Abstract

A wide variety of 2,3-dihydroquinazolin-4(1H)-ones has been prepared via one-pot three-component condensation of isatoic anhydride, aldehydes and primary amines or ammonium acetate in the presence of a catalytic amounts of l-pyrrolidine-2-carboxylic acid-4-hydrogen sulfate (supported on silica gel), as green, non-toxic and reusable catalyst, in water at 80 °C.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Within the repertoire of synthetic strategies available to organic chemists, multi-component reactions (MCRs) are mostly advantageous because they allow the creation of several bonds in a single operation [1–4]. Also usage of water addresses the several concerns of green chemistry such as easy availability, safe handling, simple workups and cost effective for small and bulk-scale process industries [5].

Compounds with biological activity are often derived from heterocyclic structures [6]. Among them, quinazolinone derivatives have been found to possess a wide spectrum of pharmacological activities, e.g. as antibacterial [7], antitumor [8], anticancer [9], and antifungal agents [10]. In this light, 2,3-dihydroquinazolin-4(1H)-one derivatives are an important class of quinazolinones, which exhibit pharmacological and biological activities. In view of these useful properties, a number of procedures have been reported toward the synthesis of 2,3-dihydroquinazolin-4(1H)-ones. These heterocyclic compounds have been prepared mainly via condensation of amines and aldehydes with isatoic anhydride or anthranilide in the presence of an appropriate catalyzed [11–17]. Some of these procedures are associated with several drawbacks such as harsh reaction conditions, non-recoverability of the catalyst, tedious work-up procedure, and low yields of products. In this light, we decided to design a new procedure for the preparation of 2,3-dihydroquinazolin-4(1H)-ones.

Experimental

Chemicals were purchased from Fluka, Merck and Aldrich chemical companies. The known products were characterized by comparison of their spectral (1H NMR, and 13C NMR) and physical data with those of authentic samples. Unknown compounds were identified by their 1H and 13C NMR spectra.

Preparation of supported l-pyrrolidine-2-carboxylic acid-4-hydrogen sulfate on silica gel

A 100 mL suction flask containing l-hydroxyproline (5 g, 38.13 mmol) was equipped with a constant-pressure dropping funnel containing chlorosulfonic acid (2.53 mL) and gas inlet tube (the HCl created during the reaction was trapped in water). Chlorosulfonic acid was added dropwise over a period of 30 min at room temperature. The resulting mixture was shaken for 30 min and kept at 50 °C for 5 h. Then, silica gel (8.05 g) was added to the resulting gummy product and shaken for 30 min. A white solid [supported l-pyrrolidine-2-carboxylic acid-4-hydrogen sulfate on silica gel (50% w/w)] of 16.10 g was obtained.

l-Pyrrolidine-2-carboxylic acid-4-hydrogen sulfate

1H NMR (400 MHz, DMSO-D6): δ = 9.70 (s, 1H), 8.74 (s, 1H), 4.40 (m, 1H), 4.36 (m, 1H), 3.31–3.33 (m, 1H), 3.00–3.10 (m, 1H), 2.15–2.20 (m, 1H), 2.00–2.06 (m, 1H), ppm; 13C NMR (100 MHz, DMSO-D6): δ = 170.1, 69.0, 58.2, 53.8, 37.5 ppm.

General procedure for the synthesis of 2,3-dihydroquinazolin-4(1H)-ones

Supported l-pyrrolidine-2-carboxylic acid-4-hydrogen sulfate on silica gel (0.42 g) was added to the mixture of isatoic anhydride (1 mmol), primary amine (1.1 mmol) or ammonium acetate (1.2 mmol) and aldehyde (1 mmol) in water (5 mL). The mixture was heated at 80 °C for the appropriate time (reaction progress was monitored by TLC). After completion of the reaction, the white solid mixture was filtered off and washed with water (4 × 20 mL). The resulting mixture was dissolved in hot ethanol (25 mL) and filtered. Then, the residue was concentrated and dried to obtain corresponding 2,3-dihydroquinazolin-4(1H)-one. To obtain high pure 2,3-dihydroquinazolin-4(1H)-one, the crude product was crystallized from water/ethanol mixture (1:1).

Selected 1H NMR and 13C NMR data

2-(4-Chlorophenyl)-3-hexyl-2,3-dihydroquinazolin-4(1H)-one (4f)

1H NMR (400 MHz, DMSO-D6): δ = 7.65 (d, 1H, J = 7.6 Hz), 7.44–7.34 (m, 5H), 7.23–7.18 (m, 1H), 6.69–6.63 (m, 2H), 5.88 (s, 1H), 3.90–3.84 (m, 1H), 2.80–2.73 (m, 1H), 1.58–1.51 (m, 1H), 1.49–1.44 (m, 1H), 1.23 (m, 6H), 0.86–0.83 (m, 3H) ppm; 13C NMR (100 MHz, DMSO-D6): δ = 162.6, 146.5, 140.7, 133.7, 133.4, 129.0, 128.5, 127.9, 117.7, 115.5, 114.8, 69.8, 45.0, 31.4, 27.9, 26.4, 22.5, 14.4 ppm.

3-Hexyl-2-p-tolyl-2,3-dihydroquinazolin-4(1H)-one (4g)

1H NMR (400 MHz, DMSO-D6): δ = 7.64 (d, 1H, J = 7.6 Hz), 7.29–7.14 (m, 6H), 6.67–6.62 (m, 2H), 5.80 (s, 1H), 3.88–3.83 (m, 1H), 2.76–2.69 (m, 1H), 2.26 (s, 3H), 1.57–1.50 (m, 1H), 1.48–1.41 (m, 1H), 1.27–1.23 (m, 6H), 0.86–0.83 (m, 3H) ppm; 13C NMR (100 MHz, DMSO-D6): δ = 162.7, 146.8, 138.7,138.1, 133.5, 129.5, 127.8, 126.6, 117.5, 115.5, 114.7, 70.4, 44.8, 31.4, 27.8, 26.5, 22.5, 21.1, 14.4 ppm.

2-(4-Bromophenyl)-3-hexyl-2,3-dihydroquinazolin-4(1H)-one (4h)

1H NMR (400 MHz, DMSO-D6): δ = 7.66 (d, 1H, J = 8.0 Hz), 7.56 (d, 2H, J = 8.4 Hz), 7.39–7.38 (m, 1H), 7.29 (d, 2H, J = 8.4 Hz), 7.22–7.18 (m, 1H), 6.69–6.63 (m, 2H), 5.87 (s, 1H), 3.92–3.85 (m, 1H), 2.80–2.73 (m, 1H), 1.58–1.51 (m, 1H), 1.49–1.44 (m, 1H), 1.23 (m, 6H), 0.86–0.82 (m, 3H) ppm; 13C NMR (100 MHz, DMSO-D6): δ = 162.6, 146.5, 141.1, 133.7, 131.9, 128.8, 127.9, 122.0, 117.8, 115.5, 114.8, 69.8, 45.0, 31.4, 27.9, 26.4, 22.5, 14.4 ppm.

3-Hexyl-2-(4-methoxyphenyl)-2,3-dihydroquinazolin-4(1H)-one (4i)

1H NMR (400 MHz, DMSO-D6): δ = 7.65 (d, 1H, J = 7.6 Hz), 7.29–7.17 (m, 4H), 6.91 (d, 2H, J = 8.4 Hz), 6.67–6.63 (m, 2H), 5.79 (s, 1H), 3.86–3.79 (m, 1H), 3.72 (s, 3H), 2.77–2.70 (m, 1H),1.55–1.49 (m, 1H), 1.47–1.42 (m, 1H), 1.25–1.23 (m, 6H), 0.86–0.83 (m, 3H) ppm; 13C NMR (100 MHz, DMSO-D6): δ = 162.7, 159.8, 146.8, 133.6, 133.5, 128.0, 127.8, 117.5, 115.5, 114.7, 114.3, 70.3, 55.6, 44.7, 31.4, 27.8, 26.5, 22.5, 14.4 ppm.

2-(3,4-Dimethoxyphenyl)-3-hexyl-2,3-dihydroquinazolin-4(1H)-one (4j)

1H NMR (400 MHz, DMSO-D6): δ = 7.66 (d, 1H, J = 7.6 Hz), 7.25–7.18 (m, 2H), 7.04 (m, 1H), 6.91–6.89 (m, 1H), 6.82–6.80 (m, 1H), 6.68–6.64 (m, 2H), 5.78 (s, 1H), 3.88–3.81 (m, 1H), 3.72 (s, 3H), 3.71 (s, 3H), 2.79–2.72 (m, 1H), 1.56–1.49 (m, 1H), 1.48–1.44 (m, 1H), 1.27–1.23 (m, 6H), 0.86–0.82 (m, 3H) ppm; 13C NMR (100 MHz, DMSO-D6): δ = 162.8, 149.3, 149.2, 146.9, 133.8, 133.5, 127.8, 118.8, 117.5, 115.6, 114.7, 111.8, 110.8, 70.5, 55.9, 55.8, 44.7, 31.4, 27.9, 26.5, 22.5, 14.4 ppm.

2-(4-Fluorophenyl)-3-p-tolyl-2,3-dihydroquinazolin-4(1H)-one (4m)

1H NMR (400 MHz, DMSO-D6): δ = 7.70 (d, 1H, J = 7.6 Hz), 7.57 (m, 1H), 7.40–7.11 (m, 9H), 6.75–6.71 (m, 2H), 6.26 (s, 1H), 2.24 (s, 3H) ppm; 13C NMR (100 MHz, DMSO-D6): δ = 162.7, 162.3 (d, 976 Hz), 147.0, 138.5, 137.4, 135.9, 134.2, 129.6, 129.3 (d, 36 Hz), 128.4, 126.9, 118.1, 115.8, 115.4 (d, 132 Hz), 73, 21.0 ppm.

2-(3,4-Dimethoxyphenyl)-3-(4-isopropylphenyl)-2,3-dihydroquinazolin-4(1H)-one (4q)

HNMR (400 MHz, DMSO-D6): δ = 7.73 (d, 1H, J = 6.8 Hz), 7.58 (m, 1H), 7.29–7.22 (m, 5H), 7.00 (s, 1H), 6.89–6.84 (m, 2H), 6.77–6.70 (m, 2H), 6.18 (s, 1H), 2.87 (sep, 1H, J = 6.8), 1.19 (d, 6H, J = 6.8) ppm; 13C NMR (100 MHz, DMSO-D6): δ = 162.7, 149.1, 149.0, 147.0, 146.5, 139.2, 134.1, 133.5, 128.3, 126.9, 126.5, 119.1, 117.9, 116.0, 115.3, 111.5, 110.8, 72.9, 55.9, 55.8, 33.4, 24.3 ppm.

2-(4-Fluorophenyl)-3-(4-isopropylphenyl)-2,3-dihydroquinazolin-4(1H)-one (4r)

1H NMR (400 MHz, DMSO-D6): δ = 7.74–7.72 (m, 1H), 7.65–7.64 (m, 1H), 7.44–7.40 (m, 2H), 7.30–7.12 (m, 7H), 6.77–6.71 (m, 2H), 6.28 (s, 1H), 2.87 (sep, 1H, J = 6.8), 1.19 (d, 6H, J = 6.8) ppm; 13C NMR (100 MHz, DMSO-D6): δ = 162.6, 162.3 (d, 972 Hz), 146.8, 146.7, 138.9, 137.6 (d, 12 Hz), 134.2, 129.1 (d, 36 Hz), 128.4, 127.0, 126.6, 118.1, 115.9, 115.7 (d, 84 Hz), 115.3, 72.4, 33.4, 24.3 ppm.

Results and discussion

In continuation of our recent success in the introduction of new catalysts for the organic functional group transformations [18–26], we became interested in preparation l-pyrrolidine-2-carboxylic acid-4-hydrogen sulfate as an efficient, non-toxic, and green catalyst. l-Pyrrolidine-2-carboxylic acid-4-hydrogen sulfate was prepared by reaction of l-hydroxyproline with chlorosulfonic acid at room temperature (Scheme 1). Because of gummy properties of this compound, it was supported on silica gel.

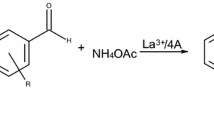

Therefore, supported l-pyrrolidine-2-carboxylic acid-4-hydrogen sulfate on silica gel was used as an effective catalyst for the one-pot three-component condensation of different types of aldehydes, primary amines or ammonium acetate and isatoic anhydride in water (as solvent) at 80 °C (Scheme 2). The results for this transformation are summarized in Table 1.

2,3-Dihydroquinazolin-4(1H)-one compounds were easily prepared by mixing an aldehyde, isatoic anhydride, a primary amine or ammonium acetate and supported l-pyrrolidine-2-carboxylic acid-4-hydrogen sulfate on silica gel (10 mol %) in water, then stirring this suspension at 80 °C for the appropriate time. After completion of the reaction, the resulting solid precipitate was filtrated off and washed with water. The resulting solid mixture was dissolved in hot ethanol and filtered off. Then, the ethanol was evaporated to obtain corresponding 2,3-dihydroquinazolin-4(1H)-one. Recrystallization of the crude product from water/ethanol gave highly pure 2,3-dihydroquinazolin-4(1H)-one.

To investigate the role of catalyst for the preparation of 2,3-dihydroquinazolin-4(1H)-ones, isatoic anhydride was reacted with 4-chlorobenzaldehyde and 4-iso-propylaniline in the absence of supported l-pyrrolidine-2-carboxylic acid-4-hydrogen sulfate on silica gel. As is evident from Scheme 3, we observed that the corresponding 2,3-dihydroquinazolin-4(1H)-one was formed in only 40% yield after 6 h.

Scheme 4 shows the reusability of the catalyst for the preparation of 3-(4-isopropylphenyl)-2-phenyl-2,3-dihydroquinazolin-4(1H)-one. It was observed from the recycle study that the efficiency of l-pyrrolidine-2-carboxylic acid-4-hydrogen sulfate remained unchanged even after the 6th recycle. It could be suggested that the catalyst was not deactivated during the catalytic or separation processes. Also, l-pyrrolidine-2-carboxylic acid-4-hydrogen sulfate could be recovered almost completely.

Suggested mechanism for this transformation has been outlined in Scheme 5.

In conclusion, we have delineated a green, versatile and facile procedure for the synthesis of 2,3-dihydroquinazolin-4(1H)-one derivatives via one-pot three-component condensation of isatoic anhydride, aldehydes and primary amines or ammonium acetate in water at 80 °C. The important features provided by this procedure are the use of l-pyrrolidine-2-carboxylic acid-4-hydrogen sulfate (supported on silica gel) as an effective, non-toxic, cost effective and recoverable catalyst. Eventually, the most important feature of described protocol is the use of water (as solvent), because water is the most abundant, cheapest and eco-friendly solvent.

References

M.B.M. Reddy, M.A. Pasha, Synth Commun. 41, 1875 (2011)

M. Guasconi, X.Y. Lu, A. Massarotti, A. Caldarelli, E. Ciraolo, G.C. Tron, E. Hirsch, G. Sorba, T. Pirali, Org. Biomol. Chem. 9, 4144 (2011)

V.P. Mehta, S.G. Modha, E. Ruijter, K. Van Hecke, L. Van Meervelt, C. Pannecouque, J. Balzarini, R.V.A. Orru, E.D. Eyckent, J. Org. Chem. 76, 2828 (2011)

A.R. Kazemizadeh, A. Ramazani, J. Braz. Chem. Soc. 20, 309 (2009)

D. Kumar, N.M. Kumar, G. Patel, S. Gupta, R.S. Varma, Tetrahedron Lett. 52, 1983 (2011)

J. Chen, D. Wu, F. He, M. Liu, H. Wu, J. Ding, W. Su, Tetrahedron Lett. 49, 3814 (2008)

N.B. Patel, J.C. Patel, Med. Chem. Res. 20, 511 (2011)

R.J. Abdel-Jalil, E. Al-Momani, L. Tahtamooni, H.J. Machulla, W. Voelter, Lett. Org. Chem. 7, 360 (2010)

A. Kamal, E.V. Bharathi, J.S. Reddy, M.J. Ramaiah, D. Dastagiri, M.K. Reddy, A. Viswanath, T.L. Reddy, T.B. Shaik, S.N.C.V.L. Pushpavalli, M.P. Bhadra, Eur. J. Med. Chem. 46, 691 (2011)

H. Wu, X.L. Xie, G. Liu, J. Comb. Chem. 12, 346 (2010)

L.Y. Zeng, C. Cai, J. Heterocycl. Chem. 47, 1035 (2010)

M. Baghbanzadeh, P. Salehi, M. Dabiri, G. Kozehgary, Synthesis 344 (2006)

Z.H. Zhang, H.Y. Lu, S.H. Yang, J.W. Gao, J. Comb. Chem. 12, 643 (2010)

S. Rostamizadeh, A.M. Amani, G.H. Mahdavinia, H. Sepehrian, S. Ebrahimi, Synthesis 1356 (2010)

O.I. El-Sabbagh, S.M. Ibrahim, M.M. Baraka, H. Kothayer, Arch. Pharm. Chem. Life Sci. 343, 274 (2010)

Y.X. Zong, Y. Zhao, W.C. Luo, X.H. Yu, J.K. Wang, Y. Pan, Chin. Chem. Lett. 21, 778 (2010)

J. Chen, W. Su, H. Wu, M. Liu, C. Jin, Green Chem. 9, 972 (2007)

A. Ghorbani-Choghamarani, M. Norouzi, Bull. Korean Chem. Soc. 32, 1399 (2011)

A. Ghorbani-Choghamarani, M. Norouzi, Chin. J. Catal. 32, 595 (2011)

A. Ghorbani-Choghamarani, M.A. Zolfigol, M. Hajjami, K. Darvishi, L. Gholamnia, Collect. Czech. Chem. Commun. 75, 607 (2010)

A. Ghorbani-Choghamarani, M.A. Zolfigol, R. Ayazi-nasrabadi, J. Braz. Chem. Soc. 21, 33 (2010)

A. Ghorbani-Choghamarani, J. Zeinivand, J. Iran. Chem. Soc. 7, 190 (2010)

A. Ghorbani-Choghamarani, N. Cheraghi-Fathabad, Chin. J. Catal. 31, 1103 (2010)

A. Ghorbani-Choghamarani, M.A. Zolfigol, T. Rastegar, Chin. J. Catal. 30, 273 (2009)

A. Ghorbani-Choghamarani, M. Hajjami, H. Goudarziafshar, M. Nikoorazm, S. Mallakpour, F. Sadeghizadeh, G. Azadi, Monatsh. Chem. 140, 607 (2009)

A. Ghorbani-Choghamarani, P. Zamani, J. Iran. Chem. Soc. 8, 142 (2011)

A. Davoodnia, S. Allameh, S. Fakhari, N. Tavakoli-Hoseini, Chin. Chem. Lett. 21, 550 (2010)

A. Ghorbani-Choghamarani, T. Taghipour, Lett. Org. Chem. 8, 470 (2011)

Acknowledgments

Financial support to this work by the Ilam University, Ilam, Iran is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ghorbani-Choghamarani, A., Zamani, P. Synthesis of 2,3-dihydroquinazolin-4(1H)-ones via one-pot three-component reaction catalyzed by l-pyrrolidine-2-carboxylic acid-4-hydrogen sulfate (supported on silica gel) as novel and recoverable catalyst. J IRAN CHEM SOC 9, 607–613 (2012). https://doi.org/10.1007/s13738-012-0074-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13738-012-0074-7