Abstract

The aim of this study was to investigate the effect of camel chymosin and different types of starter cultures on the chemical, textural, proteolytic and lipolytic characteristics of semi-hard white cheese prepared from camel milk during ripening. Two treatments of chesses consisting of thermophilic starter culture camel cheese (CC-TC) containing Streptococcus salivarius subsp. thermophilus and Lactobacillus delbrueckii subsp. bulgaricus and the mixture of thermophilic/mesophilic yogurt starter culture camel cheese (CC-YC) containing S. salivarius subsp. thermophilus, Lactobacillus delbrueckii subsp. bulgaricus, Lacticaseibacillus casei subsp. casei and Levilactobacillus brevis were manufactured. Results show that camel cheese which was produced with YC as a starter culture had more yield in comparison with TC. The chemical changes were significantly higher in CC-YC (P < 0.05). The hydrolysis of αs1-casein, β-casein and formation of their degradation products was relatively high in CC-YC. The total FFAs were significantly (P < 0.05) changed during 60 days of ripening and between CC-TC and CC-YC. The main substrate of lipolytic enzymes from both CC-TC and CC-YC was short-chain fatty acids containing butyric, caproic, capric, lauric, myristic, myristoleic, palmitic in camel cheeses which was decreased during ripening. Whereas CC-TC showed maximum hardness, adhesiveness, stringiness. However, CC-YC showed maximum resilience, cohesiveness, springiness, gumminess and chewiness. Therefore, the use of thermophilic/mesophilic yogurt culture is recommended for the production of good quality semi-hard white camel cheese, considering the chemical and textural characteristics of the cheese.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Dairy technology around the world requires finding new sources of raw materials for the production of good quality and acceptable dairy products. Camel milk is a new nutritional and super functional food [39, 49], which had been known until now. Its profound nutritional values, such as anti-hypertensive, anti-cancer, anti-autoimmune and antidiabetic properties, have made it especially important in the food and pharmaceutical industries. Although camel milk production is less in Iran, the industry is growing faster. Camel milk is the main and crucial food in nomadic culture. It plays an important role in desert areas’ economies. Despite its nutritional value and economic importance, varieties of food products from camel milk are still very limited throughout the world [24]. Camel milk products such as cheese, especially soft, semi-hard, and hard types, are not widely developed due to some processing challenges. In some cases, these challenges are created by the lack of proper coagulant, starter culture or processing methods [23].

Cheese making from camel milk is different and more complicated than its preparation from other types of dairy animal milk. The complexity is due to κ-casein structure, its content and the ratio to other total proteins. In addition, the size of casein micelles of camel milk ranged from 280 to 550 nm, which is larger in comparison with cow milk ranging from 90 to 210 nm. The larger size of casein micelles of camel milk is inversely correlated with the calcium phosphate amount in the micelles, which influences curdling. Moreover, the presence of high concentration of antimicrobial agent which prevents microbial growth that induces complexity and prevents the production of cheese from camel milk [22].

It was investigated [36] that camel milk’s κ-casein differs in structure from that reported from cow’s milk by an extra proline residue at the 95 position of its amino acids sequence. Camel chymosin splits camel milk κ-casein at Phe97-Ile98 instead of Phe105-Met106 of the bovine casein. The proximity of the extra proline residue to the catalytic site of chymosin in the κ-casein of camel milk may interfere with the enzyme activity. Nevertheless, aminopeptidases of L. delbrueckii subsp. bulgaricus have been shown to hydrolyze peptide bond including proline residue, suggesting that the use of these proteolytic Lactic Acid Bacteria (LABs) in the fermentation of camel milk along with camel chymosin would increase the hydrolysis of κ-casein resulting in increased coagulation time and increased cheese yield [7].

For the production of high quality camel cheese, it is imperative that the rennet substitute should have weak general proteolytic activity, limited specificity around the Phe97-Ile98 bond of camel milk’s κ-casein [7]. Unlike milk from other dairy animals, obtaining satisfactory rennet induced gelation of camel milk is reported [22] to be difficult when using bovine chymosin. Therefore, different coagulants were developed and used [22, 33], but success was achieved after using new recombinant camel chymosin produced by fermentation [7].

Recently, highly pure recombinant camel chymosin was marketed under the name Far-M with 12,500 IMCU/stick (Chr. Hansen A/S, Horsholm, Denmark). The product curdles camel, donkey and mare milks with low amounts of κ-casein.

Up to the present day, many researchers [1, 5, 6, 36] have tried to produce soft camel cheese from camel milk but no study has been conducted to produce semi-hard cheese from camel milk. Consequently, the aim of this study is to find the most compatible starter culture for acidification of camel milk and then produce high yield white semi-hard cheese using highly pure camel chymosin and two types of starter culture during ripening time. Subsequently, the effect of coagulant, starter cultures and ripening time on chemical composition, proteolysis and lipolysis of these cheeses have been investigated.

Materials and Methods

Materials

10 l of camel milk for each batch was supplied from Sareboona Agro-Industry located in Varamin, Tehran, Iran. Highly pure camel chymosin Far-M with 12,500 IMCU and 50U Direct Vat Set (DVS) starter cultures were purchased from Chr. Hansen Company (Horsholm, Denmark). Ewe yogurt culture was obtained from a rural area shop. All the chemicals and solvents were purchased from Merck KGaA (Darmstadt, Germany) with analytical grade.

Suitability and Bacterial Performance

In order to find the most suitable starter culture, four starter cultures suitable for the production of semi-hard white cheese were tested and evaluated for acid production. Two liter of camel milk was pasteurized and divided into four parts. 3% of each starter culture containing thermophilic, mesophilic starter culture and the mixture of thermophilic mesophilic starter cultures were added to milk and the pH of the milk was evaluated every hour with a pH meter. The results were reported as acidification curves. Afterward, 0.1% chymosin was added to them to evaluate coagulation. The strains that produced the most acid and formed a firm, cohesive curd were selected for cheese production [33].

TC Thermophile: S. salivarius subsp. thermophilus and L. delbrueckii subsp. bulgaricus (50U/500 l).

YC Mixture of Thermophile/Mesophile: S. salivarius subsp. thermophilus and L. delbrueckii subsp. bulgaricus, L. casei subsp. casei and L. brevis (50U/500 l).

MC Mesophile: Lactococcus lactis subsp. lactis, Lactococcus lactis subsp. cremoris (50U/500 l).

LC Thermophile: Lactobacillus helveticus (50U/500 l).

Cheese-Making procedure

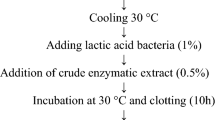

The cheese-making procedure was according to the method of Fox et al. [16] with some modifications as follows:

Camel milk was thermized at 65 °C for 15 s, the temperature was adjusted to 40 °C, pH = 6.7 for addition of thermophilic starter cultures. Next, Camel chymosin and starter cultures were added to the final concentration of 0.1% and 3% (w/w) to each batch of cheese making, respectively. The mixture was stirred completely, waited for 1 h to complete preparation and syneresis and formation of a suitable firm coagulum. The pH level reached 5.3 at this point.

The coagulum was cut into 2 × 2 × 2 cm3 cubic sizes and was placed in cotton cloth for better drainage. Following semi-hard cheese-making procedure, the curds were put into rectangular 5 × 15 × 11 cm cheese molds and a light pressure of 10 kg/m2 was applied to each cheese block. Cheese blocks were then immersed in 24% (w/v) brine for 12 h and turned over every 3 h. Afterward, salt was sprinkled on the surface of the cheeses and every two cheese blocks were transferred to plastic containers, immersed in 12% (w/v) brine and kept in the refrigerator for 60 days (Fig. 1). The experimental design was as follows:

CC-TC treatment Camel milk + 0.1% of Far-M camel chymosin + 3% of Direct Vat Set (DVS) Thermophilic starter culture containing S. salivarius subsp. thermophilus and L. delbrueckii subsp. bulgaricus.

CC-YC treatment Camel milk + 0.1% of Far-M camel chymosin + 3% of ewe yogurt containing S. salivarius subsp. thermophilus and L. delbrueckii subsp. bulgaricus, L. casei subsp. casei and L. brevis.

Chemical Composition Analysis

Protein, fat, total solid, moisture and salt were analyzed according to ISO 8968-1 [30], ISO 3433 [29], ISO 5534 [28], ISO 5337 [28] and AOAC 935.43 [25], respectively. Acidity was measured as the percent of Lactic acid [32] and pH level was measured by mixing 10 g of cheese and 10 ml of deionized water using an AZ 86,502 pH meter (AZ instrument, Taiwan) [15]. All analyses were done in duplicate.

Cheese Yield

The cheese yield was calculated according to the following formula described by Fox et al. [16]:

Proteolysis

Water soluble nitrogen (WSN), 12% trichloroacetic acid soluble nitrogen (TCA-SN) fractions and pH 4.6 insoluble fractions of cheeses were prepared according to the method Orundo et al. [40]. The pH 4.6 insoluble fractions of cheeses were freeze dried and stored at − 20 °C until analysis.

SDS-PAGE was performed according to the method of Salami et al. [46] with 15 and 5% separating and stacking gels, respectively. Freeze dried samples of pH 4.6 insoluble fractions (15 mg) were dissolved in phosphate buffer pH 7 to the final concentration of 15 mg/ml. A 15 μl of the sample was mixed with 15 μl (2x) Laemmli buffer containing 1 mol/l Tris pH 6.8, SDS 6%, glycerol, β-mercaptoethanol and 0.02% bromophenol blue. The mixture was heated at 95 °C for 5 min and then loaded into the wells. Gels were run at 120 V for 8 h and stained directly with Coomassie brilliant blue R-250.

Subsequently, they were destained with deionized water, methanol and glacial acetic acid. The dyed gels were digitized with scanner and analyzed with AlphaEaseFC software (Genetic Technologies Inc, Miami, FL, USA) and the molecular weight of bonds were determined using densitometry with ABCAM prism protein ladder 5–245 kDa (ABCAM, Cambridge, MA, USA).

Lipolysis

Acid Degree Value

The levels of free fatty acids (FFAs) in cheeses were determined by the ADV method as described by Zonoubi et al. [56]. Samples were prepared by mixing 5 g of cheese with 37.5 ml of 2% sodium citrate at 50 °C in a Sorvall Omni-mixer at setting 3 for 1 min, and then at setting 7 for 2 min. The ADV was determined on 35 ml samples of this extract.

Fatty Acid Composition

The extraction, preparation of the fatty acid methyl ester and analysis of fatty acid composition of cheeses by Gas Chromatography was according to the method of ISO14156 [26], ISO15884 [27], ISO15885 [27], respectively, as follows:

4 g cheese were mixed with 4 g sand and sodium sulfate (1:1) into a mortar to yield a dry sample. The complete test portion was transferred to the extraction thimble and inserted into the Soxhlet extraction apparatus. The flask was filled with 250 ml n-hexane and was extracted for 6 h. Next, the flask was disconnected, and its content was put in a rotary evaporator and water bath 50 °C until evaporation is visually completed. 5 mg of extracted fat was weighted and was put in a test tube. The test portion was dissolved with 5 ml n-hexane. 0.2 ml metanolic sodium methoxide (2 mol/l) was added to the mixture and mixed for 1 min. 0.5 g of solid sodium hydrogen sulfate was added and mixed again. The test portion was centrifuged for 3 min and the clear supernatant was used for gas chromatography.

An Agilent model 7890B gas chromatograph (Agilent Technology, Santa Clara, USA) equipped with a flame ionization detector (FID) was used. The carrier gas was Helium with a flow rate of 0.5 ml/ min. The pressure was considered 17.33 psi. Fatty acids were separated on Agilent J&W CP-Sil 88, a fused silica column (100 m, 25 mm) coated with cyanopropyl, stationary phase (0.25 µm layer thickness). The average velocity was adjusted to 0.1 m/s. The injector and detector temperatures were 220 and 250 °C, respectively. Chromatographic conditions were as follows: 45 °C, (4 min, 13 °C/ min), up to 175 °C (27 min, 4 °C/min), up to the final temperature 215 °C and it was held at this temperature for 25 min. The quantification (C4:0–C18:2) was performed using retention time of internal standards with enantic (C7:0) and margaric acids (C17:0) (Sigma-Aldrich, St. Louis, USA) as standards.

TPA Analysis

Texture profile analysis (TPA) was performed on cheese samples using a Brookfield CT3 Texture Analyzer (Brookfield Engineering Laboratories, Inc., Middleboro, MA, USA) fitted with a 45 kg load cell and a TA4/1000 AOAC standard cylinder probe (Clear Acrylic, 38.1 mm diameter, 20 mm l). Cubic samples were cut from cheeses using a razor blade with 20 × 20 × 20 mm dimensions. The instrument was operated from the TexturePro CT V1.1 software (Brookfield Engineering Laboratories, Inc.) and a method was made using a constant probe speed of 1 mm s−1 and a final compression of 25% of the height of the sample.

Statistical Analysis

All the cheese trials and experiments were repeated twice. One-way analysis of variance (ANOVA) was used for data analysis in SPSS version 24.0 for Windows (IBM Corp., Armonk, NY). The significant differences were obtained using Duncan’s test (P < 0.05).

Results and Discussion

Starter culture Performance

The diagram of the acidification rate of starter cultures is presented in Fig. 2. As can be seen in the Fig. 2, starter cultures acidification rate is in the following order: YC > TC > LC > MC. On the other hand, the rate of acid production in the thermophilic/mesophilic starter culture is higher than thermophilic starter culture and the thermophilic starter culture is higher than the mesophilic starter culture.

The acidification curve of camel milk based on pH with four types of starter cultures during time. TC Thermophile: S. salivarius subsp. thermophilus and L. delbrueckii subsp. bulgaricus, LC Thermophile: L. helveticus, YC Mixture of thermophile/mesophile: S. salivarius subsp. thermophilus, L. delbrueckii subsp. bulgaricus, L. casei subsp. casei and L. brevis, MC Mesophile: L. lactis subsp. lactis, L. lactis subsp. cremoris

The coagulation test showed that only YC and TC formed a cohesive coagulum and LC and MC did not form a strong coagulum. This may be due to the electrostatic repulsion and high antibacterial activity of camel milk. Other research [7] and current research shows that thermophilic starter cultures and a mixture of thermophilic/mesophilic starter cultures have become more compatible with camel milk. It may be due to the consumption of extra proline near the active site of the chymosin by starter cultures. Therefore, the action of these starter cultures reduces the electrostatic repulsion and allows the κ-caseins’ micelles to approach each other and form a suitable cohesive coagulum. It can be concluded that curd formation depends on the rate of acidification. According to the results of starter cultures’ acidification and coagulation tests, YC and TC were chosen for cheese making.

Chemical Composition of Cheeses

The chemical composition of CC-TC and CC-YC is illustrated in Table 1. The amount of protein (16.8% ± 0.17) showed a significant decrease (P < 0.05) in both CC-TC (16.8% ± 0.17 to 13.7% ± 0.38) and CC-YC samples (18.00% ± 0.11 to 14.7% ± 0.11) and during ripening. The amount of protein (16.8% ± 0.17) in this research on the first day of ripening for CC-TC was similar to the amount reported by other researchers for camel cheese [44, 55]. Proteolysis was responsible for reduction in protein in both kinds of CC-TC and CC-YC. It can cause the formation of small and medium-sized peptides by the action of residual camel chymosin, the proteinases and peptidases from TC and YC starter cultures, non-starter culture and indigenous milk proteinase and peptidases, which was calculated as WSN and TCA-SN.

There was a significant increase in CC-YC compared with CC-TC and the highest amount of protein (18.0% ± 0.11) was found for CC-YC on the first day of ripening.

The amount of fat in CC-TC (17.9 ± 0.31) and CC-YC (22.1 ± 0.28) cheeses decreased significantly (P < 0.05) until day 60. Cepoglu et al.5 [11] Show that recombinant chymosin has no effect on fat content during ripening. There was a slight increase in the amount of fat in CC-YC compared with CC-TC. In camel cheese during ripening, lipolysis reduces the amount of fats in CC-TC and converts them to FFAs by the action of lipase from starter cultures and indigenous milk lipase. Our findings are in line with other research that reported the amount of fat increased in cheese when using different starter cultures [20].

The amount of salt showed a significant increase (P < 0.05) during ripening days in both CC-TC (9.49% ± 0.09) and CC-YC (10.3% ± 0.18). According to salt equilibrium, the amount of salt that penetrates into the CC-TC and YC-TC matrix can increase the amount of total solid in both cheeses. Salt penetration was almost complete within the first 20 days of ripening, and then changed within a very narrow margin in CC-TC and CC-YC. Besides its role in preservation, salt may have a great influence on the ripening event, in the case of texture, flavor and overall quality of cheeses [50]. As mentioned before, proteolysis and lipolysis can cause significant changes in protein and fat and overall total solids in CC-TC and CC-YC. The differences in total solids and moisture observed between CC-TC and CC-YC were compensated during the ripening as a result of the dynamic equilibrium between cheese and brine. Our findings is in agreement of the effect of starter cultures on goat cheese during ripening [37].

Variation in total solid and moisture in both cheeses showed a relationship between proteolysis and lipolysis of cheeses by the action of residual camel chymosin and proteinases and lipases from TC and YC with salt diffusion [50]. In the present case, the penetration rate of salt from brine into the cheese block was assumed faster than hydrolysis of peptide bonds of proteins and steric bonds of fats on day 20 of both CC-TC and CC-YC. In addition, there was a sharp increase in salt penetration observed on day 20 of the ripening stage in CC-TC and CC-YC, which confirmed previous explanations. After day 20 of the ripening time, the total solid and moisture declined to 42.2% ± 0.60, 57.8% ± 0.40 in CC-TC and 44.4% ± 0.74, 55.6% ± 0.30 in CC-YC, respectively, which showed that the rate of proteolysis and lipolysis was higher than the rate of salt diffusion into the cheese blocks. Similar results were reported in white cheeses [31]. Significant (P < 0.05) variations between the means of total solid and moisture in CC-TC and CC-YC samples were observed. CC-YC had the highest amount of total solid and lowest amount of moisture at the end of the ripening time.pH was increased significantly to 4.58 ± 0.03 until day 40 in CC-TC and decreased significantly (P < 0.05) until day 60 (4.40 ± 0.04). In addition, acidity in CC-TC decreased significantly until day 40 and then increased significantly until day 60 (P < 0.05). In CC-YC, pH increased significantly until day 20 (5.22 ± 0.05) and then remained constant until day 60 and acidity significantly increased during ripening (P < 0.05). Significant changes (P < 0.05) were observed in the amount of pH and acidity between CC-TC and CC-YC.

Variation of pH and acidity in camel cheeses may be due to the metabolism of lactose and formation of lactic acid by the action of TC and YC starters in glycolysis stage that decreased pH and increased acidity. In addition, catabolism of lactic acid and the production of ammonia by deamination of free amino acids may be due to increase pH in CC-TC, which was earlier reported by Kirmici et al. [32]. In CC-YC, formation of lactic acid from lactose increased the amount of acidity to 1.26%, but secondary proteolysis and deamination of amino acids in cheese were carried out in concomitant with lactose metabolism, which prevented the sharp decrease in pH content. Similar results were observed in feta cheese during ripening [18].

Cheese Yield

The amount of protein and milk fat were determined as 3.33% and 3.68%, respectively. The conversion coefficient of milk to cheese was 6.54 kg of milk to 1 kg of cheese. The yield of CC-YC was 87.52% higher than CC-TC, which was 76.5%.

The amount of acid production increases the activity of chymosin, so that at pH 5.6, only 30 g of hydrolyzed casein is needed to increase the viscosity and form a gel network. Therefore, the effect of camel chymosin in CC-YC has increased due to the action of starters and has created a better cheese gel network and higher yield [22].

The main application of TC and YC starters is production of lactic acid from lactose during the manufacture of camel cheese, which caused and helped to better syneresis and protein and fat recovery. The recovery of fat and protein was higher when the CC-YC culture was used. Therefore, it may be concluded that the power of CC-YC culture for production of lactic acid was higher, which caused the entrapment of more protein and fat in the cheese matrix, which leads to higher cheese yield. Al-Zoreky et al. [1] reported similar findings in soft white camel cheese.

Proteolysis

The amounts of WSN/TN, TCA-SN/TN and ripening index (WSN + TCA-SN/ TN) of CC-TC and CC-YC during ripening are presented in Table 1. Research [16] shows that the rate and extent of proteolysis during ripening and storage time are displayed by measuring the levels of nitrogenous fractions and are indexes of cheese ripening.

The amount of WSN/TN reached to (11.6% ± 0.44) in CC-TC and to (13.9% ± 0.35) in CC-YC. There was a significant difference (P < 0.05) between CC-TC and CC-YC in nitrogenous fractions, and CC-YC had the highest amount of both nitrogenous fractions. The WSN fraction in cheese consists of small and medium-sized peptides, free amino acids separated from large peptides and proteins caused by residual coagulant, milk enzymes and enzymes from starter culture bacteria. Therefore, the rate of ripening in CC-YC was higher than CC-TC for the reason that YC cultures especially L. delbrueckii subsp. bulgaricus and L. brevis have stronger proteolytic activity compared with TC starter culture. Moreover, Moynihan et al. [38] reported less proteolytic activity of camel chymosin compared with bovine chymosin, thus most of the WSN which are performed in both CC-TC and CC-YC are due to the action of proteinases and peptidases from starter cultures and to a less degree related to residual camel chymosin.

The amount of TCA-SN/TN increased significantly (P < 0.05) to 1.23% ± 0.02 in CC-TC and 1.20% ± 0.07 in CC-YC until day 60. TCA-SN has been applied to evaluate the action of peptidases from LAB in the formation of low molecular weight components in cheese. The TCA-SN fraction contains small peptides and free amino acids generated by LAB proteinases and peptidases by hydrolyzing high and intermediate peptides which started from first days of proteolysis [13].

The amount of TCA-SN was higher in CC-YC, therefore the activity of LAB proteinases and peptidases were stronger in CC-YC. The amount of ripening index was increased by an increase in the amount of WSN and TCA-SN and reached to 12.8% ± 0.49 in CC-TC and 15.1% ± 0.41 in CC-YC. The ripening degree in both cheeses were in line with the characteristics of brined cheeses [56].

Results of SDS-PAGE of pH 4.6 insoluble fractions of fresh camel milk, CC-TC and CC-YC during ripening are illustrated in Fig. 3 and the estimated molecular weight of camel milk, camel cheese pH 4.6 casein fractions and its degradation products are presented in Table 2.

SDS-PAGE electrophoretogram of intact Lactoferrin, αs1-casein, αs2-casein, β-casein and para-κ-casein of pH 4.6 insoluble fractions and degradation products of camel cheeses made with two different starter cultures during 1, 20, 40 and 60 days of ripening. CM—camel milk, CC-TC—Camel cheese with thermophilic starter culture, CC-YC—Camel cheese with the mixture of thermophilic/mesophilic starter cultures, MM—molecular weight marker

As seen in electrophotography, camel milk lane contains αs1-casein, αs2-casein, β-casein and κ-casein with 32.91, 26.81, 24.13, 19.64 kDa molecular weight, respectively, and the predominant intact caseins in camel milk were αs-casein and β-casein. These findings are in line with Shuiep et al. [48].

There was an extensive decrease in intensity of αs1-casein during ripening days in CC-YC. The intensity of αs1-casein bond remains approximately constant in CC-TC during ripening. It was reported [8,9,10] that the hydrolysis of αs1-casein is slight when using chymosin as a coagulant. However, the primary site of chymosin action is on αs1-casein band Phe23–Phe24 and the small peptide (αs1-casein f1-23) is rapidly hydrolyzed by starter proteinases [16]. Thus, the activity of camel chymosin on αs1-casein was considerable in both cheeses and the amount of αs1-casein hydrolysis products in CC-YC was more than in CC-TC. It was concluded that the action of YC starter proteinases was high in CC-YC and starter culture peptidases are responsible for production of αs1-casein degradation products.

The intensity of the αs2-casein bond remained constant in all stages of ripening in both CC-TC and CC-YC. The camel chymosin and both thermophilic and thermophilic/mesophilic cultures’ proteinases and peptidases had no effect on camel cheeses’ αs2-casein during ripening time. αs2-casein appears to be quite resistant to proteolysis by proteinases and peptidases of the TC and YC due to cleavage sites are restricted by hydrophobic region of molecule. Similar results were reported in cow milk brined cheeses [16].

The molecular weight of β-casein in camel milk was estimated to be 24.13 kDa and the intensity of this bond in CC-TC slightly changed during ripening. The intensity of the β-casein bond region in CC-YC was increased with time owing to the accumulation of the same sized peptides due to the hydrolysis of other casein fractions, especially αs1-casein. Formation of γ-caseins from β-casein was evident in CC-TC and CC-YC, indicating considerable plasmin activity and to a lesser extent P1-type proteinase of cultures between the treatments [12].

As for plasmin and P1-type proteinases from starter cultures, it is found that the preferential casein is β-casein, giving the C-terminal fragments known as γ1-casein, γ2-casein and γ3-casein. In both CC-TC and CC-YC, γ2-casein [β-casein (f106–209)] exists at the highest concentration, followed by γ3- [β-casein (f108–209)] and γ1-casein [β-casein (f29–209)]. An increase in γ-caseins’ bond intensity is recognized as an index of plasmin and P1-type proteinases activity during 1, 20, 40 and 60 days of ripening, which produces peptides with 100 amino acids residue, but in this work, there were no substantial differences in CC-TC and CC-YC γ-casein degradation products during ripening time [12].

The hydrolysis of β-casein by the action of plasmin and P1-type proteinases during ripening is suppressed by the high level of salt in moisture ratio in the curd and β-casein degradation is adversely affected by low pH [51]. The pH and salt concentration of CC-TC and CC-YC was not suitable for plasmin activity and P1-type proteinases during ripening [35]. Consequently, αs1-casein seemed to be more hydrolyzed than β-casein in both CC-TC and CC-YC. The greater hydrolysis of αs1-casein than β-casein was found to be a characteristic of brined cheeses [56].

As previously mentioned, the amount of κ-casein in camel milk is low [2]. Camel’s κ-casein bond with 19.64 kDa molecular weight was cleaved by the action of coagulant to para-κ-casein fraction and caseinomacropeptide [16]. By the action of camel chymosin during the production of cheese, κ-casein bond disappeared in the cheese electrophotogram and the intensity of the resulting Para-κ-casein bond in cheese was increased qualitatively during ripening in CC-TC and CC-YC, which made cheese structure to be incorporated with calcium phosphate [36].

Data indicated that the amount of protein was increased significantly (P < 0.05) with using YC starter. Therefore, as seen in the electrophotogram, in this study, the use of YC starter increased the intensity of para-κ-casein bond in CC-YC compared with CC-TC, which has improved the structural and textural properties of cheese. The electrophoretic pattern showed low intention bonds of Lactoferrin, a protein with an antibacterial effect (71.64 kDa molecular weight) which was present in both CC-TC and CC-YC on all days of ripening and the intensity of these bonds remained constant. During cheese making, small amounts of whey proteins such as lactoferrin, which is trapped in curd, play an important role in cheese shelf life [41].

Lipolysis

Measurement of lipolysis is represented by the determination of ADV. The amount of ADV is presented in Table 1. ADVs were increased to amounts of 6.72 meq KOH/100 g cheese and 8.51 meq KOH/100 g cheese in CC-TC and CC-YC, respectively, until day 60. CC-YC showed significant increases (P < 0.05) compared with CC-TC during ripening.

Lipases in camel cheese originate from milk, starter and non-starter LAB. They are responsible for the breakdown of FFAs in cheeses. Although LABs, especially Lactobacillus spp. are weakly lipolytic, they are present in high numbers over an extended ripening period, LAB are responsible for the liberation of significant levels of FFAs in both CC-TC and CC-YC. In addition, camel milk in this study was thermized and the research showed that lipoprotein lipase (LPL) is partially active in thermized milk. Therefore, the lipolytic activity of cheese was increased when thermophilic/mesophilic yogurt culture was used. Researchers reported similar results in brined cheeses [54].

The fatty acid composition of camel cheeses is presented in Table 3. The data showed that camel cheese had more unsaturated fatty acids, including C14:1, C16:1 and C18:1 in comparison with cow cheese [19, 43]. Changes in fatty acids content showed significant differences (P < 0.05) between two cheese samples and over 60 days of ripening. The amount of butyric, caproic, capric, lauric, myristic, myristoleic, palmitic showed a significant decrease, but the amount of caprylic, palmitoleic, stearic, cis and trans linoleic, linolenic showed a significant increase (P < 0.05) in both CC-TC and CC-YC until day 60. The changes in CLA content of both CC-TC and CC-YC were non-significant. Fatty acid content of CC-YC has undergone more changes against CC-TC, concluding that the extent of lipolysis is higher in CC-YC.

Earlier reports also demonstrated [16, 17, 47] that lipases exhibit specificity on free fatty acids. lipases of LABs are mostly active on short-chain fatty acids like tributyrin. The lipolytic system of LABs has little or no activity on triglycerides of long-chain fatty acids. Both mesophilic and thermophilic lactobacilli possess lipolytic activity. Researchers show that both mesophile L. brevis and L. casei subsp. casei had considerable lipolytic activity and prefer to hydrolyzed tributyrin, tricaproin and tricaprylin. It was concluded that both thermophilic culture and thermophilic/mesophilic cultures’ lipolytic systems influenced more on the short-chain fatty acid content of camel cheeses which is in contrast to bovine cheese [3, 54]. The effect of lipases is more when the mesophilic/thermophilic cultures in CC-YC were used, which demonstrated stronger lipolytic activity of YC. CLA plays an important role as a micro-nutrition in cheeses. It was investigated [45] that the lipases from both TC and YC had no effect on CLA content during ripening.

Texture Profile Analysis

Table 1 shows the texture profile of cheese samples. As seen, there were significant changes (P < 0.05) during ripening days and between CC-TC and CC-YC. Cheese is a complex matrix where protein and fat hydrolysis, acidity, pH and amount of salt penetration affect the structure [53].

Data indicate that CC-TC in day 60 showed maximum hardness (9.70% ± 0.00), adhesiveness (3.21% ± 0.78), stringiness (1.61% ± 0.23) and CC-YC showed maximum resilience (1.32% ± 0.10), cohesiveness (0.59% ± 0.02) springiness (4.82% ± 0.05), gumminess (4.94% ± 0.12) and chewiness (23.80% ± 0.34).

The activity of starter culture on the extent of proteolysis and lipolysis in CC-TC was lower than in CC-YC. Changes in the amount of hardness, adhesiveness and stringiness in CC-TC are related to protein and fat hydrolysis. The number of protein–protein bonds and the ability of protein-water interactions can increase the amount of hardness, adhesiveness and stringiness [52].

As previously mentioned, the activity of starter culture and extent of proteolysis and lipolysis in CC-TC was lower than in CC-YC. The early cleavage of αs1-casein by the action of camel chymosin has been associated with a decrease in cheese firmness [36]. The amount of αs1-casein hydrolysis in CC-TC is lower than CC-YC, which explains the more hardness, adhesiveness of CC-TC.

In addition, salting and the pH of the cheeses produced a significant increase in the ionic strength of the cheese structure. In cheese, the salting out phenomenon can result in a reduction in protein solubility [14]. Under these conditions, a greater number of protein–protein interactions are established, allowing for the lower level of electrostatic repulsion between the proteins due to pH values in (4.40 ± 0.04) very close to the isoelectric point of the caseins in the CC-TC matrix, thereby increasing the firmness and hardness of CC-TC in comparison with CC-YC. Similar results were observed in soft white camel cheese [36] and goat cheese with different thermophilic and the mixture of thermophilic/mesophilic starter cultures [42].

Adhesiveness increases with the increasing ability of proteins to interact with water. Cheeses with more moisture content are more adhesive [6]. The effect of starter cultures in moisture content of CC-TC (60.4% ± 0.00) is more than CC-YC (55.4% ± 0.50). Thus, it shows more adhesiveness (3.21% ± 0.78) than CC-YC (0.99% ± 0.03) on day 60.

The amount of stringiness after 60 days of ripening was higher in CC-TC (2.08% ± 0.06) compared with (1.62% ± 0.11) in CC-YC. The activity of residual chymosin and starter cultures in hydrolysis of caseins was lesser in CC-TC compared with CC-YC. Stringiness is defined as a stretchability of cheese or the ability of cheese to form strings when pulled, is an important textural attribute of cheeses. It depends on aging of cheese and casein hydrolysis [21]. Researchers [4] showed that the variation in the amount of stringiness is due to two reasons. At first, the strands are freed from the spherical casein particles, which allows for maximum stretch; then stringiness is reduced as the strands are hydrolyzed by starter cultures into shorter and shorter particles as aging of the cheese progresses [21]. These reductions were high when the casein hydrolysis is more which explains the significant difference between CC-TC and CC-YC’s stringiness.

In CC-TC and CC-YC, cohesiveness decreased significantly (P < 0.05) until day 60. CC-YC showed the maximum cohesiveness during ripening. Cohesiveness is the strength of internal bonds making up the body of the product or tendency of cheese to adhere to itself and directly depends on protein–protein interactions and fat dispersion and reduction, which is caused by the action of residual chymosin and starter culture enzymes [4]. Therefore, the internal bond of protein–protein in CC-YC is stronger than CC-TC. In addition, fat reduction was higher in CC-YC due to the more lipolytic activity of YC, which leads to higher cohesiveness in CC-YC. Similar results were observed in the research of Kirmaci et al. [32] in feta cheese with different starter cultures.

Springiness is a measure of the recovery of the original undeformed condition after the first compression force is removed and resilience is a dimensionless parameter, which represents the ability of the cheese to regain its original position during the first bite [21]. It is a measure of rubberiness of the cheese that shows the effect of different types of coagulant on cheese structure. In addition, researchers shows that the use of L. casei subsp. casei along with S. salivarius subsp. thermophilus and L. delbrueckii subsp. bulgaricus is very important in cheese texture due to increasing cheese stretchability and rubberiness. [36].

Statistical analysis of data indicated that there was a positive correlation (r = 0.738, P < 0.05) between resilience and springiness showed that CC-YC in comparison with CC-TC can regain its original position during first deformations. CC-YC showed more springiness and resilience compared to CC-TC. Awad et al. [4] reported that the hydrolysis of para κ-casein by the action of starter culture reduces springiness. Also, Bozhao et al. [34] reported that, in contrast to the use of bovine chymosin, camel chymosin increases springiness during ripening in cheddar cheese. It can be concluded that higher amounts of para κ-casein and the use of camel chymosin unlike bovine chymosin in CC-YC increased springiness and resilience.

Chewiness in CC-TC and CC-YC increased significantly (P < 0.05) until day 60. Gumminess in CC-TC increased significantly until day 60 (P < 0.05) but in CC-YC decreased significantly (P < 0.05) on day 20 and they remained constant until day 60 (5.51 ± 0.02). In addition, CC-YC indicated more gumminess in comparison with CC-TC (P < 0.05). Gumminess is calculated from assigned hardness and cohesiveness values. The variation in these parameters during the storage was due largely to the variations in the scores for hardness. These findings are in agreement with the texture of camel cheeses that was reported by Mbye et al. [36].

Conclusions

The effect of Far-M camel chymosin and two types of starter culture on chemical composition, proteolysis, lipolysis, and texture characteristics of camel cheese during ripening time were investigated. Far-M camel chymosin and thermophilic/mesophilic yogurt culture was successfully used for the production of semi-hard white camel cheese.

The thermophilic/mesophilic yogurt culture helped better syneresis and acidification. It also had acceptable cheese yield compared with other studies that have been performed until now. Results of proteolysis and lipolysis showed that the effect of Far-M camel chymosin as a coagulant in contrary of other coagulants and two types of starter cultures on camel cheese production were advantageous and noticeable.

The most hydrolyzed caseins were αs1-casein and β-casein, revealing participation of coagulant and starter culture enzyme activities in camel cheese. The difference in amount of FFAs between the two samples showed the greater contribution of thermophilic/mesophilic cultures to lipolysis of camel cheeses.

Thermophilic cultures provided maximum hardness, adhesiveness and stringiness, while the thermophilic/mesophilic yogurt culture provided maximum resilience, cohesiveness, springiness, gumminess and chewiness. It is concluded that the mixture of thermophilic/mesophilic cultures and Far-M camel chymosin is highly suggested for production of semi-hard white camel cheese manufactured by camel milk for further researches.

References

Al-Zoreky NS, Almathen FS (2021) Using recombinant camel chymosin to make white soft cheese from camel milk. Food Chem 337:127994

Al Kanhal HA (2010) Compositional, technological and nutritional aspects of dromedary camel milk. Int Dairy J 20(12):811–821

Atasoy AF, Türkoğlu H (2009) Lipolysis in Urfa cheese produced from raw and pasteurized goats’ and cows’ milk with mesophilic or thermophilic cultures during ripening. Food Chem 115(1):71–78

Awad S, Hassan A, Muthukumarappan K (2005) Application of exopolysaccharide-producing cultures in reduced-fat Cheddar cheese: texture and melting properties. J Dairy Sci 88(12):4204–4213

Baig D, Sabikhi L, Khetra Y, Kumar D (2022) Effect of casein to fat ratio of camel milk on solids losses in cheese whey and their recovery in camel milk cheese. Int Dairy J 124:105185

Bekele B, Hansen EB, Eshetu M, Ipsen R, Hailu Y (2019) Effect of starter cultures on properties of soft white cheese made from camel (Camelus dromedarius) milk. J Dairy Sci 102(2):1108–1115

Benkerroum N, Dehhaoui M, El Fayq A, Tlaiha R (2011) The effect of concentration of chymosin on the yield and sensory properties of camel cheese and on its microbiological quality. Int J Dairy Technol 64(2):232–239

Bertolino M, Dolci P, Giordano M, Rolle L, Zeppa G (2011) Evolution of chemico-physical characteristics during manufacture and ripening of Castelmagno PDO cheese in wintertime. Food Chem 129(3):1001–1011

Bontinis TG, Mallatou H, Pappa E, Massouras T, Alichanidis E (2012) Study of proteolysis, lipolysis and volatile profile of a traditional Greek goat cheese (Xinotyri) during ripening. Small Rumin Res 105(1):193–201

Cakir Y, Cakmakci S, Hayaloglu AA (2016) The effect of addition of black cumin (Nigella sativa L.) and ripening period on proteolysis, sensory properties and volatile profiles of Erzincan Tulum (Şavak) cheese made from raw Akkaraman sheep’s milk. Small Rumin Res 134:65–73

Cepoglu F, Guler-Akin MB (2013) Effects of coagulating enzyme types (commercial calf rennet, Aspergillus niger var. awamori as recombinant chymosin and Rhizomucor miehei as microbial rennet) on the chemical and sensory characteristics of white pickled cheese. Afr J Biotechnol 12(37):5588–5594

Costabel LM, Bergamini C, Vaudagna SR, Cuatrin AL, Audero G, Hynes E (2016) Effect of high-pressure treatment on hard cheese proteolysis. J Dairy Sci 99(6):4220–4232

Diezhandino I, Fernández D, González L, McSweeney P, Fresno J (2015) Microbiological, physico-chemical and proteolytic changes in a Spanish blue cheese during ripening (Valdeón cheese). Food Chem 168:134–141

Diezhandino I, Fernández D, Sacristán N, Combarros-Fuertes P, Prieto B, Fresno J (2016) Rheological, textural, colour and sensory characteristics of a Spanish blue cheese (Valdeón cheese). LWT Food Sci Technol 65:1118–1125

Farahani G, Ezzatpanah H, Abbasi S (2014) Characterization of Siahmazgi cheese, an Iranian ewe’s milk variety: assessment of physico-chemical, textural and rheological specifications during ripening. LWT Food Sci Technol 58(2):335–342

Fox PF, Guinee TP, Cogan TM, McSweeney PL (2016) Fundamentals of cheese science, 2nd edn. Springer, New York

Georgala A, Moschopoulou E, Aktypis A, Massouras T, Zoidou E, Kandarakis I, Anifantakis E (2005) Evolution of lipolysis during the ripening of traditional Feta cheese. Food Chem 93(1):73–80

Giannoglou M, Karra Z, Platakou E, Katsaros G, Moatsou G, Taoukis P (2016) Effect of high pressure treatment applied on starter culture or on semi-ripened cheese in the quality and ripening of cheese in brine. Innov Food Sci Emerg Technol 38:312–320

Gonzalez MM, Vivar-Quintana A, Revilla I, Salvador-Esteban J (2020) The determination of fatty acids in cheeses of variable composition (cow, ewe’s, and goat) by means of near infrared spectroscopy. Microchem J 156:104854

Guidone A, Braghieri A, Cioffi S, Claps S, Genovese F, Morone G, Napolitano F, Parente E (2015) Effect of adjuncts on microbiological and chemical properties of Scamorza cheese. J Dairy Sci 98(3):1467–1478

Gunasekaran S, Ak MM (2002) Cheese rheology and texture. CRC Press, Florida

Hailu Y, Hansen EB, Seifu E, Eshetu M, Ipsen R (2016) Factors influencing the gelation and rennetability of camel milk using camel chymosin. Int Dairy J 60:62–69

Hailu Y, Seifu E, Yilma Z (2014) Physicochemical properties and consumer acceptability of soft unripened cheese made from camel milk using crude extract of ginger (Zingiber officinale) as coagulant. Afr J Food Sci 8(2):87–91

Ho TM, Zou Z, Bansal N (2022) Camel milk: a review of its nutritional value, heat stability, and potential food products. Food Res Int 153:110870

ISO 5943 (1988) Cheese and processed cheese products determination of chloride content: potentiometric titration method. International Organization for Standardization, Geneva

ISO14156 (2001) Milk and milk product-extraction method for lipid and insoluble compounds. International Organization for Standardization, Geneva

ISO 15884 (2002) Preparation of fatty acid methyl esters. International Organization for Standardization, Geneva

ISO5537 (2004) Dried milk: determination of moisture content (Reference method). International Organization for Standardization, Geneva

ISO488 (2008) Milk: determination of fat content: Gerber butyrometers. International Organization for Standardization, Geneva

ISO8968-1 (2014) Milk and milk products: determination of nitrogen content-Part 1: Kjeldahl principle and crude protein calculation. International Organization for Standardization, Geneva

Kamal M, Foukani M, Karoui R (2017) Rheological and physical properties of camel and cow milk gels enriched with phosphate and calcium during acid-induced gelation. J Food Sci Technol 54(2):439–446

Kirmaci H, Hayaloglu A, Özer H, Atasoy A, Türkoğlu H (2014) Evolution of proteolysis in Urfa cheese made from ewe’s milk by wild type starter culture systems. Small Rumin Res 119(1):120–129

Konuspayeva G, Camier B, Gaucheron F, Faye B (2014) Some parameters to process camel milk into cheese. Emir J Food Agric 26(4):354

Li B, Waldron DS, Drake M, Lyne J, Kelly AL, McSweeney PL (2022) Suitability of a novel camel (Camelus dromedarius) chymosin as a coagulant for Cheddar cheese manufacture. Int Dairy J 129:105346

Masotti F, Cattaneo S, Stuknytė M, Battelli G, Vallone L, De Noni I (2017) Composition, proteolysis, and volatile profile of Strachitunt cheese. J Dairy Sci 100(3):1679–1687

Mbye M, Ayyash M, Abu-Jdayil B, Kamal-Eldin A (2022) The texture of camel milk cheese: effects of milk composition, coagulants, and processing conditions. Front Nutr 9:868320

Miloradovic Z, Kljajevic N, Miocinovic J, Tomic N, Smiljanic J, Macej O (2017) High heat treatment of goat cheese milk. The effect on yield, composition, proteolysis, texture and sensory quality of cheese during ripening. Int Dairy J 68:1–8

Moynihan A, Govindasamy-Lucey S, Jaeggi J, Johnson M, Lucey J, McSweeney P (2014) Effect of camel chymosin on the texture, functionality, and sensory properties of low-moisture, part-skim Mozzarella cheese. J Dairy Sci 97(1):85–96

Muthukumaran MS, Mudgil P, Baba WN, Ayoub MA, Maqsood S (2022) A comprehensive review on health benefits, nutritional composition and processed products of camel milk. Food Rev Int. https://doi.org/10.1080/87559129.2021.2008953

Orundu S, Tarakci Z (2021) Effects of different starter culture applications pre-and post-scalding on the biochemical and sensory properties of pasta filata type cheeses. LWT 136:110288

Ozturkoglu-Budak S, Akal HC, Bereli N, Cimen D, Akgonullu S (2021) Use of antimicrobial proteins of donkey milk as preservative agents in Kashar cheese production. Int Dairy J 120:105090

Pappa EC, Kondyli E, Bosnea L, Malamou E, Vlachou AM (2022) Chemical, microbiological, sensory, and rheological properties of fresh goat milk cheese made by different starter cultures during storage. J Food Process Eng 45(7):e13788

Paszczyk B, Łuczyńska J (2020) The comparison of fatty acid composition and lipid quality indices in hard cow, sheep, and goat cheeses. Foods 9(11):1667

Qadeer Z, Huma N, Sameen A, Iqbal T (2015) Camel milk cheese: optimization of processing conditions. J Camelid Sci 8:18–25

Renes E, Gómez-Cortés P, de La Fuente M, Linares DM, Tornadijo ME, Fresno JM (2019) CLA-producing adjunct cultures improve the nutritional value of sheep cheese fat. Food Res Int 116:819–826

Salami M, Sadeghian Motahar SF, Ariaeenejad S, Sheykh Abdollahzadeh Mamaghani A, Kavousi K, Moosavi-Movahedi AA, Hosseini Salekdeh G (2022) The novel homologue of the human α-glucosidase inhibited by the non-germinated and germinated quinoa protein hydrolysates after in vitro gastrointestinal digestion. J Food Biochem 46(1):e14030

Sert D, Akin N, Aktumsek A (2014) Lipolysis in Tulum cheese produced from raw and pasteurized goats’ milk during ripening. Small Rumin Res 121(2):351–360

Shuiep E, Jäger S, El Zubeir I, Yousif I, Erhardt G (2016) Isolation and characterization of three camel (Camelus dromedarius) milk casein fractions. J Vet Med Anim Prod 6(1):43–50

Singh R, Mal G, Kumar D, Patil N, Pathak K (2017) Camel milk: an important natural adjuvant. J Agric Res 6(4):327–340

Soltani M, Guzeler N, Hayaloglu AA (2015) The influence of salt concentration on the chemical, ripening and sensory characteristics of Iranian white cheese manufactured by UF-Treated milk. J Dairy Res 82(3):365–374

Sulejmani E, Hayaloglu AA (2020) Influence of starter culture on nitrogen fraction and volatile compounds in Beaten cow’s milk cheese. J Food Process Preserv 44(9):e14689

Tomar O (2019) The effects of probiotic cultures on the organic acid content, texture profile and sensory attributes of Tulum cheese. Int J Dairy Technol 72(2):218–228

Tunick MH (2010) Small-strain dynamic rheology of food protein networks. J Agric Food Chem 59(5):1481–1486

Zaravela A, Kontakos S, Badeka A, Kontominas M (2021) Effect of adjunct starter culture on the quality of reduced fat, white, brined goat cheese: part I. Assessment of chemical composition, proteolysis, lipolysis, texture and sensory attributes. Eur Food Res Technol 247(9):2211–2225

Zhao DB, Bai YH, Niu YW (2015) Composition and characteristics of Chinese Bactrian camel milk. Small Rumin Res 127:58–67

Zonoubi R, Goli M (2021) The effect of complete replacing sodium with potassium, calcium, and magnesium brine on sodium-free ultrafiltration Feta cheese at the end of the 60-day ripening period: physicochemical, proteolysis–lipolysis indices, microbial, colorimetric, and sensory evaluation. Food Sci Nutr 9(2):866–874

Acknowledgments

The authors would like to thank the department of food science and nutrition, Tehran medical university, Islamic Azad University for cooperation of this research.

Author information

Authors and Affiliations

Contributions

SA contributed to conceptualization, methodology, software, formal analysis, writing and original draft preparation; YR contributed to methodology, data analysis, review and editing the manuscript, resources, validation; MS contributed to methodology, data analysis, resources, validation. All authors read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflicts of interest.

Ethical approval

The authors declare compliance with all ethics requirements.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Abbaschian, S., Ramezan, Y. & Salami, M. Chemical, Textural and Ripening Characteristics of Semi-hard White Cheese Prepared from Camel Milk Using Camel Chymosin and Different Starter Cultures. Agric Res 12, 325–338 (2023). https://doi.org/10.1007/s40003-023-00654-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40003-023-00654-x