Abstract

Natural cellulose was extracted from Sesbania sesban plant. A novel approach toward chemically modified cellulose, bearing active chelating Schiff base, was synthesized using 2-hydroxy-5-methyl benzaldehyde. The chemical and structural features of the adsorbent were characterized by Fourier transform infrared spectroscopy (FTIR), scanning electron microscopy (SEM), and energy dispersive analysis of X-ray (EDAX) observations, elemental analysis, and thermogravimetric analysis (TGA). It was used as a cheap and renewable biosorbent for removal of cadmium (II). SEM image confirmed the microfibril structure of microcomposite. TGA showed that the stability of modified cellulose was increased to 700 °C. EDAX showed the elements of C and O of cellulose and Si, Fe and Cl of modified cellulose-based ligand of 2-hydroxy-5-methyl benzaldehyde. The elemental analysis confirmed the presence of Schiff base ligand in the structure of microcomposite. The experimental conditions and adsorption parameters, including pH, initial metal ion concentration and adsorbent dosage were optimized. The cellulose biomass exhibited the highest metal ions uptake capacity (9.39 mg/g) at pH value of 4.0, biomass dosage of 0.01 g/L and cadmium concentration of 150 mg/L.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Industries generate 2.4 million tons of toxic metals annually [1]. Among these metals such as As, Cd, Cr, Cu, Hg, Ni, Pb, Se, V, and Zn, easy mobility in the environment and high toxicity of cadmium can be dangerous and are of much environmental concern [2, 3]. It causes renal dysfunction, bone degeneration, lung insufficiency, liver damage, and hypertension in humans [4, 5].

Numerous processes exist for removing dissolved heavy metals, including ion exchange, precipitation, phytoextraction, ultrafiltration, reverse osmosis, and electrodialysis [6]. The need for expensive equipment and monitoring systems, high reagent or energy requirement or generation of toxic sludge or other waste products were significant disadvantages of these techniques [7]. On the other hand, when metal ion concentration in aqueous solution is as low as ppm (parts per million), they are believed ineffective. Hence, the practical and simplest process is biosorption, which uses various natural materials of biological origin, including bacteria, fungi, yeasts, algae, molds, and composting materials [8]. Adsorption techniques have been widely used because of their simplicity and facile accessibility. Hence, adsorption has become one of the alternative treatment techniques for wastewater laden with heavy metals recently [9]. Basically, adsorption is a mass transfer process by which a substance is transferred from the liquid phase to the surface of a solid, and it is bounded by physical and/or chemical interactions [10]. Various low-cost adsorbents, derived from agricultural wastes, industrial by-products, natural materials, or modified biopolymers, have been recently developed and applied for the removal of heavy metals from metal-contaminated wastewater. Technical applicability and cost-effectiveness are the key factors that play major roles in the selection of the most suitable adsorbent to treat inorganic effluent [11]. Hence, the synthesis of cellulosic low-cost biosorbent has opened up a new horizon for this area of research. They are used in heavy metal sequestration due to their low economic value and widespread availability, and also the potential to treat wastewater at a large scale [12].

In continuing our work on the synthesis of new compound-based natural materials and also environmental friendly systems; for example, Honarmand et al. [13] have worked on a novel and recyclable organocatalyst for one-pot three-component synthesis of 2-amino-3-cyano-4H-pyran derivatives, Naeimi et al. [14] have synthesized a novel nanocomposite based on natural plant such as Sesbania sesban and investigated its catalytic activities. Also Tajik et al. [15] have studied the catalytic application of one immobilized Schiff base complex on natural cellulose. We report herein a novel microcomposite synthesized and used as a biosorbent for removing the cadmium as a heavy metal. Novelty of the present work includes the following items: the immobilization of a novel Schiff base on extracted natural cellulose from Sesbania sesban, the synthesis and characterization of a bio-microcomposite. The adsorption activity of this degradable hybrid adsorbent has been evaluated on the removal of cadmium from contaminated solution and 9.3 mg/g was the maximum adsorption capacity of this biosorbent in the optimized condition.

The effects of pH, adsorbent dosage and initial cadmium concentration on the performance of microcomposite biomass removal of Cd(II) ions were applied for the experimental design and analysis of the results.

Experimental

Materials and methods

2-Hydroxy-5-methyl benzaldehyde, (3-aminopropyl) triethoxysilane 98% (APTS), and Cd (99% extra pure) (Aldrich) were used. Sesbania sesban plant was provided from University of Jiroft. FTIR spectra of cellulose and microcomposite were recorded by FTIR spectrophotometer (Nicolet iS10). Morphology of microcomposite, before and after the removal of Cd(II), was carried by scanning electron microscopy (Hitachi, s4160, Japan) at accelerating voltage of 15 kV. The elemental composition was analyzed using an X-ray energy-dispersive spectroscopy (EDS) detector (IE 300X, Oxford, UK). Thermostability of microcomposite was investigated by a Shimadzu thermogravimetric analyzer (TG-50, Japan).

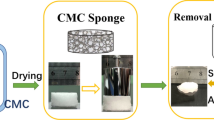

Immobilization of Schiff base using functionalized microcellulose

Extraction of cellulose and its functionalization by an amine group were performed using the methods reported previously [15]. Then, 2 g of amino cellulose was sonicated in methanol for 30 min and 2-hydroxy-5-methyl benzaldehyde (3 mmol, 0.4 g) was added. The immobilized aldehydes were removed by soxhlet extraction by methanol. The dark-yellow product was dried in an oven at 40 °C within 5 h.

Preparation of metal ions solution

Cadmium solutions were prepared by diluting 1000 mg cadmium/L stock solution, which was obtained by dissolving a weighed quantity of cadmium (1.85 g) in sulfate salt form, CdSO4 using distilled water. HNO3 (1 M) and NaOH (1 M) solutions were used for the pH of each test solutions at the start of the experiment [16].

Batch adsorption experiments

Batch systems were applied for biosorption of Cd2+ ions from aqueous solutions. The pH, initial ions concentration and initial biomass dosage of the medium on the uptake capacity were optimized. The effects of these factors on the biosorption were investigated at Cd2+ ions concentration of 50–300 mg/L, biomass dosage of 0.01–0.6 g/L and in the pH range of 2.0–8.0. For each experiment, 100 mL of cadmium solutions was added in 250 mL Erlenmeyer flasks. To acquire equilibrium, known amounts of biomass were added to metal solutions and flasks were agitated on a shaker at 150 rpm constant shaking rate within 60 min [17]. Different times (0, 10, 20, 40, and 60 min) were investigated for 5 mL cell suspension and filtered through 0.25 µm filters. Filtered samples were analyzed for residual cadmium ion concentration [16]. All the experiments were repeated three times and the data presented the average obtained values. The limit of experimental error of each duplicates was ± 5% and any experiment which resulted in higher than this limit was repeated [18, 19]. Metal uptake capacity for the cadmium ions was calculated using Eq. 1:

where qe as the metal uptake at equilibrium (mg/g), C0 is the initial metal ion concentration (mg/L), Ceq is the concentration of the equilibrium metal ion (mg/L), V is solution volume (L) and M is the initial concentration of biosorbent in the solution (g/L) [20, 21].

Analytical methods

The residual Cd2+ concentrations were analyzed using atomic absorption spectrophotometer (Perkin Elmer, USA). Elemental analysis was carried out on a Costech 4010 CHNS elemental analyzer. FTIR spectrophotometer was used to record the FTIR spectra (Nicolet iS10). Scanning electron microscopy (SEM) (Hitachi, s4160, Japan) at accelerating voltage of 15 kV was used to investigate the morphology of the products. Thermogravimetric analysis (TGA) was carried out by a Shimadzu thermogravimetric analyzer (TG-50, Japan). 2-Hydroxy-5-methyl benzaldehyde 99% and (3-aminopropyl) triethoxysilane (APTS) were purchased from Across and EXIR GmbH, respectively. Sesbania sesban was provided from University of Jiroft.

Results and discussion

Characterization of microcomposite

Cellulose was extracted from Sesbania sesban plant and modified by (3-aminopropyl) triethoxysilane and 2-hydroxy-5-methyl benzaldehyde to form Schiff base ligand supported on natural cellulose (Scheme 1).

Fourier transform infrared spectroscopy spectra of extracted cellulose from Sesbania sesban and microcomposite are shown in Fig. 1. This natural cellulose shows the absorption bands related to characteristic chemical groups bending vibrations and stretching of cellulose. A broad band at 3500–3200 and 2900 cm−1 region is related to the hydroxyl groups and alkyl groups in cellulose, respectively (Fig. 1a). In Fig. 1b, the FTIR of microcomposite in KBr matrix revealed the stretching vibrations at 2800–3000 and 3446 cm−1, attributed to APTS on cellulose. It should be noted that the strong absorption band at 1630 cm−1 could be assigned to the imine stretching frequency of the coordinated ligand. At around 1640 and 1430 cm−1, the presence of water absorbed into cellulose fiber structure and CH2 symmetric bending in cellulose were confirmed, respectively [22,23,24].

The surface morphology of microcomposite was evaluated by SEM image (Fig. 2). In this image the fibril structure can be observed very well. Figure 3 shows the EDAX of cellulose and microcomposite to confirm the formation of microcomposite from natural cellulose. EDAX analysis of microcomposite confirmed the silylation of cellulose and immobilized Schiff base ligand on the natural cellulose. In the spectra of cellulose C and O and in the spectra of microcomposite, Si and Fe and Cl peaks were observed (Fig. 3a, b). These observations confirmed that chemical modification of the cellulose was achieved.

The thermal stability of microcomposite was investigated by thermogravimetric analysis. According to the TGA, the weight loss of this novel microhybrid occurred in two steps after around 100 and 287 °C. The first step was related to the removal of physically adsorbed water, and the decomposition of hydroxyl groups on surfaces. Decrease in weight at 290 °C was rationalized to decomposition of Schiff base followed by oxidation of cellulose (Fig. 4).

The elemental analysis of natural cellulose and microcomposite is illustrated in Fig. 5. The results are shown very well that the nitrogen, carbon and hydrogen content of sample have increased significantly, by immobilizing the Schiff base on cellulose. This matter confirmed the insertion of the ligand onto the extracted cellulose [25].

By comparison, the maximum adsorption capacities of cellulose, extracted from Sesbania sesban (3.31 mg/g) with microcomposite (9.39 mg/g), ability of coordination of metal to oxygen and nitrogen ligand were confirmed (Scheme 2). The evidence clearly approved that the chelating sites of the modified cellulose can adsorb Cd(II) and this matter can be inferred from FTIR of cadmium(II) loaded on microcomposite. The strong absorption band at 1630 cm−1 can be assigned to the imine stretching frequency of the coordinated ligand, whereas for the AC the same band was observed at 1617 cm−1. The shift of this band toward lower frequency on complexation with the metal suggests coordination to the metal ion through imine nitrogen atom [26, 27]. When band of 3416 cm−1 was shifted to 3410 cm−1, it meant that OH of the ligand Schiff base was coordinated to metal (Fig. 6).

Table 1 presents the maximum adsorption capacities compared with some recent reports using cellulose or amine group modification as different types of adsorbent. The maximum adsorption capacities of this cellulose bearing Schiff base are a highly efficient one for the removal of Cd(II) ions compared to other materials. It shows that the geometry of the ligand and the high donor properties of nitrogen and oxygen toward cadmium have the potential as a commercial adsorbent.

Cadmium biosorption process

By changing the pH of the solution the surface charge of sorbent can be modified [28]. To find out the optimum pH for the adsorption process, the effect of pH 2–8 on adsorption of cadmium onto microcomposite was considered. The results showed clearly that maximum adsorption was achieved at pH 4 and the adsorption was increased by enhancing pH. It seems that the repulsive forces between the metal ions and positively charged (protonated) adsorptive surface were observed at pH 2–4. Biomass has sorption around 7.16 mg/g uptake capacity at pH 4 for cadmium metal ions. This indicates that interaction of the biomass with Cd2+ was favorable in the range of pH 3–4 with a maximum uptake being exhibited at pH 4. At lower pH, the protonation of active sites, imine groups on the adsorbent surface takes place resulting in the electrostatic repulsions between the metal cations and the protonated groups and prevents the adsorption of the metal ions and hence resulting in lower metal ion uptake [29, 30]. At higher pH, free imine groups are available on the adsorbent for ion-adsorption. The results of pH affecting cadmium sorption by microcomposite are presented in Fig. 7.

Li et al. [24] investigated the effect of pH on the adsorption of Cd(II) by orange peel cellulose adsorbents. Results showed that the optimum pH range was 5.0–7.0. Also Saravanan et al. reported that the best adsorption of Cu(II) and Pb(II) was obtained in pH 6. This value of pH was in the middle range of 2–8 [31]. Radi et al. (similar to this study) showed that optimum value of pH for cadmium adsorption was in the range of 4–5 [23]. Also Boroumand Jazi et al. evaluated the influence of pH on the adsorption of Cd(II) in the range of 1–9 and high adsorption occurred when the pH value was 4 [22].

The effect of biomass dosage on the uptake capacity of cadmium from aqueous solution was investigated. In this study, the effect of biomass dosage (0.01–0.60 g/L) on uptake of cadmium by this novel biopolymer was considered. A partial aggregation of biomass was observed at higher biomass concentrations, because of diminishing effective surface area for the biosorption. Uptake capacity in different amounts of biomass dosage was very close together, therefore, the optimum biomass dosage was selected as 0.01 g/L for further experiments because of economic costs. The results of initial biomass dosage affecting cadmium sorption by microcomposite are presented in Fig. 8.

The maximum value of biosorption capacity was 7.45 mg/g in 0.01 g/L initial biomass dosage. We proposed that limited availability of metal, increased electrostatic interactions, interference between binding sites and reduced mixing at higher biomass concentrations could affect the adsorption process [30,31,32]. Similar to this work, results from the experiments of Radi et al. showed that the best removal of Cu(II) and Pb(II) was obtained in low values (lower than 0.03 mg/g) of biosorbent and with increase in the biomass dosage, adsorption capacity was decreased [23].

Initial concentration of cadmium can have effect on the percentage removal of cadmium. The highest value of uptake capacity was 9.39 mg/g with initial ions concentration of 150 mg/L (Fig. 9). At low cadmium concentrations solution, saturation of biomass by active site of biomass could not be achieved, as the number of cadmium ions was smaller than the number of binding sites present on the biomass. Increasing the concentration of cadmium in the solution enhanced the removal till the saturation of biomass was attained. The slow increase in uptake capacity at higher concentrations could be related to different concentration gradients between the solution and inside of the microbial cells [29]. The results obtained for metal adsorption in the initial Cd(II) ions concentrations (5–100 mg/L) with Boroumand Jazi et al. [22] showed that the optimum adsorption was reported in the highest value (100 mg/L) and therefore, biosorbent exhibited high quantity of adsorption for high concentration of cadmium. This is similar to our present study.

Advantages of microcomposite for cadmium adsorption studies in comparison with other materials

There are many chemical materials for adsorption of Cd(II) from wastewater. Cadmium is very dangerous in environment, and therefore, many works have been performed on removal efficiency of this metal. According to the researches, microcomposite and chemical biomasses are suitable cases for biosorption. Results of other studies are presented in Table 2 and they focus on biosorption of cadmium with materials in different pH values, initial ion concentration and biomass dosage. In these studies, chemical materials have lower uptake capacity in comparison with this microcomposite. This table has confirmed our results on good efficiency of microcomposite for cadmium adsorption from aqueous solutions. However, these results have encouraged us to consider the change the morphology and fibril structure of this microcomposite based on SEM study. The aggregation of micro-fibril was observed after removal of cadmium (II) (Fig. 10).

Conclusion

An extracted environmentally friendly cellulose from Sesbania sesban was fabricated through a Schiff base ligand with 2-hydroxy-5-methyl benzaldehyde. The structure and thermostability of this novel organic–inorganic hybrid was characterized by SEM, IR, EDAX, elemental analysis, and TGA. The application of a biosorbent in uptake capacity of cadmium (II) was evaluated. The operating parameters, solution pH, initial cadmium concentration and initial biomass dosage were effective on the uptake capacity of Cd(II). It was shown that good uptake capacity of heavy metals form aqueous solution compared to alternative described materials. According to the experiments, microcomposite could remove as much as 9.39 mg/g of Cd2+ from aqueous solution containing 150 mg/L concentration of metal ions, 0.01 g/L biomass dosage and pH 4. Cellulose-based organometallic has natural binding capacity for heavy metals. Therefore, simple approach, inexpensive cellulose feed stock, their availability in a large scale, high adsorption speed and good adsorption capacity for highly efficient removal of cadmium ions from the aqueous solution are features of this adsorption system. This opens interesting prospects in environmental science for water cleaning processes.

References

Amini M, Younesi H, Bahramifar N, Lorestani AAZ, Ghorbani F, Daneshi A, Sharifzadeh M (2008) Application of response surface methodology for optimization of lead biosorption in an aqueous solution by Aspergillus niger. J Hazard Mater 154:694–702

Lebeau T, Bagot D, Jézéquel K, Fabre B (2002) Cadmium biosorption by free and immobilised microorganisms cultivated in a liquid soil extract medium: effects of Cd, pH and techniques of culture. Sci Total Environ 291:73–83

Amini M, Younesi H (2009) Biosorption of Cd(II), Ni(II) and Pb(II) from aqueous solution by dried biomass of Aspergillus niger: application of response surface methodology to the optimization of process parameters. Clean Soil Air Water 37:776–786

Iqbal M, Saeed A, Zafar SI (2007) Hybrid biosorbent: an innovative matrix to enhance the biosorption of Cd(II) from aqueous solution. J Hazard Mater 148:47–55

Amini M, Younesi H, Bahramifar N (2009) Statistical modeling and optimization of the cadmium biosorption process in an aqueous solution using Aspergillus niger. Colloid Surf A 337:67–73

Padma V, Padmavathy V, Dhingra SC (2003) Kinetics of biosorption of cadmium on baker’s yeast. Bioresour Technol 89:281–287

Ghorbani F, Younesi H, Ghasempouri SM, Zinatizadeh AA, Amini M, Daneshi A (2008) Application of response surface methodology for optimization of cadmium biosorption in an aqueous solution by Saccharomyces cerevisiae. Chem Eng J 145:267–275

Madrid Y, Camara C (2003) Biological substrates for metal preconcentration and speciation. TrAC Trend Anal Chem 16:36–44

Ahmad M, Ahmed S, Swami BL, Ikram S (2015) Adsorption of heavy metal ions: role of chitosan and cellulose for water treatment. Int J Pharm 79:109–155

Naeimi A, Saeednia S, Yoosefian M, Rudbari H, Nardo VM (2015) A novel dinuclear Schiff base copper complex as an efficient and cost effective catalyst for oxidation of alcohol: synthesis, crystal structure, and theoretical studies. J Chem Sci 127:1321–1328

Mudhoo A, Garg VK, Wang S (2012) Removal of heavy metals by biosorption. Environ Chem Lett 10:109–117

Guclu G, Gurdag G, Ozgumus S (2003) Competitive removal of heavy metal ions by cellulose graft copolymers. J Appl Polym Sci 90:2034–2039

Honarmand M, Naeimi A, Zahedifar M (2017) Nanoammonium salt: a novel and recyclable organocatalyst for one-pot three-component synthesis of 2-amino-3-cyano-4H-pyran derivatives. J Iran Chem Soc 14:1875–1888

Naeimi A, Amiri A, Ghasemi Z (2017) A novel strategy for green synthesis of colloidal porphyrins/silver nanocomposites by Sesbania sesban plant and their catalytic application in the clean oxidation of alcohols. J Taiwan Inst Chem Eng 80:107–113

Tajik E, Naeimi A, Amiri A (2018) Fabrication of iron oxide nanoparticles, and green catalytic application of an immobilized novel iron Schiff on wood cellulose. Cellulose 25:915–925

Gok C, Aytas S (2009) Biosorption of uranium (VI) from aqueous solution using calcium alginate beads. J Hazard Mater 168:369–375

Nasrullah A, Khan H, Sada Khan A, Muhammad N, Man Z, Ullah Khan F, Ullah Z (2016) Calligonum polygonoides biomass as a low-cost adsorbent: surface characterization and methylene blue adsorption characteristics. Desalin Water Treat 57:7345–7357

Ulusoy U, Akkaya R (2009) Adsorptive features of polyacrylamide-apatite composite for Pb2+, UO2 2+ and Th4+. J Hazard Mater 163:98–108

Bhainsa KC, D’Souza SF (2009) Thorium biosorption by Aspergillus fumigatus, a filamentous fungal biomass. J Hazard Mater 165:670–676

Amini M, Younesi H, Bahramifar N (2009) Biosorption of nickel (II) from aqueous solution by Aspergillus niger: response surface methodology and isotherm study. Chemosphere 75:1483–1491

Amini M, Younesi H, Bahramifar N (2013) Biosorption of U(VI) from aqueous solution by Chlorella vulgaris: equilibrium, kinetic, and thermodynamic studies. J Environ Eng 139:410–421

Boroumand Jazi M, Arshadi M, Amiri MJ, Mousavi S, Gil A (2014) Kinetic and thermodynamic investigations of Pb(II) and Cd(II) adsorption on nanoscale organo-functionalized SiO2Al2O3. J Colloid Interf Sci 422:16–24

Radi S, Toubi Y, El-Massaoudi M, Bacquet M, Degoutin Yahia S, Mabkhot N (2016) Efficient extraction of heavy metals from aqueous solution by novel hybrid material based on silica particles bearing new Schiff base receptor. J Mol Liq 223:112–118

Li X, Tang Y, Cao X, Lu D, Luo F, Shao W (2008) Preparation and evaluation of orange peel cellulose adsorbents for effective removal of cadmium, zinc, cobalt and nickel. Colloids Surf A Physicochem Eng Asp 317:512–521

Loof D, Hiller M, Oschkinat H, Koschek K (2016) Quantitative and qualitative analysis of surface modified cellulose utilizing TGA-MS. Materials 9:415

Tarafder M, Kasbollah A, Crouse K, Ali A, Yamin B, Fun HK (2001) Synthesis and characterization of Zn(II) and Cd(II) complexes of S-benzyl-β-N-(2-pyridyl)methylenedithiocarbazate (HNNS): bioactivity of the HNNS Schiff base and its Zn(II), Cu(II) and Cd(II) complexes and the X-ray structure of the [Zn(NNS)2] complex. Polyhedron 20:2363–2370

Vafazadeh R, Khaledi B, Willis AC, Namazian M (2011) Synthesis, crystal structure and DFT analysis of a new trinuclear complex of copper. Polyhedron 30:1815–1819

Sharma P, Tomar R (2008) Synthesis and application of an analogue of mesolite for the removal of uranium(VI), thorium(IV), and europium(III) from aqueous waste. Microporous Mesoporous Mater 116:641–652

Vaughan T, Seo CW, Marshall WE (2001) Removal of selected metal ions from aqueous solution using modified corncobs. Bioresour Technol 78:133–139

Talip Z, Eral M, Hiçsönmez U (2009) Adsorption of thorium from aqueous solutions by perlite. J Environ Radioact 100:139–143

Saravanan R, Ravikumar L (2016) Cellulose bearing Schiff base and carboxylic acid chelating groups: a low cost and green adsorbent for heavy metal ion removal from aqueous solution. Water Sci Technol 74:1780–1792

Mehta SK, Gaur JP (2005) Use of algae for removing heavy metal ions from wastewater: progress and prospects. Crit Rev Biotechnol 25:113–152

Xia K, Ferguson RZ, Losier M, Tchoukanova N, Bruning R, Djaoued Y (2010) Synthesis of hybrid silica materials with tunable pore structures and morphology and their application for heavy metal removal from drinking water. J Hazard Mater 183:554–564

Zhang L, Yu C, Zhao W, Hua Z, Chen H, Li L, Shi J (2007) Preparation of multi-amine-grafted mesoporous silicas and their application to heavy metal ions adsorption. J Non Cryst Solid 353:4055–4061

Okieimen FE, Sogbaike CE, Ebhoaye JE (2005) Removal of cadmium and copper ions from aqueous solution with cellulose graft copolymers. Sep Purif Technol 44:85–89

Tian Y, Wu M, Liu R, Li Y, Wang D, Tan J, Wu R, Huang Y (2011) Electrospun membrane of cellulose acetate for heavy metal ion adsorption in water treatment. Carbohydr Polym 83:743–748

Khan SB, Alamry KA, Marwani HM, Asiri AM, Rahman MM (2013) Synthesis and environmental applications of cellulose/ZnO2 nanohybrid as a selective adsorbent for nickel ion. Compos Part B Eng 50:253–258

Malik DS, Jain CK, Yadav AK (2017) Removal of heavy metals from emerging cellulosic low-cost adsorbents: a review. Appl Water Sci 7:2113–2136

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Naeimi, A., Amini, M. Biosorption of cadmium using a novel, renewable and recoverable modified natural cellulose bearing chelating Schiff base ligand based on 2-hydroxy-5-methyl benzaldehyde. Iran Polym J 27, 461–468 (2018). https://doi.org/10.1007/s13726-018-0623-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-018-0623-8