Abstract

Uniformly sized and shaped gold nanoparticles (AuNP) were produced by microwave irradiation using Euphorbia tirucalli latex. The AuNPs were characterized by ultraviolet visible spectroscopy (UV–Vis), Fourier transform infrared spectroscopy (FTIR), dynamic light scattering, zeta potential, and transmission electron microscopy (TEM). UV–Vis analysis was employed to detect the characteristic surface plasmon resonance pattern of the AuNPs (550 nm). The carboxylic and polyphenolic groups were associated with the euphol-capped AuNP, which was confirmed using FTIR spectroscopy. The AuNPs studied here show a z-average diameter varying from 35 to 500 ± 0.8 nm. TEM reveals that the particles were spherical and polydispersed. The latex itself is very toxic and can be harmful during manipulation, thus highlighting a negative aspect in it use. However, we have demonstrated that the isolation procedure did not impair the reduction action of the dry latex powder. This study provides a robust solution for the synthesis of stable capped gold nanoparticles. Furthermore, the dried powdered E. tirucalli latex seems to be an attractive capping agent for nanoparticles in drug delivery.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The production of metallic nanoparticles is a research field with various applications, including catalysis, drug delivery, and biomedical studies. Gold nanoparticle (AuNP) dispersions are currently employed in numerous scientific, industrial, and domestic applications [1, 2] AuNPs have been used as nanomaterials for molecular imaging and drug delivery in recent years [3]. Heterogeneous and homogeneous catalysis is another major field for AuNP applications [4]. Heterogeneous gold catalysts are commonly employed in CO oxidation [4,5,6], C–H activation [7], liquid phase oxidation reactions [8], coupling reactions [9], and hydrogenation reactions [10]. Homogeneous gold catalysts are also employed [11]. Particle size and shape, structure, composition, surface area, and porosity are found to be among the most important factors that affect the catalytic properties of supported AuNPs in different reactions.

There is a broad range of research studies involving AuNPs, because they can be modified in different ways by binding specific receptors coupled with various forms of therapeutics [12]. One of the symptoms of cancer is the pain, and as the disease grows, these symptoms increase, probably by an inflammation process [12].

The Euphorbiaceae family plants traditionally bear latex that is commonly used for therapeutic purposes, because it contains highly active constituents, such as euphol, which is found in Euphorbia tirucalli [13]. This latex is a thick white fluid that flows throughout the plant. In ancient times, this plant was used for insect pest control and herbivorous attacks [14]. Moreover, the latex has been used as an antibacterial, antifungal, anticancer, and antiviral and in the treatment of ulcers and menstrual disorders in traditional folk medicine [2]. The alcohol tetracyclic triterpene is one of the latex components in euphol, which possesses desirable pharmacological properties with anti-inflammatory qualities. A strategy for nanoparticle synthesis is the use of plant parts, introducing the pharmacological compounds of its structure with the greatest potential in cancer research [14].

The Green method is based on the endogenous or intrinsic use of the reducing compounds found in the bulk of plant parts (leaves, seeds, latex) by the simple formation of nanoparticles, as opposed to other more complex chemical methods [15, 16].

Homogeneous nucleation and growth conditions for nanoparticle synthesis can be achieved by microwave irradiation, which provides a rapid and uniform heating process [17, 18]. Liu et al. successfully synthesized silver nanoparticles using Boswellia serrata flower extract, with the aid of microwave heating [19, 20], and Kahrilas et al. produced silver nanoparticles using orange peel extract, also with the aid of microwave heating [21].

Here, we propose the use of fresh and reconstituted dried latex from E. tirucalli as both the reducing and capping agent in gold nanoparticles. The use of microwave heating for the synthesis of gold nanoparticles using euphol latex was compared to the conventional methods for gold nanoparticle synthesis (room temperature and bath heating). The synthesis of euphol latex gold nanoparticles was achieved, thus demonstrating its potential as a drug delivery for antinociception in cancer treatments.

Material and methods

Material

Tetrachloroauric acid (HAuCl4·3H2O) and sodium citrate were obtained from Sigma-Aldrich. The aqueous solutions were prepared using double-distilled water and methanol. Sodium citrate was both the reducing and capping agent, as described by Turkevich [22, 23]. Here, we used the latex of E. tirucalli as both the reducing and capping agent for the AuNPs. One of its components is euphol, which is the identifier used to label all the AuNPs produced from E. tirucalli.

Methods

The following preparations were used in this study.

Preparations | Abbreviation |

|---|---|

Euphol latex, fresh | EuLf |

Euphol latex, powder | EuL |

Citrate gold nanoparticle, room temperature | AuNPcit-r |

Citrate gold nanoparticle, hot bath | AuNPcit-h |

Citrate gold nanoparticle, microwave assisted | AuNPcit-mw |

Euphol-capped gold nanoparticle, room temperature | EuLAuNP-r |

Euphol-capped gold nanoparticle, hot bath | EuLAuNP-h |

Euphol-capped gold nanoparticle, microwave assisted | EuLAuNP-mw |

Fresh euphol-capped gold nanoparticle, room temperature | EuLfAuNP-r |

Fresh euphol-capped gold nanoparticle, hot bath | EuLfAuNP-h |

Fresh euphol-capped gold nanoparticle, microwave assisted | EuLfAuNP-mw |

Isolation of euphol latex and euphol latex powder

We isolated the fresh thick milky white latex of E. tirucalli (EuLf) from the mature plant stem. The fresh latex was dissolved in a methanol–water mixture (1:1 v/v), filtered, and dried via evaporation under constant stirring. The white power (EuL) was weighted and then stored under refrigeration at − 20 °C. The latex was collected from three different plants in the summer season and stored as one bulk stock. This bulk-dried EuL powder was used to prepare a 3% aqueous latex extract.

Green methods to produce euphol-capped gold nanoparticles

The AuNPs were synthesized using EuLf and EuL as both the capping and reducing agents in the different approaches. The standard reduction with citrate was used as the control. The nanoparticles were produced at room temperature (r, 25 °C), in a water-heated bath (h, 100 °C), and using a microwave (mw) as the heat source. A domestic microwave oven (1200 W) was used for the reaction heating. The AuNP synthesis was conducted as follows. The vessel containing gold salt in aqueous solution with latex or citrate was allowed to either boil in a water-heated bath (h assays) or boil by microwave irradiation (mw assays), followed by cooling at room temperature and further characterization, whereas the r assays were incubated at room temperature for 24 h. No AuNPcit-r was obtained. The synthesis process is illustrated in Scheme 1.

Freshly collected euphol latex

Here, 200 μL of freshly harvested latex was added to 700 μL of HAuCl4 (1 mM) and incubated at 25 °C for 24 h, producing EuLfAuNP-r. Another batch was heated in a water bath until the color change (reddish-violet-rose) or for a maximum of 30 min, producing EuLfAuNP-h. The third batch was irradiated with a conventional microwave operating at 1200 W and 60 MHz, with 30-s microwave irradiation cycles. The number of irradiation cycles was dependent on the time required to reduce Au3+ to Au0, which was confirmed from the color change of the reaction medium from pale yellow to light violet, thus indicating the production of EuLfAuNP-mw. The EuLfAuNPs produced in the reaction mixture were collected by sequential centrifugation at 14000 rpm for 20 min, followed by air-drying at room temperature, and sample characterization [15].

Dried powder euphol latex

The bulk-dried EuL was used to prepare a 3% aqueous euphol latex solution. The same procedures used on EuLf were performed on EuL to produce EuLAuNP-r, EuLAuNP-h, and EuLAuNP-mw, as described above. The EuLAuNPs formed in the reaction mixture were then separated by repeated centrifugation at 14000 rpm for 20 min, air-dried at room temperature, and analyzed for sample characterization.

Characterization of euphol-capped AuNPs

The synthesized euphol-capped AuNPs were monitored by measuring the absorbance spectra at regular intervals using ultraviolet visible spectroscopy (UV–Vis) in the 300–700 nm wavelength range. A Perkin Elmer Lambda 25 spectrophotometer (Perkin Elmer; Walton, MA, USA) was used to acquire the absorbance spectra of the AuNPs, with a 2.0 slit width, 1200 nn/min speed, and the sample placed in a 1-cm quartz cell cuvette.

The particle size distribution was acquired by photon correlation spectroscopy (PCS) using the quasi-elastic light scattering technique. A Zetasizer Nano ZS (Malvern Instruments; Worcestershire, UK) was employed to determine the size (z-average) and zeta potential distribution of the synthesized EuLAuNPs, using a 10-mW He–Ne 633-nm laser beam at 25 °C and a scattering angle of 173°. The size of particles was acquired using the size distribution by intensity mode. The zeta potential of the particles was acquired using the ZetaPlus™ software package in zeta potential analysis mode.

The euphol AuNPs were sampled onto carbon-coated copper grids and dried under an infrared lamp for the transmission electron microscopy (TEM) analysis. The TEM observations were made with Jeol (JEM-2100 at LabMic/UFG).

Fourier transform infrared spectroscopy (FTIR) was employed to obtain the reflectance spectra of the functional groups present in the euphol AuNPs and 3% euphol aqueous latex solution. Shimadzu (IR Prestige-21 FRIT-8400S; Shimadzu, Japan) was used in transmission mode, with a 400–4000-cm−1 wavelength range. The samples were first mixed with KBr powder, pelletized, and dried prior to the FTIR analysis.

Results

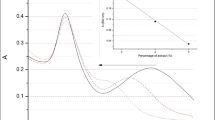

Green synthesis of the AuNPs was preliminarily confirmed by the observed color change from yellow to dark reddish in the reaction mixture, and the broad surface plasmon resonance band was centered at 550 nm, which is indicative of polydispersed nanoparticles (Figs. 1 and 2).

The AuNP solutions were kept at room temperature after 4 weeks of preparation and assayed by UV–Vis spectroscopy to evaluate the stability of the solutions. No significant differences in the band intensity or new band formation were observed, thus indicating that the new AuNPs were stable.

The control UV–Vis spectra of the AuNPs reduced by the citrate ions and prepared by the conventional method (heating bath), at room temperature, and by the microwave-assisted method displayed different profiles, as shown in Fig. 1. The AuNPcit samples prepared at water-heated bath temperature (AuNPcit-h; red line) and in the microwaver-heated (AuNPcit-mw; blue line) showed a typical gold nanoparticle band at 550 nm. However, the AuNPcit-r (black line) solution displayed a UV–Vis spectrum without a typical plasmon band appears in the spectrum.

The AuNPs capped with dried latex were able to induce a reduction of gold ions, regardless of the method employed, as shown in Fig. 2. The microwave-assisted method produced a more concentrated AuNP solution, as shown in the image by its deep color. The inset plot displayed the UV–Vis solution of fresh and dried powdered euphol latex, each with a typical band at 250 nm.

The EuLAuNP-mw samples were produced in a narrow size distribution, with a smaller nanoparticle size, and possessing a greater zeta potential in comparison to the samples produced by the other methods (Table 1).

The AuNPs have a negative charge, as confirmed by the zeta potential measurements. The surface charges of the samples produced via the citrate method ranged from − 0.6 to − 17 mV. The surface charge was significantly affected by the euphol latex coating, as the produced samples possessed surface charges ranging from − 13 to − 16 mV. The z-average size distribution of the AuNPs also suffered significant changes upon euphol coating. The size distribution by the dynamic light scattering (DLS) data proves that the euphol-coated AuNPs are polydispersed in nature (Table 1). Both individual nanoparticles and large agglomerations are observed. The citrate AuNPs had a z-average hydrodynamic diameter in the 16–20 nm range, whereas fresh and dried euphol AuNP sizes were in the 225–450 and 360–443 nm ranges, respectively.

The FTIR analysis was carried out to identify the possible functional groups of the biomolecules present in the euphol that were involved in the reduction of the gold ions and the stabilization of the synthesized AuNPs. The euphol extract showed intense absorption bands at 3419, 2972, 2109, 1608, 1419, and 1024 cm−1 (Fig. 3). The strong absorption band at 3419 cm−1 could refer to the stretching vibration of the O–H bond. The bands at 2972 cm−1 were due to the aliphatic C–H stretching vibration of carbohydrates. The band at 1419 cm−1 might be ascribed to the methylene scissoring vibration or C=C groups and 588 cm−1 for alcohol, OH out-of-plane bend, which can be found in antioxidants, phenols, flavonoids, terpene, and ascorbic acids extracts. Similar results were observed by Shi et al., who analyzed the biosynthesis of gold nanoparticles with Pycnoporus sanguineus [24].

FTIR analysis of the euphol before and after gold reduction showed spectrum displacements in the O–H peak at 3419 cm−1, shifted to 3400 cm−1, and the methylene band shifted to 1456 cm−1. AuNPs might be capped and stabilized by antioxidants, flavonoids, and polyphenols originating from euphol [25]. It has also been reported that hydroxyl, amine, and carboxyl groups played important roles in the reduction process and stabilization of synthesized AuNPs [24, 26, 25].

AuNPs have been synthesized in the presence of reducing agents and stabilizing molecules, such as chitosan, alkyl trimethyl ammonium bromide, and sodium citrate [27]. We demonstrated that microwave heating can induce the nucleation of aqueous gold salt using only euphol latex to produce EuLAuNPs. The dielectric heating promoted by microwave irradiation via the rapid dipolar rotations of the polarized water molecules can produce a local high-pressure region in the gold salt–water system. The temperature can reach 150–300 °C, such that the water molecules function as both an acid and a base [27]. The chemical-free reduction of gold salt enhanced the dissociation of water caused by the local and confined dielectric heating effects from the microwave irradiation. The shape of the gold nanoparticles, such as the sharp triangular, truncated triangular, hexagonal, globular, and dendritic morphologies, is useful for catalytic applications [1, 28]. Figure 4 displays TEM micrographs of the AuNPcit-mw and EuLAuNP-mw sample preparations. The overall size distribution of EuLAuNP-mw sample has a more uniform size, with smaller diameter particles than the AuNPcit-mw sample. This result was confirmed by DLS analysis.

Table 1 summarizes the DLS results from the preparation of gold nanoparticles capped with euphol latex under several incubation temperatures and heat sources. Citrate-capped gold nanoparticles were also assayed under similar conditions to the control.

Discussion

The white milky latex from E. tirucalli can be found in all plants, even in the roots [1, 29]. The chemical composition of the different parts of the plant has been extensively studied, and several chemical compounds have been separated from them, such as campesterol, stigmasterol, beta-sitosterol, iso-fucosterol, cycloartenol, cyclotirucanenol (triterpene), diterpene ester, euphol steroid and beta-amyrin (triterpenoids), taraxerane triterpene, and tirucalicine (diterpene) [30,31,32]. The complexity of E. tirucalli latex and most of its functions can be explained from the extensive list of compounds extracted from the plant [1]. The latex itself is very toxic and can be harmful during manipulation, thus highlighting a negative aspect regarding its use. We have demonstrated that the isolation procedure did not impair the reduction of the dry latex powder. One of the significant advances in the use of latex from E. tirucalli is in drug delivery systems. Another advantage of this isolation is the ability to control the seasonality of the latex components. The separation/drying process eliminates undesired components/debris from the fresh latex, as observed in the cleaner aspect of the nanoparticle UV–Vis spectra. It is well-known that conventional methods using citrate produce small nanoparticles [32]. Here, we produced larger particles. One of the main advantages of this AuNP preparation using dried euphol latex and microwave irradiation is the absence of organic solvents, which makes this method an environmentally friendly synthesis option. The larger-sized nanoparticles are due the fact that no other procedure was applied after preparation, such as centrifugation or cleaning/remotion of the supernatant. This feature could interfere in the latex association with the AuNP surface [32].

The fast-heating characteristic of the microwave environment provides an effective method for the preparation of gold nanoparticles [33, 34]. We have demonstrated the use of the microwave process for the synthesis of gold nanoparticles in a green environment using E. tirucalli as both the capping and reducing agent.

The SPB is due to the collective oscillations of the electron gas at the surface of the nanoparticles (6s electrons of the conduction band for AuNPs) that is correlated with the electromagnetic field of the incoming light, i.e., the excitation of the coherent oscillation of the conduction band [35].

The FTIR spectral analysis indicates that alkaloids might play a major role in the reduction of trivalent gold to zero-valent AuNPs and the subsequent stabilization of the resulting AuNPs. Here, we observed that the increase in the intensity of the band at 3419 cm−1 compared to the AuNP with capping agents alone, indicating the formation of coordination bond between the OH group of phenolic compounds and the AuNP surface (Fig. 3). The FTIR studies thus reveal that phenolic compounds may be involved in stabilizing gold nanoparticles.

The TEM images confirm the presence of spherical and irregularly shaped gold nanoparticles in the 100–500 nm size range. DLS measurements indicated the uniform size distribution from microwave-assisted production of euphol latex gold nanoparticles in the same range. The method using plant extract as a tool for the production of nanoparticles provides rapid synthesis (single step), controlled toxicity, controls on the size characteristics, and an economical and eco-friendly approach.

The latex was able to induce a reduction of gold ions in all the sample preparations. The DLS and TEM measurements revealed the presence of greater diameter nanoparticles than those produced by the traditional Turkevich method.

Similar to procedure described by Turkevich (Eq. 1), the phenolic groups present in euphol latex are responsible for the gold ion reduction (Eq. 2) [36].

Conclusion

Capped gold nanoparticles, heated by the microwave method, were obtained for the reduction of an aqueous gold salt solution using fresh and dried powdered euphol latex solutions. UV–Vis, FTIR, DLS, zeta potential, and TEM assays were conducted to ensure the formation of nanoparticles. Another benefit of this microwave-assisted approach is the elimination of organic solvents, as the reducing and stabilizing agent capability of euphol latex gold nanoparticles seems to be an attractive system for drug delivery due the fact that the gold nanoparticle substrate is used to deliver the toxic latex to a given target.

References

Mwine J, Van Damme P, Hastilestari BR, Papenbrock J (2013) Euphorbia tirucalli L. (Euphorbiaceae)—the miracle tree: current status of knowledge. In: African natural plant products volume II: discoveries and challenges in chemistry, health, and nutrition, vol 1127. ACS symposium series, vol 1127. American Chemical Society, pp 3–17. doi: 10.1021/bk-2013-1127.ch001

Tabassum N, Hamdani M (2014) Plants used to treat skin diseases. Pharmacogn Rev 8(15):52–60. https://doi.org/10.4103/0973-7847.125531

Joseph S, Mathew B (2015) Microwave-assisted facile green synthesis of silver nanoparticles and spectroscopic investigation of the catalytic activity. Bull Mater Sci 38(3):659–666. https://doi.org/10.1007/s12034-015-0892-1

Hashmi ASK, Hutchings GJ (2006) Gold catalysis. Angew Chem Int Ed 45(47):7896–7936. https://doi.org/10.1002/anie.200602454

Hutchings GJ, Brust M, Schmidbaur H (2008) Gold-an introductory perspective. Chem Soc Rev 37(9):1759–1765. https://doi.org/10.1039/B810747P

Rodriguez P, Garcia-Araez N, Koverga A, Frank S, Koper MTM (2010) CO electroxidation on gold in alkaline media: a combined electrochemical, spectroscopic, and DFT study. Langmuir 26(14):12425–12432. https://doi.org/10.1021/la1014048

Hashmi AS, Schafer S, Wolfle M, Diez Gil C, Fischer P, Laguna A, Blanco MC, Gimeno MC (2007) Gold-catalyzed benzylic C-H activation at room temperature. Angew Chem Int Ed Engl 46(32):6184–6187. https://doi.org/10.1002/anie.200701521

Mikami Y, Dhakshinamoorthy A, Alvaro M, Garcia H (2013) Catalytic activity of unsupported gold nanoparticles. Cat Sci Technol 3(1):58–69. https://doi.org/10.1039/C2CY20068F

Han J, Liu Y, Guo R (2009) Facile synthesis of highly stable gold nanoparticles and their unexpected excellent catalytic activity for Suzuki–Miyaura cross-coupling reaction in water. J Am Chem Soc 131(6):2060–2061. https://doi.org/10.1021/ja808935n

Bond GC (2016) Hydrogenation by gold catalysts: an unexpected discovery and a current assessment. Gold Bull 49(3–4):53–61. https://doi.org/10.1007/s13404-016-0182-8

Hayashi T, Tanaka K, Haruta M (1998) Selective vapor-phase epoxidation of propylene over au/TiO2 catalysts in the presence of oxygen and hydrogen. J Catal 178(2):566–575. https://doi.org/10.1006/jcat.1998.2157

Laird BJA, Scott AC, Colvin LA, McKeon A-L, Murray GD, Fearon KCH, Fallon MT (2011) Cancer pain and its relationship to systemic inflammation: an exploratory study. PAIN 152(2):460–463. https://doi.org/10.1016/j.pain.2010.10.035

Avelar BA, Lélis FJN, Avelar RS, Weber M, Souza-Fagundes EM, Lopes MTP, Martins-Filho OA, Brito-Melo GEA (2011) The crude latex of Euphorbia tirucalli modulates the cytokine response of leukocytes, especially CD4+ T lymphocytes. Rev Bras 21:662–667

Rajkuberan C, Prabukumar S, Sathishkumar G, Wilson A, Ravindran K, Sivaramakrishnan S (2016) Facile synthesis of silver nanoparticles using Euphorbia antiquorum L. latex extract and evaluation of their biomedical perspectives as anticancer agents. J Saudi Chem Soc. https://doi.org/10.1016/j.jscs.2016.01.002

Nakkala JR, Mata R, Sadras SR (2016) The antioxidant and catalytic activities of green synthesized gold nanoparticles from Piper longum fruit extract. Process Saf Environ Prot 100:288–294. https://doi.org/10.1016/j.psep.2016.02.007

Dauthal P, Mukhopadhyay M (2016) Noble metal nanoparticles: plant-mediated synthesis, mechanistic aspects of synthesis, and applications. Ind Eng Chem Res 55(36):9557–9577. https://doi.org/10.1021/acs.iecr.6b00861

Majumdar R, Bag BG, Maity N (2013) Acacia nilotica (Babool) leaf extract mediated size-controlled rapid synthesis of gold nanoparticles and study of its catalytic activity. Int Nano Lett 3(1):53. https://doi.org/10.1186/2228-5326-3-53

Kumar B, Smita K, Cumbal L (2016) Biosynthesis of silver nanoparticles using Lantana camara flower extract and its application. J Sol-Gel Sci Technol 78(2):285–292. https://doi.org/10.1007/s10971-015-3941-8

Liu W, Xu F, Li Y, Hu X, Dong B, Xiao Y (2016) Discussion on microwave-matter interaction mechanisms by in situ observation of “core-shell” microstructure during microwave sintering. Materials 9(3):120. https://doi.org/10.3390/ma9030120

Ali K, Ahmed B, Dwivedi S, Saquib Q, Al-Khedhairy AA, Musarrat J (2015) Microwave accelerated green synthesis of stable silver nanoparticles with eucalyptus globulus leaf extract and their antibacterial and antibiofilm activity on clinical isolates. PLoS One 10(7):e0131178

Kahrilas GA, Wally LM, Fredrick SJ, Hiskey M, Prieto AL, Owens JE (2014) Microwave-assisted green synthesis of silver nanoparticles using orange peel extract. ACS Sustain Chem Eng 2(3):367–376. https://doi.org/10.1021/sc4003664

Kahrilas GA, Haggren W, Read RL, Wally LM, Fredrick SJ, Hiskey M, Prieto AL, Owens JE (2014) Investigation of antibacterial activity by silver nanoparticles prepared by microwave-assisted green syntheses with soluble starch, dextrose, and arabinose. ACS Sustain Chem Eng 2(4):590–598. https://doi.org/10.1021/sc400487x

Kimling J, Maier M, Okenve B, Kotaidis V, Ballot H, Plech A (2006) Turkevich method for gold nanoparticle synthesis revisited. J Phys Chem B 110(32):15700–15707. https://doi.org/10.1021/jp061667w

Shi C, Zhu N, Cao Y, Wu P (2015) Biosynthesis of gold nanoparticles assisted by the intracellular protein extract of Pycnoporus sanguineus and its catalysis in degradation of 4-nitroaniline. Nanoscale Res Lett 10(1):147. https://doi.org/10.1186/s11671-015-0856-9

Punuri JB, Sharma P, Sibyala S, Tamuli R, Bora U (2012) Piper betle-mediated green synthesis of biocompatible gold nanoparticles. Int Nano Lett 2(1):18. https://doi.org/10.1186/2228-5326-2-18

Rajeshkumar S, Malarkodi C, Gnanajobitha G, Paulkumar K, Vanaja M, Kannan C, Annadurai G (2013) Seaweed-mediated synthesis of gold nanoparticles using Turbinaria conoides and its characterization. J Nanostruct Chem 3(1):44. https://doi.org/10.1186/2193-8865-3-44

Jasuja K, Linn J, Melton S, Berry V (2010) Microwave-reduced uncapped metal nanoparticles on graphene: tuning catalytic, electrical, and Raman properties. J Phys Chem Lett 1(12):1853–1860. https://doi.org/10.1021/jz100580x

Grzelczak M, Perez-Juste J, Mulvaney P, Liz-Marzan LM (2008) Shape control in gold nanoparticle synthesis. Chem Soc Rev 37(9):1783–1791. https://doi.org/10.1039/B711490G

Mali PY, Panchal SS (2017) Euphorbia tirucalli L.: review on morphology, medicinal uses, phytochemistry and pharmacological activities. Asian Pac J Trop Biomed 7(7):603–613. https://doi.org/10.1016/j.apjtb.2017.06.002

Wal A (2013) Medicinal value of Euphorbia tirucalli. Int J Pharm Biol Arch 4(1)

Rajasekaran P, Swaminathan KR, Jayapragasam M (1989) Biogas production potential of Euphorbia tirucalli L. along with cattle manure. Biol Wastes 30(1):75–77

Jyothi TM, Shankariah MM, Prabhu K, Lakshminarasu S, Srinivasa GM, Ramachandra SS (2008) Hepatoprotective and antioxidant activity of Euphorbia tirucalli. IJPT 7(1):25–30

Tu W, Liu H (2000) Rapid synthesis of nanoscale colloidal metal clusters by microwave irradiation. J Mater Chem 10(9):2207–2211. https://doi.org/10.1039/B002232M

Augustine AK, Nampoori VPN, Kailasnath M (2014) Rapid synthesize of gold nanoparticles by microwave irradiation method and its application as an optical limiting material. Optik Int J Light Electron Optics 125(22):6696–6699. https://doi.org/10.1016/j.ijleo.2014.08.075

Daniel M-C, Astruc D (2004) Gold nanoparticles: assembly, supramolecular chemistry, quantum-size-related properties, and applications toward biology, catalysis, and nanotechnology. Chem Rev 104(1):293–346. https://doi.org/10.1021/cr030698+

Leng W, Pati P, Vikesland PJ (2015) Room temperature seed mediated growth of gold nanoparticles: mechanistic investigations and life cycle assesment. Environ Sci : Nano 2(5):440–453. https://doi.org/10.1039/C5EN00026B

Acknowledgments

The authors thank the Brazilian National Council for Scientific and Technological Development (CNPq), the Brazilian Coordination for the Improvement of Higher Educational Personnel (CAPES), the Federal District Research Foundation (FAPDF), and the University of Brasilia Grant Commissions for the financial support. The authors also thank the LabMic/UFG for conducting the TEM analysis.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lunardi, C.N., Barros, M.P.F., Rodrigues, M.L. et al. Synthesis of gold nanoparticles using Euphorbia tirucalli latex and the microwave method. Gold Bull 51, 131–137 (2018). https://doi.org/10.1007/s13404-018-0231-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13404-018-0231-6