Abstract

This study monitors the influence of basic automotive paints on plankton and biofilms of selected microorganisms isolated from the wastewater of an automotive factory. Minimum Biofilm Eradication Concentration-High Throughput Plates system was used for the simultaneous tolerance testing. Minimal inhibitory concentration and minimal lethal concentration of the tested substances were determined for both planktonic cells and their biofilms. The resistance level of biofilms was also tested in standard 96 microtiter plates, whereby the results for bacteria and yeasts were confirmed by the fluorescence microscopy. The results were mutually compared for both plankton and biofilms, as well as for plankton and biofilm of the same microorganisms. In no case, the resistance of the planktonic form was higher than the biofilm for the same microorganism. Saccharomyces cerevisiae PMFKG-F7 in the presence of basic color, as well as Rhodotorula mucilaginosa PMFKG-F8 in the presence of the thinner for rinsing paint, shows high sensitivity in planktonic form, whereby the same species are the most resistant in the form of biofilm for the same substances. The highest resistance to all test substances was shown by the biofilm of R. mucilaginosa PMFKG-F8, as well as Candida utilis PMFKG-F9 which was significantly resistant in both tested forms. The obtained results suggest that autochthonous microorganisms that form biofilms can significantly improve the process of removing car paints from the wastewater and being thus new grounds for the development of new biotechnologies.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In the production process, the automotive industry uses a lot of natural sources, especially water, producing in the same time various types of waste (Rivera and Reyes-Carrillo 2014). The primary source of hazardous waste products in the car production plant is the car painting process (Mildenberger and Khare 2000; Rivera and Reyes-Carrillo 2014). By applying the paint with a sprayer, the paint is scattered and collected as a semi-hard, heterogeneous silt (Rivera and Reyes-Carrillo 2014). The European Union laws do not allow sludge to be stored in landfills due to the high content of organic carbon found in colors. The sludge is classified by EU code for waste disposal 080113 and is considered as a waste with hazardous characteristics (Salihoglu and Salihoglu 2016). Incineration of waste paints and varnishes is also not adequate due to the release of volatile substances that have a toxic effect (Cho et al. 2017). Most car colors, excluding those with metal ions, contain elements of organic origin that are susceptible to biological treatment (Ghosh et al. 2015).

New research, related to the degradation of color originating from the wastewater of different branches of industry, was based on the synthesis and characterization of nanoparticles of different oxide metals in photocatalyst and indicate their great potential (Divya et al. 2013; Gnanasekaran et al. 2016; Alhaji et al. 2017; Gnanasekaran et al. 2017; Salehi et al. 2017; Qin et al. 2017; Saravanan et al. 2018a, b; Mohd Adnan et al. 2019). So far, some low-cost materials, like diatomite (Aguedal et al. 2019), different low-cost adsorbents prepared from poplar sawdust (Tezcan Un and Ates 2018), or household wastes like pumpkin seed hulls, eggshells (Зelebi 2019), and walnut shells (Ghazi Mokri et al. 2015) have been investigated as color absorbents. In some research, related to removal of textile wastewater, a new eco-friendly biosorbent was investigated. Biomass of mesophilic and thermophilic lactic acid bacteria from the natural flora of whey (Sofu 2019) or dead fungal biomass Trichoderma harzianum was used (Karthik et al. 2018).

A great number of microorganisms can use everything available from the environment as a nutrient source (Ravikumar et al. 2012). Wastewaters have a lot of organisms that can metabolize certain organic pollutants. A number of papers described the use of microorganisms in the removal of textile colors containing metals (Aksu and Karabayır 2008; Aksu and Balibek 2010; Du et al. 2010, 2012; Ghosh et al. 2014a, b). The role of microorganisms in the decolorization and degradation of synthetic colors is well known and tested (Khan et al. 2013; Ali 2010), and also azo-colors (Sudha et al. 2014; Singh et al. 2015). Some of the fungi isolated from wastewater have showed a different capacity for degradation and decolorization of textile paint (Ali et al. 2016; Karim et al. 2017). The advantage of biological processes is in converting compounds into non-toxic products, using ecological, cheap materials and less energy, as well as using various microorganisms.

The researches about the role of microorganisms—biofilms to be more precise, in auto-color removal is still in the experimental phase. Based on the available literature, it is noticed that, apart from Grujić et al. (2017a), the tolerance of microorganisms in the presence of auto-color has not been examined. Because of the advantages of biological treatments in color removal from industry and insufficiently investigated impacts of autochthonous microorganisms on paint originating from the automotive industry, the aim of our research is to test the tolerance of autochthonous microorganisms, their planktonic cells and biofilms, so that they could later be applied more efficiently in the removal of waste formed by auto-colors.

Materials and methods

Microorganisms, isolation, identification and growth conditions

Microorganisms were isolated from the wastewater of the car manufacturing company (Kragujevac, Serbia). From the bioreaction and recirculation pool, the samples of wastewater were collected in sterile plastic bottles (April 2016) and transferred to the laboratory for microbiology, Faculty of Science in Kragujevac, where the isolation and identification of microorganisms were performed. Pure cultures were obtained by screening the selected isolates by the method of exhaustion.

Nutrient agar and differential and selective substrates were used for the isolation of the bacteria. The identification was carried out using standard biochemical tests. Using the commercial test for the identification of enterobacteria Mikrogen A + B (AlfaMed), the confirmation of isolated enterobacteria was performed. For the isolation of fungi, tryptic soybean agar (TSA) with streptomycin and a pH of 6.5–6.8 was used. The identification was performed using the biochemical API 20 C AUX test (BioMérieux). The identification of pure filamentous fungus cultures was carried out at the unit for Algology, Mycology and Lichenology, at the Institute of Biology and Ecology, Faculty of Science in Kragujevac, based on morphological characteristics and by the application of the fungal identification key.

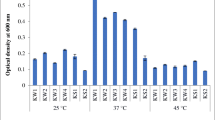

The research was carried out only on the isolated species that form biofilm. Escherichia coli PMFKG-F1, Proteus vulgaris PMFKG-F3, Saccharomyces cerevisiae PMFKG-F7, Rhodotorula mucilaginosa PMFKG-F8, Candida utilis PMFKG-F9, Cladosporium cladosporioides PMFKG-F11, Paecilomyces variotii PMFKG-F12, Penicillium chrysogenum PMFKG-F13 and Penicillium expansum PMFKG-F14 were tested. For testing bacteria and yeasts, tryptic soybean broth (TSB, MossHemoss) (Harrison et al. 2006) was used, while Sabouraud dextrose broth (SAB, MossHemoss) was used for filamentous fungi. Suspension of microorganisms was made by the direct colony method. The turbidity of the suspension was adjusted using a densitometer (DEN-1, Biosan, Latvia), McFarland 1.0 so that it corresponds to 108 CFU/mL (colony-forming unit per milliliter) for bacteria and 106 CFU/mL for yeasts. Suspensions of fungal spores were rinsed with sterile distilled water, used to determine turbidity spectrophotometrically at 530 nm, and were then further diluted to approximately 106 CFU/mL according to the procedure recommended by National Committee for Clinical Laboratory Standards, NCCLS (1998).

Tested substances

The tested substances are the primary colors of the automotive industry. The review of the tested substances and their labels is given in Table 1. Safety data sheets of all tested paints, with detailed composition/information on ingredients (section “Results and discussion”), are attached to Online Resource. Commercial paints are tested in different concentrations. Concentrated solutions in sterile glass bottles were made. Paints as a liquid were dissolved in a TSB and SAB liquid medium up to certain concentrations. The solutions were prepared on the experiment set date. Preliminary tests were carried out, with a concentration range selected. The highest tested concentration was double diluted to the lowest applied concentration. For plankton, the concentration range was 10–0.15 μL/mL, while for biofilm it was 1000–15.15 μL/mL. From the range of test substances, it is noted that the biofilm, in relation to its planktonic cells, shows significantly higher resistance to the tested substances.

Testing the resistance of planktonic cells and biofilms

The resistance of biofilm and its planktonic cells to the influence of tested substances was examined by the Minimum Biofilm Eradication Concentration-High Throughput Plates (MBEC™-HTP, BioProducts) according to the instructions described by Ceri et al. (1999). Two hundred microliters of medium and 20 μL of microorganism suspension were added to each well of the plate which corresponded to the 96-peg lid. After a period of incubation at 26 °C, the planktonic cells in the nutrient medium, as well as the biofilm formed on the pegs, were used to test the resistance in the presence of different concentrations of the tested substances. The lid with the pegs and the formed biofilm were transferred to the plate with the tested substances.

During the incubation period, some of the cells will not enter into the formation process and the biofilm composition. These cells retain their planktonic phenotype and thus are exposed to the influence of the tested substances. The growth that is recognized as a blur, in any well of the plate, shows that the plankton cells have survived testing. In this plate (challenge plate), the minimum inhibitory concentration (MIC) inhibits the growth of 50% of the cells, and the minimal lethal concentration (MLC) kills 90–100% of the cells, which is detected by the absence of turbidity when reading on an ELISA reader, OD650 (Rayito, China).

After the exposure time of the transferred biofilm to the tested substances (24 h and 48 h for bacteria; 48 h and 72 h for yeasts; 72 h and 94 h for filamentous fungi), the peg lid was removed and washed with 0.9% sterile saline, after which the lid was transferred to a new fresh medium (200 μL per well). The plate was exposed to ultrasonic waves (Aquasonic 250 HT Ultrasonic Cleaner, VWR International, Radnor, PA, USA), which removed the biofilm from the pegs into each well. The minimum inhibitory concentration (MICb) and the minimum lethal concentration (MLCb) of biofilms were determined by spectrophotometric readings on the ELISA reader, OD650.

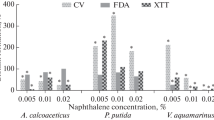

The formation of biofilms and the degree of tolerance to the tested substances were confirmed in polystyrene microtiter plates with 96 wells (SARSTEDT, Belgrade) according to the described method by Adam et al. (2002) with certain modifications. One hundred microliters of medium and 10 μL of suspension of microorganisms were added into plates. The plates were then placed in an incubator at 26 °C for 24 h for bacteria, 48 h for yeasts and 72 h for filamentous fungi. After the incubation period, the tested substances were added on the formed biofilms and their influence was monitored (24 h and 48 h for bacteria, 48 h and 72 h for yeasts, 72 h and 94 h for filamentous fungi). The quantification was determined using a crystal violet (CV) assay by Almeida et al. (2011) with certain modifications. After incubation the content from the plates was removed and 50 μL of methanol 98% (vol/vol) was added. Fifteen minutes later, the methanol content was removed, and the plates were allowed to dry at room temperature. Then, 50 μL of CV was added for 5 min and washed three times with distilled water and then 100 μL of glacial acetic acid of 33% (vol/vol) was added. The plates were read on an ELISA reader at OD650. All the tests were performed in duplicate, and the MICs and MLCs were constant.

Fluorescence microscopy

Fluorescence microscopy was used to visualize the impact of tested substances on biofilms for bacteria and yeasts (Harrison et al. 2006). The influence of the tested substances on bacterial biofilm was monitored after 48 h and yeast biofilms after 72 h. The plates with tested biofilms were washed with a sterile saline solution to remove the medium and the non-adherent cells. The fixation of biofilm was performed with methanol (30 min to 1 h at 30 °C), and washing was done with a sterile saline solution. The biofilms were treated with a suitable fluorescent dye, SYTO 9 and ConA-Texas Red (Molecular Probes) and monitored on the Olympus BX51 fluorescent microscope (Olympus, Shinjuku, Tokyo, Japan) and analyzed using the Cytovision 3.1 software package (Applied Imaging Corporation, Santa Clara, California, USA).

Results and discussion

Resistance of planktonic cells and biofilms in the presence of tested substances

The level of tolerance of planktonic cells and biofilms in the presence of tested substances was investigated by determining the minimum inhibitory concentration (MIC) and minimum lethal concentration (MLC). The obtained results are shown in Tables 2 and 3. From the preliminary testing of the concentration range, it can be noted that the planktonic form of the treated microorganisms was more sensitive to the action of the test substances compared to their formed biofilm, and this rule has not been distorted throughout the whole examination. There was no case of a higher resistance of the planktonic form compared to the biofilm for the same microorganism.

When comparing plankton-tested microorganisms, the highest resistance in the presence of test substances 1 and 2 was shown by C. utilis (MICp-5 μL/mL; 10 μL/mL) and in the presence of test substances 2 and 3 by E. coli PMFKG-F1 (MICp-5 μL/mL; 0.62 μL/mL) as well as R. mucilaginosa PMFKG-F8 (MICp-0.62 µL/mL) in the presence of test substance 3. Plankton C. cladosporioides PMFKG-F11 (MICp-5 μL/mL; 10 μL/mL) showed the greatest resistance in the presence of test substances 4 and 5, whereas P. expansum PMFKG-F14 (MICp-0.62 μL/mL) and P. variotii PMFKG-F12 (MICp-0.62 μL/mL) as plankton were also resistant in the presence of test substance 4, whereby this resistance is significantly lower than in C. cladosporioides PMFKG-F11.

When comparing the biofilms of the tested microorganisms, the most resistant in the presence of test substances 1 and 2 was R. mucilaginosa PMFKG-F8 (MICb-125 μL/mL; 62.5 μL/mL) while S. cerevisiae PMFKG-F7 (MICb-62.5 μL/mL) was substantially resistant to the presence of test substance 1. In the presence of test substance 3, the biofilm of almost all tested strains showed exceptional resistance (MICb 31.25-62.5 μL/mL), with the most resistant biofilms of E. coli PMFKG-F1 and C. utilis PMFKG-F9 (MICb-125 μL/mL). Biofilms of E. coli PMFKG-F1, P. vulgaris PMFKG-F3, R. mucilaginosa PMFKG-F8, P. chrysogenum PMFKG-F13 were the most resistant in the presence of test substance 4 (MICb-62.5 μL/mL), while in the presence of a test substances 5 R. mucilaginosa PMFKG-F8 biofilm was the most resistant (MICb-125 μL/mL).

The organisms in the planktonic form were the most sensitive to test substance 3 (MIC ranged < 0.08–0.62 μL/mL) and the most resistant to test substance 2 (MIC at 0.31–10 μL/mL), while there was no such difference in biofilm forms. (For all test substances for most microorganisms, MIC is from 7.81 to 62.5; 125 μL/mL.) The most resistant, equally to all test substances, was the biofilm of R. mucilaginosa PMFKG-F8 (MICb-62.5; 125 μL/mL), and C. utilis PMFKG-F9, which was significantly resistant to both tested forms.

Fluorescence microscopy

The influence of the tested substances on the biofilms of the selected microorganisms (bacteria and yeasts) was confirmed by fluorescence microscopy. The results are shown in Figs. 1, 2, 3, 4 and 5.

The results noted on the fluorescence microscope coincide with the results of the obtained values for MLCb (Tables 2 and 3). In the figures, MLCb is estimated as a concentration that causes a lethal effect on the test organism (Andrews 2001). The results of fluorescence microscopy also show that the color of the ConA-Texas Red that colors the extracellular matrix in red was not observed during the microscopy of the biofilm S. cerevisiae PMFKG-F7, in the presence of test substance 1, meaning it did not produce EPS (Fig. 1g). The same results were obtained for the biofilms of R. mucilaginosa PMFKG-F8, C. utilis PMFKG-F9, S. cerevisiae PMFKG-F7 in the presence of the test substance 5 (Fig. 5e, f, g).

The validation of biofilm sensitivity results from a fluorescence microscope was carried out by the authors who monitored the impact of heavy metals on individual and mixed biofilms of some bacteria and yeasts (Buzejić et al. 2016; Grujić et al. 2017b, c), as well as the influence of car colors on individual biofilms of bacteria and yeasts (Grujić et al. 2017a). Similarly, in this study, the results obtained by reading the MLCb by using the MBEC-HTP device and by reading the ELISA reader (OD650) were confirmed by this method.

A high degree of biofilm resistance in relation to planktonic cells can be explained by the matrix as the main protective component that cells produce in order to increase the degree of protection against various adverse effects, especially antimicrobial agents (Corning 2002; Høiby et al. 2010; Flemming et al. 2016). Extracellular polymeric substances (EPS) represent the primary structural component and affect the physical properties of biofilm (stabilization and protection of the microenvironment). In addition, the activity of cells within the biofilm can be enhanced by the production of EPS (Decho 2000). Within the biofilm, there are also various physical, physiological and genetic processes that allow microorganisms to develop better tolerance mechanisms that provide them with the resistance to negative effects (Harrison et al. 2007). The physiology of biofilm differs from the physiology of planktonic forms, with biofilm about 600 times more resistant to the effects of stressors (Harrison et al. 2006). It is more resistant to the effects of antimicrobial agents than its planktonic cells due to the existence of a metabolic difference or the existence of persist cells within the biofilm (Harrison et al. 2005), which can explain the highest sensitivity of planktonic S. cerevisiae PMFKG-F7 in the presence of a test substance 1, or R. mucilaginosa in the presence of test substance 2, with the same species within the biofilm being the most resistant to the same substances.

Similar results were obtained in Grujić et al. (2017a), where E. coli PMFKG-F2, P. mirabilis PMFKG-F4 and S. cerevisiae PMFKG-F6 biofilms showed notable resistance in the presence of test substance 3, in contrast to their planktonic cells which showed great sensitivity. Flemming (2016) states that the interior of biofilm has dynamic and synergistic interactions that involve the exchange of genes, resulting in the development of multicellular properties, which can explain the difference in the biofilm and planktonic cell resistance. Successful way of life of microbes, within the framework of biofilm, is also related to the creation of new structures, activities and traits that occur during the biofilm formation process in new conditions, but also as a result of self-organizing cells within the biofilm (Corning 2002).

Specificity in the study was shown by P. variotii whose planktonic cells were shown to be one of the more resistant and, on the other hand, P. variotii biofilm was one of the most sensitive when compared to other tested microorganisms in the presence of test substances 4 and 5. This phenomenon may be conditioned by the EPS chemical properties in the biofilm of the microorganism itself (Decho 2000), with small changes in functional groups being able to change the properties of EPS (Potts 1994). It may be assumed that during the exposure of P. variotii biofilm to the effects of test substances 4 and 5, these substances would cause certain changes in EPS that lead to lower biofilm resistance.

Conclusion

The results suggest that autochthonous microorganisms that had the ability to form biofilms are generally more resistant to the presence of auto-color in the form of biofilm, compared to planktonic form of the same microorganism. S. cerevisiae PMFKG-F7 in the presence of basic color, as well as R. mucilaginosa PMFKG-F8 in the presence of thinner for rinsing paint in planktonic form exhibited high sensitivity, with the same species being the most resistant in the form of biofilm for the same substances. The highest resistance to all tested substances was shown by the biofilm of R. mucilaginosa PMFKG-F8, while C. utilis PMFKG-F9 was significantly resistant in both tested forms. Based on the data on microorganisms inhabiting a certain environment, as well as on the basis of detoxification mechanisms used by microorganisms in the framework of biofilm, it should be possible to develop an efficient, ecologically and economically suitable biotechnology process for the removal of the automotive paints from the wastewaters. Based on the results from our research, it could be concluded that natural strains of microorganisms need to be investigated, because they can be a natural barrier for pollution and toxic material originated from car industry.

References

Adam B, Baillie GS, Douglas LJ (2002) Mixed species biofilms of Candida albicans and Staphylococcus epidermidis. J Med Microbiol 51(4):344–349. https://doi.org/10.1099/0022-1317-51-4-344

Aguedal H, Iddou A, Aziz A, Shishkin A, Ločs J, Juhna T (2019) Effect of thermal regeneration of diatomite adsorbent on its efficacy for removal of dye from water. Int J Environ Sci Technol 16:113–124. https://doi.org/10.1007/s13762-018-1647-5

Aksu Z, Balibek E (2010) Effect of salinity on metal-complex dye biosorption by Rhizopus arrhizus. J Environ Manage 91(7):1546–1555. https://doi.org/10.1016/j.jenvman.2010.02.026

Aksu Z, Karabayır G (2008) Comparison of biosorption properties of different kinds of fungi for the removal of Gryfalan Black RL metal-complex dye. Bioresour Technol 99(16):7730–7741. https://doi.org/10.1016/j.biortech.2008.01.056

Alhaji MH, Sanaullah K, Khan A, Hamza A, Muhammad A, Ishola MS, Rigit ARH, Bhawani SA (2017) Recent developments in immobilizing titanium dioxide on supports for degradation of organic pollutants in wastewater—a review. Int J Environ Sci Technol 14:2039–2052. https://doi.org/10.1007/s13762-017-1349-4REVIEW

Ali H (2010) Biodegradation of synthetic dyes—a review. Water Air Soil Pollut 213(1–4):251–273

Ali HM, Shehata SF, Ramadan KMA (2016) Microbial decolorization and degradation of crystal violet dye by Aspergillus niger. Int J Environ Sci Technol 13:2917–2926. https://doi.org/10.1007/s13762-016-1117-x

Almeida C, Azevedo NF, Santos S, Keevil CW, Vieira MJ (2011) Discriminating multi-species populations in biofilms with peptide nucleic acid fluorescence in situ hybridization (PNA FISH). PLoS ONE 8(6):10–1371. https://doi.org/10.1371/journal.pone.0014786

Andrews JM (2001) Determination of minimum inhibitory concentrations. J Antimicrob Chemother 48:5–16

Buzejić A, Grujić S, Radojević I, Ostojić A, Lj Čomić, Vasić S (2016) Pb and Hg heavy metal tolerance of single- and mixed species biofilm (Rhodotorula mucilaginosa and Escherichia coli). Kragujevac J Sci 38:115–124. https://doi.org/10.5937/KgJSci1638115B

Çelebi H (2019) The applicability of evaluable wastes for the adsorption of Reactive Black 5. Int J Environ Sci Technol 16:135–146. https://doi.org/10.1007/s13762-018-1969-3

Ceri H, Olson ME, Stremick C, Read RR, Morck D, Buret A (1999) The Calgary biofilm device: new technology for rapid determination of antibiotic susceptibilities of bacterial biofilms. J Clin Microbiol 37(6):1771–1776

Cho M, Kim KH, Szulejko JE, Dutt T, Jo SH, Lee MH, Lee SH (2017) Paint booth volatile organic compounds emissions in an urban auto-repair center. Anal Sci Technol 30(6):329–337

Corning PA (2002) The re-emergence of “emergence”: a venerable concept in search of a theory. Complexity 7:18–30. https://doi.org/10.1002/cplx.10043

Decho AW (2000) Microbial biofilms in intertidal systems: an overview. Cont Shelf Res 20:1257–1273. https://doi.org/10.1016/S0278-4343(00)00022-4

Divya N, Bansal A, Jana AK (2013) Photocatalytic degradation of azo dye Orange II in aqueous solutions using copper-impregnated titania. Int J Environ Sci Technol 10:1265–1274. https://doi.org/10.1007/s13762-013-0238-8

Du LN, Yang YY, Li G, Wang S, Jia XM, Zhao YH (2010) Optimization of heavy metal-containing dye Acid Black 172 decolorization by Pseudomonas sp. DY1 using statistical designs. Int Biodeterior Biodegrad 64(7):566–573. https://doi.org/10.1016/j.ibiod.2010.06.009

Du LN, Wang B, Li G, Wang S, Crowley DE, Zhao YH (2012) Biosorption of the metal-complex dye Acid Black 172 by live and heat-treated biomass of Pseudomonas sp. strain DY1: kinetics and sorption mechanisms. J Hazard Mater 205:47–54. https://doi.org/10.1016/j.jhazmat.2011.12.001

Flemming HC, Wingender J, Szewzyk U, Steinberg P, Rice SA, Kjelleberg S (2016) Biofilms: an emergent form of bacterial life. Nat Rev Microbiol 14:563–575. https://doi.org/10.1038/nrmicro.2016.94

Ghazi Mokri HS, Modirshahla N, Behnajady MA, Vahid B (2015) Adsorption of C.I. Acid Red 97 dye from aqueous solution onto walnut shell: kinetics, thermodynamics parameters, isotherms. Int J Environ Sci Technol 12:1401–1408. https://doi.org/10.1007/s13762-014-0725-6

Ghosh A, Dastidar MG, Sreekrishnan TR (2014a) Bioremediation of chromium complex dye (Acid Orange 86) by Aspergillus flavus. Int J Appl Eng Res 9(1):35–40. https://doi.org/10.1002/ceat.201500515

Ghosh A, Dastidar MG, Sreekrishnan TR (2014b) Biosorption and biodegradation of chromium complex dye using Aspergillus species. J Hazard Toxic Radioact Waste 18(4):1–9. https://doi.org/10.1061/(ASCE)HZ.2153-5515.0000230

Ghosh A, Dastidar MG, Sreekrishnan TR (2015) Recent advances in bioremediation of heavy metals and metal complex dyes: review. J Environ Eng 142(9):C4015003. https://doi.org/10.1061/(ASCE)EE.1943-7870.0000965

Gnanasekaran L, Hemamalini R, Saravanan R, Ravichandran K, Gracia F, Gupta VK (2016) Intermediate state created by dopant ions (Mn, Co and Zr) into TiO2 nanoparticles for degradation of dyes under visible light. J Mol Liq 223:652–659

Gnanasekaran L, Hemamalini R, Saravanan R, Ravichandran K, Gracia F, Agarwald S, Gupta VK (2017) Synthesis and characterization of metal oxides (CeO2, CuO, NiO, Mn3O4, SnO2 and ZnO) nanoparticles as photo catalysts for degradation of textile dyes. J Photochem Photobiol B 173:43–49

Grujić SM, Radević SD, Radojević ID, LjR Čomić, Ostojić AM (2017a) Difference in influence of commercial industrial paints on microbial biofilms and planktonic cells. Kragujevac J Sci 39:145–156. https://doi.org/10.5937/KgJSci1739145G

Grujić S, Vasić S, Radojević I, Lj Čomić, Ostojić A (2017b) Comparison of the Rhodotorula mucilaginosa biofilm and planktonic culture on heavy metal susceptibility and removal potential. Water Air Soil Pollut 228:73. https://doi.org/10.1007/s11270-017-3259-y

Grujić S, Vasić S, Lj Čomić, Ostojić A, Radojević I (2017c) Heavy metal tolerance and removal potential in mixed-species biofilm. Water Sci Technol 76(4):806–812. https://doi.org/10.2166/wst.2017.248

Harrison JJ, Ceri H, Roper NJ, Badry EA, Sproule KM, Turner RJ (2005) Persister cells mediate tolerance to metal oxyanions in Escherichia coli. Microbiology 151(10):3181–3195. https://doi.org/10.1099/mic.0.27794-0

Harrison JJ, Rabiei M, Turner RJ, Badry EA, Sproule KM, Ceri H (2006) Metal resistance in Candida biofilms. FEMS Microbiol Ecol 55(3):479–491. https://doi.org/10.1111/j.1574-6941.2005.00045.x

Harrison JJ, Ceri H, Turner RJ (2007) Multimetal resistance and tolerance in microbial biofilms. Nat Rev Microbiol 5(12):928–938. https://doi.org/10.1038/nrmicro1774

Høiby N, Bjarnsholt T, Givskov M, Molin S, Ciofu O (2010) Antibiotic resistance of bacterial biofilms. Int J Antimicrob Agents 35(4):322–332. https://doi.org/10.1016/j.ijantimicag.2009.12.011

Karim E, Dhar K, Hossain T (2017) Co-metabolic decolorization of a textile reactive dye by Aspergillus fumigatus. Int J Environ Sci Technol 14:177–186. https://doi.org/10.1007/s13762-016-1136-7

Karthik V, Saravanan K, Patra C, Ushadevi B, Vairam S, Selvaraju N (2018) Biosorption of acid yellow 12 from simulated wastewater by non-viable T. harzianum: kinetics, isotherm and thermodynamic studies. Int J Environ Sci Technol. https://doi.org/10.1007/s13762-018-2073-4

Khan R, Bhawana P, Fulekar MH (2013) Microbial decolorization and degradation of synthetic dyes: a review. Rev Environ Sci Biol 12(1):75–97. https://doi.org/10.1007/s11157-012-9287-6

Mildenberger U, Khare A (2000) Planning for an environment-friendly car. Technovation 20(4):205–214

Mohd Adnan MA, Muhd Julkapli N, Amir MNI, Maamor A (2019) Effect on different TiO2 photocatalyst supports on photodecolorization of synthetic dyes: a review. Int J Environ Sci Technol 16:547–566. https://doi.org/10.1007/s13762-018-1857-x.REVIEW

NCCLS (National Commitee for Clinical Laboratory Standards) (1998) Reference method for broth dilution antifungal susceptibility testing of conidium-forming filamentous fungi: proposed Standard M38-P. Wayne PA, USA

Potts M (1994) Desiccation tolerance of prokaryotes. Microbiol Rev 58:755–805

Qin J, Yang C, Cao M, Zhang X, Rajendran S, Limpanart S, Ma M, Liu R (2017) Two-dimensional porous sheet-like carbon-doped ZnO/g-C3N4 nanocomposite with high visible-light photocatalytic performance. Mater Lett 189:156–159

Ravikumar HR, Rao SS, Karigar CS (2012) Biodegradation of paints: a current status. Indian J Sci Technol 5(1):1977–1987

Rivera JL, Reyes-Carrillo T (2014) A framework for environmental and energy analysis of the automobile painting process. Proc CIRP 15:171–175. https://doi.org/10.1016/j.procir.2014.06.022

Salehi K, Bahmani A, Shahmoradi B, Pordel MA, Kohzadi S, Gong Y, Guo H, Shivaraju HP, Rezaee R, Pawar RR, Lee S-M (2017) Response surface methodology (RSM) optimization approach for degradation of Direct Blue 71 dye using CuO–ZnO nanocomposite. Int J Environ Sci Technol 14:2067–2076

Salihoglu G, Salihoglu NK (2016) A review on paint sludge from automotive industries: generation, characteristics and management. J Environ Manage 169:223–235. https://doi.org/10.1016/j.jenvman.2015.12.039

Saravanan R, Aviles J, Gracia F, Mosquera E, Gupta VK (2018a) Crystallinity and lowering band gap induced visible lightphotocatalytic activity of TiO2/CS (Chitosan) nanocomposites. Int J Biol Macromol 109:1239–1245

Saravanan R, Manoj D, Qin J, Naushad Mu, Gracia F, Lee AF, Khan MM, Gracia-Pinilla MA (2018b) Mechanothermal synthesis of Ag/TiO2 for photocatalytic methylorange degradation and hydrogen production. Process Saf Environ 120:339–347

Singh S, Chatterji S, Nandini PT, Prasad ASA, Rao KVB (2015) Biodegradation of azo dye Direct Orange 16 by Micrococcus luteus strain SSN2. Int J Environ Sci Technol 12:2161–2168. https://doi.org/10.1007/s13762-014-0588-x

Sofu A (2019) Investigation of dye removal with isolated biomasses from whey wastewater. Int J Environ Sci Technol 16:71–78. https://doi.org/10.1007/s13762-018-1977-3

Sudha M, Saranya A, Selvakumar G, Sivakumar N (2014) Microbial degradation of azo dyes: a review. Int J Curr Microbiol Appl Sci 3(2):670–690

Tezcan Un U, Ates F (2018) Low-cost adsorbent prepared from poplar sawdust for removal of disperse orange 30 dye from aqueous solutions. Int J Environ Sci Technol. https://doi.org/10.1007/s13762-018-1716-9

Acknowledgements

This investigation was supported by the Ministry of Education, Science and Technological Development of the Republic of Serbia, grant No. III 41010.

Author information

Authors and Affiliations

Corresponding author

Additional information

Editorial responsibility: R Saravanan.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Radojević, I.D., Grujić, S.M., Ranković, B.R. et al. Single-species biofilms from autochthonous microorganisms: biotechnological potential in automotive wastewater treatment. Int. J. Environ. Sci. Technol. 16, 6189–6198 (2019). https://doi.org/10.1007/s13762-019-02265-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-019-02265-y