Abstract

The disposal of waste plastics has turned into a huge global environmental dilemma. This paper aims to assess the economic viability of the current level of energy recovery out of plastic waste by using a pyrolysis thermal treatment. The primary objective is to assess the potential calorific value of plastic waste in order to utilize as an energy source and generate value-added materials from waste. First, a generalized process flowsheet is employed, and the material balance is specified. Then, a profitability analysis is conducted for the proposed pyrolysis process. For the economic assessment, a waste plastic feed rate of 40 tonnes/day is assumed. Costs for individual pieces of equipment are either rigorously calculated or adapted from the literature. The results indicate that a 54% rate of return on investment (ROI) can be achieved if the plastic is collected, transported, and delivered at the processing site free of charge. This is a reasonable assumption as this is mostly carried out by the local councils using the revenue from ratepayers and the waste can be combined with no separation required for various types of plastic. This ROI can be further improved by increasing the size of the plant, due to economies of scale. Therefore, the outcomes of this research affirm that the pyrolysis treatment of waste plastics is viable in Australia from a technical as well as economical point of view.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Waste plastic disposal is considered as one of the main growing environmental issues in Australia. The rapid consumption rate of plastic has led to a booming waste generation, and this causes major problems for disposal as plastic lifespan is short (approximately forty per cent of waste plastics have life expectancy under a month) (Achilias et al. 2007) and the length of service of plastic stocks can vary between 1 and 35 years (Mutha et al. 2006) which is varying in different countries (Panda et al. 2010; Tabinda et al. 2018). In 2014–2015, 2.5 million tonnes of plastic waste was being produced in Australia, and around 80% of that was sent to landfill sites (Pickin and Randell 2017). However, the landfill is becoming a more expensive option because of decreasing the availability of suitable depot sites near the point where wastes are generated. This leads to an increase not only in transportation cost but the cost of disposal (Williams and Williams 1997a, b). Moreover, new levies imposed by different states in Australia restrict the current landfilling trend and help to promote practical ways of pricing the environmental and social areas of waste disposal. One promising alternative for the reuse of plastic waste is pyrolysis, which transforms plastic waste into fuel or useful chemical products. Generally, pyrolysis is a thermal cracking-based process associated with breaking down compound organic molecules without the presence of oxygen (Chang 1996). Pyrolysis process can also be employed in transforming biological substances into fuel/oil-based products (El-Sheikh 2014). Pyrolysis process hence is considered as a prime technology to serve energy and natural resource conservation (Frigo et al. 2014; Zaman 2013). Furthermore, liquid products can be kept in reserve until needed or readily transported to where it can be best employed (Rofiqul Islam et al. 2008). Municipal waste-to-energy facilities as a promising investment opportunity in the Australia made it a place of great interest for both energy sectors and scientific research. Based on a state-by-state updated report released by Australian government in 2016, 23 million tonnes of solid waste was disposed into landfill yearly all over the country. That being the case, waste-to-energy plans can take the lead in sustainable development and renewable energy production.

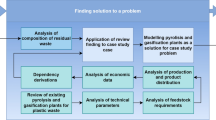

Designing waste-to-energy plants is driven by researchers, industrial people, and government with both economic and environmental goals. A cost–benefit analysis proposes an approach for decision-makers to find the balance between the amount of effort contributed to building and running waste-to-energy plants and the revenues comprehended. The principal objectives of this research include:

-

To assess the applicability of pyrolysis technology for processing plastic waste

-

To evaluate the economic viability of using pyrolysis technique for treating plastic waste in the Australian context.

The current study is aimed to analyse a case of the waste plastic processing facility in Sydney, Australia, with a feed rate of 40 tonnes/day at 2017. The scope of the work, therefore, focuses on presenting a case study-based economic assessment, along with evaluating the most important variables influencing the feasibility of the proposed plastic waste-to-energy scenarios.

Process description

In pyrolysis, the feed input is heated by an exterior source of heat at a temperature greater than 400 °C and usually lower than 800 °C (Lombardi et al. 2015). The outputs are generally pyrolysis gas, liquid, and char. The approximate percentages of them are subjected to the pyrolysis method and the used reactor (Bosmans et al. 2013). Pyrolysis of waste plastic leads to the generation of green pollution-free energy in the form of a high calorific value fluid. The fluids coming from hydrocarbon chains thermally extracted from waste plastic are appropriate for many applications (Ivanov et al. 2015). Some researchers found that the calorific value of the disposed materials highly depends on the amount of hydrocarbon they have. The calorific value may change between 22 and 30 MJ/m3 with biomass has the lower and synthetic materials the higher limit (Lombardi et al. 2015). For the sake of making the most out of the plant, pyrolysis plus combustion was considered in this study which is shown schematically in Fig. 1.

In general, three different product types can be extracted from the pyrolysis process: gas, liquid fuel, and solid residue (char) (Zaman 2010). Oil is the foremost product extracted from pyrolysis of mixed plastic waste excluding PCV. In the case of having PVC in our plastic waste feed, the main product is HCl gas (Williams and Williams 1997b). The key fact which makes pyrolysis oil being comparable with conventional fuels is the equivalent calorific value of the obtained oil.

The pyrolysis oil is also useful to be sold to the energy and chemical companies. Those oils which require further treatments would be distilled to be marketable as diesel and other petrochemical products. In order to satisfy the New South Wales Government standards, the produced pyrolysis gases have to be combusted within the plant. The main reason for that is, based on the governmental benchmarks, a fraction of the products needed to be recovered as electricity or heat inside the facility.

Based on “The Australian Energy from Waste Policy Statement” published by EPA (The Environment Protection Authority), facilities in Australia generating secondary fuel or process-engineered fuel are obliged to verify the content of halogenated materials in waste and waste derivative fuels. These facilities are also needed to fulfil, at the lowest level, the prerequisites of the group six emission criteria specified by “Clean Air Regulation” (New South Wales Environment Protection Authority 2010). This guideline involves all municipal thermal waste-to-energy facilities to meet the emission and efficiency confines detailed in Australian Standard AS/NZS 4013 (Australian New Zealand Standard AS/NZS 4013 2013). The present emission border for all combustion chambers in Australia is 2.5 grams of particulate emissions per kilo of fuel burnt. All licensed combustion chambers must have an efficiency prerequisite of 55% (Todd 2006).

The produced char could be put up for sale to other businesses/trades or combust in the combustion chamber. Figure 1 shows the flow chart for the considered energy recovery plant along with the inputs and outputs of the process.

Adding combustion to the main pyrolysis process requires higher capital investment, but helps to make sure that all the yields are of high value. Moreover, combustion makes the system more flexible in terms of input and output and also helps to prevent extra treatments for some of the low-quality outputs by combusting them within the combustion compartment.

Figure 2 shows the considered pyrolysis flow chart for the proposed plastic waste-to-energy (PWTE) plant. In order to treat a portion of the liquid yield that has not reached the standard level, a distillation machine is installed inside the warehouse. The key drive of including the distillation stage is to generate a quality fuel such as petrol or diesel. Fuels which are derived from plastic feedstock show lower sulphur levels compared to regular fuels. A higher cetane value derived from plastic feedstock also specifies that synthetic diesel extracted from pyrolysis and hydrothermal processes establishes fewer emissions (including hydrocarbons and CO2) from the engine, because of the improved fuel effectiveness.

Considered pyrolysis flow chart for plastic waste-to-energy (PWTE) plant (Al-Salem et al. 2009)

Oil products are then treated in a distillation unit to form products with higher calorific values. The way it happens is usually through breaking down the compound of oil in the input. First, mixed plastic waste is injected into the reactor along with the nitrogen to create an inert atmosphere. This will help to avoid the burning of inlet materials. Once heating the input materials takes place within the reactor either through thermal-coupled or heat recovery system, the plastic vaporizes and undergoes condensation process in which vapours separated into liquid and gas. These products can then be analysed further to assess the viability of selling as a value-driven commodity. Products that cannot be considered as valuable by-products either blew out (after filtering) or burnt within the combustion chamber. Char and gases that are neither valuable by-products nor feasible to treat further can be used as part of the fuel for the combustion process and generate thermal energy for the reactor and distillation unit.

Thermodynamic modelling

In this study, thermodynamic modelling was used to model the flowsheet of the pyrolysis process. The modelled flowsheet was then used to calculate the mass and energy flow during the processing of waste plastic through pyrolysis. FactSage 7.0 thermochemical packages and HSC Chemistry 9.0 were employed for modelling purpose. HSC employs thermodynamics data and figures from “Barin and JANAF databases” (Bale et al. 2009). The elements listed in Table 1 were incorporated in the modelling, and analysis of the modelling results was mainly performed based on the flow and behaviour of these elements. The HSC software was employed to create a Ellingham diagram to calculate the steadiness of the plastic materials together with creating the comprehensive flow sheet for the pyrolysis and energy and mass balance. The total amount of plastic waste treated in this facility was assumed to be 40 tonnes/day. This is based on the tonnage of waste plastic fed into the plant (including associated water and contamination) for 10 h continuously. Figure 3 presents the flowsheet of proposed waste plastic pyrolysis route modelled by HSC.

The product gas consisted of carbon dioxide and hydrogen, with small quantities of methane, benzene, carbon monoxide, and toluene also produced. Because of similar structures of HDPE, LDPE, PP, and PVC, the gases produced during thermal treatment are alike. Hydrocarbon gas and oil-based segment are among the main products generated through thermal treatment of all sorts of polymers, and some other polymers produce small amount of solid residue (char) when they go through thermal processes. Polyvinyl chloride (PVC) produces hydrogen chloride gas once heated; however, the produced level is relatively low compared with the oil. Overall, all generated gases are somehow useful as they are mainly hydrocarbon based. In this study, products yield from pyrolysis of waste plastic mixture was estimated from the modelling. The calculated gas yields as shown in Table 2 are slightly lower than the theoretical amounts given in (Williams and Williams 1997b). The key reason might be attributed to the reduced number of subsidiary reactions considered in the current study.

The off-gases generated here pass into a process off-gas system, which comprises a special series of filters and bedded material. The off-gases need toxic waste control before releasing to the atmosphere. Furthermore, the process entails careful consideration towards treating particular chemical reactions.

In Australia, “National Environment Protection Measures (NEPMs)” are sets of goals which have been tailored to assist in safeguarding specific environmental features (National Environment Protection Measures 2016). The Air Toxins section of NEPM was launched in 2004 to classify and assess at-risk sites for key pollutants such as polycyclic aromatic hydrocarbons, xylene, formaldehyde, and toluene. The method for classifying at-risk sites for one or more air toxics is given in Table 3. According to NEPMs for considerably raised air toxic levels to happen, the following conditions are needed:

-

Direct locality for air toxics elements.

-

Localized amounts of emission

-

Geographical and climatological limitation in spreading of the emissions.

According to the modelling results for emitted gas out of combustion chamber (pyrolysis reactor), the level of air toxics for the proposed plant is below the standard.

Economic evaluation

The cost–benefit analysis is conducted to compare the economic viability of the proposed plastic waste-to-fuel plant. The net income of the proposed facility is the difference between benefits and expenses and charges (Molinos Senante et al. 2010) (Eq. 1)

where NI is the net income for a given year; Bi is the worth of the benefit item i (revenue) in the same year; and Ci is the expenditure value for item i in the same year. For a proposed plant, if the calculated net income for a given year is greater than zero (NI > 0), then the plant is considered to be economically feasible; however, if the outcome of net income is negative (NI < 0), the plant is regarded as economically not doable (Ghodrat et al. 2017; Molinos Senante et al. 2010; Wang et al. 2018). All the prices were considered in Australian dollars (AUD). For the economic analysis, the interest rate is taken the same as the expected internal rate of return (IRR) and is assumed to be 10% per year. The key intention of the study is to evaluate the economic viability of the proposed plastic waste-to-fuel plant based on benchmarks employed in economic analysis in order to facilitate decision-making process. Overall a scenario is considered to be economically appealing when it has the highest internal rate of return (IRR) along with its net present value (NPV) greater than zero (Luz et al. 2015). The NPV is another index to rate how project acts in terms of adding value to the investment. NPV is estimated by using Eq. (2) (Luz et al. 2015):

where CFn is the yearly cash flow, which is the difference between benefit (B) and cost (C). CIC is defined as the overall capital installation costs (ICs). t is defined as the lifespan of the investment set as 25 years. The considered plant lifespan is based on a “straight line depreciation method” for common plants and utilities given by Perry’s handbook for chemical engineers (Perry et al. 1999). The yearly cash flow, including all the costs and revenues, was built based on the profits from the commercialization of the diesel, fuel oil, heating oil, and synthetic oil produced in the facility.

The IC was split into capital costs and operating capitals. The costs of investment consist of the cost of equipment, construction, automation and control section of the plant, engineering-related jobs, land and other amenities. The CIC was calculated based on the costs of the main equipment. The operating capitals are the approximated values to warrant the operation and maintenance costs along with any other unforeseen costs until the beginning of the site set-up. The operational costs (CO) consist of the labour costs, the costs of machinery replacement and repair, and the costs associated with the facility’s overall operation which were estimated based on the equations, listed in Table 4. (FCI is fixed capital investment.)

The cost of transporting raw materials into the site was not included in the primary economic calculation. Capital cost considered in this study covered total indirect and direct capital expenses, and the operating costs included utility cost (cost of energy), labour cost, cost of materials, repair and maintenance along with plant overhead costs. For the proposed plastic waste-to-fuel plant, the reference prices were estimated first and the key process factors were determined based on published resources and available data related to public or private organizations. The plant operation cost was then determined by adding each unit operational expense.

Materials and methods

The proposed pyrolysis–incineration facility is built up in Mount Lewis, 15.5 km away from Sydney central business district. The proposed location is selected as it is closer to the industrial area, where manufacturing factories linked to plastic/polymeric products are situated. The total amount of plastic waste treated in this facility is assumed to be 40 tonnes/day. Mixed plastic waste collected from an old landfill located close to Chullora without any pretreatment. The most dominant components of plastic waste feed were 60–70% polyethylene and polypropylene plus 30–40% polyethylene terephthalate by weight.

The model used to analyse the economic viability of the proposed PWTE plant is the input–output model. In this model, costs and benefits (revenue) of all involved unit operation along with other influencing factors which affect the profit of the facility were explored and calculated. Adding up each operational unit cost and revenue, the total income and expenses can be calculated. Running sensitivity analysis would help to analyse the sensitivity of the model to changing main input variables. Technical cost modelling (TCM) approach was employed to build the economic model of the proposed PWTE facility. The model was firstly introduced by Rosato (2013) and it then improved by Schoenung (1995) and Kang and Schoenung (2006).

TCM is associated with two key parts, namely “inputs” and “output”. Inputs are defined as quantified variables in the model, and “outputs” are the outcomes exerted from the model covering the estimation of profits and expenses.

Technical cost modelling (TCM) has three stages. The first stage is involved in looking over the basic operational unit to find different process alternatives. The second stage included a detailed assessment of the starting point cost of each operational unit along with the main factors affecting this cost and related revenue. And finally, the last stage is involved in creating a practical relationship between defined process parameters. The total operational unit cost can be calculated by adding the main process-related costs. Revenues follow the same pattern with a positive sign, whereas for the costs the sign is considered to be negative in our calculations (Ghodrat et al. 2016).

In this study, the considered capital costs consist of the cost of land, cost of foundations and building, cost of machinery and equipment. Considered variable costs include the cost of labour, energy cost, cost of raw materials, and maintenance and repair costs. The incomes are due to selling products produced in the facility which are largely liquid fuels, char, and gases. Char is marketable in some industries such as cement, concrete and asphalt manufacturing. The calculated fixed capital costs depended on a mixture of vendors price list and data from the literature (Lang 1947; Perry et al. 1999; Peters et al. 1968; Seider et al. 2009). The data found in the literature were scaled up or down by the “capacity power-law” (Ghodrat et al. 2016):

For all currency change, the chosen factors were based on October 15, 2017. Table 5 presents the economic parameters defined in the project.

The generated products are proportions of the weight of the materials, which were fed into the reactor: 52% oil, 27% carbon black, 10% steel wire, and 11% exhaust gas. Some other techniques used for pyrolysis may produce more oil but work at higher temperatures and cannot be fed with mixed plastic.

Results and discussion

Capital and operating costs

As mentioned in Sect. 3, the estimation of capital costs was conducted by calculating the total cost of purchased machinery (vendors price lists or the literature) and linking that with the capacity of the selected machinery. Capacity power-law expression was employed in particular for scaling down of different used machineries (Ghodrat et al. 2016).

Design features of the proposed waste-to-energy plant were drawn up from different kinds of the literature (Al-Salem et al. 2009; Frigo et al. 2014; Lombardi et al. 2015; Rofiqul Islam et al. 2008). The present assumption for economic analysis in this study was obtained from Chemical Engineering Handbooks and process design main codes (Perry et al. 1999; Seider et al. 2009; Peters et al. 1968) as shown in Table 2. Variable costs employed in this study are listed in Table 1. The energy market price was extracted from data for Australian energy average price of 2017 (State of the energy market, Australian Energy Regulator 2017). Obtaining capital costs of the proposed facility was based on the “Lang factor technique”. In this technique, purchased cost of all key types of machineries was multiplied by a factor named the “Lang factor” (Lang 1947). This factor is equal to 3.63 for solid–fluid processing plants (plastic waste-to-energy plant). The land area includes 6500 m2 as basic space and 4200 m2 held for a possible extension of the waste-to-energy site in the future. The capital cost of the waste plastic pyrolysis unit is based on the vendor quotes and available data in the literature (Table 6).

Table 6 also presents pyrolysis unit costs, taking into account the size of the unit “30 × 15 m2 “and 40 tonnes/day of the treated waste plastic. Table 7 presents the cost of equipment and facilities required for building the plant along with project-related costs and total fixed costs. Project-related costs are defined as the required investment for the set-up period. This cost is usually added to the project cash flow as “net” working capital cost which for the following years is set as ten per cent of that year anticipated sale.

Operational cost calculation for PWTE is a complex task as the costs are governed by some unforeseen parameters. Cost of operation can be divided into five groups. Cost of energy involves fixed and variable costs. Fixed energy cost includes power-related costs and variable that referred to the cost of installation, cost of labour, insurance, and taxes. General operating cost such as machinery maintenance or replacement also needed to be added up (Table 4). With the capacity power-law expression [The m parameter used here is 0.6 based on the sixth–tenth rule of The Chemical Engineering Plant Index (CEPI) (Perry et al. 1999)]. The gas value required for a 40 tonnes capacity plant is 181 kg/day, and since the pyrolysis reactor generates 10% of gases (Syamsiro et al. 2014), it produces 4000 kg/day of gases. The produced gases are composed of methane, ethane, and propane. Methane and propane form up to 30% of the gaseous product of the pyrolysis process at 600 °C; which is equal to 11,080 kg/day. Therefore, pyrolysis reactor and distillation machine can be run by burning these gases in the combustion chamber, that way the required energy is only limited to wastewater treatment facility which is insignificant as the required recycled water estimated for the PWTE plant is only 10 m3/day.

Revenues

Annual income gained in the proposed PWTE plant is partly due to the sale of the fuel products generated in the process. Around 51.5% of the injected materials changed into oils, which become as follows:

365 days × 40 tonnes/day × 90% running time × 52% = 6,767,100 kg/year, with density of 0.915 kg/L, and the whole volume for the oil is calculated as: 6,767,100 kg/year × (1/0.915) L/kg = 7,395,738 L/year.

Out of this amount, that changed into diesel is 1 tonne per day as the selected equipment supply has that capacity; therefore, the produced diesel is calculated as 365,000 kg/year × (1/0.915) L/kg × 90% operating time = 359,016 L/year.

Assuming 48% was converted to diesel and 26% to fuel oil, 1 tonne of oils distilled per day produces (Waste To Energy International, 2017): 359,016 L/year × 48% diesel = 172,327-L diesel per year and 93,344 litres per year fuel oil. The remainder of the oil which is not converted into diesel is equal to: 7,395,738 L/year–359,016 L/year = 7,036,722 L/year. This surplus includes 50% fuel oil and 32% synthetic oil, and the residues are heating oil which is sellable (IPART 2007).

The market price of heating oil and fuel oil is expected to be similar. The same scenario is expected for crude oil and synthetic oil. The assumption made here is based on the average data extracted from “Mundi Index” (U.S. Energy Information Administration 2017) for the last 24 months of the calculation date.

The produced char and gases were employed fully in the combustion chamber to generate energy for the reactor and distillation unit. A summary of the annual benefit gained from the sale of diesel, fuel oil, heating oil, and synthetic oil is given in Table 8.

It was revealed that the IRR of the facility over 25 years working is 14% and the NPV of income from investment over the similar working period is $ 17.4 million. Generally, the plant has positive cash flow in the estimated period. The reimbursement period was estimated to be 8 years that is relative and illustrates that the proposed investment plan is very favourable.

For estimating the profitability of the investment and making a comparison between the income and cost of investment, ROI was calculated to be 0.54 for the proposed PWTE plant.

The positive ROI means that the profit obtained from the investment was higher than the expenditure. The other revealing factor employed to assess the effectiveness of the plant for transforming sale to income is the “operating cash flow margin” that is defined as the income from operating activities as a portion of sales in a certain time span.

The 25% operating cash flow margin obtained in the proposed PWTE plant shows that the plant is comparatively effective in transforming sale products to income and moreover is an evidence of high profitability of the suggested facility (Fig. 4).

Scenario analysis

To assess the comparative prominence of input factors over the project’s economic outcomes, a sensitivity analysis was conducted. Sensitivity analysis estimates the influence of changing different input values on project results when some uncertainties exist around those inputs. In the case of economic study, the sensitivity analysis was carried out over the main economic factors of the selected scenarios.

Sensitivity analysis is of great importance in evaluating unforeseen parameters which may influence the inherent uncertainties behind different possible scenarios. The uncertainties in economic analysis are often deeply rooted in costs and benefits of each scenario being highly volatile changing within a short time span and with different causes.

In this study, sensitivity analysis was carried out by changing cost of sold unit product and price of sold unit product. The sold price of unit product is defined as the product unit item multiplied by item unit price. The nominal value is considered to be one dollar. Changing item unit price corresponds to either changing the production, the price or an arrangement of both. In this sensitivity study, the item unit price was gone through both ascending and descending trends by 10% and up to 30%.

On the other hand, the cost of unit sold is a representative for variable cost and total revenue, in that the cost of unit product sold signifies the fraction of operation cost out of total profit. Changing this amount therefore is a sign of effectiveness of our investment. Combination of different scenarios and resulted NPV is shown in Table 9.

The grey cell represents the nominal NPV calculated in the project. The plus numbers in the table mean profits over zero, and minus figures represent losses in the investment. As shown in Table 8, it is evident that if the price of each unit sold is increased, the profit is increased and vice versa. The reverse set-up occurs with the unit sold cost, whereas reducing the cost of unit sold leads to lower expenses and higher incomes. It is of great interest to point that the worst value for NPV is − $ 12,186,182, which means our investment will lead to a 24% loss in capital cost at the start of the project. Overall in 32 out of the 36 cases study, investment is predicted to be successful.

Figure 5 shows the effect of production costs on the net present value (NVP) for the main case and the scaled designs. As can be seen from this figure, if the price of the unit sold is increased, the NPV increases and vice versa. A further analysis was also conducted to understand the influence of decreasing unit sold price. Two different approaches were considered. Firstly the production was assumed to increase even if this implies spending more on variable costs. Table 10 shows the first approach taken.

Another scenario is involved in decreasing variable cost of the investment via boosting the effectiveness of the asset (the facility). In both the above-mentioned scenarios, it is anticipated that the investment on the proposed PWTE plant is profitable. In case of any unexpected occurrence or surprising costs such as increasing variable costs or decreasing the price of sold products, two solutions are recommended: first is to increase investing in variable cost such as buying pieces of machinery and equipment to enhance the marketability of the products. And second is to improve the effectiveness of the facility which leads to reduced variable costs.

It is worthwhile to mention that the stated figures are studied to date and are not dynamic; therefore, the results of this study should be considered as a case study assessment due to the fact that condition can be changed through the project. The main aim of running scenario analysis hence was mainly to assist with gaining better insight into parameters which influence the economic viability of the PWTE plant.

Australian policies in energy recovery

The Australian Environment Protection Authority (AEPA) recognized that the energy recovery through thermal processing of waste has the perspective to deliver favourable results for the public and the environment. In Australia, two main policy schemes are maintained in the national waste legislation. At the outset, the “Protection of the Environment Operations Act 1997 (POEO Act)” places the outline to make sure that human health and the environment are preserved from the unsuitable use of waste. In addition, the “Waste Avoidance and Resource Recovery Act 2001 (WARR Act)” works towards the promotion of the avoidance of waste generation. The entities of this Act are:

-

a.

To inspire the most effective use of resources and to lessen environmental damage correspondence to the ethics of sustainable development.

-

b.

To warrant that the resource management decisions are reflected alongside a pecking order of prevention of inessential resource consumption, resource recovery, and disposal.

The thermal treatment of waste offers a chance to regain the energy contained in the waste, counterbalance the consumption of non-renewable energy resources, and bypass the methane emission from the landfill. However, to guarantee emissions are lower than the levels that create a risk of danger or damage to the community, facilities suggesting energy recovery from waste are obliged to be aligned with the present global best practice methods, especially with regard to process design, emission control, and monitoring equipment design. The Australian Energy from Waste Policy Statement delineated an act along with this policy outline which refers to facilities in Australia suggesting to thermally treat waste for regaining embodied energy of the waste. The scope of the policy extends over all facilities dealing with the thermal treatment of any waste materials including combustion, thermal oxidation, thermal or plasma gasification and pyrolysis. However, as pyrolysis and gasification technologies can only process plastics, many local councils do not see major benefits in using them as they have to manage better waste sorting.

Policy involvements to decrease the usage of single-use plastic bags and Styrofoam products have been employed at the national level. The government has announced various policy gears such as prohibitions or economic motivations. Most of the states in Australia have excluded lightweight single-use plastic bags. From the beginning of 2018, some main supermarkets publicized that they will phase out lightweight plastic bags or offer bags but charge AUD 0.15 ($0.12) per bag.

Compared to countries such as Norway and Denmark with thermal energy from the waste rate of 700 and 500 kg of waste per capita, respectively, Australia stands in much lower step, with recovering energy from just 8 kg of waste per capita. Even though there is currently no large-scale energy from waste facilities dedicated to core wastes in Australia, generally speaking, the sustainability contour of energy recovery in Australia is promising also when plastics are thermally recycled at the correct circumstances; energy recovery tactics occur within governing limits. Overall, based on the existing prototype plants established in laboratory scale around different states and territories in Australia it has been found that the following features are helping to side-track most plastic waste from landfills and convert them into alternative forms of energy

-

1.

Increasing industry involvement.

-

2.

Proving the energy potential of used plastic.

-

3.

Developing the infrastructure.

-

4.

Commitment to energy recovery.

Above and beyond, the Australian Government supports the efforts of many industry associations, research centres and higher education organizations conducting energy recovery trials or actively working to validate the energy recovery prospects for plastics waste. Being committed to working with value chain partners, other influencers in the field are the key to increasing the viability and use of integrated end-of-life options in Australia.

A detailed survey on mixed plastics waste recycling schemes on a global scale indicates the major obstacle faced by many developing countries is technology while regulation and environmental matters are the slightest of the impediments. In Europe, energy recovery is the most used way of plastic waste disposal. However, recycling rates by country vary a lot.

The main issues complicating waste plastic recycling found by the European Union are the quality and price of the recycled product, compared with their unrecycled equivalent. Plastic processors need large amounts of recycled plastic, manufactured to firmly controlled conditions and at a competitive price. However, as plastics are simply customized to the requirements of each manufacturer, the variety of the raw materials complicates the recycling process, turning it to an expensive process and affecting the quality of the end product. As a result, the demand for recycled plastics accounts for the only minor level of plastic demand in Europe.

In a global context, the causes of the obstacle in plastic waste recycling are identified to be linked to social, environmental, or economic phases of sustainability. Economic features consist of overlong distance from outstanding distribution point; comparatively smaller regional markets for recycled products in some countries and high logistic, labour and input materials cost. Environmental aspects include lack of robust regulations on plastic waste gathering and recycling; the absence of extended producer accountability; shortage of design requirements for the environment. And finally for the social features, the following were recognized: low local request for recycled products, demand for high-quality recycled materials, and limited machine manufacturers in some countries.

Lesson learned

In favour of achieving effective recycling of mixed plastic waste, high geared classification of the input materials requires to be implemented to guarantee that various plastics are separated from each other based on their types; nevertheless, further growth of end markets for each recyclable plastic streams is essential. The productiveness of post-consumer packaging recycling can be significantly improved if a variety of materials were to be reorganized to a subclass of current usage. Based on the lessons learned thus far, the following are the steps needed to be taken to encourage the energy recovery from plastic waste in Australia:

-

Government can provide incentives for companies to invest in building waste plastic pyrolysis plants and to improve waste recovery rate within the cities. Since induction-heated pyrolysis facility has a relatively small operational footprint, it can be built close to the industrial areas in order to absorb plastic waste from factories.

-

The government can also provide incentives for commercial waste plastic producers (factories, supermarket, packaging suppliers, etc.) to divert waste from landfill by lowering the tipping rate for pyrolysis facility.

-

The government can subsidy plastic waste logistic to collect waste plastic from waste producers.

-

The government can also provide grants and interest-free loan for companies to improve their waste sorting and management system.

-

Corporate can provide technical support on setting up and operating waste plastic to fuel facilities.

-

Researchers and engineers can improve the efficiency of the system, quality of products, and safety and emission control of the process.

-

Government can provide financial incentives for operators. The government can also encourage its departments and subsidiary to purchase the products (fuel such as diesel).

-

The government can facilitate the application of rules/regulations to encourage the usage of eco-friendly design codes by manufacturers/businesses in order to enhance recycling process performance.

-

The government can provide incentives to improve the share of packaging that can economically be gathered and separated from landfill.

Conclusion

This paper presents an economic analysis of a pyrolysis technology that can be used to recover fuel from waste plastic. The study analysed a case of waste plastic processing facility with a feed rate of 40 tonnes/day. To make the plant more efficient, pyrolysis plus combustion was considered in this study. The economic investigation of the considered waste plastic to fuel plant revealed that pyrolysis of plastic waste has an ROI of 54% which shows that the profit gained out of this investment was more than the cost. The comparatively high operating cash flow margin calculated for the pyrolysis of plastic scrap in this study is evidence of high earnings quality and indicates that the plant is competent at transforming sales to cash. The overall results of this study showed that the determined annual profit for the considered case study was competitive with the capital and variable cost of the proposed plant, and hence, processing plastic waste through pyrolysis is economically viable for a broad range of possible future market circumstances. In future works, the possibility for refining the economics of this process by adapting different outlines and intensifications may be considered.

References

Achilias DS, Roupakias C, Megalokonomos P, Lappas AA, Antonakou EV (2007) Chemical recycling of plastic wastes made from polyethylene (LDPE and HDPE) and polypropylene (PP). J Hazard Mater 149:536–542. https://doi.org/10.1016/j.jhazmat.2007.06.076

Al-Salem SM, Lettieri P, Baeyens J (2009) Recycling and recovery routes of plastic solid waste (PSW): a review. Waste Manag 29:2625–2643. https://doi.org/10.1016/j.wasman.2009.06.004

Australian Energy Regulator (2017) Final decision. Tariff structure statement proposals

Australian New Zealand Standard AS/NZS 4013 (2013) Domestic solid fuel burning appliances—method for determination of flue gas emission https://ablis.business.gov.au/service/vic/australian-new-zealand-standard-as-nzs-4013-domestic-solid-fuel-burning-appliances-method-for-determination-of-flue-gas-emission/38135. Accessed 15 Nov 2018

Bale CW, Belisle E, Chartrand P, Decterov SA, Eriksson G, Hack K, Jung IH, Kang YB, Melançon J, Pelton AD, Robelin C, Petersen S (2009) FactSage thermochemical software and databases—recent developments. Calphad 33:295–311

Bosmans A, Vanderreydt I, Geysen D, Helsen L (2013) The crucial role of waste-to-energy technologies in enhanced landfill mining: a technology review. J Clean Prod 55:10–23. https://doi.org/10.1016/j.jclepro.2012.05.032

Chang Y-M (1996) On pyrolysis of waste tire: degradation rate and product yields. Resour Conserv Recycl 17:125–139. https://doi.org/10.1016/0921-3449(96)01059-2

ElQuliti SAH (2016) Techno-economical feasibility study of waste-to-energy using pyrolysis technology for Jeddah municipal solid waste. Int J Power Eng 7(1):622–635

El-Sheikh AH (2014) Partial pyrolysis of olive wood to improve its sorption of chlorophenols and nitrophenols. Int J Environ Sci Technol 11:1459–1472. https://doi.org/10.1007/s13762-013-0333-x

Frigo S, Seggiani M, Puccini M, Vitolo S (2014) Liquid fuel production from waste tyre pyrolysis and its utilisation in a diesel engine. Fuel 116:399–408. https://doi.org/10.1016/j.fuel.2013.08.044

Ghodrat M, Rhamdhani MA, Brooks G, Masood S, Corder G (2016) Techno economic analysis of electronic waste processing through black copper smelting route. J Clean Prod. https://doi.org/10.1016/j.jclepro.2016.03.033

Ghodrat M, Rhamdhani MA, Brooks G, Rashidi M, Samali B (2017) A thermodynamic-based life cycle assessment of precious metal recycling out of waste printed circuit board through secondary copper smelting. Environ Dev 24:36–49. https://doi.org/10.1016/j.envdev.2017.07.001

Ivanov V, Stabnikov V, Ahmed Z, Dobrenko S, Saliuk A (2015) Production and applications of crude polyhydroxyalkanoate-containing bioplastic from the organic fraction of municipal solid waste. Int J Environ Sci Technol 12:725–738. https://doi.org/10.1007/s13762-014-0505-3

Kang HY, Schoenung JM (2006) Economic analysis of electronic waste recycling: modeling the cost and revenue of a materials recovery facility in California. Environ Sci Technol 40:1672–1680. https://doi.org/10.1021/es0503783

Lang HJ (1947) Cost relationships in preliminary cost estimation. Chem Eng 54:27

Lombardi L, Carnevale E, Corti A (2015) A review of technologies and performances of thermal treatment systems for energy recovery from waste. Waste Manag 37:26–44. https://doi.org/10.1016/j.wasman.2014.11.010

Luz FC, Rocha MH, Lora EES, Venturini OJ, Andrade RV, Leme MMV, del Olmo OA (2015) Techno-economic analysis of municipal solid waste gasification for electricity generation in Brazil. Energy Convers Manag 103:321–337. https://doi.org/10.1016/j.enconman.2015.06.074

Molinos Senante M, Hernández Sancho F, Sala Garrido R (2010) Economic feasibility study for wastewater treatment: a cost–benefit analysis. Sci Total Environ 408:4396–4402. https://doi.org/10.1016/j.scitotenv.2010.07.014

Mutha NH, Patel M, Premnath V (2006) Plastics materials flow analysis for India. Resour Conserv Recycl 47:222–244. https://doi.org/10.1016/j.resconrec.2005.09.003

National Environment Protection (Air Toxics) Measure (2011) as amended, sch 1. https://www.legislation.gov.au/. Details/F2011C00855 archived at https://perma.cc/6KAW-QHNE. Accessed 26 Nov 2018

National Environment Protection Measures, National Environment Protection Council (NEPC) (2016) http://www.nepc.gov.au/nepms archived at https://perma.cc/X5JB-8EB8. Accessed 26 Nov 2018

Panda AK, Singh RK, Mishra DK (2010) Thermolysis of waste plastics to liquid fuel: A suitable method for plastic waste management and manufacture of value added products—a world prospective. Renew Sustain Energy 14:233–248. https://doi.org/10.1016/j.rser.2009.07.005

Perry RH, Green DW, Maloney JO (1999) Perry’s chemical engineers’ platinum edition. McGraw Hill, New York

Peters MS, Timmerhaus KD, West RE, Timmerhaus K, West R (1968) Plant design and economics for chemical engineers. McGraw-Hill, New York

Pickin J, Randell P (2017) Australian national waste report 2016. Department of the Environment and Energy

Rofiqul Islam M, Haniu H, Rafiqul Alam Beg M (2008) Liquid fuels and chemicals from pyrolysis of motorcycle tire waste: Product yields, compositions and related properties. Fuel 87:3112–3122. https://doi.org/10.1016/j.fuel.2008.04.036

Rosato D (2013) Designing with plastics and composites: a handbook. Springer, Berlin

Schoenung JM (1995) Process cost modeling-a summary. In: Smart processing of materials symposium, 27th International SAMPE technical conference, Albuquerque, NM

Seider WD, Seader JD, Lewin DR (2009) Product & process design principles: synthesis, analysis and evaluation (with CD). Wiley, London

Syamsiro M, Saptoadi H, Norsujianto T, Noviasri P, Cheng S, Alimuddin Z, Yoshikawa K (2014) Fuel oil production from municipal plastic wastes in sequential pyrolysis and catalytic reforming reactors. Energy Procedia 47:180–188. https://doi.org/10.1016/j.egypro.2014.01.212

Tabinda AB, Arshed F, Yasar A, Afzaal M, Iqbal A (2018) Comparative analysis of desulphurization methods of tyre pyrolysis oil (TPO). Int J Environ Sci Technol. https://doi.org/10.1007/s13762-018-1898-1

The NSW Environment Protection Authority, Environment Operations (Clean Air) Regulation (2010) https://www.epa.nsw.gov.au/licensing-and-regulation/legislation-and-compliance/acts-administered-by-the-epa/regulation-summaries#poeoca. Accessed 25 Nov 2018

Todd JJ (2006) Determination of particle emissions factors, proposed changes to AS/NZS 4013, http://www.environment.gov.au/resource/proposed-changes-asnzs-4013-%E2%80%93-determination-particle-emissions-factors. Accessed 20 Nov 2018

Wang H, Wang X, Song J, Wang S, Liu X (2018) Uncovering regional energy and environmental benefits of urban waste utilization: A physical input-output analysis for a city case. J Clean Prod 189:922–932. https://doi.org/10.1016/j.jclepro.2018.04.107

Williams EA, Williams PT (1997a) Analysis of products derived from the fast pyrolysis of plastic waste. J Anal Appl Pyrolysis 40–41:347–363. https://doi.org/10.1016/S0165-2370(97)00048-X

Williams EA, Williams PT (1997b) The pyrolysis of individual plastics and a plastic mixture in a fixed bed reactor. J Chem Technol Biotechnol Int Res Process Environ Clean Technol 70:9–20

Xiao R, Jin B, Zhou H, Zhong Z, Zhang M (2007) Air gasification of polypropylene plastic waste in fluidized bed gasifier. Energy Convers Manag 48:778–786. https://doi.org/10.1016/j.enconman.2006.09.004

Zaman AU (2010) Comparative study of municipal solid waste treatment technologies using life cycle assessment method. Int J Environ Sci Technol 7:225–234. https://doi.org/10.1007/BF03326132

Zaman AU (2013) Identification of waste management development drivers and potential emerging waste treatment technologies. Int J Environ Sci Technol 10:455–464. https://doi.org/10.1007/s13762-013-0187-2

Acknowledgements

The authors thank Professor Samali, CIE manager, at Western Sydney University for the financial provision of this project. The authors declare no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Editorial responsibility: Ta Yeong.

Rights and permissions

About this article

Cite this article

Ghodrat, M., Abascall Alonso, J., Hagare, D. et al. Economic feasibility of energy recovery from waste plastic using pyrolysis technology: an Australian perspective. Int. J. Environ. Sci. Technol. 16, 3721–3734 (2019). https://doi.org/10.1007/s13762-019-02293-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-019-02293-8