Abstract

A new amino-functionalized Fe3O4–graphene oxide nanocomposite (AF-Fe3O4–GO) was synthesized. The properties were characterized by Fourier-transform infrared spectrometry and scanning electron microscopy. The obtained adsorption results showed that the AF-Fe3O4–GO had great adsorptive ability toward Cu(II). Based on these, an effective magnetic solid-phase extraction (MSPE) procedure coupled with flame atomic absorption spectrometry for the pre-concentration and determination of Cu(II) in food samples was developed. Various experimental parameters that could affect the extraction efficiency were investigated in detail. Under optimum conditions, enhancement factor of the method for Cu(II) was found to be 95.08. The proposed method was successfully applied for the analysis of food samples with recoveries ranging from 97.2 to 99.1 % and a correlation coefficient (R 2) of 0.999. Good linearity was obtained, ranging from 1 to 100 µg L−1. The limit of detection and precision of the method were 0.9 ng mL−1 and 1.23 %, respectively. It was confirmed that AF-Fe3O4–GO nanocomposite can be a highly effective MSPE adsorbent used for trace Cu(II) analyses.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Heavy metals can easily enter the food chain through a number of pathways, and long-term exposure in a contaminated environment can cause progressive toxic effects [1–3]. Copper is one such heavy metal harmful to human health. The presence of Cu(II) causes serious toxicological concerns [4]. Consequently, it is desirable to develop simple, selective, efficient, and eco-friendly methods for the extraction and analysis of trace heavy metals in environmental and biological samples.

In spite of great improvements in sensitivity and selectivity of modern analytical methods, the direct determination of these elements in real samples is a difficult task. The main reasons come from the complexity of the matrix and low concentration of analytes in some samples, which are often below the detection limits of available techniques. Thus, the use of separation techniques to overcome matrix interference or enhance sensitivity through pre-concentration of the analyte is required. There are many processes of separating and enriching metal ions from aqueous solution such as precipitation [5], liquid–liquid extraction [6], and solid-phase extraction (SPE) [7]. Among these methods, SPE is the most popular [8, 9]. SPE has many obvious advantages, such as low consumption of organic solvents, simplicity, and ability to achieve a higher enrichment factor.

Recently, research has focused on the use of nanoparticles, particularly magnetic nanoparticles (MNPs), in many scientific fields. For instance, an SPE called magnetic solid-phase extraction (MSPE), due to its the extremely small size, high surface area-to-volume ratio and the absence of internal diffusion resistance, provides better kinetics for adsorption of metal ions from aqueous solutions [10–13].

Graphene nanosheets have been intensively researched as adsorbent for metal ions since the ideal two-dimensional material is characterized by a large specific surface area (2630 m2g−1) and can be prepared from graphite at low cost [14].

In the present study, we synthesized a new adsorbent for the extraction, pre-concentration, and determination of trace amounts of copper. Magnetic Fe3O4–graphene nanosheets coated with 1,6-hexadiamine were chosen as the adsorbent due to low cost, simplicity of use, and high synthesis yields.

Experimental

Reagents

All reagents used were of analytical grade. Ferric chloride (FeCl3·6H2O), potassium permanganate (KMnO4), 1,6-hexadiamine, hydrochloric acid, sulfuric acid, nitric acid, H2O2, NaOH, and graphite powder (50 mesh) were all purchased from Merck (Darmstadt, Germany). The stock standard solutions (1000 mg L−1) of Cu(II) were prepared by dissolving appropriate amount of Cu(NO3)2·3H2O. Daily working solutions were prepared through serial dilutions of the stock solution with deionized water prior to analysis. All vessels in the experiments were kept in 10 % HNO3 for at least 24 h and subsequently washed with deionized water before application.

Instrumentation

The concentration of Cu(II) ion was determined by flame atomic absorption spectrometry (FAAS) using a Shimadzu model Spect. AA-670 apparatus. A copper hollow-cathode lamp as the radiation source was used for the absorbance measurements at a wavelength of 328.4 nm and a 3 mA current. All measurements were carried out in an air/acetylene flame. Details of operating conditions for the determination of Cu(II) ion were as per the manufacturer’s manual. FT-IR spectra in KBr were recorded on a Bruker tensor 27 spectrometer. A Metrohm model E-691 (Herisau, Switzerland) pH-meter with a combined glass electrode was used for pH measurements. X-ray powder diffraction (XRD) data were collected on a D/Max 2500 V/PC X-ray powder diffractometer using Cu Kα radiation (λ = 0.154056 nm, 40 kV, 200 mA). SEM images were obtained using a Hitachi S-4160 field emission scanning electron microscope operating at 17 kV. An ultrasonic mode Parsonic 7500 was used for dispersion of experimental solutions.

Preparation of amino-functionalized Fe3O4–graphene oxide nanocomposite (AF-Fe3O4–GO)

Prior to the preparation of AF-Fe3O4–GO nanocomposite, GO was obtained based on Hummers method [15, 16], for which KMnO4 was used as oxidant. Next, the AF-Fe3O4–GO was prepared through the solvothermal method and using an autoclave at high temperature [17]. As per the typical method, a GO dispersion was prepared by sonicating it (0.5 g) for 3 h in ethylene glycol (35 mL). Then, FeCl3·6H2O (0.7 g) and 1,6-hexadiamine (4.5 g) as well as sodium acetate (1.4 g) were added to the GO dispersion with continuous sonicating at 50 °C for 30 min to form a clear solution. Finally, the obtained clear solution was sealed in a teflon lined stainless-steel autoclave. The autoclave was heated and maintained at 200 °C for 8 h, and allowed to cool down to room temperature. The obtained product was collected by the aid of a magnet, and then washed with deionized water and ethanol. The resultant precipitates (AF-Fe3O4–GO) were dried at 45 °C.

Procedure for magnetic solid-phase extraction (MSPE)

Extraction procedure of Cu(II) ion was performed by the batch equilibrium technique. First, 50 mL of sample solution spiked with the appropriate amounts of Cu(II) ions was placed in a beaker and its pH was adjusted to six by the addition of dilute HNO3 or NaOH. Then, 5 mg of nanocomposite was dispersed into the solution. After sonicating at 30 °C for 10 min, the adsorbent were isolated from the suspension with a Nd–Fe–B magnet (10 × 5×4 cm with 1.4 T magnetic field). Subsequently, 0.5 mL of eluent (0.1 mol L−1 HCl) was introduced to desorb the adsorbed analytes from the adsorbent surface by sonicating for 2 min. Finally, the eluate was magnetically separated and introduced into the nebulizer of the FAAS. Scheme 1 displays the steps for MSPE of the target Cu(II) ions using synthesized AF-Fe3O4–GO nanocomposite.

Preparation of real samples

Firstly, the food samples were washed thoroughly with tap and deionized water. Secondly, the samples were dried at 105 °C for 24 h and grounded. One gram of the sample was placed in a 100 mL beaker, and then 10 mL of concentrated HNO3 (65 % w/w) was added. The mixture was evaporated near to dryness on a hot plate at approximately 130 °C for 4 h. After cooling to room temperature, 3 mL of concentrated hydrogen peroxide (30 % w/w) was added. The mixture was again evaporated near to dryness. The resultant solution was diluted to 25 mL with deionized water. The filtration procedure was undertaken for samples which were not completely dissolved [18]. The MSPE procedure described was applied to the sample solutions.

Results and discussion

In order to select the optimum MSPE conditions for the extraction of Cu(II) ions, 50 mL copper solution (10 µg L−1) was used to study the extraction performance of the MSPE under different experimental conditions. All the experiments were performed in triplicate and the results were used for optimization.

Characterization

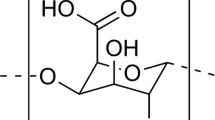

The formations of GO and AF-Fe3O4–GO nanocomposite were investigated using FT-IR spectrometry. FT-IR spectrum of GO is shown in Fig. 1a. The strong wide absorption band at 3419 cm−1 is characteristic of the stretching vibration of hydroxyl groups. There are also bands pertaining to carbonyl C=O and C=C groups (1708 and 1049 cm−1, respectively), carboxylic acid C–O band (1387 cm−1), and C–O–H deformation peak (at 1220 cm−1). Furthermore, FT-IR spectrum of nanocomposite is shown in Fig. 1b. The production of iron oxide nanocomposite can be seen from the occurrence of a strong absorption band at 576 cm−1 [19]. The band of amine groups at 3436 cm−1, the stretching vibration peak of aliphatic C–N at 1183 cm−1, N–H deformation band at 1648 cm−1, and also C-H stretching band at 2924 cm−1 can be a confirmation of the formation of AF-Fe3O4–GO magnetic nanocomposite adsorbent.

Figure 2 shows the X-ray diffraction (XRD) patterns of the Fe3O4 and AF/Fe3O4/GO nanocomposite. As can be seen, the pattern of AF/Fe3O4/GO displayed obvious diffraction peaks of Fe3O4, and the peak positions and intensities match well with the standard XRD data for magnetite (JCPDS card, file No. 79-0419). In the presence of GO, another new diffraction peak was found at 24° (curve b), which was corresponded to carbon for GO. The X-ray diffraction pattern of Fe3O4/GO was similar to AF/Fe3O4/GO (not shown) that shows the amine modification does not result in the phase change of Fe3O4/GO.

The typical SEM images of GO and AF-Fe3O4–GO nanocomposite are shown in Fig. 3. The SEM observation shows that GO has a crumbled wave-like structure and quite smooth (Fig. 3a) and precipitated Fe3O4 nanoparticles on the GO nanosheets with a size less than 100 nm (Fig. 2b).

Effect of extraction time

In the MSPE process, contact time is one of the important factors influencing target analyte extraction. To study the effect of extraction time on the extraction efficiency of Cu(II) ions, extraction time was varied between 6 and 16 min, while other parameters were held at constant values. The results indicated that the extraction efficiency remained almost constant after 10 min. Therefore, the extraction time of 10 min was selected as the optimum time (Fig. 4).

Effect of pH in sample solution

Acidity of the sample solution plays a significant role in the extraction of target metal ions by affecting their adsorption due to both chemistry of target metal ions in the solution and the protonation of the adsorbent donor atoms. Therefore, extraction efficiency of the copper ions on the adsorbent structure as a function of the pH of the sample solution was investigated. The results (Fig. 5) showed that maximum adsorption efficiency occurred at pH 6. When the pH value was low, the adsorption of copper ions was less. However, the adsorption amount sharply increased when pH increased to six. At the lower pH values, the low adsorption amount was due to competition of copper ions with hydrogen ions and probably the surface protonation of the adsorbent and occupation of active sites by protons rather than copper ions. At higher pH values, decrease in the extraction efficiency can be explained by the hydrolysis of copper ions or the precipitation of copper ions when pH value is too high. Based on the obtained results, pH 6 was selected for all subsequent work and real sample analyses.

Effect of adsorbent amount

The amount of adsorbent is another important parameter in obtaining quantitative recovery. Nanocomposites have been used as better adsorbents for their high surface areas than conventional adsorbents. Therefore, fewer amounts of nano adsorbents can achieve satisfactory results. To choose the optimum amount of the adsorbent for the extraction of Cu(II), different quantities of nanocomposite were tested in the range 2.5–20 mg. As shown in Fig. 6, the maximum extraction efficiency was obtained at 5 mg and when the amount of adsorbent was above 5 mg, the recovery remained almost invariant. Therefore, 5 mg of adsorbent was used in all experiments.

Effect of sample volume

In order to obtain a higher enrichment factor, a large volume of the sample solution is required. For this purpose, the effect of sample volume on extraction efficiency of the target analyte was studied in the range 25–250 mL and the obtained results are shown in Fig. 7. It is clear that the effect of increasing sample volume on the extraction efficiency of copper ions was not observed until 50 mL and further increasing the volume decreased efficiency. This can be attributed to the more difficult transport of target analytes onto the adsorbent surface in larger volume samples because of a lower amount of adsorbent in the volume unit of the sample solution.

Desorption conditions

The effect of desorption time was studied and this revealed that within 2 min the copper ions could be quickly desorbed and more desorption time was not necessary. To obtain a high enrichment factor, a suitable eluent should be used. The eluent should elute the adsorbed analytes quantitatively in small volumes. Figure 5 shows that the adsorption of copper ions at pH <6 is low; thus, one can expect elution to favor acidic solutions. Therefore, various concentrations of HNO3 and HCl were used for desorption of adsorbed analytes. The obtained results showed that 0.1 mol L−1 HCl solution is suitable for the elution of copper.

The effect of interfering elements

The influence of other ions in the extraction of Cu(II) was studied under optimized conditions. Solutions containing 10 µg L−1 Cu(II) and different concentrations of other ions were prepared and subjected to the pre-concentration procedure. The tolerance limits of potentially interfering ions are defined as the largest amount that cause an error in the absorbance value of no more than ±5 %. The results, summarized in Table 1, showed that within ±5 % error range, the presence of major cations and anions in natural water had no significant influence on the adsorption of Cu ion under the selected conditions.

Reusability studies

The effect of the frequent use of nanocomposite as an adsorbent of MSPE is an important factor. In order to evaluate the reusability of the adsorbent after the desorption of copper ions from the adsorbent, it was washed with 0.1 mol L−1 HCl aqueous solution and dried at a temperature of 50 °C. The results illustrated that the adsorbent could be re-used until the fifth time without a significant loss in the adsorption capacity. This represents another advantage of the use of nanocomposite for the removal of Cu(II) ions from aquatic environments.

Analytical figures of merit

Under the optimum conditions described above, calibration curves were constructed for the determination of Cu(II) ions based on the general procedure. The calibration curves were linear within the range 1–100 µg L−1 with good coefficient estimate (R 2 = 0.999). The repeatability of the method was evaluated by eight replicate extractions of the spiked deionized water samples with the analyte at 10 µg L−1 level under same operational conditions and presented as relative standard deviation (RSD) which was 1.23 % indicating the good repeatability of the method. The enhancement factor was calculated by comparing the slopes of the calibration curves with and without pre-concentration and was found to be 95.08. The limit of detection (LOD) of the method was 0.9 µg L−1 based on a signal to noise ratio of 3.

Comparison with other methods

A comparison of the MSPE-FAAS and some previously reported methods for the extraction and determination of Cu(II) are summarized in Table 2. Compared to published methods, the linearity, LOD, and precision of the method are comparable or better. Furthermore, its low cost, simplicity as well as its high selectivity for copper ions made it a suitable quantitative determination method.

Analysis of the real samples

The method was applied in the determination of trace amounts of Cu(II) ion in a wide variety of samples. The samples were also analyzed after spiking with obvious concentrations of Cu(II). Eggplant, red lentil, and mushroom were analyzed. The analytical results are presented in Table 3. In view of the high selectivity provided by FAAS, the recovery of spiked samples is satisfactory (in the range of 97.2–99.1 %), which indicates the capability of the system in the determination of Cu(II) in real samples with different matrices.

Conclusions

In this study, the AF-Fe3O4–GO nanocomposite was successfully synthesized with the solvothermal method and using autoclave at a high temperature as a new adsorbent for the MSPE procedure. The synthesized adsorbent was confirmed by SEM and FT-IR techniques. To test the feasibility of AF-Fe3O4–GO adsorbent in MSPE, it was used as an extraction adsorbent for pre-concentration of trace amounts of copper in food samples such as eggplant, red lentil, and mushroom. The results proved that AF-Fe3O4–GO-based MSPE method had great potential in pre-concentration of copper and the presence of major cations and anions in natural water had no significant effect on the adsorption of copper ion under the selected conditions. The proposed method based on the new adsorbent has an easy, simple, and inexpensive synthesis method. Moreover, its extraction operation is convenient, precise, effective, and sensitive in the pre-concentration and determination of copper in real samples such as food samples.

References

J. Dai, H. Yan, R.S. Cheng, Chem. Eng. J. 165, 240 (2010)

X.W. Liu, Q.Y. Hu, Z. Fang, X.J. Zhang, B.B. Zhang, Langmuir 25, 3 (2009)

V. Antochshuk, M. Jaronic, Chem. Commun. 3, 258 (2002)

K. Vijayaraghava, J.R. Jegan, K. Palanivelu, M. Velan, Electron. J. Biotechnol. 7(1), 61 (2004)

D. Atanassova, V. Stefanova, Talanta 17, 1237 (1998)

O.M. EI-Hussaini, N.M. Rice, Hydrometallurgy 72, 259 (2004)

Z. Zhang, Z. Li, L. Zhang, R. Li, Z. Hu, X. Chang, X. Cui, Anal. Chim. Acta 663, 213 (2010)

M.E. Thurman, M.S. Mills, Solid-Phase Extraction; Principle and Practice (Wiley, Hoboken, 1998)

D. Kara, N. Tekin, Microchim. Acta 149, 193 (2005)

A. Duran, M. Tuzen, M. Soylak, J. Hazard. Mater. 169, 466 (2009)

I. Durukan, M. Soylak, M. Dogan, At. Spectrosc. 34, 20 (2013)

E. Yilmaz, Z.A. ALOthman, H.M.T. Sumayli, M. Ibrahim, M. Soylak, J. AOAC Int. 95, 1205 (2012)

M. Soylak, L. Elci, M. Dogan, Anal. Lett. 26, 1997 (1993)

B. Wang, Y. Chang, L. Zhi, New Carbon Mater. 26, 31 (2011)

W.S. Hummers, R.E. Offerman, J. Am. Chem. Soc. 80, 1339 (1958)

R. Hallaj, S. Bahar, B. Babamiri, S. Zandi, Can. J. Chem. 92, 62 (2014)

H. Yang-Mein, C. Mana, H. Zhong-Bob, J. Hazard. Mater. 184, 392 (2010)

S. Tokalıoglu, F. Gurbuz, Food Chem. 123, 183 (2010)

M.Z. Kassaee, E. Motamedi, M. Majidi, Chem. Eng. J. 172, 540 (2011)

M.A. Farajzadeh, M. Bahram, B.G. Mehr, J.A. Josson, Talanta 75, 832 (2008)

K. Shrivas, Monit. Assess. 168, 315 (2010)

X.W. Wu, Q.H. Wu, C. Wang, Z. Wang, Chin. Chem. Lett. 22, 473 (2011)

R. Khani, F. Shemirani, B. Majidi, Desalination 266, 238 (2011)

M. Ghaedi, K. Niknam, K. Taheri, H. Hossainian, M. Soylak, Food Chem. Toxicol. 48, 891 (2010)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bahar, S., Karami, F. Amino-functionalized Fe3O4–graphene oxide nanocomposite as magnetic solid-phase extraction adsorbent combined with flame atomic absorption spectrometry for copper analysis in food samples. J IRAN CHEM SOC 12, 2213–2220 (2015). https://doi.org/10.1007/s13738-015-0699-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13738-015-0699-4