Abstract

Laccases represent a family of copper-containing oxidases involved in the biocatalysis of the one electron enzymatic oxidation of phenolic and aromatic compounds with a resultant reduction of oxygen to water. Their wide substrate variability on both phenolic and non-phenolic compounds arising from the activities of mediator systems lends a potential for their varying applications in the environmental, pharmaceutical, and food industries, especially the bioremediation of poly-aromatic hydrocarbon-contaminated soils. Thus, playing essential roles in the realization of United Nations Sustainable Development Goal (SDG) number eleven, which is aimed at the achievement of safe, reliable, and sustainable cities and communities. However, product recovery and purification remain critical concerns in laccase production, with reports showing that downstream processing accounts for approximately eighty percent of the total costs of industrial enzymes production. In light of this and considering the emerging and increasing biotechnological applications of laccases, an effective purification procedure would be key in the post-production processing. This review, therefore, explores the current affordable, quick, and efficient approaches that offer minimal processing steps at reduced production costs as well as laccase immobilization and mediator systems. A highlight of the various biotechnological applications of laccases alongside the current challenges and future prospects of laccase use in industries and environmental remediation of recalcitrant contaminants is presented.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

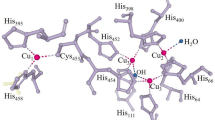

Laccases (EC 1.10.3.2) are important industrial enzymes with great biotechnological potential. They are part of a large community of enzymes called polyphenol oxidases also called multicopper oxidases (MCOs) – enzymes that oxidize their substrates by transferring electrons to a trinuclear copper center from a mononuclear copper core (Bento et al. 2005). Ceruloplasmine (EC 1.16.3.1), nitrite reductase (EC 1.7.2.1), and ascorbate oxidase (EC 1.10.3.3) are some recognized members of the MCO family. Laccase catalyzes the one-electron oxidation of anilines, phenols, and aromatic thiols into their radicals, which results in the reduction to water of oxygen, oxidizing a broad spectrum of compounds, mostly phenolic, and even aromatic and aliphatic amines (Karaki et al. 2016); such free radicals undergo further oxidation or non-enzymatic reactions, including disproportionation, polymerization, or hydration (Shraddha et al. 2011). Laccase was first discovered in Rhus vernicifera , the Japanese lacquer tree, sap. In 1985, Bertrand discovered its feature as a metal which contains oxidase (Giardina et al. 2010). Over time, laccases were detected in various basidiomycetic and ascomycetic fungi as well as in different bacteria and plant species. As a result of their ability to catalyze the oxidation by one-electron of aromatic and phenol-containing compounds, laccases are used in numerous applications such as bleaching, delignification, and degradation processes. Hence, laccases are very useful in the actualization of the SDG 11 in the UN’s agenda for safe, reliable, and sustainable cities and communities. Recently, laccases have also found use in biosensor design and obtainment of biofuel cells (Huber et al. 2018).

Laccase catalysis includes the reduction to water of one molecule of oxygen, which allows for wide spectrum oxidation of molecules (including compounds which are aromatic). Polyphenols, aromatic amines, and methoxy-substituted monophenols are among these substances. However, for laccases to oxidize non-phenolic compounds, there is need for the presence of mediators – low molecular weight organic compounds which undergo laccase oxidation. Without these mediators, laccases cannot oxidize non-phenolic substances, such as phenoxyl radicals and other non-phenolic antioxidants that may be polluting the environment (Arregui et al. 2019).

Inadequacies in the purification and recovery of laccase enzyme remain an issue in the economical production and application of laccases. High cost of equipment and long periods of existing purification processes necessitate research and development of more cost-friendly yet effective procedures. This will bring about the effective optimization of laccase production at an economical rate. This review focuses on identifying the currently developed methods to bring about this optimal and cost-friendly yield of laccase. The review also focuses on the existent types of mediators available to broaden laccase substrate range, as well as the immobilization techniques that are useful for laccase recovery. This review hopes to shed light on the current advances in these areas of laccase purification and applications, as well as give insight to the current challenges and future perspectives for research. This will aid more informed research strategies for the development of more effective laccases for diverse industrial applications.

2 Recovery and Purification of Laccases

Development of the application potential of laccase brings about an increase in efficient purification and extraction on a large scale. The downstream process (DSP) is a very important aspect of industrial production of biomolecules, especially the recovery, purification, and concentration of fermentation products. The DSP only comes after the desired product has been biosynthesized and is considered to be expensive and consumes a lot of time; DSP determines up to 80% of the cost of biomolecule production (Madadlou et al. 2017). DSP often requires various concentration and separation process stages and procedures; however, the feasibility of these procedures depends on the correct choice of process conditions and purification techniques (Antecka et al. 2019). Industrial laccase production also follows the same principle; although, in their natural state, the enzymes are relatively active, they do not meet expected industrial application specifications in terms of fermentation concentration and activity; hence the need for effective purification methods (Antecka et al. 2019).

Laccase purification from supernatants of culture of diverse microbes has brought about several publications exist. Chromatography, involving various ion exchange, affinity, and hydrophobic interaction mechanisms, is the technique that is commonly applied (Madadlou et al. 2017; Agrawal et al. 2019). Microfiltration, ultrafiltration, and acetone precipitation are some other techniques that have been applied in DSP of laccase. The purification process applied is often dependent on the intended application as well as commercial production (Junior et al. 2020). These processes help to highly concentrate products with a relative high purity. The operation time, however, for these processes is long, and the operating cost is relatively high for the yielded capacity; the manufacturing process as a whole, as a result of the high cost of the above processes, is not economically effective. Laccase industrial production therefore requires more effective and cheaper methods of DSP. An example of such techniques recently explored has proven to be economical for recovery of biomolecule is ATPE (aqueous two-phase extraction) (Antecka 2019; Junior et al. 2020).

ATPE refers to an extraction using aqueous two-phase systems (ATPS); it involves use of two compounds that are soluble in water. Both compounds are thoroughly mixed, these result in two phases that are immiscible – with water concentration between 70% and 90% (Grilo et al. 2016). The mixture of two polymers that are mutually immiscible, alcohol and salt, a salt and a polymer, two surfactant solutions, or ionic liquid and salt leads to their formation. The specific reactions between solution and phase-forming components result in this parathion process (Glyk et al. 2014; Antecka et al. 2019). ATPSs have advantages in protein purification including significant decrease in denaturation and high rate of mass transfer as a result of low surface tension between phases. In addition, the relatively low cost ensures excellent purity and enzymatic operation (Prinz et al. 2014; Rajagopalu et al. 2016). Diverse studies were conducted on purification of enzymes using ATPS based on polymers and salts; high concentration was observed of Cerrena unicolor laccase, when PEG 6000 and PEG 400 ATPE were used, with exceeding yields of 0.9 and 0.85, respectively. Further purification proved that PEG 6000 was more preferable, due to its less complicated salt phase. New series of ionic liquid-based constituents are under investigation. Junior et al. (2020) observed in PEG-rich phase up to 99.9% recovery of laccase in single step ATPS Pleurotus sajor-caju laccase purification. It is however very important, for industrial separation processes, to consider the chemical cost. For commercial applications, polymer ATPSs are recommended (Lee et al. 2017; Agrawal et al. 2019).

Another method of downstream processing that has shown great potential is foam fractionation which involves the continuous feeding of steam from dispersed gas into a liquid phase thereby forming a foam phase. Chemical compounds are attracted by the foam, as they show affinity for gas–liquid interface and leave the liquid bulk phase. Foam is collapsed upon extraction, and a liquid phase is newly formed which contains product in concentrated form (Antecka et al. 2019). Ostwald and Mischke (1940) carried out foam fractionation for purification of protein for the first time; it was used to separate yeast fermentation products from fermentation broth. In foam fractionation, although a recently rediscovered DSP technique, there has not been wide investigation of its application towards laccase purification. The source of the enzyme has been demonstrated to be essential for partitioning ability; experimental results have been specifically obtained for C. unicolor and Pleurotus sapidus laccases (Blatkiewicz et al. 2017). In the foamate, recovery of activity up to 94% and activity losses of at most 2% were observed by Link et al. (2007) in the research to examine foam fractionation of Trametes sp. laccase and influence of pH. A comparison of different laccase purification methods – ultrafiltration, foam fractionation, and ATPE revealed ultrafiltration as the most effective method, having closely similar laccase yield as in ATPE (about 97.5%) but lesser activity loss; the least effective was observed in foam fractionation having about 24.9% yield and even more activity loss (Antecka et al. 2019). The following sequence of concentration of laccase was proposed for the application of all three methods (Fig. 1):

Separation and concentration sequence of laccase as proposed by Antecka et al. (2019)

3 Laccase Immobilization

Different materials are useful as supports in immobilization of enzyme, including a variety of biopolymers and polymers of different sizes (nano- and micro-sizes) and unique physical and chemical characteristics, for example, functional group diversity and availability, inertness to the immobilized biomolecule, insolubility in the reaction environment, high ratio of surface-to-volume, and high porosity (Temoçin et al. 2018; Jankowska et al. 2020). Enzymes, upon immobilization, become more resilient and impervious to environmental change, enabling for simple reuse and recycling for a variety of uses (Shraddha et al. 2011; Bayramoglu et al. 2018). The above pros and their need in the improvement of enzyme action have mandated the need for efficient methods of immobilization; hence, various techniques of immobilization and substrates have been studied. Methods of immobilization are self-immobilization, covalent binding, adsorption, entrapment, and synergy of the above (Yang et al. 2017) (Fig. 2).

Laccase immobilization techniques (Datta et al. 2021)

Recovery of activity is diverse according to method of choice for immobilization, the enzyme, and the parameters of preparation. The material and enzyme’s capacity to form strong and long-lasting bonds can be influenced by the polymer used as a support for biomolecule immobilization (Balogh-Weiser et al. 2018). Immobilization of laccases has been accomplished with a variety of materials such as polymeric microspheres (Vera et al. 2020), electrospun materials (Ge et al. 2012; Balogh-Weiser et al. 2018; Jankowska et al. 2020), and mesoporous Al2O3 (Kołodziejczak-Radzimska et al. 2020). Due to their effective degradation, at a low cost, of refractory chemicals, such as dyes, phenolic pollutants, antibiotics, and insecticides (Pezzella et al. 2014; Ammann et al. 2014; Yang et al. 2017; Vera et al. 2018), immobilized laccases have gotten a lot of attention. Laccase immobilization has also become a major role player in the design and application of biosensors for compound detection (Su et al. 2018; Datta et al. 2021).

4 Laccase Mediator Systems

Mediators serve as carriers of electrons to the compounds targeted from laccase; this extends laccase substrate range. Laccase may thus oxidize non-phenolic materials when a sufficient redox mediator is present, overcoming its restriction to phenolic components alone (Yang et al. 2012). A broad spectrum of pollution-causing substances, including those from personal care items, herbicides, and dyes, has been degraded using both natural and manufactured mediator systems. Mediators function by providing a step referred to as indirect oxidation which yields a radical in its oxidized form capable of oxidizing a broad spectrum of non-phenolic substrates and big molecules. The first artificial mediator used as a laccase-mediator system was 2, 20–azino–bis 3-ethylbenzothiazoline-6-sulfonic acid (ABTS) (Bourbonnais and Paice 1990); other synthetic materials include violuric acid (VLA), the oxime, and 1-hydroxybenzotriazole (HBT) – these have also shown great capacity in the decomposition of recalcitrant aromatic compounds (Blanquez et al. 2019).

Laccase mediators that are synthetic like HBT and VLA, however, have a degree of toxicity and high cost that accompanies their use. Hence, natural laccase mediators are regarded as more suitable, and researches have and are being conducted to find more natural mediators (vanillin, syringaldehyde, and acetosyringone); lignin-related phenolic compound has been found to show their capacity to behave as natural laccase mediators as well as the effectiveness with which they do so (Camarero et al. 2005). A point of concern in the research and application of natural mediators is their limitation to commercial application of laccase; extra research is therefore necessary to assess further the potential commercial applications of natural mediators to laccases. Oxidation by laccase of the substrate with a mediator may not always go in a different way. For example, Malachite green degradation has been shown to yield similar products in ABTS presence and/or absence for some enzymes and different for others (Fig. 3).

(a) Mechanism of substrate oxidation by laccase mediator systems; (b) some synthetic laccase mediators (Wells et al. 2006)

There are different catalytic mechanisms displayed by different types of mediators. Substrate oxidation mediated by ABTS works using transfer of electron. First is oxidation ABTS to ABTS+ (radical cation) and to ABTS2+ (dication) with 472 mV and 885 mV redox potentials, respectively. Unlike ABTS, when laccase is oxidized and then deprotonated, HBT and violuric acid (N-OH type mediators) produce the N-oxy radical, which then abstracts the benzylic hydrogen atom from the substrate. Phenolic mediators, in a similar manner follow abstraction mechanism by radical hydrogen, but in its case have a radical phenoxy as intermediate (Wong 2009; Hu et al. 2009) (Table 1).

5 Applications of Laccase

Many biotechnological processes involve laccase due to their being able to oxidize a wide spectrum of compounds (non-phenolic and phenolic). Laccases are especially useful in major procedures including clean-up of industrial effect, water purification, etc. (Imran et al. 2012). Laccase application in different industries include the following:

5.1 Laccase Application in Food Industry

Laccase enzyme is used in the food industry in the manufacturing of juices and wine and for baking (Minussi et al. 2002). High concentration of phenolic compounds in fruit juices, wine, and beer and the natural polymerization and co-oxidation reactions that occur with them over long periods of time give rise to undesirable colors and aroma – this is referred to as enzymatic darkening. Laccase treatment aids the efficient reduction of this phenolic content. Compared to other conventional treatment methods for this purpose (e.g., adding ascorbic acid), laccases were observed to be more efficient, in fruit juices, for flavor stability and color (Ribeiro et al. 2010) (Fig. 4).

Applications of laccase (Imran et al. 2012)

In baking, it has been found to improve gluten strength, dough machinability (improved strength and stability as well as a reduction in stickiness), freshness, softness, and dough crumb structure and products of baking (Minussi et al. 2002). This improvement has been observed even when low quality dough is used. Laccase plays an important function in the production of baking goods that are free of gluten using cereal flours such as oats and starches (rice, potato, and maize). However, laccase is not approved as a food additive and therefore has to be filtered out of product by using membrane filtration, for example (Brijwani et al. 2010), or better still the use of immobilized laccase in order to overcome legal barriers (Imran et al. 2012).

5.2 Laccase Application in Textile Industry

In the textile industry, vast quantities of water and inorganic and organic chemicals are used for wet processing; some of these chemicals include synthetic dyes that are commonly used in diverse sectors, such as the textile industry (Imran et al. 2012). The textile and paper industries manufacture vast quantities of synthetic dyes that maintain their durability upon light exposure and microbial degradation and in the presence of diverse chemicals. There are currently more than 10,000 synthetic dyes used worldwide (Blanquez et al. 2019). The high resistance of these dyes causes them to remain in sewage plants or on soil and eventually washed up into rivers causing pollution. Specific treatment procedures are existent, which can degrade recalcitrant dyes – oxic and anoxic processes are mixed in these processes. However, anoxic processes bring about generation of amines from azo dyes which are carcinogenic posing health risks; hence, in textile industry, laccase application is highly important (Asgher et al. 2013; Blanquez et al. 2019). Fungal and bacterial laccases have proven to successfully decolorize and degrade dyes and inks that are flexographic (Fillat et al. 2012).

5.3 Application of Laccase in Pharmaceutical Industry

Laccases are also used to make pharmaceuticals like actinocin, which is derived from 4-methyl-3-hydroxyanthranilic acid. As an anticancer agent, actinocin works by preventing tumor cells from transcribing deoxyribonucleic acid (DNA). Another example is vinblastine – also an anticancer medication, which is effective in leukemia therapy. Catharanthus roseus plant produces vinblastine naturally in small quantity. Precursors of vinblastine – katarantine and vindoline – are produced in larger amounts. Laccase has been observed to have 40% conversion of these into vinblastine (Imran et al. 2012). Laccases are also important in biodegradation of PPCP (personal care product and pharmaceutical) organic contaminants with rising ubiquity and antibiotics which may not have been metabolized and cause environmental pollution (Yang et al. 2017). They have been used as ingredients in the production of PPCPs which possess antioxidant, anticancer, detoxifying, antimicrobial, or other things (Upadhyay et al. 2016; Senthivelan et al. 2016).

5.4 Application of Laccase in Biodegradation of PAH and Other Contaminants

Rapid industrialization in the world today, including agricultural processes with the extensive use of pesticides and herbicides, has brought about increase in contamination of the environment – soil, water, and air pollution. Some of these carcinogenic and mutagenic pollutants include benzene, polycyclic aromatic hydrocarbons (PAH), polychlorinated biphenyls (PCB), toluene, xylene (BTEX), ethyl benzene, trinitrotoluene (TNT), ethane (DDT), 1,1,1-trichloro2,2-bis (4-chlorophenyl), and pentachlorophenol (PCP). The ability of laccase to play essential roles in the biodegradation of these recalcitrants and increasingly discovered information about that through research have created rising interest in the use of laccase in bioremediation.

Diazinon, classified as a moderately dangerous chemical (class 2) by the World Health Organization (WHO), is an organophosphorus pesticide that was observed to be degraded by A. bisporus and T. versicolor laccases co-immobilized on poly-(glycidylmethacrylate) microsphere (Vera et al. 2020). Zeng et al. (2017) also researched the T. versicolor laccase breakdown of the isoproturon, an herbicide, and also that of its laccase-mediator systems. Laccase from Aspergillus niger was discovered to affect significantly oxidation indices of oxygenated PAH (OPAH) and polycyclic aromatic hydrocarbon (PAH) material, especially anthracene-9,10-dione, 9-fluorenone, and phenanthrene, in wasted oil for cooking after frying youtiao, nuggets, and pie made from pumpkin (Teng et al. 2019).

5.5 Application of Laccase in Forest Products Industry

Laccase has shown potential to help extract from materials made from wood and water phenolic residues, pitch, and coloring; the technology of laccase is applicable in almost all stages of the paper product supply chain, from pulping to secondary fiber recovery and effluent treatment. The majority of laccase and laccase-mediator systems applications in forestry has to do with the paper and pulp industry, where special focus is majorly on the study of laccase and/or laccase-mediated systems for treatment mill water and biobleaching (Widsten and Kandelbauer 2008). Laccase-mediated systems are used with oxygen-based chemical oxidants and chlorine for lignin degradation and separation needed for paper preparation on industrial scale. This helps solve issues like toxicity, cost, and recycling as it results in replacement of ClO2 partially in pulp mills (Shraddha et al. 2011).

5.6 Application of Laccase in Petroleum Industry

Laccase in the petroleum industry plays major roles in bioremediation, especially in cases of oil spills. After 100 days of remediation, research of bacteria, and laccase immobilized in the intertidal zones, bioremediation of major oil spills found about 66.5 percent effectiveness of bacteria-laccase consortium immobilized for heavy oil. (Dai et al. 2020). It was also observed in that research that n-alkanes having long-chain C26-C35 and PAHs having above 3 ring were efficiently broken down. Laccase was also found to be expressed most abundantly – alongside peroxidases and catalase – in strains of fungi which inhabit the rhizosphere of areas where there have been oil spills which showed tolerance to a concentration of crude oil of about 20% (Asemoloye et al. 2018). The strains were identified by Asemoloye et al. (2018) as Trichoderma harzianum asemoJ, Talaromyces purpurogenus asemoF, A. flavus asemoM, and A. niger asemoA. In the research, while 87 U/ml and 145 U/ml of peroxidases and catalase were produced respectively, the volume of laccase produced was up to 180 U/ml.

5.7 Applications of Laccase in Biosensors and Enzymatic Biofuels

Biosensors , embedded medical devices, and other gadgets employ enzymatic biofuel cells (EBFCs) as a portable source of environmentally benign energy. Due to its comparatively high redox potential in contrast to other commercial fuel cells, laccase has been frequently employed as an EBFC cathode (Ghosh et al. 2019). On functionalized screen-printed carbon electrodes (SPCEs) , laccase from Coriolus hirsuta was immobilized by Othman and Wollenberger (2020) using different methods of enzyme modification and immobilization. Carboxyl functionalized multi-walled carbon nanotubes (COOH–MWCNT) immobilized laccase had the highest electrochemical response. The biosensors produced were seen to be relatively stable showing no activity loss even beyond 20 days of storage. Christwardana (2017) combined physico-entrapment and crosslinking for the immobilization on carboxylated carbon nanotube of low activity laccase in order to increase its biofuel performance using polyethylenimine and glutaraldehyde. Glutaraldehyde was observed to have higher catalytic activity.

6 Current Challenges and Future Perspectives

Edible mushroom production is a major area in laccase production and application in the food industry. The cultivation of these edible fungal species provides a significant opportunity for laccase production, as evidenced by various studies (Chanakya et al. 2015). However, there are few studies on the increase in laccase concentration in these fungi during industrial production without affecting their nutritional value. This is a major opportunity in terms of optimization of producing fungus while also optimizing laccase and other ligninolytic enzyme production. As a result, it is required to refine the enzyme recovery process from residual compost, as well as to investigate various main recovery approaches and purification steps that allow for high purities. Because the crude extract is complicated and poorly defined, this is a significant difficulty. In this regard, including ultrasonication into the main laccase recovery utilizing ATPS may be a viable alternative for increasing yield. Postemsky et al. (2017) have been observed that, in addition to enhancing activity, it can enhance yield, particularly of phenolic chemicals; therefore, treating the residual compost crude extract and evaluating its effect on activity of laccase could be an excellent strategy (Postemsky et al. 2017).

Laccase application appears to be limited in comparison to its potential. Reduced manufacturing costs and the development of technology to effectively regulate the reactions on specific substrates, including polyphenols, to be handled by laccase should be the research focus. Laccase manufacturing costs and their vast substrate specificity are two key obstacles to their industrial application (Zerva et al. 2019). While laccases’ broad substrate range might be beneficial for biodegradation, difficulty may arise as a result, for their application commercially in biocatalysis due to the production of by-products as a result of free radicals. Furthermore, laccases’ wide spectrum of reaction with substrates is a disadvantage in the realm of biosensor production. Biosensors , particularly those applied in biomedical procedures, necessitate a significant level of specificity with regard to targeted substance, which most commercially available laccases cannot currently achieve (Mayolo-Deloisa et al. 2015; Zerva et al. 2019). Given the high cost of manufacturing, the necessity for the discovery or creation of new enzymes with desired properties appears to be critical. Because the information on laccase manufacturing costs is limited, additional study into the development of manufacturing techniques is required.

Laccase production under submerged cultivation in the lab has been frequently documented in current years. There is a limited representation, however, of laccases commercially, with low purity degrees and not well-defined extracts, complicating the repeatability of many of the methods used in production and purification (Mayolo-Deloisa et al. 2020). As a result, increased interest in the manufacture and concentration of laccases commercially is required for generation of novel products.

Laccase’s potential for pretreatment of lignocellulosic residues in order to incorporate them into biorefinery processes and produce biofuels has been widely documented in the literature (Agrawal et al. 2019). However, in order to get the maximum degradation yields, it is important to consider further optimization of circumstances, as the fungus’ efficacy is often larger than that of the enzyme. This might be indicative of additional enzymes capable of modifying lignin being present; therefore, the potential of employing enzyme combinations, increasing laccase affinity by chemical modifications, or altering the conditions of the processes being performed should be investigated.

PEGylation – attaching PEG to laccase (a single molecule) – could also be used to increase stability. It is a well-known method for modifying protein medicines, and its effectiveness has been well established. Despite the fact that there are few data on laccase PEGylation, they show that it improves its catalyzing ability and activity (Mayolo-Deloisa et al. 2015; Su et al. 2018). If the procedure warrants it, specifically if enzyme is employed to identify specific chemicals using biosensors, this can be a viable option. One of laccase’s uses in this regard is the identification of different chemicals in specific meals. Laccase is also employed in the production of chemicals, as well as detection of these compounds, and it was recently discovered that it can remove morphine from environments that are aqueous in nature (Huber et al. 2018). This demonstrates the enzyme’s enormous potential industrially and in recovery of polluted regions, highlighting the significance and importance of the data given here.

7 Conclusion

Laccase purification and application remains very essential to the industrial advancement in the world today; hence laccase research is continuously on the increase to develop economical and effective purification procedures, efficient laccase mediator systems, and durable laccase immobilization techniques. With improved downstream processing and continued increase in research, there is an increased possibility of enhanced yield, stability, and recovery of laccase. This will further widen the application reach of laccases in various industries as it continues to play a major part in the provision of reliable and sustainable communities worldwide.

References

Agrawal K, Bhardwaj N, Kumar B, et al (2019) Process optimization, purification and characterization of alkaline stable white laccase from Myrothecium verrucaria ITCC-8447 and its application in delignification of agro-residues. Int. J. Biol. Macromol 125:1042–1055.

Ammann E, Gasser C, Hommes G, Corvini P (2014) Immobilization of defined laccase combinations for enhanced oxidation of phenolic contaminants. Appl. Microbiol. Biotechnol 98: 1397–1406.

Antecka A, Blatkiewicz M, Boruta T et al (2019) Comparison of downstream processing methods in purification of highly active laccase. Bioprocess Biosyst Eng 42: 1635–1645.

Arregui L, Ayala M, Gómez-Gil X, et al (2019) Laccases: structure, function, and potential application in water bioremediation. Microb. Cell Factories 18:200.

Asgher M, Ahmad Z, Iqbal H (2013) Alkali and enzymatic delignification of sugarcane bagasse to expose cellulose polymers for saccharification and bio-ethanol production. Ind Crops Prod 44: 488-495.

Asemoloye M, Ahmad R, Jonathan S (2018) Transcriptomic responses of catalase, peroxidase and laccase encoding genes and enzymatic activities of oil spill inhabiting rhizospheric fungal strains. Environ. Pollut. 235: 55–64. https://doi.org/10.1016/j.envpol.2017.12.042.

Balogh-Weiser D, Nemeth C, Ender F et al (2018) Electrospun Nanofibers for Entrapment of Biomolecules. ChemCatChem 10(16): 3490–3499.

Bayramoglu G, Karagoz B, Arica Y (2018) Cyclic-carbonate functionalized polymer brushes on polymeric microspheres: Immobilized laccase for degradation of endocrine disturbing compounds. J Ind Eng Chem 60: 407–417.

Bento I, Martins L, Lopes G, Carrondo M, Lindley P (2005) Dioxygen reduction by multi-copper oxidases; a structural perspective. Dalton Trans 21: 3507–3513.

Blánquez A, Rodríguez J, Brissos V et al (2019) Decolourization and detoxification of textile dyes using a versatile Streptomyces laccase-natural mediator system. Saudi J. Biol. Sci. 26: 913–920.

Blatkiewicz M, Antecka A, Górak A et al (2017) Laccase concentration by foam fractionation of Cerrena unicolor and Pleurotus sapidus culture supernatants. Chem Eng Process 38(3): 455–464.

Bourbonnais R, Paice M (1990) Oxidation of Non-phenolic Substrates – an expanded role for laccase in lignin biodegradation. FEBS Lett. 267: 99–102.

Brijwani K, Huss R, Vadlani P (2010) Fungal Laccases: Production, Function, and Applications in Food Processing. Enzyme Res. 2010(5):149748.

Camarero S, Ibarra D, Martínez M et al (2005) Lignin-derived compounds as efficient laccase mediators for decolourization of different types of recalcitrant dyes. Appl. Environ. Microbiol. 71: 1775–1784.

Chanakya H, Malayil S, Vijayalakshmi C (2015) Cultivation of Pleurotus spp. on a combination of anaerobically digested plant material and various agro-residues. Energy Sustain Dev 27: 84–92

Christwardana M (2017) Combination of physico-chemical entrapment and crosslinking of low activity laccase-based biocathode on carboxylated carbon nanotube for increasing biofuel cell performance. Enzyme Microb. Technol. 106: 1-10.

Dai X, Liv J, Yana G et al (2020) Bioremediation of intertidal zones polluted by heavy oil spilling using immobilized laccase-bacteria consortium. Bioresour. Technol. 309: 123305.

Datta S, Veena R, Samuel M et al (2021) Immobilization of laccases and applications for the detection and remediation of pollutants: a review. Environ. Chem. Lett. 19: 521–538.

Fillat A, Gallarda O, Vidal T et al (2012) Enzymatic grafting of natural phenols to flax fibres: Development of antimicrobial properties. Carbohydr. Polym. 87(1):146–152.

Ge L, Zhao Y, Mo T et al (2012) Immobilization of glucose oxidase in electrospun nanofibrous membranes for food preservation. Food Control 26: 188–193.

Ghosh B, Saha R, Bhattacharya D et al (2019) Laccase and its source of sustainability in an enzymatic biofuel cell. Bioresource Technology Reports 6: 268-278.

Giardina P, Faraco V, Pezzella C et al (2010) Laccases: a never-ending story. Cell. Mol. Life Sci. 67: 369–385.

Glyk A, Scheper T, Beutel S (2014) Influence of Different Phase-Forming Parameters on the Phase Diagram of Several PEG-Salt Aqueous Two-Phase Systems. J. Chem. Eng. Data 59: 850–859.

Grilo A, Aires-Barros M, Azevedo A et al (2016) Partitioning in aqueous two-phase systems: fundamentals, applications and trends. Sep. Purif. Rev. https://doi/abs/10.1080/15422119.2014.983128.

Huber D, Bleymaier K, Pellis A et al (2018) Laccase catalyzed elimination of morphine from aqueous systems. N Biotechnol 42: 19–25.

Hu R, Chao P, Zhang Q et al (2009) Laccase-mediator system in the decolorization of different types of recalcitrant dyes. J. Ind. Microbiol. Biotechnol. 36: 45–51.

Imran M, Asad M, Hadri S et al (2012) Production and industrial applications of laccase enzyme. J. Mol. Cell Biol. 10(1): 1-11.

Jankowska K, Zdartaa J, Grzywaczyka A et al (2020) Electrospun poly (methyl methacrylate)/polyaniline fibres as a support for laccase immobilization and use in dye decolourisation. Environ. Res. 184: 109332.

Junior A, Vieira A, Cruz I et al (2020) Sequential degradation of raw vinasse by a laccase enzyme producing fungus Pleurotus sajor-caju and its ATPS purification. Biotechnol. Rep. 25; e00411.

Karaki N, Aljawish A, Humeau C et al (2016) Enzymatic modification of polysaccharides: mechanisms, properties, and potential applications: a review. Enzyme Microb. Technol. 90: 1–18.

Kołodziejczak-Radzimska A, Budna A, Ciesielczyk F, Moszynski D, Jesionowski T (2020) Laccase from Trametes versicolor supported onto mesoporous Al2O3: stability tests and evaluations of catalytic activity. Process Biochem 95:71–80. https://doi.org/10.1016/j.procbio.2020.05.008

Lee S, Khoiroh I, Ooi C et al (2017) Recent Advances in Protein Extraction Using Ionic Liquid-based Aqueous Two-phase Systems. Sep. Purif. Rev. 46: 291–304.

Li K, Xu F, Eriksson K (1999) Comparison of fungal laccases and redox mediators in oxidation of a nonphenolic lignin model compound. Appl. Environ. Microbiol 65(6): 2654–2660.

Link D, Zorn H, Gerken B et al (2007) Laccase isolation by foam fractionation – new prospects of an old process. Enzyme Microb. Technol. 40: 273–277.

Mayolo-Deloisa K, González-González M, Simental-Martínez J et al (2015) Aldehyde PEGylation of laccase from Trametes versicolor in route to increase its stability: effect on enzymatic activity. J. Mol. Recognit. 28: 173–179.

Mayolo-Deloisa, K, González-González M, Rito-Palomares M (2020) Laccases in Food Industry: Bioprocessing, Potential Industrial and Biotechnological Applications. Front. Bioeng. Biotechnol. 8:222.

Madadlou A, O’Sullivan S, Sheehan D (2017) Fast protein liquid chromatography. Methods Mol Biol 1485: 365–373.

Minussi R, Pastore G, Duran N (2002) Potential applications of laccase in the food industry, Trends Food Sci. Technol., 13: 205–216.

Ostwald W, Mischke W (1940) Untersuchungen über Zerschäumung mit besonderer Rücksicht auf Fragen der. angewandten Chemie I. Kolloid Zeitschrift 90:17–25.

Othman A, Wollenberger U (2020) Amperometric biosensor based on coupling aminated laccase to functionalized carbon nanotubes for phenolics detection. Int. J. Biol. Macromol. 153: 855-864.

Pezzella C, Russo M, Marzocchella A et al (2014) Immobilization of a Pleurotus ostreatus laccase mixture on perlite and its application to dye decolourisation. Biomed Res. Int. 1–11.

Postemsky P, Bidegain M, González-Matute R et al (2017) Pilot-scale bioconversion of rice and sunflower agro-residues into medicinal mushrooms and laccase enzymes through solid-state fermentation with Ganoderma lucidum. Bioresour. Technol. 231: 85–93.

Prinz A, Hönig J, Schüttmann I et al (2014) Separation and purification of laccases from two different fungi using aqueous two-phase extraction. Process Biochem 49: 335–346.

Rajagopalu D, Show P, Tan Y et al (2016) Recovery of laccase from processed Hericium erinaceus (Bull. : Fr) Pers. Fruiting bodies in aqueous two-phase system. J. Biosci. Bioeng. 127: 600-609.

Ribeiro D, Henrique S, Oliveira L et al (2010) Enzymes in juice processing: a review. International J. Food Sci. Technol. 45: 635–641.

Senthivelan T, Kanagaraj J, Panda R (2016) Recent trends in fungal laccase for various industrial applications: an eco-friendly approach- a review. Biotechnol. Bioprocess Eng. 21: 19–38.

Shraddha, Ravi S, Simran S et al (2011) Laccase: Microbial Sources, Production, Purification and Potential Biotechnological Applications. Enzyme Res. 217861.

Su J, Noro J, Fu J et al (2018) Exploring PEGylated and immobilized laccases for catechol polymerization. AMB Express 8:134. doi: https://doi.org/10.1186/s13568-018-0665-5

Temoçin Z, İnal M, Gökgöz M et al (2018) Immobilization of horseradish peroxidase on electrospun poly (vinyl alcohol)–polyacrylamide blend nano-fiber membrane and its use in the conversion of phenol. Polym. Bull. 75: 1843–1865.

Teng C, Wu S, Gong G (2019) Bio-removal of phenanthrene, 9-fluorenone and anthracene-9,10-dione by laccase from Aspergillus niger in waste cooking oils. Food Control 105: 219-225.

Upadhyay P, Shrivastava R, Agrawal P (2016) Bioprospecting and biotechnological applications of fungal laccase. 3 Biotech 6: 15.

Vera M, Nyanhongo G, Guebitz G et al (2018) Immobilization of Myceliophthora thermophila laccase on poly (glycidyl methacrylate) microspheres enhances the degradation of azinphos- methyl. J. Appl. Polym. Sci. 136: 1–10.

Vera, M, Nyanhongo, G, Guebitz, G et al (2020) Polymeric microspheres as support to co-immobilized Agaricus bisporus and Trametes versicolor laccases and their application in diazinon degradation. Arab. J. Chem. 13: 4218–4227.

Wells A, Terria M, Eve T et al (2006) Green oxidations with laccase mediator systems. Biochem. Soc. Trans. 34(2): 304–8.

Widsten P, Kandelbauer A (2008) Laccase Applications in the Forest Products Industry A Review. Enzyme Microb. Technol. 42: 293–307

Wong D (2009) Structure and action mechanism of ligninolytic enzymes. Appl. Biochem. Biotechnol. 157: 174–209.

Yang Y, Fan F, Zhuo R, Ma F, Gong Y, Wan X (2012) Expression of the laccase gene from a white rot fungus in Pichia pastoris can enhance the resistance of this yeast to H2O2-mediated oxidative stress by stimulating the glutathione-based anti-oxidative system. App. Environ. Micro. 78: 5845–5854.

Yang J, Lin Y, Yang X et al (2017) Degradation of tetracycline by immobilized laccase and the proposed transformation pathway. J. Hazard. Mater. 322: 525–531.

Zeng S, Qin X, Xia L et al (2017) Degradation of the herbicide isoproturon by laccase-mediator systems. Biochem. Eng. J. 119: 92–100.

Zerva A, Simic S, Topakas E et al (2019) Applications of Microbial Laccases: Patent Review of the Past Decade (2009–2019). Catalysts 9: 1023.

Acknowledgments

The authors appreciate Covenant University Research, Innovation, and Discovery (CUCRID) for conference and publication support.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Akinyemi, O.D., Ahuekwe, E.F., Oziegbe, O., Nwinyi, O.C. (2022). Trends in Downstream Processing Approaches, Laccase Mediator Systems and Biotechnological Applications of Laccases. In: Ayeni, A.O., Sanni, S.E., Oranusi, S.U. (eds) Bioenergy and Biochemical Processing Technologies. Green Energy and Technology. Springer, Cham. https://doi.org/10.1007/978-3-030-96721-5_15

Download citation

DOI: https://doi.org/10.1007/978-3-030-96721-5_15

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-96720-8

Online ISBN: 978-3-030-96721-5

eBook Packages: EnergyEnergy (R0)