Abstract

Heavy metal contamination of groundwater is a worldwide problem. Landfill leachate and acid mine drainage are possible sources for groundwater contamination by heavy metals. Heavy metals from groundwater can enter the food chain through bio-accumulation and bio-magnification, posing a threat to all forms of life. A permeable reactive barrier is one of the technologies employed for remediation of heavy metal contaminated groundwater. The concept of a permeable reactive barrier involves the emplacement of a permeable barrier containing reactive materials across the flow path of the heavy metal contaminated groundwater to intercept and treat the heavy metals as the plume flows through it under the influence of the natural hydraulic gradient. Site selection and selection of reactive media, as well as construction and operation, are some of the challenges faced in the application of permeable reactive barriers. A variety of inorganic and organic reactive media are employed in a permeable reactive barrier to remove the heavy metals. Heavy metal removal is accomplished through processes such as adsorption, precipitation and biodegradation. In this chapter, various aspects of treating heavy metal groundwater contamination using the permeable reactive barrier technology have been reviewed. The major topics include: (1) causes of heavy metal contamination in groundwater, (2) types of reactive media used in a permeable reactive barrier, (3) criteria for selection of reactive media, (4) mechanisms for removal of heavy metals by reactive media, and (5) comparison of performance of various reactive media.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

- Permeable reactive barrier

- Heavy metals

- Adsorption

- Precipitation

- Reactive media

- Coal ash

- Natural clay

- Activated charcoal

- Zero valent iron

- Organic residue

3.1 Heavy Metals in Groundwater

Groundwater exists in the pore spaces and fractures in rocks and sediments beneath the earth’s surface. It originates as rainfall or snow, moves through the soil, and back to surface streams, lakes or oceans (TGF 2012). Although groundwater represents only a small percentage of the total water resources on earth, its contribution is vital, considering that up to two billion people depend directly upon aquifers for drinking water and 40% of the world’s food is produced by irrigated agriculture that relies largely on groundwater (Thiruvenkatachari et al. 2008). TGF (2012) reported that groundwater is used for drinking water by more than 50% of the people in the United States, including almost everyone who lives in rural areas, and the largest use for groundwater is to irrigate crops. Likewise, in Australia groundwater use has increased significantly in the last 10 years owing to surface water scarcity. South Australia uses more than 60% of groundwater for irrigation, while Western Australia uses 72% of groundwater for urban and industrial purposes (Thiruvenkatachari et al. 2008).

Inside the earth’s crust, the heavy metals are adsorbed to soil particles. These heavy metals can become mobilised in the groundwater as a result of natural processes or by changes in soil pH or redox. Speciation as well as mobility of metal contaminants can be significantly influenced by a variety of natural processes in the soil environment such as acid/base reactions, precipitation/dissolution, oxidation/reduction, adsorption/desorption and ion exchange processes. The rate and extent of these reactions will be dictated by factors such as pH, redox potential, sorption and ion exchange. Anthropogenic sources such as sewage, landfill leachate, acid mine drainage or industrial waste disposal sites can also contaminate groundwater with heavy metals (Evanko and Dzombak 1997; Hashim et al. 2011). Once mobilised, metal contaminants can be transported through the flow of groundwater. Heavy metal speciation depends upon pH, redox potential, temperature and moisture and it has a significant influence on their toxicity, mobility and reactivity (Allen and Torres 1991; Evanko and Dzombak 1997; Hashim et al. 2011).

At higher concentrations, heavy metals can pose a significant threat to any form of life owing to their associated deleterious effects. Heavy metals tend to persist in natural ecosystems for an extended period of time. Furthermore, heavy metals can also accumulate in successive levels of the biological chain, leading to acute and chronic diseases (Akpor and Muchie 2010; Hashim et al. 2011). For example, copper is the most serious toxic element in mine drainage in Norway, where copper concentrations have reached critical levels for the survival of Atlantic salmon and brown trout in large water courses (Christensen et al. 1996). The fish in the water are exposed directly to heavy metals through their gills. Therefore impaired respiration of fish may result from acute and chronic toxicity. Fish are also exposed to heavy metals through ingestion of food and contaminated sediments (Jennings et al. 2008). Since the human being occupies the top most position in the food chain, the human being always faces the danger of being exposed to a higher concentration of heavy metals through ingestion of contaminated food. Table 3.1 shows the effect of heavy metals on human health (Martin and Griswold 2009; Akpor and Muchie 2010).

3.1.1 Acid Mine Drainage

Acid mine drainage is a problem faced by humanity worldwide. Acid mine drainage is produced when pyrite containing mine tailings is exposed to oxygen in the atmosphere and water as per the following equations (Akcil and Koldas 2006):

Acid mine drainage generated from abandoned mines and mine tailings has contaminated water bodies and created large acidified lakes all over the world. Acid mine drainage, which is highly acidic by nature, solubilises heavy metals present in the mine tailings. Owing to its low pH and high heavy metal content, acid mine drainage is highly toxic and poses a significant environmental threat. Virtually no life can survive in such acidified waters. Heavy metals in soluble form can enter the food chain through bio-accumulation and bio-magnification, posing a greater threat to all forms of life (Kijjanapanich et al. 2012). Acid mine drainage from these lagoons percolates through soil, thereby affecting the soil chemistry and contaminating the groundwater which is a valuable source for drinking water and for agriculture (Gibert et al. 2011).

Some examples of the characteristics of acid mine drainage are presented in Table 3.2. Acid mine drainage of the Figueira coal mine (Brazil) is acidic and contains a high concentration of heavy metals, particularly Mn, Zn, Ni, As, Cd and Cr. The groundwater in the vicinity of the tailing storage facility in the Figueira coal mine is contaminated by acid mine drainage, with acidic pH and high concentration of heavy metals, particularly Mn, Zn, Ni and Cd. The surface water in the vicinity of the Figueira coal mine is also contaminated by acid mine drainage, with high concentrations of Mn (Campaner et al. 2014). Acid mine drainage of the Ban Pu coal mine (Thailand) is acidic and contains a high concentration of Mn (Pakdeerattanamit 2011). The groundwater in the vicinity of the tailing storage facility of the Black Swan nickel mine (Australia) is contaminated by acid mine drainage, with a high concentration of Mn and Ni, while the groundwater away from the tailing storage facility is also contaminated by acid mine drainage with high concentrations of Ni (Liang-qi et al. 2010).

3.1.2 Landfill Leachate

Leachate generated from landfills can be a major source of heavy metals. Landfill leachate is generated when rainwater percolates through the waste layers deposited in the landfill. Physicochemical as well as microbial processes prevailing in the waste pile of a landfill may mobilise and transfer pollutants from the waste material into the percolating water. Landfill leachate may contain organic carbon, inorganic components and heavy metals as well as xenobiotic organic compounds at lower concentrations (Christensen et al. 2001).

Improper management of landfill leachate has led to many cases of serious groundwater pollution in recent decades (Mor et al. 2006; Jun et al. 2009; Sabahi et al. 2009; Akinbile and Yusoff 2011). Heavy metals in the dumping sites originate from a variety of sources such as pharmaceuticals, photographic chemicals, certain types of detergents, personal care products, fluorescent tubes, waste oil, batteries, electronic waste, electrical equipment and paint. As a result, the clean up of landfill leachate contaminated groundwater is essential (Mohan and Gandhimathi 2009).

Some examples of the characteristics of landfill leachate are presented in Table 3.3. Landfill leachate in the Rowfabad landfill (Bangladesh) contains a high concentration of heavy metals, particularly Mn, As, Cd and Cr. The groundwater and surface water in the vicinity of the Rowfabad landfill are contaminated by landfill leachate, with a high concentration of heavy metals, particularly As and Cr (Hossain et al. 2014). Landfill leachate of the Effurum dump site (Nigeria) contains a high concentration of heavy metals, particularly Cu, Cr and Pb. The groundwater and surface water in the vicinity of the Effurum dump site (Nigeria) are contaminated by landfill leachate, with a high concentration of Cr (Ohwoghere-Asuma and Aweto 2013). Landfill leachate in the Narela Bawana landfill (India) contains a high concentration of heavy metals, particularly Cu and Cr. The groundwater of the Narela Bawana landfill (India) is contaminated by landfill leachate with high concentrations of Cr (Gupta and Rani 2014).

3.2 Technologies for the Treatment of Heavy Metal Contaminated Groundwater

3.2.1 Active Techniques

Active remediation techniques of heavy metal contaminated groundwater such as chemical precipitation, ion exchange, electrochemical technology, member technology and adsorption have been employed (Mohan and Chander 2001; Vaclav and Eva 2005; Gaikwad et al. 2010; Brousseau et al. 2000). The chemical precipitation of heavy metal contaminated groundwater occurs by pH adjustment to the alkaline range followed by metal hydroxide precipitation (Mohan and Chander 2001). The method is expensive and produces large volumes of inorganic sludge which is often difficult to dispose of owing to its toxic nature (Johnson and Hallberg 2005). Benefits and drawbacks of other active remediation techniques of heavy metal contaminated groundwater are presented in Table 3.4 (Asokbunyarat 2015). Pump and treat remediation methods are often difficult to employ when dealing with groundwater contamination from acid mine drainage and landfill leachate (Kijjanapanich et al. 2012).

3.2.2 Passive Techniques

Also passive remediation techniques of heavy metal contaminated water, such as the permeable reactive barrier technology, have been employed (Thiruvenkatachari et al. 2008). Treatment in a permeable reactive barrier can be both biotic and abiotic (Hashim et al. 2011). As a result, a permeable reactive barrier may employ organic and inorganic media, depending upon the type of treatment imparted. Organic media are often used in permeable reactive barriers as electron donors to initiate the growth of specific microorganisms. Earlier research has shown that suitable natural organic substrates such as rice husks, coconut husk chips, bamboo chips and sludge from wastewater treatment facilities can be used as electron donors to initiate the growth of sulphate reducing bacteria in permeable reactive barriers. Accordingly, sulphide produced by biological sulphate reduction was capable of removing the heavy metals from acid mine drainage through sulphide precipitation (Kijjanapanich et al. 2012).

In abiotic treatment systems, activated charcoal, clay, limestone, red mud, fly ash, zeolite and zero valent iron have been used as reactive materials (Komnitsas et al. 2004a, b, 2006, 2007; Yang et al. 2010; Chaari et al. 2011). These media are capable of removing pollutants such as heavy metals from contaminated groundwater. Researchers have also shown that bottom ash can be used as effective sorption material for removing heavy metals from aquatic solutions (Gorme et al. 2010; Asokbunyarat et al. 2015a). Bottom ash is an attractive low cost adsorbent owing to its coarse particle size, large surface area, its high porosity and chemical composition (high SiO2, Al2O3 and Fe2O3 and calcium content) (Mohan and Gandhimathi 2009; Hashim et al. 2011).

3.3 Permeable Reactive Barrier

3.3.1 Permeable Reactive Barrier: The Basic Principle

A permeable reactive barrier is one of the most promising groundwater remediation technologies. A permeable reactive barrier is ‘an emplacement of reactive media in the sub-surface designed to intercept a contaminated plume, provide a flow path through the reactive media and transform the contaminants(s) into environmentally acceptable forms’ to attain remediation concentration goals down-gradient of the barrier, as shown in Fig. 3.1 (USEPA 1997, 1998).

A permeable reactive barrier consists of an underground emplacement containing permanent, semi-permanent or replaceable reactive media placed across the flow path of a contaminated groundwater plume. This plume moves through the permeable reactive barrier under its gradient, creating a passive treatment system. As the contaminant moves through the reactive material, reactions occurring inside the permeable reactive barrier transform the contaminants into less harmful (non-toxic) or immobile species (USEPA 1998, 2002).

Currently, two basic designs are being used in full-scale implementations of reactive barriers: (1) the continuous trench and (2) the funnel and gate. The continuous trench is simply a trench that has been excavated and simultaneously backfilled with reactive material, allowing the water to pass through the barrier under its natural gradient and its natural flow velocity, as shown in Fig. 3.2a. The groundwater flow velocity through the permeable reactive barrier will be similar to the velocity in the aquifer. The funnel and gate system consists of a permeable gate (reactive zone) placed between two impermeable funnels, shown in Fig. 3.2b. An impermeable funnel directs the flow of contaminated water to a gate containing the permeable zone of reactive material. The impermeable funnel also helps to increase the velocity of the groundwater flow though the permeable reactive barrier by directing it through a much smaller cross sectional area (USEPA 1997). Factors such as site characteristics, including its hydro-geological details, barrier characteristics like its physical dimensions and placement, and the reactive material characteristics like its quantity and cost dictate the selection between the two permeable reactive barrier configurations. The ‘funnel and gate’ configuration is preferred when the reactive zone employs a lower quantity of reactive material, which is expensive. On the other hand, when cheap reactive material is used, a continuous barrier without construction of the impermeable side walls would be profitable (Roehl et al. 2005; Naidu et al. 2015).

3.3.2 Permeable Reactive Barrier Design

The following factors need to be addressed during the planning and installation of a permeable reactive barrier system (Roehl et al. 2005):

-

The boundaries of the property where the permeable reactive barrier is to be installed;

-

Mapping of underground utilities such as water, sewage and gas distribution networks, electrical wires and cables;

-

Any disruption of site activities that may be caused by the construction of the permeable reactive barrier;

-

The need to dewater the excavation pit and the disposal of potentially contaminated water and soil during placement;

-

The logistics and on-site material management and its placement, such as reactor filling and dust prevention;

-

Occupational hazard and safety issues;

-

Undetected underground utilities and abandoned foundations from demolished structures.

Furthermore, the details of the contaminated site, such as the contaminant characterisation, including its type, concentration and total mass, the groundwater composition and hydraulic setting need to be properly investigated when planning a permeable reactive barrier system. Feasibility studies are always helpful, involving the following steps (Roehl et al. 2005):

-

What type of remediation approach is preferred, which reactive material is to be used and what the predominant contaminant removal mechanisms are;

-

Batch and column investigations which quantitatively measure the contaminant removal capacity, such as mg of contaminant/g of reactive medium;

-

Assessment of the residence time in the permeable reactive barrier based on possible reaction kinetics;

-

Calculation of the reactive zone thickness.

3.4 Criteria for Selection of Reactive Material

Once the details about the site characteristics are obtained, selection of suitable reactive media such as coal ash, natural clay, activated charcoal and organic residue, as shown in Fig. 3.3, should be made based on the following criteria (Gavaskar et al. 2000; Roehl et al. 2005; ITRC 2011; Naidu et al. 2015):

-

Reactivity: The reaction rate and equilibrium constant of the contaminant with the reactive material dictate the residence time inside the permeable reactive barrier - hence they should be quantitatively evaluated. A high reaction rate coupled with a low residence time is desirable so that the barrier thickness is kept within acceptable limits.

-

Stability: Since the reactive material inside the permeable reactive barrier cannot be replaced frequently, it is desirable that the reactive material remains active for a longer period of time. Ideally, the reactive material also should be able to withstand the variations in pH, temperature, pressure and antagonistic factors.

-

Quantity, availability and cost: Proper estimation of the quantity of the reactive media required must be made. Furthermore, the required quantity of the reactive material must be available at an affordable cost.

-

Hydraulic performance: The particle size of the reactive material will dictate its hydraulic conductivity (permeability). The hydraulic conductivity of the reactive media must be higher than the surrounding soil so that the groundwater flow penetrates easily through the permeable reactive barrier. As a result, selection of the particle size of the reactive media is critical.

-

Environmental compatibility: It should be ensured that the reactive media do not form any undesirable by-products with the contaminant and do not dissolve or release any undesirable substance and thereby become a new source of contamination.

-

Safety: Health and safety issues are of prime importance since handling of the material should not result in any risk to worker health.

3.5 Removal of Heavy Metals by Reactive Media

3.5.1 Removal Mechanisms

The physical and chemical processes involved in the removal of contaminants in permeable reactive barriers can be classified broadly into three categories: (I) sorption, (II) precipitation and (III) degradation.

-

(I)

Sorption: permeable reactive barriers which employ sorption barriers utilise retention mechanisms involving fixation of the target pollutant to the reactive media (Simon et al. 2002). Moreover, the removal process does not destroy or change the oxidation state of the contaminant. The processes include surface adsorption, ion exchange, surface complexation, precipitation and co-precipitation. The extent of adsorption is mainly governed by the size and specific surface area of the sorbent (Roehl et al. 2005). Possible materials employed in permeable reactive barriers include activated charcoal, natural clays, and surface-modified minerals such as organophilic zeolites and diatomites (Simon et al. 2002).

-

(II)

Precipitation: When precipitation is the predominant mechanism, contaminants are immobilised within the reactive material zone by the formation of insoluble precipitates (Roehl et al. 2005; Thiruvenkatachari et al. 2008). The reactive materials can modify the pH and redox potential which is favourable for precipitation of metals as metal hydroxides (Hashim et al. 2011). The reactive materials that can be used include lime, limestone, coal ash, powders of chemicals such as Mg(OH)2, MgCO3, CaCl2, CaSO4 and BaCl2 and zero valent metals (Yin and Allen 1999; Hashim et al. 2011). Furthermore, under anaerobic conditions, sulphide may be generated due to biological sulphate reduction which also may lead to metal sulphide precipitation.

-

(III)

Degradation: the conversion of pollutants to less harmful compounds also may occur through chemical or biological reactions whenever organic residues are used in permeable reactive barriers. The organic residues serve as electron donors for biological reactions, whereas the heavy metal contaminants serve as electron acceptors. Biological reactions such as sulphate removal may occur in the permeable reactive barriers which facilitate removal of heavy metal contaminants. As an example, sulphate reducing bacteria utilize the organic substrates under the anaerobic conditions to reduce the sulphates to sulphides, and the sulphides can react with heavy metals, resulting in their precipitation as metal sulphides (Nyarko et al. 2014). Organic residues such as alfalfa, leaves, biological sludge, sawdust, agricultural residues, manure and compost can be used in biodegrading permeable reactive barriers (ITRC 2011).

On the other hand, the permeable reactive barrier technology may also offer some disadvantages as:

-

(I)

Life time of permeable reactive barrier: When the capacity of the reactive material in the permeable reactive barrier is exhausted, removal of metal ions from groundwater is no longer possible. Under such circumstances, the used media from the permeable reactive barrier must be removed and the permeable reactive barrier must be recharged with fresh reactive media.

-

(II)

Leaching of adsorbed metal ions: Sorption of metal ions onto inorganic media is a reversible process. Changes in the operating conditions, such as pH and redox, may result in desorption of sorbed metal ions.

-

(III)

Formation of metal complexes: Some heavy metals may form complexes with natural organic matter, which can lead to increased metal mobility.

-

(IV)

Clogging of permeable reactive barrier: Whenever precipitation is the dominant metal removal mechanism, the pore volume in the permeable reactive barrier can reduce over the time of the permeable reactive barrier operation. In such a case, clogging can occur inside the reactive media, leading to reduced hydraulic conductivity and distorted groundwater flow.

3.5.1.1 Adsorption

3.5.1.1.1 Adsorption Isotherms

Equilibrium sorption isotherm model: Isotherm models, such as the Langmuir, Freundlich and Brunauer-Emmett-Teller models, were tested to fit the experimental data to estimate the equilibrium relationships between sorbent and sorbate in solution at equilibrium of metal sorption. The Langmuir model is based on the assumption that a solid surface has a finite number of identical sites which are energetically uniform (Sawyer et al. 2007; Lalhruaitluanga et al. 2010). The Langmuir isotherm is expressed as:

where:

-

C e : equilibrium concentration (mg/L)

-

q e : sorption capacity at equilibrium (mg/g)

-

q m : maximum sorption capacity (mg/g)

-

b: sorption equilibrium constant (L/mg)

The Freundlich model assumes a monolayer sorption with a heterogeneous energetic distribution of active sites accompanied by interaction between adsorbed molecules (Sawyer et al. 2007; Lalhruaitluanga et al. 2010). The Freundlich isotherm can be expressed as:

where:

-

K f : Freundlich constants related to sorption capacity (mg/g)

-

n: sorption intensity (g/L)

The Brunauer-Emmett-Teller isotherm is widely applied in the gas-solid equilibrium systems in which the multilayer adsorption phenomena exists (Foo and Hameed 2010). The BET isotherm can be expressed as:

where:

-

C BET : the Brunauer-Emmett-Teller adsorption isotherm (L/mg)

-

C s : adsorbate monolayer saturation concentration (mg/L)

-

q s : theoretical isotherm saturation capacity (mg/g)

3.5.1.1.2 Removal Kinetics

Sorption kinetic model: Sorption of heavy metal ions onto reactive media has been modelled by researchers as pseudo-first- or pseudo-second-order kinetics (Bhattacharyya and Gupta 2006; Amarasinghe and Williamas 2007; Lalhruaitluanga et al. 2010; Sukpreabprom et al. 2014) to fit experimental batch sorption data.

The pseudo-first-order model is based on the assumption that the rate is proportional to the number of unoccupied sites. A linear form for the pseudo-first-order model is given as:

where:

-

q t : amount of adsorbate adsorbed at time t (min) (mg/g)

-

q e : sorption capacity at equilibrium (mg/g)

-

k 1 : rate constant for the pseudo-first-order model (min−1)

The first-order rate constant k 1 and q e can be obtained from the slope and intercept of the straight line of log (q e −q t ) versus t, respectively.

On the other hand, the pseudo-second-order model is based on the assumption that the rate is proportional to the square of the number of unoccupied sites. A linear form of the pseudo-second-order model is given as:

where:

-

k 2 : rate constant for the pseudo-second-order model (g/mg.min)

The second-order rate constant k 2 and q e can be obtained from the slope and intercept of the straight line of t/q t versus t respectively.

3.5.2 Performance Evaluation

Laboratory tests are often needed to evaluate the suitability of reactive materials, which may include the removal rate of the contaminant and the removal mechanism (including the formation of by-products). Laboratory tests along with site characteristics form the basis for permeable reactive barrier design (Geranio 2007). Two types of laboratory tests are performed: (I) batch studies and (II) column studies.

-

(I)

Batch studies: Batch tests are useful as an initial screening tool for the selection of the reactive materials for the permeable reactive barrier. Batch tests are carried out under controlled conditions to assess the rate of pollutant removal. Furthermore, the longevity of different materials also can be evaluated. Typically, batch tests include the removal of dissolved contaminants from aqueous solution by an individual or a mixture of different reactive materials to be tested (Geranio 2007).

Some examples of the trends expected in metal removal during batch studies are presented in Fig. 3.4. In this figure, the results obtained from the kinetic of sorption of Mn(II) from aqueous solution onto coal fly ash at an L/S ratio of 100 mL:0.2 g. The residual Mn(II) concentration reduced sharply in the first 40–50 min and reached a value of less than 10 mg/L within 120 min. In the initial stages, when the sorption sites on the adsorbent surface were not occupied, sorption of heavy metal ions was rapid. However, as time progressed, the sorption sites were occupied by the heavy metal ions. As a result, the number of unoccupied sites available reduced in time, and hence the sorption rate also dropped significantly (Asokbunyarat et al. 2015a).

-

(II)

Column studies: Column tests are a favoured method for treatability testing because of the possibility of extrapolating the results to the dynamic flow conditions which may exist in the field. The layout of a column reactor is shown in Fig. 3.5. Column tests are also used to estimate the half-life of the contaminant removal reaction. The half-lives of the contaminants are then used either to select the reactive media or to design of an appropriate thickness of the reactive wall (Gavaskar et al. 2000).

Some examples of the trends expected in metal removal during column studies are presented in Fig. 3.6. The results obtained from the kinetics of sorption of Mn(II) from acid mine drainage onto coal bottom ash are illustrated in this figure. In the initial stages, the residual Mn(II) concentration was the lowest and remained constant, and then a gradually increased with increase in pore volumes, reaching a steady state close to the initial Mn(II) concentration. As a result, the Mn(II) removal efficiency remained close to maximal in the initial stage owing to the reaction with fresh reactive materials, whereas the Mn(II) removal efficiency decreased in the end stage to fairly low values owing to the decline of the reactive material surfaces caused by second mineral precipitates and re-dissolution of previously formed unstable precipitates (Jahangiri-rad et al. 2014).

3.6 Types of Reactive Media Used in Permeable Reactive Barriers

3.6.1 Coal Ash

At present, the world energy demand is over 2.2 million MW and it is increasing at a rate of 1.5% per year, mainly owing to population growth and increasing living standards worldwide (USEIA 2013). Today, coal is one of the world’s primary sources for power generation, accounting for about 36% of the global electricity generation (IEA 2014).

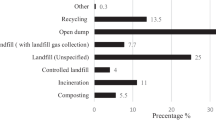

The use of coal in power plants generates fly ash, bottom ash and flue gas desulfurisation gypsum as its main by-products. Typically, 1 wt of electricity can be generated from 15 to 18.75 tons of coal, producing 4.3–11 tons of fly ash and bottom ash, depending upon the quality of coal (Asokan et al. 2005). About 600–800 million tons of coal ash are generated worldwide every year, of which fly ash and bottom ash constitute about 65–95% and 5–35%, respectively. Currently, USA, Europe, China and India are the major contributors of coal ash (Jayaranjan et al. 2014).

Coal ash dump sites may contain coal ash in wet or dry form. In the wet disposal system, coal ash is mixed with water as slurry and disposed of in ponds or lagoons, while in the dry disposal systems, coal ash is disposed of in special local landfills (Kim and Prezzi 2008). Coal fly ash and bottom ash can contain several heavy metals, such as arsenic, lead, cadmium, chromium, manganese, copper, zinc and nickel, usually at trace levels. These heavy metals can be leached from coal ash under acidic conditions and can contaminate the soil, surface water and groundwater, and could eventually enter the food chain, leading to genotoxic effects (Brigden et al. 2002; Ahmed et al. 2010).

Several reuse options exist for coal ash. Coal fly ash and bottom ash are extensively reused in concrete, cement, structural fill, road base/sub-base, mining applications, hazardous waste stabilisation and as soil amendment material in agriculture (Kurama and Kaya 2008). However, only a small proportion (about 15%) of bottom ash generated in the world is reused (Jayaranjan and Annachhatre 2013). As a result, reuse of bottom ash is a great challenge.

One of the possible reuse options for coal ash is to use it as a sorbent material for the removal of heavy metal ions from aqueous solutions such as wastewater and groundwater. Coal fly ash has been successfully used as an adsorbent for the removal of heavy metals in acid mine drainage (Komnitsas et al. 2004b) and landfill leachate (Mohan and Gandhimathi 2009). Coal bottom ash has also been successfully used as a sorbent for the removal of lead from water (Gorme et al. 2010) and the removal of iron, manganese, copper and zinc from aqueous solutions and acid mine drainage (Asokbunyarat et al. 2015a, b). The fly ash and bottom ash are attractive choices as a low cost sorbent, mainly because of the SiO2, Al2O3 and Fe2O3 and high calcium content.

3.6.1.1 Properties of Coal Fly Ash

Physical properties of coal fly ash: Coal fly ash particles are grey in colour. Typical values of properties are specific gravity: 2.10–2.81 (Kim and Prezzi 2008), particle size distribution: 0.001–0.075 mm (Kim and Prezzi 2008), moisture content: 7.75 wt%, bulk density: 1.12–1.28 g cm−3 and specific surface area: 1.0–9.44 m2 g−1 (Theis and Gardner 1990).

Chemical composition of coal fly ash: The chemical composition of coal fly ash from burning of lignite, bituminous, or anthracite coal is presented in Table 3.5. The data reveal that coal fly ash contains mainly oxides such as SiO2, Al2O3, Fe2O3, CaO and MgO (Ahmaruzzaman 2010; Silva et al. 2010).

The diffractogram in Fig. 3.7a shows X-ray diffraction of a sample of coal fly ash. It was found that coal fly ash consisted mainly of anhydrite (CaSO4) and mullite (Al6Si2O13). Coal fly ash also consisted of some quartz (SiO2) and magnetite (Fe2+Fe3+ 2O4).

3.6.1.2 Properties of Coal Bottom Ash

Physical properties of coal bottom ash: Coal bottom ash, has a dark grey colour and a particle size of 0.1–10 mm. Other properties include specific gravity of 2.30–3.00, bulk density of 1.15–1.76 g cm−3 and specific surface area in the range of 0.17–1.0 m2 g−1 (Theis and Gardner 1990; Ahmaruzzaman 2010).

Chemical composition of coal bottom ash: Coal bottom ash consists mainly of oxides such as SiO2, Al2O3, Fe2O3, CaO and MgO. Table 3.6 presents the typical composition of coal bottom ash from burning of lignite, bituminous and anthracite coal.

The diffractogram in Fig. 3.7b shows X-ray diffraction of a sample of coal bottom ash. It was found that coal bottom ash was mainly amorphous in nature, but also crystalline phases such as feldspar (KAlSi3O8 – NaAlSi3O8 – CaAl2Si2O8), mullite (Al6Si2O13), magnetite (Fe2+Fe3+ 2O4) and quartz (SiO2) are present.

The main clean-up mechanisms involved for fly ash and bottom ash with heavy metals are:

-

(I)

Precipitation as metal hydroxide and metal oxyhydroxide

The high calcium content in the fly ash and bottom ash (Tables 3.5 and 3.6) helps in raising the pH of the solution by the generation of hydroxide alkalinity, thereby initiating hydroxide precipitation of heavy metals as a stable phase (Komnitsas et al. 2004b; Hashim et al. 2011). The hydroxide precipitation of heavy metals can been described as follows:

-

(II)

Surface adsorption

The chemical composition and surface charge of fly ash and bottom ash are expected to influence the sorption of heavy metal ions. Fly ash and bottom ash contain mainly oxides of silicon (SiO2), aluminum (Al2O3), iron (Fe2O3) and calcium (CaO) (Fig. 3.7). SiO2 and Al2O3 have excellent sorption characteristics, mainly because they exhibit a surface charge depending upon the pH of the metal ion containing solution. The central silicon atom has a strong affinity for electrons, which yields a low basicity to the oxygen atoms bound to the silicon atom. As a result, this in turn makes the silica surface act as a weak acid. As a result, silanol (SiOH) groups are formed when the oxygen atoms on the silica surface react with water. Giving the silica surface acquires a positive charge at low pH. On the other hand, at high pH values, a negatively charged surface prevails on the silica surface (Mohan and Gandhimathi 2009). Alumina and iron also show a similar behaviour depending upon the solution pH. Under these conditions, the silica, alumina and iron content of fly ash and bottom ash are expected to be negatively charged, which would allow metal ions (M(II)) and metal hydroxides (M(OH)2) to be complexed at the surface of coal ash, resulting in heavy metal ion removal through adsorption (Chaiyasith et al. 2006; Wang et al. 2006).

where: SO − are the free sites on the surface of an adsorbent.

Komnitsas et al. (2004b) studied the efficiency of lignite fly ash barriers for the removal of heavy metals from acid mine drainage. Laboratory investigations were carried out through continuous column experiments with 50% w/w of Greek fly ash and 50% w/w of silica sand as reactive media and synthetic acid mine drainage as feed. pH, Eh, heavy metal (Fe, Zn, Mn, Al, Ni, Cu, Co and Cd), SO4 2− and solid samples were analysed at the end. The results showed that the effluent pH remained strongly alkaline in the range from 11 to 12.9 while the redox potential varied between 200 and 350 mV. Iron, aluminum, copper, zinc, nickel, cobalt, cadmium, copper and manganese concentrations in the effluent remained below detection limit. Geochemical modeling (PHREEQC) indicated that Al(OH)3 could precipitate at pH values higher than 5, while copper could precipitate as cupric and cuprous ferrite at pH values between 5 and 6. Zn co-precipitated mainly with Si to form Zn2SiO4 and Cd removal was accomplished by co-precipitation as CdSiO3. The toxicity characteristic leaching procedure (TCLP) tests indicated that the toxicity of the resulting precipitates was below compliance limits. Results from continuous column experiments indicated that a permeable reactive barrier containing lignite fly ash could effectively remove high loads of heavy metals from acidic leachates.

Mohan and Gandhimathi (2009) studied the adsorption of heavy metals from landfill leachate using fly ash from a lignite power plant through batch studies. The results indicated that, as the fly ash dosage increased from 0.5 up to 2 g/L, the heavy metal removal efficiency also increased concomitantly and attained a constant value thereafter. The highest heavy metal removal was recorded at the optimum fly ash dose of 2 g/L. The pH increased rapidly and stabilised to a value of 8.54.

Asokbunyarat et al. (2015a) studied the sorption of heavy metal ions from aqueous solution onto coal bottom ash. X-ray diffraction analysis of coal bottom ash indicated the presence of feldspar (KAlSi3O8 – NaAlSi3O8 – CaAl2Si2O8), mullite (Al6Si2O13) and magnetite (Fe2+Fe3+ 2O4). The toxicity characteristic leaching procedure tests revealed that heavy metal ions such as Fe(II), Fe(III), Mn(II), Cu(II), Zn(II), As(III), As(V), Pb(II) and Cd(II) could be leached out from coal bottom ash. Continuous column tests with the bottom ash showed negligible heavy metal ion leach-out at pH 6.0, although some heavy metal ion leaching, mainly of Mn(II), was observed at pH 4.2. Batch sorption studies with individual heavy metal ions (Fe(II), Cu(II), Zn(II) and Mn(II)) revealed that the heavy metal ion sorption onto coal bottom ash followed pseudo-second-order kinetics. Sorption isotherm studies revealed that the Langmuir isotherm could adequately describe the heavy metal ion sorption onto coal bottom ash with maximum adsorption capacity (qm) ranging from 1 to 25 mg/g for various heavy metal ions. The removal of heavy metal ions by coal bottom ash is attributed to both adsorption and hydroxide precipitation of heavy metals owing to the presence of different oxides such as SiO2, Al2O3, Fe2O3 and CaO in coal bottom ash.

Asokbunyarat et al. (2015b) studied the sorption of heavy metals from acid mine drainage onto coal bottom ash. Process parameters such as pH, L/S (liquild-to-solid ratio) and contact time strongly affected the metal adsorption onto coal bottom ash. The heavy metal adsorption onto bottom ash increased with increasing initial heavy metal concentration and contact time. However, it was restricted in sorption behaviour at much higher metal concentrations. Adsorption of heavy metal ions from single and multi component solutions based on the acid mine drainage characteristics of lignite coal mine in Thailand onto coal bottom ash followed the sequence: Fe(II) > Cu(II) > Mn(II) > Zn(II). The adsorption of heavy metal ions from a single-component solution was higher than that from a multi-component solution owing to the effect of competing ions. The pseudo-second-order model satisfactorily described the heavy metal adsorption onto bottom ash. On the other hand, the Langmuir isotherm satisfactorily described the isotherm data indicating that the bottom ash is made up of homogenous and single layered surfaces which are available for heavy metal adsorption.

3.6.2 Natural Clay

Clays are hydrous aluminosilicates broadly defined as those minerals that make up the colloid fraction (lower than 2 μm) of soils, sediments, rocks and water. One of the important properties of clay is their plasticity which is obtained when mixed with water. Clays are capable of removing contaminants from the environment through ion exchange and adsorption. As a result, clay surfaces always attract cations and anions owing to the electrostatic forces existing between the ions present in the solution and the surface charge that the clay acquires when it is mixed with water (Bhattacharyya and Gupta 2008a). There are two basic classes of clays: kaolinite and montmorillonite (Bailey et al. 1999).

Kaolinite includes a tetrahedral sheet of SiO4 and an octahedral sheet with Al3+ as the octahedral cation. The formula of kaolinite is (Si4)IV(Al4)VIO10(OH)8 and the theoretical composition is SiO2 46.54%, Al2O3 39.50% and H2O 13.96%. Considering the speciation of different metals in this formula, the theoretical net surface charge on kaolinite is zero. However, kaolinite acquires a small net negative charge owing to the fact that its surface is not completely inert (Bhattacharyya and Gupta 2008a).

Montmorillonite is a clay mineral including units made up of two silica tetrahedral sheets with a central alumina octahedral sheet. Its formula is (Si7.8Al0.2)IV(Al3.4Mg0.6)VIO20(OH)4 and the theoretical composition without the interlayer material is SiO2 66.7%, Al2O3 28.3%, and H2O 5%. Considering the speciation of different metals in this formula, the theoretical net surface charge on montmorillonite is −0.8 charge/unit cell, which is responsible for the adsorption of cations (Bhattacharyya and Gupta 2008a).

Physical and chemical properties of natural clays: Natural clays have a large specific surface area (up to 800 m2/g). They have a layered structure and high cation-exchange capacity (CEC). Clays are chemically and mechanically stable. These characteristics of natural clays have made them excellent adsorbents (Bhattacharyya and Gupta 2008b; Chaari et al. 2011). The properties of kaolinite and montmorillonite are shown in Table 3.7. The values of the specific surface area reported in the literature range from 5 to 25 m2/g for kaolinite and 15.5–82.0 m2/g for montmorillonite depending on the particle size distribution, particle shape, and distribution of pores in the material. On the other hand, the cation-exchange capacities have been reported to be 0.13 and 2.25 meq/g for kaolinite and montmorillonite, respectively (Bhattacharyya and Gupta 2008b). Of the two species, montmorillonite clays have the smaller crystals, larger surface area and higher cation-exchange capacity. Thus montmorillonite clays exhibit a higher adsorption capacity (Bailey et al. 1999).

The adsorption of metal ions from the aqueous solutions by kaolinite and montorillonite by varying pH, liquid/solid ratio, time and metal ions concentration have been investigated (Bhattacharyya and Gupta 2008b). The results showed that adsorption increased with pH, and montmorillonite had a higher adsorption capacity than kaolinite at all pH values. The adsorption followed second-order kinetics and the second-order rate constant was higher for montmorillonite than for kaolinite, confirming the higher affinity of the metal ions for montmorillonite. Montmorillonite had a higher Langmuir monolayer adsorption capacity (qm) of 28.4–28.9 mg g−1, compared to kaolinite ranging from 10.4 to 11.2 mg g−1. Adsorption isotherms of copper, nickel and chromium from Jebel chakir leachate onto smectite-rich clayed rock exhibited an S-shaped curve owing either to precipitation or the presence of competitive effects of other solutes (Chaari et al. 2011). The removal of metal ions in column tests was 69.40%, 57.02%, and 70.21% for copper, nickel and chromium respectively. Asokbunyarat and Annachhatre (2015) studied arsenic removal from arsenic groundwater using mixtures of fly ash, bottom ash, and bentonite clay in different proportions. Column arsenic removal studies revealed that arsenic removal was the highest for the mixture ratio of 60% bottom ash, 20% fly ash and 20% bentonite clay. The removal of arsenic is attributed mainly to its sorption on the negatively charged surfaces of fly ash, bottom ash, and bentonite clay.

3.6.3 Activated Charcoal

Activated charcoal (activated carbon) is extensively used for the removal of impurities from liquid solutions. Surface adsorption is the predominant removal mechanism in activated charcoal treatment, in which molecules of a liquid or gas are trapped by external or internal surface pores. Activated charcoal is a crude form of graphite that has a random or amorphous structure with high porosity, which results in a very high specific surface area ranging from 300 to 2,500 m2/g (Kobya et al. 2005; Ansari and Shadegh 2007; Wang et al. 2008). The force that fixes the impurities to the adsorbent surface is called the London dispersion force, which is very strong at a short distance. As a result, adsorbate molecules are held tightly in the pores composed of carbon atoms (Calgon 2007).

Activated charcoal can be produced through chemical or thermal processes and the end product can be in granular or powdered form (Calgon 2007). The different physical properties attributed to activated charcoal are primarily due to the raw material and production processes used in its manufacture. Activated charcoal is mainly produced from coal, wood, peat, coconut shells or petroleum coke that all have a high carbon content. Other raw materials such as bamboo are also used as raw material for the manufacture of activated charcoal, mainly owing to its high carbon content and low nitrogen, sulphur and hydrogen content. As a result, bamboo based activated charcoal has a large number of micro-pores and an extremely large surface area compared to wood charcoal (Wang and Yan 2011).

Chemical activation is a single-step method of preparing activated charcoal in the presence of dehydrating chemical agents such as KOH, ZnCl2, CaCl2 and H3PO4. Physical activation involves carbonisation followed by activation in the presence of activating agents such as CO2 or steam. The carbon yield from chemical activation is higher than that from physical activation, primarily owing to the lower temperatures employed during chemical activation (Pirajan and Giraldo 2012).

Lalhruaitluanga et al. (2010) studied lead (II) adsorption from aqueous solutions by raw and activated charcoals of bamboo. The activated charcoal was a more suitable adsorbent than raw charcoal for the removal of lead (II) from an aqueous solution. The adsorption rate followed the pseudo-second-order model. The adsorption isotherm followed the Langmuir model with a maximum adsorption capacity (qmax) of 10.66 mg g−1 for raw charcoal and 53.76 mg g−1 for activated charcoal. Wang et al. (2008) studied the effect of manufacturing conditions on the adsorption capacity for heavy metal ions by Makino bamboo charcoal. The specific surface area of activated charcoal prepared at 900 °C (794 m2/g) was larger than at 800 °C (594 m2/g). The activated charcoal produced from steam activation had a larger average pore diameter as well as better adsorption capacity compared to activated charcoal produced from carbon dioxide activation (Wang et al. 2008).

3.6.4 Zero Valent Iron

Researchers have successfully used zero valent iron to treat acidic water contaminated with heavy metals such as chromium, uranium, arsenic, manganese and zinc (Puls et al. 1999; Wilkin and McNeil 2003; Komnitsas et al. 2007; Jun et al. 2009). Metal removal mechanisms by zero valent iron are not very well understood. However, both adsorption and reductive mineral precipitation processes contribute to metal removal (Wilkin and McNeil 2003).

The mechanisms of heavy metal removal by zero valent iron can involve either chemical reaction followed by precipitation or biochemical reaction followed by precipitation:

-

(I)

Removal through chemical reaction and precipitation as metal hydroxide and metal oxyhydroxide

Contaminant reaction with zero valent iron (ZVI) leads to iron corrosion and generation of hydroxide ion (OH−) which raises the pH of the water (Jun et al. 2009) as per the following reaction:

OH− thus generated can react with heavy metals to form hydroxide precipitates, facilitating their removal from water as per the following reaction:

Oxyanions may be formed in some cases and heavy metals may exist in the oxidized states in natural water as in the case of hexavalent chromium as CrO4 2−. In some cases, reductive precipitation may occur as described in the following redox reaction (Komnitsas et al. 2007):

-

(II)

Removal through biochemical reaction and precipitation as metal sulphide and metal hydroxide

Under anaerobic conditions, hydrogen gas (H2) is formed as a product of zero valent iron (ZVI) corrosion. Alternatively, sulphate reducing bacteria can utilize hydrogen gas as an electron donor or an energy source to reduce sulphate with the release of hydrogen sulphide. The hydrogen sulphide then reacts with heavy metals to form an insoluble precipitate as metal sulphide. For example, the precipitation of iron sulphides can be described by the following reactions (Bartzas and Komnitsas 2010):

Researchers studied the capacity of zero valent iron to treat landfill leachates containing heavy metals and other hazardous contaminants (Jun et al. 2009). Zero valent iron could selectively remove Zn, Mn, Ca, Mg, Cd, Cr, Sr and Al and removal efficiencies ranged between 46% and 93%. The heavy metals precipitated as hydroxide, carbonate and sulphide compounds as the pH value increased from 6.9 to 8.2. In another study, researchers evaluated the acid-neutralisation and metal removal rates with zero valent iron (Wilkin and McNeil 2003). Experiments at an initial pH of 2.3, 3.5 and 4.5 achieved significant reduction in metal concentrations with an increase in pH value from 2.3–4.5 to 5.5–10.0. The heavy-metal removal rates followed the following sequence: Al>Cu>As>Cd>Ni>Zn, while the corresponding reaction half-lives were from 1.50 (±0.09) h for Al to 8.15 (±0.36) h for Zn. The dominant corrosion product from the reaction was sulphate green rust (likely Fe6(OH)12SO4).

3.6.5 Organic Residues

In biological systems, permeable reactive barriers employ natural organic substrates as electron donors to facilitate the growth of sulphate reducing bacteria. When an acid mine drainage plume containing sulphate and heavy metals passes through the reactive barrier, the sulphate reducing bacteria in the reactive barrier converts sulphate into sulphide, while consuming the organic substrates as electron donors (Tsukamoto et al. 2004). Heavy metals present in the contaminated feed water are then removed as metal sulphides (Dvorak et al. 1992; Jong and Parry 2003), according to:

Sulphate-reducing bacteria, which are heterotrophic, require specific environmental conditions for their growth and activity, such as anaerobic conditions, pH of 5–8, temperature of 20–35 °C and the presence of a carbon compound to act as carbon source and electron donor.

A variety of organic substrates can be used as electron donors for sulphate-reducing bacteria (Liamleam and Annachhatre 2007). Organic residues such as alfalfa, leaves, biological sludge, sawdust, agricultural residues, manure and compost are commonly used in permeable reactive barriers (Waybrant et al. 1998; Pagnaneli et al. 2009; Gibert et al. 2011). A physical support for bacterial attachment increases their concentration. However, in subsurface soil environments, a lack of readily available organic carbon is the most common limitation for biological sulphate reduction (Gibert et al. 2002). The use of natural organic substrates as electron donors for sulphate reducing bacteria in permeable reactive barriers is more appropriate because of their ease of availability and cost considerations (Costa et al. 2007).

The biodegradable fraction in an organic residue often dictates its selection as an electron donor since the lignin content in the organic residue can affect its biodegradability. Lignin, which is a complex phenolic polymer (Pouteau et al. 2003), serves an important function in plant defence owing to its insolubility and complexity, which makes it resistant to degradation by most microorganisms (Campbell and Sederoff 1996). Chandler et al. (1980) showed that the biodegradable fraction can be an important indicator for the overall degradability of an organic substrate and put forward the following equation:

where biodegradable fraction (B) is based on a volatile solid content and X is the lignin content of the volatile solid, expressed as percent dry weight. The biodegradability of the organic substrate decreased with increase in its lignin content (Gibert et al. 2004). Concomitantly, its ability to develop bacterial activity also decreased.

Kijjanapanich et al. (2012) used plant and microbial organic substrates as electron donors for sulphate reducing bacteria for their possible use in permeable reactive barriers. Plant organic residues such as rice husk, coconut husk chips and bamboo chips had a higher lignin content (24.4–46.5%), while the microbial organic residues such as pig farm wastewater treatment sludge and municipal wastewater treatment sludge had lower lignin contents (He et al. 1998; Vu et al. 2003). Kijjanapanich et al. (2012) studied the sulphide precipitation of heavy metals by mixed populations of sulphate reducing bacteria in batch as well as continuous columns. These investigations clearly showed that organic substrates with a lower lignin content degraded faster than organic substrates from plant, which had a higher lignin content. Consequently, a mixture of organic substrates with microbial as well as plant was proposed as electron donor in permeable reactive barriers.

3.7 Comparison of Reactive Materials

A comparison of the relative order of sorption of metal ions onto various sorbents as reported in the literature is presented in Table 3.8. As this data brings out, all researchers indicate that Mn(II) is the most difficult ion to remove by sorption onto various sorbents as evidenced by the fact that its relative order is always the last in comparison with other metal ions. Otherwise, the reported observations are not conclusive with respect to the relative order of metal ion sorption with various adsorbents. It is anticipated that the metal ion removal by various adsorbents depends upon the adsorbent composition, surface charge distribution and the pore size vis-à-vis the metal ion characteristics such as hydration radius, hydration energy and electro negativity. These factors make it difficult to predict the relative order of metal ion sorption for a specific sorbent.

Table 3.9 compares the removal mechanism, metal sorption capacity, kinetic model and isotherm model followed by various sorbents as reported in the literature. As these data reveal, adsorption and precipitation (hydroxide and sulphide precipitation) are the predominant metal removal mechanisms. The data also bring out that the sorption capacity of coconut shell activated charcoal and bituminous-activated charcoal is higher than that of other sorbents. On the other hand, silica-alumina based adsorbents such as natural zeolite, kaolinite, coal fly ash and coal bottom ash have similar sorption capacities. The data also reveal that the sorption capacity of Fe(II) is always the highest, while that of Mn(II) is always the lowest. In most cases, the heavy metal removal follows a pseudo-second-order kinetic fit, while the adsorption follows the Langmuir isotherm model.

3.8 Conclusion

The permeable reactive barrier is now a matured technology for the treatment of heavy metal containing groundwater. Contamination of groundwater can take place from seepage of acid mine drainage or from landfill leachate. A permeable reactive barrier, which employs reactive media, is placed across the contaminated groundwater flow and the contaminants are then removed by reactive media in the permeable reactive barrier. For this reason, proper soil and groundwater flow characterisation is of utmost importance. Groundwater flow can be directed through the permeable reactive barrier at the necessary velocity by the use of the funnel and gate system. The necessary residence time of groundwater flow in the permeable reactive barrier is estimated through laboratory scale investigations undertaken to evaluate the kinetics of contaminant removal by reactive media. Media employed in the permeable reactive barrier can be either organic or inorganic by nature. The mechanisms for contaminant removal by media may involve sorption, precipitation or degradation. Organic media may include a variety of agricultural residues as electron donors to initiate biological sulphate reduction activity by sulphate reducing bacteria. Sulphide produced by sulphate reducing bacteria can remove the contaminant heavy metals from the groundwater flow through sulphide precipitation. On the other hand, inorganic media employed in a permeable reactive barrier may consist of natural clays, coal ash, activated charcoal or zero valent iron. Adsorption and hydroxide precipitation can be the dominant mechanisms for the removal of heavy metals by inorganic media. The capacity and the kinetics of the contaminant removal by the inorganic media need to be evaluated through laboratory investigations. The capacity and quantity of the media in the permeable reactive barrier may dictate its life time, beyond which the used media in the permeable reactive barrier must be removed and the permeable reactive barrier must be refilled with new media. Advantages offered by a permeable reactive barrier over conventional pump and treat technologies include low energy requirements as well as reduced cost due to little or no operation and maintenance. On the other hand, the permeable reactive barrier technology may also offer certain disadvantages such as finite life of the reactive barrier as well as possibility of its clogging.

References

Agarwal AK, Kadu MS, Pandhurnekar CP, Muthreja IL (2012) Kinetics and adsorption isotherm study of removal of Zn+2 ions from aqueous solution using thermal power plant fly ash. Int J Environ Sci Dev 3(4):376–381. doi:10.7763/IJESD.2012.V3.251

Ahmaruzzaman M (2010) A review on the utilization of fly ash. Prog Energy Combust Sci 36(3):327–363. doi:10.1016/j.pecs.2009.11.003

Ahmed AT, Khalid HA, Ahmed AA, Chen D (2010) A lysimeter experimental study and numerical characterization of the leaching of incinerator bottom ash waste. Waste Manag 30(8–9):1536–1543. doi:10.1016/j.wasman.2010.03.034

Akcil A, Koldas S (2006) Acid mine drainage (AMD): causes, treatment and case studies. J Clean Prod 14(12–13):1139–1145. doi:10.1016/j.jclepro.2004.09.006

Akinbile CO, Yusoff MS (2011) Environmental impact of leachate pollution on groundwater supplies in Akure, Nigeria. Int J Environ Sci Dev 2(1):81–86. doi:10.7763/IJESD.2011. V2.101

Akpor OB, Muchie M (2010) Remediation of heavy metals in drinking water and wastewater treatment systems: processes and applications. Int J Phys Sci 5(12):1807–1817

Allen JP, Torres IG (1991) Physical separation techniques for contaminated sediment. In: Li NN (ed) Recent developments in separation science. CRC Press, West Palm Beach

Amarasinghe BMWPK, Williams RA (2007) Tea waste as a low cost adsorbent for the removal of Cu and Pb from wastewater. Chem Eng J 132(1–3):299–309. doi:10.1016/j.cej.2007. 01.016

Ansari R, Sadegh M (2007) Application of activated carbon for removal of arsenic ions from aqueous solutions. E- J Chem 4(1):103–108. doi:10.1155/2007/829187

Asokan P, Saxena M, Asolekar SR (2005) Coal combustion residues-environmental implications and recycling potentials. Resour Conserv Recycl 43(3):239–262. doi:10.1016/j.resconrec.2004.06.003

Asokbunyarat V (2015) Reactive media in permeable reactive barrier for removal of metal ions from acid mine drainage. PhD Dissertation, Asian Institute of Technology, Bangkok, Thailand

Asokbunyarat V, Annachhatre AP (2015) Permeable reactive barrier for arsenic removal from arsenic groundwater. Int J Manage Appl Sci 1(5):24–29. doi:IJMAS-IRAJ-DOI-2285

Asokbunyarat V, van Hullebusch ED, Lens PNL, Annachhatre AP (2015a) Coal bottom ash as sorbing material for Fe(II), Cu(II), Mn(II), and Zn(II) removal from aqueous solutions. Water Air Soil Pollut 226(5):1–17. doi:10.1007/s11270-015-2415-5

Asokbunyarat V, van Hullebusch ED, Lens PNL, Annachhatre AP (2015b) Adsorption of heavy metals from acid mine drainage by coal bottom ash. In: Rene ER, Bhattarai S, Nancharaiah YV, Lens PNL (eds) Proceeding of the 4th international conference on research frontiers in chalcogen cycle science and technology (G16 Conference). Delft, The Netherlands

Baba A, Kaya A (2004) Leaching characteristics of solid wastes from thermal power plants of western Turkey and comparison of toxicity methodologies. J Environ Manag 73(3):199–207. doi:10.1016/j.jenvman.2004.06.005

Bailey SE, Olin TJ, Bricka RM, Adrian DD (1999) A review of potentially low-cost sorbents for heavy metals. Water Res 33(11):2469–2479. doi:10.1016/S0043-1354(98)00475-8

Bartzas G, Komnitsas K (2010) Solid phase studies and geochemical modeling of low-cost permeable reactive barriers. J Hazard Mater 183(1–3):301–308. doi:10.1016/j.jhazmat. 2010. 07.024

Bhattacharyya KG, Gupta SS (2006) Kaolinite, montmorillonite, and their modified derivatives as adsorbents for removal of Cu(II) from aqueous solution. Sep Purif Technol 50(3):388–397. doi:10.1016/j.seppur.2005.12.014

Bhattacharyya KG, Gupta SS (2008a) Adsorption of a few heavy metals on natural and modified kaolinite and montmorillonite: a review. Adv Colloid Interf Sci 140(2):114–131. doi:10.1016/j.cis.2007.12.008

Bhattacharyya KG, Gupta SS (2008b) Kaolinite and montmorillonite as adsorbents for Fe(II), Co(II) and Ni(II) in aqueous medium. Appl Clay Sci 41(1–2):1–9. doi:10.1016/j.clay. 2007.09.005

Brigden K, Santillo D, Stringer R (2002) Hazardous emissions from Thai coal-fired power plants: toxic and potentially toxic elements in fly ashes collected from Mae Moh and Thai petrochemical industry coal-fired power plants in Thailand, 2002. http://www.greenpeace.org/seasia/ph/Global/seasia/report/2002/8/hazardous-emissions-from-thai.pdf. Accessed 2 Jun 2015

Brousseau JHR, Seed LP, Lin MY, Shelp GS, Fyfe JD (2000) Electrochemical prevention of acid mine drainage. In: Singhal RK, Mehrotra AK (eds) Environmental issues and waste management in energy and mineral production. A.A. Balkema, Rotterdam/Brookfield, pp 539–542

Calgon (2007) Activated carbon principles. http://www.calgoncarbon.com. Accessed 7 Jun 2015

Campaner VP, Luiz-Silva W, Machado W (2014) Geochemistry of acid mine drainage from a coal mining area and processes controlling metal attenuation in stream waters, southern Brazil. Ann Braz Acad Sci 86(2):539–554. http://dx.doi.org/10.1590/0001-37652014113712

Campbell MM, Sederoff RR (1996) Variation in lignin content and composition (Mechanisms of control and implications for the genetic improvement of plants). Plant Physiol 110:3–13. doi:10.1104/pp.110.1.3

Chaari I, Medhioub M, Jamoussi F (2011) Use of clay to remove heavy metals from Jebel Chakir landfill leachate. J Appl Sci Environ Sanit 6(2):143–148

Chaiyasith S, Chaiyasith P, Septhum C (2006) Removal of cadmium and nickel from aqueous solution by adsorption onto treated fly ash from Thailand. Thammasat Int J Sci Tech 11(2):13–20

Chandler JA, Jewell WJ, Gossett JM, vanSoest PJ, Robertson JB (1980) Predicting methane fermentation biodegradability. Biotechnol Bioeng Symp 10:93–107

Choi SK, Lee S, Song YK, Moon HS (2002) Leaching characteristics of selected Korean fly ashes and its implications for the groundwater composition near the ash disposal mound. Fuel 81(8):1083–1090. doi:10.1016/S0016-2361(02)00006-6

Christensen B, Laake M, Lien T (1996) Treatment of acid mine water by sulfate-reducing bacteria; results from a bench scale experiment. Water Res 30(7):1624–1624. doi:10.1016/0043-1354(96)00049-8

Christensen TH, Kjeldsen P, Bjerg PL, Jemsen DL, Christensen JB, Baun A, Albrechtsen HJ, Heron G (2001) Biogeochemistry of landfill leachate plumes. Appl Geochem 16(7–8):659–718. doi:10.1016/S0883-2927(00)00082-2

Costa MC, Martins M, Jesus C, Duarte JC (2007) Treatment of acid mine drainage by sulfate-reducing bacteria using low cost matrices. Water Air Soil Pollut 189(1):149–162. doi:10.1007/s11270-007-9563-1

Dvorak DH, Hedin RS, Edenborn HM, McIntire PE (1992) Treatment of metal-contaminated water using bacterial sulfate reduction: results from pilot-scale reactors. Biotechnol Bioeng 40(5):609–616. doi:10.1002/bit.260400508

Erdem E, Karapinar N, Donat R (2004) The removal of heavy metal cations by natural zeolites. J Colloid Interface Sci 280(2):309–314. doi:10.1016/j.jcis.2004.08.028

Evanko CR, Dzombak DA (1997) Remediation of metals-contaminated soils and groundwater. https://clu-in.org/download/toolkit/metals.pdf. Accessed 15 May 2015

Foo KY, Hameed BH (2010) Insights into the modeling of adsorption isotherm systems. J Chem Eng 156(1):2–10. doi:10.1016/j.cej.2009.09.013

Gaikwad RW, Sapkal RS, Sapkal VS (2010) Removal of copper ions from acid mine drainage wastewater using ion exchange technique: factorial design analysis. J Water Resour Prot 2:984–989. doi:10.4236/jwarp.2010.211117

Gavaskar A, Gupta N, Sass B, Janosy R, Hicks J (2000) Design guidance for application of permeable reactive barriers for groundwater remediation. https://clu-in.org/conf/itrc/ prbll_061506/prb-2.pdf. Accessed 28 May 2015

Geranio L (2007) Review of zero valent iron and apatite as reactive materials for permeable reactive barrier. http://www.up.ethz.ch/education/term_paper/geranio_termpaper_fs07_ final.pdf. Accessed 9 Jun 2015

Gibert O, de Pablo J, Cortina JL, Ayora C (2002) Treatment of acid mine drainage by sulfate-reducing bacteria using permeable reactive barrier: a review from laboratory to full-scale experiments. Rev Environ Sci Biotechnol 1(4):327–333. doi:10.1023/A:1023227616422

Gibert O, de Pablo J, Cortina JL, Ayora C (2004) Chemical characterization of natural organic substrates for biological mitigation of acid mine drainage. Water Res 38(19):4186–4196. doi:10.1016/j.watres.2004.06.023

Gibert O, Rotting T, Cortina JL, de Pablo J, Ayora C, Carrera J, Bolzicco J (2011) In-situ remediation of acid mine drainage using a permeable reactive barrier in Aznalcollar (SW Spain). J Hazard Mater 191(1–3):287–295. doi:10.1016/j.jhazmat.2011.04.082

Gorme JB, Maniquiz MC, Kim SS, Son YG, Kim YT, Kim LH (2010) Characterization of bottom ash as an adsorbent of lead from aqueous solutions. Environ Eng Res 15(4):207–213. doi:10.4491/eer.2010.15.4.207

Gupta L, Rani S (2014) Leachate characterization and evaluating its impact on groundwater quality in vicinity of landfill site area. J Environ Sci Toxicol Food Technol 8(10):1–7

Hashim MA, Mukhopadhyay S, Sahu JN, Sengupta B (2011) Remediation technologies for heavy metal contaminated groundwater. J Environ Manag 92(10):2355–2388. doi:10.1016/j.jenvman.2011.06.009

He BJ, Zhang Y, Riskowski GL, Funk TL (1998) Thermochemical conversion of swine manure: temperature and pressure responses. http://www.cabdirect.org/abstracts/19992400413.html. Assessed 25 May 2015

Hossain ML, Das SR, Hossain MK (2014) Impact of landfill leachate on surface and ground water quality. J Environ Sci Technol 7(6):337–346. doi:10.3923/jest.2014.337.346

IEA (2014) The impact of Global Coal Supply on Worldwide Electricity Prices. https://www.iea.org/publications/insights/insightpublications/ImpactGlobalCoalSupply_WorldwideElectricityPrices_FINAL.pdf. Accessed 8 Jun 2015

ITRC (2011) Permeable reactive barrier: technology update. http://www.itrcweb.org/GuidanceDocuments/PRB-5-1.pdf. Accessed 22 May 2015

Jahangril-rad M, Jamshidi A, Rafiee M, Nabizadeh R (2014) Adsorption performance of packed bed column for nitrate removal using PAN-oxime-nano Fe2O3. J Environ Health Sci Eng 12(1):1–5. doi:10.1186/2052-336X-12-90

Jayaranjan MLD, Annachhatre AP (2013) Precipitation of heavy metals from coal ash leachate using biogenic hydrogen sulfide generated from FGD gypsum. Water Sci Technol 67(2):311–318. doi:10.2166/wst.2012.546

Jayaranjan MLD, van Hullebusch ED, Annachhatre AP (2014) Reuse options for coal fired power plant bottom ash and fly ash. Rev Environ Sci Biotechnol 13(4):467–486. doi:10.1007/s11157-014-9336-4

Jennings SR, Neuman DR, Blicker PS (2008) Acid mine drainage and effects on fish health and ecology: a review. http://reclamationresearch.net/publications/Final_Lit_Review_ AMD.pdf. Accessed 20 May 2015

Johnson DB, Hallberg KB (2005) Acid mine drainage remediation options: a review. Sci Total Environ 338(1–2):3–14. doi:10.1016/j.scitotenv.2004.09.002

Jong T, Parry DL (2003) Removal of sulfate and heavy metals by sulfate-reducing bacteria in short term bench scale up flow anaerobic packed bed reactor runs. Water Res 37(14):3379–3389. doi:10.1016/S0043-1354(03)00165-9

Jun D, Yongsheng Z, Weihong Z, Mei H (2009) Laboratory study on sequenced permeable reactive barrier remediation for landfill leachate-contaminated groundwater. J Hazard Mater 161(1):224–230. doi:10.1016/j.jhazmat.2008.03.086

Kijjanapanich P, Pakdeerattanamint K, Lens PNL, Annachhatre P (2012) Organic substrates as electron donors in permeable reactive barriers for removal of heavy metals from acid mine drainage. Environ Technol 33(22–24):2635–2644. doi:10.1080/09593330.2012. 673013

Kim B, Prezzi M (2008) Compaction characteristics and corrosivity of Indiana class-F fly ash and bottom ash mixtures. Constr Build Mater 22(4):694–702. doi:10.1016/j.conbuildmat. 2006.09.007

Kobya M, Demirbas E, Senturk E, Ince M (2005) Adsorption of heavy metal ions from aqueous solutions by active carbon prepared from apricot stone. Bioresour Technol 96(13):1518–1521. doi:10.1016/j.biortech.2004.12.005

Komnitsas K, Bartzas G, Paspaliaris I (2004a) Efficiency of limestone and red mud barriers: laboratory column studies. Miner Eng 17(2):183–194. doi:10.1016/j.mineng.2003.11.006

Komnitsas K, Baztzas G, Paspaliaris I (2004b) Clean up of acidic leachates using fly ash barriers: laboratory column studies. Global Nest the Int J 6(1):81–89

Komnitsas K, Bartzas G, Paspaliaris I (2006) Inorganic contaminant fate assessment in zero-valent iron treatment walls. Environ Forensic 7(3):207–217. doi:10.1080/152759206 00840479

Komnitsas K, Bartzas G, Fytas K, Paspaliaris I (2007) Long-term efficiency and kinetic evaluation of ZVI barriers during clean-up of copper containing solutions. Miner Eng 20(13):1200–1209. doi:10.1016/j.mineng.2007.05.002

Kurama H, Kaya M (2008) Usage of coal combustion bottom ash in concrete mixture. Constr Build Mater 22(9):1922–1928. doi:10.1016/j.conbuildmat.2007.07.008

Lalhruaitluanga H, Jayaram K, Prasad MNV, Kumar KK (2010) Lead(II) adsorption from aqueous solutions by raw and activated charcoals of Melocanna baccifera Roxburgh (bamboo)-A comparative study. J Hazard Mater 175(1–3):311–318. doi:10.1016/j.j hazmat.2009.10.005

Liamleam W, Annachhatre AP (2007) Electron donors for biological sulfate reduction. Biotechnol Adv 25(5):452–463. doi:10.1016/j.biotechadv.2007.05.002

Liang-qi L, Ci-an S, Xiang-li X, Yan-hong L, Fei W (2010) Acid mine drainage and heavy metal contamination in groundwater of metal sulfide mine at arid territory (BS mine, Western Australia). Trans Nonferrous Metals Soc China 20(8):1488–1493. doi:10.1016/ S1003-6326(09)60326-5

Martin S, Griswold W (2009) Human health effects of heavy metals. http://www.engg.ksu.edu/ chsr/files/chsr/outreach-resources/15HumanHealthEffectsofHeavyMetals.pdf. Accessed 20 May 2015

Mohan D, Chander S (2001) Single component and multi-component adsorption of metal ions by activated carbons. Colloids Surf A Physicochem Eng Asp 177(2–3):183–196. doi:10.1016/S0927-7757(00)00670-1

Mohan S, Gandhimathi R (2009) Removal of heavy metal ions from municipal solid waste leachate using coal fly ash as an adsorbent. J Hazard Mater 169(1–3):351–359. doi:10.1016/j.jhazmat.2009.03.104

Mor S, Ravindra K, Dahiya RP, Chandra A (2006) Leachate characterization and assessment of groundwater pollution near municipal solid waste landfill site. Environ Monit Assess 118(1):435–456. doi:10.1007/s10661-006-1505-7

Naidu R, Bekele DN, Birke V (2015) Permeable reactive barriers: cost-effective and sustainable remediation of groundwater. In: Naidu R, Birke V (eds) Permeable reactive barrier: sustainable groundwater remediation. CRC Press, Boca Raton

Nyarko FO, Mesa SJG, Malina G (2014) An overview of permeable reactive barriers for in situ sustainable groundwater remediation. Chemosphere 111:243–259. doi:10.1016/j. chemosphere.2014.03.112

Ohwoghere-Asuma O, Aweto KE (2013) Leachate characterization and assessment of groundwater and surface water qualities near municipal solid waste dump site in Effurun, Delta state, Nigeria. J Environ Earth Sci 3:126–134

Pagnaneli F, Viggi CC, Mainlli S, Toro L (2009) Assessment of solid reactive mixtures for the development of biological permeable reactive barriers. J Hazard Mater 170(2–3):998–1005. doi:10.1016/j.jhazmat.2009.05.081

Pakdeerattanamit K (2011) Electron donor for heavy metal removal from acid mine drainage (AMD) through permeable reactive barrier (PRB). PhD Thesis, Asian Institute of Technology, Bangkok, Thailand

PCD (2016) Water quality standard. http://www.pcd.go.th/info_serv/en_reg_std_water.html. Accessed 23 Jan 2016

Pirajan JCM, Giraldo L (2012) Heavy metal ions adsorption from wastewater using activated carbon from orange peel. E- J Chem 9(2):926–937. doi:10.1155/2012/383742

Pires M, Querol X (2004) Characterization of Candiota (South Brazil) coal and combustion by-product. Int J Coal Geol 60(1):57–72. doi:10.1016/j.coal.2004.04.003

Pouteau C, Dole P, Cathala B, Averous L, Boquillon N (2003) Antioxidant properties of lignin in polypropylene. Polym Degrad Stab 81(1):9–18. doi:10.1016/S0141-3910(03)00057-0

Puls RW, Paul CJ, Powell RM (1999) The application of in situ permeable reactive (zero-valent iron) barrier technology for the remediation of chromate-contaminated groundwater: a field test. Appl Geochem 14(8):989–1000. doi:10.1016/S0883-2927(99)00010-4

Roehl KE, Czurda K, Meggyes T, Simon FG, Stewart DI (2005) Permeable reactive barriers. In: Roehl KE, Meggyes T, Simon FG, Stewart DI (eds) Long-term performance of permeable reactive barriers. Elsevier, Amsterdam

Russell NV, Mendez LB, Wigley F, Williamson J (2002) Ash deposition of a Spanish anthracite: effects of included and excluded mineral matter. Fuel 81(5):657–663. doi:10.1016/S0016-2361(01)00155-7

Sabahi EA, Rahim SA, Zuhairi WY, Nozaily FA, Alshaebi F (2009) The characteristics of leachate and groundwater pollution at municipal solid waste landfill of Ibb City, Yemen. Am J Environ Sci 5(3):256–266. doi:10.3844/ajessp.2009.256.266

Sawyer CN, McCarty PL, Perkin GF (2007) Chemistry for environmental engineering and science, 15th edn. McGraw-Hill, New York

Silva LFO, Ward CR, Hower JC, Izquierdo M, Waanders F, Oliverira MLS, Li Z, Hatch RS, Querol X (2010) Mineralogy and leaching characteristics of coal ash from a major Brazilian power plant. Coal Combust Gasif Prod 2(1):51–65. doi:10.4177/CCGP-D-10-00005.1

Simon FG, Meggyes T, Tunnermeier T (2002) Groundwater remediation using active and passive process. In: Simon FG, Meggyes T, McDonald C (eds) Advanced groundwater remediation: active and passive technologies. Thomas Telford, London

Sukpreabprom H, Arquero OA, Naksata W, Sooksamiti P, Janhom S (2014) Isotherm, kinetic and thermodynamic studies on the adsorption of Cd(II) and Zn(II) ions from aqueous solutions onto bottom ash. Int J Environ Sci Dev 5(2):165–170. doi:10.18178/IJESD

TGF (2012) What is groundwater? http://www.groundwater.org/gi/whatisgw.html. Accessed 18 May 2015

Theis TL, Gardner KH (1990) Environmental assessment of ash disposal. Crit Rev Environ Sci Contr 20(1):21–42. doi:10.1080/10643389009388388

Thiruvenkatachari R, Vigneswaran S, Naidu R (2008) Permeable reactive barrier for groundwater remediation. J Ind Eng Chem 14(2):145–156. doi:10.1016/j.jiec.2007.10. 001

Tsukamoto TK, Killion HA, Miller GC (2004) Column experiments for microbiological treatment of acid mine drainage: low-temperature, low pH and matrix investigations. Water Res 38(6):1405–1418. doi:10.1016/j.watres.2003.12.012

USEIA (2013) International Energy Outlook 2013 with Projections to 2040. http://www.eia gov/forecasts/ieo/pdf/0484(2013).pdf. Accessed 24 May 2015

USEPA (1997) Permeable reactive subsurface barriers for the interception and remediation of chlorinated hydrocarbon and chromium (VI) plumes in ground water. https://clu-in.org/download/toolkit/remediat.pdf.ʠAccessed 26 May 2015

USEPA (1998) Permeable reactive barrier technologies for contaminant remediation. https://clu-in.org/download/rtdf/prb/reactbar.pdf. Accessed 26 May 2015

USEPA (2002) Field applications of in situ remediation technologies: permeable reactive barriers. https://clu-in.org/download/rtdf/fieldapp_prb.pdf. Accessed 26 May 2015

Vaclav P, Eva G (2005) Desalting of acid mine drainage by reverse osmosis method – field tests. Paper presented at the 9th International Mine Water Congress, University of Oviedo, Asturias, 5–7 Sept 2005

Vu THM, Pakkanen H, Alén R (2003) Delignification of bamboo (Bambusa procera acher): part 1. Kraft pulping and the subsequent oxygen delignification to pulp with a low kappa number. Ind Crop Prod 19(1):49–57. doi:10.1016/j.indcrop.2003.07.001

Wang LG, Yan GB (2011) Adsorptive removal of direct yellow 161 dye from aqueous solution using bamboo charcoals activated with different chemicals. Desalination 274(1–3):81–90. doi:10.1016/j.desal.2011.01.082

Wang J, Ban H, Teng X, Wang H, Ladwig K (2006) Impacts of pH and ammonia on the leaching of Cu(II) and Cd(II) from coal fly ash. Chemosphere 64(11):1892–1898. doi:10.1016/j.chemosphere.2006.01.041

Wang SY, Tsai MH, Lo SF, Tsai MJ (2008) Effect of manufacturing conditions on the adsorption capacity of heavy metal ions by Makino bamboo charcoal. Bioresour Technol 99(15):7027–7033. doi:10.1016/j.biortech.2008.01.014

Waybrant KR, Blowes DW, Ptacek CJ (1998) Selection of reactive mixtures for use in permeable reactive walls for treatment of mine drainage. Environ Sci Technol 32(13):1972–1979. doi:10.1021/es9703335