Abstract

In this work, succinimidinium hydrogensulfate ([H-Suc]HSO4), a newly reported Brönsted acidic ionic liquids is used as an efficient, homogeneous and reusable catalyst for the synthesis of 5-arylidenepyrimidine-2,4,6(1H,3H,5H)-trione and pyrano[2,3-d]-pyrimidine dione derivatives. The products were formed in excellent yields over short reaction times and the catalyst can be reused several times without any appreciable loss in its activity.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The development of environmentally friendly catalysts and solvents for organic reactions is an area of considerable importance. In this area and from both economic and environmental points of view, the use of non-volatile solvents and non-metallic catalysts is very promising. In the past few decades, and because of the fascinating properties such as their low vapor pressure, reusability, high thermal and chemical stability, ionic liquids (ILs) were successfully used as environmentally benign solvents and catalysts in numerous catalytic reactions. Among these types of componds, Brönsted acidic ionic liquids have been planned to replace traditional mineral liquid acids, such as sulfuric acid and hydrochloric acid [1]. For example it has been reported that many organic reactions, such as esterification [2–4], alkylation [5], alcoholysis [6], acylation [7], Claisen-Schmidt condensation [8], carbonylation [9], nitration [10] and hydrolyzation [11] can be accelerated in the presence of the functionalized Brønsted acidic ILs.

5-Arylidenepyrimidine-2,4,6(1H,3H,5H)-trione (A) and pyrano-pyrimidinones (B) as two important derivatives of barbituric acid show considerable pharmaceutical and biological activities including anticonvulsant, sedative-hypnotic, antiparkinsonian, antitumor, hepatoprotective, antimalarial, analgesics, antifungal, antibacterial and antiallergic [12–26] activities. Furthermore, 5-monosubstituted barbituric acids are precursors for the synthesis of a large number of annulated uracils of biological significance.

Because of the above mentioned applications, many methods using different types of catalysts are reported for the preparation of 5-arylidenepyrimidine-2,4,6(1H,3H,5H)-trione and pyrano[2,3-d]pyrimidinones derivatives which of them Nickel nanoparticles [25], sodium p-toluene sulfonate (NaPTSA) [26], basic alumina [27], IR lamp [28], Ce1MgxZr1-xO2 (CMZO) [29], l-proline [30], Zn[(L)proline]2 [31], [BMIm]BF4 [32], 1,4-dioxane [33, 34], Diammonium hydrogen phosphate (DAHP) [35], SBA-Pr-SO3H [36], Tetra-n-butylammonium bromide (TBAB) [37], 1,4-Diazabicyclo[2.2.2]octane (DABCO) [38], are examples. However, many of these methods suffer from disadvantages such as low yields, long reaction times, harsh reaction conditions, tedious work-up and requirement of excess amounts of reagents or catalysts. Therefore, it is important to find more convenient methods for the synthesis of these types of compounds.

Experimental

General

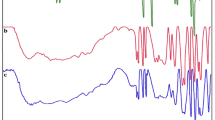

Chemicals were purchased from Fluka, Merck, and Aldrich chemical companies. All yields refer to the isolated products. Products were characterized by comparison of, their physical constants, IR and NMR spectroscopy with authentic samples and those reported in the literature. The purity determination of the substrate and reaction monitoring were accompanied by TLC on silicagel polygram SILG/UV 254 plates.

Instrumentation

The IR spectra were recorded on a Perkin Elmer 283 B, 781 and 843 Spectrophotometers and FT-IR spectra were recorded on a perkin-Elmer spectrum BX series and Thermo Nicolet Nexus 670 Spectrophotometers. In all the cases the 1H NMR and 13C NMR spectra were recorded with Varian Gemini 300 and 200 and BrukerAvance 400 and 300 MHz instruments, respectively. All chemical shifts are quoted in parts per million (ppm) relative to TMS using deuterated solvent. The MS were measured on a Agilent Technology (HP) manufacturer company under 70 eV conditions.

Preparation of succinimidinium hydrogensulfate ([H-Suc]HSO4) [36]

In a round-bottomed flask, 0.53 mL sulfuric acid (98 %, d = 1.84) was added drop-wise to a mixture of succinimide (0.99 g, 10 mmol) in 50 mL of dichloromethane on an ice bath. The reaction mixture was stirred at room temperature for 30 min, and then the solvent was evaporated under reduced pressure. The solid residue was washed with 2 × 5 mL ether and dried under vacuum. After this process [H-Suc]HSO4 was obtained as a cream solid (1.94 g, 97 %) (M.P. 78–80 °C) (Scheme 1).

General procedure for the preparation of 5-arylidenepyrimidine-2,4,6(1H,3H,5H)-trione

A mixture of an aldehyde (1 mmol), barbituric acid (1 mmol) and [H-Suc]HSO4 (0.009 g) in water (4 mL) was heated in an oil bath (50 °C). After completion of the reaction, as monitored by TLC [eluent: n-hexane:EtOAc (1:4)] the crude product was filtered off, washed with water and recrystallized from ethanol to offered the pure compound.

General procedure for the preparation of pyrano[2,3-d]pyrimidinones

A solution of an aldehyde (1 mmol), malononitrile (1.2 mmol), barbituric (1 mmol) and [H-Suc]HSO4 (0.009 g) in water (4 mL) was heated in an oil bath (80 °C). After completion of the reaction, as monitored by TLC [eluent: n-hexane:EtOAc (1:4)] the crude product was filtered off, washed with water and recrystallized from ethanol to offered the pure compound.

Spectral data of derivatives of 5-arylidenepyrimidine-2,4,6(1H,3H,5H)-triones:

5-(2-Nitrobenzylidene)pyrimidine-2,4,6(1H,3H,5H)-trione (Table 2, entry 5): White solid, M.p. 276–278 °C; FT-IR(KBr) ν = 3427, 3318, 3181, 2956, 2892, 1678, 1574, 1519, 1350, 790; MS: m/z = 261 (M++1); 1HNMR (400 MHz, DMSO-d 6 ) δ = 7.58 (d, J = 7.6, 1H), 7.68 (dt, J 1 = 8, J 2 = 0.8, 1H), 7.79 (dt, J 1 = 7.6, J 2 = 1.2, 1H), 8.24 (dd, J 1 = 8, J 2 = 1.2, 1H), 8.61 (s, 1H, HC = C), 11.26 (NH, s, 1H), 11.51(NH, s, 1H); 13CNMR (400 MHz, DMSO-d 6) δ = 120.9, 124.5, 130.6, 130.8, 132.1, 134.2, 146.7, 150.7, 152.9, 161.6, 162.8.

5,5′-(1,3-Phenylenebis(methanylylidene))bis(pyrimidine-2,4,6(1H,3H,5H)-trione) (Table 2, entry 17): Yellow solid, M.p. > 300 °C; FT-IR(KBr) ν = 3535, 3201, 3074, 1757, 1682, 1571, 800, 682; MS: m/z = 354 (M+); 1HNMR (400 MHz, DMSO-d 6 ) δ = 7.55 (t, J = 7.6, 1H), 8.20 (dd, J 1 = 7.8, J 2 = 1.6, 2H), 8.29 (s, 2H, HC = C), 8.49 (s, 1H), 11.29 (NH, s, 2H), 11.44 (NH, s, 2H); 13CNMR (400 MHz, DMSO-d 6) δ = 120.3, 128.0, 132.9, 135.9, 137.6, 150.6, 153.9, 161.9, 163.6.

5,5′-(1,4-Phenylenebis(methanylylidene))bis(pyrimidine-2,4,6(1H,3H,5H)-trione) (Table 2, entry 18): Yellow solid, M.p. > 300 °C; FT-IR(KBr) ν = 3495, 3202, 3085, 1749, 1685, 1584, 808; MS: m/z = 354 (M+); 1HNMR (400 MHz, DMSO-d 6 ) δ = 8.05 (s, 4H), 8.29 (s, 2H, HC = C), 11.30 (NH, s, 2H), 11.45 (NH, s, 2H) ppm; 13CNMR (400 MHz, DMSO-d 6) δ = 120.9, 129.0, 132.3, 136.1, 150.6, 153.4, 161.9, 163.6 ppm.

Results and discussion

In continuation of the successful design, synthesis and application of ILs in organic chemistry [39–43], very recently we have reported the preparation of succinimidinium hydrogen sulfate ([H-Suc]HSO4) and its applicability in the acceleration of the N-Boc protection of amines [44]. The obtained results in this study clarified that this reagent is able to catalyze the reactions which need the acidic catalyst to speed-up. On the basis of these results we were interested in investigating the applicability of this reagent in the promotion of the synthesis of the barbituric acid derivatives.

At first, we focused our attention on the synthesis of 5-arylidenepyrimidine-2,4,6(1H,3H,5H)-triones. For optimization of the reaction conditions, the condensation of 4-chlorobenzaldehyde with barbituric acid to the corresponding product was selected as a model reaction. For this purpose various conditions using different amounts of the catalyst and temperatures under solvent-free conditions or different types of solvents were examined (Table 1). After careful studies the optimal reaction conditions for this reaction was selected as follow: 1 mmol aldehyde, 1 mmol barbituric acid and 10 mg [H-Suc]HSO4 as the catalyst at 50 °C in water as the solvent (Scheme 2). It is important to note that lower amounts of the catalyst led to the lower yields, while higher amounts of [H-Suc]HSO4 did not affect the reaction yields. Nearly no product could be detected in the absence of the catalyst.

After optimization of the reaction conditions and in order to explore the scope of this method, the condensation of barbituric acid with different types of aryl aldehydes in the presence of [H-Suc]HSO4 (10 mg) was investigated under the selected conditions. The studied reactions yielded the desired 5-arylidenepyrimidine-2,4,6(1H,3H,5H)-trione derivatives during very short reaction times (3–15 min) in excellent yields.

The study on the influence of electron-withdrawing and electron-donating substituents on the aromatic ring of aldehydes upon the reaction times and yields showed that the changing of the substituents had a negligible effect on the reaction results (Table 2). Using this method unsaturated aldehydes, were also successfully converted to the desired products in high yields (Table 2, entry 15).

This method was also found to be useful for the usage of dialdehydes. In this reaction, 2 equivalents of barbituric acid successfully condensed with 1 equivalent of isophthalaldehyde and/or terephthalaldehyde and the desired products were obtained in high yields during acceptable reaction times. This result shows the practical synthetic efficiency of this reaction (Table 2, entry 17, 18).

In the next step, [H-Suc]HSO4 was used in the synthesis of pyrano[2,3-d]pyrimidinones from the condensation of barbitoric acid, malononitrile and aldehydes. In order to optimize the reaction conditions, the condensation of 4-chlorobenzaldehyde (1 mmol) with barbituric acid (1 mmol) and malononitrile was studied in the presence of [H-Suc]HSO4 (10 mg), and the results are tabulated in Tables 3. On the basis of these results, the optimized conditions are selected as shown in Schemes 3.

After determination of the optimized temperature, a series of aromatic aldehydes bearing electron withdrawing or donating groups were reacted with barbitoric acid and malononitrile producing pyrano[2,3-d]pyrimidinones in short reaction times (8–15 min) with high yields (Table 4).

In a plausible mechanism, the aldehyde is firstly activated by [H-Suc]HSO4. Next, the carbonyl group is attacked by barbituric acid and the related 5-arylidenepyrimidine-2,4,6(1H,3H,5H)-trione products (A) were formed. The subsequent addition of malononitrile to Knoevenagel products (A), gives the acyclic adduct intermediate, which undergoes intramolecular cyclization to afford the pyrano[2,3-d]pyrimidinones (B) derivatives (Scheme 4).

In order to highlight the merits of our newly developed procedures, in Table 5 we have compared our results obtained from the synthesis of 5-(4-chlorobenzylidene) pyrimidine-2,4,6(1H,3H,5H)-trione (Table 2, entry 9) and 7-amino-5-(4-nitrophenyl)-2,4-dioxo-1,3,4,5-tetrahydro-2H-pyrano[2,3-d]pyrimidine-6-carbonitrile (Table 4, entry 10) catalyzed by [H-Suc]HSO4 with other results reported in the literature. As shown in Table 5, this method avoids some of the disadvantages associated with the other procedures such as long reaction times, low yields, and hard conditions for the catalyst preparation, using infrared or microwave irradiation and high catalyst loading.

To check the reusability of the catalyst, the reaction of 4-chlorobenzaldehyde with barbituric acid and malononitrile under the optimized reaction conditions was studied again. After separation of the product the catalyst was recovered by evaporation of water, washed with diethyl ether, dried at 50 °C under vacuum for 1 h, and reused in another reaction with only slim reduction in the catalytic activity. This method was used at least for 5 runs and the obtained yields were above 90 % (Fig. 1).

Conclusions

In conclusion, in this article, we have introduced a Brønsted acidic ionic liquid named as succinimidium hydrogensulfate ([H-Suc]HSO4) as a novel, highly efficient, general and homogeneous catalyst for the synthesis of 5-arylidenepyrimidine-2,4,6(1H,3H,5H)-trione and pyrano[2,3-d]pyrimidinones derivatives. The promising reasons for the presented protocol is efficiency, generality, high yields of the products, short reaction times, cleaner reaction profile, simplicity, low cost, ease of preparation and recycling of the catalyst.

References

V.I. Parvulescu, C. Hardacre, Chem. Rev. 107, 2615 (2007)

F.J. Hernandez-Fernandez, A.P. delos Rios, L.J. Lozano-Blanco, C. Godinez, J. Chem. Technol. Biotechnol. 85, 1423 (2010)

Y.W. Zhao, J.X. Long, F.G. Deng, X.F. Liu, Z. Li, C.G. Xia, J.J. Peng, Catal. Commun. 10, 732 (2009)

M.H. Han, W.L. Yi, Q. Wu, Y. Liu, Y.C. Hong, D.Z. Wang, Bioresour. Technol. 100, 308 (2009)

X.H. Yuan, M. Chen, Q.X. Dai, X.N. Cheng, Chem. Eng. J. 146, 266 (2009)

D. Jiang, Y.Y. Wang, M. Tu, L.Y. Dai, Chin. Chem. Lett. 19, 889 (2008)

P. Elavarasan, K. Kondamudi, S. Upadhyayula, Chem. Eng. J. 166, 340 (2011)

J.H. Shen, H. Wang, H.C. Liu, Y. Sun, A.M. Liu, J. Mol. Catal. A Chem. 280, 24 (2008)

A.L. Lapidus, O.L. Eliseev, Solid Fuel Chem. 44, 197 (2010)

D. Fang, Q.R. Shi, J. Cheng, K. Gong, Z.L. Liu, Appl. Catal. A. Gen. 345, 158 (2008)

Q.W. Yang, Z.J. Wei, H.B. Xing, Q.L. Ren, Catal. Commun. 9, 1307 (2008)

L. S. Goodman, A. Gilman, Mc Graw-Hill; New Delhi, p. 358 (1991)

G. Andrews, Medical pharmacology. p. 243 (1976)

WO. Foye, Principles of medicinal chemistry. PA. 143 (1989)

P. Kumar, C. Nath, J.C. Agarwal, K.P. Bhargava, K. Shanker, Indian J. Chemistry B. 22B, 955 (1983)

E.M. Griva, S. Lee, C.W. Siyal, D.S. Duch, C.A. Nichol, J. Med. Chem. 23, 327 (1980)

G.L. Anderson, J.L. Shim, A.D. Broom, J. Org. Chem. 41, 1095 (1976)

S. Furuya, T. Ohtaki, Chem. Abstr. 121(1994), 205395 (1994)

D. Heber, C. Heers, U. Ravens, Pharmazie. 48, 537 (1993)

J. Davoll, J. Clarke, E.F. Eislager, J. Med. Chem. 15, 837 (1972)

E. Kretzschmer, Pharmazie. 35, 253 (1980)

V.K. Ahluwalia, R. Batla, A. Khurana, R. Kumar, Indian J. Chem. Sec. 29, 1141 (1990)

M.M. Ghorab, A.A.Y. Hassan, Phosphorus Sulfur Silicon Relat. Elem. 141, 251 (1998)

N. Kitamura, A. Onishi, Eur. Pat, Chem. Abstr. 104(1984), 186439 (1984)

J.M. Khurana, K. Vij, Catal. Lett. 138, 104 (2010)

S. Kamble, G. Rashinkar, A. Kumbhar, K. Mote, R. Salunkhe, Arch. Appl. Sci. Res. 2, 217 (2010)

A. Khalafi-Nezhad, A. Hashemi, Iran J. Chem. Chem. Eng. 20, 9 (2001)

G. Alcerreca, R. Sanabria, R. Miranda, G. Arroyo, J. Tamariz, F. Degado, Synth. Commun. 30, 1295 (2000)

S.B. Rathod, A.B. Gambhire, B.R. Arbad, M.K. Lande, Bull. Korean Chem. Soc. 31, 339 (2010)

M. Bararjanian, S. Balalaie, B. Movassagh, A.M. Amani, J. Iran. Chem. Soc. 6, 436 (2009)

M.M. Heravi, A. Ghods, K. Bakhtiari, F. Derikvand, Synth. Commun. 40, 1927 (2010)

J. Yu, H. Wang, Synth. Commun. 35, 3133 (2005)

Y.A. Sharanin, G.V. Klokol, Zh Org Khim. 20, 2448 (1984)

H.H. Zoorob, M. Abdelhamid, M.A. El-Zahab, M. Abdel-Mogib, I. AMA Arzneim Forsch. 47, 958 (1997)

S. Balalaie, S. Abdolmohammadi, H.R. Bijanzadeh, A.M. Amani, Mol. Divers. 12, 85 (2008)

G.M. Ziarani, S. Faramarzi, S. Asadi, A. Badiei, R. Bazl, M. Amanlou, DARU J. Pharm Sci. 21, 3 (2013)

A. Mobinikhaledi, M.A. Bodaghi Fard, Acta Chim. Slov. 57, 931 (2010)

J. Azizian et al., Orient. J. Chem. 28(1), 327 (2012)

F. Shirini, N.G. Khaligh, S. Akbari-Dadamahaleh, J. Mol. Catal. A Chem. 365, 15 (2012)

F. Shirini, M. Abedini, M. Seddighi, O.G. Jolodar, M.S.N. Langroodi, S. Zamani, RSC Adv. 4, 63526 (2014)

M.A. Zolfigol, A. Khazaei, A.R. Moosavi-Zare, A. Zare, Org. Prep. Proced. Int. 42, 95 (2010)

M.A. Zolfigol, V. Khakyzadeh, A.R. Moosavi-Zare, G. Chehardoli, F. Derakhshan-Panah, A. Zare, O. Khaledian, Scientia Iranica 19, 1584 (2012)

M.A. Zolfigol, A. Khazaei, A.R. Moosavi-Zare, A. Zare, Z. Asgari, V. Khakyzadeh, A. Hasaninejad, J. Indust. Eng. Chem. 19, 721 (2013)

F. Shirini, O.G. Jolodar, M. Seddighi, H. Takbiri Borujeni, RSC Adv. 5, 19790 (2015)

C.S. Reddy, A. Nagaraj, P. Jalapathi, Indian J. Chem. 46B, 660 (2007)

J.T. Li, H.G. Dai, D. Liu, T.S. Li, Synth. Commun. 36, 789 (2006)

S. Mashkouri, M.R. Naimi-Jamal, Molecules 14, 474 (2009)

H. Kefayati, M. Valizadeh, A. Islamnezhad, Anal. Bioanal. Electrochem. 6, 80 (2014)

Acknowledgments

We are thankful to the University of Guilan Research Council for the partial support of this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Goli-Jolodar, O., Shirini, F. & Seddighi, M. Succinimidinium hydrogensulfate ([H-Suc]HSO4) as an efficient ionic liquid catalyst for the synthesis of 5-arylidenepyrimidine-2,4,6(1H,3H,5H)-trione and pyrano-pyrimidinones derivatives. J IRAN CHEM SOC 13, 457–463 (2016). https://doi.org/10.1007/s13738-015-0754-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13738-015-0754-1