Abstract

The purpose of this study was to develop and evaluate a novel amorphous solid dispersion system for tectorigenin (TG). TG is one of isoflavone aglycones extracted from Iris tectorum and flowers of Pueraria thunbergiana, but its poor water solubility and low membrane permeability have severely restricted the clinical application. To increase the aqueous solubility and oral bioavailability of TG, we prepared the solid dispersions of tectorigenin (TG-SD) using a simple solvent evaporation process with TG, polyvinylpyrrolidone (PVP) and PEG4000 at weight ratio of 7:54:9 after tested in several ratios. The prepared solid dispersions of tectorigenin are duly characterized for drug morphological conversion, in vitro dissolution and in vivo bioavailability. The X-ray diffraction (XRD), differential scanning calorimetry (DSC) and scanning electron microscopy (SEM) studies have indicated the morphological conversion of tectorigenin to amorphous form. In vitro release profiles revealed that the % release of TG-SD was achieved 4.35-fold higher than that of the pure drug after 150 min. The oral bioavailability of the solid dispersion in rats was also increased based on AUC0–t and C max of TG-SD, which were 4.8- and 13.1-fold higher than that of TG crystal, respectively. It is worth noting that physical mixture containing TG, PEG4000 and PVP produced a similar level of oral exposure as TG-SD, suggesting that PEG4000 and PVP were able to enhance bioavailability of TG in rats. However, with the reduction of particle size, TG-SD provided the fastest oral absorption compared to physical mixture and pure drug. These results demonstrated that the efficacy of solid dispersions for the enhancement of TG oral bioavailability was by increasing its aqueous solubility and the solid dispersion formulation could be a viable option for enhancing the oral bioavailability of TG.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Tectorigenin (TG) is an isoflavone aglycone, which can be isolated from Iris tectorum and flowers of Pueraria thunbergiana. In the ancient, the plants above had been used as Chinese traditional medicines as antipyretic, antidiarrhetic, diaphoretic and antiemetic agents (Keung and Vallee 1998). It had been indicated that isoflavone was one of the native components of the medicines by several groups (Choudhary et al. 2001; Miyazawa et al. 2001; Qi et al. 2005; Choudhary et al. 2008; Farag et al. 2009; Penetar et al. 2012). Isoflavones in plants were presented in the forms of glycosides and aglycones; glycosides were the main forms (Kim et al. 2006). Though most of isoflavone glycosides were water-soluble compounds, they were poorly absorbed by the intestinal epithelium and had weaker biological activities than the corresponding aglycones (Vitale et al. 2013). It was reported that after isoflavone glycosides were ingested, they were hydrolyzed to aglycones in apical membrane of the lumen of the small intestine (Xu et al. 1995). In addition, isoflavone aglycones were absorbed faster than isoflavone b-glucosides (Izumi et al. 2000). Therefore, TG was considered to be the pharmacodynamic substance foundation. Till recently, various pharmacological effects had been reported for TG, including antidiabetic (Jung et al. 2002; Chen et al. 2010; Kwon et al. 2011), antioxidative activity (Pool-Zobel et al. 2000; Kang et al. 2005; Wozniak et al. 2010), preventing prostate cancer (Farhan et al. 2002; Thelen et al. 2005; Hedlund et al. 2006; Iranshahi et al. 2012), estrogen-like effect (Yildiz et al. 2005; Shimozawa et al. 2007), chemoprevention (Jung et al. 2003; Sarkar et al. 2006; Lien et al. 2009), antiangiogenic and antitumor potency (Zhang et al. 2008; Kapoor 2013). Thus, TG was expected to be an active material in the clinical treatment. TG, belonging biopharmaceutical classification system (BCS) class IV drugs (Lindenberg et al. 2004) with low aqueous solubility and low permeability, exhibited a poor absolute bioavailability in pharmacokinetic studies. Hence formulation approaches which enhance solubility of TG in the gastrointestinal fluid were considered crucial to increase oral absorption. To our knowledge, studies on TG formulation had not been reported. The present study aimed to develop an optimized formulation, which efficiently enhanced the dissolution rate and oral bioavailability of TG. The efficient approaches had been investigated, including salt formation, prodrug formation, particle size reduction, complexation, micelles, microemulsions, nanoemulsions, nanosuspensions, solid lipid nanoparticle and solid dispersion (Vo et al. 2013).

Solid dispersion was one of the most applicable formulation strategies to structurally transform poorly water-soluble drugs with a wide range of physicochemical properties and had been extensively studied to improve the bioavailability of poorly soluble compounds (Bhatnagar et al. 2013). The techniques included spray-dried dispersion, solvent evaporation and hot-melt extrusion. The ultimate formulations including eutectic, solid solution or amorphous solid dispersion could improve solubility and dissolution rate of compounds by dispersing the poorly water-soluble drug in a biologically inert solid matrix carrier.

In the present study, we described the preparation of TG-loaded solid dispersion (TG-SD) using a conventional solvent evaporation method. PVP, PEG4000 and PEG6000 had been previously shown to enhance drug solubilization in the gastrointestinal tract (Thanki et al. 2013). Therefore, these hydrophilic polymers were used as carriers to enhance dissolution rate of TG. Characterization of the drug in the various formulations was performed by XRD, SEM and drug release was quantified by dissolution studies. In addition, the bioavailabilities of TG from the pure drug, solid dispersion formulation and physical mixture were also compared in vivo.

2 Materials and methods

2.1 Materials

TG was obtained from Must bio-technology Co., Ltd. (Chengdu, China), and the purity was ≥98 %. PEG4000 was purchased from sigma Co., Ltd. (USA). PVP (PLASDONE K-29/32) was obtained from ISP Co., Ltd. (USA). Ethanol was received from Tianhua chemical industry science and technology Co., Ltd. (Chengdu, China). All the other reagents were of analytical grade and purity.

2.2 Preparation of tectorigenin-loaded solid dispersions (TG-SD)

The solid dispersion of TG was prepared by a conventional solvent evaporation method. The weight ratios of drug to mixed carrier (PEG4000/PVP at the weight ratio of 1:6 in previous study)were 1:3, 1:6 and 1:9. TG and mixed carrier were dispensed into a beaker. While the beaker was placed in a water bath held at 60 °C, TG and mixed carrier were dissolved in a defined amount of absolute ethyl alcohol. The solution was transferred to a rotary evaporator and the solvent was evaporated under vacuum. Following that, the preparation was cooled immediately at −20 °C and solidified for 12 h. The solidified masses were stored in a thermostatic Air-blower-driven drying closet for 12 h and then pulverized by a pestle. The powders were passed through a 0.154-mm sieve and then collected.

2.3 Preparation of physical mixture

Physical mixture was prepared with mixed carrier and TG at weight ratio of 9:1. Each component was accurately weighed out according to the desired amount and mingled by simple mixing.

2.4 Preparation of drug-loaded CMC–Na suspension

The drug-loaded CMC–Na suspension was prepared by adding small amounts of 0.5 % (w/v) CMC–Na suspension to the drug and mixing thoroughly. The 0.5 % (w/v) CMC–Na suspension was prepared by adding the required amount of CMC–Na and mixing in hot water followed by adequate agitation until solution was clear.

2.5 Characterization of formulations

2.5.1 Powder X-ray diffraction (XRD)

The diffraction patterns of samples were recorded using a DX-1000 diffractometer (Dandong instrument Ltd, Dandong, China) with a copper anode (Cu Kα radiation), a voltage of 40 kV, a current of 25 mA radiation scattered in the crystalline regions of the samples. Patterns were obtained using a step width of 0.06 °C with a detector resolution in 2θ (diffraction angle) between 2 and 50 °C.

2.5.2 Differential scanning calorimetry (DSC)

Thermal characteristics of TG crystal, carrier, physical mixture and TG-SD were investigated using a differential scanning calorimeter (DSC Q2000 TA Instruments, USA). Samples were accurately weighed into sealed aluminum pans. The temperature range for the thermogram was 25–250 °C at a heating rate of 5 °C/min. Samples were purged in a stream of dry nitrogen flowing at 50 mL/min.

2.5.3 Scanning electron microscopy (SEM)

The surface morphology and particle size of TG, carrier, physical mixture and TG-SD were determined by JSM-7500F scanning electron microscopy (SEM) (JEOL, Japan), with an accelerating voltage of 5 kv. The samples were sputter coated with gold primarily.

2.5.4 In vitro dissolution rate

Release of TG from the solid dispersion was evaluated with a stirring rate of 100 rpm in 1,000 mL of dissolution media using the basket method, according to the method in the Chinese Pharmacopoeia 2010 (Appendix XC, the first method) at 37 ± 0.5 °C. Dissolution samples of 5 mL were collected at 10, 20, 30, 60, 90, 120 and 150 min, respectively, and immediately followed by addition of an equal volume of fresh dissolution medium maintained at the same temperature to keep the volume of dissolution media constant and to maintain the sink conditions. The samples were filtered through a membrane filter (0.45 μm) within 30 s, and the absorbance value of TG was analyzed by UV at 268 nm (UV 759CRT, Youke instrument Co., Ltd. Shanghai, China).

2.6 In vivo bioavailability study

2.6.1 Animals

Male Sprague–Dawley rats, weighing ca. 250 ± 20 g (8–9 weeks of age; animal experiment center of Sichuan university, Sichuan, China), were housed two per cage in the laboratory with free access to food and water, and maintained on a 12-h dark/light cycle in a room with controlled temperature (24 ± 1 °C) and humidity (55 ± 5 %). All procedures used in the present study were conducted in accordance with the guidelines approved by the Institute of Animal Resources of Sichuan University.

2.6.2 Pharmacokinetic study

The rats were fasted overnight before dosed at 40 mg/kg by gavage. All the formulations were suspended by 0.5 % (w/v) CMC–Na before administration. Blood samples were obtained at a volume of 500 μL from the tail vein of unanesthetized rats at the indicated times (0.083, 0.167, 0.33, 0.5, 1, 2, 4, 6, 8, 10, 12, 14, 16, 24 and 36 h). Each blood sample (500 μL) was centrifuged at 8,000 rpm to prepare plasma samples. The samples were kept frozen at below −40 °C until they were analyzed. TG concentrations in plasma were determined by HPLC. In brief, 400 μL of precipitator (methanol: acetic acid, 9:1) was added to 200 μL of plasma sample, and the solution was vortex-mixed for 5 min and centrifuged at 8,000 rpm for 5 min. The upper layer was transferred to another tube and evaporated at 40 °C by a nitrogen evaporator. The residue was reconstituted by 100 μL of mobile phase and centrifuged at 12,000 rpm for 5 min, after that, 20 μL of the solution was injected for HPLC analysis.

2.6.3 High-performance liquid chromatography analysis

All compounds and internal standard were separated on a Waters Symmetry reverse C-18 column (150 × 4.6 mm, 5 μm). Mobile phase consisted of methanol and phosphate buffer solution at pH 3.0 (55:45, volume ratio). The effluent was monitored at a UV absorption wavelength of 268 nm at a flow rate of 1.0 mL/min (Liu et al. 2009). The retention times of TG and internal standard (kaempferol) were 9.7 min and 14.3 min, respectively. The calibration curve of TG was linear within the concentration range of 0.03 ~10.00 µg/mL, and the lower limit of qualification was 0.03 µg/mL. The intra-day and inter-day precision (RSD) of TG were lower than 9.28 %, and the recovery rates were up to 89.29 %. All the data obtained in the method validation met the requirements of quantitative analysis. The maximum plasma concentration (C max) after oral administration and the time at which it was observed (T max) were observed directly from the individual plasma concentration–time profiles. Area under the plasma concentration–time curve from 0 to 60 h (AUC0–60) was calculated by the linear trapezoid rule. The terminal half-life (t ½) was calculated as ln(2) divided by the absolute value of the slope of the terminal log-linear phase. The relative bioavailability was calculated by dividing mean AUC value of TG physical mixture or solid dispersion formulation by mean AUC of CMC–Na formulation.

2.6.4 Statistical analysis

All the results obtained from pharmacokinetic study were expressed as mean ± standard deviation. Pharmacokinetic parameters were obtained using drug and statistics (DAS) version 2.1.1 software (Mathematical Pharmacology Professional Committee of China, Shanghai, China). Statistical differences among groups were assessed using the ANOVA test among three means for unpaired data. When P < 0.05, statistical significance was considered to be achieved.

3 Results and discussion

3.1 Preparation of solid dispersion

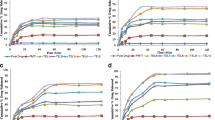

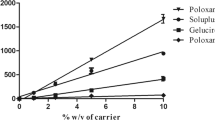

The solid dispersions of TG were prepared with the mixed carrier(PEG4000/PVP at the weight ratio of 1:6 in previous study)in the ratios of 1:3, 1:6 and 1:9 (drug:carrier) by a conventional solvent evaporation method through preliminary study using dissolution profiles. The results were presented in Fig. 1. The solvent evaporation method involves dissolution of TG and mixed carrier in absolute ethyl alcohol, hot bath, evaporation of the solvent and cooling to obtain the product. The key procedure was to ensure TG powder dispersed uniformly. In addition, with the improved ratio of mixed carrier in solid dispersions, the dissolution of TG from solid dispersions was obviously increased. Ultimately, we obtained the optimal formulation of TG-SD with drug, polyvinylpyrrolidone (PVP) and PEG4000 at weight ratio of 7:54:9. PVP and PEG were the most frequently used polymers for the preparation of solid dispersions (Bikiaris 2011a, b; Alam et al. 2012). PVP was a polymeric lactam, which had low toxicity, strong hydrophilic properties, and physiological tolerance (Narang and Srivastava 2002). PVP was extensively used as carrier in preparation of solid dispersion by solvent methods because of its universal solubility in hydrophilic and hydrophobic solvents (Sharma and Jain 2010; Barmpalexis et al. 2011). In addition, PEGs were widely used in preparation of solid dispersion because of their low melting point (50–60 °C), rapid solidification rate and capability of forming solid drug solutions. Consequently, a mixed carrier containing two polymers was designed aimed at preparing an optimized solid dispersion with enhanced dissolution rate and oral bioavailability. The effect of various carriers on the solubility of TG was selected as the evaluation indicator. The absorbance value of TG in the filtrate was analyzed by UV at 268 nm (UV 759CRT, Youke instrument Co., Ltd. Shanghai, China). According to the previous studies, PVP and PEG4000 were the most effective solubilizers for TG, and the mixed carrier of PEG4000 and PVP at the ratio of 1:6 (w/w) could be used to prepare a TG-SD with the highest dissolution rate of TG in vitro.

3.2 Characterization of formulations

3.2.1 Powder X-ray diffraction analysis

Powder X-ray diffractograms of TG alone, TG-SD, physical mixture and carrier are shown in Fig. 2. The presence of TG distinct peaks in the XRD spectrum indicated that TG was present in nature as a crystalline material with major characteristic diffraction peaks appearing at a diffraction angle of 2θ at 5°–30°. The carrier exhibited a distinct pattern with diffraction peaks at 2θ value of 19.2° and 23.6°. Diffraction peak intensity of physical mixture weaken comparing with that of TG alone, but there were still many obvious diffraction peaks in comparison to that of carrier, demonstrating that there still existed a crystal form of TG in the physical mixture, which attributed to TG crystal and excipients. Meanwhile, the diffraction pattern of TG-SD showed an absence of major diffraction peaks corresponding to TG crystal, indicating that TG in TG-SD presented predominantly as the amorphous state. Moreover, no peaks other than those that could be assigned to pure TG and carrier were detected in the solid dispersions of TG, indicating no chemical interaction in the solid state between the entities.

3.2.2 Differential scanning calorimetry analysis

A sharp endothermic peak corresponding to the melting point of crystalline TG was recorded at 230.98 °C in the DSC thermogram (Fig. 3). However, a less intense and broader melting peak for TG was observed in the DSC thermogram of physical mixture, with a peak shift toward lower temperature 210.19 °C. This may result from the impact of the melted carrier on crystalline TG within the physical blend. There was no distinct TG melting peak observed in TG-SD thermogram, which confronted well with the XRD results.

3.2.3 Scanning electron microscopy analysis

To investigate the morphological differences of samples and to further explain the XRD/DSC results, SEM analysis was performed and the results are shown in Fig. 4. TG was observed as prismatic crystals. Carrier which contained PVP and PEG4000 existed as spherical or irregularly shaped particles with smooth surfaces. The figure of the physical mixture of TG with carrier showed the presence of drug crystals surrounded by carrier. On the other hand, in TG-SD, the irregularly shaped particles of carrier could be observed, and the smooth surface was covered by many small lamellas attributed to TG. Figure. 4 shows TG had lost its crystalline structure, suggesting that TG had converted to amorphous form in TG-SD. This speculation was confirmed by the results of XRD/DSC analysis. Meanwhile, it can be observed that the particle size of TG reduced appreciably with variable degrees. Theoretically, an amorphous formulation of poorly soluble chemicals tended to exceed its crystalline formulation markedly in terms of aqueous solubility and dissolution behavior.

3.2.4 Dissolution analysis

It is interesting to compare the results of TG dissolution tests from solid dispersion samples performed by solvent evaporation method with those of the corresponding physical mixture as well as plain TG. As shown in Fig. 5, enhancement of TG dissolution rate was achieved. The % release of TG-SD was 99.22 ± 8.36 % at the end of 150 min, signifying that TG had dissolved completely, meanwhile, the % release of TG crystal and physical mixture was 22.80 ± 2.94 and 46.18 ± 2.83 %, respectively. Obviously, the TG-SD gave significantly higher dissolution ratios compared to the pure drug powder and physical mixture in defined time, which supported the result that TG crystal transformed to amorphous material in TG-SD. In addition, physical mixture exhibited higher dissolution ratio than pure drug powder, which attributed mainly to the improved solubilization efficacy of PEG4000 and PVP. The dissolution tests of TG, physical mixture and TG-SD were ensured under sink conditions and pH 6.8 PBS was selected as dissolution media to simulate the intestinal environments.

The dissolution study indicated that the mixture of PEG4000 and PVP as the carrier in solid dispersions leads to an improvement in the solubility of TG. Enhancement of TG dissolution rate was achieved significantly by preparing an innovative solid dispersion of TG with the mixed carrier of PEG4000 and PVP, but the full mechanism behind the improved dissolution rates for amorphous drug compounds stabilized by a hydrophilic carrier is still not fully understood. Comprehensive reviews of the subject have been given by others (Leuner and Dressman 2000; Craig 2002; Vasconcelos et al. 2007; Dhirendra et al. 2009; Bao et al. 2014). This dissolution has been suggested to either be carrier controlled or drug controlled (Khan et al. 2014; Prasad et al. 2014). For the carrier controlled, the dissolution is dominated by the properties of the carrier and the weight ratio of mixed carriers, whereas for the drug controlled, drug properties such as particle size and physical form can be linked to the dissolution rate. The possible reasons for leading to improvement in dissolution rate were that the solvent evaporation method, synergistic effect of trituration and solubilization of used solvent reduced crystallinity of drugs. The other reason may be due to availability of increased surface area of particles and dispersing uniformity.

3.3 Rat pharmacokinetics analysis

The dose for pharmacokinetic study was 40 mg/kg based on the previous study (Park et al. 2004; Lee et al. 2005). The mean plasma concentration profiles of TG after oral administration of TG crystal, physical mixture and solid dispersion to rats at a dose of 40 mg/kg as TG are shown in Fig. 6, which displayed TG from TG-SD formulation and physical mixture exhibited more rapid absorption, compared with the TG crystal. Moreover, TG existed in TG-SD had the highest C max than that of corresponding to physical mixture and TG crystal. The key pharmacokinetic parameters of TG are listed in Table 1, from which we could observe that both TG-SD and physical mixture exhibited distinct improvements in the C max, T max and AUC0–t over TG crystal (P < 0.05). In particular, C max from the TG-SD was 13.1 and 5.86-fold higher than TG crystal and physical mixture, respectively, the AUC0–t from the TG-SD was 4.8- and 1.5-fold higher than TG crystal and physical mixture, respectively, and T max was significantly shorter than those of the other two preparations (P < 0.05). All of the results above suggested that developed solid dispersion formulation could improve the drug release and absorption rate in the gastrointestinal tract and consequently improve the oral bioavailability of TG.

As the results of XRD, DSC and SEM analysis for characterization of formulations, it could be inferred that TG crystal transformed to amorphous nature in TG-SD. An amorphous solid was a material which was similar to a crystalline solid, but had no long-range order of molecular energy surface corresponding to different molecular packing or well-defined molecular conformation. Structure like this resulted in some properties which were valuable in pharmaceutical research, including higher solubility and higher dissolution rate (Yu 2001). Therefore, it could be anticipated that TG-SD would exhibit a higher dissolution rate compared to the pure drug. In dissolution study, the % release of TG-SD was 4.35-fold higher than the pure drug (Fig. 5), which supported the above point.

The most ponderable result was obtained in the pharmacokinetic study. The key pharmacokinetic parameters of TG showed that the AUC0–t and C max of TG-SD were increased by 4.8- and 13.1-fold, respectively, compared to TG crystal. In brief, the relative bioavailability of TG-SD was 4.8-fold higher than that of TG crystal. The results could be attributed to the amorphous nature of TG in this formulation. The enhanced dissolution rate and solubility of amorphous material were able to improve the bioavailability of the drugs, of which the solubility or dissolution rate could be the limiting step for their absorption (Gao 2008). Interestingly, the physical mixture exhibited a similar relative bioavailability compared to TG-SD (P > 0.05), which was significantly different with pure drug (P < 0.05). One possible explanation for this result was the presence of PVP and PEG4000. According to Noyes–Whitney equation, the main possibilities for improving drug dissolution would be to increase the drug surface area available for dissolution by decreasing the particle size of the solid compound and/or by optimizing the wetting characteristics of the compound surface (Finia et al. 2005). Excipients from physical mixture and TG-SD maintained the drug in a supersaturated state in the gastrointestinal tract, and particularly maximized the drug solubility within the prime absorptive site of the gut (Janssens and Van den Mooter 2009). Especial for PVP, which had been indicated to prevent drug precipitation or increase absorption by increasing drug-free fraction (Gosangari and Dyakonov 2013). In addition, TG-SD exhibited a shortest T max, relative to pure drug and physical mixture, which suggested that TG-SD provided the fastest oral absorption of TG. The shortest T max was attributed mainly to the highest dissolution rate influenced by the decreased particle size, combined with the results observed from the SEM results (Fig. 4) and dissolution profiles of TG, physical mixture and TG-SD (Fig. 5) and the plasma profiles shown in Fig. 6. On the other hand, it was once reported that drugs with smaller particle size enhanced bioavailability not only by enhancing dissolution but also the increased uptake by the gastrointestinal lymphatic system, a route from which drug nanoparticles could enter into circulation circumventing the first-pass effect (Nassar et al. 2011). Although amorphous material existed a widely use in pharmaceutical researches, it was thermodynamically unstable and may recrystallize during storage (Konno and Taylor 2006). Thus storage stability of this formulation should be investigated in further studies.

TG belonged to BCS class IV drugs with low solubility and low permeability. As dissolution was a rate-limiting step for oral absorption of these drugs, it had been widely demonstrated that development of solubility could lead to a correspond enhancement in oral bioavailability (Leuner and Dressman 2000). Hence, the present study focused on the attempts to increase the dissolution rates of the drug. Finally, we successfully developed a TG-SD with an enhancement of 4.8-fold in oral bioavailability, relative to TG crystal. In addition, lipid-based formulation approaches may be successfully employed to enhance the uptake of drug in gastrointestinal tract for drugs class IV (O’Driscoll and Griffin 2008), such as microemulsion and self-emulsifying drug delivery systems. In recent years, it had been reported that various novel formulations that based on combined formulations (Venishetty et al. 2012; Faisal et al. 2013; Onoue et al. 2013; Siddiqui et al. 2013) enhanced the oral bioavailability via developing both solubility and permeability of drugs, and were expected to become optimized formulations of BSC class II/IV drugs. Since formulation studies of TG had not been reported, further studies would be needed to screen formulations of TG using novel or conventional strategies, which aimed at improving the physicochemical properties and in vivo behavior of compounds.

4 Conclusion

Solid dispersion in the enhancement of aqueous solubility and oral bioavailability of poorly soluble drugs has been becoming prominent. In the present work, an innovative solid dispersion with mixed carrier for an aqueous insoluble drug, TG, is prepared by a solvent evaporation method. TG-SD could obviously improve the dissolution rate of TG in vitro and the oral bioavailability in vivo compared to plain drug. The results of characterization indicated that the enhancement of aqueous solubility and oral bioavailability can be attributed to the factors such as reduced particle size, amorphous form of drug, which resulted in the enhancement of dissolution rate and intestinal uptake. This formulation could be applied as a new, effective and viable option for enhancing the oral bioavailability of TG. In the future, we are going to optimize the strategies for lipid-based formulations to develop an optimal oral formulation with the higher oral bioavailability of TG.

References

Alam MA, Ali R, Al-Jenoobi FI, Al-Mohizea AM (2012) Solid dispersions: a strategy for poorly aqueous soluble drugs and technology updates. Expert Opin Drug Deliv 9:1419–1440

Bao L, Ma J, Long W, He P, Zhang T, Nguyen AV (2014) Fractal analysis in particle dissolution: a review. Rev Chem Eng 30:261–287

Barmpalexis P, Kachrimanis K, Georgarakis E (2011) Solid dispersions in the development of a nimodipine floating tablet formulation and optimization by artificial neural networks and genetic programming. Eur J Pharm Biopharm Off J Arbeitsgemeinschaft fur Pharmazeutische Verfahrenstechnik e.V 77:122–131

Bhatnagar P, Dhote V, Chandra S, Mahajan SC, Mishra PK, Mishra DK (2013) Solid dispersion in pharmaceutical drug development: from basics to clinical applications. Curr Drug Deliv 11:155–171

Bikiaris DN (2011a) Solid dispersions, part I: recent evolutions and future opportunities in manufacturing methods for dissolution rate enhancement of poorly water-soluble drugs. Expert Opin Drug Deliv 8:1501–1519

Bikiaris DN (2011b) Solid dispersions, part II: new strategies in manufacturing methods for dissolution rate enhancement of poorly water-soluble drugs. Expert Opin Drug Deliv 8:1663–1680

Chen QC, Zhang WY, Jin W, Lee IS, Min B-S, Jung H-J, Na M, Lee S, Bae K (2010) Flavonoids and isoflavonoids from Sophorae Flos improve glucose uptake in vitro. Planta Med 76:79–81

Choudhary MI, Nur-e-Alam M, Baig I, Akhtar F, Khan AM, Ndognii PO, Badarchiin T, Purevsuren G, Nahar N, Atta ur R (2001) Four new flavones and a new isoflavone from Iris bungei. J Nat Prod 64:857–860

Choudhary MI, Hareem S, Siddiqui H, Anjum S, Ali S, Atta Ur R, Zaidi MI (2008) A benzil and isoflavone from Iris tenuifolia. Phytochemistry 69:1880–1885

Craig DQM (2002) The mechanisms of drug release from solid dispersions in water-soluble polymers. Int J Pharm 231:131–144

Dhirendra K, Lewis S, Udupa N, Atin K (2009) Solid dispersions: a review. Pak J Pharm Sci 22:234–246

Faisal W, Ruane-O’Hora T, O’Driscoll CM, Griffin BT (2013) A novel lipid-based solid dispersion for enhancing oral bioavailability of Lycopene-in vivo evaluation using a pig model. Int J Pharm 453:307–314

Farag SF, Kimura Y, Ito H, Takayasu J, Tokuda H, Hatano T (2009) New isoflavone glycosides from Iris spuria L. (Calizona) cultivated in Egypt. J Nat Med 63:91–95

Farhan H, Wahala K, Adlercreutz H, Cross HS (2002) Isoflavonoids inhibit catabolism of vitamin D in prostate cancer cells. J Chromatogr B Anal Technol Biomed Life Sci 777:261–268

Finia A, Moyanob JR, Gines JM, Perez-Martinez JI, Rabasco AM (2005) Diclofenac salts, II. Solid dispersions in PEG6000 and Gelucire 50/13. Eur J Pharm Biopharm 60:99–111

Gao P (2008) Amorphous pharmaceutical solids: characterization, stabilization, and development of marketable formulations of poorly soluble drugs with improved oral absorption. Mol Pharm 5:903–904

Gosangari S, Dyakonov T (2013) Enhanced dissolution performance of curcumin with the use of supersaturatable formulations. Pharm Dev Technol 18:475–480

Hedlund TE, van Bokhoven A, Johannes WU, Nordeen SK, Ogden LG (2006) Prostatic fluid concentrations of isoflavonoids in soy consumers are sufficient to inhibit growth of benign and malignant prostatic epithelial cells in vitro. Prostate 66:557–566

Iranshahi M, Vu H, Pham N, Zencak D, Forster P, Quinn RJ (2012) Cytotoxic evaluation of alkaloids and isoflavonoids from the Australian tree Erythrina vespertilio. Planta Med 78:730–736

Izumi T, Piskula MK, Osawa S, Obata A, Tobe K, Saito M, Kataoka S, Kubota Y, Kikuchi M (2000) Soy isoflavone aglycones are absorbed faster and in higher amounts than their glucosides in humans. J Nutr 130:1695–1699

Janssens S, Van den Mooter G (2009) Review: physical chemistry of solid dispersions. J Pharm Pharmacol 61:1571–1586

Jung SH, Lee YS, Lee S, Lim SS, Kim YS, Shin KH (2002) Isoflavonoids from the rhizomes of Belamcanda chinensis and their effects on aldose reductase and sorbitol accumulation in streptozotocin induced diabetic rat tissues. Arch Pharmacal Res 25:306–312

Jung SH, Lee YS, Lee S, Lim SS, Kim YS, Ohuchi K, Shin KH (2003) Anti-angiogenic and anti-tumor activities of isoflavonoids from the rhizomes of Belamcanda chinensis. Planta Med 69:617–622

Kang KA, Lee KH, Chae S, Zhang R, Jung MS, Kim SY, Kim HS, Kim DH, Hyun JW (2005) Cytoprotective effect of tectorigenin, a metabolite formed by transformation of tectoridin by intestinal microflora, on oxidative stress induced by hydrogen peroxide. Eur J Pharmacol 519:16–23

Kapoor S (2013) Tectorigenin and its inhibitory effects on tumor growth in systemic malignancies. Immunopharmacol Immunotoxicol 35:533

Keung WM, Vallee BL (1998) Kudzu root: an ancient Chinese source of modern antidipsotropic agents. Phytochemistry 47:499–506

Khan AW, Kotta S, Ansari SH, Sharma RK, Ali J (2014) Enhanced dissolution and bioavailability of grapefruit flavonoid Naringenin by solid dispersion utilizing fourth generation carrier. Drug Dev Ind Pharm 1–8 (ahead of print)

Kim SL, Berhow MA, Kim JT, Chi HY, Lee SJ, Chung IM (2006) Evaluation of soyasaponin, isoflavone, protein, lipid, and free sugar accumulation in developing soybean seeds. J Agric Food Chem 54:10003–10010

Konno H, Taylor LS (2006) Influence of different polymers on the crystallization tendency of molecularly dispersed amorphous felodipine. J Pharm Sci 95:2692–2705

Kwon DY, Hong SM, Ahn IS, Kim MJ, Yang HJ, Park S (2011) Isoflavonoids and peptides from meju, long-term fermented soybeans, increase insulin sensitivity and exert insulinotropic effects in vitro. Nutrition 27:244–252

Lee HU, Bae EA, Kim DH (2005) Hepatoprotective effect of tectoridin and tectorigenin on tert-butyl hyperoxide-induced liver injury. J Pharm Sci 97:541–544

Leuner C, Dressman J (2000) Improving drug solubility for oral delivery using solid dispersions. Eur J Pharm Biopharm 50:47–60

Lien TF, Hsu YL, Lo DY, Chiou RY (2009) Supplementary health benefits of soy aglycons of isoflavone by improvement of serum biochemical attributes, enhancement of liver antioxidative capacities and protection of vaginal epithelium of ovariectomized rats. Nutr Metab 6:15

Lindenberg M, Kopp S, Dressman JB (2004) Classification of orally administered drugs on the World Health Organization Model list of Essential Medicines according to the biopharmaceutics classification system. Eur J Pharm Biopharm 58:265–278

Liu T, Chen Z, Guo Y, Jiang X, Ma G (2009) Determination of tectoridin in rat plasma by high-performance liquid chromatography and its application to pharmacokinetic studies. Biomed Chromatogr BMC 23:754–758

Miyazawa M, Sakano K, Nakamura S, Kosaka H (2001) Antimutagenic activity of isoflavone from Pueraria lobata. J Agric Food Chem 49:336–341

Narang AS, Srivastava AK (2002) Evaluation of solid dispersions of Clofazimine. Drug Dev Ind Pharm 28:1001–1013

Nassar T, Attili-Qadri S, Harush-Frenkel O, Farber S, Lecht S, Lazarovici P, Benita S (2011) High plasma levels and effective lymphatic uptake of docetaxel in an orally available nanotransporter formulation. Cancer Res 71:3018–3028

O’Driscoll CM, Griffin BT (2008) Biopharmaceutical challenges associated with drugs with low aqueous solubility—the potential impact of lipid-based formulations. Adv Drug Deliv Rev 60:617–624

Onoue S, Kojo Y, Suzuki H, Yuminoki K, Kou K, Kawabata Y, Yamauchi Y, Hashimoto N, Yamada S (2013) Development of novel solid dispersion of tranilast using amphiphilic block copolymer for improved oral bioavailability. Int J Pharm 452(1):220–226

Park EK, Shin YW, Lee HU, Lee CS, Kim DH (2004) Passive cutaneous anaphylaxis-inhibitory action of tectorigenin, a metabolite of tectoridin by intestinal microflora. Biol Pharm Bull 27:1099–1102

Penetar DM, Toto LH, Farmer SL, Lee DY, Ma Z, Liu Y, Lukas SE (2012) The isoflavone puerarin reduces alcohol intake in heavy drinkers: a pilot study. Drug Alcohol Depend 126:251–256

Pool-Zobel BL, Adlercreutz H, Glei M, Liegibel UM, Sittlingon J, Rowland I, Wähälä K, Rechkemmer G (2000) Isoflavonoids and lignans have different potentials to modulate oxidative genetic damage in human colon cells. Carcinogenesis 21:1247–1252

Prasad D, Chauhan H, Atef E (2014) Amorphous stabilization and dissolution enhancement of amorphous ternary solid dispersions: combination of polymers showing drug–polymer interaction for synergistic effects. J Pharm Sci 103:3511–3523

Qi BM, Cai CC, Deng XM, Zhang L (2005) Protective effect of purariae isoflavone on apoptosis cells of nasal mocosas in ovariectomized rats. Zhongguo Zhong yao za zhi Zhongguo zhongyao zazhi China J Chin Mater Med 30:855–857

Sarkar FH, Adsule S, Padhye S, Kulkarni S, Li Y (2006) The role of genistein and synthetic derivatives of isoflavone in cancer prevention and therapy. Mini Rev Med Chem 6:401–407

Sharma A, Jain C (2010) Preparation and characterization of solid dispersions of carvedilol with PVP K30. Res Pharm Sci 5:49

Shimozawa N, Okajima K, Harada N (2007) Estrogen and isoflavone attenuate stress-induced gastric mucosal injury by inhibiting decreases in gastric tissue levels of CGRP in ovariectomized rats. Am J Physiol Gastrointest Liver Physiol 292:G615–G619

Siddiqui A, Alayoubi A, El-Malah Y, Nazzal S (2013) Modeling the effect of sonication parameters on size and dispersion temperature of solid lipid nanoparticles (SLNs) by response surface methodology (RSM). Pharm Dev Technol 19(3):342–346

Thanki K, Gangwal RP, Sangamwar AT, Jain S (2013) Oral delivery of anticancer drugs: challenges and opportunities. J Control Release Off J Control Release Soc 170:15–40

Thelen P, Scharf J-G, Burfeind P, Hemmerlein B, Wuttke W, Spengler B, Christoffel V, Ringert R-H, Seidlová-Wuttke D (2005) Tectorigenin and other phytochemicals extracted from leopard lily Belamcanda chinensis affect new and established targets for therapies in prostate cancer. Carcinogenesis 26:1360–1367

Vasconcelos T, Sarmento B, Costa P (2007) Solid dispersions as strategy to improve oral bioavailability of poor water soluble drugs. Drug Discov Today 12:1068–1075

Venishetty VK, Chede R, Komuravelli R, Adepu L, Sistla R, Diwan PV (2012) Design and evaluation of polymer coated carvedilol loaded solid lipid nanoparticles to improve the oral bioavailability: a novel strategy to avoid intraduodenal administration. Colloids Surf B Biointerfaces 95:1–9

Vitale DC, Piazza C, Melilli B, Drago F, Salomone S (2013) Isoflavones: estrogenic activity, biological effect and bioavailability. Eur J Drug Metab Pharmacokinet 38:15–25

Vo CL, Park C, Lee BJ (2013) Current trends and future perspectives of solid dispersions containing poorly water-soluble drugs. Eur J Pharm Biopharm Off J Arbeitsgemeinschaft fur Pharmazeutische Verfahrenstechnik e.V 85:799–813

Wozniak D, Janda B, Kapusta I, Oleszek W, Matkowski A (2010) Antimutagenic and anti-oxidant activities of isoflavonoids from Belamcanda chinensis (L.) DC. Mutat Res 696:148–153

Xu X, Harris KS, Wang HJ, Murphy PA, Hendrich S (1995) Bioavailability of soybean isoflavones depends upon gut microflora in women. J Nutr 125:2307–2315

Yildiz MF, Kumru S, Godekmerdan A, Kutlu S (2005) Effects of raloxifene, hormone therapy, and soy isoflavone on serum high-sensitive C-reactive protein in postmenopausal women. Int J Gynaecol Obstet Off Organ Int Fed Gynaecol Obstet 90:128–133

Yu L (2001) Amorphous pharmaceutical solids: preparation, characterization and stabilization. Adv Drug Deliv Rev 48:27–42

Zhang W-D, Qi L-W, Yang X-L, Lu Y-W, Li P, Yang Z-L (2008) Determination of tectorigenin in rat plasma: application to a pharmacokinetic study after oral administration of tectorigenin or its prodrug tectoridin. Chromatographia 68:1021–1025

Acknowledgments

The authors are grateful to the skilled technical assistance from Prof. Liming Ye during TG Analysis.

Conflict of interest

The authors declare that they have no conflicts of interest to disclose.

Author information

Authors and Affiliations

Corresponding author

Additional information

S. Shuai, S. Yue, Q. Huang, and J. Yang contributed equally to this work.

Rights and permissions

About this article

Cite this article

Shuai, S., Yue, S., Huang, Q. et al. Preparation, characterization and in vitro/vivo evaluation of tectorigenin solid dispersion with improved dissolution and bioavailability. Eur J Drug Metab Pharmacokinet 41, 413–422 (2016). https://doi.org/10.1007/s13318-015-0265-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13318-015-0265-6