Abstract

The pollution of groundwater by organic or inorganic pollutants, originating from either soil leaching or anthropogenic activities, is one of the major environmental issues. Remediation of this water source is of highest priority because many countries use it for drinking purpose. Pump-and-treat method is represented for many decades the major technique to treat groundwater infected with organic/inorganic pollutants. In last two decades, this technique becomes to be in lack with the sense of modern concepts of sustainability and renewable energy. Permeable reactive barriers (PRBs) technology was introduced as an alternative method for traditional pump-and-treat systems to remediate contaminated groundwater that was achieving these concepts. Within this issue, this technology has been proven to be a successful and most efficient promising method used by many researchers and in several projects due to its direct and simple techniques to remediate groundwater. A rapid progress from bench scale to field scale implementation in the PRB technique is recognized through the last few years. In addition, this technique was modeled theoretically for characterizing the migration of contaminants spatially and temporally through the barrier and, consequently, these models can be used for estimating the longevity of this barrier. An overview of this technique and the promising horizons for scientific research that integrates this method with sustainability and green technology practices are presented in the present study.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

There had been a sustained obsession (premonition) about developing new strategies to reduce the effects of civil activities on environment. These activities have a deep effect on the life and health of humans. Many efforts have been made to understand the size and dimensions of this problem in the field of the conservation of water resources and then solve the problem or at least prevent deterioration of the case. One of the most widespread problems in this field is water pollution with inorganic and/or organic pollutants, which are associated with many industrial activities such as metal processing, mining, power generation, electroplating, and pigments (Hashim et al. 2011).

Efforts to prevent the harmful effects of these metals are varied according to the characteristics of the contaminated field elements. In general, the source of the contamination in groundwater is either external (spills, leakages and recharges of contaminants into the soil) or internal due to natural geogenic processes (leaching of contaminants from soil during water flow such as in mining process) (Zaporozec 1981).

Groundwater, which is the water found beneath the surface of the ground and seeped down from the surface by migration through the soil matrix and spaces in geologic formations, is generally more reliable for use than surface water (Bear 1979). It is vital because approximately 2 billion people directly depend upon aquifers for drinking water, and 40% of the world’s food production depended on the irrigation by groundwater (Thiruvenkatachari et al. 2008). Studies by the USEPA proved that the pump-and-treat technology (pump the water and treat it at the surface) is not effective in the long-term restoration of contaminated groundwater. Accordingly, PRBs technology was introduced as an alternative method for treating this water and has been proven to be a successful and most efficient promising technology used extensively by many researchers in many projects.

Simultaneously, and especially since the beginning of the present century, efforts have been made to integrate the concept of sustainability and green technology practices, which is considered a key design element in all treatment strategies by regulatory agencies (ITRC 2011). USEPA called for implementing the best management practices (BMPs) program for green remediation that defines “sustainable practices” as cleanups processes that minimize the environmental and energy footprint of actions taken during a project life. In other words, “green remediation” can be defined as the considering all environmental effects of cleanup actions and incorporating options to minimize the environmental footprints of cleanup actions (USEPA 2012).

Definition and growth of PRB

PRBs are formerly defined according to the USEPA as follows:

an emplacement of reactive materials in the subsurface designed to intercept a contaminant plume, provide a flow path through the reactive media, and transform the contaminant(s) into environmentally acceptable forms to attain remediation concentration goals down gradient of the barrier.

The PRBs was put forth when high interest prevailed among researchers to find cost-effective and sustainable remedy strategies to solve water and soil pollution problems through power consumption, materials, and labor efforts. These promising strategies have been highlighted as passive methods. Passive methods are defined as “the deliberate improvement of water quality using only naturally available energy sources (e.g. gravity, microbial metabolic energy, photosynthesis), in systems which require only infrequent (albeit regular) maintenance in order to operate effectively over the entire system design life” (Younger 2007). An open channel filled with limestone called limestone open channel or limestone flumes was one of the first of these methods used to treat acid mine drainage metals. Pearson and Potter (1989) introduced this method to treat toxic heavy metals from copper mine drainage at an isolated, subalpine site in Northern California. This system was combined with the classical active method and somewhat passive method by constructing limestone flumes in the last part of the project to neutralize effluents that spilt into flume as filter basin. This passive method was found to be a more efficient and highly durable in various climate situations, in addition to its low costs.

Subsequently, these types of remediation techniques became rapidly popular due to their attractive benefits. As an extension to limestone open channel, limestone drains were introduced by dredging drains filled with limestone to treat contaminated water and drain it to groundwater in a passive manner. Brodie et al. (1991) attempted to assess the early experiment projects for use in several sites throughout the USA and suggested design criteria for constructing limestone drains. After that, many studies were conducted focusing on this method of treating acid mine drainage on both the directions of surface water and groundwater (Hedin and Nairn 1992; Skousen and Faulkner 1992; Watzlaf and Hedin 1993; Hedin et al. 1994; Skousen et al. 1995).

Particularly, in shallow unconfined groundwater aquifers, passive remedy methods were performed in the form of what came to be later known as permeable reactive barriers (PRBs). Simply, this formation contains a medium of geochemically suitable material that intercepts the direction of the contaminated groundwater in the form of a filter wall, which improves the water quality due to beneficial (bio)geochemical reactions in a passive manner (Younger 2007). The PRBs have typical dimensions of <5 m in width (parallel to flow), 10 m in depth, and 50 m in length (transverse to flow), and these barriers are filled with reactive media. Inert media such as sand can be mixed with reactive materials to improve the hydraulic behavior of this barrier (Henderson and Demond 2007).

Longmire et al. (1991) performed a set of batch tests to examine a mixture of tailing material, deionized water, sphagnum beat, calcium carbonate, and hydrated lime as reactive materials for binding and fixing some contaminant minerals such as As, Mo, NO3, and U(VI). A geochemical barrier from this mixture was introduced to treat uranium tailing leachate at Gunnison, Colorado, and a successful decrease in the contaminant concentrations was achieved.

At this stage, a permeable reactive passive barrier was developed, which was also identified using many other terms such as chemical barriers (Morrison and Spangler 1993), permeable in situ treatment wall (Gillham and Burris 1992), in situ permeable reactive wall (Gillham and O’Hannesin 1994), in situ treatment curtains (Starr and Cherry 1994), porous permeable reactive walls (Blowes et al. 1995), porous reactive walls (Blowes et al. 1997), permeable treatment beds (Cheremisinoff 1997), reactive walls (Warner et al. 1998), and groundwater treatment walls (Finkel et al. 1998). In addition, more specific names have been used such as denitrification barriers (Robertson and Cherry 1995), reactive iron walls (Focht et al. 1996), subsurface microbial barriers (Tucker 1996), in situ iron walls (O’Hannesin and Gillham 1998), sorbing vertical barriers (Rabideau et al. 2001), and passive biobarrier system (Shashidhar et al. 2007).

Configurations and techniques of PRB

PRBs can be achieved as replaceable, semipermanent, or permanent units. Continuous wall or curtain is the basic configuration of barriers that stands up and transversely faces the direction of the contaminant front. The advantages of this configuration are they: rely on conventional methods of installation, are easy to conceptualize, creating fewer disturbances to the natural groundwater flow pattern, and can be constructed using relatively simple design methods. Furthermore, their effectiveness has been documented in the literature (Dwyer et al. 1996; Gavaskar 1999; Hocking and Well 2002; Mountjoy et al. 2003).

Starr and Cherry (1994) introduced the term “funnel and gate” which its concept was first mentioned by McMurtry and Elton (1985) and sometime used interchangeably with PRBs; however, funnel and gate configuration consisted of impermeable walls that directed groundwater to the reactive middle gate or panel.

The election between these two configurations is based on the characteristics of the reactive medium and site. Expensive reactive materials use funnel and gate configuration to restrict the relatively high construction costs, when compared to continuous barriers (Thiruvenkatachari et al. 2008). Furthermore, the adoption of funnel and gate configuration promotes the use of double or multi-reactive barriers for multi-action, improving the efficiency of treatment for more than one type of contaminants (Conca et al. 2002).

Day et al. (1999) presented a special type of funnel and gate, which uses a buried vessel to contain the reactive materials in removable/replaceable “cassettes.” The cassette system permitted the regular removal and replacement of the reactive material and/or maintenance of the system without excavating and removing the vessel. Furthermore, Elder (2000) achieved groundwater flow through reactive barrier set vertically upward inside caisson formation to more shallow level that assisted in obtaining more uniform flow and easy monitoring of the flow. This configuration is known as caisson PRB (Elder 2000; Courcelles 2012).

USDOE (2002) modified an existing funnel and gate PRB to improve its operation by bringing the effluent through vertical well and in a siphoned manner to zero-valent iron (ZVI) treatment vessel, so that there is no remediation in the path till the effluent reaches the vessel, which draws out the treated water finally to the drain field. This configuration was termed as trench permeable reactive barrier (TPRB). However, the trench was meant for groundwater transfer only and there was no treatment effort through it (Lee et al. 2007). A similar technique used passive groundwater capture and treatment by reactor cells in the remediation process (Thiruvenkatachari et al. 2008). A GeoSiphone™/GeoFlow technology introduced the same technique by utilizing the natural hydraulic gradient between two locations to enhance water flow carrier with plume. This flow was directed toward the cell containing the reactive material, which intercepted with contaminant front to complete the treatment process (Lee et al. 2007). Hudak (2010) suggested longitudinal reactive barriers instead of transverse barriers with respect to groundwater flow direction and modeled this configuration. The author concluded that longitudinal trenches are suitable choice for narrow contaminant plumes moved with flow in low velocities.

As an advancement in this technology, development of undredged reactive barriers that can be suitable for remediation of deep groundwater contaminant plume or confined aquifers was introduced. Istok et al. (1999) and Fruchter et al. (2000a) established an in situ treatment technique to create subsurface permeable reactive zone inside the deep or confined aquifer by injecting treatment reagent using injection non-discharge wells. This system was called “in situ redox manipulation (ISRM)” and was developed and applied at the Hanford disposal pond site in the Washington State to achieve the required treatment. Non-excavation techniques such as deep soil mixing (Gavaskar 1999), hydraulic fracturing, or in situ redox manipulation (ISRM) (Fruchter et al. 2000b) were used for installation of PRBs at greater depths.

Another similar most recent technique is to create virtual PRBs (vPRBs) using quasi-passive in situ groundwater circulation well system, GCW. An in situ vPRB is located within the groundwater contamination plume in combination with overlapped circulation cells; this generates effective hydraulic control within the aquifer through large-diameter spherical capture zone. The polluted water is captured by this system and treated within the aquifer in the well. Several studies have focused on this type of remediation to improve the role of PRB in treating the wider range of pollutants such as dense non-aqueous phase liquids (DNAPLs) with less expensive and more efficient technique in comparison with pump-and-treat system (Ryan et al. 2000; Henry et al. 2002; Jackson 2002; Elmore and Graff 2002).

Furthermore, electrokinetic (EK) concepts have been recently integrated to the PRB technology to improve its functions in groundwater remediation. This process is able to remove contaminants from low-permeable media; thus, the EK process can be used to overcome clogging problems in the PRB due to precipitation reactions (Weng 2009). In addition, Chung and Lee (2007) investigated the potential application of atomizing slag used as reactive material for RPB in combination with EK for removal of inorganic or organic pollutants from the contaminated groundwater. The results indicated that the applied configuration increased the removal rate of cadmium due to electromigration mechanism. In other work, Cang et al. (2009) used a coupled EK with PRB of ZVI for treating Cr-contaminated soil and concluded that this technique is feasible in the cleanup process due to the rationing of the precipitate portions that occur between anode and cathode reservoirs on the one side and PRB porous volume on the other side.

Recently, with worldwide spreading of nanotechnology, many researchers have started to utilize nanotechnology concepts to treat passively contaminated groundwater. Rajan (2011) summarized the use of nanomaterials such as nZVI and carbon nanotubes (CNT) in groundwater remediation for drinking and reuse. The use of nanotechnology can be considered a faster and more cost-effective solution for in situ remediation (Zhang 2003). Nanomaterials have been evaluated for use in nanoremediation such as nanoscale zeolites, nanoscale ZVI particles, carbon nanotubes, metal oxides, noble metals and titanium dioxide, nanoclays, magnetic nanoparticles, and nanomembrane. In comparison with other remediation methods, this approach provides an overall reduction in the contaminant levels; however, it is still under research with limited field applications (Ponder et al. 2000; Zhang 2003; Karn et al. 2009; Rajan 2011; Prabhakar and Bibi 2013). Araújo et al. (2016) reviewed the researches of using both metallic iron and nanomaterials within permeable reactive barriers to reduce of nitrate concentration in drinking water which has been worldwide prevalence over the last two decades. In general, they support the concept that truly in short term, the utilization of nZVI materials with permeable reactive barriers is a good performance technology for denitrification, but the long-term impact of the use of this materials in this remediation process, both on the environment and on the human health, is far to be conveniently known. They recommended that further research work is needed on this issue to decide that nanosized iron-based permeable reactive barriers for the removal of nitrate from drinking water can be truly considered an eco-efficient technology.

Reactive materials

Reactive media used in permeable barriers should be compatible with the subsurface environment. That is, the media should cause no adverse chemical reactions or by-products when reacting with constituents in the contaminant plume and should not act as a possible source of contaminants itself. This requires that the material be well understood and characterized. To keep PRB costs to a minimum, the material should persist over long periods of time, i.e., it should not be readily soluble or depleted in reactivity, and the material should be readily available at a low to moderate cost. This material should minimize constraints on groundwater flow by not having excessively small particle size, and it should not consist of a wide range of particle sizes that might result in blocked inter-granular spaces. Worker safety, with regard to handling the material, should also be considered (Ott 2000; Ambrosini 2004; Bronstein 2005).

Granular activated carbon (GAC), zeolite, ZVI, red mud, fly ash, peat, activated sludge, tree leaves, recycled concrete, shredded cast iron, steel fibers from tires, blast furnace slag, steel slag dust, basalt dust, paper ash, plant shell and weed, bone char, non-living biomass, maize cob, phosphatic compounds, waste foundry sand, etc., are examples for materials that can be used in the PRB for containment of the pollutants (Böhm et al. 2005; ITRC 2005; Wantanaphong et al. 2005; Golab et al. 2006; Geranio and Elzinga 2007; Wright and Ghazireh 2009; Bakir 2010; Brooks et al. 2010; Gappai et al. 2012; Pathirage et al. 2012; Faisal and Hmood 2015; Faisal and Ahmed 2015; Faisal et al. 2015; Indraratna et al. 2014; Sulaymon et al. 2015a, b).

Decontamination mechanisms

The common target contaminants in the groundwater are sorted into two main groups (Thiruvenkatachari et al. 2008):

-

1.

Organic compounds that include methane, ethane, propane, aromatics compounds, etc.

-

2.

Inorganic compounds that include zinc, cadmium, copper, nickel, chromium, manganese, anion compounds, etc.

The decontamination mechanisms in the PRB can be classified into three categories (Ott 2000; Roehl et al. 2005):

-

Degradation it is a chemical or biological decomposition of contaminants into harmless compounds. An example of chemical degradation is oxidation of ZVI.

-

Precipitation it is retaining contaminants by immobilization, and their chemical state is not altered. For example, by increasing the pH, some metals are reduced and precipitated in the form of sulfites or hydroxides.

-

Sorption it is retaining contaminants by adsorption or complex formation, and their chemical state is not altered. The most often used media are GAC, zeolites, and others for the removal of inorganic and organic compounds.

Blowes et al. (2000) mentioned that the treatment can be grouped into abiotic reduction and immobilization, biologically mediated reduction and immobilization, and adsorption and precipitation reactions. Accordingly, the reactive materials used in the remediation process undergo one of the following reactions (Bronstein 2005; Thiruvenkatachari et al. 2008):

-

1.

Chemical precipitation of heavy metal compounds

-

2.

Sorption of inorganic or organic compouds

-

3.

Retardation and biodegradation of organic pollutants

-

4.

Abiotic reduction

-

5.

Biotic reduction

In fact, in many cases, remediation of contaminated groundwater can be achieved by two or more of these processes that take place simultaneously (Roehl et al. 2005).

Treatment of contaminants

Limestone

Limestone, a raw natural cheap material, was the first type of reactive materials used in the PRB technology (Pearson and Potter 1989; Brodie et al. 1991). In 1999, a contaminated groundwater produced from a coal pile at the US Department of Energy (DOE) Savannah River Site in South Carolina was treated by installation of limestone PRB (Morrison et al. 2002). Although this material is effective in remediation process, satisfied treatment was difficult because it cannot produce the required pH for the direct precipitation of wider range of metal hydroxides or create conditions necessary to promote sulfate reduction.

Many studies have suggested improving limestone according to the contaminant type and condition by either adding another type of reactive material with limestone as a mixture to overcome the limitations in limestone action and work together in an integrated manner or using sequence process as multiple reactive barriers and creating integrated action. Lee et al. (2007) combined calcium carbonate (limestone chemical base) with hydrated lime in continuous column experiments fed with artificially contaminated groundwater to improve the As, Zn, and Ni removal efficiencies. They found that the uptake capacity of this mixture for mentioned metals was very high. Furthermore, Komnitsas et al. (2004) used multiple permeable reactive barriers of limestone and red mud in a sequence manner.

ZVI

A conventional reactive material that is most commonly used with PRBs is the ZVI. ZVI was first used in groundwater treatment by the University of Waterloo (UW), Ontario, Canada, in 1992, and has been shown to destroy chlorinated compounds and immobilize several hazardous inorganics by means of redox (reduction–oxidation) and precipitation reactions of anion and cations (Indelicato 1998; Blowes et al. 2000). Based on column tests, Mackenzie et al. (1999) studied the plugging of the treatment zone and precipitation in the iron media for characterizing the performance of ZVI barrier. The reactive media in these tests were investigated for periods reaching 1400 min with the aid of SEM, energy-dispersive X-ray spectroscopy (EDS), and WDS. The authors proved that there were small effects of precipitates on porosity, hydraulic conductivity and iron reactivity with respect to chlorinated solvent reduction. However, dissolved oxygen in the influent groundwater control porosity changed within the iron and this can cause the plugging at the entrance of barrier. Similar result was achieved by Johnson et al. (2005) using field columns in addition to laboratory columns. In the same direction, Li et al. (2005) prepared a model to simulate performance of ZVI barrier. A series of simulations were introduced using MODFLOW (groundwater flow model) and RT3D (reactive transport model) to evaluate the fouling effects on the hydraulic behavior of barrier in carbonate-rich alluvial soils. The authors found no significant change in the hydraulic behavior within first 10 years of barrier life. However, considerable change was recognized after 30 years and after 50 years, the barrier was expected to exhibit failure in hydraulic function. In another direction, many researches were directed to improve the efficiency of ZVI barrier by mixing different proportions of ZVI with other porous medium such as sand (Komnitsas et al. 2007; Bartzas and Komnitsas 2010), lignite (Klinger et al. 2001), limestone (Gilbert et al. 2010), and pumice (Moraci and Calabrò 2010; Calabrò et al. 2012).

Ruíz et al. (2011) used ZVI reactive barrier with electro-remotion technology depending upon a set of columns for removing contaminants from the soil in addition to water. Geiger et al. (2001) applied the ultrasonic energy on the field scale PRB to enhance the degradation of trichloroethylene (TCE). The authors presented a wide range of laboratory and field analyses data for two PRBs: the first located at NASA Kennedy Space Center, FL, USA, and the other in the western USA. The results indicated that 30-min sonication period had a positive impact on the degradation of the contaminant. Zhao and Reardon (2012) studied the de-halogenation and improvement in the ZVI degradation efficiency due to the possible role of hydrogen gas bound in its lattice.

Many works done attempt to use nZVI particles in PRB technology. Hosseini et al. (2011a, b) evaluated the injection process of the nZVI to the funnel and gate PRB configuration for nitrate removal using a series of batch and column test to support a design of PBR. In this study, the results of PRB indicate that, however, increasing the initial nitrate concentration and pore velocity has inhibitor effect against the effect of nZVI concentration on the process of nitrate removal; the proposed PRB can solve the low permeability of medium in down-gradient.

Activated carbon

GAC is one of the conventional reactive materials that are used in ex situ pump-and-treat techniques for groundwater treatment as well as in general treatment plants of water and wastewater. The treatment potential of activated carbon is presented by adsorption of contaminant particles in a physical manner on its high lattice surface area. However, in passive groundwater remediation technology, the use of GAC as a reactive material is somewhat limited because it is a fabricated material and is expensive. Accordingly, Suthersan (1999) recommended using a certain configuration of funnel and gate such as bioreactor wells, air stripping gate for shallow water table and air stripping well for deeper water table. The virgin carbon can be slurried into the reactor and the exhausted carbon can be vacuum-slurried out of the reactor. Also, replaceable cassettes filled with carbon can be retrofitted into the reactor. Subsequently, an attempt was made to use activated carbon in a limited manner as a mixture with other reactive materials to reduce the cost of a variety of its action, especially with ZVI (Tillman 1996; Indelicato 1998).

Köber et al. (2001) investigated the efficiency of the Fe0 and GAC mixtures as fillings for PRBs in the remediation of TCE and monochlorbenzene (MCB). Column tests proved that the durability of GAC was increased by a factor of 4 when mixed with Fe0 and no substantial limitations in the use of activated carbon by Fe0. Fronczyk et al. (2010) examined the feasibility of using selected activated carbon with ZVI, zeolite, and geza rock for the removal of chlorides in road runoffs. The results signified that the activated carbon and ZVI seemed to be reasonable materials for the reduction of chlorides in PRB technology. Furthermore, Suponik (2010) studied the mechanisms used for benzene and phenol (spilled from the dumping site located somewhere in Upper Silesia, Poland) removal from contaminated groundwater using GAC or mixture of coarse sand and granulated peat as reactive medium in PRB. GAC utilization in PRB was confirmed as an efficient technology to various contaminant remediation policies. Mumford et al. (2015) and Statham et al. (2016) proved that the GAC permeable barrier installed during 2005/2006 at the Main Power House, Casey Station, Antarctica, was able to remediate a fuel spill for operation time equal to 10 years. The performance efficiency of the PRB is conducted via interpretation of total petroleum hydrocarbon (TPH) concentrations, degradation indices and most probable number (MPN) counts of total heterotroph and fuel-degrading microbial populations. They reach through the results to conclude that the PRB with GAC is the most appropriate groundwater remediation technology used in cold and nutrient-limited environments with fuel and TPH polluted sites.

By mean of combined interactive role between low reactive materials ZVI and GAC associated with the concepts of nanotechnology, Hu et al. (2016) introduced a composite combination of nZVI and GAC to obtain a complete nitrate transformation into nitrogen with minimum by-products via chemical reduction which represent a promising technique can be used with PRB in the future. They showed that there is an excellent cooperative role in activity between these two reactive materials in releasing nitrate pollution without any obvious bad interaction between them. Instead of that both the dispersion and long-term reactivity of nZVI were improved with minimizing the by-products of nitrite and ammonium formation in reduction process that reach below 0.008 and 0.04 mg/L, respectively. X-ray photoelectron spectroscopy analysis achieved that the nitrogen was the main end product. They found that these techniques are very beneficial to develop an efficient and low-cost chemical remediation method for nitrate-contaminated groundwater.

Zeolites

Zeolites can be classified according to its source into:

-

Natural zeolites such as clinoptilolite, chabazite, analcime, erionite, faujasite, laumontite, phillipsite, ferrierite, mordenite, and heulandite.

-

Synthetic zeolites such as those from natural materials, waste materials, coal fly ash (CFA), municipal solid waste incineration ash (MSWIA), oil shale ash (OSA), rice husk ash (RHA), or modified natural and synthetic zeolites (SMZ) (Shoumkova 2011).

The utilization of described zeolites as a reactive material in PRB is based on their characteristics such as mechanical strength, chemical stability, sorption capacity, plasticity, and thermal conductivity. Park et al. (2002) performed batch and column tests to specify the possibility of using clinoptilolite in PRBs for remediating the groundwater contaminated with ammonium, copper, and lead cations. The results showed that the removal efficiencies in all cases were >80% with using 1 g of clinoptilolite, except in very high concentrations of ammonium and copper. However, the longevity characteristic of these PRBs was not investigated.

Bowman and Sullivan (1995) and Bowman (2003) evaluated the use of surfactant-modified zeolite (SMZ) as a reactive material in PRB for the removal of chromate and PCE from subsurface water. In addition, SMZ was also used for treating the oilfield wastewaters contaminated with organics such as benzene, toluene, methylbenzene, and xylenes, and it was concluded that the main challenge for successful application of SMZ in environmental remediation is the maintenance and improvement in its long-term physical and chemical stability.

Woinarski et al. (2003) investigated the effects of low temperatures which ranged from 22 to 2 °C on the exchange capacity of copper with clinoptilolite in natural and pretreated sodium forms. The results showed that these temperatures decreased the copper uptake and appeared to slow the reaction kinetics.

Furthermore, Woinarski et al. (2006) studied the ion exchange characteristics of Cu2+ in the natural zeolite clinoptilolite at 2 and 22 °C for development of a PRB to treat heavy metal polluted waters in Antarctica. A one-dimensional mass transfer transport model describing non-equilibrium sorption of Cu2+ in fixed-bed flow revealed that the saturation capacities are independent of flow rate, but mass transfer coefficients increase with water velocity. Clinoptilolite capacity in fixed-beds was approximately 50% of the capacity in equivalent batch systems, and the mass transfer coefficients were between two and eight times the batch-estimated values. Moreover, fixed-bed performance was significantly reduced at cold temperature, with breakthrough points and saturation capacities at 2 °C being between 60 and 65% lower than those at 22 °C.

For the nitrate contamination removal, Zeng et al. (2017) proposed to use of nanoparticles Fe, Cu/Fe, and Mn/Fe coated to NaY zeolite grains (F@Y, CF@Y, and MF@Y) that are prepared by two-step processes consisting of ion exchange and liquid-phase reduction. They showed that Fe, Cu/Fe, and Mn/Fe nanoparticles were successfully loaded onto NaY zeolite and exhibited larger BET surface area compared to nZVI by means of XRD, SEM-EDX, and BET-N2 adsorption tests. In addition, the experiments they have accomplished showed that nitrate removal by metals@Y in unbuffered conditions reached nearly 100% at a dosage of 4 g/L after 6 h of reaction by not affecting the initial solution pH. However, at a high pH of 9.0, metals@Y nitrate reduction still not below 94%. CF@Y exhibit high N2 selectivity, due to the high content of Cu (20 wt%) and Fe (41 wt%) in CF@Y and the highly active metallic sites on its surface with positive charge.

Mixed materials

Organic carbon-based barriers associated with sulfate reduction mechanism in releasing contaminants from groundwater were studied. These reactive barriers were investigated by Blowes et al. (1995) who generated a reactive zone in the test cell from the growth of sulfate-reducing bacteria (SRB) that resulted in metal precipitation in the presence of organic carbon. The barrier was built by providing organic carbon source (organic materials), source of SRB, and pH-neutralization agent. The SRB catalyzed the oxidation of organic carbon ((CH2O2) x (NH3) y (H3PO4) z ) in combination with the reduction of sulfate to sulfide as follows:

where x, y, and z are the stoichiometric coefficients. An increase in H2S concentrations coupled with the low solubility of metal sulfides results in the removal of dissolved metals as follows (Waybrant et al. 2002):

This technique appealed numerous researchers to study groundwater remediation due to its promising outcomes as a result of its use of waste material as a part of the remedy process. Benner et al. (1997) evaluated one barrier of Nickel Rim mine site near Sudbury, Ontario, installed in August 1995, and used organic carbon-based SRB technology. The reactive mixture was composed of 20% wood chips, 40% leaf compost, and 40% municipal compost. It was designed to achieve bacterially mediated sulfate reduction and subsequent metal sulfide precipitation. The results of column tests proved that the reactive barrier remains effective for period not <15 years.

Furthermore, Smyth et al. (2001) used PRB technology as a promising sustainable application for the remediation of mine tailings impoundment. Three treatment cells (3 m × 3 m) within tens of meters of the perimeter drain installed in September 1999 at the Kidd Creek Metallurgical Site near Timmins, Ontario, were investigated. The tailings were deposited in a conical pile having depth of 15 m and diameter of several thousand meters within the 1200-ha impoundment. The results proved that these cells are efficient in the removal of high concentrations of sulfate, iron, and zinc from pore water within 1 m of the ground surface in this cell. Later, additional evaluation for this type of reactive material was performed by many researchers with different considerations (Herbert et al. 1998; Benner et al. 2002; Ludwig et al. 2002; Waybrant et al. 2002; Pruden et al. 2006; Bilek and Wagner 2012). Sulfate reduction geochemical approach as PRB was considered to be the most feasible approach in comparison with other classical reactive materials for treating of the groundwater plumes with low pH (Phifer and Denham 2000).

Liu et al. (2016) improved the performance of PRB of bone char reactive material base by coatings its particles by nanosized manganese. Surface coating technology is used in the recent years to improve the adsorption performance of low-cost synthetic sorbents. Their pioneering work attempts to fix a relationship between the coating and As(V) sorption performance by means of a series of batch and column experiments to investigate the adsorption and desorption of As(V). In addition, this study searches to introduce breakthrough curves by fitting the convection–diffusion equation (CDE), and retardation factors are used to quantify the effects of the Mn coatings on the retention of As(V). The results of this study suggest that using Mn-coated bone char in permeable reactive barriers would be an effective method for remediating As(V)-bearing solutions such as acid mine drainage.

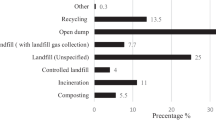

Waste and by-product materials

PRB technology requires little operational and maintenance costs, and, consequently, it can be considered a sustainable technology (Phillips 2009). Use of high-duty green recycled waste, byproduct, or non-manufactured material for treatment process is the base of this consideration. As mentioned for organic carbon-based barriers, with the use of recycled or “waste” material as the reactive media, this technology confirms its rank as a sustainable technology and as a cornerstone for the green remediation movement (Wilson 2010). In fact, this technology paved the road to wide exploration of alternate low-cost waste and recycled materials for utilization in PRBs to minimize its impact on the ecosystem by means of its contribution in waste disposal (Smyth et al. 2001). For instance, in cement industry, a large amount of a very fine powder by-product, cement kiln dust (CKD), is emitted. Every ton of produced cement will be accompanied with the generation of 41 kg CKD where the yearly production of cement around the world ranges from 2.5 to 4.0 billion tons. This means that the huge quantities of CKD will be banished to the ecosystem (Adaska and Taubert 2008; Khanna 2009; Van Oss 2014). Sulaymon et al. (2015a, b, 2016a, b) investigated in detail the possibility of using CKD in the PRB technology, especially the predominant mechanisms of removal process and the design criteria of the reactive bed. They attempt to improve the understanding of a complex behavior of this material in releasing heavy metals during its utilization in PRB. They reported that the removal of heavy metals by CKD can be governed by adsorption and precipitation mechanisms which occurred simultaneously. Accordingly, using this waste as reactive medium in the PRB appears attractive in terms of sustainable development and green projects, as well as a means of cutting disposal costs (Adaska and Taubert 2008).

Christophoridis et al. (2007) proposed various reactive media for application in PRBs according to the range of contaminants, prevailing physicochemical conditions, and financial restrictions. Tests were conducted to assess the potential of natural clinoptilolite, Na-modified clinoptilolite, and ZVI to reduce the concentration of Cd(II) and Cr(III) from water solutions. Optimum pH conditions, metal selectivity, and maximum sorption capacities were determined for each material and metal. Batch tests showed that zeolite modification increased the efficiency of metal uptake dramatically, with respect to maximum sorption capacity and time of equilibrium. Furthermore, the use of ZVI reduced the metal concentration effectively, following reduction and precipitation mechanisms. Geranio and Elzinga (2007) investigated the mechanisms controlling the removal of organic or inorganic compounds using apatite and ZVI as reactive materials. The results proved that the main mechanism for immobilization of metals on the apatite is surface sorption and precipitation (for metals and lanthanides) on the ZVI.

Yuncu et al. (2006) studied the application of activated sludge as an alternative reactive material for treating heavy metals in the PRB. The removal of these metals could be achieved by biosorption process enhanced with functional groups such as carboxyl, hydroxyl, and phenolic of extracellular polymeric substance. Plamondon et al. (2011) tested the following four reactive systems: (i) granular zeolite (clinoptilolite-GZ), (ii) granular organoclay (GO), (iii) 1:1 mixture of GZ and model sandy clayey soil, and (iv) 1:1:1 mixture of GZ, GO, and model soil for removal of Pb, Cu, Zn, Cd, and Ni from contaminated water. The results signified that the efficiency order of these materials was found to be GZ > GZ–soil mix > GZ–soil–GO mix > GO. Furthermore, Bazdanis et al. (2011) studied the use of organic material and certain quantities of fly ash, ZVI, or red mud for remediating leachates contaminated with Cu, Zn, Ni, and Mn metals in up-flow packed columns. The experimental results showed adequate metal removal efficiency in most cases. Chalermyanont et al. (2013) assessed the performance of activated sludge and ZVI as reactive materials for two configurations of PRB: continuous and funnel and gate. The simulation results showed that these materials have the same performance in remediation of groundwater contaminated with zinc metal.

Considerable theoretical and experimental studies using different types of reactive medium such as red mud, peat, recycled concrete, shredded cast iron, steel fibers from tire, blast furnace slag, steel slag dust, basalt dust, paper ash, plant shell and weed, tree leaves, non-living biomass, and maize cob for the treatment of heavy metals in water have been achieved (Wantanaphong et al. 2005; Böhm et al. 2005; Golab et al. 2006; Wright and Ghazireh 2009; Brooks et al. 2010; Bakir 2010; Pathirage et al. 2012; Cappai et al. 2012; Indraratna et al. 2014). However, using waste, recycled by-product materials in PRB technology was adopted in response to sustainable (green) development concepts.

Advantages and disadvantages of PRBs

There are several advantages of PRB technology in comparison with other remediation methods which can be summarized as follows (Carey et al. 2002):

-

1.

It is more effective for treating different types of pollutants in groundwater and is considered as sustainable treatment method.

-

2.

It is maintained on groundwater resources.

-

3.

It is underground systems, and the interactions with surface development are very low.

-

4.

PRBs minimize the quantities of groundwater and soil that should be handled.

-

5.

This technique required low maintenance and operation costs.

-

6.

The longevity of PRBs can be extended for decades of time.

However, PRBs have many disadvantages as follows (Carey et al. 2002):

-

1.

Management and monitoring of risks resulted from persistent contaminant source required long period of time.

-

2.

Underground structures, geological conditions, and site characterization are common constrains for construction of this technology.

-

3.

Frequently, reactive media are removed at the end of operation or changed during operation.

Modeling of contaminant transport through PRB

In PRBs simulation, three aspects must be considered: the hydrogeologic (groundwater flow) aspect in 1D, 2D, or 3D; geochemical (chemical reactions) aspect; and economic aspect (construction and operational costs) to specify the construction and operational costs (Painter 2005). A modeling of PRB can be represented physically or mathematically. A mathematical model is a numerical expression of the conceptual model, which can be either an analytical solution involved in solving differential equations, representing the conceptual model, with appropriate initial and boundary conditions, or numerical solution involved in solving a set of algebraic linear equations, representing the conceptual model, instead of the differential equations used in the previous approach (Ijoor 1999).

On the physical side, a model should simulate groundwater flow directly by using a scaled reproduction of the real world. Many researchers have combined physical and numerical simulations to obtain the most feasible representative predictions of PRBs behavior and response. Most of the studies mentioned in the present review had used 1D pilot model of column test to simulate the processes that occur within the PRBs and utilize them to assess and investigate the real behavior in short and long terms of these barriers either at a laboratory or field scale. Although the column test is generally adequate to simulate remedy processes, some studies based on floor scale test in simulation treatment processes in PRBs have helped to represent the 2D or 3D flow (Böhm et al. 2005).

Nevertheless, with the aid of computers, solving complex problems numerically becomes easier. Many computer simulation codes are available to solve the PRB problems, and the selection of the desired code is based on many considerations such as availability, applicability, and price. The popular groundwater modeling code is MODFLOW (McDonald and Harbaugh 1988), and its latest version is Visual MODFLOW® Flex, which provides solution for controlled equation on finite different method. For integral solution, other codes and modules such as MODPATH, RWLK3D, and MT3D, RWLK3D have been used in conjunction with MODFLOW and marketed as software packages such as GMS (groundwater modeling system), Model Cad, Visual MODFLOW, Groundwater Vistas, Horizontal Flow Barrier (HFB), and ZONEBUDGET.

Furthermore, other 2D and 3D models are able to simulate contaminant transport with water flow and in PRBs, such as FRAC3DVS (Therrien and Sudicky 1996), FLOWPATH (Waterloo Hydrogeologic 1996), and FEMWATER (Lin et al. 1997). At the Royal Institute of Technology in Stockholm, Sweden (2005), graduate students of Germund Dahlquist developed COMSOL Multiphysics code which can be utilized for groundwater contaminant transport and treatment process (COMSOL User’s Guide 2008). This code is based on finite-element numerical method in the solution of coupled partial differential equations (PDEs) with applications including flow and transport in porous media (Li et al. 2009).

Di Natale et al. (2008) used a commercial 2D model flow, SEEP™, in combination with FORTRAN code to describe the groundwater flow and Cd(II) transport through GAC barrier.

Bakir (2010) used COMSOL for predicting the breakthrough curves in comparison with experimental data for removal of metals in the fixed-bed sorption column with seaweed as reactive material. The results signified that COMSOL was an effective tool for generating models accurately and describing metal biosorption onto biomass for single metal systems. Furthermore, Di Nardo et al. (2010) developed a 2D numerical model for describing the transport of tetrachloroethylene (PCE) spilled from a solid waste landfill within groundwater and activated carbon PRB. The results showed that the barrier had a good efficiency because the PCE concentration flowing out of the PRB was always lower than the limits provided in the currently enforced Italian legislation. Moreover, Eljamal et al. (2011) developed a 1D numerical model for arsenite transport through ZVI barrier taken the chemical reaction into account. The results of the column tests showed that the adsorption rate of As(V) was faster than that of As(III).

Orjuela and González (2011) proposed a model with COMSOL Multiphysics to simulate mass transfer through packed column in the bioadsorption process of Cr(VI) in the S-layer of immobilized Bacillus sphaericus pellets, whereas Sachdev et al. (2012) used the modern computational fluid dynamics (CFD) code COMSOL Multiphysics 4.2a for modeling and simulation of packed bed reactors. A detailed description of the flow behavior and heat transfer aspects within the bed was established and validated with the literature data. Furthermore, Faisal and Hmood (2015) developed a 1D model solved numerically by finite difference for description of Cd(II) transport through zeolite barrier. In addition, Faisal et al. (2015) used COMSOL Multiphysics 3.5a software for simulating the Zn(II) transport through sandy soil in the presence of ZVI barrier. The experimental and predicted results proved that the barrier was able to restrict Zn(II) migration.

Benner et al. (1999) evaluated and analyzed the performance of a permeable reactive barrier, designed to remove metals and generate alkalinity by promoting sulfate reduction and metal sulfide precipitation, by means of chemical analysis coupled with geochemical speciation modeling using MINTEQA2 code. This analysis result in that the pore water in the barrier becomes supersaturated with respect to amorphous Fe sulfide in addition to the accumulation of Fe monosulfide precipitates in solid phase with the shifting in the saturation states of carbonate, sulfate, and sulfide minerals. They reported that the dominant changes in water chemistry in the barrier and down-gradient aquifer can be attributed to bacterially mediated sulfate reduction.

Weber et al. (2013) used an enhanced version of the geochemical simulation code MIN3P to simulate dominating processes in chlorinated hydrocarbons (CHCs) treating ZVI PRBs including geochemical dependency of ZVI reactivity, gas phase formation and a basic formulation of degassing. A laboratory column test experiments with distinct chemical conditions were simulated to parameterize the model. The calibrated model was applied on the field site (i.e. Bernau, Germany) for the prediction of the long-term performance of ZVI-PRB installed to treat the groundwater contaminated with the chlorinated hydrocarbons (CHCs). The results of model of field site demonstrated that temporarily enhanced groundwater carbonate concentrations caused an increase in gas phase formation due to the acceleration of anaerobic iron corrosion.

Indraratna et al. (2014) prepared a geochemistry model with geohydraulics model that are coupled to simulate the remediation of acidic groundwater using an alkaline permeable reactive barrier (PRB). In this work, a geochemical algorithm using the transition state theory was developed for treating acidic groundwater using recycled concrete filled PRB. A laboratory column test was accomplished to simulate a real one-dimensional reactive flow that occurs in real reactive barrier whose results are used thereafter to assess the numerical model predictions. The developed algorithm calculates the saturation indices (SI) from PRHEEQC software that in turn used with the governing equations that are incorporated into commercial numerical codes, MODFLOW and RT3D. Using this model, chemical clogging due to secondary mineral precipitates was monitored with a good agreement between both laboratory model results and numerical model predictions and it was found that the hydraulic conductivity reduction due to mineral precipitation occurs at the start of permeation and continues until halfway through the testing phase.

Other modeling techniques are also used to simulate the processes and performance of PRBs with desired reliability. Heuristic methods are one of these techniques that are used recently worldwide in many environmental modeling policies. Artificial neural networks (ANNs)-based model was developed by Santisukkasaem et al. (2015) which enables evaluation of long-term permeability losses that occur in permeable reactive barriers (PRBs) used in groundwater remediation. The results of this model were compared with the multiple regression analysis (MRA) which is a statistical analysis method. MRA-based linear and nonlinear regression model results were used for comparison to assess their performance. The encouraging results lead authors to decide that ANN modeling is a promising tool for the simulation and assessment of the permeability decline in PRBs.

Conclusion

The new concepts related to sustainable (green) technology and use of waste (by-product) materials in the field of environmental remediation with the assistance of physical and numerical simulation provide considerable and wide horizons for scientific research. PRB is a promising technology, and studies about the possibility of using different reactive gates composed of strong chemicals, zeolites, surfactants, iron, adsorptive substances, organisms, and bioactive materials are still underway. In this study, several sorbents have been described, which are actually used for treating of water contaminated with inorganic and/or organic compounds. Accordingly, extensive studies and extra attempts are required for selecting new waste (by-product) reactive materials, determining their properties and behavior in the removal of contaminants from groundwater and, consequently, identifying their appropriateness for use in PRBs.

References

Adaska WS, Taubert DH (2008) Beneficial uses of cement kiln dust. In: Proceedings of the IEEE/PCA 50th cement industry technical conference, Miami, IEEE-IAS Cement Industry Committee, May 19–22, pp. 1–19

Ambrosini GSD (2004) Reactive materials for subsurface remediation through permeable reactive barriers. D.Sc. Dissertation, Swiss Federal Institute of Technology, Zurich

Araújo R, Meira Castro A, Baptista CS, Fiúza A (2016) Nanosized iron based permeable reactive barriers for nitrate removal—systematic review. Phys Chem Earth 94:29–34

Bakir A (2010) Development of a seaweed-based fixed-bed sorption column for the removal of metals in a waste stream. Ph.D. thesis, Waterford Institute of Technology

Bartzas G, Komnitsas K (2010) Solid phase studies and geochemical modelling of low-cost permeable reactive barriers. J Hazard Mater 183:301–308

Bazdanis G, Komnitsas K, Sahinkaya E, Zaharaki D (2011) Removal of heavy metals from leachates using permeable reactive barriers filled with reactive organic/inorganic mixtures. In: Proceedings of the 3rd international conference on environmental management, engineering, planning, and economics (CEMEPE) & SECOTOX conference, June 19–24, Skiathos Island

Bear J (1979) Dynamics of fluids in porous media. Elsevier, New York, p 763

Benner SG, Blowes DW, Ptacek CJ (1997) A full-scale porous reactive wall for prevention of acid mine drainage. Groundw Monit Remediat XVII(4):99–107

Benner SG, Blowes DW, Gould WD, Herbert RB Jr, Ptacek CJ (1999) Geochemistry of a permeable reactive barrier for metals and acid mine drainage. Environ Sci Technol 33(16):2793–2799. doi:10.1021/es981040u

Benner SG, Blowes DW, Ptacek CJ, Mayer KU (2002) Rates of sulfate reduction and metal sulfide precipitation in a permeable reactive barrier. Appl Geochem 17:301–320

Bilek F, Wagner S (2012) Long term performance of an AMD treatment bioreactor using chemolithoautotrophic sulfate reduction and ferrous iron precipitation under in situ groundwater conditions. Bioresour Technol 104:221–227

Blowes DW, Ptacek CJ, Bain JG, Waybrant KR, Robertson WD (1995) Treatment of mine drainage water using in situ permeable reactive walls. In: Hynes TP, Blanchette MC (eds) Proceedings of Sudbury 95, mining and the environment conference, Sudbury, May 28th–Jun, vol 3, pp 979–987

Blowes DW, Ptacek CJ, Jambor JL (1997) In-situ remediation of chromate contaminated groundwater using permeable reactive walls. Environ Sci Technol 31:3348–3357

Blowes DW, Ptacek CJ, Benner SG, McRae CWT, Bennett TA, Puls RW (2000) Treatment of inorganic contaminants using permeable reactive barriers. J Contam Hydrol 45:123–137

Böhm J, Debreczeni A, Gombkötö I, Simon FG, Csovfari M (2005) Laboratory tests using natural groundwater. In: Roehl KE, Meggyes T, Simon FG, Stewart DI (eds) Long-term performance of permeable reactive barriers, ch 5. Elsevier, Amsterdam, pp 111–136

Bowman RS (2003) Applications of surficnt-modified zeolites to environmental remediation. Microporous Mesoporous Mater 61:43–56

Bowman RS, Sullivan EJ (1995) Surfactant-modified zeolites as permeable barriers to organic and inorganic groundwater contaminants. In: Proceedings of conference of environmental technology development through industry partnership, Morgantown, October 3–5. US Department of Energy, Office of Environmental Management

Brodie GA, Britt CR, Tomaszewski TM, Taylor HN (1991) Use of passive anoxic limestone drains to enhance performance of acid drainage treatment wetlands. In: Oaks W, Bowden J (eds) Proceedings of the reclamation 2000: technologies for success, Durango, pp 211–222

Bronstein K (2005) Permeable reactive barriers for inorganic and radionuclide contamination. National Network of Environmental Management Studies Fellow. http://www.epa.gov/aml/news/prbinorg.htm (http://www.clu-in.org/download/studentpapers/bronsteinprbpaper.pdf)

Brooks RM, Bahadory M, Tovia F, Rostami H (2010) Removal of lead from contaminated water. Int J Soil Sediment Water 3(2). Article 14. http://scholarworks.umass.edu/intljssw/vol3/iss2/14

Calabrò PS, Moraci N, Suraci P (2012) Estimate of the optimum weight ratio in zero-valent iron/pumice granular mixtures used in permeable reactive barriers for the remediation of nickel contaminated groundwater. J Hazard Mater 207–208:111–116

Cang L, Zhou DM, Wu DY, Alshawabkeh AN (2009) Coupling electrokinetics with permeable reactive barriers of zero-valent iron for treating a chromium contaminated soil. Sep Sci Technol 44:2188–2202

Cappai G, De Gioannis G, Muntoni A, Spiga D, Zijlstra JJP (2012) Combined use of a transformed red mud reactive barrier and electrokinetics for remediation of Cr/As contaminated soil. Chemosphere 86:400–408

Carey MA, Fretwell BA, Mosley NG, Smith JWN (2002) Guidance on the use of permeable reactive barriers for remediating contaminated groundwater. Environment Agency, National Groundwater and Contaminated Land Centre ISBN: 1 85705 665 5

Chalermyanont T, Chetpattananondh P, Riyapan N (2013) Numerical modeling of permeable reactive barriers to treat heavy metal contaminated groundwater. In: 6th PSU-UNS international conference on engineering and technology (ICET), Novi Sad, University of Novi Sad, Faculty of Technical Sciences

Cheremisinoff NP (1997) Groundwater remediation and treatment technologies. Noyes Publications, Westwood

Christophoridis C, Fytianos K, Zouboulis A (2007) Comparable evaluation of alternative substrates for permeable reactive barriers. In: Proceedings of 10th international conference on environmental science and technology, Kos Island

Chung HI, Lee MH (2007) A new method for remedial treatment of contaminated clayey soils by electrokinetics coupled with permeable reactive barriers. Electrochim Acta 52:3427–3431

COMSOL Multiphysics User’s Manual (2008) COMSOL user forums. www.comsol.com/support/forums

Conca J, Strietelmeier E, Lu N, Ware SD, Taylor TP, Kaszuba J, Wright J (2002) Treatability study of reactive materials to remediate groundwater contaminated with radionuclides, metals, and nitrates in a four-component permeable reactive barriers. In: Naftz DL, Morrison SJ, Davis JA, Fuller CC (eds) Groundwater remediation of metals, radionuclides, and nutrients, with permeable reactive barriers, chapter 8. Academic Press, New York, pp 221–252

Courcelles B (2012) Radial filtration in permeable reactive barriers. Int J Environ Pollut Remediat 1(1):104–110

Day SR, O’Hannesin SF, Marsden L (1999) Geotechnical techniques for the construction of reactive barriers. J Hazard Mater B67:285–297

Di Nardo A, Di Natale M, Erto A, Musmarra D, Bortonea I (2010) Permeable reactive barrier for groundwater PCE remediation: the case study of solid waste landfill pollution. Elsevier, Amsterdam

Di Natale F, Di Natale M, Greco R, Lancia A, Laudante C, Musmarra D (2008) Groundwater protection from cadmium contamination by permeable reactive barriers. J Hazard Mater 160:428–434

Dwyer BP, Marozas DC, Cantrell K, Stewart W (1996) Laboratory and field scale demonstration of reactive barrier systems. Sandia report, Sand96-2500, UC-2040

Elder CR (2000) Evaluation and design of permeable reactive barriers amidst heterogeneity. Ph.D. thesis, Civil and Environmental Engineering, University of Wisconsin, Madison

Eljamal O, Sasaki K, Hirajima T (2011) Numerical simulation for reactive solute transport of arsenic in permeable reactive barrier column including zero-valent iron. Appl Math Modell 35(10):5198–5207

Elmore AC, Graff T (2002) Best available treatment technologies applied to groundwater circulation wells. Remediat J. doi:10.1002/rem.10034

Faisal AAH, Ahmed MD (2015) Removal of copper ions from contaminated groundwater using waste foundry sand as permeable reactive barrier. Int J Environ Sci Technol 12:2613–2622

Faisal AAH, Hmood ZA (2015) Groundwater protection from cadmium contamination by zeolite permeable reactive barrier. Desalin Water Treat 53:1377–1386

Faisal AAH, Abbas TR, Jassam SH (2015) Removal of zinc from contaminated groundwater by zero-valent iron permeable reactive barrier. Desalin Water Treat 55:1586–1597

Finkel M, Liedl R, Teutsch G (1998) A modelling study on the efficiency of groundwater treatment walls in heterogeneous aquifers. In: Groundwater quality: remediation and protection, proceedings of the GQ ´98 conference, Tübingen. IAHS Publ. No. 250, pp 467–474

Focht R, Voaun J, O’Hunnesin S (1996) Field application of reactive iron walls for in situ degradation of volatile organic compounds in groundwater. Remediat J 6(3):81–94

Fronczyk J, Pawluk K, Michniak M (2010) Application of permeable reactive barriers near roads for chloride ions removal. Ann Warsaw Univ Life Sci SGGW Land Reclam 42(2):249–259

Fruchter J, Cole CR, Williams M, Vermeul V, Amonette JE, Szecsody J, Istok JD, Humphrey MD (2000a) Creation of a subsurface permeable treatment zone for aqueous chromate contaminant using in situ redox manipulation. Groundw Monit Remediat 20(2):66–77

Fruchter J, Williams M, Vermeul V, Szecsody J, Martin W, Henckel G, April J, Tortoso A, Hanson J, Biancosino D, Wright J, Hicks T (2000b) In-situ redox manipulation for treatment of chromate in groundwater at the Hanford 100d area: partnership for technology deployment. In: WM’00 conference, Tucson

Gappai G, De Gioannis G, Muntoni A, Spiga D, Zijlstra JJP (2012) Combined use of a transformed red mud reactive barrier and electrokinetics for remediation of Cr/As contaminated soil. Chemosphere 86:400–408

Gavaskar AR (1999) Design and construction techniques for permeable reactive barriers. J Hazard Mater 68(1–2):41–71

Geiger CL, Clausen CA, Reinhart DR, Sonawane A, Ruiz NE, Quinn JW (2001) The use of ultrasound to restore the dehalogenation activity of iron in permeable reactive barriers. In: International containment & remediation technology conference & exhibition, June 10–13, Orlando. Conference Program. University of Florida, Tallahassee

Geranio L, Elzinga E (2007) Review of zero valent iron and apatite as reactive materials for permeable reactive barrier. Term paper SS 07/08, major in Biogeochemistry and Pollutant Dynamics Department of Environmental Sciences, ETH Zurich

Gilbert O, De Pablo J, Cortina JL, Ayora C (2010) In situ removal of arsenic from groundwater by using permeable reactive barriers of organic matter/limestone/zero-valent iron mixtures. Environ Geochem Health 32:373–378

Gillham RW, Burris DR (1992) Recent developments in permeable in situ treatment walls for remediation of contaminated groundwater. In: Proceedings of the subsurface restoration conference, Dallas, June 21–24

Gillham RW, O’Hannesin SF (1994) Enhanced degradation of halogenated aliphatics by zero-valent iron. Groundwater 32(6):958–967

Golab AN, Peterson MA, Indraratna B (2006) Selection of potential reactive materials for a permeable reactive barrier for remediating acidic groundwater in acid sulphate soil terrains. Q J Eng Geol Hydrogeol 39:209–223

Hashim MA, Mukhopadhyay S, Sahu JN, Sengupta B (2011) Remediation technologies for heavy metal contaminated groundwater. J Environ Manag 92:2355–2388

Hedin RS, Nairn RW (1992) Designing and sizing passive mine drainage treatment systems. In: Proceedings of the thirteenth annual west virginia surface mine drainage task force symposium, Ramada Inn, Morgantown

Hedin RS, Watzlaf GR, Nairn RW (1994) Passive treatment of acid mine drainage with limestone. J Environ Qual 23:1338–1345

Henderson AD, Demond AH (2007) Long-term performance of zero-valent iron permeable reactive barriers: a critical review. Environ Eng Sci 24(4):401–423

Henry SM, Hardcastle CH, Warner SD (2002) Chlorinated solvent and DNAPL remediation: an overview of physical, chemical, and biological processes. In: Henry S, Warneret SD (eds) Chlorinated solvent and DNAPL remediation, ch 1. ACS Symposium Series; American Chemical Society, Washington, DC

Herbert JRB, Benner SG, Blowes DW (1998) Reactive barrier treatment of groundwater contaminated by acid mine drainage: sulphur accumulation and sulphide formation. In: Proceedings of the groundwater quality: remediation and protection, Tubingen, September, pp 451–457

Hocking G, Well SL (2002) Groundwater performance monitoring of an iron permeable reactive barrier. In: 3rd International conference on remediation of chlorinated and recalcitrant compounds, Monterey, pp 1–7

Hosseini S, Ataie-Ashtiani B, Kholghi M (2011a) Bench-scaled nano-Fe0 permeable reactive barrier for nitrate removal. Groundw Monit Remediat 31:82–94

Hosseini S, Ataie-Ashtiani B, Kholghi M (2011b) Nitrate reduction by nano-Fe/Cu particles in packed column. Desalination 276:214–221

Hu S, Zhang C, Yao H, Lu C, Wu Y (2016) Intensify chemical reduction to remove nitrate from groundwater via internal microelectrolysis existing in nano-zero valent iron/granular activated carbon composite. J Desalin Water Treat 57(30):14158–14168

Hudak PF (2010) Viability of longitudinal trenches for capturing contaminated groundwater. Bull Environ Contam Toxicol 84:418–421

Ijoor GC (1999) Modeling of a permeable reactive barrier. M.Sc. thesis, Department of Civil and Environmental Engineering, New Jersey Institute of Technology

Indelicato BM (1998) Comparison of zero-valent iron and activated carbon for treating chlorinated contaminants in groundwater. M.Sc. thesis, Civil and Environmental Engineering, MIT

Indraratna B, Pathirage P, Rowe K, Banasiak L (2014) Coupled hydro-geochemical modelling of a permeable reactive barrier for treating acidic groundwater. Comput Geotech 55:429–439

Istok JD, Amonette JE, Cole CR, Fruchter JS, Humphrey MD, Szecsody JE, Teel SS, Vermeul VR, Williams MD, Yabusaki SB (1999) In situ redox manipulation by dithionite injection-intermediate-scale laboratory experiments. Groundwater 37(6):884–889

ITRC (Interstate Technology & Regulatory Council) (2005) Permeable reactive barriers: lessons learned/new directions. PRB-4. Interstate Technology & Regulatory Council, Permeable Reactive Barriers Team, Washington, DC. www.itrcweb.org

ITRC (Interstate Technology & Regulatory Council) (2011) Permeable reactive barrier: technology update. Technical/regulatory guidance, prepared by The Interstate Technology & Regulatory Council, PRB: Technology Update Team, Washington, DC. www.itrcweb.org

Jackson RE (2002) The evolution of DNAPL remediation practice. In: Henry S, Warneret SD (eds) Chlorinated solvent and DNAPL remediation, ch 2. ACS Symposium Series; American Chemical Society, Washington, DC

Johnson RL, Tratnyek PG, Miehr R, Thoms RB, Bandstra JZ (2005) Reduction of hydraulic conductivity and reactivity in zero-valent iron columns by oxygen and TNT. National Ground Water Association. Groundw Monit Remediat 25(1):129–136

Karn B, Kuiken T, Otto M (2009) Nanotechnology and in situ remediation: a review of the benefits and potential risks. Environ Health Perspect 117(12):1823–1831

Khanna OS (2009) Characterization and utilization of cement kiln dusts (CKDs) as partial replacements of Portland cement. Ph.D. thesis, University of Toronto

Klinger C, Jenk U, Schreyer J (2001) Applicability of zero-valent iron with lignite additives as geochemical in situ barrier for acid mine water. In: International contaminant and remediation technology conference and exhibition, June 10–13, Orlando

Köber R, Schäfer D, Ebert M, Dahmke A (2001) Coupled in situ reactors using Fe0 and activated carbon for the remediation of complex contaminant mixtures in groundwater. In: Groundwater quality: natural and enhanced restoration of groundwater pollution (proceedings of the groundwater 2001 conference held at Sheffield, Jun 2001), pp 435–439

Komnitsas K, Bartzas G, Paspaliaris I (2004) Efficiency of limestone and red mud barriers: laboratory column studies. Miner Eng 17:183–194

Komnitsas K, Bartzas G, Fytas K, Paspaliaris I (2007) Long-term efficiency and kinetic evaluation of ZVI barriers during clean-up of copper containing solutions. Miner Eng 20:1200–1209

Lee M, Paik IS, Kima I, Kang H, Lee S (2007) Remediation of heavy metal contaminated groundwater originated from abandoned mine using lime and calcium carbonate. J Hazard Mater 144:208–214

Li L, Benson CH, Lawson EM (2005) Impact of mineral fouling on hydraulic behavior of permeable reactive barriers. Groundwater 43(4):582–596

Li Q, Ito K, Wu Z, Lowry CS, Loheide SP (2009) COMSOL multiphysics: a novel approach to ground water modeling. Groundwater 47(4):480–487

Lin HCJ, Richards DR, Talbot CA, Yeh GT, Cheng JR, Cheng HP, Jones NL (1997) FEMWATER: a Three-dimensional finite element computer model for simulating density-dependent flow and transport in variably saturated media. Technical report CHL-97-12

Liu J, He L, Dong F, Hudson-Edwards KA (2016) The role of nano-sized manganese coatings on bone char in removing arsenic(V) from solution: implications for permeable reactive barrier technologies. Chemosphere 153:146–154

Longmire PA, Brookins DG, Eiler PG, Thomson BM (1991) Application of sphagnum peat for immobilizing radioactive and hazardous contaminants in the subsurface. Waste Manag 1:941–948

Ludwig RD, McGregor RG, Blowes DW, Benner SG, Mountjoy K (2002) A permeable reactive barrier for treatment of heavy metals. Groundwater 40(1):59–66

Mackenzie PD, Horney DP, Sivavec TM (1999) Mineral precipitation and porosity losses in granular iron columns. J Hazard Mater 68:1–17

McDonald MG, Harbaugh AW (1988) A modular three-dimensional finite-difference ground-water flow model: techniques of water-resources investigations of the United States Geological Survey. Book 6, Chapter A1

McMurtry DC, Elton RO (1985) New approach to in situ treatment of contaminated groundwater. Environ Prog 4(3):168–170

Moraci N, Calabrò PS (2010) Heavy metals removal and hydraulic performance in zero-valent iron/pumice permeable reactive barriers. J Environ Manag 91:2336–2341

Morrison SJ, Spangler RR (1993) Chemical barriers for controlling groundwater contamination. Environ Prog 12:175–181

Morrison SJ, Naftz DL, Davis JA, Fuller CC (2002) Introduction to groundwater remediation of metals, radionuclides, and nutrients with permeable reactive barriers. In: Naftz DL, Morrison SJ, Fuller CC, Davis JA (eds) Handbook of groundwater remediation using permeable reactive barriers: applications to radionuclides, trace metals, and nutrients, ch 1. Elsevier, Academic Press, New York

Mountjoy KJ, Pringle EK, Choi M, Gowdy W (2003) The use of permeable reactive barriers for in situ remediation of groundwater contaminants. In: Remediation technologies symposium, Banff

Mumford KA, Powell SM, Rayner JL et al (2015) Evaluation of a permeable reactive barrier to capture and degrade hydrocarbon contaminants. Environ Sci Pollut Res 22(16):12298–12308. doi:10.1007/s11356-015-4438-2

O’Hannesin SF, Gillham RW (1998) Long-term performance of an in situ iron wall for remediation of VOCs. Ground Water 36(1):164–170

Orjuela JP, González A (2011) Model of a heavy metal adsorption system using the S-Layer of Bacillus Sphaericu. In: Proceedings of the COMSOL conference 2011, Boston, October 13–15

Ott N (2000) Permeable reactive barriers for inorganics. United States Environmental Protection Agency, Office of Solid Waste and Emergency Response, Washington, DC

Painter BDM (2005) Optimization of permeable reactive barrier systems for the remediation of contaminated groundwater. Ph.D. thesis, Lincoln University, College of Engineering

Park JB, Lee SH, Lee JW, Lee CY (2002) Lab scale experiments for permeable reactive barriers against contaminated groundwater with ammonium and heavy metals using clinoptilolite (01–29B). J Hazard Mater B95:65–79

Pathirage PU, Indraratna B, Nghiem LD, Banasiak L, Regmi G (2012) Armoring by precipitates and the associated reduction in hydraulic conductivity of recycled concrete aggregates used in a novel PRB for the treatment of acidic groundwater. In: Narsilio GA, Arulrajah A, Kodikara J (eds) 11th Australia–New Zealand conference on geomechanics: ground engineering in a changing world, pp 828–833

Pearson FH, Potter JL (1989) Copper mine drainage treatment plant driven by water wheel. In: Proceeding of metal waste management alternatives symposium, vol 1. California Department of Health Services, Pasadena, pp 226–246

Phifer MA, Denham ME (2000) DEXOU low pH plume baseline permeable reactive barrier options. Demonstration final report, WSRC-TR-2000-00146, Westinghouse Savannah River Company, Aiken

Phillips DH (2009) Permeable reactive barriers: a sustainable technology for cleaning contaminated groundwater in developing countries. Desalination 248:352–359

Plamondon CO, Lynch R, Al-Tabbaa A (2011) Metal retention experiments for the design of soil-mix technology permeable reactive barriers. Clean Soil Air Water 39(9):844–852

Ponder SM, Darab JG, Mallouk TE (2000) Remediation of Cr(VI) and Pb(II) aqueous solutions using supported, nanoscale zero-valent iron. Environ Sci Technol 34(12):2564–2569

Prabhakar V, Bibi T (2013) Nanotechnology, future tools for water remediation. Int J Emerg Technol Adv Eng 3(7):54–59

Pruden A, Pereyra LP, Hiibel SR, Inman LY, Kashani N, Reardon KF, Reisman D (2006) Microbiology of sulfate-reducing passive treatment systems. In: Barnhisel RI (ed) Proceedings of the 7th international conference on acid rock drainage (ICARD), March 26–30. The American Society of Mining and Reclamation (ASMR), St. Louis, pp 1620–1630

Rabideau AJ, Benschoten JNV, Khandelwal A, Repp CR (2001) Sorbing vertical barriers. In: Smith JA, Burns SE (eds) Physicochemical groundwater remediation, Ch 6. Kluwer Academic/Plenum Publishers, Dordrecht, London, pp 115–138

Rajan CS (2011) Nanotechnology in groundwater remediation. Int J Environ Sci Dev 2(3):182

Robertson WD, Cherry JA (1995) In situ denitrification of septic-system nitrate using reactive porous media barriers: field trials. Groundwater 33(1):99–111

Roehl KE, Czurda K, Meggyes T, Simon F, Stewart DI (2005) Long-term performance of permeable reactive barriers. Elsevier, New York, p 326

Ruíz C, Anaya JM, Ramírez V, Alba GI, García MG, Carrillo-Chávez A, Teutli MM, Bustos E (2011) Soil arsenic removal by a permeable reactive barrier of iron coupled to an electrochemical process. Int J Electrochem Sci 6:548–560

Ryan KW, Dwight DM, Hlousek DA (2000) Recirculating wells: ground water remediation and protection of surface water resources. J Am Water Resour Assoc 36(1):191–201

Sachdev S, Pareek S, Mahadevan B, Deshpande A (2012) Modeling and simulation of single phase fluid flow and heat transfer in packed beds. In: Proceedings of the 2012 COMSOL conference in Bangalore

Santisukkasaem U, Olawuyi F, Oye P, Das DB (2015) Artificial neural network (ANN) for evaluating permeability decline in permeable reactive barrier (PRB). Environ Process 2:291–307. doi:10.1007/s40710-015-0076-4

Shashidhar T, Bhallamudi SM, Philip L (2007) Development and validation of a model of bio-barriers for remediation of Cr(VI) contaminated aquifers using laboratory column experiments. J Hazard Mater 145:437–452

Shoumkova A (2011) Zeolites for water and wastewater treatment: an overview. The Australian Institute of High Energetic Materials. http://www.ausihem.org

Skousen J, Faulkner B, Sterner P (1995) Passive treatment systems and improvement of water quality. In: Proceedings of the sixteenth annual west virginia surface mine drainage task force symposium, Ramada Inn, Morgantown, West Virginia

Smyth D, Blowes D, Benner S, Hulshof A (2001) In situ treatment of acid mine drainage in groundwater using permeable reactive materials. In: Proceedings of international contaminant and remediation technology conference and exhibition, Florida

Starr RC, Cherry JA (1994) In situ remediation of contaminated ground water: the funnel-and-gate system. Groundwater 32:465–476

Statham TM, Stark SC, Snape I et al (2016) A permeable reactive barrier (PRB) media sequence for the remediation of heavy metal and hydrocarbon contaminated water: a field assessment at Casey Station, Antarctica. Chemosphere 147:368–375

Sulaymon AH, Faisal AAH, Khaliefa QM (2015a) Cement kiln dust (CKD)-filter sand permeable reactive barrier for the removal of Cu(II) and Zn(II) from simulated acidic groundwater. J Hazard Mater 297:160–172

Sulaymon AH, Faisal AAH, Ziad TAA (2015b) Performance of granular dead anaerobic sludge as permeable reactive barrier for containment of lead from contaminated groundwater. Desalin Water Treat 56:327–337

Sulaymon AH, Faisal AAH, Khaliefa QM (2016a) Dominant mechanisms for metal removal from acidic aqueous solutions by cement kiln dust. Mine Water Environ. doi:10.1007/s10230-016-0416-2

Sulaymon AH, Faisal AAH, Khaliefa QM (2016b) Simultaneous adsorption–precipitation characterization as mechanisms for metals removal from aqueous solutions by cement kiln dust (CKD). Desalin Water Treat 57(2):819–826

Suponik T (2010) Adsorption and biodegradation in PRB technology. Environ Prot Eng 36:43–57

Suthersan SS (1999) In situ reactive walls. In: Suthersan SS (ed) Remediation engineering: design concepts. CRC Press LLC, Boca Raton

Therrien R, Sudicky EA (1996) Three-dimensional analysis of variably-saturated flow and transport in discretely-fractured porous media. J Contam Hydrol 23:1–44

Thiruvenkatachari R, Vigneswaran S, Naidu R (2008) Permeable reactive barrier for groundwater remediation. Rev J Ind Eng Chem 14:145–156

Tillman DE (1996) Combination of zero-valent iron and granular activated carbon for the treatment of groundwater contaminated with chlorinated solvent. M.Sc. thesis, Civil and Environmental Engineering, MIT

Tucker MD (1996) Technical considerations for the implementation of subsurface microbial barriers for restoration of groundwater at UMTRA sites. SAND96-1459, Category UC-511, Unlimited Release Distribution, New Mexico, p 47

USDOE (US Department of Energy) (2002) Passive reactive barrier. Subsurface Contaminants Focus Area, Office of Environmental Management, Office of Science and Technology, DOE/EM-0623

USEPA (2012) Methodology for understanding and reducing a project’s environmental footprint. Office of Superfund Remediation and Technology Innovation, EPA 542-R-12-002

Van Oss HG (2014) Cement. Technical report, US Geological Survey, Mineral Commodity Summaries [(703) 648-7712, hvanoss@usgs.gov]