Abstract

Atmospheric indirect steam-blown and pressurised direct oxygen-blown gasification are the two major technologies discussed for large-scale production of synthetic natural gas from biomass (bio-SNG) by thermochemical conversion. Published system studies of bio-SNG production concepts draw different conclusions about which gasification technology performs best. In this paper, an exergy-based comparison of the two gasification technologies is performed using a simplified gasification reactor model. This approach aims at comparing the two technologies on a common basis without possible bias due to model regression on specific reactor data. The system boundaries include the gasification and gas cleaning step to generate a product gas ready for subsequent synthesis. The major parameter investigated is the delivery pressure of the product gas. Other model parameters include the air-to-fuel ratio for gasification as well as the H2/CO ratio in the product gas. In order to illustrate the thermodynamic limits and sources of efficiency loss, an ideal modelling approach is contrasted with a model accounting for losses in, e.g. the heat recovery and compression operations. The resulting cold-gas efficiencies of the processes are in the range of 0.66–0.84 on a lower heating value basis. Exergy efficiencies for the ideal systems are from 0.79 to 0.84 and in the range of 0.7 to 0.79 for the systems including losses. Pressurised direct gasification benefits from higher delivery pressure of the finished gas product and results in the highest exergy efficiency values. Regarding bio-SNG synthesis however, a higher energetic and exergetic penalty for CO2 removal results in direct gasification exergy efficiency values that are below values for indirect gasification. No significant difference in performance between the technologies can be observed based on the model results, but a challenge identified for process design is efficient heat recovery and cogeneration of electricity for both technologies. Furthermore, direct gasification performance is penalised by incomplete carbon conversion in contrast to performance of indirect gasification concepts.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Background

The production of synthetic natural gas from biomass (bio-SNG) via thermal gasification is a process for second-generation biofuel production that is close to commercialisation, with several industrial scale projects ongoing [1–3]. For the major conversion step from solid to gaseous state—the thermal gasification process—two technology options are available: indirect or allothermal gasification with steam as gasification agent and direct or autothermal gasification with a mixture of oxygen and steam. Two large industrial bio-SNG projects currently conducted in Sweden are planning to implement different gasification technologies, with the GoBiGas project using indirect gasification [1] and the Bio2G project applying direct gasification [2]. The GoBiGas project is currently constructing its phase 1 plant producing 20 MWSNG that is scheduled to be in operation by November 2013. Based on the experience from phase 1, it is planned to build a second plant resulting in a total capacity of 100 MWSNG. The Bio2G project aims at 200 MWSNG production based on direct gasification, but this project is currently put on hold because of uncertain economic conditions [4]. Hamelinck and Faaij [5] state that for a number of biomass-based fuel production routes, systems based on pressurised gasification have higher energy conversion efficiencies than atmospheric gasifier-based systems.

In system studies of SNG production from biomass, no clear consensus has emerged about which gasification technology leads to higher efficiency. A modelling-based comparison of entrained flow, indirect, and direct O2-blown gasification technology [6] states that indirect gasification has a cold-gas biomass to SNG efficiency of 67 % (LHV basis) compared with direct gasification (58 %, LHV basis), accounting for the net process electricity balance. Gassner and Maréchal [7,8] use a multi-objective optimisation approach for systematically synthesising bio-SNG process schemes including heat recovery systems for power generation, optimising them for thermodynamic and economic performance. They conclude that pressurised O2-blown gasification outperforms indirect gasification both from an economic and thermodynamic viewpoint. A recent comparison of indirect and direct gasification for bio-SNG production with different options for converting the process excess heat to electrical power indicates that O2-blown gasification is slightly more advantageous considering exergetic and economic efficiency, but that indirect gasification is more favourable with respect to carbon footprint evaluation measured as emission of CO2-equivalents per MJSNG produced [9]. Finally, a comparison for coal to SNG production [10] states that indirect gasification has both a higher energy and exergy efficiency than direct O2-blown gasification for a process with a thermal input of 5 MWLHV. Most system studies use experimental data regression of a specific experimental dataset derived from equipment ranging from lab to pilot scale. This regression implies the risk of intrinsically favouring a certain gasification technology as experimental conditions between different types of equipment vary considerably. Energy efficiency calculations accounting for different energy forms (fuel, electricity, and heat) are difficult to compare between different studies as there is currently no common agreement on how to weigh different forms of energy in such calculations. Exergy analysis in contrast is a rigorous way of combining first and second law of thermodynamics with the ambient conditions being the main reference point, allowing for a more transparent comparison of different technologies.

The aim of this paper is to present a clear picture of the difference in performance for the two different gasification technologies based on an exergy analysis approach and using a simplified gasification reaction scheme. The major parameter investigated is the pressure of the product gas at the inlet of the methanation section. Varying both H2/CO ratio and the air-to-fuel ratio λ for the gasification as additional parameters, an in-depth comparison is achieved. In order to reduce the influence of specific differences concerning reactor design and operating conditions (such as bed material choice) on the comparison, a simple stoichiometric model for the gasification step is used. This allows the two gasification technologies to be compared on a common basis. Starting from an ideal process, the inherent exergy losses are illustrated and thereafter technological constraints are considered so as to identify the major technical sources of efficiency losses for the two technologies. Based on the results obtained, possible process improvements and technical barriers for the two gasification technologies in the framework of bio-SNG production are thereafter discussed.

2 Methodology

2.1 System definition

The two gasification systems are compared on the same basis within the bio-SNG production process focusing on the conversion of solid fuel to a clean product gas ready for downstream conversion to methane. The biomass feed considered in this study is a generic biomass containing no ash and moisture with a composition as defined in Table 1.

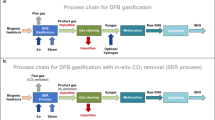

Figure 1 illustrates the general set-up for a biomass to SNG process and the boundary limits for the comparison of the two gasification technologies adopted in this study.

Prior to gasification a drying step reduces the moisture content of the incoming biomass. In the current study, the effect of varying moisture on the exergetic efficiency is not assessed but dry and ash-free biomass assumed as input to the gasification unit. The effects of drying the gasification feedstock can be expected to be similar for indirect and direct gasification with lower moisture content leading to a higher exergetic efficiency of the gasification process [13]. The clean product gas resulting from gasification is converted to methane in a synthesis step and has to be cleaned from CO2 and residual moisture in order to comply with natural gas standards. Commercially available methanation technologies were originally developed for coal to SNG processes. Fixed-bed methanation in a series of intercooled reactors at higher pressure is state of the art [14]. Even fluidised bed technology has been developed for methanation [15] and further developed specifically for methanation of product gas from biomass gasification [16], but no industrial scale technology development has been achieved so far. The two main reactions forming methane from product gas are:

The conversion of carbon dioxide to methane (Eq. 2) is actually a combination of Eq. 1 and the reverse water gas shift reaction and only occurs to a very limited degree as high levels of hydrogen are necessary. In common industrial methanation processes—such as the TREMP process by Haldor Topsøe implemented in the GoBiGas project—most of the CO2 is separated from the product gas prior to methanation [1]. As indicated by the stoichiometry of Eqs. 1 and 2, increased pressure favours the methane yield according to Le Chatelier’s principle. The delivery pressure of the product gas fed to the methanation section is varied from 1 to 30 bars as one of the major parameters investigated in this study. The CO2 content of the clean product gas and the consequences for downstream separation demands or opportunities for increased methane generation are also discussed. In addition to variation of the pressure, the impact of H2/CO ratio of the resulting product gas and the relative air-to-fuel ratio λ (in the range from 0.3 to 0.4) are also investigated. This choice of operating parameters is mainly aimed at achieving good comparability of the results. The aim of the study is not to determine optimum operating conditions but rather to identify fundamental differences in impact on performance of key process conditions for both gasification technologies.

2.2 Gasification modelling

In order to exclude effects of equipment-specific differences between the two technologies on the results, the gasification process is modelled using a simplified stoichiometric model accounting for five species only: CO, H2, CH4, CO2, and H2O. The conversion of biomass to product gas in the gasification step is a very complex process depending on numerous parameters. Published data on gas yield and composition differ significantly even for a single gasification technology. For example, Hannula and Kurkela [17] report carbon conversions close to 100 % for direct oxygen-blown gasification and product gas composition at equilibrium with regard to the water gas shift reaction whereas Siedlecki and de Jong [18] present experimental results with carbon conversion in the range of 65–90 % and a product gas composition far from equilibrium with respect to WGS. Even effects of pressurisation on the product gas composition are difficult to model as little experimental data (e.g. Kitzler [19], Puchner [20], and Valin [21]) are published and data trends are not consistent. Based on the previously mentioned studies [19–21], an increase in CH4 and CO2 concentrations and a decrease in CO concentration can be identified as general trends. As no reliable correlation of general character can be derived from the data, the effect of pressure on the gas composition is not taken into account in the current study. It can be assumed that pressurisation effects will result in similar changes for both indirect and direct gasification concepts as the chemical environments are comparable. The simplified reaction scheme for determining the product gas composition is illustrated in Fig. 2. The decomposition of the biomass fraction entering the gasifier is maximised so as to favour CO yield. After potential steam reforming of the CH4 present by addition of steam, a gas composition with maximum CO concentration (case CO max) is obtained. By further addition of water for a complete water gas shift reaction, it is possible to gradually increase the H2/CO ratio of the product gas with the limiting case corresponding to all CO being converted to H2 (case H 2 max). The aim of this major simplification is to reduce effects of, e.g. different bed materials and reactor setups on the comparability of the two technologies that might otherwise result in a biased comparison of the two gasification technologies. Carbon conversion is assumed to be complete in both cases. The effect of carbon conversion during gasification will be discussed on a qualitative basis in the results section.

2.3 Process setup for ideal gasification systems

The two gasification concepts are compared using an exergy-based approach. The exergy content of the streams entering and leaving the system are related to each other in order to quantify the inherent losses for the two concepts at different operating conditions. For both systems, the oxidising agents (air, steam, or oxygen) are assumed to be supplied at 300 °C. The basic setup is illustrated in Fig. 3 for the indirect gasification concept, including an atmospheric process with final compression to the specified delivery pressure. The direct gasification is assumed to be pressurised with all streams being supplied at the specified pressure. In addition, for the ideal system comparison, atmospheric direct gasification with subsequent compression of the product gas, as well as pressurised indirect gasification, was investigated.

The exergy efficiency of the ideal system η ex, ideal relates the combined exergy flows of all resulting output streams to combined exergy flows of the input streams as defined in Eq. 3. The exergy flow \( \overset{\cdot }{E_{\mathrm{i}}} \) of each material stream i is based on the sum of the physical and chemical exergies according to the methodology proposed by Szargut [12] using atmospheric conditions as reference state (298.15 K, 1.01325 bars). For heat streams, the exergy flow \( \overset{\cdot }{E_{\mathrm{q},\mathrm{i}}} \) is related to the energy flow using the Carnot factor and for work streams, the exergy flow \( \overset{\cdot }{E_{\mathrm{w},\mathrm{i}}} \) is equal to the energy flow.

2.4 Process setup for gasification system including losses

In a further step, the two gasification concepts are investigated with respect to their performance in systems including losses, i.e. accounting for losses associated with heat exchange, compression, as well as supply of feed streams. The process performance and the losses occurring in the auxiliary systems are again quantified using exergy analysis. The excess heat from gas cooling and available excess heat from the gasification process are assumed to be used for generation of high-pressure superheated steam from feedwater as well as district heat generation. It is assumed that steam generation is possible without restrictions and the gas cleaning section is simply represented as pressure losses. In reality, product gas from biomass gasification requires substantial treatment for particle and tar removal as well as removal of trace substances such as sulphur compounds (mainly H2S and COS) and ammonia. For the thermal efficiency of the process, tars are the most important problem to solve as they represent a significant amount of the product gas energy content even though their mass fraction is rather low. For example, for indirect gasification without any primary measures for tar reduction (e.g. by using catalytic bed material), the tar content can be in the range of 30 g/Nm3 dry gas, corresponding to about 8 % of the chemical energy content of the dry gas on a LHV basis [22]. For atmospheric indirect gasification, a cold-gas cleaning section with a scrubber using oil or water removing the tars is common practice [23,24]. This puts some penalty on the heat recovery from the product gas as only the gas can be cooled down to a certain temperature prior to scrubbing. For pressurised oxygen-blown gasification, hot gas cleaning is the commonly proposed technology with all sensible heat from the product gas being available for heat recovery. Tar reforming is a very versatile process that can be tailored for the specific application by choosing the active catalyst. For bio-SNG production it is desirable to have a catalyst that is active for tar reforming without catalysing reforming of the methane present in the product gas. Tar reforming of product gas from biomass gasification is still at the research stage but very promising results have been published [25,26]. The simplified representation of the gas cleaning chain in this study again aims at comparing the two systems on a common basis. The indirect gasification concept is assumed to have a cold-gas cleaning chain consisting of a filter and a scrubber while the pressurised direct gasification system is based on a high-temperature tar reformer and a filter enabling hot gas cleaning. The two gas cleaning concepts can in principle be applied to either of the gasification concepts as will be taken up in the discussion section of the paper.

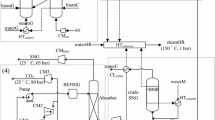

Figure 4 shows the overall setup for atmospheric indirect gasification and pressurised gasification including gas cleaning considered in this study as well as the system boundary and streams accounted for in the efficiency calculations.

Indirect (a) and direct (b) gasification. System definition and associated exergy streams accounted for in efficiency calculations accounting for losses according to Eq. 4

The exergy efficiency of the system including losses η ex, loss again relates system output to input according to Eq. 4:

Table 2 illustrates the process parameters for the two gasification concepts as well as the high-pressure steam data and district heating water conditions assumed. The latter are based on data for a generic biomass-based combined heat and power plant with a thermal boiler load of 80 MWth, LHV [27]. The thermodynamic state of the steam extracted for heating the gasification steam is determined by assuming that high-pressure steam is used with given expansion characteristics, as listed in the table. The pressure level is adjusted to ensure a minimum temperature difference between the hot and cold stream of 10 K with the extraction steam being cooled to saturated liquid state.

2.5 Auxiliary system modelling assumptions

Feeding of solid biomass into the gasification reactor is often the most critical process step during gasification. A continuous and uniform feed to the gasifier is a central aspect in ensuring reliable operation of biomass gasification systems [28]. A number of different feeding technologies for biomass are available with lock-hopper systems and piston feeders being the most mature systems that are available at large scale and allow for pressurisation [28,29]. The most commonly used feeding system is a lock-hopper system with feeding screws as proposed by, e.g. TR Miles [30]. The major performance parameters of the feeding system are the amount of inert gas that is needed and the electric power consumption. The void fraction of the bulky feed material has to be filled with inert gas (e.g. N2 or CO2) to avoid entrainment of air into the gasification reactor. Increasing pressure of the reactor will increase the amount of inert gas necessary and consequently the amount of inert gases entering the gasifier with the feed material.

Given the effective solid volume fraction in the feeding system φ and the density of the feed material ρ f , as well as the pressure level P of the feeding system, the theoretically necessary mass flow of inert gas \( {\overset{\cdot }{m}}_{\mathrm{inert}} \) can be estimated using the ideal gas law.

M, R, and T denote the molar weight of the inert gas, the gas constant, and the temperature in the feeding system, respectively, and \( {\overset{\cdot }{m}}_{\mathrm{f}} \) denotes the solid feed material mass flow.

Direct O2-blown gasification requires an air-separation unit (ASU) for providing pure oxygen for the gasification reactor. For large-scale applications, cryogenic ASU is the most common technology, and in connection to integrated gasification combined cycles (IGCC), the process has been optimised with significant reductions in power consumption due to tight integration of the processes [31]. In this work, we assume standard ASU technology with an energy consumption of 882 kJ/kg O2 (245 kWh/t O2) [32] delivering oxygen at 1.15 bars and a final compression of the oxygen to a pressure above the gasification pressure level. This specific power consumption is somewhat higher compared with published ASU data for IGCC or oxy-fuel combustion applications (e.g. 720 kJ/kg O2 [33]). This is because the O2-purity needed in biomass gasification for fuel production is higher and no process integration benefits between the ASU and the biofuel synthesis process can be expected, as stated by Gassner [8]. This implies that neither integration of the ASU compressors nor low temperature cooling can be provided by the biofuel synthesis process. In the models, it is assumed that the ASU delivers pure O2 to the gasifier reactors.

The compressors assumed in the process models are multistage compressors with intercooling and a maximum compression ratio of 4. Aspen Plus [34] flowsheeting software was used for all simulations using the Peng–Robinson equation of state for thermodynamic property calculations of all gaseous streams and steam table data for water streams. A summary of the auxiliary system simulation assumptions is given in Table 3.

2.6 Additional performance indicators

In order to be able to compare the two gasification technologies, a number of additional performance indicators in addition to the exergy efficiency are required. A common indicator for gasification performance is the cold-gas efficiency η cg relating the thermal input in form of fuel to the chemical energy content in the product gas:

The product gas heating value LHVpg is the sum of products of mass fraction and mass-specific lower heating value of the combustible components present in the product gas.

For further treatment of the product gas for production of bio-SNG, the amount and concentration of CO2 can be used as an indicator of downstream upgrade energy demands. Assuming that CO2 is not participating in the methanation reactions but needs to be separated from the product gas, an energy or exergy penalty can be determined assuming complete separation of CO2 with, e.g. amine-based absorption. The exergy efficiency defined in Eq. 4 will thus be reduced as an additional term representing the exergy input for CO2 separation will figure in the denominator. The exergy efficiency \( {\eta}_{\mathrm{ex},\mathrm{loss}\;{\mathrm{CO}}_2} \) accounting for the CO2 separation penalty can thus be defined according to:

The exergy demand for the CO2 separation can be determined according to

\( {\overset{\cdot }{m}}_{{\mathrm{CO}}_2} \) is the mass flow of CO2 in the product gas and \( {e}_{{\mathrm{CO}}_2\mathrm{sep}} \) the specific exergy demand of 0.975 MJ/kg CO2 assuming amine based adsorption with a specific heat energy demand of 3.3 MJ/kg CO2 at 150 °C [39] for separation. It has to be mentioned that the definition of Eq. 7 gives approximate values for the exergy efficiency penalty associated to CO2 separation only as more streams would need to be accounted for when extending the system boundaries to CO2 separation. For the scope of this study and the way Eq. 7 is used in the discussion of the results, this approach is considered sufficiently detailed, however.

Finally, the specific electricity consumption per product gas fuel energy produced w gasif can be calculated adding an additional dimension to the comparison of the two processes:

The consumption w gasif then can be analysed in relation to the specific exergy output w steam to the cogeneration steam cycle:

3 Results

3.1 Ideal gasification system analysis

As neither pressure nor temperature dependence of the gas composition is implemented in the model, the product gas yield is constant over the pressure range investigated. Because of the model structure, the combustible components composition is similar for both gasification technologies for a given combination of relative air-to-fuel ratio λ and H2/CO ratio. However, at low λ values (e.g. λ = 0.3 at CO max), the composition may differ as the carbon stock entering the indirect gasifier may exceed the oxygen stock, resulting in methane formation and subsequent reforming with steam. For direct gasification, methane formation only occurs at very low λ values based on the stoichiometric model used. The resulting cold-gas efficiency for the parameter range investigated is given in Table 4. It should be noted that η cg has the same values for the pressurised and atmospheric gasification technologies and is also the same for the cases including losses. An increase in the relative air-to-fuel ratio λ obviously leads to a lower cold-gas efficiency since more fuel is burnt. Increased H2/CO ratio in the product gas also leads to a decrease in the cold-gas efficiency due to the exothermal nature of the water gas shift reaction which converts CO to H2 with steam that is added to the gasifier, thereby reducing the chemical energy content of the product gas.

It can be observed that the exergy efficiency of the ideal systems η ex,ideal is virtually constant for both direct and indirect gasification operating at atmospheric conditions. Pressurised systems show increased exergy efficiency at higher pressures and indirect gasification even outperforms direct gasification for the ideal case. The increase in exergy efficiency between atmospheric and pressurised operation is about 2 % points for direct gasification and 3 % points for indirect gasification at the highest pressure level of 30 bars investigated. Figure 5 illustrates two examples of the variation of exergy efficiency with increasing pressure at λ = 0.35. The representation on a y-scale starting at zero is used to illustrate the small difference between the two gasification technologies on an absolute scale. The largest gain in exergy efficiency is achieved at moderate pressurisation levels of 5–10 bars while a further increase only yields rather small benefits.

Table 5 gives the minimum (at atmospheric pressure) and maximum (at 30 bars) exergetic efficiencies for the ideal systems for a H2/CO ratio of 3. Varying the H2/CO ratio has a negligible effect on the exergy efficiency for all technology alternatives and air-to-fuel ratios with a maximum relative difference between the two extreme cases CO max and H 2 max of less than 0.5 %. It is shown that increasing the air-to-fuel ratio leads to a decrease in exergetic performance but the influence is less pronounced than on the cold-gas efficiency η cg .

3.2 Gasification systems including losses

For the systems including losses, the cold-gas efficiency is similar to the ideal cases (see Table 4) as the reaction scheme applied is the same. The exergy efficiency in contrast is lower as heat losses and losses due to heat transfer, compression, and pressure drop are accounted for. Table 6 presents the minimum and maximum exergetic efficiencies. Even here, the relative difference in exergetic efficiency between different H2/CO ratios is small (below 3 %) but a more pronounced influence compared with the ideal systems can be observed. For atmospheric indirect gasification, this is partly due to the higher amount of product gas to be compressed, putting a penalty on the exergy efficiency. For both technologies, increased steam extraction for preheating the steam for gasification at higher H2/CO ratios puts a penalty on the exergy efficiency. For a given air-to-fuel ratio and H2/CO ratio, indirect gasification basically shows an exergy efficiency that is highest at 1 bar and decreases marginally with pressure. Direct gasification benefits from pressurisation with an increase of more than two 2 % points over the whole parameter range (from 1 to 30 bars).

Figure 6 shows that, for indirect gasification, the compression work for the product gas dominates the specific electricity consumption per energy unit of product gas at higher pressures, again being higher for higher H2/CO ratios due to the larger volume flow. The flue gas blower consumption for indirect gasification is constant and not significant since both the gasification and combustion processes operate at atmospheric pressure with the product gas being compressed to delivery pressure downstream of the gasification process. The discontinuities in the curves of Fig. 6 are at points where changes in number of compression stages occur due to compression ratio limits (see Table 3). Because of the pressure drop in the upstream gasification and product gas cleaning operations, the pressure prior to compression for the indirect gasification technology is below atmospheric and the discontinuities do not occur at 4 and 16 bars, respectively, but already at lower gas delivery pressures. For direct gasification, the ASU is the major contributor to the electricity consumption and the influence of pressure is less pronounced. At atmospheric pressure, the specific electricity consumption for direct gasification exceeds the one for indirect gasification by a factor of three. w gasif for indirect gasification exceeds the values for direct gasification in the pressure range from 3 to 8 bars, depending on the H2/CO ratio. The potential for electricity generation given by the specific steam exergy output w steam is constant over the whole range of product gas delivery pressure for indirect gasification. For direct gasification, there exists a slight dependence on the pressure, mainly due to effects of changing numbers of compressor stages as well as varying compressor outlet temperatures. This leads to varying heat loads in heat exchangers (refer to Fig. 4b) and in consequence to small variations in w steam . However, the values determined for w steam clearly indicate that is possible to cover the electricity demand internally when integrating a steam power cycle, even when accounting for exergy losses in the turbomachinery part (well below 20 % based on [40]).

Specific electricity consumption w gasif (left) and steam exergy output w steam (right) for the two gasification technologies at λ = 0.35 (black, indirect gasification; grey, direct gasification; solid line, CO max; dotted line, H2/CO = 2; dashed line, H2/CO = 3; dashed–dotted line, H2 max). The discontinuities in the curves are at points where changes in number of compression stages occur due to compression ratio limits (see Table 3)

When considering the downstream process operations within the bio-SNG process, the concentration of CO2 in the product gas is of particular interest as it needs to be separated using energy-intensive processes. In Fig. 7, the molar fraction of CO2 is illustrated for λ = 0.35. Even at atmospheric pressure the CO2 concentration in the product gas for direct gasification is substantially higher due to the fact that the combustion products supplying the gasification energy are present in the product gas. The difference increases with pressure due to the increased amount of inert gas necessary for the pressurised direct gasification. For the CO max case, the relative increase in CO2 concentration is about 50 % from 1 to 30 bars whereas it is about 15 % for the H 2 max case. The specific amount of feed gas used for direct gasification increases linearly from 0.013 Nm3 CO2/kg biomass (0.566 mol CO2/s for 1 kg/s of biomass) at 1 bar product gas delivery pressure to 0.296 Nm3 CO2/kg biomass at 30 bars. For indirect gasification operating at atmospheric conditions with compression of the product gas to delivery pressure, the specific amount of feed gas is constant over the whole pressure range at 0.011 Nm3 CO2/kg biomass. This number is even lower than for direct gasification delivering product gas at 1 bar because of the fact that direct gasification is operated at slightly higher pressure to compensate for all downstream pressure drops (refer to Fig. 4). Improvements in the feeding system reducing the gas void fraction could decrease these numbers but the CO2 concentration in the product gas for direct pressurised gasification will increase with increasing reactor pressure.

This in consequence implies a penalty on the exergy efficiency when accounting for downstream CO2 separation. Figure 8 illustrates the effect of accounting for the CO2 penalty on the exergy efficiency according to Eq. 7 for two selected cases. It can be seen that the direct gasification performance is decreased below indirect gasification efficiency. The increase in CO2 with direct gasification pressure causes the exergy efficiency to decline with further increase in pressure after a maximum at around 10 bars for the presented cases. Reduced entrainment with the feeding system will minimised the dampening effect on the exergy efficiency with increasing pressure, but direct gasification efficiency will still be below indirect gasification efficiency at atmospheric pressure.

Exergy efficiency of the two systems including losses η ex,loss at λ = 0.35 for two H2/CO ratios (left, H2/CO = 2 and right, H2/CO = 3). Black lines, indirect gasification; grey lines, direct gasification. Dotted lines represent modified exergy efficiency \( {\eta}_{\mathrm{ex},\mathrm{loss}\;{\mathrm{CO}}_2} \) accounting for CO2 separation exergy penalty

In order to illustrate the sources of exergy performance decrease for the two technologies in more detail, the different in- and outputs as well as the exergy losses are depicted in Table 7 for a selected case at 10 bars based on an exergetic input of biomass of 100 MW. For indirect gasification, the major sources of electricity consumption are the product gas compressor and the flue gas blower whereas it is the ASU and the oxygen compressor for the direct gasification. Direct gasification produces larger amounts of product gas on an exergetic basis, and the steam generation is similar for both technologies. The major source of exergy loss is the gasification process itself accounting for about 74 % of the losses. It is higher for the indirect gasification due to the fact that the internal heat transfer between combustion and gasification chamber inevitably causes exergy losses. Another important source of loss is heat transfer from the product gas to the steam cycle. For the direct gasification, the ASU represents an important source of exergy loss while for the indirect gasification the flue gas (leaving the system at just below 100 °C) and compressor losses are of importance. Finally, the heat loss from the gasification unit is also a significant source of exergy loss. The remainder of the exergy loss sources is in the range of or below 1 % of the total exergy losses within the system. As already mentioned the gasification steam preheating with steam extraction can cause higher losses to some extent when more steam is added to the gasifier to achieve a higher H2/CO ratio.

4 Discussion

The results of the ideal process comparison indicate that pressurised operation of the gasification reactor achieves higher exergetic performance within the whole parameter range investigated. Pressurised indirect gasification even outperforms pressurised direct gasification options by 1 % point. However, this configuration would be a rather complex one with two pressurised vessels and an air compressor for the combustion unit and turbine for recovering the pressure energy of the flue gases. Practical issues such as particulate matter in the flue gases as well as a more complex pressure balance to be handled between the gasification and combustion vessel make this option unlikely to be realised.

For the process comparison including losses, the exergy efficiency of the indirect gasification process is more or less constant over the whole pressure range while pressurised direct gasification performance improves with higher pressure and outperforms indirect gasification by 2–3 % points. However, the CO2 concentration in the product gas for direct gasification is substantially higher compared to indirect gasification putting a penalty on the performance if the CO2 must be separated as is the case in, e.g. a bio-SNG production process in particular and gasification-based biofuel synthesis processes in general. Increasing the reactor pressure for direct gasification even increases the penalty due to a larger amount of CO2 entrained with the feeding system. Little data are available on feeding systems’ inertisation gas demands and the numbers assumed imply a certain level of uncertainty. Design of pressurised gasification units will aim at minimising the entrainment of CO2 as inertisation material. The exergy penalty for CO2 separation might in consequence increase less with increasing product gas delivery pressure for direct gasification, but \( {\eta}_{\mathrm{ex}}{}_{,\mathrm{loss},{\mathrm{CO}}_2} \) at atmospheric conditions will still be lower for direct gasification than for indirect gasification. Given the current assumptions, the exergy penalty on direct gasification decreases the efficiency below indirect gasification exergetic performance for a limiting case of complete separation of the CO2. This trend is of importance even for other biofuel processes based on gasification (such as for example Fischer–Tropsch fuels, methanol, or dimethyl ether) that all include a CO2 separation stage prior to synthesis [41], reducing the potential advantages of pressurised direct gasification due to a higher CO2 removal penalty. The conclusions might differ for a bio-SNG process when considering CO2 conversion in the methanation section according to Eq. 2 by addition of hydrogen from external sources, as proposed for example by Gassner [42].

The large CO2 penalty for direct gasification basically indicates that there is no significant difference in performance for the two gasification technologies within the framework of bio-SNG production. Consequently, the choice between the two gasification technologies is based on other technical and practical issues. Direct pressurised gasification leads to smaller equipment but at higher complexity whereas indirect gasification implies larger equipment but reduced complexity. In addition, indirect gasification can be operated more flexibly and even allows for integration with existing power generation infrastructure, as proposed by Heyne et al. [43]. Another key issue for bio-SNG production is the capability of the gasification unit to produce a gas with high CH4 concentration that in turn is related to reactor design and bed material, among other factors. Methane formation has not been accounted for in the current model in order to be able to compare the two technologies on a common basis. Methane formation data from experimental results differ considerably from equilibrium-based estimations. Gasification process design for bio-SNG production is basically an optimisation process between two conflicting objectives; obtaining high methane yields while keeping tar concentrations at low levels. No superior technology between direct and indirect gasification can be identified per se related to this criterion.

It also has to be kept in mind when analysing the results that a simplified reaction scheme has been applied in order to compare the two technologies on a common basis. The advantage of this approach is that reactor specific differences are not accounted for and the two concepts are compared on a common basis. In reality however, there are a number of aspects that will influence the performance of the processes differently. An important parameter for gasification performance is the carbon conversion efficiency. Considering a decrease in carbon conversion, this will result in direct losses for the direct gasification technology as the unconverted carbon is lost with the bottom and fly ash discharge streams. For indirect gasification, a decrease in product gas yield will occur while more carbon will be burnt in the combustion chamber where complete conversion can be ensured. Another dimension to this problem is the disposal of ashes that is not allowed if they contain considerable amounts of carbon. A common practice is to burn the ashes with the remaining carbon in an adjacent combustion unit, as is done for example in the Great Plains coal gasification plant [44]. The carbon conversion in a direct gasification process is closely related to the air-to-fuel ratio. The higher the oxygen content in the gasifier the more likely a good carbon conversion can be achieved. The ambition of operating at low air-to-fuel ratios for achieving high fuel conversion efficiency in this case is contradictory to the aim of reaching high carbon conversions. For indirect gasification, this is less of a problem as carbon conversion is ensured in the combustion chamber or an additional post-combustion chamber operating with high excess air. Generally, for both gasification technologies improvements compared with the presented results can be achieved by reducing the relative air-to-fuel ratio in order to maximise the product gas yield. The chosen air-to-fuel ratios were selected to enable a comparison on similar basis considering product gas composition between the two gasification technologies. Similar effects are obtained by reducing the heat losses that were assumed in this study to be 2 % of the lower heating value thermal input. The effects of these measures will be beneficial in a similar way for both gasification technologies. Another aspect of the simplified model that has to be accounted for is the fact that the product gas produced does not contain any water vapour. This represents a limiting case with complete conversion of the fuel that will not be possible to reach in a real gasification process. Steam addition in excess of the stoichiometric demand is necessary to improve, e.g. char gasification. Steam in the product gas will put a higher penalty on the indirect gasification concept as the latent heat of the water vapour is lost during the cooling prior to compression. For the direct gasification process with hot gas cleaning, the influence of the water content in the product gas is of minor importance considering the exergy efficiency. In general, the gasification process exergy efficiency decreases with increasing steam addition due to the fact that high-temperature heat at the gasification (or combustion) temperature level is used for heating up the steam supplied.

An additional option for improving the performance of both gasification technologies could be to use the excess electricity that amounts to 0.02–0.1 MW/MWPG,LHV (difference between w steam and w gasif based on Fig 6. neglecting turbomachinery losses) in the gasification unit as high-temperature heat supply (plasma gasification is used, e.g. for waste gasification [45]). This concept—that even could be extended using excess exergy from the down-stream methanation process—allows for a decrease of the air-to-fuel ratio without decreasing fuel conversion to product gas.

Finally, heat recovery in the analysed cases is a large source of exergy losses besides the gasification step itself but also leads to generation of an important exergy output improving the performance of the process. Current process designs based on biomass gasification do not integrate a steam cycle for heat recovery but often use a hot oil circuit supplying heat to sinks within the process or externally (e.g. [1,46]). This is mainly due to material issues, impurities in the product gas with tar being the major obstacle, and scale of size making steam cycle integration unfeasible. Future large-scale production units should aim at steam cycle integration to improve process performance and process economics. The gas cleaning chain is of particular importance in that respect. A tar free product gas is necessary to safely recover most of the heat. Hot gas cleaning of the product gas considerably increases opportunities for an efficient recovery of the sensible heat from the product gases and the technology is by no means restricted to direct gasification. Chemical-looping reforming is such an example of high-temperature tar reforming that is investigated for indirect atmospheric gasification [25,47]. Assuming hot gas cleaning for the indirect gasification process in this study would lead to a slight increase in exergy efficiency. Cold-gas cleaning would similarly penalise the direct gasification process. However, the sensible heat losses when applying a scrubber for final particle removal in the cold-gas cleaning chain are of minor importance for the overall process efficiency as illustrated by the exergy losses shown in Table 7. The focus for efficient process design needs to be on overcoming restrictions for high-temperature heat recovery that do exist in real processes but have not been accounted for in this study.

5 Conclusions

This paper presented the results of an exergy-based comparison of indirect and direct biomass gasification technologies within the framework of production of bio-SNG. The performance of the gasification and gas cleaning processes are investigated for a simplified gasification reaction scheme with the product gas delivery pressure as the main parameter investigated. Calculated cold-gas efficiencies (lower heating value basis) for the gasification processes range from 0.665 to 0.842 for a product gas delivery pressure range of 1 to 30 bars within the whole parameter domain investigated. The varied parameters are the relative air-to-fuel ratio λ (0.3 to 0.4) and the H2/CO ratio, that was varied from cases with maximum CO yield (cases CO max with lowest H2/CO ratio of 1.08 for λ = 0.3) to complete conversion of CO to H2 by the water gas shift reaction (cases H 2 max with H2/CO = ∞). The exergy performance results of comparable ideal processes indicate a slight advantage for the pressurised gasification process that achieves exergetic efficiency values that are 2–3 % points higher compared with atmospheric gasification in the higher pressure range (about 81–83 % for direct pressurised compared with 79–81 % for indirect atmospheric, within the studied range of relative air-to-fuel and H2/CO ratio values). Even when a number of important source of losses are considered, pressurised gasification is still shown to achieve superior performance by up to 3 % points in exergy efficiency at 30 bars. However, when considering bio-SNG production with CO2 separation as an inherent process step, a higher exergy penalty associated for the pressurised direct gasification process makes the two gasification processes perform similarly with an exergy efficiency in the range of 0.7–0.72. It is concluded that neither direct nor indirect gasification can be identified as intrinsically superior for bio-SNG production based on the results presented. The key aspect for biomass gasification is the efficient heat integration and cogeneration of power rather than the choice of gasification technology. In particular, the conversion of high-temperature process heat to steam for power generation contributes considerably to the exergy output from the process, standing for about 10 % with the product gas exergy representing the remaining 90 %. Considering the gasification step itself, high fuel conversion to product gas is the main objective for both technologies. Lowered carbon conversion is a threat in particular for direct gasification as the unconverted carbon cannot be used efficiently within the process as is the case for indirect gasification.

Abbreviations

- ASU:

-

Air-separation unit

- e :

-

Specific exergy (mass)

- \( \overset{\cdot }{E} \) :

-

Exergy flow

- HHV:

-

Higher heating value

- LHV:

-

Lower heating value

- \( \overset{\cdot }{m} \) :

-

Mass flow

- M :

-

Molar mass

- P :

-

Pressure

- R :

-

Gas constant

- T :

-

Temperature

- w :

-

Specific work

- \( \overset{\cdot }{W} \) :

-

Work flow/power

- λ :

-

Relative air-to-fuel ratio

- η :

-

Efficiency

- φ :

-

Effective solid volume fraction

- ρ :

-

Density

- Π:

-

Compression ratio

- air:

-

Air

- biomass:

-

Biomass

- cg:

-

Cold gas

- ASU:

-

Air separation unit

- CO2 :

-

CO2

- CO2sep:

-

CO2 separation

- comp:

-

Compressor

- DH:

-

District heat

- el:

-

Electricity

- ex:

-

Exergetic

- f:

-

Feed

- fuel:

-

Fuel

- gasif:

-

Gasification

- ideal:

-

Ideal system

- inert:

-

Inert gas (CO2)

- intcool:

-

Intercooling

- is:

-

Isentropic

- loss:

-

Accounting for losses

- loss CO2 :

-

Accounting for losses and CO2 separation penalty

- pg:

-

Product gas

- pump:

-

Pump

- screw:

-

Screw feeder

- steam:

-

Steam

References

Gunnarsson I (2011) The GoBiGas Project. In: International Seminar on Gasification 2011—Gas Quality, CHP and New Concepts, Malmö, Sweden, 6–7 October 2011

Fredriksson Möller B (2011) The E.ON Bio2G Project. In: International Seminar on Gasification 2011—Gas Quality, CHP and New Concepts, Malmö, Sweden, 6–7 October 2011

Adelt M, Vogel A (2010) Bio-SNG—prospective renewable energy carrier in the E.ON gas grid (in German: bio-SNG zukünftiger regenerativer Energiträger im E.ON Gasnetz). Erdöl Erdgas Kohle 126(10):338–341

Hennius M (2012) E.ON delays large-scale biogas project in Scania (In Swedish: E.ON avvaktar med storskaligt biogasprojekt i Skåne). Press release. E.ON Sverige AB, Malmö

Hamelinck CN, Faaij APC (2006) Outlook for advanced biofuels. Energy Policy 34(17):3268–3283. doi:10.1016/j.enpol.2005.06.012

van der Meijden CM, Veringa HJ, Rabou LPLM (2010) The production of synthetic natural gas (SNG): a comparison of three wood gasification systems for energy balance and overall efficiency. Biomass Bioenergy 34(3):302–311. doi:10.1016/j.biombioe.2009.11.001

Gassner M, Maréchal F (2012) Thermo-economic optimisation of the polygeneration of synthetic natural gas (SNG), power and heat from lignocellulosic biomass by gasification and methanation. Energy and Environmental Science 5(2):5768–5789. doi:10.1039/c1ee02867g

Gassner M, Maréchal F (2009) Thermo-economic process model for thermochemical production of synthetic natural gas (SNG) from lignocellulosic biomass. Biomass Bioenergy 33(11):1587–1604. doi:10.1016/j.biombioe.2009.08.004

Rönsch S, Kaltschmitt M (2012) Bio-SNG production—concepts and their assessment. Biomass Conversion and Biorefinery 2(4):285–296. doi:10.1007/s13399-012-0048-0

Karellas S, Panopoulos KD, Panousis G, Rigas A, Karl J, Kakaras E (2012) An evaluation of substitute natural gas production from different coal gasification processes based on modeling. Energy 45(1):183–194. doi:10.1016/j.energy.2012.03.075

Channiwala SA, Parikh PP (2002) A unified correlation for estimating HHV of solid, liquid and gaseous fuels. Fuel 81(8):1051–1063. doi:10.1016/S0016-2361(01)00131-4

Szargut J, Morris DR, Steward FR (1988) Exergy analysis of thermal, chemical, and metallurgical processes. Hemisphere, New York

Schuster G, Loffler G, Weigl K, Hofbauer H (2001) Biomass steam gasification—an extensive parametric modeling study. Bioresour Technol 77(1):71–79. doi:10.1016/S0960-8524(00)00115-2

Kopyscinski J, Schildhauer TJ, Biollaz SMA (2010) Production of synthetic natural gas (SNG) from coal and dry biomass—a technology review from 1950 to 2009. Fuel 89(8):1763–1783. doi:10.1016/j.fuel.2010.01.027

Friedrichs G, Proplesch P, Lommerzheim W (1982) Comflux pilot plant for converting coal conversion gas into SNG. Gaswärme International 31(6):261–264

Seemann M (2006) Methanation of biosyngas in a fluidized bed reactor. Ph.D. thesis, Swiss Federal Institute of Technology, Zürich, Switzerland

Hannula I, Kurkela E (2012) A parametric modelling study for pressurised steam/O2-blown fluidised-bed gasification of wood with catalytic reforming. Biomass Bioenergy 38:58–67. doi:10.1016/j.biombioe.2011.02.045

Siedlecki M, de Jong W (2011) Biomass gasification as the first hot step in clean syngas production process—gas quality optimization and primary tar reduction measures in a 100 kW thermal input steam-oxygen blown CFB gasifier. Biomass Bioenergy 35(suppl 1):S40–S62. doi:10.1016/j.biombioe.2011.05.033

Kitzler H, Pfeifer C, Hofbauer H (2011) Pressurized gasification of woody biomass—variation of parameter. Fuel Process Technol 92(5):908–914. doi:10.1016/j.fuproc.2010.12.009

Puchner B, Pfeifer C, Hofbauer H (2009) Bed material and parameter variation for a pressurized biomass fluidized bed process. In: Yue G, Zhang H, Zhao C, Luo Z (eds) Proceedings of the 20th International Conference on Fluidized Bed Combustion, Xian, China, 18–21 May 2009. Tsinghua University Press, Beijing, pp 700–705. doi:10.1007/978-3-642-02682-9_108

Valin S, Ravel S, Guillaudeau J, Thiery S (2010) Comprehensive study of the influence of total pressure on products yields in fluidized bed gasification of wood sawdust. Fuel Process Technol 91(10):1222–1228. doi:10.1016/j.fuproc.2010.04.001

Lind F, Israelsson M, Seemann M, Thunman H (2012) Manganese oxide as catalyst for tar cleaning of biomass-derived gas. Biomass Conversion and Biorefinery 2(2):133–140. doi:10.1007/s13399-012-0042-6

Zwart RWR, Van Der Drift A, Bos A, Visser HJM, Cieplik MK, Könemann HWJ (2009) Oil-based gas washing-flexible tar removal for high-efficient production of clean heat and power as well as sustainable fuels and chemicals. Environmental Progress and Sustainable Energy 28(3):324–335. doi:10.1002/ep.10383

Pröll T, Aichernig C, Rauch R, Hofbauer H (2007) Fluidized bed steam gasification of solid biomass—performance characteristics of an 8 MWth combined heat and power plant. Int J Chem React Eng 5:54. doi:10.2202/1542-6580.1398

Lind F, Seemann M, Thunman H (2011) Continuous catalytic tar reforming of biomass derived raw gas with simultaneous catalyst regeneration. Ind Eng Chem Res 50(20):11553–11562. doi:10.1021/ie200645s

Pfeifer C, Hofbauer H (2008) Development of catalytic tar decomposition downstream from a dual fluidized bed biomass steam gasifier. Powder Technol 180(1–2):9–16. doi:10.1016/j.powtec.2007.03.008

Brodén H, Nyström O, Jönsson M (2012) Optimum power yield for bio fuel fired combined heat and power plants (In Swedish: optimal elverkningsgrad för biobränsleeldade kraftvärmeverk). Värmeforsk, Stockholm

Dai J, Cui H, Grace JR (2012) Biomass feeding for thermochemical reactors. Prog Energy Combust Sci 38(5):716–736. doi:10.1016/j.pecs.2012.04.002

Cummer KR, Brown RC (2002) Ancillary equipment for biomass gasification. Biomass Bioenergy 23(2):113–128. doi:10.1016/S0961-9534(02)00038-7

Swanson ML, Musich MA, Schmidt DD, Schultz JK (2003) Feed system innovation for gasification locally economical alternative fuels (FIGLEAF). U.S. Department of Energy, National Energy Technology Laboratory, Pittsburgh

Jones D, Bhattacharyya D, Turton R, Zitney SE (2011) Optimal design and integration of an air separation unit (ASU) for an integrated gasification combined cycle (IGCC) power plant with CO2 capture. Fuel Process Technol 92(9):1685–1695. doi:10.1016/j.fuproc.2011.04.018

Beysel G (2009) Enhanced cryogenic air separation—a proven process applied to oxyfuel: future prospects. In: 1st International Oxyfuel Combustion Conference, Cottbus, Germany, 8–11 September 2009

Tranier J-P, Dubettier R, Perrin N (2009) Air separation unit for oxy-coal combustion systems. Paper presented at the 1st International Oxyfuel Combustion Conference, Cottbus, Germany

Aspen Engineering Suite V7.2 (2010). Aspen Technology Inc.

Edberg U, Engstrom L, Hartler N (1973) The influence of chip dimensions on chip bulk density. Svensk Papperstidning 14:529–533

Plötze M, Niemz P (2011) Porosity and pore size distribution of different wood types as determined by mercury intrusion porosimetry. European Journal of Wood and Wood Products 69(4):649–657. doi:10.1007/s00107-010-0504-0

Screw conveyor speed calculation. (2013) Bulk Handling Global Pty Ltd. http://www.bulksolidsflow.com/free_programs/screw_conveyor_design/screw_conveyor_design.html. 28 Accessed February 2013

Rautalin A, Wilén C (1992) Feeding biomass into pressure and related safety engineering. VTT Research Notes 1428. VTT—Technical Research Centre of Finland, Espoo

Götz M, Köppel W, Reimert R, Graf F (2012) Potential to optimize scrubbers for biogas cleaning. Part 2. Chemical Scrubbers (in German; Optimierungspotenzial von Wäschen zur Biogasaufbereitung Teil 2. Chemische Wäschen). Chemie Ingenieur Technik 84(1–2):81–87. doi:10.1002/cite.201100129

Stecco SS, Manfrida G (1986) Exergy analysis of compression and expansion processes. Energy 11 (6):573–577. doi:10.1016/0360-5442(86)90105-2

Tock L, Gassner M, Maréchal F (2010) Thermochemical production of liquid fuels from biomass: thermo-economic modeling, process design and process integration analysis. Biomass Bioenergy 34(12):1838–1854

Gassner M, Maréchal F (2008) Thermo-economic optimisation of the integration of electrolysis in synthetic natural gas production from wood. Energy 33(2):189–198. doi:10.1016/j.energy.2007.09.010

Heyne S, Thunman H, Harvey S (2012) Extending existing combined heat and power plants for synthetic natural gas production. International Journal of Energy Research 36(5):670–681. doi:10.1002/er.1828

Panek JM, Grasser J (2006) Practical experience gained during the first twenty years of operation of the great plains gasification plant and implications for future projects. US Department of Energy-Office of Fossil Energy, Washington

Heberlein J, Murphy AB (2008) Thermal plasma waste treatment. J Phys D-Appl Phys 41 (5). doi:10.1088/0022-3727/41/5/053001

Hofbauer H, Rauch R, Loeffler G, Kaiser S, Fercher E, Tremmel H (2002) Six years experience with the FICFB-gasification process. In: 12th European Conference and Technology Exhibition on Biomass for Energy, Industry and Climate Protection, Amsterdam, Netherlands, 17–21 June 2002

Dutta A, Talmadge M, Hensley J, Worley M, Dudgeon D, Barton D, Gronendijk P, Ferrari D, Stears B, Searcy EM, Wright CT, Hess JR (2011) Process design and economics for conversion of lignocellulosic biomass to ethanol. National Renewable Energy Laboratory, Golden

Acknowledgements

This project was funded by the Swedish Energy Agency’s program for Energy Efficiency in Industry, Göteborg Energi’s Research Foundation, and E.ON as well as the Swedish Gasification Centre (SFC).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Heyne, S., Thunman, H. & Harvey, S. Exergy-based comparison of indirect and direct biomass gasification technologies within the framework of bio-SNG production. Biomass Conv. Bioref. 3, 337–352 (2013). https://doi.org/10.1007/s13399-013-0079-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-013-0079-1