Abstract

This paper presents the design and development of a novel, fuzzy-based algorithm for the detection and diagnosis of drive faults in an induction motor drive system (IMDS). A detailed investigation on the performance of IMDS under various faults and load conditions revealed that the combination of root-mean-square value and total harmonic distortion (THD) of the stator currents can accurately transpire various fault conditions. In this work, the efficacy of fuzzy logic is employed to characterize and diagnose the fault since it is difficult to find crisp boundaries for the correlation between the extracted parameters and fault conditions. The performance of the developed algorithm is tested and verified using simulation in MATLAB Simulink.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Induction motors (IMs) have dominated the industrial environment ever since their invention. This domination bears testimony to the manifold advantages of the induction motor, viz. simple and rugged construction, reliable operation irrespective of operating environment, absence of brushes, reasonable efficiency, etc. Owing to rapid industrial automation, majority of IMs in the industries are currently controlled automatically with IMDS. Yet, certain tasks continue to demand manual interference. Detection and diagnosis of faults in IMDS is one such task that demands the presence of experienced operators for instantaneous management of post-fault activities. Therefore, an interest has arisen to develop innovative solutions to aid the operators in these tasks.

There have been many studies discussing the different types of faults and associated detection techniques in the IMs [1,2,3,4,5,6]. The important factors that determine the genre of the faults are the nature of fault and the part where the fault occurs. Accordingly, faults occurring in the IM, such as broken rotor bar faults, stator faults, bearing failures, are termed as internal faults and the faults external to the IM are called external faults. Supply faults and drive faults (in rectifier, dc link capacitor, and inverter) constitute the external faults.

The onset of faults in an IM is marked by alterations in the motor’s operation, such as variations in temperature, vibration, stator current fluctuations, electromagnetic field variations. Careful monitoring of these trends is the key to precise detection and diagnosis of faults. Accordingly, researchers have suggested fault detection techniques based on variations in nonelectrical parameters like vibration, temperature, acoustics, etc. [7,8,9,10,11] and electrical parameters, particularly motor current [12,13,14].

The analysis of motor current gained tremendous popularity due to the availability of simple signal processing techniques like wavelet analysis [12], fast Fourier transform (FFT) [13], Hilbert transform [14], etc. In addition to the above-mentioned signal processing techniques, the literature also records the extensive use of soft computing techniques. These systems mainly use fuzzy, neural network and rule-based expert systems to detect and diagnose faults [15,16,17,18]. Hybrid systems have also been proposed by many researchers in this area to improve the effectiveness of the system [19].

An analysis of the existing research works reveals that even though the literature is rich in works related to internal faults in the IMs [12,13,14,15,16,17,18,19,20],the studies related to drive faults are not so diverse. In [21], the classification of external faults of the IM has been presented. Faults such as single phase, unbalanced, under voltage, over voltage, and over load have been included in the study. Though the study provides reliable analysis for specific external faults, the proposed methodology is yet to be implemented with online condition monitoring and fault diagnosis. The various faults in the drive of an IMDS have been analyzed in [22,23,24,25,26,27,28,29,30,31]. Normalized values of voltage ripple and the energy profiles of the first three harmonics are used in [22] to detect faults in the rectifier stage of the IMDS. The work proposes a two-stage algorithm for the diagnosis of open-circuit faults in uncontrolled rectifiers. However, this algorithm is based on the assumption that the input to the rectifier is always periodic.

Open-circuit and short-circuit faults in uncontrolled rectifier have been investigated in [23]. Detection is done based on the DC link voltage and root-mean-square value of the input. In [24], several detection methods for open-circuit faults are evaluated. However, the detection time in these techniques is relatively long and is dependent on the frequency of current. The symmetry of the physical topology of voltage source inverter(VSI) and allelic points have been proposed as parameters for fault diagnosis in [25]. Diagnosis of open circuit in power electronic switches in the inverter side has been studied in [26] using Park’s vector approach on average current.

Soft computing techniques have been extensively used to detect and diagnose power converter faults in IMDS. Among the various soft computing techniques, fuzzy systems have been preferred in many works due to its effectiveness in representing expert knowledge. Researchers have considered different parameters to formulate membership functions in fuzzy-based systems. In [27], the electrical fault analysis of a three-phase IMDS was performed in MATLAB/Simulink. An algorithm based on fuzzy logic for detecting and analyzing the electrical faults in the IM was then developed based on the stator current amplitudes, negative sequence current and speed of the drive. Fundamental component and the polarity of DC component of voltage have been chosen as fuzzy inputs in [28]. While this system can successfully identify the switching faults, spurious supply side voltage variations can also trigger false positives. In [29], instantaneous current and time are the fuzzy membership function parameters chosen to identify the fault. Similarly, stator current magnitude has been used in [30] for fault detection. The dependence of instantaneous currents on the load condition of the motor reduces the effectiveness of this strategy. Concordia stator current pattern, which claims cost-effectiveness through reduction in number of sensors, is suggested in [31]. However, practical implementation of the technique in pulse width modulation (PWM)-based VSI is not feasible.

Despite the varied research in the field of detecting and analyzing faults in IMDSs, it is observed that many of them are restricted to instantaneous values of voltages or currents or similar parameters that are prone to vary with load. In other words, these works were developed at specific load conditions. Further, a fair share of the researches was limited to diagnosing a single genre of external fault at a time. Hence, a single system capable of taking care of all the drive fault conditions, based on fault characteristics at different load condition, is yet to be investigated. This paper proposes the design and development of an intelligent system for accurate, timely detection and diagnosis of drive faults in an IMDS.

Section 2 elaborates the step-by-step development of the proposed system. Design of the IM is presented in Sect. 3, and the analysis of faults is detailed in Sect. 4. The proposed fuzzy-based fault diagnosis algorithm and the validation of the proposed fuzzy-based fault diagnosis algorithm are explained in Sects.5 and 6, respectively. The conclusions and future scope are given in Sect. 7.

2 Development of Decision Support System

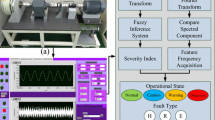

Development of the intelligent decision support system for fault detection and diagnosis starts with offline simulation-based examination of the drive behavior, followed by the design of the fault detection system. Figure 1 depicts the various phases involved in the process.

First phase involves the design of the IM using ANSYS Maxwell software. The parameters of IM are extracted from this phase. Further, the IMDS is modeled in MATLAB/Simulink using these parameters. The simulation studies are then done to acquire the various parameters of the IMDS under normal and faulted conditions. Detailed analysis of the parameters is then conducted to identify the variables that can be used as fault features to diagnose the fault. The fault detection and diagnosis algorithm are then designed based on the observations made from the fault analysis and tested using simulation.

3 Design of Induction Motor

The three-phase IMDS consists of an IM fed from a VSI that uses sinusoidal PWM technique for its control. In this study, a 5-HP squirrel cage IM is used for the analysis. The IM model developed using ANSYS Maxwell is shown in Fig. 2. The specifications of the IM and the parameters extracted from the ANSYS Maxwell model of IM are given in Tables 1 and 2, respectively. These parameters are used for modeling the IMDS in MATLAB/Simulink.

4 Fault Analysis

The faults in the drive are analyzed under two heads— switching faults and DC link faults. The open-circuit and short-circuit faults in the power switches of the rectifier and inverter constitute the switching faults. In IMDS, switching devices such as IGBT and MOSFET with appropriate gate drive circuit are used as switches in the inverter circuit. Inappropriate gate trigger signals and high thermal stresses in the switching devices may result in switching faults. On the other hand, earth faults and short circuit in the DC link capacitor comprise the DC bus faults.

Figure 3 shows the circuit diagram of a PWM-based IMDS in which various switching faults are represented. These faults are F1: short circuit of diode in rectifier, F2: open circuit of diode in rectifier, F3: the earth fault in DC bus, F4: DC link capacitor short circuit, F5: inverter IGBT open circuit, and F6: inverter IGBT short circuit. In this study, the performance of the three-phase IMDS under normal and faulty operating conditions with varying loads is analyzed by simulating PWM-controlled IMDS in MATLAB/Simulink.

The stator current response of the developed PWM-controlled IMDS when operated in normal condition (without fault) with load torque of 6 Nm is shown in Fig. 4. To simulate the response of the system under various fault conditions, a breaker-switch arrangement is used at the appropriate fault locations. With the intention of deducing an index to identify the fault, the stator currents Ia, Ib, and Ic are recorded. Figures 5, 6, 7, 8, 9, and 10 show the stator current responses at various fault conditions with 6 Nm load torque. Similar analysis is done for various load conditions, and the results are illustrated in Figs. 11, 12, and 13, and the parameters are tabulated in Table 3.

From a detailed analysis of the recorded data, it is inferred that while magnitude of Ia, Ib, and Ic can often indicate fault states clearly for a particular load condition; they fail under circumstances of varying load. Table 4 illustrates three typical cases to demonstrate the disadvantage of relying solely on stator current magnitude for fault diagnosis. In Case 1, the stator current magnitudes of a healthy IMDS operating at 18 Nm load and during Fault F5 with 6 Nm load are listed. From the values, it is evident that the stator currents magnitudes are comparable and hence cannot distinguish the fault. Similarly, in Case 2, the magnitudes of stator currents observed under fault F2 and fault F3 with a load torque of 6 Nm are seen to be identical. Case 3 shows yet another instance where comparable current magnitudes are obtained for different operating conditions of the IMDS. Thus, a fault diagnosis system relying solely on stator current magnitudes fails to make a correct diagnosis and hence necessitates the search for more reliable fault identifiers.

Therefore, in this work, THD analysis is also carried out for different fault and load conditions to analyze its effectiveness in fault identification. The variation of % THD of stator currents under different fault conditions with variable load is shown in Fig. 14, 15, and 16. These parameters are tabulated in Table 5. From the detailed analysis of Table 5, it is realized that the combination of stator currents and their respective THD may be potential fault identifiers. However,it is evident from Table 5 that a direct mapping between the extracted performance parameters and fault condition is not possible. Moreover, the nonlinear variation of the extracted features with respect to the fault condition makes the boundaries between the severity levels of a specific fault or between two faults hard to define. A typical true or false logic fails due to this lack of crisp boundaries. Thus, the fault signatures necessitate the use of fuzzy approach for fault detection and diagnosis.

5 Proposed Fuzzy-Based Fault Diagnosis Algorithm

The fault detection and diagnosis strategy proposed in this work are based on the relationship between the stator currents and their THD. However, the use of six variables (current in each phase and their respective THD) can impact the computational effectiveness of fuzzy systems. Therefore, this work considers the sum of the magnitudes of the rms value of the stator current in each phase as one input variable to fuzzy system. In addition, the THD of each phase accounts for the other three variables. Thus, fuzzy rules are formulated using the four inputs. Each input is divided into four fuzzy sets, and output is divided into seven fuzzy sets, and these are shown in Figs. 17 and 18, respectively.

Linguistic variables, the fundamental tool in fuzzy logic, form the bridge between the input and output variables. They systematically manage ambiguous concepts through words or sentences. In this paper, output fuzzy linguistic variable can be expressed as normal (N), rectifier short-circuit fault (F1), rectifier open-circuit fault (F2), DC link earth fault (F3), DC link capacitor short-circuit fault (F4), inverter IGBT open-circuit fault(F5), and inverter IGBT short-circuit fault (F6). The input variables of the fuzzy system can also be expressed in a similar manner. The sum of the RMS currents which forms the first input is interpreted as I. The linguistic variable I can be expressed as very small (IVS), small (IS), large(IL), and very large (IVL). The linguistic variables of all input fuzzy sets and their membership values are given in Table 6, and the output fuzzy set and their membership values are listed in Table 7. A partial representation of fuzzy rule system is shown in Fig. 19, and the main fuzzy rules are listed in Table 8.

The structure of the proposed fault detection algorithm is shown in Fig. 20. The continuous online monitoring of stator current of the IMDS forms the crux of the algorithm. The stator currents in all the phases are measured and given as input to the algorithm. In the next stage, the rms value of the stator currents and the THD of the currents are computed. Further, the sum of the rms value of the currents and the computed THD is given as the input to the fuzzy inference system. The output from the fuzzy inference system is the type of fault in the IMDS. This information can be communicated to the operating personnel through graphical user interfaces specially designed to suit the industry. As the fault features that form, the inputs to the fuzzy inference system can be computed by measuring the stator current alone; the requirement of cumbersome measurement and acquisition setup is eliminated in this system.

6 Validation of Fuzzy-Based Fault Detection and Diagnosis Algorithm

In this section, the performance of the proposed fuzzy-based detection and diagnosis algorithm under various fault scenarios is presented. First, the normal operating condition of the IMDS is considered. In Fig. 21, it is seen that when the membership function value of I is 7.64 (IVS), % THD of Ia is 1.78 (TAVS), %THD of Ib is 0.585 (TBVS), and %THD of Ic is 0.568 (TCVS), the output fuzzy set is 0.586. Any fuzzy output value between 0 and 1 is indicative of normal operating condition of the IMDS. Thus, by providing an output of 0.586 as depicted by Fig. 21, the fuzzy algorithm successfully identifies the normal condition of the IMDS. On a similar note, IMDS under fault F5 was tested next. As seen from Fig. 22, when I is (14.3), %THD of Ia is 17.7, %THD of Ib is 8.3, and %THD of Ic is 5.36, the output membership function is 1.48. This clearly lies within the range specified for Fault F5 in Table 6. Similar testing was done for the other faults as well. Figure 23 shows the simulation results in the event of Fault F6. From simulation studies, it is evident that the designed fuzzy algorithm is capable of detecting the faults based on the variations in the four inputs, viz. the total rms value and the THD of IM stator currents corresponding to the three phases.

In order to illustrate the performance of the proposed algorithm for multiple faults, the algorithm has also been tested for multiple faults scenarios, even though the probability of occurrence of such faults simultaneously is fairly small. Figure 24 shows the fuzzy rule viewer for IMDS when operated in combined fault condition (F1,F2, and F6) with load torque of 12 Nm. From Fig. 24, it is seen that the algorithm identifies the fault as F6 which is the most severe fault as compared to F1 and F2. Thus, in the event of combined faults, the most severe fault among the combination is diagnosed.

7 Conclusion

A fuzzy-based intelligent fault diagnosis algorithm for IMDS is designed and developed in this work. All drive fault conditions are simulated with different load conditions and analyzed to extract the characteristics that are affected by the fault conditions. From the fault analysis, it is observed that the stator current alone cannot accurately diagnose the fault. On detailed investigation of the results, it is identified that the sum of the rms value and the THD of the stator currents can accurately diagnose various drive fault conditions. Since the direct mapping between the input and output condition at different loads involves fuzziness, a fuzzy rule-based system is designed and tested using MATLAB. The system proposed in this work involves the measurement of rms value of stator currents alone which makes system design simple and cost-effective. It is envisaged that with the help of the proposed algorithm, the burden of cumbersome manual fault diagnosis process on the operating staff can be greatly reduced, and shut down time can be significantly minimized. In future, the system can be enhanced with the analysis and diagnosis of supply side faults of IMDS.

References

Nandi, S.; Toliyat, H.A.; Li, X.: Condition monitoring and fault diagnosis of electrical motors-a review. IEEE Trans. Energy Convers. 20(4), 719–729 (2005)

Bellini, A.; Filippetti, F.; Tassoni, C.; Capolino, G.A.: Advances in diagnostic techniques for induction machines. IEEE Trans. Ind. Electron. 55(12), 4109–4126 (2008)

Henao, H.; et al.: Trends in fault diagnosis for electrical machines: a review of diagnostic techniques. IEEE Ind. Electron. Mag. 8(2), 31–42 (2014)

Riera-Guasp, M.; Antonino-Daviu, J.A.; Capolino, G.A.: Advances in electrical machine, power electronic, and drive condition monitoring and fault detection: state of the art. IEEE Trans. Ind. Electron. 62(3), 1746–1759 (2015)

Liu, Y.; Bazzi, A.M.: A review and comparison of fault detection and diagnosis methods for squirrel-cage induction motors: state of the art. ISA Trans. 70, 400–409 (2017)

Huang, S.-R.; Huang, K.-H.; Chao, K.-H.; Chiang, W.-T.: Fault analysis and diagnosis system for induction motors. Comput. Electr. Eng. 54, 195–209 (2016)

Glowacz, A.; Glowacz, Z.: Diagnosis of the three-phase induction motor using thermal imaging. Infrared Phys. Technol. 81, 7–16 (2017)

Singh, G.; Naikan, V.: Infrared thermography based diagnosis of inter-turn fault and cooling system failure in three phase induction motor. Infrared Phys. Technol. 87, 134–138 (2017)

Gangsar, P.; Tiwari, R.: Investigation of vibration and current monitoring for prediction of mechanical and electrical faults in induction motor based on multiclass-support vector machine lgorithms. Mech. Syst. Signal Process. 94, 464–481 (2017)

Prieto, M.D.; Cirrincione, G.; Espinosa, A.G.; Ortega, J.A.; Henao, H.: Bearing fault detection by a novel condition-monitoring scheme based on statistical-time features and neural networks. IEEE Trans. Ind. Electron. 60(8), 3398–3407 (2013)

Glowacz, A.; Glowacz, W.; Glowacz, Z.; Kozik, J.: Early fault diagnosis of bearing and stator faults of the single-phase induction motor using acoustic signals. Measurement 113, 1–9 (2018)

da Costa, C.; Kashiwagi, M.; Mathias, M.H.: Rotor failure detection of induction motors by wavelet transform and Fourier transform in non-stationary condition. Case Studies Mech. Syst. Signal Process. 1, 15–26 (2015)

Singh, S.; Kumar, A.; Kumar, N.: Motor current signature analysis for bearing fault detection in mechanical systems. Procedia Mater. Sci. 6, 171–177 (2014)

Rangel-Magdaleno, J.; Peregrina-Barreto, H.; Ramirez-Cortes, J.; Cruz-Vega, I.: Hilbert spectrum analysis of induction motors for the detection of incipient broken rotor bars. Measurement 109, 247–255 (2017)

Soualhi, A.; Clerc, G.; Razik, H.: Detection and diagnosis of faults in induction motor using an improved artificial ant clustering technique. IEEE Trans. Ind. Electron. 60(9), 4053–4062 (2013)

Singh, H.; Seera, M.; Abdullah, M. Z.: Detection and diagnosis of broken rotor bars and eccentricity faults in induction motors using the Fuzzy Min-Max neural network. In: Proceeeings of the international joint conference on neural networks (IJCNN), Dallas, TX, pp. 1–5 (2013)

Adouni, A.; Ben Hamed, M.; Flah, A.; Sbita, L.: Sensor and actuator fault detection and isolation based on artificial neural networks and fuzzy logic application on induction motor. In: Proceeedings of the international conference on control, decision and information technologies (CoDIT), Hammamet, pp. 917–922 (2013)

Sreeja, V.; Mini, V. P.; Ushakumari, S.: Rotor fault detection and diagnosis of three phase induction motor drive system. In: Proceedings of the international conference on control communication & computing India (ICCC), Trivandrum, pp. 212–217 (2015)

Seera, M.; Lim, S.P.; Ishak, D.; Singh, D.: Offline and online fault detection and diagnosis of induction motors using a hybrid soft computing model. Appl. Soft Comput. 13(12), 4493–4507 (2013)

Nandi, S.: Stator fault detection in induction machines using triplen harmonics at motor terminal voltage after switch-off. In: proceedings of the IEEE power engineering society general meeting, pp. 2285–2290 Vol. 3 (2005)

M. V. P Ushakumari, S.: Incipient fault detection and diagnosis of induction motor using fuzzy logic. In: Proceedings of IEEE recent advances in intelligent computational systems, Trivandrum, pp. 675–681 (2011)

Rahiminejad, M.; Diduch, C.; Stevenson, M.; Chang, L.: Open-circuit fault diagnosis in 3-phase uncontrolled rectifiers. In: Proceedings of the 3rd IEEE international symposium on power electronics for distributed generation systems (PEDG), Aalborg, pp. 254–259 (2012)

Mahmoud, G.; Masoud, M.; El-Arabawy, I.: Rectifier Faults In Variable Voltage Variable Frequency Induction Motor Drives. In: Proceedings of the IEEE international electric machines & drives conference, Antalya, pp. 1125–1130 (2007)

Rothenhagen, K., Fuchs, F. W.: Performance of diagnosis methods for IGBT open circuit faults in three phase voltage source inverters for AC variable speed drives. In: Proceedings of the European conference on power electronics and applications, Dresden, pp. 10–17 (2005)

Wu, F.; Zhao, J.: A real-time multiple open-circuit fault diagnosis method in voltage-source-inverter fed vector controlled drives. IEEE Trans. Power Electron. 31(2), 1425–1437 (2016)

Kamel, T.; Biletskiy, Y.; Chang, L.: Open circuit fault diagnosis for the power electronic converter stages using ANFIS algorithm. In: Proceedings of IEEE 28th Canadian conference on electrical and computer engineering (CCECE), Halifax, NS, pp. 656–662 (2015)

Reema, N.; Mini, V. P.; Ushakumari, S.: Switching fault detection and analysis of induction motor drive system using fuzzy logic. In: Proceedings of the international conference on advances in green energy (ICAGE), Thiruvananthapuram, pp. 132–137 (2014)

Khater, F.; El-Sebah, M.I.; Osama, M.: Fault diagnostics in an inverter feeding an induction motor using fuzzy logic. J. Electr. Syst. Inf. Technol. 4, 10–17 (2017)

Ibrahim, S.; Faris, khaled Nagdy; Elzahab, E.A.: Implementation of fuzzy modeling system for faults detection and diagnosis in three phase induction motor drive system. J. Electr. Syst. Inf. Technol. 2, 27–46 (2015)

Zidani, F.; Diallo, D.; Benbouzid, M.E.H.; Nait-Said, R.: A fuzzy-based approach for the diagnosis of fault modes in a voltage-fed PWM inverter induction motor drive. IEEE Trans. Ind. Electron. 55(2), 586–593 (2008)

Surwase, D. A.; Jalit, A. S.; Chavan, M. D.: Fault detection and protection of induction motor using fuzzy logic. In: Proceedings of the international conference on innovations in electrical, electronics, instrumentation and media technology (ICEEIMT), Coimbatore, pp. 66–70 (2017)

Acknowledgements

The authors would like to thank Kerala State Council for Science, Technology and Environment (KSCSTE) for the financial support for this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mayadevi, N., Mini, V.P., Hari Kumar, R. et al. Fuzzy-Based Intelligent Algorithm for Diagnosis of Drive Faults in Induction Motor Drive System. Arab J Sci Eng 45, 1385–1395 (2020). https://doi.org/10.1007/s13369-019-03935-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-019-03935-2