil nitrate reducing processes—drivers, mechanisms for spatial variation, and significance for nitrous oxide production. Front Microbiol 3:1–16. https://doi.org/10.3389/fmicb.2012.00407

Gruber N, Galloway J (2008) An Earth-system perspective of the global nitrogen cycle. Nature 451:293–296. https://doi.org/10.1038/nature06592

Gulnaz O, Kaya A, Matyar F, Arikan B (2004) Sorption of basic dyes from aqueous solution by activated sludge. J Hazard Mater 108(3):183–188. https://doi.org/10.1016/j.jhazmat.2004.02.012

ISO (International Organization for Standardization) 7890-3:1988, Water quality, determination of nitrate, Part 3: Spectrometric method using sulfosalicylic acid, Geneva, Switzerland

Keren R, Grossl PR, Sparks DL (1994) Equilibrium and kinetics of borate adsorption-desorption on pyrophyllite in aqueous suspensions. Soil Sci Soc Am J 58:1116–1122. https://doi.org/10.2136/sssaj1994.03615995005800040016x

Lin YF, Jing SR, Lee DY, Chang YF, Shih KC (2007) Nitrate removal and denitrification affected by soil characteristics in nitrate treatment wet lands. J Environ Sci Health A 42:471–479. https://doi.org/10.1080/10934520601187690

Liu X, Bai M (2017) Effect of chemical composition on the surface charge property and flotation behavior of pyrophyllite particles. Adv Powder Technol 28(3):836–841. https://doi.org/10.1016/j.apt.2016.12.009

Liu X, Wu Y, Sun R, Hu S, Qiao Z, Wang S, Mi X (2020) NH4+-N/NO3–N ratio controlling nitrogen transformation accompanied with NO2–N accumulation in the oxic-anoxic transition zone. Environ Res 189:109962. https://doi.org/10.1016/j.envres.2020.109962

Mansouri A, Lurie AA (1993) Concise review: methemoglobinemia. Am J Hematol 42:7–12. https://doi.org/10.1002/ajh.2830420104

Nabizadeh R, Jahangiri-rad M, Rafiee M (2014) Counterion effects on nitrate adsorption from aqueous solution onto functionalized polyacrylonitrile coated with iron oxide nanoparticles. Res J Environ Sci 8:287–293. https://doi.org/10.3923/rjes.2014.287.293

Novikova L, Belchinskaya L (2016) Adsorption of industrial pollutants by natural and modified aluminosilicates. In: Do Nascimento GM (ed) Clays, clay minerals and ceramic materials based on clay minerals. IntechOpen. https://doi.org/https://doi.org/10.5772/61678

Olgun A, Atar N, Wang S (2013) Batch and column studies of phosphate and nitrate adsorption on waste solids containing boron impurity. Chem Eng J 222:108–119. https://doi.org/10.1016/j.cej.2013.02.029

Öztürk N, Bektaş TE (2004) Nitrate removal from aqueous solution by adsorption onto various materials. J Hazard Mater 112(1–2):155–162. https://doi.org/10.1016/j.jhazmat.2004.05.001

Parmelee CW, Barrett LR (2006) Some pyrochemical properties of pyrophyllite. J Am Ceram Soc 21(11):388–393. https://doi.org/10.1111/j.1151-2916.1938.tb15739.x

Qiao Z, Wu Y, Qian J, Hu S, Chan J, Liu X, Sun R, Wang W, Zhou B (2020) A lab-scale study on heterotrophic nitrification-aerobic denitrification for nitrogen control in aquatic ecosystem. Environ Sci Pollut Res 27:9307–9317. https://doi.org/10.1007/s11356-019-07551-3

Riley WJ, Ortiz-Monasterio I, Matson PA (2001) Nitrogen leaching and soil nitrate, nitrite, and ammonium levels under irrigated wheat in Northern Mexico. Nutr Cycl Agroecosys 61:223–236. https://doi.org/10.1023/A:1013758116346

Šabanović E, Memić M, Sulejmanović J, Huremović J (2016) Sorption of Metals on Pulverized Pumpkin (Cucurbita pepo L.) Peels. Anal Lett 49(15):2446–2460. https://doi.org/10.1080/00032719.2016.1152580

Saxena S, Prasad M, Amritphale SS, Chandra N (2001) Adsorption of cyanide from aqueous solutions at pyrophyllite surface. Sep Purif Technol 24(1,2):263–270. https://doi.org/10.1016/S1383-5866(01)00131-9

Soaresa M, Vale M, Vasconcelos V (2011) Effects of nitrate reduction on the eutrophication of an urban man-made lake (Palácio De Cristal, Porto, Portugal). Environ Technol 32(9–10):1009–1015. https://doi.org/10.1080/09593330.2010.523437

Strebel O, Duynisveld WHM, Bottcher J (1989) Nitrate pollution of groundwater in western Europe. Agric Ecosyst Environ 26:189–214. https://doi.org/10.1016/0167-8809(89)90013-3

Thomson TS (2001) Nitrate concentration in private rural drinking water supplies in Saskatchewan. Canada. Bull Environ Contam Toxicol 66:6470. https://doi.org/10.1007/s0012800206

Uygun A, Solakoġlu E (2002) Geology and origin of the pyrophyllite—deposits in Thepϋtϋtge massif (Malatya—Eastern Turkey). Miner Res Expl Bul 123–124:13–19

Vatrenjak-Velagić V (1997) Analitička kontrola kvalita. Studentska štamparija Univerziteta u Sarajevu, Sarajevo

Žero S, Huremović J, Memić M, Muhić-Šarac T (2017) Determination of total and bioaccessible metals in airborne particulate matter from an urban and a rural area at Sarajevo. Toxicol Environ Chem 99(4):641–651. https://doi.org/10.1080/02772248.2016.1207173

Zhang S-Y, Zhang H-F (2020) Genesis of the Baiyun pyrophyllite deposit in the central Taihang Mountain, China: Implications for gold mineralization in wall rocks. Ore Geol Rev 120:103313. https://doi.org/10.1016/j.oregeorev.2020.103313

Zhang J, Lü F, Shao L, He P (2014) The use of biochar-amended composting to improve the humification and degradation of sewage sludge. Bioresour Technol 168:252–258. https://doi.org/10.1016/j.biortech.2014.02.080

Zhang J, Zhou Y, Jiang M, Li J, Sheng J (2015) Removal of methylene blue from aqueous solution by adsorption on pyrophyllite. J Mol Liq 209:267–271. https://doi.org/10.1016/j.molliq.2015.05.056

Zhang Y, Sui B, Shen H, Wang Z (2018) Estimating temporal changes in soil pH in the black soil region of Northeast China using remote sensing. Comput Electron Agric 154:204–212. https://doi.org/10.1016/j.compag.2018.09.005

Acknowledgements

Authors are very grateful for the pyrophyllite provided by Parsovići pyrophyllite deposit near Konjic, Bosnia and Herzegovina, as well as AD Harbi d.o.o. Sarajevo, Bosnia and Herzegovina.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Editorial responsibility: Samareh Mirkia.

Rights and permissions

About this article

Cite this article

Hasanbegović, E., Huremović, J. & Žero, S. Adsorption capacity of nitrate from artificial fertilizers and soil on pyrophyllite. Int. J. Environ. Sci. Technol. 18, 3731–3738 (2021). https://doi.org/10.1007/s13762-021-03135-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-021-03135-2