Abstract

The combination of a laccase–hydroxybenzotriazole (HBT) mediator system with/without cellobiose dehydrogenase (CDH) or an additional Fenton reaction step for the elimination and/or detoxification of phenolic compounds in dry olive mill residues (DOR) and liquid olive mill wastewaters (OMW) was evaluated. The laccase–HBT–CDH and laccase–HBT–CDH–Fenton system were the most effective, removing at least 69 and 72 % of phenolic compounds from a total of 698 and 683 mg in OMW and DOR, respectively, in 12 h. The efficient removal of phenolic compounds was also accompanied by >80 % reduction in biochemical oxygen demand and chemical oxygen demand in both DOR and OMW. Microbial community analysis using single-strand conformation polymorphism (SSCP) gels showed that biogas reactors supplemented with untreated and laccase–HBT–CDH–Fenton-treated DOR and OMW strongly inhibited growth of microorganisms. In contrast, the laccase–HBT- and laccase–HBT–CDH-pretreated OMW and DOR were detoxified as evidenced by SSCP analysis, which also indicated a distinct sensitivity of the individual members of the anaerobic population toward the toxicants. Further, although the laccase–HBT–CDH–Fenton system was effective in bleaching and removing phenolic compounds in both OMW and DOR, it was not able to support methane production. However, laccase–HBT and laccase–HBT–CDH indeed supported biogas production. This study therefore shows that the laccase–HBT–CDH system has a potential for the detoxification of olive mill residues, which can be potentially used as substrates for downstream processes.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Olive mill residues (OMR) are a complex material obtained from the extraction and processing of olive oil. They have high organic and inorganic nutrients with great potential as fertilizers, soil amendments or raw materials for other downstream processes. However, their high phenolic content together with the long-chain fatty acids makes them toxic to both microorganisms and plants (Dermeche et al. 2013; Blika et al. 2009; Sampedro et al. 2007a, b). This has made the use, disposal and/or treatment of OΜR a major problem in the Mediterranean region that accounts for approximately 95 % of the world’s olive oil production (Aranda et al. 2007, 2009; Sampedro et al. 2008; Volante et al. 2005).

Many strategies and technologies have been and/or are being investigated for the treatment of OMR including physicochemical methods (simple evaporation, photocatalysis-TiO2, flotation and settling, use as organic fertilizer by spreading in agricultural fields, filtration, neutralization with H2SO4, oxidation using O3 or Fenton’s reagent (Ouzounidou et al. 2010; Paraskeva and Diamadopoulos 2006). Recently there has been growing interest in developing biological processes (aerobic, anaerobic, co-digestion with other effluents, composting, enzymatic treatments) for the treatment of OMR (Ouzounidou et al. 2010; Paraskeva and Diamadopoulos 2006) or producing added value products (Dermeche et al. 2013; Ramosa et al. 2013). These biological processes are considered environmentally friendly and less energy demanding as compared to their physicochemical counterparts. Although a number of in vitro studies including those by our group have shown the ability of fungi to detoxify OMR (Aranda et al. 2007, 2009, 2010; Sampedro et al. 2007a, b, 2009; Volante et al. 2005), success in the development of a whole-organism-based biological treatment process is hampered by OMR toxicity. Current efforts aimed at overcoming the toxicity have shifted toward pretreatment of OMR using isolated oxidative enzymes (peroxidases, laccases and other phenol oxidases) produced by these fungi. This is not surprising since laccases (benzenediol:oxygen oxidoreductase, EC 1.10.3.2) together with peroxidases are responsible for the complete mineralization of lignin (a complex wood polymer) in the environment leaving behind a fibrous cellulose material during wood decomposition. Investigations so far have shown the ability of these oxidative enzymes especially laccases to remove or precipitate phenolic compounds in olive mill residues, leading to a partial decrease in toxicity as summarized by Ouzounidou et al. (2010). However, the remaining toxicity has been attributed to the phenoxy radicals and quinonoids generated by oxidative enzymes (Field and Lettinga 1989; Martirani et al. 1996).

In an effort to further detoxify the phenoxy radicals and quinonoids generated by oxidative enzymes, this study investigates the possibility of further treating laccase-treated OMR with cellobiose dehydrogenase. Cellobiose dehydrogenase (CDH). CDH (EC 1.1.3.25), is an extracellular enzyme secreted by wood degrading fungi (fungi producing lignolytic enzymes) under cellulolytic conditions (Schmidhalter and Canevascini 1993) and is partly credited with providing a detoxification mechanism for the fungi by reacting with phenoxy radicals and quinones generated by ligninolytic enzymes (lignin peroxidase, manganese peroxidase, versatile peroxidases and laccase) during lignin degradation (Ludwig et al. 2010). It is believed that the ability of CDH to use a variety of cellooligosaccharides present in the OMR, its ability to reduce quinones and ability to produce hydrogen peroxide will help decrease the amount of detoxify OMR. For the first time, CDH is assessed together with laccase for detoxification of OMR. The enzyme-treated OMR are the used as substrates for biogas production while monitoring the effect of the different treatments on the microbial communities present in the biogas reactors. The study was carried out during the course of 2013 at Graz University of Technology and University of Natural Resources and Life Sciences, Vienna, Austria.

Materials and methods

Materials

Unless otherwise stated, the chemical reagents used in this study were of analytical grade purchased from Sigma-Aldrich, Steinheim, Germany; Merck, Darmstadt, Germany or Lactan, Vienna, Austria. Olive mill residues (OMR) in the form of dry olive residues (DOR) were from Aceites Sierra Sur S.L., Granada, Spain an olive oil manufacturer supplied by the Spanish Council of Scientific Research (CSIC). The OMR in liquid form (OMW) was supplied from the National Technical University of Athens (NTUA). Trametes hirsuta and Trametes modesta laccases were produced in 500-ml buffer Erlenmeyer flasks containing 2 g yeast extract, 1 g wheat bran and 2 g ammonium sulfate in a total volume of 200 ml. Trametes villiosa laccase was a kind gift from Novozyme, Denmark. The recombinant Myriococcum thermophilum cellobiose dehydrogenase (MtCDH) was produced as described in Flitsch et al. (2013).

Laccase activity assay

Laccase activity was measured according to a method by Almansa et al. (2004) and modified by Nugroho Prasetyo et al. (2010). The reaction mixture in a total volume of 1 ml contained 50 mM succinate buffer (pH 4.5), enzyme solution and 10 mM ABTS solution. The change in absorbance of ABTS, due to its oxidation was monitored in time scan mode using a Hitachi U2001 UV–VIS spectrophotometer at 436 nm for 1 min. Enzyme activity was calculated from the molar extinction coefficient (ε) of 29.2 mM−1 cm−1 and expressed in units (mole of substrate converted per minute).

Cellobiose dehydrogenase activity assay

The activity of cellobiose dehydrogenase was assayed according to Baminger et al. (1999) with slight modifications. Briefly, CDH activity was measured by monitoring the decrease in absorbance of 2,6-dichlorophenol-indophenol (DCIP), at 520 nm (ε 520 = 6.8 × 103 M−1 cm−1), pH 4.0 and 37 °C using a Hitachi UV–VIS 2001 spectrophotometer. The reaction mixture (in a total volume of 1 ml) contained the following: 100 μl DCIP solution (3 mM in water containing 10 % v/v ethanol), 100 μl lactose (300 mM in 100 mM sodium acetate buffer, pH 4.5) and the appropriate amount of the same buffer. After temperature adjustment, the reaction was started by addition of a CDH sample and the decrease in absorbance monitored over a period of 2 min. One unit of enzyme activity was defined as the amount of enzyme reducing 1 μmol of DCIP per min under the above reaction conditions.

Olive oil residue treatment

Into 500 ml of sodium citrate buffer pH 4.5 containing a volumetric activity of 12 U ml−1 laccase, 10 g of either OMW or DOR were added. The mixture was incubated in 1-l Erlenmeyer flasks at 40 °C while shaking at 150 rpm for 24 h. Controls were run under similar conditions. After 24 h of incubation part of the laccase, oxidized OMW and DOR were further treated with 5 U ml−1 CDH activity supplemented with 200 mM cellobiose (final concentration) and the mixture further incubated under similar conditions. Another part of the laccase- and CDH-treated samples were subjected to a Fenton’s reaction by adding 3 mM FeCl3 and 10 mM hydrogen peroxide. Reaction mixtures were incubated at 40 °C while shaking at 150 rpm for 24 h. Controls were prepared and incubated under similar conditions.

Measurement of phenolic content

Phenolics concentration was monitored according to the Folin–Ciocalteu method (Osono and Takeda 1999) using the Folin–Ciocalteu reagents (Singleton and Rossi 1965). Briefly, 100 μl of the sample was mixed with 100 μl of Folin–Ciocalteu reagent and stirred. Subsequently, 500 μl of double distillate water, 100 μl of sample and 100 μl of Folin–Ciocalteu reagent were added to a 2-ml eppendorf reaction tube. The contents were mixed and allowed to stand for 8 min at 25 °C. Thereafter, 1 ml of a 7 % sodium carbonate solution was added, followed by the addition of nanopure water and allowed to stand at 30 °C for 2 h. Total phenolic content was measured using Hitachi UV–VIS spectrophotometer at 650 nm wavelength using 2 ml polystyrene cuvette. Total phenolic content was determined as gallic acid equivalents (GAE) expressed as milligrams per liter of gallic acid per milligram of extract (Peschel et al. 2006).

Monitoring methane production

Laboratory batch experiments were carried out according to Friedmann et al. (2004) based on DIN DEV 38414 S8, 1985. A second stage sludge containing 2.31 % dry matter (DM), 1.7 % organic dry matter (ODM) from a biogas plant primary digesting maize silage in Fürstenfeld, Austria was used as inoculum. The fermentation mixture in a 600-ml ground flasks contained 37 % (v/v) of seeding sludge adjusted to 2 % ODM using deionised H2O, 10 g of either enzyme-treated or untreated OMW or DOR supplemented with 0.7 % (w/v) powder of xylan from birchwood was set up. Prior to incubation at 35 °C, flasks were flushed with nitrogen gas for 20 min in order to remove CO2. The generated biogas was allowed to pass through 2 M NaOH solution and the NH4 + as well as H2S was removed using an acidic solution containing Na2SO4·10H2O, 200 g l−1 and 98 % H2SO4, 30 ml l−1. The amount of CH4 in liters per kilogram of ODM was calculated from displaced acidic solution volumes following VDI 4630 (Friedmann et al. 2004). Data were obtained from the average of triplicate samples collected daily over a total fermentation period of 15 days whereupon methane production was measured cumulatively.

Monitoring chemical oxygen demand (COD)

COD was determined as outlined by APHA (Eaton et al. 2005). Briefly, a 10 ml of 0.25 N potassium dichromate was added to 5 ml sample and 20 ml of sulfuric acid and used to digest the OMR sample for half an hour after which five drops of ferroin indicator were added and titrated against 0.25 N ferrous ammonium sulfate solution. The change in color from blue green to wine red indicated the end point. The COD was estimated as follows;

where B = volume of the titrant used against blank, A = volume of the titrant used against sample and C = volume of the sample.

Measuring biochemical oxygen demand (BOD5)

BOD5 was measured according to the 5210D APHA (Eaton et al. 2005). Thoroughly shaken 5 ml of OMR were added to 155 ml of distilled water in a brown bottle and allowed to stand for 5 days. The generated CO2 was bound from the gas mixture by potassium hydroxide placed in the bottle stopper. The quantity of oxygen expressed in mg O2 dm−3, which is consumed by the organic matter under test conditions from the following equation;

Monitoring the effect of OMR treatment on biogas production and microbial community PCR-based community analysis

DNA extraction

The total bacterial community DNA was extracted as described by Martin-Laurent et al. (2001). Briefly, 1 g sample was centrifuged for 15 min at 16,750×g. The pellet was then resuspended in 1 ml of extraction buffer containing (in g l−1): ethylenediaminetetraacetic acid (EDTA), 37.25; NaCl, 5.85; polyvinylpyrrolidone (PVP), 10; Tris–HCl, 12 and 20 % (v/v) sodium dodecyl sulfate (SDS), 100 ml l−1. To ensure complete cell lysis, glass beads from 0.15 to 2.00 μm in diameter were added to crush cell structures using FastPrep Instrument (Qbiogene, Heidelberg, Germany) for 2 × 30 s including cooling steps on ice in between for 2 min. After centrifugation for 1 min at 16,750×g, the supernatant was mixed with 5 M sodium acetate, 100 μl and incubated on ice for 15 min for protein precipitation. Following another centrifugation step for 5 min, an equal volume of chloroform–phenol–isoamylalcohol mixture (15:24:1) was added to the supernatant. Subsequently, the genomic DNA was precipitated by adding an equal volume of isopropanol to the supernatant. The precipitated DNA was recovered by centrifugation for 10 min, washed once with 70 % (v/v) ethanol and resuspended in a total volume of 50 μl of 10 mM Tris–HCl buffer (pH 8.0).

Polymerase chain reaction (PCR) amplification

Fingerprinting of OMR associated total bacterial communities by single-strand conformation polymorphism (SSCP) was carried out as described by Schwieger and Tebbe (1998). Specific primers used for amplification of total bacteria 16S ribosomal RNA (rRNA) genes in include 0.5 μM Unibac-II-525f (5′-GTGCCAGCAGCCGC-3′) (27) and phosphorylated 0.5 μM Unibac-II-927rP (5′-CCCGTCAATTYMTTTGAG-3′) (27), 12 μl Taq-&GOTM PCR Mastermix (Qbiogen BIO 101 Systems, Carlsbad, USA) and 3 μl of template DNA (95 °C, 5 min; 31 cycles of 95 °C, 20 s; 54 °C, 15 s; 72 °C, 30 s; and elongation at 72 °C, 10 min). Negative control PCR contained no DNA template. The cycling conditions were set as follows: (1) denaturation at 94 °C for 4 min, (2) annealing at 53 °C for 30 s, (3) extension at 72 °C for 60 s, (4) final extension at 72 °C for 10 min, (5) hold at 4 °C. Steps (2) to (4) were repeated 35 times. For the purification of PCR-generated DNA products, Gene Clean Turbo Kit (Qbiogene, Heidelberg, Germany) was used following the manufacturer’s recommendations. All purified (peqGOLD MicroSpin Cycle Pure Kit, PEQLAB, Erlangen, Germany) DNA fragments were separated with a TGGE Maxi apparatus (Biometra, Göttingen, Germany) at 400 V and 26 °C. Gels were silver stained in order to visualize the bands (Bassam et al. 1991).

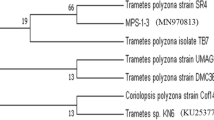

Sequence analysis

Some major dominant and disappearing bands were excised from the gel for sequencing performed by the ZMF Laboratory of the Medical University of Graz (Graz, Austria). The obtained sequences were compared to those in the NCBI GenBank (Altschul et al. 1997) (http://www.ncbi.nlm.nih.gov/blast/), using BLAST searches.

Results and discussion

Enzymatic treatment of olive oil mill waste

During the initial phase, the ability of laccases from different sources supplemented with 1 mM HBT to oxidize and polymerize phenolic compounds in OMW was investigated. As shown in Fig. 1, the highest phenolic removal of 64 % was obtained with T. villosa laccase. M. thermophila laccase only removed 32 % of the phenolic compounds. This removal efficiency which is most likely due to oligo/polymerization eventually with concomitant precipitation seems directly related to the redox potential of the enzyme. For example, the redox potential of laccases from T. villosa, M. thermophila and T. hirsuta is estimated to be 0.79, 0.45, 0.75 V, respectively (Alcalde 2007; Durão et al. 2006). Previous studies by Nugroho Prasetyo et al. 2010 also demonstrated that laccases from different sources even in the presence of same mediator produced different polymeric products with different molecular weights. This means that the low-redox-potential laccases could not effectively oxidize some of the phenolic compounds in OMR with a higher redox potential. T. villosa was therefore chosen for further studies.

The ability of T. villosa laccase–HBT in combination with CDH or the Fenton reaction to enhance the removal of phenolics in OMW was further investigated. As visible in Fig. 2, laccase–HBT, laccase–HBT–CDH and laccase–HBT–CDH–Fenton were effective in bleaching the phenolic compounds in the OMW. This observation is in line with the well-known ability of laccase to decolorize and detoxify many different effluents including textile dye and pulp and paper effluents (Abadulla et al. 2000; Kudanga et al. 2012; Nyanhongo et al. 2002; Rodríguez Couto et al. 2005). Samples treated with laccase–HBT–CDH showed a slightly lighter color than laccase–HBT-treated samples. This may be attributed to the ability of CDH to oxidize a variety of cellooligosaccharides present in the OMR to also produce hydrogen peroxide, resulting in enhanced bleaching as well as reduction of colored quinones or phenoxy radicals (Nyanhongo et al. 2013). Similarly, incorporation of iron in the laccase–HBT–CDH system also resulted in remarkable decolorization. This suggests that the hydrogen peroxide produced by CDH also enhanced the generation of hydroxyl radicals through Fenton’s chemistry.

Further analysis of total residual phenolic compounds in treated and untreated OMW and DOR also confirmed that laccase–HBT, laccase–HBT–CDH as well as laccase–CDH–Fenton reaction systems were more effective in the removal of phenolic compounds (Fig. 3). In both cases, laccase–HBT alone removed 48 and 50 % of the phenolic compounds in OMW and DOR, respectively (Fig. 3). However, the combination of laccase–HBT–CDH increased the removal of phenolic compounds to 62 % in DOR and 57 % in OMW (Fig. 3). Incorporation of iron even further increased the removal of phenolic compounds, leading to the removal of 68 and 73 % of the total phenolics in DOR and OMW, respectively. CDH alone was not able to effectively remove the phenolic compounds (Fig. 3). These results taken together with previous studies by various groups (Aranda et al. 2007, 2009, 2010; Sampedro et al. 2007a, b, 2009; Volante et al. 2005), shows that laccase plays a major role in the removal of the phenolic compounds in OMR. However, here we show for the first time that the addition of CDH can dramatically enhance this effect.

The removal of phenolic compounds also resulted in significant reduction of COD and BOD in both DOR and OMW samples especially in samples incubated with laccase + CDH and laccase + CDH + Fenton (Table 1). This is attributed to the ability of laccase to oxidize many phenolic compounds, leading to copolymerization and precipitation of even non-laccase substrates (carbohydrates, hemicellulose, etc.) in the OMR. In reaction setups containing laccase and CDH, it is speculated that laccase-oxidized species were further oxidized by CDH and in the presence of iron; the CDH-produced hydrogen peroxide was used to generate hydroxyl radicals that even further decreased the COD and BOD.

Methane production in laboratory scale batch reactors

The treated and untreated OMW and DOR were used as substrates for biogas production. The biogas reactors supplemented with laccase–HBT- and laccase–HBT–CDH-pretreated OMW produced 7.9 and 8.6 l methane/Kg ODM while the biogas reactors supplemented laccase–HBT- and laccase–HBT–CDH-pretreated DOR produced 7.8 and 8.4 l methane per kg ODM (Fig. 4). In comparison with the biogas reactors supplemented with untreated OMW and DOR as well as samples laccase–HBT–CDH–Fenton, this represents over 80 % increase in methane production (Fig. 4). These results suggest that laccase–CDH pretreatment of OMR, which is rich in organic and inorganic nutrients could lead to their exploitation as feed material for many biotechnological applications.

Biogas production using OMR is attractive since it has a high in COD (>100 kg/ton of olive fruits) and BOD (>45 kg-BOD/ton of olive fruits), which theoretically is estimated to produce 25 normal m3 methane/ton of olives, an equivalent gross heat-production potential of about 1 GJ/ton olives (Gelegenis et al. 2007). In addition, laccase–CDH pretreatment of OMR is a better option compared to the dilution approach which is limited to 40 % dilution of OMR as reported by Gelegenis et al. (2007). In previous similar studies, OMW treatment with Aspergillus wentii and Aspergillus niger resulted in the 59.3 % reduction of COD and 80 % reduction in phenolic compounds (Afify et al. 2009), and in a recent screening study, several fungi producing laccases and peroxidase achieved up to 65 % decolorization, 81 % reduction in phenolics, 29 % reduction in COD and reduced the in inhibition of Aliivibrio fischeri luminescence (Ntougias et al. 2012). These advantages of laccase pretreatments are further reinforced by Blika et al. (2009) who showed that pretreatment of OMR with laccase producing white-rot fungi allowed a stable operation of the anaerobic reactor at hydraulic retention times of 30 days and gave higher biogas yields. However, the combination of laccase and CDH even lead to higher detoxification of phenolic compounds, leading to higher production of higher methane. The biogas reactors fed with laccase–HBT–CDH–Fenton-treated sample produced methane almost similar to the blank samples (Fig. 4). This may be attributed to the presence of reactive species that inhibited the microorganisms. Lower biogas production in the control also confirms the toxicity of phenolic compounds in OMR reported by many authors discussed above.

The inhibitory effects of untreated OMR and benefits of laccase–HBT or Laccase–HBT–CDH pretreatment of OMR were confirmed by analyzing microbial communities in the different reactors using PCR-based SSCP analysis of amplified bacterial 16S rRNA gene fragments. Since successful biogas production largely depends on the ability of the premethanogenic fermentation populations (syntrophic bacteria) to produce acetic acid, CO2 and H2, which is used by methanogenic archaea, SSCP analysis also focused on these microorganisms rather than a direct effect on methanogenesis. Although the same inoculum was used in all experiments, there was a striking difference especially between OWM- and DOR-treated samples (Fig. 5). These findings suggest a difference between the inhibitory effects OWM and DOR, which leads us to conclude that they may contain different phenolic compounds or different concentration of the different phenolic compounds.

SSCP gels showing the effect of treated and untreated a DOR and b OMR samples on the microbial community after 15 days of incubation. The positively identified excised bands, similarity (%) and accession number are follows: (1) Desulfovibrio marrakechensis (90 %) NR_042704.1; (2) Hydrogenophaga bisanensis (98 %) NR_044268.1; (3) Desulfovibrio bastinii (84 %) NR_025766.1; (4) Comamonas denitrificans (99 %) NR_025080.1; (5) Bacillus azotoformans (97 %) NR_041641.1; (6) Alkaliflexus imshenetski (89 %) NR_042317.1; (7) Caldithrix abyssi (89 %) NR_028969.1; (8) Gracilibacter thermotolerans (92 %) NR_043559.1; (9) Proteiniphilum acetatigenes (86 %) NR_043154.1; (10) Prolixibacter bellariivorans (86 %) NR_043273.1; (11) Petrimonas sulfuriphila (95 %) NR_042987.1

Microorganisms in the inoculum of biogas samples supplemented with OMR pretreated with CDH, Fenton and laccase–HBT–CDH–Fenton were strongly inhibit, leading to the complete disappearance of some bands on the SSCP gels. Biogas reactors containing laccase–HBT and laccase–CDH-treated OMR or DOR samples were able to support the growth of microorganisms especially in the later as evidenced by the bands intensity. Among the sequenced bands obtained from biogas samples supplemented with untreated DOR, DOR samples treated with CDH only and DOR samples treated with Fenton or laccase–CDH–Fenton showed that bands corresponding to Desulfovibrio marrakechensis, Desulfovibrio bastinii, Comamonas denitrificans, Alkaliflexus imshenetskii, Caldithrix abyssi completely disappeared after 15 days incubation. However, bands corresponding to Hydrogenophaga bisanensis, Bacillus azotoformans, Gracilibacter thermotolerans, Proteiniphilum acetatigenes, Prolixibacter bellariivorans and Petrimonas sulfuriphila remained visible in the same samples and were even more predominant in samples supplemented with laccase and laccase–CDH-treated OMR. In biogas samples supplemented with different OMW treated samples, bands corresponding to Sporosarcina globispora, Bacteroides intestinalis, Vitis vinifera, Syntrophomonas zehnderi, Clostridium mesophilum, completely disappeared after 15 days of incubation. However, bands corresponding to Proteiniphilum acetatigenes, Proteiniphilum acetatigenes, Solibacillus silvestris, Bacillus psychrodurans were visible throughout the incubation period although their intensity decreased. These differences in population shifts indicate distinct tolerance of microorganism to the toxic phenolics.

Conclusion

In conclusion, this study shows that the laccase–HBT–CDH systems is very good system to remove and detoxifying phenolic compounds in OMR, making it suitable as a feed material for biogas production given its high amount of organic and inorganic nutrients. From these studies, we can also infer that laccase–HBT–CDH-treated OMR could be used as soil amendment with no inhibitory effect on plants and microorganisms. However, although pretreatment of OMR with laccase–HBT–CDH–Fenton system effectively bleaches the OMR and reduces COD, this did not result in reduction of toxicity as evidenced by the inhibition of microorganisms and low biogas production; therefore, this approach is not good for producing a biotechnologically valuable OMR.

References

Abadulla E, Tzanov T, Costa S, Robra K, Cavaco-Paulo A, Gübitz GM (2000) Decolorization and detoxification of textile dyes with a Laccase from Trametes hirsuta. Appl Environ Microbiol 66:3357–3362

Afify AS, Mahmoud MA, Emara HA, Abdelkreem KL (2009) Phenolic compounds and COD removal from olive mill wastewater by chemical and biological procedures. AJBAS 3:1087–1095

Alcalde M (2007) Laccases: biological functions, molecular structure and industrial applications. In: Polaina J, MacCabe A (eds) Industrial enzymes: structure, function and applications. Springer, Netherlands, pp 461–476

Almansa E, Kandelbauer A, Pereira L, Cavaco-Paulo A, Guebitz GM (2004) Influence of structure on dye degradation with laccase mediator systems. Biocatal Biotransform 22:315–324

Altschul SF, Madden TL, Schäffer AA, Zhang J, Zhang Z, Miller W, Lipman DJ (1997) Gapped BLAST and PSI-BLAST: a new generation of protein database search programs. Nucleic Acids Res 25:3389–3402

Aranda E, García-Romera I, Ocampo JA, Carbone V, Mari A, Malorni A, Sannino F, De Martino A, Capasso R (2007) Chemical characterization and effects on Lepidium sativum of the native and bioremediated components of dry olive mill residue. Chemosphere 69:229–239

Aranda E, Sampedro I, Daaz R, Garcia-Sa¡nchez M, Arriagada CA, Ocampo JA, Garcia-Romera I (2009) The effects of the arbuscular mycorrhizal fungus Glomus deserticola on growth of tomato plants grown in the presence of olive mill residues modified by treatment with saprophytic fungi. Symbiosis 47:133–140

Aranda E, Sampedro I, Díaz R, García-Sánchez M, Siles JA, Ocampo JA, García-Romera I (2010) Dry matter and root colonization of plants by indigenous arbuscular mycorrhizal fungi with physical fractions of dry olive mill residue inoculated with saprophytic fungi. Span J Agric Res 8:S79–S85

Baminger U, Nidetzky B, Kulbe KD, Haltrich D (1999) A simple assay for measuring cellobiose dehydrogenase activity in the presence of laccase. J Microbiol Methods 35:253–259

Bassam BJ, Caetano-Anollés G, Gresshoff PM (1991) Fast and sensitive silver staining of DNA in polyacrylamide gels. Anal Biochem 196:80–83

Blika PS, Stamatelatou K, Kornaros M, Lyberatos G (2009) Anaerobic digestion of olive mill wastewater. Glob NEST J 11:364–372

Dermeche S, Nadoura M, Larroche C, Moulti-Matia F, Michaud P (2013) Olive mill wastes: biochemical characterizations and valorization strategies. Process Biochem 48:1532–1552

Durão P, Bento I, Fernandes A, Melo E, Lindley P, Martins L (2006) Perturbations of the T1 copper site in the CotA laccase from Bacillus subtilis: structural, biochemical, enzymatic and stability studies. JBIC 11:514–526

Eaton AD, Clesceri LS, Rice EW, Greenberg AE (2005) Standard methods for the examination of water and wastewater. APHA, Washington, DC

Field JA, Lettinga G (1989) The effect of oxidative coloration on the methanogenic toxicity and anaerobic biodegradability of phenols. Biol Wastes 29:161–179

Flitsch A, Nugroho Prasetyo E, Sygmund C, Ludwig R, Nyanhongo GS, Guebitz GM (2013) Cellulose oxidation and bleaching processes based on recombinant Myriococcum thermophilum cellobiose dehydrogenase. Enzyme Microb Technol 52:60–67

Friedmann H, Görtz G, Helm M, Kaltschmitt M, Knopf U, Kretschmer A, Kübler H, Langhans G, Linke B, Pätz R, Rosenwinkel K, Shan M, Weiland P, Wendler D, Zellmann H, Konstantinidou E (2004) Vergärung organischer Stoffe (VDI 4630). In: Ingenieure VD (ed) VDI-Handbuch Energietechnik. Beuth Publishing, Berlin, Düsseldorf, Germany, pp 1–48

Gelegenis J, Georgakakis D, Angelidaki I, Christopoulou N, Goumenaki M (2007) Optimization of biogas production from olive-oil mill wastewater, by codigesting with diluted poultry-manure. Appl Energy 84:646–663

Kudanga T, Burton S, Nyanhongo GS, Guebitz GM (2012) Versatility of oxidoreductases in the remediation of environmental pollutants. Front Biosci 4:1127–1149

Ludwig R, Harreither W, Tasca F, Gorton L (2010) Cellobiose dehydrogenase: a versatile catalyst for electrochemical applications. ChemPhysChem 11:2674–2697

Martin-Laurent F, Philippot L, Hallet S, Chaussod R, Germon JC, Soulas G, Catroux G (2001) DNA extraction from soils: old bias for new microbial diversity analysis methods. Appl Environ Microbiol 67:2354–2359

Martirani L, Giardina P, Marzullo L, Sannia G (1996) Reduction of phenol content and toxicity in olive oil mill waste waters with the ligninolytic fungus Pleurotus ostreatus. Water Res 30:1914–1918

Ntougias S, Baldrian P, Ehaliotis C, Nerud F, Antoniou T, Merhautová V, Zervakis GI (2012) Biodegradation and detoxification of olive mill wastewater by selected strains of the mushroom genera Ganoderma and Pleurotus. Chemosphere 88:620–626

Nugroho Prasetyo E, Kudanga T, Østergaard L, Rencoret J, Gutiérrez A, del Río JC, Ignacio Santos J, Nieto L, Jiménez-Barbero J, Martínez AT, Li J, Gellerstedt G, Lepifre S, Silva C, Kim SY, Cavaco-Paulo A, Seljebakken Klausen B, Lutnaes BF, Nyanhongo GS, Guebitz GM (2010) Polymerization of lignosulfonates by the laccase–HBT (1-hydroxybenzotriazole) system improves dispersibility. Bioresour Technol 101:5054–5062

Nyanhongo GS, Gomes J, Gübitz GM, Zvauya R, Read J, Steiner W (2002) Decolorization of textile dyes by laccases from a newly isolated strain of Trametes modesta. Water Res 36:1449–1456

Nyanhongo GS, Sygmund C, Ludwig R, Nugroho Prasetyo E, Guebitz GM (2013) An antioxidant regenerating system for continuous quenching of free radicals in chronic wounds. Eur J Pharm Biopharm 83(3):396–404

Osono T, Takeda H (1999) Decomposing ability of interior and surface fungal colonizers of beech leaves with reference to lignin decomposition. Eur J Soil Biol 35:51–56

Ouzounidou G, Zervakis GI, Gaitis F (2010) Raw and microbiologically detoxified olive mill waste and their impact on plant growth. Terres Aqua Environ Toxicol 4:21–38

Paraskeva P, Diamadopoulos E (2006) Technologies for olive mill wastewater (OMW) treatment: a review. J Chem Technol Biotechnol 81:1475–1485

Peschel W, Sánchez-Rabaneda F, Diekmann W, Plescher A, Gartzía I, Jiménez D, Lamuela-Raventós R, Buxaderas S, Codina C (2006) An industrial approach in the search of natural antioxidants from vegetable and fruit wastes. Food Chem 97:137–150

Ramosa P, Santos SAO, Guerraa AR, Guerreiro O, Felício L, Jerónimo E, Silvestre AJD, Neto CP, Duarte M (2013) Valorization of olive mill residues: Antioxidant and breast cancer antiproliferative activities of hydroxytyrosol-rich extracts derived from olive oil by-products. Ind Crops Prod 46:359–368

Rodríguez Couto S, Sanromán M, Gübitz GM (2005) Influence of redox mediators and metal ions on synthetic acid dye decolourization by crude laccase from Trametes hirsuta. Chemosphere 58:417–422

Sampedro I, D’Annibale A, Ocampo JA, Stazi SR, García-Romera I (2007a) Solid-state cultures of Fusarium oxysporum transform aromatic components of olive-mill dry residue and reduce its phytotoxicity. Bioresour Technol 98:3547–3554

Sampedro I, Marinari S, D’Annibale A, Grego S, Ocampo JA, García-Romera I (2007b) Organic matter evolution and partial detoxification in two-phase olive mill waste colonized by white-rot fungi. Int Biodeterior Biodegrad 60:116–125

Sampedro I, Aranda E, Díaz R, García-Sanchez M, Ocampo JA, García-Romera I (2008) Saprobe fungi decreased the sensitivity to the toxic effect of dry olive mill residue on arbuscular mycorrhizal plants. Chemosphere 70:1383–1389

Sampedro I, Cajthaml T, Marinari S, Petruccioli M, Grego S, D’Annibale A (2009) Organic matter transformation and detoxification in dry olive mill residue by the saprophytic fungus Paecilomyces farinosus. Process Biochem 44:216–225

Schmidhalter DR, Canevascini G (1993) Isolation and characterization of the cellobiose dehydrogenase from the brown-rot fungus Coniophora puteana (Schum ex Fr.) Karst. Arch Biochem Biophys 300:559–563

Schwieger F, Tebbe CC (1998) A new approach to utilize PCR–single-strand-conformation polymorphism for 16S rRNA gene-based microbial community analysis. Appl Environ Microbiol 64:4870–4876

Singleton VL, Rossi JA (1965) Colorimetry of total phenolics with phosphomoly diphosphotungstic acid reagents. Am J Enol Viticult 16:144–158

Volante A, Lingua G, Cesaro P, Cresta A, Puppo M, Ariati L, Berta G (2005) Influence of three species of arbuscular mycorrhizal fungi on the persistence of aromatic hydrocarbons in contaminated substrates. Mycorrhiza 16:43–50

Acknowledgments

The authors are grateful for the financial support given by the K-project “Future Lignin and Pulp Processing Research” (FLIPPR).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nugroho Prasetyo, E., Rodríguez, R.D., Lukesch, B. et al. Laccase–cellobiose dehydrogenase-catalyzed detoxification of phenolic-rich olive processing residues. Int. J. Environ. Sci. Technol. 12, 1343–1352 (2015). https://doi.org/10.1007/s13762-014-0526-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-014-0526-y