Abstract

Silver nanoparticles have been successfully synthesized in aqueous medium by a green, rapid and cost-efficient synthetic approach based on microwave irradiation. In this study, iota-carrageenan (I-carrageenan) is used both as reducing and stabilizing agent. The formation of nanoparticles is determined using UV–vis, Fourier transform infrared (FTIR), X-ray diffraction (XRD), energy-dispersive X-ray (EDX) and high-resolution-transmission electron microscopic (HR-TEM) analysis. Transmission electron microscopic (TEM) images show that the nanoparticles are of spherical shape with an average diameter of 18.2 nm. I-carrageenan-stabilized silver nanoparticles show outstanding catalytic activity for the reduction of 4-nitrophenol in the presence of NaBH4 in aqueous medium. The reaction follows pseudo-first-order kinetics and the reaction rate increases with the increase in amount of the catalyst. The study of the temperature dependence of reaction rate gives activation energy of 42.81 kJ mol−1. The synthesized silver nanoparticles are anticipated to be a promising material for pollution abatement.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Nanoscience and nanotechnology has emerged as one of the most active areas of research all over the globe in the last decades. This is due to the unique properties of nano-sized particles and because of their potential applications in various fields such as catalysis,[1] optics[2] and biomedical.[3] Nanomaterials may provide solutions to many of our technological and environmental challenges. Among noble metal nanoparticles, silver has received considerable attention owing to its interesting physicochemical properties and the strong toxicity to a wide range of microorganisms. The chemical and physical properties of silver nanoparticles (AgNPs) are highly dependent on their size and shape, and these are strongly influenced by the experimental conditions. In recent years, a number of methods have been explored to synthesize silver nanostructures of suitable size and morphology. These include chemical reduction,[4] polyol process,[5] electrochemical,[6] photochemical,[7]sonochemical[8] and biological methods.[9] The synthesis and the application of AgNPs require the stabilization of them in suitable protecting systems. Systems such as polymers,[10–12]hydrogels,[13] microgels,[14] dendrimers,[15] etc. were used for this purpose. Among these, the most popular method for the preparation of Ag colloids is chemical reduction of silver salt in the presence of a stabilizing agent. The advantage of chemical method is that it takes short time for the synthesis of large amount of nanoparticles. However, the chemical reagents used in this method as reducing and stabilizing agents are highly toxic and pose huge environmental hazards. Therefore, it is necessary to develop environmentally benign synthetic strategies for the preparation of AgNPs, especially in large scale.

Green synthesis is more advisable than chemical methods as it is cost effective, eco-friendly and thus can be easily scaled up for bulk synthesis. In green synthesis, three important rules of green chemistry should be considered including (i) selection of an environmentally benign solvent medium, (ii) selection of a non-toxic reducing agent and (iii) selection of a cost effective and easily renewable stabilizing agent for AgNPs.[16]With the increase in focus on greener methods, natural compounds,[17] plant extracts[18] and microorganisms[19] have aroused much interest as safer alternatives to chemical reducing and stabilizing agents. But one main drawback of biological methods is the longer reaction time. Microwave-assisted synthesis is particularly important in this regard. Microwave-assisted synthesis using biomaterials as both reducing and capping agents is a feasible way for the rapid and facile green synthesis of AgNPs. It provides several desirable features such as shorter reaction time, lower energy consumption and better product yield. Microwave irradiation offers rapid and uniform heating of the reaction medium and thus provides uniform nucleation and growth conditions for nanoparticles. Transfer of energy from the microwave radiation to the reactants is achieved through the interaction of radiation with water or other solvents with high dielectric constant or solvent molecules with large dipole moments.[20] In recent years, many flourishing reports on microwave-assisted green synthesis of AgNPs have been published.[21–24]

Nitrophenols are considered to be one of the most hazardous and toxic unmanageable organic pollutants in waste waters generated from agricultural and industrial sources, including those manufacturing dyes, explosives, pesticides and other products. These pollutants are chemically stable and so traditional water treatment methods are usually ineffective. Therefore, developing an efficient and eco-friendly method for removing these pollutants from waste water is of immense importance from the view point of pollution abatement. In recent times, nanotechnology has been extended to the area of waste water treatment. Several groups reported the use of nanomaterials for the elimination of nitrophenols from water by reducing them into aminophenols which is an important intermediate in drug industry.[25–30]

In the present study, we report a facile green method for the synthesis of AgNPs in aqueous medium. Here, AgNPs are synthesized by microwave irradiation using iota-carrageenan (I-carrageenan) as both reducing and stabilizing agent. I-carrageenans are sulphated linear polysaccharides extracted from certain red edible seaweeds. The structure is built up of alternating 1,3-linked β-D-galactopyranosyl and 1,4-linked α-D-galactopyranosyl units. I-carrageenan has two sulphates per disaccharide. The presence of hydroxyl and sulphate groups in carrageenan structure makes them likely to be hydrophilic. Hydrogels produced from I-carrageenan are soft, flexible and fast setting. They have been extensively used in the food industry as a thickening and gelling agent. In recent times, they are used as excepient in pills and tablets. Because I-carrageenan is an easily renewable naturally occurring biopolymer, this method offers a simple, environmentally friendly and cost-effective method for the synthesis of AgNPs. The catalytic efficiency of the synthesized nanoparticles was investigated using the reduction of 4-nitrophenol to 4-aminophenol by NaBH4.

2 Materials and methods

2.1 Materials

Silver nitrate (AgNO3), 4-nitrophenol and sodium borohydride (NaBH4) of analytical grade were purchased from Merck India Ltd. I-carrageenan was obtained from Himedia Chemicals (Mumbai, India). Double distilled water was used for all experiments.

2.2 Methods

2.2.1 Synthesis of AgNP-carrageenan

In a typical synthesis, 0.1 g of carrageenan was dissolved in 90 ml of hot water in a beaker. To this, 10 ml of 0.05 M AgNO3 solution was added so as to keep the concentration of AgNO3 in the reaction mixture as 0.005 M and the solution was stirred for 15 min. The reaction mixture was then placed in a domestic microwave oven (Sharp R-219T (W)) operating at a power of 800 W and frequency 2450 MHz and was subjected to microwave irradiation for 2 min. Upon microwave irradiation, the colourless solution turned into dark brown, indicating the reduction of silver ions into silver colloids. The formation of AgNPs was monitored using UV–vis spectrophotometer by analysing the reaction mixture after different irradiation times.

2.2.2 Reduction of 4-nitrophenol to 4-aminophenol

The reduction of 4-nitrophenol to 4-aminophenol by NaBH4 was used to study the catalytic activity of AgNP-carrageenan. To follow this reaction, 2 ml of 4-nitrophenol (0.08 × 10−3 M) was taken in a quartz cuvette of 1 cm path length and to this 0.5 ml freshly prepared NaBH4 solution (0.06 M) was added. Then 0.5 ml of AgNP-carrageenan hydrosol was added to start the reaction. The reaction was monitored by analysing the absorption peak at 400 nm using UV–vis spectrophotometer. The absorption spectra were taken in 1 min intervals in the range of 200–600 nm at 24°C.

2.2.3 Characterization

The UV–vis spectra were recorded on a Shimadzu UV-2450 spectrophotometer. Fourier transform infrared (FTIR) spectra were measured using Perkin-Elmer-400 spectrometer with ATR facility. Energy-dispersive X-ray (EDX) measurement was carried out using JEOL JSM-6390 scanning electron microscope (SEM) with EDX attachment. X-ray diffraction (XRD) measurements were carried out using PANalytic XPERT-PRO X-ray spectrometer. High-resolution transmission electron microscopic (HR-TEM) images were obtained using a JEOL JEM-2100 microscope.

3 Results and discussion

3.1 Synthesis of AgNPs

The evidence for the successful formation of carrageenan-stabilized AgNPs (AgNP-carrageenan) is obtained from UV–vis absorption spectral studies. The UV–vis absorption spectra of the solution recorded at 1 min intervals during microwave irradiation process are shown in figure 1. No obvious absorption is observed in the range of 250–600 nm for I-carrageenan. After microwave irradiation for 1 min, an absorption band was observed at about 416 nm and the intensity of which became stronger with passage of reaction time. This prominent absorption band is attributed to the characteristic surface plasmon resonance (SPR) absorption of silver nanoparticles. Also, there is no obvious absorption in the range of 450–800 nm, which indicates that negligible aggregation occurs in this reaction system and the nanoparticles are well dispersed.[31] Initially when AgNO3 was added to carrageenan solution, the solution remained colourless. But upon microwave irradiation, the colourless solution gradually changes to dark brown. This colour difference also indicates the formation of AgNPs. The silver colloids are found to be stable for 3 months due to efficient capping by I-carrageenan molecules. These results indicate that I-carrageenan is able to reduce Ag+ ions into Ag nanoparticles and it is also a good stabilizer for the generated AgNPs. When AgNO3 solution is added to I-carrageenan solution, Ag+ ions get entrapped within the carrageenan chain because the polar –OH groups and electron-rich oxygen atoms on the carrageenan chain act as templates for the incoming Ag+ ions. The sulphate groups of carrageenan efficiently reduce the Ag+ ions into Ag under the influence of microwave radiation which combines to form highly dispersed AgNPs. The problem of inhomogeneous heating with conventional thermal methods is overcome in microwave method. The use of microwave radiation provides increased reaction kinetics, rapid initial heating and hence enhanced reaction rates with rapid consumption of starting materials.[32] This will prevent agglomeration of nanoparticles to a greater extent resulting in monodispersed AgNPs. Thus microwave irradiation is an effective and economically viable heating method for the production of nanomaterials.

3.2 FTIR spectral studies

The FTIR spectrum of I-carrageenan (figure 2) shows a broad band at 3200–3400 cm−1. This is due to stretching vibrations of OH groups of I-carrageenan. The peak observed at 2930 cm−1 is attributed to the C–H stretching vibrations of CH2 groups. A strong band observed at 1386 cm−1 is characteristic of asymmetric stretching vibrations of S=O group of sulphate esters. The strong band at 1023 cm−1 is ascribed to stretching vibrations of C–O–C glycosidic linkage and that at 843 cm−1 is due to C–O–S vibrations of D-galactose-4-sulphate. The spectrum of AgNP-carrageenan is almost similar to that of pristine I-carrageenan. However one can see some minor shifts in the various stretching frequencies especially that for the peaks due to S=O group and C–O–C glycosidic linkage. These observations afford an obvious indication for the formation and stabilization of AgNPs by I-carrageenan.

3.3 XRD pattern

XRD study was performed to confirm the crystalline nature of AgNPs. In figure 3, four distinct XRD peaks are clearly observed at 2𝜃 values of 38.30°, 44.32°, 64.56° and 77.53°. These peaks are indexed, respectively, to the reflections of the (111), (200), (220) and (311) crystallographic planes of face centred cubic (fcc) silver particles. All diffraction peaks are in good agreement with the standard values (JCPDS file no. 04-0783). The intensity of the peak due to reflections of (111) plane is relatively higher than that of other planes. This indicates that the AgNPs are enriched in (111) facets and the (111) plane appears to be preferentially oriented parallel to the surface of the supporting material.

3.4 EDX analysis

The elemental characterization of the synthesized AgNPs was conducted by EDX analysis. The peaks located between 2.6 and 3.6 keV in the EDX spectrum of AgNP-carrageenan (figure 4) are directly related to the characteristic K and L lines of silver. The maximum observed at about 0.3 keV is characteristic of carbon. The peak located at about 0.5 keV is related with oxygen. The carbon and oxygen signals observed in the spectrum of the sample originate from carrageenan. This confirms the stabilization of AgNPs by carrageenan chains.

3.5 HR-TEM analysis

The size and morphology of the synthesized AgNPs were investigated using HR-TEM analysis. The TEM images of AgNP-carrageenan are given in figure 5. As is clear from figure 5a, the nanoparticles are more or less uniformly distributed and they are almost spherical in shape. They are also highly crystalline. The particle size histogram drawn using the data obtained from the TEM image is shown in figure 5b. The average particle size is observed as 18.2 nm ± 2. As can be seen, nearly 60% of the particles have diameter between 16 and 20 nm and the size distribution plot appears to be almost symmetrical with all the nanoparticles coming within the range of 14–24 nm. The HR-TEM image (figure 5c) shows clear lattice fringes. The fringe spacing is measured as 2.39 A°. This spacing corresponds to that between (111) planes of fcc silver (JCPDS file no. 04-0783). This also reveals that the crystal growth of nanoparticles occurred mainly on the (111) plane. The selected area electron diffraction (SAED) pattern is shown in figure 5d. The diffraction rings are visible clearly and these can be indexed to the (111), (200), (220) and (311) reflections of fcc AgNPs. All these results give a clear indication of the highly crystalline nature of the AgNPs synthesized by this method.

3.6 Catalytic reduction of 4-nitrophenol to 4-aminophenol

To investigate the competence of AgNP-carrageenan as a catalyst, the reduction of 4-nitrophenol by NaBH4 was selected as a model reaction. The UV–vis absorption spectrum of 4-nitrophenol has maximum absorption at 317 nm. When NaBH4 was added to the aqueous solution of 4-nitrophenol, the yellow colour of the solution became more intense and the peak due to 4-NP was shifted to 400 nm (figure 6). This is due to the formation of 4-nitrophenolate ions under the alkaline condition created on the addition of NaBH4.[33]

The intensity of the peak at 400 nm due to 4-nitrophenolate ion remained almost unchanged even after several hours indicating that NaBH4 alone is unable to effectively reduce 4-nitrophenol (4-NP) to 4-aminophenol (4-AP). But the reduction reaction started immediately upon the addition of a small amount of AgNP-carrageenan catalyst. This is evident from the fading and ultimate bleaching of the yellow colour of the reaction mixture. The UV–vis absorption spectra for the NaBH4 reduction of 4-NP at 24°C catalysed by 0.03 mg ml−1 AgNP-carrageenan is shown in figure 7. The spectrum was recorded every 1 min after the addition of the catalyst to the reaction medium in order to follow the progress of the reaction.

It is evident from the figure that, after the addition of AgNP-carrageenan catalyst, the intensity of the peak at 400 nm decreases continuously with time and a new peak appears at 292 nm whose intensity increases with elapse of time. This new peak is due to the formation of the product 4-aminophenol (equation (1)). The reaction is found to be complete in 9 min.

As reaction progresses, not only a decrease in the intensity of the peak at 400 nm but also a blue shift of the peak from 400 to 382 nm was observed. The peak at 382 nm is not that of 4-nitrophenol. This peak is due to the surface plasmon resonance (SPR) of silver hydrosol. In the intermediate stage of the reaction, the SPR band of AgNPs is not observed because it remains masked under the absorption band of 4-nitrophenolate ion. But finally, this band become visible when all the reactants are converted to 4-AP. The SPR band of AgNP-carrageenan is actually at 416 nm. When AgNP-carrageenan is added as catalyst to the reaction mixture containing 4-NP and excess of NaBH4, the borohydride ions inject electrons on to the catalyst surface. This leads to a blue shift in the SPR band of AgNP-carrageenan from 416 to 382 nm.[34]

The mechanism of this reduction reaction involves the initial adsorption of both 4-nitrophenolate ions and BH\(_{4}^{-}\) ions on the catalyst surface. Because of the close proximity of the reacting groups on the catalyst surface, the reduction reaction becomes very easy. The catalyst helps this reduction process by relaying electrons from the donor BH\(_{4}^{-}\) ions to the acceptor 4-nitrophenolate ions.

The kinetics of this reaction can be followed quantitatively by monitoring the change in the intensity of the peak at 400 nm with time. In this study, the concentration of NaBH4 largely exceeds that of 4-NP. As the initial concentration of NaBH4 is very high, it remains essentially constant during the course of the reaction. Hence pseudo-first-order kinetics with respect to 4-nitrophenol could be used to evaluate the reaction rate. The kinetics of the reaction can be represented using the equation ln[A]/[ A ∘] = −kt, where k is the first-order rate constant, t is the reaction time, [ A ∘] is the concentration of 4-NP at time t = 0 and [A] is the concentration at time t. The value of [A] can be obtained from the absorbance of the peak at 400 nm.

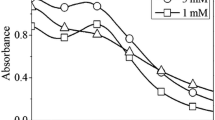

To study the effect of amount of the catalyst upon rate of the reduction reaction, the reaction was conducted by varying the concentration of AgNP-carrageenan hydrosol in the reaction mixture, keeping other parameters constant. The reaction rate was analysed by following the decrease in the absorbance value at 400 nm with time. As shown in figure 8, a linear relation between ln[A] and time has been observed in all catalytic reactions studied. This confirms the pseudo-first-order nature of the reaction. The first-order rate constant k for these reactions is obtained from the slope of the linear plots.

The first-order rate constant obtained from the slope of ln[A] vs. time plot for different amounts of catalyst and the corresponding correlation coefficients are given in table 1.

It is clear from the table that, these reactions are very fast and strictly follows pseudo-first-order kinetics. Also, the values of the rate constant obtained for different concentrations of the catalyst are plotted in figure 9. We can see that, the rate constant increases with the increase in the concentration of the catalyst. Moreover, a strictly linear relation between k and the concentration of catalyst can be observed. The reaction time decreases with the increase in the amount of catalyst. The absorbance value of the peak observed at 389 nm after complete reduction of 4-NP due to surface plasmon resonance of nano-silver increases with the increase in catalyst concentration. This is due to the presence of more amount of catalyst in the reaction medium after the reduction process.

Furthermore, initially an induction time (IT), the time taken to observe any appreciable change in the absorbance at 400 nm was found for all the catalytic reaction when carried out under air and after that the rate increases gradually with time. This observation has been made by several other research groups.[7,28,34,35]It was also found that the induction time in nitrogen atmosphere is less and negligible in comparison to that in ambient condition.[34] This is because of the surface oxidation of the catalyst in oxygen atmosphere resulting in the formation of oxide layer on the catalyst surface which may poison the catalyst. NaBH4 reduces the oxide layer and regenerate fresh catalyst surface for the adsorption of reactants. Another reason for the IT is the time taken for the reduction of O2 by NaBH4.[36] The reduction of 4-NP starts only after O2 is removed from the reaction medium by reduction. Because NaBH4 is taken in large excess, its consumption for the above processes does not alter its concentration appreciably. Moreover, the hydrogen liberated during the reduction process scavenges O2 and thus prevent the oxidation of the reduction product as well as the catalyst. IT is observed to decrease with increase in the catalyst concentration as well as temperature.

To study the effect of temperature on the rate of AgNP-carrageenan catalysed reduction of 4-nitrophenol, the reaction was carried out at four different temperatures (24, 26, 28 and 30°C) and the pseudo-first-order rate constant was calculated in each case. The activation energy ( E a) for the reaction can be calculated using the well-known Arrhenius equation

In this equation, k is the rate constant, R the gas constant (8.314 J K−1 mol−1), T the absolute temperature and A the Arrhenius parameter. From equation (2), it follows that the plot of ln k vs. 1/T should yield a straight line, the slope of which is equal to −E a/R. From this, E a can be evaluated. The values of ln k obtained in our study at different temperatures are plotted against 1/T in figure 10. As is clear, the value of k increases with the increase in temperature showing that the reaction is accelerated by increasing temperature.

From the Arrhenius plot, the activation energy for the reaction is calculated to be 42.81 kJ mol−1. Pradhan et al[34] studied the AgNP catalysed reduction of 4-nitrophenol and reported the activation energy of 41 kJ mol−1. Shin et al[36] also studied the same reaction using silver-deposited magnetic nanoparticles and the activation energy was found to be 45 kJ mol−1. However, Sahiner and group[37] conducted the reduction of 4-NP using polyacrylamidoglycolic acid–silver composite and reported the activation energy of 33.8 kJ mol−1. The result obtained in our study is in good agreement with the results of Pradhan et al. [34]

4 Conclusions

In this study, we have reported a rapid facile microwave based method for the green synthesis of AgNPs in aqueous medium which are stable for a long period. This method uses the easily renewable biopolymer I-carrageenan as both reducing and capping agent. The various characteristics of the synthesized silver colloids are analysed by UV–vis, FTIR, XRD, EDX and TEM analyses. The catalytic activity is scrutinized using the reduction of 4-nitrophenol to 4-aminophenol by NaBH4 as a model reaction. The reaction follows pseudo-first-order kinetics and the rate constant is found to increase as the concentration of the catalyst increases. The temperature dependence of reaction rate is studied by conducting the reaction at four different temperatures. The rate of reaction is found to increase with the increase in temperature and the activation energy is found to be 42.81 kJ mol−1. Since this method for the synthesis of nanoparticles is relatively simple, fast and economic, this has the potential for the bulk production of silver colloids and their industrial application as a catalyst for the reduction of toxic nitrocompounds.

References

Esumi K, Miyamoto K and Yoshimura T 2002 J. Colloid Interface Sci. 254 402

Eychmuller A 2000 J. Phys. Chem. B 104 6514

Salata O V 2004 J. Nanobiotechnol. 2 3

Pastoriza-Santos I and Liz-Marzan L M 2002 Langmuir 18 2888

Sun Y and Xia Y 2002Adv. Mater. 14 833

Yin B, Ma H, Wang S and Chen S 2003 J. Phys. Chem. B 107 8898

Kundu Mandal M, Ghosh S K and Pal T 2004 J. Colloid Interface Sci. 272 134

Okitsu K, Yue A, Tanabe S and Matsumoto H 2000 Chem. Mater. 12 3006

Shankar S S, Rai A, Ahmad A and Sastry M 2004 J. Colloid Interface Sci. 275 496

Debnath D, Kim C and Kim S H 2010 Macromol. Rapid Commun. 31 549

Luo C, Zhang Y, Zeng X, Zeng Y and Wang Y 2005 J. Colloid Interface Sci. 288 444

Rastogi P K, Ganesan V and Krishnamoorthi S 2012 Mater. Sci. Eng. B 177 456

Bajpai S K, Bajpai M and Gautam D 2013 J. Macromol. Sci.: Pure Appl. Chem. 50 46

Khan A, El-Toni A M, Alrokayan S, Alsalhi M, Alhoshan M and Aldwayyan A S 2011 Colloids Surf. A 377 356

Esumi K, Isono R and Yoshimura T 2004 Langmuir 20 237

Raveendran P, Fu J and Wallen S L 2003 J. Am. Chem. Soc. 125 13940

Vigneshwaran N, Nachane R P, Balasubramanya R H and Varadarajan P V 2006 Carbohydr. Res. 341 2012

Vidhu V K, Aromal S A and Philip D 2011 Spectrochim. Acta A 83 392

Vigneshwaran N, Ashtaputre N M, Varadarajan P V, Nachane R P, Par-Alikar K M and Balasubramanya R H 2007 Mater. Lett. 61 1413

Galema S A 1997 Chem. Soc. Rev. 26 233

Sreeram K J, Nidhin M and Nair B U 2008 Bull. Mater. Sci. 31 937

Hu B, Wang S, Wang K, Zhang M and Yu S 2008 J. Phys. Chem. C 112 11169

Peng H, Yang A and Xiong J 2013 Carbohydr. Polym. 91 348

Siby J and Beena M 2014 J. Mol. Liquids 197 346

Ghosh S K, Mandal M, Kundu S, Nath S and Pal T 2004 Appl. Catal. A 268 61

Saha S, Pal A, Kundu S, Basu S and Pal T 2010 Langmuir 26 2885

Wunder S, Polzer F, Lu Y, Mei Y and Ballauff M 2010 J. Phys. Chem. C 114 8814

Wei D, Ye Y, Jia X, Yuan C and Qian W 2010 Carbohydr. Res. 345 74

Sen I K, Maity K and Islam S S 2013 Carbohydr. Polym. 91 518

Nemanashi M and Meijboom R 2013 J. Colloid Interface Sci. 389 260

Gutierrez M and Henglein A 1993 J. Phys. Chem. B 97 11368

Nadagouda M N, Speth T F and Varma R S 2011 Acc. Chem. Res. 44 469

Pradhan N, Pal A and Pal T 2001 Langmuir 17 1800

Pradhan N, Pal A and Pal T 2002 Colloids Surf. A 196 247

Lu Y, Mei Y, Walker R, Ballauff M and Drechsler M 2006 Polymer 47 4985

Shin K S, Choi J Y, Park C S, Jang H J and Kim K 2009 Catal. Lett. 133 1

Butun S and Sahiner N 2011 Polymer 52 4834

Acknowledgement

This work was supported by UGC Bangalore, Government of India, under FIP scheme.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

JOSEPH, S., MATHEW, B. Microwave-assisted facile green synthesis of silver nanoparticles and spectroscopic investigation of the catalytic activity. Bull Mater Sci 38, 659–666 (2015). https://doi.org/10.1007/s12034-015-0892-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12034-015-0892-1