Abstract

A fast and effective microextraction (ME) technique coupled with ultrasonication (US) was applied for extracting a commercially valuable antioxidant compound lutein, from marine microalgae Chlorella salina (C. salina). The extraction of lutein from C. salina was studied in detail under various operating conditions. Several variables influencing the relative response of the target analyte such as temperature (T = 20–60 °C), time (10–50 min), and frequency (15–55 kHz) were optimized. Results showed maximum yield at temperature 40 °C, extraction time of 30 min duration with 35-kHz frequency. Under optimal conditions, the concentration of lutein was 2.92 ± 0.40 mg/g D.W (dry weight). The results obtained are beneficial for the full utilization of Chlorella biomass, which also indicated that ultrasound-assisted microextraction (US-ME) is a very useful method for extracting lutein from microalgae.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Microalgae are the established commercial sources of high-regard chemicals, for instance, lutein, β-carotene, astaxanthin, docosahexaenoic acid, phycobilin pigments, and algal concentrates, for use in beauty care products. Lutein is a commercially available, high-value product. It belongs to the group of the carotenoids and is responsible for their natural yellow to orange color [1]. The carotenoid lutein has potential nutraceutical and pharmaceutical applications including prevention and treatment of age-related blindness, cataracts, atherosclerosis, and some types of cancers [2,3,4]. Lutein is very effective in neutralizing the reactive oxygen species, and a high concentration of lutein in the macula lutea protects against age-related macular degeneration [5,6,7]. Thus, diets containing lutein may help reduce these health-related problems of the eye [8]. The most typical feature of lutein as well as other carotenoids is the long polyene chain. Such a conjugated double-bond system determines the photochemical properties and chemical reactivity that give the basic biological functions of carotenoids, such as antioxidant activities [9]. It is also used for nutraceutical and pharmaceutical applications. Because of significant useful applications of lutein, extraction of β-carotene has been a topic of interest for many researchers and a lot of efforts have been made for extracting these pigments from various raw materials. Different extraction techniques such as simple solvent extraction, supercritical fluid extraction, and microwave-assisted extraction have been used with limited success.

Application of ultrasound for the intensification of the extraction is becoming popular and ultrasound-assisted extraction (UAE) has been used extensively for enhancing the rate and yield of extraction of different compounds from plant materials [10]. Recent studies also show that ultrasonic treatment improves the efficiency of liquid-liquid extraction [11, 12], aqueous two-phase extraction [13], and enzymatic extraction [14] etc. In recent years, with the developing interest in miniaturization in analytical chemistry for solvent and sample savings, some newer miniaturized approaches to liquid extraction have been reported. Microextraction techniques are gaining importance since they are fast, simple, inexpensive, environmentally friendly, and compatible with many analytical instruments [15]. Solvent microextraction was first introduced by Jeannot and Cantwell [16], and it is based on analyte partition between a drop of organic solvent (extraction phase) and the aqueous sample bulk.

The microextraction technique coupled with ultrasound is based on the use of ultrasonic (US) radiation for accelerating the emulsification phenomenon. During the sonication stage, the solution becomes turbid due to the dispersion of fine extraction solvent droplets into the aqueous bulk. The emulsification phenomenon favors the mass-transfer process of the analytes from the aqueous bulk into the organic phase. This leads to an increase in the extraction efficiency of the technique in a minimum time [17, 18]. By combining the benefit of microextraction and ultrasound radiation, it is possible to establish an efficient preconcentration technique for determining analytes at trace concentration levels. The enhancement in extraction obtained by using ultrasound is primarily attributed to the impacts of acoustic cavitations produced in the solvent by the ultrasonic wave. Ultrasound also exerts a mechanical effect, allowing greater penetration of solvent into the sample matrix, increasing the contact surface area between solid and liquid phase [19]. Ultrasound-assisted extraction (UAE) has been found to be a more effective and environmentally friendly way of extracting natural antioxidants from samples for its characteristics of shorter extraction time and less utilization of organic solvents [20,21,22,23,24,25,26]. Ultrasound-assisted extraction was also adopted to extract carotenoids, chlorophyll a, and lipids from microalgae, such as Dunaliella salina, Botryococcus sp., Chlorella vulgaris, and Scenedesmus sp. [27, 28].

Hence, the main objective of the present work was to study the effect of US-ME conditions for extraction of total lutein content of the C. salina. The study includes understanding the effect of different parameters such irradiation frequency, extraction time, and extraction temperature on the extraction yield. Conventional extraction was also applied to compare its effectiveness with the optimum extraction conditions.

2 Materials and methods

2.1 Microalgae cultivation

Prior to use, the stock cultures were maintained at 22 ± 2 °C under artificial light with a photoperiod consisting of a 16:8-h light-dark cycle. The Walne’s culture media was used for the production of inoculum from a volume of 20 mL until it reaches to 200 mL and, afterwards, was transferred to a 3-L flask when the culture volume reached 350 mL. The culture in the 3-L glass flask was subjected to constant aeration at an air flow rate of 2 L/min. Illumination was set at 20 lE/cm2 s and was provided by 40-W fluorescent lamps. The room temperature was maintained at 22 ± 2 °C, and the cultivation was carried out at constant volume.

2.2 Determination of total lutein content of C. salina

To protect carotenoids from degradation and oxidation, the extraction was carried under low light. Approximately, 0.1 g of sample was weighed in a 2-mL microcentrifuge tube, 1 mL of methanol, and 0.5 ml of a solution containing 2.5% ascorbic acid and 10 M KOH was added. The mixture was subjected to agitation at maximum speed for 1 min, and then, the mixture was centrifuged at 10000 rpm, 4 °C for 2 min. The extraction procedure was repeated three or four times until the extract no longer exhibited the characteristic color of carotenoids. Then, the extract was washed three times using ultrapure water or until the wash water became translucent. The extract was allowed to stand for 3 min before water decantation. The supernatant (organic phase) was then purged with nitrogen gas, and the precipitate was dissolved in acetone for further analysis using HPLC. All analyses were performed in triplicate.

2.3 Ultrasound-assisted microextraction of lutein using ultrasonic bath

Ultrasonic-assisted extraction of lutein was performed using digital ultrasonic bath capable of operating at varying frequencies. The main influence factors of extraction were temperature, duration, and ultrasonic power. Effect of different solvents, duration of ultrasound-assisted extraction (20, 30, 40, 50, and 60 min), temperature (20, 30, 40, 50, and 60 °C), and ultrasonic irradiation frequency (15, 25, 35, 45, and 55 kHz) was investigated using one variable at a time (OVAT) analysis. A 30-min extraction time, 40 °C temperature, and 35-kHz frequency are the general parameters used for all optimization experiment based on the OVAT analysis.

2.4 Conventional solvent extraction

The conventional solvent extraction was carried out according to Yu et al. [29] with some modifications. 0.1 g of biomass with 1 ml of solvent and the temperature was set constant at 40 °C for 30 min; then, the supernatant was collected and stored for further analysis.

2.5 HPLC analysis of lutein

The carotenoid extracts were then determined by high-performance liquid chromatography (Waters-2545, USA). Separation was performed using a C18 column (5 μm, 150 mm × 46) at 30 °C. The mobile phase consisted of methanol/acetonitrile (90:10 V/V). The extracts were eluted at a flow rate of 1 ml/min, and the lutein content was detected by measuring absorbance at the wavelength range of 220–750 nm. The maximal absorbance (450 nm) was chosen for quantification of lutein extracts [30].

where A = absorbance at 450 nm, V = volume of extract in milliliters, ε = absorption coefficient (2589), and W = dry weight of sample.

3 Results and discussion

The efficiency of the US-ME technique was found to be affected by several variables, including type of extraction solvent and its extraction solvent volume, extraction time temperature, and irradiation frequency as well. The abovementioned variables were optimized by modifying each factor at a time while keeping the remaining ones constant. With the introduction of ultrasound, lutein yield rises rapidly. Because of the increase in sound power, sound intensity and the effect of ultrasonic vibration increase, leading to accelerated movement of solute molecules and the enhancement of the mass transfer inside the material, thereby improving the yield of lutein. This result is consistent with the findings of many other researchers on natural product extraction [31,32,33,34].

3.1 Effect of different solvent in US-ME

The solubility of a certain compound in a particular solvent varies with the nature of the solvent, i.e., a polar solute is soluble in polar solvents whereas a non-polar solute dissolves in non-polar solvents. But the complex structure of natural products and chemical characteristics of the solvent make it difficult to predict the chemical interaction between them. The effect of different solvents on the extraction yield was investigated using different solvents like hexane, diethyl ether, acetone, dichloromethane, ethanol, and methanol, with 4–6 extraction runs until the supernatant phase were colorless. Results shows that the maximum extraction is obtained using methanol (2.76 mg/g D.W) followed by hexane (2.01 mg/g D.W). Solubility of the solute in the solvent plays an important role in the extraction process. The solubility of lutein is higher in methanol than in other solvents. It has been reported by Luo et al. [35] that the solvent viscosity, surface tension, and vapor pressure affect the cavitation. A solvent that has high surface tension and high viscosity probably has an increased energy barrier for the formation of cavities, which is unfavorable for cavitation [35]. The higher extraction obtained for methanol is probably due to its higher polarity, lower viscosity, and lower surface tension as compared to other solvents. Hence, for further experiments, methanol was used as solvent.

3.2 Effect of ultrasound irradiation time

Extraction time is also an important variable in US-ME procedure. It plays an important role in the mass transfer phenomena, influencing the extraction efficiency. The effect of time on lutein yield was examined, while the algal biomass was disrupted by methanol. The sample was subjected to ultrasound treatment for 10, 20, 30, 40, 50, and 60 min to find out the optimum extraction time required to achieve maximum recovery of lutein from algal biomass. Operating conditions maintained during the study were temperature of 40 °C, and frequency was 30 kHz. The obtained results for the variation in extraction of lutein have been shown in Fig. 1. It can be seen from the figure that extraction yield increases significantly by increasing the extraction time; the relative response could be increased, reaching the maximum value at 30 min; after which, it decreased sharply with a further extension of extraction time, since a long time for disrupting may lead to oxidative degradation of lutein. It was observed that the extraction rate is high initially when the solvent is relatively fresh, and as the extraction continues, the concentration of the lutein in the solvent increases and concentration gradient for lutein between the solvent and the biomass decreases which results in slowing down the process. So disrupting time of 30 min resulted in the maximal lutein concentration of 2.92 mg/g D.W. The results indicate that under the ultrasound irradiation treatment, the diffusion of the bioactive compounds from material to solvent might be improved and the equilibrium for dissolution might be established in a short time. But the antioxidant compounds might be degraded due to prolonged exposure to ultrasonic irradiation. A similar result was presented in research by Deenu et al. [31] in which when the temperature was fixed, the lutein yield increased until a certain amount of time and then decreased. This could be explained as the chemical decomposition of the bioactive compound present in the extract may occur as the extraction time prolongs, resulting in a decrease in the extraction yield. At 30 min, maximum extraction was obtained, and hence, it was selected as optimum extraction time for US-ME.

3.3 Effect of ultrasound irradiation temperature

Extraction temperature is also an important parameter that affects the extraction procedure, since it affects kinetics of the mass transfer process. Additionally, it concerns the analyte and the solubility of organic solvent in the sample. Therefore, it was found important to study this variable in the perspective of the microextraction technique. In the case of UAE, temperature also affects the number of cavities generated and overall intensity of the collapse of cavities. At lower temperature, the number of cavities generated is less but the intensity of their collapse is more, whereas at higher temperatures, higher vapor pressure causes formation of more number of cavities, but their collapse is less intense [36]. In temperature study, the biomass was subjected to ultrasound treatment for 30 min at different temperatures, viz. 20, 30, 40, 50, and 60 °C. The temperature of the system was maintained at desired value using a chiller bath. Operating conditions maintained during the study were time of 30 min, and frequency was 30 kHz. When extraction of lutein was performed at a range of temperatures, it was observed that the extraction yield continuously increased with temperature as shown in Fig. 2. Increase in the extraction yield with temperature was due to the increased solubility of lutein in the solvent which is more dominating and increase in the number of cavities generated through ultrasound. At low temperatures (< 20 °C), the relative responses were low. Too low temperature affects the mass transfer process which in turn reduces the yield of response. The amounts of lutein were enhanced with increasing temperature to the maximum at 40 °C, after which the lutein content decreased. At a temperature above 40 °C, the relative response decreased because of the instability of the compound. Temperature at 40 °C supported the highest lutein content of 2.91 mg/g D.W. The extent of increase in the extraction yield decreases with temperature because the intensity of the collapse of the cavities reduces with an increase in temperature. These current results were in agreement with Palma and Taylor [37]. It is true that higher temperatures lead to increase in diffusion coefficient and solubility, but at the same time, the high temperatures may result in degradation of phenolic natural products. Conventional maceration and Soxhlet extraction requires high temperatures (over 70 °C) for optimal carotenoid yields as opposed to UAE [38]. Pingret et al. [39] have also reported the degradation of lipids at high ultrasonic temperatures. Maximum extraction yield was obtained at temperature of 40 °C, and hence, it was selected as optimum temperature for US-ME of lutein.

3.4 Effect of ultrasound irradiation frequency

The extent of intensification of extraction using ultrasound is also dependent on the frequency of irradiation as the extent of physical and chemical effects is dependent on the frequency. The extraction was carried out with a range of frequencies, viz. 15, 25, 35, 45, and 55. Operating conditions maintained during the study were time of 30 min and temperature of 40 °C. Figure 3 also shows that the extracted lutein (2.92 mg/g D.W) significantly is more effective in a frequency of 35 kHz. The extraction yield of lutein is 20% higher when compared with the conventional extraction methods. Higher ultrasonic frequency can generate stronger cavitation effects during the extraction process, thus increasing the mass transfer at the biomass-solvent surface. High mass transfer rate will stimulate the diffusion process of lutein in C. salina into solvent. At lower frequencies, the rate of diffusion of the solvent into the material is not optimal because the emitted frequency is only partially able to disrupt or break the cell wall from biomass. During extraction, two physical phenomena may involve: (1) diffusion of solvent through the cell walls and (2) washing out the cell contents after the cell wall was broken. These phenomena were influenced by the ultrasound irradiation [40].

3.5 Comparison of extraction methods on lutein

The extraction was running at 40 °C for 30 min. The result shows that lutein concentration is significantly increased in US-ME method under varied conditions, which reaches twice larger than conventional method (simple stirring method). This also proves that the ultrasonic wave eases the preparation steps such as dissolution, fusion, and leaching. The ultrasonic cavitation also creates local temperature and movement of interface between solid and liquid, so it leads the increase of mass transfer rate. As compared to conventional method, ultrasonic method has more advantages and one of them is its ability to increase the yield of product [41]. The US-ME method obtained a yield of 2.92 mg/g D.W which was more than the conventional method: 1.38 mg/g D.W. Overall, the US-ME also proves that the method was really powerful for increasing extraction efficiency, and therefore, it will be economically viable.

3.6 Chromatographic analysis of lutein

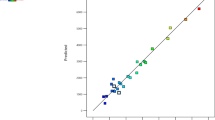

Figure 4 shows the chromatograms and UV-Vis spectrum obtained for lutein from C. salina. The chromatographic profile was similar for both extractions as expected. The time required for extraction was an important advantage of the method. US-ME was faster than commonly used, since it took about 30 min per extraction instead of 50 min per the commonly used extraction. For the routines performed in an analytical laboratory, it represents low solvent consumption and excellent savings in terms of time. Based on the OVAT analysis, the extraction conditions which gave maximum extraction yield have been established for both the methods. Chromatographic analysis of these processed materials revealed that selective degradation of carotenoids did not occur. The leaching of carotenoids, under gentle conditions, from biological materials into an organic solvent provides a simple, rapid estimation of the extent to which the cell wall is disrupted. In addition, the extractability of lutein from these processed cells were very efficient suggesting effective disruption of the cell wall.

4 Conclusion

The present work has clearly illustrated the importance of the selection of operating parameters and the type of ultrasonic irradiations for maximizing the extraction yields for a specific application. The obtained results are important as the differences in the most favorable conditions for extraction using different approaches have been clearly established. Using US-ME, maximum extraction of lutein was obtained with 30 min of ultrasound irradiation, 40 °C temperature, and 35-kHz frequency. The main advantages of the method is the minimum use of toxic organic solvent which is suitable for low lab experiments. Experiments performed under the optimal conditions reached 2.75 mg/g C. salina. Currently, efforts are underway in many laboratories to develop cheaper and cleaner methodologies for rapid and accurate determinations.

References

Taylor RL, Rand JD, Caldwell GS (2012) Treatment with algae extracts promotes flocculation, and enhances growth and neutral lipid content in Nannochloropsis oculata-a candidate for biofuel production. Mar Biotechnol 14:774–781

Fernandez-Sevilla JM, Acien Fernandez FG, Molina Grima E (2010) Biotechnological production of lutein and its applications. Appl Microbiol Biotechnol 86:27–40

Del Campo JA, Garcia-Gonzalez M, Guerrero MG (2007) Outdoor cultivation of microalgae for carotenoid production: current state and perspectives. Appl Microbiol Biotechnol 74:1163–1174

Lin JH, Lee DJ, Chang JS (2015) Lutein production from biomass: marigold flowers versus microalgae. Bioresour Technol 184:421–428

Lakshminarayana R, Aruna G, Sangeetha RK, Bhaskar N, Divakar S, Baskaran V (2008) Possible degradation/biotransformation of lutein in vitro and in vivo: isolation and structural elucidation of lutein metabolites by HPLC and LC-MS (atmospheric pressure chemical ionization). Free Radic Biol Med 45:982–993

Seddon JM, Ajani UA, Sperduto RD, Hiller R, Blair N, Burton TC, Farber MD, Gragoudas ES, Haller J, Miller DT et al (1994) Dietary carotenoids, vitamins A, C, and E, and advanced age-related macular degeneration. JAMA 272:1413–1420

Olmedilla B, Granado F, Blanco I, Vaquero M (2003) Lutein, but not alpha-tocopherol, supplementation improves visual function in patients with age-related cataracts: a 2-year double blind, placebo-controlled pilot study. Nutrition 19:21–24

Krinsky NI, Landrum JT, Bone RA (2003) Biologic mechanisms of the protective role of lutein and zeaxanthin in the eye. Annu Rev Nutr 23:171–193

Britton G (1995) Structure and properties of carotenoids in relation to function. FASEB 9:1551–1558

Shirsath SR, Sonawane SH, Gogate PR (2012) Intensification of extraction of natural products using ultrasonic irradiations - a review of current status. Chem Eng Process 53:10–23

Jadhav D, Rekha BN, Gogate PR, Rathod VK (2009) Extraction of vanillin from vanilla pods: a comparison study of conventional Soxhlet and ultrasound assisted extraction. J Food Eng 93:421–426

Luque de Castro MD, Priego-Capote F (2007) Ultrasound assistance to liquid–liquid extraction: a debatable analytical tool. Anal Chim Acta 583:2–9

Guo X, Han J, Zhang Y, Wang H, Zhou L (2012) An ammonium sulfate/ethanol aqueous two-phase system combined with ultrasonication for the separation and purification of lithospermic acid B from Salvia miltiorrhiza Bunge. Ultrason Sonochem 19:719–724

Li D, Mu C, Cai S, Lin W (2009) Ultrasonic irradiation in the enzymatic extraction of collagen. Ultrason Sonochem 16:605–609

Lambropoulou DA, Albanis TA (2007) Liquid-phase micro-extraction techniques in pesticide residue analysis. J Biochem Biophys Methods 70:195–228

Jeannot MA, Cantwell FF (1996) Solvent microextraction into a single drop. Anal Chem 68:2236–2240

Luque de Castro MD, Priego-Capote F (2007) Ultrasound-assisted preparation of liquid samples. Talanta 72:321–334

Luque de Castro MD, Priego-Capote F (2007) Ultrasound assistance to analytical heterogeneous liquid-liquid systems. In: Analytical applications of ultrasound, 1st edn. Elsevier, Amsterdam

Wang J, Sun B, Cao Y, Tian Y, Li X (2008) Optimization of ultrasound-assisted extraction of phenolic compounds from wheat bran. Food Chem 106:804–810

Hamdaoui O, Naffrechoux E (2007) An investigation of the mechanisms of ultrasonically enhanced desorption. AICHE J 53:363–373

Vilkhu K, Mawson R, Simons L, Bates D (2008) Applications and opportunities for ultrasound assisted extraction in the food industry—a review. Innovative Food Sci Emerg Technol 9:161–169

Garcia-Salas P, Morales-Soto A, Segura-Carretero A, Fernandez-Gutierrez A (2010) Phenolic-compound-extraction systems for fruit and vegetable samples. Molecules 15:8813–8826

Majd MH, Rajaei A, Bashi DS, Mortazavi SA, Bolourian S (2014) Optimization of ultrasonic-assisted extraction of phenolic compounds from bovine pennyroyal (Phlomidoschema parviflorum) leaves using response surface methodology. Ind Crop Prod 57:195–202

Yolmeh M, Najafi MBH, Farhoosh R (2014) Optimization of ultrasound-assisted extraction of natural pigment from annatto seeds by response surface methodology (RSM). Food Chem 155:319–324

Rosello-Soto E, Galanakis CM, Brncic M, Orlien V, Trujillo FJ, Mawson R, Knoerzerf K, Tiwari BK, Barba FJ (2015) Clean recovery of antioxidant compounds from plant foods, by-products and algae assisted by ultrasounds processing. Modeling approaches to optimize processing conditions. Trends Food Sci Technol 42:134–149

Vuong QV, Thanh DT, Bhuyan DJ, Goldsmith CD, Sadeqzadeh E, Scarlett CJ, Bowyer MC (2015) Optimization of ultrasound-assisted extraction conditions for euphol from the medicinal plant, Euphorbia tirucalli, using response surface methodology. Ind Crop Prod 63:197–202

Macias-Sanchez MD, Mantell C, Rodríguez M, Martínez de la Ossa E, Lubian LM, Montero O (2009) Comparison of supercritical fluid and ultrasound-assisted extraction of carotenoids and chlorophyll a from Dunaliella salina. Talanta 77:948–952

Lee JY, Yoo C, Jun SY, Ahn CY, Oh HM (2010) Comparison of several methods for effective lipid extraction from microalgae. Bioresour Technol 101:S75–S77

Yu X, Dong T, Zheng Y, Miao C, Chen S (2015) Investigations on cell disruption of oleaginous microorganisms: hydrochloric acid digestion is an effective method for lipid extraction. Eur J Lipid Sci Technol 117(5):730–737

Gayathri S, Radhika Rajasree SR, Kirubagaran R, Aranganathan L, Suman TY (2016) Spectral characterization of β, ε-carotene-3, 3′-diol (lutein) from marine microalgae Chlorella salina. Renew Energy 98:78–83

Deenu A, Naruenartwongsakul S, Kim SM (2013) Optimization and economic evaluation of ultrasound extraction of lutein from Chlorella vulgaris. Biotechnol Bioprocess Eng 18:1151–1162

Mandal V, Dewanjee S, Sahu R, Mandal SC (2009) Design and optimization of ultrasound assisted extraction of curcumin as an effective alternative for conventional solid liquid extraction of natural products. Nat Prod Commun 4:95–100

Cenci SM, Cox LR, Leeke GA (2014) Ultrasound-induced emulsification of subcritical carbon dioxide/water with and without surfactant as a strategy for enhanced mass transport. Ultrason Sonochem 21:401–408

Daneshvand B, Ara KM, Raofie F (2012) Comparison of supercritical fluid extraction and ultrasound-assisted extraction of fatty acids from quince (Cydonia oblonga Miller) seed using response surface methodology and central composite design. J Chromatogr A 1252:1–7

Luo J, Fang Z, Smith RL Jr (2014) Ultrasound-enhanced conversion of biomass to biofuels. Prog Energy Combust Sci 41:56–93

Tiwari H, Singh P, Mishra P, Srivastava P (2010) Evaluation of various techniques for extraction of natural colorants from pomegranate rind-ultrasound and enzyme assisted extraction. Indian J Fibre Text Res 35:272–276

Palma M, Taylor LT (1999) Extraction of polyphenolic compounds from grape seeds with near critical carbon dioxide. J Chromatogr A 849:117–124

Guo X, Zou X, Sun M (2010) Optimization of extraction process by response surface methodology and preliminary characterization of polysaccharides from Phellinus igniarius. Carbohydr Polym 80:344–349

Pingret D, Fabiano-Tixier AS, Bourvellec CL, Renard CMGC, Chemat F (2012) Lab and pilot-scale ultrasound-assisted water extraction of polyphenols from apple pomace. J Food Eng 111(1):73–81

Vinatoru M (2001) An overview of the ultrasonically assisted extraction of bioactive principles from herbs. Ultrason Sonochem 8:303–313

Luque-Garcia JL, Luque de Castro MD (2004) Ultrasound-assisted Soxhlet extraction: an expeditive approach for solid sample treatment—application to the extraction of Total fat from oleaginous seeds. J Chromatogr A 1034:237–242

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gayathri, S., Rajasree Radhika, S.R., Suman, T.Y. et al. Ultrasound-assisted microextraction of β, ε-carotene-3, 3′-diol (lutein) from marine microalgae Chlorella salina: effect of different extraction parameters. Biomass Conv. Bioref. 8, 791–797 (2018). https://doi.org/10.1007/s13399-018-0331-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-018-0331-9