Abstract

In this article, we present a convenient and green method for synthesis of β-amino carbonyl compounds through ball-milling technique by using aqueous formic acid, which is an inexpensive and highly efficient catalyst. This multi-component reaction was done at room temperature with high anti-selectivity and easy workup. The use of solvent-free ball-milling technique helped to have high yields and more cleanness, besides omitting the need for solvent in this method.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The Mannich reaction is one of the most important carbon–carbon bond forming reactions in organic synthesis. This reaction is one of the most basic methods for preparation of β-amino carbonyl compounds, which are important synthetic intermediates for various pharmaceuticals and natural products [1]. Mannich reaction is also used in the synthesis of N-heterocyclic compounds, such as pyrazolone derivatives [2], 1,6-naphthyridine derivative [3] and many other heterocyclic compounds. Mannich reactions are classified into two categories: direct and indirect [4]. List et al. reported the first direct organocatalytic asymmetric three-component Mannich reaction of an aldehyde, 4-methoxyaniline and a ketone catalyzed by proline [5]. Indirect Mannich reaction relies on the two-component system using preformed electrophiles, such as imines or iminium ions, and stable nucleophiles, such as enolates, enol ethers, and enamines [6]. Various catalysts such as Lewis acids [7–14], Bronsted acids [15, 16], ionic liquids [17–20], organic catalysts [21–27] or nano-catalysts [28, 29] have been investigated in this reaction over the past decades. Moreover, most of these methods have some drawbacks such as long reaction time, harsh reaction condition, difficulty in product separation, expensive reagents or catalysts and use of toxic organic solvents.

Many efforts have been recently described to develop more environmentally friendly methods for the preparation of β-amino carbonyl compounds. For example, numerous studies have been performed in the recent years to use the advantages of solvent-free routes to establish green methods for preparation of carbonyl derivatives. However, most of the methods suffer from disadvantages such as the use of excess of reagents, low yields of the desired products, and long reaction times. Therefore, development of simple, efficient and fast procedures, which operate under solvent-free and mild conditions is a very engaging research effort. In addition, the use of ball-milling technique in organic reactions has been developed in recent years [30–33]. In order to overcome these problems and to facilitate product formation, we decided to examine the application of ball-milling technique in the synthesis of β-amino carbonyl compounds. Herein, we wish to report a superior, green, and facile synthesis of diverse β-amino carbonyl compounds through a one-pot three-component reaction of aromatic aldehydes, ketones and amines at room temperature by ball-milling technique.

Results and discussion

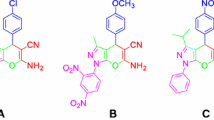

At first, the aqueous formic acid-catalyzed three-component Mannich reaction of benzaldehyde (1.0 mmol), aniline (1.0 mmol), and cyclohexanone (1.0 mmol) at room temperature was examined as model reaction (Scheme 1). To start with, the reaction was screened with varying amounts of the catalyst. The results have been summarized in Table 1. It is noteworthy that the reaction was not carried out in the absence of catalyst (entry 1, Table 1). According to these data, the optimum amount of the catalyst was 20 mol% per 1.0 mmol of model substrates. Screening of the solvents was also carried out under similar reaction conditions. The results are shown in Table 2. According to these data, the best result was afforded in a solvent-free method (entry 5, Table 2). With optimized the amount of catalyst loading (20 mol%), the Mannich reaction of different aromatic aldehydes, aniline and cyclic ketones were carried out at room temperature under solvent-free conditions. The results have been presented in Table 3. As it is shown, different aromatic aldehydes bearing both electron withdrawing and electron releasing groups afforded the β-amino ketones in good-to-excellent yields with good-to-excellent anti-selectivity. Benzaldehyde derivatives with electron-rich substituents such as o- and p-methoxybenzaldehydes led to a better stereoselectivity than the benzaldehydes with electron-poor substituents. The possible transition states have been proposed in Fig. 1. If hydrogen bonds are formed between formic acid, the imine and the enol form of cyclohexanone, the aryl groups of aldimine would be anti to each other and there should be less steric repulsion in anti-transition state, between the methylene groups of cyclohexanone and aryl group on the carbon atom. So the most stable transition state would produce the anti-isomer (Fig. 1). It is known that the chemical shifts and coupling constants of CH-hydrogens in 1H-NMR spectra of anti-isomer is different from the syn isomer, but because in most of the products in this work, the hydrogen peak of NH group appears at 4–5 ppm and interfere with the CH signals, we were unable to determine the diastereoselectivity of the method by using NMR technique. Therefore, we employed HPLC for determination of anti/syn ratio (Fig. 2). A series of experiments with benzaldehyde, aniline, and acetophenone in the presence of aqueous formic acid as catalyst was also conducted. The results have been tabulated in Table 4. In order to clarify the rule of formic acid in catalyzing the Mannich reaction, a mixture of benzaldehyde and cyclohexanone was stirred at room temperature, in the presence of formic acid. After 1 h, no aldol condensation product was observed. This rules out the path-A for the product formation suggested in Scheme 2. However, when preformed imine (the condensation product of benzaldehyde and aniline) was allowed to react with cyclohexanone in the presence of formic acid, the β-amino ketone was formed at room temperature. Based on these observations, it can be concluded that path-B is operative in the present catalytic protocol. According to the obtained results, a plausible mechanism can be proposed for the Mannich reaction in the presence of formic acid (Scheme 3). In summary, we have explored the applicability of formic acid as an efficient catalyst in a reliable protocol for the Mannich reaction. In comparison with recently reported methods for the synthesis of the titled compounds (Table 5), this method proceeds smoothly under mild conditions to furnish the respective products in short reaction times and high yields.

Experimental

All chemicals and solvents were purchased from Merck and Aldrich and used without further purification. Ethylacetate and normal hexane were used as solvents of TLC. Methanol, acetonitrile and water were used for preparation of mobile phase of column chromatography. The ball-milling reactions were done in a Retsch MM 200 ball mill apparatus. Melting points were measured on an Electrothermal 9100 apparatus. NMR spectra were recorded on a Bruker 500 MHz spectrometer in CDCl3 and with TMS as an internal standard. Ratio of anti/syn was determined with HPLC-Younglin 91200. FT-IR spectra were recorded as KBr pellets on a Shimadzu FT IR-8400S spectrometer.

Typical procedure for synthesis of 2-(phenyl (aminophenyl) methyl) cyclohexane (4a) or 1, 3-diphenyl-3-(amino phenyl)-propan-1-one (6a)

A mixture of benzaldehyde (1 mmol), aniline (1 mmol), cyclohexanone (1 mmol) or acetophenone (1 mmol), and 37 % aqueous formic acid (20 mol%) as catalyst was poured in ball mill vessel. Two stainless steel balls of 10 mm diameter were added to the grinding vessel. After completion of reaction as indicated by TLC, the product was separated and washed with hot water in order to separation of formic acid from the product. The product was dried in air at room temperature and crystallized from n-hexane, if needed.

References

L. Gang, L. Ruiling, Y. Jiangli, Kinet. Catal. 52, 397 (2011)

S. Kobayashi, T. Furuta, K. Sugita, O. Okitsu, H. Oyamada, Tetrahedron Lett. 40, 1341 (1999)

T. Siener, U. Muller, M. Jansen, U. Holzgrabe, Pharmazie. 53, 442 (1998)

L. Gang, L. Ruiling, Y. Suling, Z. Liping, Kinet. Catal. 52, 559 (2011)

F.-F. Yong, Y.-C.H. Teo, Synth. Commun. 41, 1293 (2011)

T. He, K. Li, M.Y. Wu, X.W. Feng, N. Wang, H.Y. Wang, Ch. Li, X.Q. Yu, J. Mol. Catal. 67, 189 (2010)

T.P. Loh, S.B. Liung, K.L. Tan, L.L. Wei, Tetrahedron 56, 3227 (2000)

R. Wang, B.G. Li, T.K. Huang, L. Shi, X.X. Lu, Tetrahedron Lett. 48, 2071 (2007)

Ch. Zhang, J. Dong, T. Cheng, R. Li, Tetrahedron Lett. 42, 461 (2001)

M.R. Naimi-Jamal, J. Ipaktschi, M.R. Saidi, Eur. J. Org. Chem. 9, 1735 (2000)

M.R. Naimi-Jamal, J. Ipaktschi, M.R. Saidi, J. Chem. Soc. Perkin Trans. 1(24), 3709 (1999)

A. Zarghi, M.R. Naimi-Jamal, S.A. Webb, S. Balalaie, M.R. Saidi, J. Ipaktschi, Eur. J. Org. Chem. 197, 197–200 (1998)

M.R. Saidi, N. Azizi, Tetrahedron 14, 389 (2003)

M.R. Saidi, N. Azizi, M.R. Naimi-Jamal, Tetrahedron Lett. 42, 8111 (2001)

Ch. Mukhopadhyay, A. Datta, R.J. Butcher, Tetrahedron Lett. 50, 4246 (2009)

N. Azizi, L. Torkiyan, M.R. Saidi, Org. Lett. 8, 2079 (2006)

S. Sahoo, T. Joseph, S.B. Halligudi, J. Mol. Catal. A—Chem. 244, 179 (2006)

X.F. Yang, M. Wang, R.S. Varma, J. Mol. Catal. A—Chem. 214, 147 (2004)

ShL Chen, S.J. Ji, T.P. Loh, Tetrahedron Lett. 44, 2405 (2003)

S.G. Lee, J.H. Park, B. Kor. Chem. Soc. 23, 1367 (2002)

P. Dziedzic, I. Ibrahem, A. Co´rdova, Tetrahedron Lett. 49, 803 (2008)

A. Berkessel, H. Groger, Asymmetric organocatalysis (Wiley-VCH, Weinheim, 2005)

M. Arend, B. Westermann, N. Risch, Angew. Chem. Int. Edit. 37, 1044 (1998)

W. Notz, F. Tanaka, C.F. Barbas, J. Am. Chem. Soc. 37, 580 (2004)

W. Notz, S.H.-I. Watanabe, N.S. Chowdari, G. Zhong, J.M. Betancort, F. Tanaka, C.F. Barbas, Adv. Synth. Catal. 346, 1131 (2004)

YCh. Teo, J.J. Lau, MCh. Wu, J.S. Yadav, Tetrahedron Lett. 19, 186 (2008)

Y.K. Kang, D.Y. Kim, J. Org. Chem. 74, 5734 (2009)

D.I. MaGee, M. Dabiri, P. Salehi, L. Torkian, Arkivoc. 11, 156 (2011)

M.Z. Kassaee, R. Mohammadi, H. Masrouri, F. Movahedi, Chin. Chem. Lett. 22, 1203 (2011)

G. Kaupp, M.R. Naimi-Jamal, J. Schmeyers, Tetrahedron 59, 3753 (2003)

M.R. Naimi-Jamal, J. Mokhtari, M.G. Dekamin, G. Kaupp, Eur. J. Org. Chem. 21, 3567 (2009)

S. Mashkouri, M.R. Naimi-Jamal, Molecules 14, 474 (2009)

M.R. Naimi-Jamal, J. Mokhtari, M.G. Dekamin, Sh Javanshir, Iran. J. Chem. Chem. Eng. 31, 2 (2012)

H. Wu, X.M. Chen, Y. Wan, L. Ye, H.Q. Xin, H.H. Xu, C.H. Yue, L.L. Pang, R. Ma, D. Shi, Tetrahedron Lett. 50, 1062 (2009)

V. Kumar, U. Sharma, P. Kumar, N. Kumar, B. Singh, Chem. Pharm. Bull. 59, 639 (2011)

A.R. Massah, R.J. Kalbasi, N. Samah, B. Kor, Chem. Soc. 32, 1703 (2011)

P. Kulkarni, B. Totawar, P.K. Zubaidha, Monatsh. Chem. 143, 625 (2012)

C.H. Ying-Ying, Y.-J. Jiang, Y.-S. Fan, D. Sha, Q. Wang, G. Zhang, L. Zheng, S. Zhang, Tetrahedron Asym. 23, 904 (2012)

P. Goswami, B. Das, Tetrahedron Lett. 50, 2384 (2009)

N. Azizi, R. Baghi, E. Batebi, S.M. Bolourtchian, C. R. Chim. 15, 278 (2012)

Q.I.-X. Guo, H. Liu, C.H. Guo, S.H.-W. Luo, Y. Gu, L.-Z.H. Gong, J. Am. Chem. Soc. 129, 3790 (2007)

Acknowledgments

We are grateful to the research council of Iran University of Science and Technology for partial financial support. We are also thankful to Prof. Gerd Kaupp for his kind donation of ball-mill apparatus and Ms. Shahrzad Esmaili for HPLC analysis.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ghafuri, H., Khodashenas, S. & Naimi-Jamal, M.R. Aqueous formic acid: an efficient, inexpensive and environmentally friendly catalyst for diastereoselective synthesis of β-amino carbonyl derivatives. J IRAN CHEM SOC 12, 599–604 (2015). https://doi.org/10.1007/s13738-014-0517-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13738-014-0517-4