Abstract

Solar cell devices are one of the most promising technologies for generating green energy. Forefront perovskite-based solar cells have increased worldwide hope for solving global warming issues. Tight bandgap formamidinium lead iodide (TB-FAPbI3) perovskite as an active layer to absorb sunlight along with a desired electron transport layer (ETL) can produce efficient and stable perovskite solar cells (PSCs). Here, TB-FAPbI3 with tin oxide (SnO2) as an ETL was employed to fabricate PSCs. These PSCs recorded a low champion efficiency of 18.35%. A cobalt-doped SnO2 layer was designed to increase the efficiency of TB-FAPbI3 solar cells. The modified SnO2 boosted the solar cell efficiency to 20.10% due to the improved conductivity of the ETL and increased charge transfer phenomena in the PSCs. From one side, electron transfer is facilitated at the ETL/perovskite interface. On another side, the reduced surface defects on the fabricated perovskite layer over the modified ETL diminish charge traps in the solar cell. In addition, cobalt doping does not hinder the light transmission from the SnO2 into the perovskite layer. The modified SnO2 assists in the formation of a more compact TB-FAPbI3 layer and promotes the stability properties of PSCs.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In recent years, there has been a surge in research on organic–inorganic metal halide perovskite materials owing to the fact that these materials have a high light absorbance value, a tuneable bandgap, a high diffusion length, and enhanced carrier mobility [1,2,3,4,5]. These materials have found widespread use in a variety of sectors, including photodetectors, fuel cells with electrochemical sensing, solar cells, and many more [6,7,8,9,10,11]. The use of perovskite materials in the area of solar cells is the most exciting development that has occurred with regard to these materials. Perovskite solar cells (PSCs) have seen a rise in their power conversion efficiency (PCE), which has gone from 3.8% in 2009 to around 26% currently [12, 13].

Planar and mesoporous structures are the two primary types of structures found in PSCs. Both of these architectural types provide outstanding performance. Planar PSCs do not need a mesoporous layer like mesoporous PSCs, which may be challenging to create without resorting to high temperatures and laborious procedures [14,15,16]. Planar PSCs have several practical benefits for mass manufacturing, including solution machinability, reduced temperature fabrication, and cheap cost [17,18,19,20,21]. A PSC is made up of many layers of various materials. Because TiO2 forms a thin, compact layer that is stable and aids in the development of compact films, most PSCs continue to employ it as an n-type contact. However, PSCs' long-term stability is hindered by their high temperature, their dissolution perovskite under light, and their strong hysteresis effects [22,23,24,25,26,27]. Therefore, it is required to construct an electron transport layer (ETL) with high carrier mobility, an optimum energy level in relation to perovskite, and good transmittance.

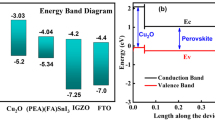

Reports of SnO2 as a new ETL have surfaced in recent years [28,29,30,31]. SnO2 is different from other ETL materials in that it can be readily synthesized at low temperatures, has a high transmittance, a fast charge carrier transport capacity, and a broad bandgap [32, 33]. There are certain limitations to SnO2, such as a poor internal electric field and inadequate strength for electron–hole pair dissociation since the location of the conduction band is still somewhat lower and cannot perfectly match that of perovskite [34, 35]. Pinholes, as well as local shunt pathways, may also be produced by SnO2-based ETL when it is combined with spontaneous aggregation. These defective films make it difficult for photo-generated electrons to be injected into the SnO2 electron acceptor. Previous efforts have resolved this issue by using a variety of preparation techniques, mixing a number of other doping materials, or using surface passivation [36,37,38,39,40].

It is anticipated that the presence of alkali metallic ions, such as Mg2+, Al3+, Li+, and K+, would increase the conductivity as well as the durability of the SnO2 layer. Because of their excellent conductivity, alkali ions are capable of reducing the series resistance, which ultimately results in an increase in open-circuit voltage (VOC) [41,42,43]. Other dopants, like n-type Y3+, Nb5+, Cd3+, and Sb3+ are used to make donor centres that speed up the movement of charges and reduce the build-up of photogenerated electrons [41, 44]. This improves the fill factor and short-circuits current density [45]. Anion dopants, such as fluoride and chloride, have also been used by a variety of research groups in order to improve the overall performance of the device.

An enhanced open-circuit voltage was seen as a consequence of the improved conductivity of anion-doped SnO2 as well as the decreased band offset [46,47,48]. The researchers discovered both of these effects. Xiong and his team reported in 2016 that using SnO2 layers with Mg doping as ETL layers decreased the band position of the conduction band with respect to perovskite [49]. This doping enhanced the interfacial contact, significantly reduced the free electron density and increased the PCE to 14.5%. Using Nb-doped SnO2 that was treated in a low-temperature solution, Liu and his team were able to create an efficient ETL with a PCE of 17.5% [45]. Poly(vinylpyrrolidone) (PVP)-doped SnO2 (PVP-SnO2) was reported as an ETL for PSCs by Huang and colleagues, who found that it improved efficiency and decreased hysteresis [50]. This research team showed that by using ETL on PVP-doped SnO2, the crystallinity of the perovskite was enhanced, and more electrons were successfully extracted. As a result, the highest-efficiency PSC device using PVP-SnO2 as the ETL had a power conversion efficiency of 19.5%. In order to improve solar cell efficiency, experimental evaluations have shown that the Nb: SnO2 ETL considerably increases electron extraction and successfully reduces charge recombination. A SnO2 ETL was manufactured by Hagfeldt and co-workers at low temperatures via atomic layer deposition [17]. This process produced a device that was stable and had a PCE of 18%. There was essentially no hysteresis in the device. After that, they published an Nb-doped SnO2 ETL that was made via chemical bath deposition, and they attained a PCE of 20.1% [44]. In addition, many different research groups have looked at SnO2 ETLs that have been doped with lithium, gallium, antimony, and yttrium [14, 34, 42, 51].

In the current study, the team's efforts are focused on increasing the efficiency of TB-FAPbI3 PSCs. The electrical conductivity of SnO2 ETL is improved via cobalt incorporation. The introduced cobalt-doped SnO2 improves the TB-FAPbI3 PSCs' PCE to 20.10% from 18.37% recorded for the control system. This is brought about by facilitating the charge transport in the PSC devices, improving the crystalline properties of the TB-FAPbI3 layer, and reducing surface defects in the perovskite layer. In addition, the enlarged perovskite grains with passivated boundaries improve the stability behavior of PSCs.

2 Experimental Procedure

2.1 Solution Preparation

To prepare tin(iv) oxide (SnO2) precursor solution, 1 mL of tin(iv) isopropoxide (99%, 10% w/v in isopropyl, Alfa Aesar) is diluted with 10 mL of isopropyl alcohol (IPA, 99.8%, Merck). The obtained solution is stirred for 60 min at room temperature (RT). To prepare the cobalt-doped SnO2 precursors, 0 to 4 mol% of cobalt(II) nitrate hexahydrate (Co(NO3)2.6H2O, 99.8%, Merck) are added into the SnO2 solutions and reflux at 50 °C for 24 h. Tight bandgap formamidinium lead iodide (TB-FAPbI3) perovskite is prepared by a reaction of lead iodide (PbI2) and formamidinium iodide (FAI) in mixed solvents of N, N-dimethylformamide (DMF) and dimethyl sulfoxide (DMSO) by employing methylammonium chloride (MACl) additive. In detail, PbI2 (737 mg, 99.9%, LumTec) is dissolved in DMF (890 μL, 99.8%, Merck) and DMSO (110 μL, 99.8%, Merck) by stirring at 80 °C for 60 min. After cooling down the PbI2 precursor to RT, FAI (275 mg, 99.9%, LumTec) and MACl (33 mg, 99.9%, LumTec) salts are added to it and stirred at RT for 15 min. To prepare a hole transport material, 144.6 mg of Spiro-OMeTAD (99.8%, LumTec) is dissolved in 2 mL of chlorobenzene (CB, 99.8%, Merck) with stirring at 50 °C for 15 min. To improve the spiro-OMeTAD conductivity, 35 μl of bis (trifluoromethane)sulfonimide lithium (LiTFSI, 99.8%, Sigma Aldrich) solution (520 mg/mL−1 in acetonitrile), and 57.6 μL of 4-tertbutylpyridine (tBP, 98%, Sigma Aldrich) are added to it and further stirred at RT for 30 min [52].

2.2 Fabrication of Device

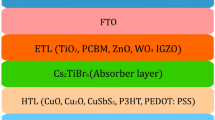

The FTO glasses are cleaned with soap, distilled water, ethanol, and IPA through an ultrasonic cleaner, followed by drying with hot air flow. First, 70 μL of SnO2 precursor is spread on the FTO substrate and spin-coated at a speed of 4500 rpm for 30 s, followed by a post-heating step at 210 °C for 15 min to fabricate SnO2-based ETL. After that, 75 μL of TB-FAPbI3 precursor is spin-coated on the SnO2-based ETL with a two-spin coating program at a speed of 1000 rpm for 3 s and later at 6000 rpm for 30 s. During the second step, 200 µL of CB anti-solvent is poured on the TB-FAPbI3 to induce the perovskite crystallization process. The TB-FAPbI3 layers are post-heated at 100 °C for 2 min and 155 °C for 20 min. To form a hole transport layer (HTL) over the TB-FAPbI3 layer, 80 μL of the Spiro-OMeTAD solution is poured on perovskite and spin-coated at a speed of 4000 rpm for 30 s. The last layer was a gold (Au) electrode and was deposited on the HTL with the evaporating of an Au target at a rate of 2 A°/s to reach a thickness of 100 nm. The step-wise process of fabrication of the proposed device is depicted in Fig. 1.

2.3 Measurements

A steady-state PL spectra of devices were measured by an Edinburgh FLS920P spectrometer. The absorbance spectra of TB-FAPbI3 layers were measured via a Perkin Elmer Lambda 950 spectrophotometer. The surface morphology of TB-FAPbI3 layers was monitored by recording images with a TESCAN Mira3-XMU FE-SEM instrument. XRD patterns of TB-FAPbI3 layers were recorded with a PANalytical 80 X-ray diffractometer [53,54,55]. The J–V characteristics of solar cells or ETLs were measured with a 2400 Keithley digital source meter under simulated and calibrated irradiation.

3 Results and Discussion

First, the effects of SnO2 ETL modification with cobalt on the absorbance ability of the fabricated TB-FAPbI3 layer on ETLs are monitored. In Fig. 2a, the absorbance spectra of different TB-FAPbI3 layers have been shown. It is observed that by increasing the level of cobalt doping in the SnO2 ETL from 0 to 4%, TB-FAPbI3 absorbance capability almost remains constant. In addition, Fig. 2b shows Tauc curves for different TB-FAPbI3 and indicates an equal energy band gap of 1.54 eV, referring to an absorbance edge of 805 nm. The unchanged absorbance edge points to the fact that the modification of ETL with cobalt has not changed the compositional structure of TB-FAPbI3.

Next, different PSCs based on various SnO2 ETLs with the same TB-FAPbI3 light-harvesting layer were fabricated, and their J–V characteristics were recorded. In Fig. 3a, the J–V curves of the best-performing devices have been shown. Figure 3b shows the statistical distribution of photovoltaic (PV) parameters obtained from the J–V responses of 10 PSCs in each group. The calculated PV parameters are summarized in Table 1. The champion solar cell in the control group (based on the un-doped ETL) shows a PCE of 18.35% with an open-circuit voltage (VOC) of 1.05 V, a short-circuit current density (JSC) of 22.96 mA cm−2, and a fill factor (FF) of 75.94%. After processing the SnO2 ETL with 2% of cobalt dopant, the maximum PCE of PSCs reached 20.10% along with a VOC of 1.11 V, a JSC of 23.12 mA cm−2, and FF of 78.23%. Clearly, PCE improvement in the PSCs with doped ETL is due to boosting the VOC and FF parameters and this will be discussed more later.

To find reasons for PCE improvement caused by doping of SnO2 ETL with cobalt, a series of measurements were employed. Figure 4a shows the PL spectra of a fabricated TB-FAPbI3 layer on the different ETLs, i.e., un-doped and cobalt-doped SnO2 layers. As can be seen, the PL peak intensity in the whole TB-FAPbI3 layers fabricated on cobalt-doped SnO2 layers is weaker than the TB-FAPbI3 layer fabricated on the un-doped SnO2. For the TB-FAPbI3 layer fabricated on the SnO2 doped with 2% of cobalt, the PL peak has the weakest intensity, referring to better charge transfer in the solar cell along with suppressing charge recombination process in the bulk and interface of ETL/TB-FAPbI3 [13, 56, 57]. Later, our hypothesis will be more discussed. In Fig. 4b, the conductivities (\({\sigma }_{0}\)) of SnO2 ETLs with different amounts of cobalt dopant are compared together by measuring their dark J-V from − 3 to 3 V. To calculate \({\sigma }_{0}\), dark J–V responses were fitted with a formula \(J=\frac{V{\sigma }_{0}}{d}\), where d is the thickness of ETL (50 nm). Slope of dark J–V curve refers to \({\sigma }_{0}\) [58]. As shown in Fig. 4b, by increasing dopant level, J–V slope increases step by step. Values of 2.5 and 3.97 µS.cm−1 were measured for \({\sigma }_{0}\) of 0% and 2% ETLs, respectively. Bluntly, by doping cobalt material into the SnO2 ETL, the electrical conductivity of the SnO2 layer is increased. It leads to faster charge transfer at the ETL/TB-FAPbI3 layer and hinders charge accumulation at this interface [59]. The improved electrical conductivity of SnO2 due to cobalt dopant is supported by PL analysis for 1 and 2 mol% cobalt-doped ETLs. While by increasing the cobalt dopant to 3 and 4 mol%, SnO2 conductivity is increased, but the related PL profiles indicate weaken charge transfer processes in corresponding PSCs. Our hypothesis is that by increasing the dopant level, surface defects in the fabricated perovskite layer are enhanced, increasing charge accumulation centers and attenuating charge transfer in PSCs. It should be noted that J–V conductivity and PL findings suggest that the optimal level of cobalt doping in the SnO2 ETL is 2 mol% ratio. From here onwards, the fabricated devices based on un-doped and doped ETL with 2 mol% of cobalt are labeled "control" and "target".

The micro-morphology of TB-FAPbI3 layers was characterized via recording top-view FESEM images (Fig. 5). In the control layer, there are pinholes or surface defects (Fig. 5a). As shown in Fig. 5b, these defects vanished in the target layer. For comparison, the FESEM image of the TB-FAPbI3 layer fabricated on the doped ETL with 4 mol% of cobalt was recorded (Fig. 5c). It is observed that the high doping level of cobalt in the SnO2 precursor hurts the morphology of TB-FAPbI3. It may be due to changing the wettability of the SnO2 layer, which later would be deeply monitored. In addition, TB-FAPbI3 grain sizes in the target layer are larger than those in the control layer (See Fig. 5e, f). The enlarged perovskite grains bring fewer boundaries in the perovskite layer and lead to reduction of charge accumulation and recombination sites. FESEM findings agree with PL analysis and cause an increase in FF and VOC parameters [60, 61]. Figure 5d shows the contact angle of TB-FAPbI3 droplets on different SnO2 ETLs. It was observed by ETL doping with cobalt, the contact angle value increases from 14° in control SnO2 to 24° in target SnO2 and finally to 31° in the 4%-doped SnO2, which indicates an increment of cobalt doping level boosts the non-wetting behavior of SnO2 ETL. As reported by Gong et al. [62], partially increasing ETL hydrophobicity be useful for the fabrication of a perovskite layer with large grains, but higher-level hydrophobic behavior in ETL is harmful and brings the formation of a perovskite layer that fully doesn’t cover ETL and has a lot of surface defects.

Figure 6 shows FESEM images of different SnO2 layers to gain more information on the effects of cobalt dopant on SnO2 morphology. In all layers SnO2 nanoparticles covered FTO substrate, and formed SnO2 ETLs. By increasing the cobalt dopant level, the FTO substrate is more effectively covered with SnO2 nanoparticles, while some particle accumulations become manifest in the layer. For the 4 mol%-doped layer, these particle accumulations are increased, making 4 mol%-doped SnO2 unfavorable for deposition of perovskite layer (See Fig. 5c). To get a deeper insight into the correlation of ETL modification and perovskite crystallinity, XRD patterns of the control and target TB-FAPbI3 layers were monitored and plotted in Fig. 7a. The XRD pattern of the control layer has two prominent peaks at 13.7° and 27.9° related to (100) and (200) plane directions, respectively. These two peaks indicate the formation of a well-oriented and photoactive phase of FAPbI3 perovskite (α-FAPbI3) [13]. In the XRD pattern of the target layer, just these two planes with an intensification in their intensity are observable. It was found that not only XRD peaks intensity are increased, but also their FWHM reduced in the target layer (See Figs. 7b and 6c), indicating enlarging perovskite grains in the target layer [63,64,65].

As one of the most critical obstacles to PSC commercialization, the stability behavior of control and target TB-FAPbI3 PSCs was monitored in an atmosphere with a humidity level of 25% at room temperature (RT) in dark conditions during the 1440-h aging time (Fig. 8). The target TB-FAPbI3 PSC showed higher stability behaviour than the control TB-FAPbI3 PSC, maintaining 78% of its initial efficiency after 1440 h of aging. In contrast, the control TB-FAPbI3 PSC remains at 31% of its initial PCE. The improved stability in target devices could be attributed to the enlarged perovskite grains with passivated grain boundaries and well-oriented perovskite obtained in the target systems.

4 Conclusion

In this study, a facile method based on the modification of SnO2 ETL with cobalt dopant was developed to increase the stability and efficiency of TB-FAPbI3 PSCs. It was observed that adding 2 mol% of cobalt material to the ETL precursor not only improved its electrical conductivity but also affected the formation of its top perovskite layer. Indeed, cobalt-doped ETL severs as a desirable substrate for the TB-FAPbI3 layer formation and induces perovskite grain growth. The ETL modification reduces charge accumulation and facilitates charge transfer in the ETL/TB-FAPbI3 layer, leading to a record champion PCE of 20.10% higher than 18.35% for the control PSCs. In addition, the fabricated PSCs based on the modified ETL show higher stability behaviour than the control PSCs. The improved stability of the target devices correlates with their improved perovskite crystallinity with passivated grain boundaries.

Data Availability

Data will be available based on reasonable request.

References

Ahmed, D.S., Mohammed, B.K., Mohammed, M.K.: Long-term stable and hysteresis-free planar perovskite solar cells using green antisolvent strategy. J. Mater. Sci. 56(27), 15205–15214 (2021)

Humadi, M.D., Hussein, H.T., Mohamed, M.S., Mohammed, M.K., Kayahan, E.: A facile approach to improve the performance and stability of perovskite solar cells via FA/MA precursor temperature controlling in sequential deposition fabrication. Opt. Mater. 112, 110794 (2021)

Kumar, A., Singh, S., Al-Bahrani, M.: Enhancement in power conversion efficiency and stability of perovskite solar cell by reducing trap states using trichloroacetic acid additive in anti-solvent. Surf. Interfaces 34, 102341 (2022)

Kumar, A., Singh, S., Sharma, A., Ahmed, E.M.: Efficient and stable perovskite solar cells by interface engineering at the interface of electron transport layer/perovskite. Opt. Mater. 132, 112846 (2022)

Moharam, M.M., El Shazly, A.N., Anand, K.V., Rayan, D.E., Mohammed, M.K., Rashad, M.M., Shalan, A.E.: Semiconductors as effective electrodes for dye sensitized solar cell applications. Top. Curr. Chem. 379(3), 1–17 (2021)

Burschka, J., Pellet, N., Moon, S.-J., Humphry-Baker, R., Gao, P., Nazeeruddin, M.K., Grätzel, M.: Sequential deposition as a route to high-performance perovskite-sensitized solar cells. Nature 499(7458), 316–319 (2013)

Ball, J.M., Lee, M.M., Hey, A., Snaith, H.J.: Low-temperature processed meso-superstructured to thin-film perovskite solar cells. Energy Environ. Sci. 6(6), 1739–1743 (2013)

Yang, W.S., Noh, J.H., Jeon, N.J., Kim, Y.C., Ryu, S., Seo, J., Seok, S.I.: High-performance photovoltaic perovskite layers fabricated through intramolecular exchange. Science 348(6240), 1234–1237 (2015)

Saliba, M., Matsui, T., Seo, J.-Y., Domanski, K., Correa-Baena, J.-P., Nazeeruddin, M.K., Zakeeruddin, S.M., Tress, W., Abate, A., Hagfeldt, A.: Cesium-containing triple cation perovskite solar cells: improved stability, reproducibility and high efficiency. Energy Environ. Sci. 9(6), 1989–1997 (2016)

Kadhim, M.J., Mohammed, M.K.: Fabrication of efficient triple-cation perovskite solar cells employing ethyl acetate as an environmental-friendly solvent additive. Mater. Res. Bull. 158, 112047 (2023)

Majeed, S.M., Ahmed, D.S., Mohammed, M.K.: Anti-solvent engineering via potassium bromide additive for highly efficient and stable perovskite solar cells. Org. Electron. 99, 106310 (2021)

Kojima, A., Teshima, K., Shirai, Y., Miyasaka, T.: Organometal halide perovskites as visible-light sensitizers for photovoltaic cells. J. Am. Chem. Soc. 131(17), 6050–6051 (2009)

Jeong, J., Kim, M., Seo, J., Lu, H., Ahlawat, P., Mishra, A., Yang, Y., Hope, M.A., Eickemeyer, F.T., Kim, M.: Pseudo-halide anion engineering for α-FAPbI3 perovskite solar cells. Nature 592(7854), 381–385 (2021)

Bai, Y., Fang, Y., Deng, Y., Wang, Q., Zhao, J., Zheng, X., Zhang, Y., Huang, J.: Low temperature solution-processed Sb: SnO2 nanocrystals for efficient planar perovskite solar cells. ChemSusChem 9(18), 2686–2691 (2016)

Mohammed, M.K., Al-Azzawi, R.K., Jasim, H.H., Mohammed, S.H., Singh, S., Kadhum, H.H., Kumar, A., Sasikumar, P., Revathy, M., Jabir, M.S.: Adaption of MAPbI3 perovskite with copper phthalocyanine inorganic hole transport layer via nitrosonium tetrafluoroborate additive to enhance performance and stability of perovskite solar cells. Opt. Mater. 133, 112901 (2022)

Mohammed, M.K., Al-Mousoi, A.K., Singh, S., Younis, U., Kumar, A., Dastan, D., Ravi, G.: Ionic liquid passivator for mesoporous titanium dioxide electron transport layer to enhance the efficiency and stability of hole conductor-free perovskite solar cells. Energy Fuels 36(19), 12192–12200 (2022)

Anaraki, E.H., Kermanpur, A., Steier, L., Domanski, K., Matsui, T., Tress, W., Saliba, M., Abate, A., Grätzel, M., Hagfeldt, A.: Highly efficient and stable planar perovskite solar cells by solution-processed tin oxide. Energy Environ. Sci. 9(10), 3128–3134 (2016)

Ke, W., Fang, G., Liu, Q., Xiong, L., Qin, P., Tao, H., Wang, J., Lei, H., Li, B., Wan, J.: Low-temperature solution-processed tin oxide as an alternative electron transporting layer for efficient perovskite solar cells. J. Am. Chem. Soc. 137(21), 6730–6733 (2015)

Bencherif, H., Hossain, M.K.: Design and numerical investigation of efficient (FAPbI3)1–x(CsSnI3)x perovskite solar cell with optimized performances. Sol. Energy 248, 137–148 (2022)

Bencherif, H., Meddour, F., Elshorbagy, M., Hossain, M.K., Cuadrado, A., Abdi, M., Bendib, T., Kouda, S., Alda, J.: Performance enhancement of (FAPbI3)1–x(MAPbBr3)x perovskite solar cell with an optimized design. Micro Nanostruct. 171, 207403 (2022)

Pandey, R., Bhattarai, S., Sharma, K., Madan, J., Al-Mousoi, A.K., Mohammed, M.K., Hossain, M.K.: Halide composition engineered a non-toxic perovskite-silicon tandem solar cell with 30.7% conversion efficiency. ACS Appl. Electron. Mater. (2023). https://doi.org/10.1021/acsaelm.2c01574

Song, J., Zheng, E., Bian, J., Wang, X.-F., Tian, W., Sanehira, Y., Miyasaka, T.: Low-temperature SnO2-based electron selective contact for efficient and stable perovskite solar cells. J. Mater. Chem. A 3(20), 10837–10844 (2015)

Méndez, P.F., Muhammed, S.K., Barea, E.M., Masi, S., Mora-Sero, I.: Analysis of the UV–ozone-treated SnO2 electron transporting layer in planar perovskite solar cells for high performance and reduced hysteresis. Sol. RRL 3(9), 1900191 (2019)

Song, J., Li, G., Wang, D., Sun, W., Wu, J., Lan, Z.: High-efficiency low-temperature-processed mesoscopic perovskite solar cells from SnO2 nanorod self-assembled microspheres. Sol. RRL 4(4), 1900558 (2020)

Mohammed, M.K., Sarusi, G., Sakthivel, P., Ravi, G., Younis, U.: Improved stability of ambient air-processed methylammonium lead iodide using carbon nanotubes for perovskite solar cells. Mater. Res. Bull. 137, 111182 (2021)

Mohammed, M.K., Al-Mousoi, A.K., Majeed, S.M., Singh, S., Kumar, A., Pandey, R., Madan, J., Ahmed, D.S., Dastan, D.: Stable hole-transporting material-free perovskite solar cells with efficiency exceeding 14% via the introduction of a malonic acid additive for a perovskite precursor. Energy Fuels 36(21), 13187–13194 (2022)

Hossain, M.K., Arnab, A., Das, R.C., Hossain, K., Rubel, M., Rahman, M.F., Bencherif, H., Emetere, M., Mohammed, M.K., Pandey, R.: Combined DFT, SCAPS-1D, and wxAMPS frameworks for design optimization of efficient Cs2BiAgI6-based perovskite solar cells with different charge transport layers. RSC Adv. 12(54), 35002–35025 (2022)

Wang, C., Zhang, C., Wang, S., Liu, G., Xia, H., Tong, S., He, J., Niu, D., Zhou, C., Ding, K.: Low-temperature processed, efficient, and highly reproducible cesium-doped triple cation perovskite planar heterojunction solar cells. Sol. Rrl 2(2), 1700209 (2018)

Liu, D., Wang, Y., Xu, H., Zheng, H., Zhang, T., Zhang, P., Wang, F., Wu, J., Wang, Z., Chen, Z.: SnO2-based perovskite solar cells: configuration design and performance improvement. Sol. RRL 3(2), 1800292 (2019)

Huang, X., Du, J., Guo, X., Lin, Z., Ma, J., Su, J., Feng, L., Zhang, C., Zhang, J., Chang, J.: Polyelectrolyte-doped SnO2 as a tunable electron transport layer for high-efficiency and stable perovskite solar cells. Sol. RRL 4(1), 1900336 (2020)

Xu, X., Xu, Z., Tang, J., Zhang, X., Zhang, L., Wu, J., Lan, Z.: High-performance planar perovskite solar cells based on low-temperature solution-processed well-crystalline SnO2 nanorods electron-transporting layers. Chem. Eng. J. 351, 391–398 (2018)

Zhu, Z., Bai, Y., Liu, X., Chueh, C.C., Yang, S., Jen, A.K.Y.: Enhanced efficiency and stability of inverted perovskite solar cells using highly crystalline SnO2 nanocrystals as the robust electron-transporting layer. Adv. Mater. 28(30), 6478–6484 (2016)

Jiang, Q., Zhang, L., Wang, H., Yang, X., Meng, J., Liu, H., Yin, Z., Wu, J., Zhang, X., You, J.: Enhanced electron extraction using SnO2 for high-efficiency planar-structure HC(NH2)2PbI3-based perovskite solar cells. Nat. Energy 2(1), 1–7 (2016)

Yang, G., Lei, H., Tao, H., Zheng, X., Ma, J., Liu, Q., Ke, W., Chen, Z., Xiong, L., Qin, P.: Reducing hysteresis and enhancing performance of perovskite solar cells using low-temperature processed Y-doped SnO2 nanosheets as electron selective layers. Small 13(2), 1601769 (2017)

Hasan, S.A.U., Lee, D.S., Im, S.H., Hong, K.-H.: Present status and research prospects of tin-based perovskite solar cells. Solar RRL 4(2), 1900310 (2020)

Yang, D., Yang, R., Wang, K., Wu, C., Zhu, X., Feng, J., Ren, X., Fang, G., Priya, S., Liu, S.F.: High efficiency planar-type perovskite solar cells with negligible hysteresis using EDTA-complexed SnO2. Nat. Commun. 9(1), 1–11 (2018)

Lee, Y., Paek, S., Cho, K.T., Oveisi, E., Gao, P., Lee, S., Park, J.-S., Zhang, Y., Humphry-Baker, R., Asiri, A.M.: Enhanced charge collection with passivation of the tin oxide layer in planar perovskite solar cells. J. Mater. Chem. A 5(25), 12729–12734 (2017)

Wang, Y., Duan, C., Li, J., Han, W., Zhao, M., Yao, L., Wang, Y., Yan, C., Jiu, T.: Performance enhancement of inverted perovskite solar cells based on smooth and compact PC61BM: SnO2 electron transport layers. ACS Appl. Mater. Interfaces 10(23), 20128–20135 (2018)

Liu, Z., Sun, B., Liu, X., Han, J., Ye, H., Tu, Y., Chen, C., Shi, T., Tang, Z., Liao, G.: 15% efficient carbon based planar-heterojunction perovskite solar cells using a TiO2/SnO2 bilayer as the electron transport layer. J. Mater. Chem. A 6(17), 7409–7419 (2018)

Wang, D., Wu, C., Luo, W., Guo, X., Qu, B., Xiao, L., Chen, Z.: ZnO/SnO2 double electron transport layer guides improved open circuit voltage for highly efficient CH3NH3PbI3-based planar perovskite solar cells. ACS Appl. Energy Mater. 1(5), 2215–2221 (2018)

Liu, X., Zhang, Y., Shi, L., Liu, Z., Huang, J., Yun, J.S., Zeng, Y., Pu, A., Sun, K., Hameiri, Z.: Exploring inorganic binary alkaline halide to passivate defects in low-temperature-processed planar-structure hybrid perovskite solar cells. Adv. Energy Mater. 8(20), 1800138 (2018)

Park, M., Kim, J.-Y., Son, H.J., Lee, C.-H., Jang, S.S., Ko, M.J.: Low-temperature solution-processed Li-doped SnO2 as an effective electron transporting layer for high-performance flexible and wearable perovskite solar cells. Nano Energy 26, 208–215 (2016)

Xiong, L., Qin, M., Chen, C., Wen, J., Yang, G., Guo, Y., Ma, J., Zhang, Q., Qin, P., Li, S.: Fully high-temperature-processed SnO2 as blocking layer and scaffold for efficient, stable, and hysteresis-free mesoporous perovskite solar cells. Adv. Func. Mater. 28(10), 1706276 (2018)

Halvani Anaraki, E., Kermanpur, A., Mayer, M.T., Steier, L., Ahmed, T., Turren-Cruz, S.-H., Seo, J., Luo, J., Zakeeruddin, S.M., Tress, W.R.: Low-temperature Nb-doped SnO2 electron-selective contact yields over 20% efficiency in planar perovskite solar cells. ACS Energy Letters 3(4), 773–778 (2018)

Ren, X., Yang, D., Yang, Z., Feng, J., Zhu, X., Niu, J., Liu, Y., Zhao, W., Liu, S.F.: Solution-processed Nb: SnO2 electron transport layer for efficient planar perovskite solar cells. ACS Appl. Mater. Interfaces 9(3), 2421–2429 (2017)

Gong, X., Sun, Q., Liu, S., Liao, P., Shen, Y., Grätzel, C., Zakeeruddin, S.M., Grätzel, M., Wang, M.: Highly efficient perovskite solar cells with gradient bilayer electron transport materials. Nano Lett. 18(6), 3969–3977 (2018)

Khan, J., Yang, X., Qiao, K., Deng, H., Zhang, J., Liu, Z., Ahmad, W., Zhang, J., Li, D., Liu, H.: Low-temperature-processed SnO2–Cl for efficient PbS quantum-dot solar cells via defect passivation. J. Mater. Chem. A 5(33), 17240–17247 (2017)

Wang, P., Wang, J., Zhang, X., Wang, H., Cui, X., Yuan, S., Lu, H., Tu, L., Zhan, Y., Zheng, L.: Boosting the performance of perovskite solar cells through a novel active passivation method. J. Mater. Chem. A 6(32), 15853–15858 (2018)

Xiong, L., Qin, M., Yang, G., Guo, Y., Lei, H., Liu, Q., Ke, W., Tao, H., Qin, P., Li, S.: Performance enhancement of high temperature SnO2-based planar perovskite solar cells: electrical characterization and understanding of the mechanism. J. Mater. Chem. A 4(21), 8374–8383 (2016)

Wang, D., Chen, S.-C., Zheng, Q.: Poly (vinylpyrrolidone)-doped SnO2 as an electron transport layer for perovskite solar cells with improved performance. J. Mater. Chem. C 7(39), 12204–12210 (2019)

Ma, Z., Zhou, W., Xiao, Z., Zhang, H., Li, Z., Zhuang, J., Peng, C., Huang, Y.: Negligible hysteresis planar perovskite solar cells using Ga-doped SnO2 nanocrystal as electron transport layers. Org. Electron. 71, 98–105 (2019)

Mohammed, M.K., Jabir, M.S., Abdulzahraa, H.G., Mohammed, S.H., Al-Azzawi, W.K., Ahmed, D.S., Singh, S., Kumar, A., Asaithambi, S., Shekargoftar, M.: Introduction of cadmium chloride additive to improve the performance and stability of perovskite solar cells. RSC Adv. 12(32), 20461–20470 (2022)

Ahmed, D.S., Mohammed, M.K.: Studying the bactericidal ability and biocompatibility of gold and gold oxide nanoparticles decorating on multi-wall carbon nanotubes. Chem. Pap. 74(11), 4033–4046 (2020)

Mohammad, M.R., Ahmed, D.S., Mohammed, M.K.: ZnO/Ag nanoparticle-decorated single-walled carbon nanotubes (SWCNTs) and their properties. Surf. Rev. Lett. 27(03), 1950123 (2020)

Mohammed, M.K., Mohammad, M., Jabir, M.S., Ahmed, D.: Functionalization, characterization, and antibacterial activity of single wall and multi wall carbon nanotubes. IOP Conf. Ser. Mater. Sci. Eng. 757, 012028 (2020)

Dehghanipour, M., Behjat, A., Bioki, H.A.: Fabrication of stable and efficient 2D/3D perovskite solar cells through post-treatment with TBABF 4. J. Mater. Chem. C 9(3), 957–966 (2021)

Yoo, J.J., Seo, G., Chua, M.R., Park, T.G., Lu, Y., Rotermund, F., Kim, Y.-K., Moon, C.S., Jeon, N.J., Correa-Baena, J.-P.: Efficient perovskite solar cells via improved carrier management. Nature 590(7847), 587–593 (2021)

Mohseni, H., Dehghanipour, M., Dehghan, N., Tamaddon, F., Ahmadi, M., Sabet, M., Behjat, A.: Enhancement of the photovoltaic performance and the stability of perovskite solar cells via the modification of electron transport layers with reduced graphene oxide/polyaniline composite. Sol. Energy 213, 59–66 (2021)

Khaleel, O.A., Ahmed, D.S.: Interface engineering at electron transport/perovskite layers using wetting mesoporous titanium dioxide to fabricate efficient and stable perovskite solar cells. Int. J. Energy Res. 46, 11163–11173 (2022)

Lyu, M., Lee, D.-K., Park, N.-G.: Effect of alkaline earth metal chloride additives BCl2 (B=Mg, Ca, Sr and Ba) on the photovoltaic performance of FAPbI3 based perovskite solar cells. Nanosc. Horiz. 5(9), 1332–1343 (2020)

Mohammed, M.K., Shalan, A.E., Dehghanipour, M., Mohseni, H.: Improved mixed-dimensional 3D/2D perovskite layer with formamidinium bromide salt for highly efficient and stable perovskite solar cells. Chem. Eng. J. 428, 131185 (2022)

Gong, W., Guo, H., Zhang, H., Yang, J., Chen, H., Wang, L., Hao, F., Niu, X.: Chlorine-doped SnO2 hydrophobic surfaces for large grain perovskite solar cells. J. Mater. Chem. C 8(33), 11638–11646 (2020)

Dehghan, N., Behjat, A., Zare, H., Mohseni, H., Dehghanipour, M.: Modification of electron-transport layers with mixed RGO/C60 additive to boost the performance and stability of perovskite solar cells: a comparative study. Opt. Mater. 119, 111313 (2021)

Gao, Y., Wu, Y., Liu, Y., Lu, M., Yang, L., Wang, Y., William, W.Y., Bai, X., Zhang, Y., Dai, Q.: Interface and grain boundary passivation for efficient and stable perovskite solar cells: the effect of terminal groups in hydrophobic fused benzothiadiazole-based organic semiconductors. Nanosc. Horiz. 5(12), 1574–1585 (2020)

Ochoa-Martinez, E., Ochoa, M., Ortuso, R.D., Ferdowsi, P., Carron, R., Tiwari, A.N., Steiner, U., Saliba, M.: Physical passivation of grain boundaries and defects in perovskite solar cells by an isolating thin polymer. ACS Energy Lett. 6(7), 2626–2634 (2021)

Acknowledgements

The authors extend their appreciation to the Deanship of Scientific Research at King Khalid University for partially funding this work through the Research Group Program under grant number RGP. 2/195/43.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

There is no conflict of interest by any author.

Consent to Participate

We comply with the ethical standards. We provide our consent to take part.

Consent for Publication

All the authors are giving consent to publish.

Ethical Approval

This article does not contain any studies with human participants or animals performed by the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kumar, A., Al-Mousoi, A.K., Saadh, M.J. et al. Investigation of the Cobalt-Additive Role in Improving the Performance of Formamidium Lead Triiodide Based Solar Cells. Electron. Mater. Lett. 19, 471–482 (2023). https://doi.org/10.1007/s13391-023-00417-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13391-023-00417-4