Abstract

Biotreatment of methylparathion (O,O-dimethyl-O-4-nitrophenyl phosphorothioate) was studied in aqueous mineral salts medium containing fungal culture to demonstrate the potential of the pure culture (monoculture) of Fusarium sp in degrading high concentration of methylparathion. A statistical Box–Behnken design of experiments was performed to evaluate the effects of individual operating variables and their interactions on the methylparathion removal with initial concentration of 1,000 mg/L as fixed input parameter. A full factorial Box–Behnken design of experiments was used to construct response surfaces with the removal, the extent of methylparathion biodegradation, removal of chemical oxygen demand and total organic carbon, and the specific growth rate as responses. The temperature (X 1), pH (X 2), reaction time (X 3) and agitation (X 4) were used as design variables. The result was shown that experimental data fitted with the polynomial model. Analysis of variance showed a high coefficient of determination value of 0.99. The maximum biodegradation of methylparathion in terms of the methylparathion removal (Y 1), chemical oxygen demand removal (Y 2) and total organic carbon removal (Y 3) were found to be 92, 79.2 and 57.2 % respectively. The maximum growth in terms of dry biomass (Y 4) was 150 mg/L. The maximum biodegradation corresponds to the combination of following factors of middle level of temperature (X 1 = 30 °C), pH (X 2 = 6.5), agitation (X 4 = 120 rpm) and the highest level of reaction time (X 3 = 144 h). The removal efficiency of methylparathion biodegradation was achieved 92 %. It was observed that optimum biotreatment of methylparathion can be successfully predicted by response surface methodology.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Water contamination is mainly caused by industrial effluents, agricultural runoff and chemical spills which contain several non-biodegradable substrates that can be harmful to the environment. A current environmental concern is the contamination of aquatic ecosystem due to pesticide discharges from manufacturing plant, agricultural runoff, leaching, accidental spills and other sources. The drinking water directive (Council directive 98/83/EC of 3 November 1998), sets an allowed contaminant level of 0.1 mg/L for a single pesticide and 0.5 mg/L for the total sum of pesticides. According to the previous report, the pesticide pollution due to wastewater from formulating or manufacturing pesticide plants released the effluent up to 1,000 mg/L (Chiron et al. 1997). Industries manufacturing these pesticides release wastewater in water bodies or land. Although industries treat their wastewater by activated sludge process, no attention is paid to removal of specific pesticides or their metabolites which exert toxicity at very low concentrations. Among the organophosphate insecticides, the methylparathion was found to be widely used insecticides in India as an alternate of organochlorine compounds. OP compounds poisoning is a world-wide health problem with around 3 million poisonings and 200,000 deaths annually (Sogorb et al. 2004).The compounds have been implicated in several nerve and muscular diseases in human beings in addition to various acute adverse effects (Ragnarsdottir 2000). The intermediates such as paranitrophenol, picric acid are similar to the intermediates that are found in explosive compounds. To date, biotransformations have been the main focus in research on organophosphate pesticide degradation. Studies on pesticide metabolism by other fungi such as Aspergillus niger degrading Chlorpyrifos (Karas et al. 2011), pyrethroid (Liang et al. 2005), fenitrothion (Kanaly et al. 2005), dimethoate (Liu et al. 2001) and Aspergillus flavus for metolachlor (Sanyal and Kulshrestha 2004) are also reported. Moreover, Phanerochaete chrysosporium, Trametes versicolor and Pleurotus ostreatus for Chlorpyrifos degradation are reported (Karas et al. 2011). All these reports emphasize the enormous potential of soil fungi for bioremediation. Use of specific microflora adapted to these pesticides, in treatment of industrial effluents is not in practice (Kanekar et al. 2004). Therefore, research should be concentrated to develop economical but effective microbial processes for treatment of industrial effluents containing these pesticides and take them to field.

Response surface methodology (RSM) is a collection of statistical and mathematical techniques used to study the interactions of different variables. RSM is very useful for modeling and analyzing a complex process, allowing the construction of a model that contains a full description of the independent variables that are effective under optimal conditions (Meilgaard et al. 2002; Chun et al. 2004). RSM requires less runs, and is suitable for multiple factor experiments, search for relationships between factors, and for finding the most suitable condition and prediction of response (Seth and Chand 2000). However, there are few reports of biotreatment processes using RSM, and it is important to make use of RSM in this area to utilize manpower and resources most effectively. The optimization of experiments was carried out using RSM to understand the effect of important variables (temperature, pH, time and agitation) and their interactions on the biotreatment process. A novel strain of Fusarium sp was isolated from agricultural soil at a pesticide contaminated site by Coimbatore, India and used it for the biotreatment process of methylparathion in the laboratory. Hence, the objective of the study was to examine the biotreatment efficiency and optimization of aqueous methylparathion removal by Fusarium strain using Box–Behnken design. This work was done at Bharathiar University, India, and was completed in August 2011.

Materials and methods

Fungal culture conditions

A potential fungal strain (Fusarium sp mpd-1) was isolated from pesticide exposed agricultural soil. The initial enrichment cultures were established in synthetic wastewater containing mineral salts medium amended with the methylparathion (DevithionTM 50 % EC) as the sole source of carbon and energy. The concentration of methylparathion used was 0.1 %, pH was adjusted using 1 N NaOH and 1 N HCl (ELICO-L1127, India). The methylparathion-contaminated synthetic wastewater was of neutral pH and the mean value of methylparathion (MP) content was 1,000 mg/L, chemical oxygen demand (COD) was 41,950 mg/L and total organic carbon (TOC) was 10,459 mg/L. The synthetic wastewater containing higher concentration of methylparathion with maximum level of 1,000 mg/L was used in the present study. Stock solution of pure methylparathion (98.5 %) was prepared by dissolving 1 g in 100 mL methanol, made up to 1,000 mL of distilled water and was used as a reference for instrumental analysis. Organisms were subsequently grown on Czapek’s-Dox agar medium plates to obtain single colonies. A pure culture of methylparathion-degrading Fusarium was isolated by series of replating on MSM with methylparathion agar plates. It was preliminarily identified as Fusarium on the basis of morphological and physiological characteristics. For degradation studies, Fusarium was inoculated into sterile shake-bottles containing 250 mL of MSM, 0.1 % (w/v) methylparathion and incubated under aerobic conditions on a shaker (120 rpm) for 7 days. The other parameters, i.e., pH value, culture temperature, time and agitation, were part of the experimental design. All experiments were performed in triplicate, and the results are expressed as an average of three replicates.

Optimization of methylparathion degrading condition by Fusarium sp mpd-1

In order to study the effect of variables on methylparathion degradation during fungal biotreatment, temperature, pH, time and agitation were adjusted for analysis. In this study an experimental design was set such that pH, temperature and time were adjusted. The synthetic wastewater containing mineral salts medium amended with the methylparathion was set at various temperature (25–35 °C), pH (4–9), time (24–264 h) and agitation (100–140 rpm) for analysis. The pH was adjusted using 1 N NaOH and 1 N HCl (ELICO-L1127, India). Response surface methodology (RSM) based on the Box–Behnken design of experiment was used to optimize these parameters and their interaction which significantly influenced methylparathion biodegradation by strain Fusarium sp mpd-1. In this work, attempts were made to optimize the culture conditions for the biodegradation of the organophosphate pesticide methylparathion by Fusarium sp mpd-1 using an RSM Box–Behnken’s design. The effects of operating variables of factors such as methylparathion concentration, incubation time, pH, temperature and agitation were investigated. The response process parameters including methylparathion removal (%), COD removal (%), TOC removal (%) and fungal growth rate in terms of dry biomass (mg/L) were determined via response surface methodology.

Experimental designs: Box–Behnken design (BBD)

A four-factor, three-level Box–Behnken design was used in this study. The Box–Behnken statistical experiment design method was used to determine the effects of operating variables such as temperature, pH, time and agitation on the percentage removal of methylparathion, COD and TOC. Four important operating variables temperature (X 1), pH (X 2), time (X 3) and agitation (X 4) were considered as independent variables. The low, middle and high levels of each variable were designated as −1, 0, and +1 respectively, as given in Table 1.

The Box–Behnken design is an independent, rotatable quadratic design with no embedded factorial or fractional factorial points where the variable combinations are at the mid-points of the edges of the variable space and at the center. Among all statistical experiment designs, Box–Behnken design requires fewer runs than the others, e.g., 29 runs for a 4-factor experimental design. The variables and their values (in brackets) were of three levels: temperature (25–30 °C), pH (4–9), time (24–264 h) and agitation (100–120 rpm), at constant methylparathion concentration 1,000 mg/L (0.1 %). This also enabled the identification of significant effects of interactions for the batch studies. In system involving four significant independent variables X 1, X 2, X 3, and X 4, the mathematical relationship of the response of these variables can be approximated by quadratic (second degree) polynomial equation (Box and Behnken 1960; Annadurai et al. 2008). This design is suitable for exploration of quadratic response surfaces and construction of a second order polynomial model, thus helping in optimizing a process using a small number of experimental runs. A total of 29 experiments were carried out (Table 2).

The design consists of three replicated center points, and a set of six points lying at the midpoints of each edge of the multidimensional cube. Response functions describing variations of dependent variables (methylparathion removal, COD removal, TOC removal and growth of fungi) with the independent variables (Xi) can be written as follows:

where, Y is the predicted response (percentage of methylparathion, COD removal, TOC removal and growth of fungi), b 0 is the offset term and b i is the linear effect while b ii and b ij are the square and the interaction effects, respectively. Experimental data points used in Box–Behnken statistical experiment design are presented in Table 2. The response function coefficients were determined by regression using the experimental data and the Stat-Ease Design Expert 8.0.4 computer program. The response functions for percent methylparathion removal, COD removal, TOC removal and growth of fungi were approximated by the standard quadratic polynomial equation as presented below. The following equation describes the regression model of the present system, which includes the interaction terms:

where Y is the predicted response, i.e., the methylparathion removal; X 1, X 2, X 3 and X 4 are the coded levels of the independent variables: temperature, pH, time and agitation. The regression coefficients are: b 0—the intercept term; b 1, b 2, b 3 and b 4—the linear coefficients; b 12, b 13, b 14, b 23, b 24, b 34—the interaction coefficients and b 11, b 22, b 33, b 44—the quadratic coefficients. The model evaluates the effect of each independent variable on the response. The normal practice is to test within the feasible range, so that the variation in the process does not mask the factor effect. A total of 29 trials were necessary to estimate the coefficients of the model using multiple linear regressions. Hence, about 29 treatments were conducted in the present study and the variance analysed. The data obtained from 29 experiments were used to find out the optimum point of the process parameters using Box–Behnken Design in Response surface methodology. All the data were treated with the aid of Design Expert by Stat Ease Inc, Minneapolis (Design Expert.-8.0.4) (Box and Behnken 1960; Myers and Montgomery 2002; Hanrahan and Lu 2006). Methylparathion removal conditions are presented in Table 2, according to the experimental design (Table 1).

Methylparathion determination

The effect of biotreatment on the degradation of methylparathion was determined in terms of COD, TOC and the fungal biomass in the synthetic wastewater, before and after treatment process. The samples were withdrawn at different time intervals after biotreatment (from 0 to 264 h)) from shake flask and were analyzed for COD, as per standard procedure laid down in APHA (1998). The TOC was measured using TOC analyser (Shimadzu). Growth of Fusarium sp in terms of dry weight (mg/L) was estimated gravimetrically. All experiments were performed in triplicates.

Analysis of methylparathion biodegradation using spectral studies

The samples were centrifuged at 10,000 rpm for 30 min using high-speed refrigerator centrifuge (CR22GII-Hitachi, Japan) and filtered through 25 mm/0.2 μm sterile syringe nylon filters. The filtered samples were then used for analysis of residual methylparathion and intermediate products.

UV–Vis spectral analysis

Degradation of methyl parathion and subsequent formation and eventual disappearance of intermediate products in the reaction mixture as a function of pH and time was monitored using UV–Vis spectroscopy. The filtered samples were scanned using UV–Vis–NIR Spectrophotometer (Shimadzu-UV-3,600 Japan), at 277 nm. HPLC analysis: the centrifuged and filtered samples were analyzed for residual methylparathion using HPLC. Residual methylparathion and intermediates were analysed by HPLC (Shimadzu, Japan) on a reverse phase C18 column [(250 × 4.60 mm) (Desc. Luna 5μ C18 (20)-100A Phenomenex)] at a flow rate of 1.5 ml/min. Mobile phases consisted of solution A (HPLC grade water) and solution B (HPLC grade methanol) in the ratio of 1:4, respectively. The isocratic gradient mode was applied with a pressure limit of 20 MPa and the analysis was carried out with a total run time of 20 min. The elute was delivered at a rate of 1.5 ml/min. The sample was injected at a rate of 20 μL and was detected at 277 nm using UV detector (SPD-20A, Japan). Under the conditions described above, the retention time (RT) of methylparathion standard was 3.3 min.

Result and discussion

Optimization of methylparathion biotreatment :Box–Behnken Statistical Experiment Design (BBD) Response surface methodology is an empirical modelling technique, which is used to evaluate the relationship between a set of controllable experimental factors and observed results (Annadurai 2000). Box–Behnken statistical experiment design and the response surface methodology was used to investigate the effects of the three independent variables on the response function and to determine the optimal conditions maximizing the percentage of methylparathion removal, COD removal, TOC removal and fungal growth (biomass). The optimization procedure involves studying the response of the statistically designed combinations, estimating the coefficients by fitting the experimental data to the response functions, predicting the response of the fitted model and checking the adequacy of the model. The independent variables were the temperature (X 1), pH (X 2), time (X 3) and agitation (X 4). The low, center (middle) and high levels of each variable are designated as −1, 0 and +1, respectively as shown in Table 1. The dependent variables (or objective functions) were the methylparathion removal (Y 1), COD removal (Y 2), TOC removal (Y 3) and fungal growth (Y 4). The dependent and independent variable values and the observed results are presented in Table 2. The center point (0, 0, 0, 0, 0) was repeated five times and the same results were obtained indicating the reproducibility of the data. Observed percent removal for methylparathion, COD, TOC and growth of fungi (dry biomass—mg/L) is compared in Table 2.

Analysis of variance (ANOVA) and empirical model fitting

Based on design of experiment, 29 combinations were developed and processed to remove methylparathion from wastewater as mentioned in the Tables 1 and 2. The data obtained from the experiments were used to the analysis of variance. Tables 3 and 4 show the ANOVA results of the model of Response surface showing methylparathion removal by fungal strain and its growth in terms of dry biomass as a function of temperature, pH, time and agitation. The model F value obtained (188.64, 416.52, 777.17 and 430.98) from each source implied the respective model was significant for methylparathion removal, COD and TOC removal and growth of fungi in terms of dry weight. A ‘P’ value lower than 0.01 % (or 0.0001) indicates that the respective model is considered to be statistically significant (Montgomery 1991, 2004; Evans 2003; Annadurai et al. 2008). Also, as can be seen in Table 3, the “lack of fit F value” of 0.24 (methylparathion removal), 0.53 (COD removal), 0.25 (TOC removal) and 1.05 (growth in dry weight) implies that the lack of fit phenomenon is not important relatively to pure error, indicating the suggested model is well fitted to the observed methylparathion removal, COD and TOC removal and growth of Fusarium sp in dry biomass.

The regression model coefficients

This approach was selected because relatively fewer combinations of the variables were used to estimate a potentially complex response function. A total of 29 experiments are needed to calculate 14 coefficients of the second-order polynomial regression model. This model contains one block term, four linear, four quadratic and six interaction terms. The coefficients of the response functions for different dependent variables were determined correlating the experimental data with the response functions using a Stat-Ease regression program. Different response functions with the determined coefficients are presented by Eqs. (1) and (4). By applying multiple regression analysis of the experimental data, the experimental results were fit with a second-order polynomial equation. The regression equations given are obtained by the analysis of variance and give the percentage level of methylparathion removal. Thus, mathematical regression models for methylparathion removal using the coded factors are given as:

Regression model for phosphate removal (%) (Y 1)

Regression model for COD removal (%) (Y 2)

Regression model for TOC removal (%) (Y3)

Regression model for growth (dry biomass-mg/L) (Y 3)

where Y 1 is the predicted response of the methylparathion degradation rate, temperature (X 1), initial pH (X 2), time (X 3) and agitation (X 4) are the coded variables. Equations (1–3) and (4) represent the approximating function of methylparathion removal (Y 1), COD removal (Y 2), TOC removal (Y 3) and fungal growth (Y 4) in terms of biomass (mg/L) of coded factors for the surface response. In the models of Y 1, Y 2, Y 3 and Y 4, the probability value of <0.0001 implies that these models were significant. The ANOVA results for the parameters Y 1, Y 2, Y 3 and Y 4, showed that the significant (P < 0.05) response surface models with high R 2 value of R 2 = 0.9947, 0.9976, 0.9987 and 0.9976, respectively (Table 3). Quadratic model was found to be maximum in adjusted R 2 and predicted R 2. However, Cubic model was found to be aliased. The temperature (A-X 1), pH (B-X 2), time (C-X 3) and agitation (D-X 4) have positive influence on methylparathion removal and the interaction among temperature with pH, time and agitation has also positive response on methylparathion removal.

Analysis of process variables by response surface plots

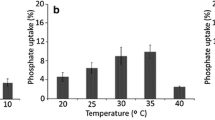

The optimum values of the selected variables were obtained by solving their regression equation and analyzing response surface contour plots. Response surface plots as a function of four factor at a time maintaining all other factors at a fixed level (zero for instance) are more helpful in understanding both the main and interaction effects of the four factors. The plots can be easily obtained by calculating the data from the model. The values were taken by one factor, where the second varies with constant of a given Y values. The yield values of the different concentrations and range of the variable can also be predicted from respective response surface plots. Figure 1 shows the relative effect of the four variables (temperature, pH, time and agitation) with methylparathion removal. The coordinates of the central point contained the highest optimum level of the respective components. Figures 1, 2, 3 and 4 show their response surface obtained as a function of temperature, pH, time and agitation versus methylparathion removal, COD and TOC removal and growth of fungi in terms of dry biomass.

Figure 5 shows their actual and predicted plot for (a) methylparathion removal (93 %), (b) COD removal (80 %), (c) TOC removal (58 %) and (d) growth of fungi in biomass (150 mg/L). The actual values are the measured response data for particular run and the predicted values are the results generated using the approximating functions. It is found that the methylparathion removal, COD removal, TOC removal and growth (biomass) which measured the signal-to-noise ratio were greater than 4, reaching the ratio of 42.79, 63.67, 85.74, and 61.07, respectively. This indicates the model is adequate to be used to navigate the design space.

Optimization and validation of the model

The methylparathion removal by Fusarium sp mpd-1 was predominantly influenced by the combined effects of the environmental factors like temperature, pH, incubation period (time) and agitation. The point prediction from the analysis of variables for the response surface model showed the maximum methylparathion removal (93 %), COD removal (80 %), TOC removal (58 %) and growth/biomass (150 mg L−1) by fungal strain Fusarium sp (mpd-1) in synthetic wastewater containing 1,000 mg L−1 of methylparathion at conditions of pH (6.5) and temperature (30 oC) and agitation at 120 rpm for 144 h of incubation period. As can be seen, there is not much difference between the experimental values and model response values obtained. This, therefore, confirmed that RSM could be effectively used to predict the removal performance of methylparathion from wastewater by potential fungal strain (Fusarium sp mpd-1). The maximum experimental response for methylparathion removal was 93 %, whereas the predicted value was 91.6 % indicating a strong agreement between them. The optimum values of the tested variables are at pH 7, 30 °C temperature and agitation at 120 rpm for 144 h of incubation time as shown in perturbation graph (Fig. 6). The model was also validated by repeating the experiments under the optimized conditions, which resulted in the methylparathion removal of 93 % (Predicted response 91.6 %), thus proving the validity of the model.

Analysis of MP degradation using spectral studies

UV–Vis NIR spectral analysis

In order to investigate the formation and eventual disappearance of intermediate compounds in the reaction mixture, the biotreated synthetic wastewater containing methylparathion was monitored using UV–Vis spectroscopy as a function of time. The UV–Vis spectroscopy scanning profile shows a peak formation with lambda max (λmax) at 277 nm. Methylparathion produces a maximum absorbance peak at 277 nm. The extended biotreatment after 144 h, shows the decrease its intensity and eventually disappeared as shown in Fig. 7. The degradation of methylparathion by Fusarium sp mpd-1 was found to be decrease in the peak value at 277 nm with increase in time. The absorbance value was found to be reduced at maximum time of 144 h at optimized process variables. The wavelength at 277 nm shows a displacement to higher wavelengths and formation of new peak at 400 nm that can be attributed to the p-nitrophenol absorption bands. Zhongli et al. (2001) reported that the maximum absorption peak of methylparathion was recorded at 273 nm by Plesiomonas sp strain M6. Wu and Linden (2008) reported that the parathion produces a maximum absorbance (λmax) band at 275 nm. Further, the biotreated samples were analysed by HPLC for the confirmation of the residual MP and intermediates formation.

HPLC analysis

The retention time for methylparathion was found to be 3.3 min which was confirmed by the spectra (Fig. 8). The percentage degradation of methylparathion by Fusarium sp mpd-1 was found to be 93 %. Treated samples showed that the peak reduction at 3.3 retention time (RT), hence it proves the degradation of methylparathion by biotreatment (Fusarium sp mpd-1) process. Moreover, methylparathion was rapidly oxidized into other organic compounds. The peaks at retention time of 4.0, 4.4 and 10 min in treated sample were observed as the intermediate products of methylparathion degradation during the biotreatment process (Fig. 8).

Dumas et al. (1989) reported the hydrolysis of parathion, diazinon, fensulfothion and coumaphos by the enzyme phosphotriesterase. Biodegradation of organophosphorus pesticides by organophosphorus hydrolase has been reported by Richins et al. (1997). Marinho et al. (2011) reported that the presence of glucose in the medium helped the removal of the pollutant. Fungus possesses several enzymatic systems such as glucose oxidase, catalase, lactanase, cytochrome P450 monooxygenase and ligninolytic enzymes. Cytochrome P450 monooxygenase is coupled to NADPH reductase, which works as a source of electrons for oxidation reactions. Its system plays a central role in the oxidative metabolism as well as in the detoxification of xenobiotics. The enzyme catalyses the epoxidation of the aromatic ring, producing arene oxides that are formed through the epoxide hydrolase trans-dihydrodiols or rearranged nonenzymatically to form phenols (Marinho et al. 2011) Therefore, this enzymatic system must have been activated, promoting the partial degradation of methylparathion. The enzymatic action of the fungus may have been responsible for the degradation of methylparathion.

Conclusion

RSM was used in this study to establish the optimum: variables: initial pH, time, culture temperature and agitation for methylparathion biodegradation. It was concluded that the optimal conditions for methylparathion biodegradation are pH 6.5 and 30 °C temperature and agitation at 120 rpm for 144 h of incubation period. The predicted extent of methylparathion biodegradation by the strain Fusarium sp under these optimum conditions was 93 %, and the experimental results were in close agreement with this prediction. The predicted results from the response surface model for methylparathion removal (93 %), COD removal (80 %), TOC removal (58 %) and the growth in dry biomass (150 mg/L) were found at optimum conditions in biotreated MSM with 1,000 mg/L of methylparathion. The predicted optimal and experimentally measured methylparathion removal efficiencies agreed well with high coefficients of determination (R 2 = 0.9); the COD removal and TOC removal (R 2 = 0.9) also agreed well. Moreover, the growth of the fungal strain in terms of its dry biomass also agreed well. Hence, this study was an attempt at methylparathion removal using Fusarium strain with RSM model; it has helped to recognize the important operating variables and optimum levels with least effort and time. The isolate of the present study was found to have potential in methylparathion removal at optimized condition and is suggested for biotreatment of methylparathion wastewater. This study will form the basis for further exploitation of this fungus, grown on suitable substrates, in biofiltration systems for the treatment of pesticide wastewaters.

References

American Public Health Association (1998) In: Standard methods for the examination of water and wastewater, 20th edn. APHA, Washington, DC

Annadurai G (2000) Design of optimum response surface experiments for adsorption of direct dye on chitosan. Bioprocess Biosyst Eng 23(5):451–455. doi:10.1007/s004499900164

Annadurai G, Ling Lai Yi, Lee Jiunn-Fwu (2008) Statistical optimization of medium components and growth conditions by response surface methodology to enhance phenol degradation by Pseudomonas putida. J Hazard Mater 151:171–178

Box GEP, Behnken DW (1960) Some new three level designs for the study of quantitative variables. Technometrics 2:455–475

Chiron S, Fernandez Alba AR, Rodriguez A (1997) Trends in analytical chemistry. vol 16, No.9, Elsevier Sciences. [pii s0165-9936 (97) 00078-2]

Chun M, Chngchun S, Yanghao G, Shi Xian’ai, Jianfeng C, Fen Y (2004) Study on characteristics of bio-cometabolic removal of omethoate by the Aspergillus spp. Wat Res 38(5):1139–1146

Council directive 98/83/EC of 3 November (1998) On the quality of water intended for human consumption, Off J Eur Communities, L 330/32

Dumas DP, Caldwell SR, Wild JR, Raushel FM (1989) Purification and properties of phosphotriesterase from Pseudomonas diminuta. J Biol Chem 264:19659–19665

Evans M (2003) Optimisation of manufacturing processes: a response surface approach. Maney Publishing, London

Hanrahan G, Lu K (2006) Application of factorial and response surface methodology in modern experimental design and optimization. Crit Rev Anal Chem 36:141–151

Kanaly RA, Kim IS, Hur HG (2005) Biotransformation of 3-methyl-4-nitrophenol, a main product of the insecticide fenitrothion by Aspergillus niger. J Agric Food Chem 53:6426–6431

Kanekar PP, Bhadbhade BJ, Deshpande NM, Sarnaik SS (2004) Biodegradation of organophosphorus pesticides. Proc Indian Nat Sci Acad B 70(1):57–70

Karas P, Perucchon C, Exarhou C, Ehaliotis C, Karpouzas DG (2011) Potential for bioremediation of agro-industrial effluents with high loads of pesticides by selected fungi. Biodegradation 22:215–228

Liang WQ, Wang ZY, Li H, Wu PC, Hu JM, Luo N, Cao LX, Liu YH (2005) Purification and characterization of a novel pyrethroid hydrolase from Aspergillus niger ZD11. J Agric Food Chem 53:7415–7420

Liu YH, Chung YC, Xiong Y (2001) Purification and characterization of dimethoate- degrading enzyme of Aspergillus niger ZHY256 isolated from sewage. Appl Environ Microbiol 67:3746–3749

Marinho G, Rodrigues K, Araujo R, Pinheiro ZB, Marinho Silva GM (2011) Glucose effect on degradation kinetics of methyl parathion by filamentous fungi species Aspergilus Niger AN400. Eng Sanit Ambient 16(3):225–230

Meilgaard M, Civille GV, Carr BT (2002) Advanced statistical methods. In: Sensory evaluation techniques (2nd edn. chap 2). CRC Press, Boca Raton, pp 275–304

Montgomery DC (1991) Design and analysis of experiments, 3rd edn. Wiley, New York, p 270

Montgomery DC (2004) Design and analysis of experiments, 5th edn. Wiley, New York

Myers RH, Montgomery DC (2002) Response surface methodology: process and product optimization using designed experiments, 5th edn. Wiley, New York

Ragnarsdottir KV (2000) Environmental fate and toxicology of organophosphate pesticides. J Geol Soc 157:859–876

Richins R, Kaneva I, Mulchandani A, Chen W (1997) Biodegradation of organophosphorus pesticides using surface expressed organophosphorus hydrolase. Nature Biotechnol 15:984–987

Sanyal D, Kulshrestha G (2004) Degradation of metolachlor in crude extract of Aspergillus flavus. J Environ Sci and Health B 39:653–664

Seth M, Chand S (2000) Biosynthesis of tannase and hydrolysis of tannins to gallic acid by Aspergillus awamori—optimization of process parameters. Process Biochem 36(1):39–44

Sogorb MA, Vilanova E, Carrera V (2004) Future application of phosphotriesterases in the prophylaxis and treatment of organophosphorus insecticide and nerve agent poisoning. Toxicol Lett 151:219–233

Wu C, Linden KG (2008) Degradation and byproduct formation of parathion in aqueous solutions by UV and UV/H2O2 treatment. Water Res 42:4780–4790

Zhongli C, Shunpeng L, Guoping F (2001) Isolation of parathion-degrading strain M6 and cloning of the methylparathion hydrolase gene. Appl Environ Microbiol 67(10):4922–4925

Acknowledgments

The author Ms. K. Usharani expresses her sincere thanks to Bharathiar University and DRDO-BU CLS, India, for providing SRF. The author also wishes to extend her sincere gratitude to editor and anonymous reviewers and all who assisted in promoting the present work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Usharani, K., Muthukumar, M. Optimization of aqueous methylparathion biodegradation by Fusarium sp in batch scale process using response surface methodology. Int. J. Environ. Sci. Technol. 10, 591–606 (2013). https://doi.org/10.1007/s13762-012-0144-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-012-0144-5