Abstract

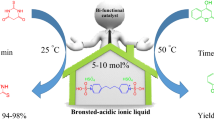

In this work, succinimidinium hydrogensulfate ([H-Suc]HSO4), a newly reported Brönsted acidic ionic liquid, is used as an efficient and reusable catalyst in the synthesis of tetrahydrobenzimidazo[2,1-b]quinazolin-1(2H)-ones, 1-(benzothiazolylamino)phenylmethyl-2-naphthols, 1,8-dioxo-octahydroxanthenes and bis(indolyl)methanes. All reactions were performed during relatively short reaction times with excellent yields. The structures of the products were characterized by IR, 1H NMR and 13C NMR spectroscopy and confirmed by comparison authentic samples.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nowadays, selectivity atom economy, time saving, environmental friendliness, cost effectiveness and the reconciliation of molecular complexity with experimental simplicity are the most important pieces of the puzzle needing to be assembled by modern academic and industrial synthetic chemists to reach the maximum of efficiency [1–3]. Attention to these constraints has resulted in the tremendous development of new concepts and new methodologies able to produce valuable elaborated compounds [3]. Among of these compounds synthesis of heterocyclic compounds has always been a subject of great interest due to their wide applicability in industry such as pharmaceutical industry (drugs), catalysts in petroleum processing, catalysts and reagents in fine chemical synthesis, dyes, agrochemicals, health-care consumables and additives in polymer manufacturing [4–13].

In recent decades, preparation and use of ionic liquids (ILs) in organic transformations became one of the remarkable and important branches in catalyst science because of their unique properties such as negligible volatility, non-flammability, good thermal stability, high conductivity and great chemical and electro-chemical stability [14]. Also, ILs being accepted as environmentally benign media and have been widely applied in many reactions as catalysts or dual catalyst-solvent due to their defined properties.

In this media Brönsted acidic ionic liquids, which combine the advantages of solid acids (e.g., non-volatility and recyclability) and those of liquid acids (e.g., greater effective surface area and potential activity of liquid phase), have been designed and used as dual solvent-catalysts for many famous organic reactions [15]. Among these types of compounds Brönsted-acidic ionic liquids having a functional group into cations or anions of ionic liquids, especially SO3H and SO4H functional groups, obviously show enhancement in their acidities and water solubility [16, 17]. Furthermore, their polar nature makes them useful for use under solvent-free conditions [18].

Experimental

General

Chemicals were purchased from Fluka, Merck, Aldrich and Southern Clay Products Chemical Companies. Yields refer to isolated products. The products were characterized by their physical constants, comparison with authentic samples, FT-IR and NMR spectroscopy. The purity determination of the substrate and reaction monitoring were accomplished by TLC on silica-gel polygram SILG/UV 254 plates.

Instrumentation

The FT-IR spectra were run on a Perkin-Elmer bio-spectrometer and Bruker Vector 22. The 1HNMR (400 MHz) and 13CNMR (100 MHz) were run on a Bruker AVANCE III-400 spectrometer using TMS as an internal reference (δ in ppm). Microanalyses were performed on a Perkin-Elmer 240-B microanalyzer. Melting points were recorded on a Büchi B-545 apparatus in open capillary tubes.

General procedure for the preparation of the succinimidinium hydrogensulfate ([H-Suc]HSO4) [19]

In a round-bottomed flask, 0.53 mL sulfuric acid (98 %, d = 1.84) was added drop wise to a succinimide (0.99 g, 10 mmol) in 25 mL of dichloromethane on an ice bath. The reaction mixture was stirred at room temperature for 30 min, and then the solvent was evaporated under reduced pressure. The solid residue was washed with Et2O and dried under vacuum. [H-Suc]HSO4 was obtained as a cream solid (1.94 g, 97 %) (M.P. 78 °C); FT-IR (neat) ν = 3128, 1693, 1404, 1295, 1180, 1071, 1007, 883, 579 cm−1; 1H NMR (400 MHz, DMSO-d6): d = 2.55 (s, 4H, CH2CH2), 7.31 (s, 2H, NH2), 10.93 (br s, 1H, HSO4) ppm; 13C NMR (100 MHz, DMSO-d6): d = 29.76 (CH2CH2), 180.14 (C=O) ppm. Also and to determine the acidity of the prepared reagent, to 25 mL of an aqueous solution of NaCl (1 M) with a primary pH 5.2, [H-Suc]HSO4 (0.5 g) was added and the resulting mixture was stirred for 2 h at room temperature. The pH of the solution decreased to 1.7. This is equal to a loading of 1.23 mmol H+ per gram of the catalyst.

General procedure for the synthesis of tetrahydrobenzimidazo[2,1-b]quinazolin-1(2H)-one derivatives

A mixture of the requested aldehyde (1 mmol), 2-aminobenzimidazole (1 mmol), dimedone (1 mmol), [H-Suc]HSO4 (20 mg, 10 mol %) was heated at 90 °C under solvent-free conditions for the appropriate time. After completion of the reaction [monitored by TLC (n-Hexane: EtOAc, 70:30)], it was cooled to room temperature and 3 mL of water was added to the mixture. The ionic liquid was dissolved in water and filtered for separation of the crude product and the separated product was washed twice with water (2 × 5 mL). The crude products were purified by recrystallization from EtOH and water.

General procedure for the synthesis of 1-(benzothiazolylamino)phenylmethyl-2-naphthols

A mixture of the aldehyde (1 mmol), 2-aminobenzothiazole (1 mmol), 2-naphthol (1 mmol) and [H-Suc]HSO4 (30 mg, 15 mol %) was heated at 80 °C under solvent-free conditions for the appropriate time as identified by TLC (n-Hexane: EtOAc, 70:30). After completion of the reaction, it was cooled to room temperature and 3 mL of water was added to the mixture. The ionic liquid was dissolved in water and filtered for separation of the crude product and the separated product was washed twice with water (2 × 5 mL). The crude products were purified by recrystallization from ethyl acetate.

Synthesis of 1,8-dioxo-octahydro-xanthenes

A mixture of [H-Suc]HSO4 (10 mg, 5 mol %), aldehyde (1 mmol) and dimedone (2.1 mmol) was stirred in an oil-bath at 90 °C under solvent-free conditions. After completion of the reaction [monitored by TLC:n-hexane–EtOAc (2:8)], the reaction mixture was cooled, H2O (5 mL) was added and filtered to separate the catalyst. Then the product was recrystallized from EtOH to give the pure product.

Synthesis of bis-indolylmethanes

A mixture of [H-Suc]HSO4 (10 mg, 5 mol %), aldehyde (1 mmol) and indole (2 mmol) under solvent-free condition was heated at 80 °C. After completion of the reaction, as monitored by TLC, using n-hexane:EtOAc (1:4) as the eluent, the crude product was filtered off, washed with water, and recrystallized from ethanol to give the pure compound.

Spectral (1H and 13C NMR) data of new compounds are presented below:

3,3-dimethyl-12-(4-thiomethyl-phenyl)-3,4,5,12-tetrahydrobenzimidazo [2,1-b]quinazolin-1(2H)-one (M1)

FT-IR (neat) ν = 3418, 3148, 2954, 1671, 1568, 1375, 1262, 744 cm−1; 1H NMR (DMSO-d6, 400 MHz): δ = 1.07 (6H, s, CH3), 2.15 (4H, s, CH2), 2.40 (3H, s, SCH3), 6.12 (1H, s), 6.93 (2H, d, J = 8.0 Hz), 7.03 (2H, d, J = 7.6 Hz), 7.07–7.11 (2H, m), 7.25–7.28 (2H, m), 7.65 (1H, s, NH) ppm; 13C NMR (DMSO-d6, 100 Mz): δ = 15.8, 28.8, 30.3, 31.6, 48.8, 111.8, 114.8, 122.1, 126.1, 128.1, 132.7, 133,1, 142.8, 152.5 ppm.

3,3-dimethyl-12-(4-cyano-phenyl)-3,4,5,12-tetrahydrobenzimidazo[2,1-b]quinazolin-1(2H)-one (N1):

FT-IR (neat) ν = 3425, 3045, 2962, 2227,1567, 1448,1358, 1264, 748 cm−1; 1H NMR (DMSO-d6, 400 MHz): δ = 0.92 (3H, s, CH3), 1.07 (3H, s,CH3), 2.07 (1H, d, J = 16.0 Hz), 2.28 (1H, d, J = 16.0 Hz), 2.67–2.69 (2H, m), 6.56 (1H, s), 6.98 (1H, td, J 1 = 8.0 Hz, J 2 = 0.8 Hz), 7.08 (1H, td, J 1 = 8.2 Hz, J 2 = 0.8 Hz), 7.41 (1H, d, J = 8.0 Hz), 7.24 (1H, d, J = 8.0 Hz), 7.54 (2H, dd, J 1 = 5.0 Hz, J 2 = 1.6 Hz), 7.75 (2H, dd, J 1 = 5.0 Hz, J 2 = 1.6 Hz), 11.26 (1H, s, NH) ppm. 13C NMR (DMSO-d6, 100 Mz): Sample solubility was too low for 13C NMR.

3,3-dimethyl-12-(2-naphthyl)-3,4,5,12-tetrahydrobenzo[4,5]imidazo[2,1-b]quinazolin-1(2H)-one (P1)

FT-IR (neat) ν = 3443, 3050, 2964,1575, 1370, 1261, 746 cm−1; 1H NMR (DMSO-d6, 400 MHz): δ = 0.94 (3H, s, CH3), 1.08 (3H, s, CH3), 2.04 (1H, d, J = 16.0 Hz), 2.29 (1H, d, J = 16.0 Hz), 2.67- 274 (2H, m), 6.60 (1H, s), 6.93 (1H, t, J = 7.6 Hz), 7.03 (1H, t, J = 7.6 Hz), 7.31 (2H, m), 7.38 (1H, d, J = 8.0 Hz), 7.49 (2H, m), 7.80 (2H, t, J = 7.6 Hz), 7.92 (1H, d, J = 7.6), 8.04 (1H, s), 11.19 (1H, s, NH) ppm; 13C NMR (DMSO-d6, 100 Mz): sample solubility was too low for 13C NMR.

12-(2-fluorenyl)-3,3-dimethyl-3,4,5,12-tetrahydrobenzo[4,5]imidazo[2,1-b]quinazolin-1(2H)-one (Q1)

FT-IR (neat) ν = 3431, 3047, 3229, 2908, 1575, 1372, 1264, 741 cm-1; 1H NMR (DMSO-d6, 400 MHz): δ = 0.96 (3H, s, CH3), 1.08 (3H, s, CH3), 2.07 (1H, d, J = 16.0 Hz), 2.28 (1H, d, J = 16.0 Hz), 2.65–2.69 (2H, m), 3.85 (2H, s, CH2), 6.50 (1H, s), 6.96 (1H, td, J 1 = 7.2 Hz, J 2 = 1.2 Hz), 7.05 (1H, td, J 1 = 7.2 Hz, J 2 = 1.2 Hz), 7.28 (1H, td, J 1 = 7.2 Hz, J 2 = 1.2 Hz), 7.31 (2H, d, J = 7.6 Hz), 7.38 (2H, d, J = 7.6 Hz), 7.54 (1H, d, J = 7.2 Hz), 7.54 (1H, s), 7.78 (1H, d, J = 7.6 Hz), 7.81 (1H, d, J = 7.2 Hz), 11.1 (1H, s, NH) ppm; 13C NMR (DMSO-d6, 100 Mz): sample solubility was too low for 13C NMR.

1-((benzo[d]thiazol-2-ylamino)(pyridin-2-yl)methyl)naphthalen-2-ol (O2)

FT-IR (neat) ν = 3310, 1599, 1545, 1510, 1449 cm−1; 1H NMR (DMSO-d6, 400 MHz): δ = 7.00 (s, 1H), 7.02–7.80 (m, 15H), 8.80 (s, 1H), 10.28 (br, 1H) ppm; 13C NMR (DMSO-d6, 100 MHz): δ = 21.7, 119.3, 121.4, 121.4, 122.9, 123.7, 123.7, 125.9, 126.0, 126.8, 126.9, 127.1, 127.4, 127.5, 128.4, 128.5, 129.1, 130.0, 131.2, 132.6, 137.5, 143.0, 152.6, 153.6, 166.8 ppm.

Results and discussion

Very recently and in continuation of our previous reports on the preparation and use of ionic liquids in different types of organic transformations [20–23], we have reported the preparation of succinimidinium hydrogen sulfate ([H-Suc]HSO4) and its applicability in the acceleration of the N-Boc protection of amines. On the basis of these results we were interested in investigating the applicability of [H-Suc]HSO4 in the acceleration of the synthesis of some of the heterocyclic compounds.

Tetrahydrobenzimidazo[2,1-b]quinazolin-1(2H)-ones, one of the most important class of quinazolines, are very interesting heterocycles as they serve as building blocks in numerous natural and synthetic products that exhibit a wide spectrum of biological and pharmacological activities. Because of these important activities various types of catalysts were used for the promotion of the synthesis of these compounds via the three-component reaction between an aldehyde, 2-aminobenzimidazole and dimedone (5,5-dimethyl-1,3-cyclohexanedione) [24–27]. Although these methods are useful, but introduction of more efficient and green catalysts for the promotion of the preparation of tetrahydrobenzimidazo[2,1-b]quinazolin-1(2H)-one is under considerable attention yet.

To optimize the amount of the catalyst and the reaction temperature in the synthesis of tetrahydrobenzimidazo[2,1-b]quinazolin-1(2H)-ones, the condensation of 2-aminobenzimidazole, benzaldehyde and dimedone under thermal solvent-free conditions was selected as a model reaction. This study showed that the best results can be obtained using 20 mg [H-Suc]HSO4 at 90 °C under solvent-free conditions (Scheme 1). To explore the general applicability of this reaction, a variety of tetrahydrobenzimidazo [2,1-b] quinazolin-1(2H)-one were prepared under the optimized reaction conditions. As it is clear from Table 1, under the selected conditions various aldehydes with different electron-donating and electron-withdrawing groups were well tolerated and yields are almost quantitative in all cases.

To highlight the merits of our newly developed procedure, we compared the obtained results for the synthesis of 3,3-dimethyl-12-(4-nitro-phenyl)-3,4,5,12-tetrahydrobenzimidazo[2,1-b]quinazolin-1(2H)-one (Table 1, entry K1) using the [H-Suc]HSO4 as the catalyst with the other results reported in the literature for the same transformations. As shown in Table 2, the newly developed method avoids some of the disadvantages associated with the other procedures such as long reaction times, large excesses of the reagents, use of organic solvents, reflux conditions, toxic reagents and low yields of the products.

Benzothiazole derivatives are important classes of heterocyclic compounds that occur significantly in pharmaceutical industry. Compounds containing 2-aminobenzothiazole motif have attracted an interest because they demonstrate a wide range of biological activities such as anti-tumor, anti-inflammatory, analgesic, anti-microbial, anti-leishmanial, anti-convulsant, anti-malarial and anti-HIV activities [32].

The preparation of 1-(benzothiazolylamino)phenylmethyl-2-naphthols is establish the three-component condensation reaction of an aldehyde, 2-aminobenzothiazole and 2-naphthol. For this aim several catalysts including LiCl [33], sodium dodecyl sulfate (SDS) [34], HPA [35], NaHSO4.H2O [36], trichloroisocyanuric acid (TCCA) [37], 3-methyl-1-(4-sulfonic acid)propylimidazolium hydrogen sulfate ([(CH2)3SO3HMIM][HSO4]) [38], have been used to facilitate this reaction that suffers from prolonged reaction times, low yields, difficulties in work-up, use of stoichiometric amounts of the catalysts and often expensive catalysts.

Aimed at the synthesis of the 1-(benzothiazolylamino)phenylmethyl-2-naphthols derivatives in the presence of [H-Suc]HSO4 as catalyst, at first and for optimization of the reaction conditions, the reaction of 4-chloro benzaldehyde, 2-aminobenzothiazole and 2-naphthol was selected as a model reaction in various conditions. For choosing the reaction media, different solvents and solvent free conditions were used by various amounts of the [H-Suc]HSO4 at several temperatures. The chosen optimized condition is shown in Scheme 2. It should be noticed that any further increase of the catalyst or temperature did not improve the reaction time and yield. Also to illustrate the efficiency of [H-Suc]HSO4 in these reactions, the model reaction was carried out in the absence of the catalyst and the reaction was not proceeded at all that indicated the catalyst is necessary to produce the products.

After the optimization of the reaction conditions, we explored the protocol with a variety of aromatic, aliphatic and heterocyclic aldehydes under the optimal conditions. The results are presented in Table 3. It was observed that under similar conditions, a wide range of aromatic aldehydes containing electron-withdrawing as well as electron-donating groups such as Cl, Br, CH3, OCH3, and NO2 in the ortho, meta, and para positions of the benzene ring easily converted to the corresponding products in short reaction times with high isolated yields (Table 3, entries A2–L2). Polycyclic aromatic aldehydes such as 2-naphthaldehyde and fluorene-3-carbaldehyde were also provided the desired products in very good yields (Table 3, entries M2–N2). Pyridine-2-carbaldehyde, Pyridine-3-carbaldehyde and pyridine-4-carbaldehyde as the heterocyclic aldehydes were also used as substrates under the selected conditions and the desired products were successfully obtained with high yields (Table 3, entries O2–Q2).

To show the efficiency of the present method, we have compared our result obtained from the reaction of 3-nitro benzaldehyde, 2-aminobenzothiazole and 2-naphthol catalyzed by [H-Suc]HSO4 with the other results reported in the literature (Table 4). It is clear that the present method is superior in terms of the reaction times and yields.

In the next step we focused our attentions on the synthesis of 3, 3, 6, 6-tetramethyl-1, 8-dioxo-octahydroxanthenes as an important derivative of xanthenes that exhibit a broad spectrum of applications in pharmacology, dyes, pH-sensitive fluorescent materials for visualization of biomolecular assemblies and in laser technologies [39]. These derivatives of xanthenes can be prepared via the reaction of aromatic aldehydes and dimedone in the presence of different types of catalysts.

In this regards and to extension of the applications of [H-Suc]HSO4 in the organic reactions, the synthesis of 3, 3, 6, 6-tetramethyl-1,8-dioxo-octahydroxanthenes (DOXs) in the presence of this reagent was investigated. At the first step and for the optimization of the reaction conditions, the interaction of benzaldehyde (1 mmol) and dimedone (2.1 mmol) was studied using [H-Suc]HSO4 as the catalyst. These studies revealed that the best results can be obtained under solvent-free conditions at 90 °C using 10 mg of [H-Suc]HSO4 (Scheme 3). After determination of the optimized reaction conditions the same reaction was performed on different types of aromatic aldehydes. The obtained results are presented in Table 5. On the basis of the obtained results, it can be concluded that the electron property of the substituent, on the aromatic ring of the aldehydes has a little effect on the reaction times.

After determination of the optimized reaction conditions the same reaction was performed on different types of aromatic aldehydes. The obtained results are presented in Table 5. On the basis of the obtained results, it can be concluded that the electron property of the substituent, on the aromatic ring of the aldehydes has a little effect on the reaction times.

The advantages of [H-Suc]HSO4 over some of the other catalysts for the synthesis of 3, 3, 6, 6-tetramethyl-1,8-dioxo-octahydroxanthene derivative of 4-chlorobenzaldehyde are shown in Table 6. This Table clearly shows that the other methods require harsh reaction conditions and longer reaction times.

Furthermore, bis(indolyl)methanes (BIMs) derivatives are the subject of considerable levels of interest because of their numerous applications in pharmaceutical and biological research, where they show antitumor, antileishmanial, antihyperlipidemic, and anticancer [50] activities. The preparation of BIMs via the reaction of aldehyde and indole accelerated using different types of catalysts such as, N-sulfonic acid poly(4-vinylpyridinium) chloride [51], sulfonated rice husk ash (RHA-SO3H) [52], I2 [53], sulfamic acid [54], benzyltriphenylphosphonium tribromide [55], ceric ammonium nitrate [56], [hmim]HSO4 acidic ionic liquid [57], ZrOCl2.8H2O and camphor sulphonic acid [58], PEG-SO3H [59]. In spite of the potential utility of the above routes for the synthesis of BIMs, most of them suffer from several disadvantages such as long times, poor yields of the products, use of toxic solvents and catalysts, use of expensive reagents and catalysts and harsh reaction conditions. Therefore, it is important to find more convenient methods for the synthesis of these types of compounds.

After the above mentioned studies, investigation on the effect of [H-Suc]HSO4 in the acceleration of the synthesis of bis(indolyl)methane via the reaction of aldehydes with indoles became the other part of our research program. This study was also started by the optimization of the reaction conditions using the reaction of benzaldehyde and indole in the presence of [H-Suc]HSO4. The obtained results showed that the best results can be obtained at 80 °C in the presence of 10 mg of [H-Suc]HSO4 under solvent-free conditions (Scheme 4). After optimization of the reaction conditions a series of aromatic aldehydes bearing electron withdrawing or donating groups underwent the same reaction with indole and 2-methyl indole, to afford the requested bis(indolyl)methanes in good to excellent yields (Table 7).

Table 8 shows that this procedure is superior, compared to the previously reported methods, with respect to the catalyst, solvent and eco-friendliness.

The suggested mechanism for the preparation of benzo[4,5]imidazo[1,2-a]pyrimidine, 1-(benzothiazolylamino)-phenylmethyl-2-naphthols, xanthenedione and bis(indolyl)methanes derivatives using [H-Suc]HSO4 as the catalyst is shown in Scheme 5. On the basis of this mechanism and in the first step, the catalyst activates the carbonyl group of the aldehyde, which then reacts with dimedone, 2-naphthol or indole to produce the adduct products.

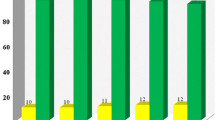

The reusability of the catalyst was also checked in four types of the above mentioned reactions. For this purpose, the model reactions were studied again under the optimized reaction conditions. When the reactions completed, water was added and the precipitated mixtures were filtered off for separation of crude products. After washing the solid products with water completely, the water containing ionic liquid (IL is soluble in water) was evaporated under reduced pressure and the ionic liquid was recovered and reused (Table 9). The recovered catalyst was reused for five runs without any considerable loss of its activity. FT-IR spectroscopy they showed that reused ionic liquid was not consumed or degraded.

Conclusions

In summary, we have developed an environmentally friendly, high yielding and mild condition protocol for the three-component synthesis of benzo[4,5]imidazo[1,2-a]pyrimidine, 1-(benzothiazolylamino)-phenylmethyl-2-naphthol, xanthenedione and bis(indolyl)methanes derivatives using [H-Suc]HSO4 as the catalyst. These methods offer several advantages, compared to those reported in literature, i.e., (1) mild and highly efficient catalyst activity, (2) cost efficiency of the catalyst, (3) avoidance of the troublesome preparation of enol derivatives and pre-formed imines, (4) wide substrate scope, and (5) ease of product isolation/purification, making it a useful and attractive strategy for the synthesis of products.

References

T. Horvath, Chem. Rev. 95, 1 (1995)

C. Simon, J.-F. Peyronel, F. Clerc, J. Rodriguez, Eur. J. Org. Chem. 2002, 3359 (2002)

G. Kaupp, M.R. Naimi-Jamal, J. Schmeyers, Chem. Eur. J. 8, 594 (2002)

V. Alagarsamy, G. Murugananthan, R. Venkatesh Perumal, Biol. Pharm. Bull. 26, 1711 (2003)

G. Daidone, B. Maggio, D. Raffa, S. Plescia, M.L. Bajardi, A. Caruso, V.M.C. Cutuli, M. Amico-Roxas, Eur. J. Med. Chem. 29, 707 (1994)

V. Alagarsamy, R. Revathi, S. Meena, K.V. Ramaseshu, S. Rajasekaran, E. De Clercq, Indian J. Pharm. Sci. 66, 462 (2004)

R.O. Dempcy, E.B. Skibo, Bioorg. Med. Chem. Lett. 1, 39 (1993)

B. Prameela, D.R. Rajanarender, A.L. Murthy, Indian J. Heterocycl. Chem. 2, 115 (1992)

M.F. Branã, M.J. Pérez De Vega, D. Perron, D. Conlon, P.F. Bousquet, S.P. Robinson, J. Heterocycl. Chem. 34, 807 (1997)

A.M. Abdel-Hafez, Arch. Pharmacol. Res. 30, 678 (2007)

V. Alagarsamy, V.R. Solomon, M. Murugan, Bioorg. Med. Chem. 15, 4009 (2007)

R. Paramashivappa, P.P. Kumar, P.V.S. Rao, A.S. Rao, Bioorg. Med. Chem. Lett. 13, 657 (2003)

L. Racane, V. Tralic-Kulenovic, L. Fiser-Jakic, D.W. Boykin, G. Karminski-Zamola, Heterocycles 55, 2085 (2001)

P. Wasserscheid, T. Welton, Ionic liquids in synthesis, 2nd edn. (VCH, Weinheim, 2003)

J. Feng, L. Ying-jie, D. Hai-feng, L. Zong-han, C. Jun-gang, L. Da-peng, Chem. Res. Chin. Univ. 26, 384 (2010)

A. Arfan, J.P. Bazureau, Org. Process Res. Dev. 9, 743 (2005)

P. Wasserscheid, M. Sensing, W. Korth, Green Chem. 4, 134 (2002)

F. Shirini, N.G. Khaligh, S. Akbari-Dadamahaleh, J. Mol. Catal. A. Chem. 365, 15 (2012)

F. Shirini, O.G. Jolodar, M. Seddighi, H. TakbiriBorujeni, RSC Adv. 5, 19790 (2015)

F. Shirini, S. Akbari-Dadamahaleh, M. Rahimi-Mohseni, O. Goli-Jelodar, J. Mol. Liq. 198, 139 (2014)

F. Shirini, NGh Khaligh, Chin. J. Catal. 34, 1890 (2013)

F. Shirini, NGh Khaligh, Chin. J. Catal. 34, 695 (2013)

F. Shirini, M. Abedini, M. Seddighi, O.G. Jolodar, M.S.N. Langroodi, S. Zamani, RSC Adv. 4, 63526 (2014)

G.M. Ziarani, A. Badie, Z. Aslani, N. Lashgari, Arab. J. Chem. 8, 54 (2015)

R.G. Puligundla, S. Karnakanti, R. Bantu, N. Kommu, S.B. Kondra, L. Nagarapu, Tetrahedron Lett. 54, 2480 (2013)

G. Krishnamurthy, K.V. Jagannath, J. Chem. Sci. 125, 807 (2013)

M.R. Mousavi, M.T. Maghsoodlou, Monatsh. Chem. 145, 1967 (2014)

M.M. Heravi, L. Ranjbar, F. Derikvand, B. Alimadadi, H.A. Oskooie, F.F. Bamoharram, Mol. Divers. 12, 181 (2008)

E. Shaabani, A. Farhangi, Rahmati. Comb. Chem. High. T. Scr. 9, 771 (2006)

E. Mourad, A.A. Aly, H.H. Farag, E.A. Beshr, Beilstein J. Org. Chem. 3, 1 (2007)

M.M. Heravi, F. Derikvand, L. Ranjbar, Synth. Commun. 40, 677 (2010)

M. Seddighi, F. Shirini, M. Mamaghani, C R Chimie 18, 573 (2015)

A. Shaabani, A. Rahmati, E. Farhangi, Tetrahedron Lett. 48, 7291 (2007)

A. Kumar, M.S. Rao, V.K. Rao, Aust. J. Chem. 63, 1538 (2010)

S. Javanshir, A. Ohanian, M.M. Heravi, M.R. Naimi-Jamal, F.F. Muharram, J. Saudi Chem. Soc. 5, 502 (2011)

A. Hosseinian, H.R. Shaterian, Phosphorus Sulfur. 187, 1056 (2012)

L. Yang, E J Chem. 9, 2424 (2012)

H.R. Shaterian, A. Hosseinian, Res. Chem. Intermed. 39, 4221 (2013)

J.M. Khurana, D. Magoo, Tetrahedron Lett. 50, 4777 (2009)

S. Kokkirala, N.M. Sabbavarapu, V.D.N. Yadavalli, Eur. J. Chem. 2, 272 (2011)

K. Venkatesan, S.S. Pujari, R.J. Lahoti, K.V. Srinivasan, Ultrason Sonochem. 15, 548 (2008)

M.R. Poor, Heravi. J. Iran. Chem. Soc. 6, 483 (2009)

H.N. Karade, M. Sathe, M.P. Kaushik, Arkivoc 13, 252 (2007)

M. Dabiri, M. Baghbanzadeh, E. Arzroomchilar, Catal. Commun. 9, 939 (2008)

Kg Niknam, M. Damya, J. Chin. Chem. Soc. 56, 659 (2009)

G.H. Mahdavinia, M.A. Bigdeli, Y. Saeidi, Hayeniaz. Chin. Chem. Lett. 20, 539 (2009)

H.A. Oskooie, L. Tahershamsi, M.M. Heravi, B. Baghernejad, J. Chem. 7, 717 (2010)

S. Kantevari, R. Bantul, L. Nagarapu, Arkivoc xvi, 136 (2006)

F. Shirini, S. Akbari-Dadamahaleh, A. Mohammad-Khah, C. R. Chimie. 16, 945 (2013)

F. Shirini, S. Esmaeeli-Ranjbar, M. Seddighi, Chin. J. Catal. 35, 1017 (2014)

F. Shirini, N.G. Khaligh, O.G. Jolodar, Dyes Pigm. 98, 290 (2013)

M. Seddighi, F. Shirini, M. Mamaghani, RSC Adv. 3, 24046 (2013)

S. Ji, S. Wang, Y. Zhang, T. Loh, Tetrahedron 60, 2051 (2004)

L. An, F. Ding, J. Zou, X. Lu, L. Zhang, Chin. J. Chem. 822, 25 (2007)

F. Shirini, M. S. Langroodi, M. Abedini, Chin. Chem. Lett. 21, 1342 (2010)

S. Wang, S. Ji, Tetrahedron 62, 1527 (2006)

D. Gu, S. Ji, Z. Jiang, M. Zhou, T. Loh, Synlett, 959 (2005)

S. Mishra, R. Ghosh, Indian J. Chem., Sect. B: Org. Chem. Incl. Med. Chem. 50, 1630 (2011)

A. Hasaninejad, M. Shekouhy, A. Zare, S.M.S.H. Ghattali, N. Golzar, J. Iran. Chem. Soc. 8, 411 (2011)

M.L. Deb, P.J. Bhuyan, Tetrahedron Lett. 47, 1441 (2006)

N. Azizi, E. Gholibeghlo, Z. Manocheri, Sci Iran. 19, 574 (2012)

S. Mishra, R. Ghosh, Indian J. Chem. 50B, 1630 (2011)

H. Firouzabadi, N. Iranpoor, A.A. Jafari, J. Mol. Catal. A Chem. 244, 168 (2006)

J.S. Yadav, B.V.S. Reddy, S. Sunitha, Adv. Synth. Catal. 345, 349 (2003)

S.J. Ji, M.F. Zhou, D.G. Gu, Z.Q. Jiang, T.P. Loh, Eur. J. Org. Chem. 7, 1584 (2004)

K. Niknam, M.A. Zolfigol, T. Sadabadi, A. Nejati, J. Iran. Chem. Soc. 3, 318 (2006)

J. Azizian, F. Teimouri, M.R. Mohammadizadeh, Catal. Commun. 8, 1117 (2007)

Acknowledgments

We are thankful to the University of Guilan Research Council for the partial support of this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Goli-Jolodar, O., Shirini, F. Succinimidinium hydrogensulfate ([H-Suc]HSO4) as a new, green and efficient ionic liquid catalyst for the synthesis of tetrahydrobenzimidazo[2,1-b]quinazolin-1(2H)-one, 1-(benzothiazolylamino)phenylmethyl-2-naphthol, 1, 8-dioxo-octahydroxanthene and bis(indolyl)methane derivatives. J IRAN CHEM SOC 13, 1077–1092 (2016). https://doi.org/10.1007/s13738-016-0822-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13738-016-0822-1