Abstract

This paper evaluates the fermentative potential of Kluyveromyces marxianus grown in sugarcane bagasse cellulosic and hemicellulosic hydrolysates obtained by acid hydrolysis. Ethanol was obtained from a single glucose fermentation product, whereas xylose assimilation resulted in xylitol as the main product and ethanol as a by-product derived from the metabolism of this pentose. Fermentation performed in a simulated hydrolysate medium with a glucose concentration similar to that of the hydrolysate resulted in ethanol productivity (Qp = 0.86 g L−1 h−1) that was tenfold higher than the one observed in the cellulosic hydrolysate. However, the use of hemicellulosic hydrolysate favored xylose assimilation in comparison with simulated medium with xylose and glucose concentrations similar to those found in this hydrolysate, without toxic compounds such as acetic acid and phenols. Under this condition, xylitol yield was 53.8 % higher in relation to simulated medium. Thus, the total removal of toxic compounds from the hydrolysate is not necessary to obtain bioproducts from lignocellulosic hydrolysates.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Introduction

Environmental preservation has been an increasing matter of concern, as has the interest to develop sustainable technologies for the optimized use of lignocellulosic biomass resulting from both agriculture and forest sectors, in order to obtain different products such as second-generation ethanol. Within such a context, biorefineries play an important role, as they offer sustainable economic growth and make it possible to transform residues, by-products and/or co-products of industrial segments into a diversity of bioproducts. In Brazil, sugarcane bagasse has been employed in distilleries as a source of steam and electricity, and the surplus is sold to distribution networks for the co-generation of electric power (UNICA 2012).

The chemical constitution of sugarcane bagasse is mainly represented by the fractions of cellulose, hemicellulose, and lignin (Fengel and Wegener 1984). The ability presented by a few microorganisms to ferment either C5 or C6 sugars has increased the interest in using this biomass in order to obtain biotechnological products such as xylitol and ethanol (Gírio et al. 2010). The solubilization of its sugars through hydrolytic processes, such as acid hydrolysis (Lenihan et al. 2010; Rodrigues et al. 2010; Rocha et al. 2012), is a critical stage for the bioprocess to succeed, since compounds that inhibit microbial activity are released along with sugars during this phase. These compounds include acetic acid, furfural, 5-hydroxymethylfurfural, and lignin-degrading products (phenols) (Palmqvist and Hahn-Hägerdal 2000; Nigam 2001; Lima et al. 2004; Silva et al. 2004; Alvira et al. 2010). The concentrations of toxic compounds in hydrolysates depend on the type of lignocellulosic material and also on the type of detoxification process used. The use of activated charcoal has been employed in hydrolysate detoxification (Marton et al. 2006), and more recently, vegetal polymer has been used (Chaud et al. 2012). They act as adsorption and flocculation agents, respectively. The efficiency of detoxification depends on the type of toxic agent to be removed (Canilha et al. 2012). Residuals such as acetic acid, furfural, hydroxymethilfurfural and phenolic compounds are usually found in the hydrolysates (Marton et al. 2006; Canilha et al. 2010; Chaud et al. 2012), which is relevant not only to the C5 and C6 assimilation capacity by the microorganism in use, mainly due to the possibility that such microorganism is or is not able to resist to the action of the toxic compounds remaining in the hydrolysates.

The yeast Kluyveromuces marxianus is known for its ability to assimilate a mixture of sugars (Wilkins et al. 2008; Zhang et al. 2010), including xylose (Banat et al. 1998; Wilkins et al. 2008; Lane and Morrissey 2010; Matsuzaki et al. 2012). It is a thermotolerant yeast that shows considerable growth in the temperature range between 25 °C and 45 °C (Fonseca et al. 2008), and it has been studied in simultaneous saccharification and fermentation (SSF) of lignocellulosic biomass (Banat et al. 1998; Zhang et al. 2013). Besides, according to Lark et al. (1997), this yeast tolerates temperatures up to 42 °C but its growth is better at 30 °C, at which it also consumes glucose and produces ethanol. This versatility could be economically explored in a variety of applications, such as the production of ethanol, protein, bio-ingredients, and so forth (Fonseca et al. 2008; Gabardo et al. 2012; Kang et al. 2012), which requires further research towards a broader understanding of this yeast growth in hydrolysates derived from vegetal biomasses, to guarantee their use in industrial processes.

Under these circumstances, this paper evaluates the fermentative potential of the yeast Kluyveromyces marxianus ATCC 36907 during its cultivation in sugarcane bagasse hemicellulosic and cellulosic hydrolysates.

Materials and methods

Microorganisms and inoculum preparation

The experiments were performed with K. marxianus ATCC 36907 maintained on malt-extract agar slants at 4 °C. A loopful of cells grown on a malt-extract agar slant was transferred to the medium used for inoculum preparation containing xylose (30.0 g L−1), rice bran extract (20.0 g L−1), (NH4) 2SO4 (2.0 g L−1) and CaCl2.2H2O (0.1 g L−1). Erlenmeyer flasks (125 mL) containing 50 mL medium were incubated on a rotary shaker (200 rpm) at 30 °C for 24 h. Afterwards, the cells were separated by centrifugation (2,000 g; 20 min), rinsed twice with distilled water, and then the cell pellet was once again suspended in an adequate volume of distilled water. The initial cell concentration for all experiments was around 1.0 g L−1.

Preparation of the sugarcane bagasse hemicellulosic and cellulosic hydrolysates

The pre-treatment of sugarcane bagasse was performed employing H2SO4 1 % (w/v), 1:10 solid–liquid ratio, at the temperature of 121 °C for 20 min (Pessoa Júnior et al. 1997). The hemicellulosic hydrolysate obtained was filtered through a paper filter for solid mass separation (cellulignin). Cellulignin underwent alkaline hydrolysis for delignification purposes by using NaOH 1.5 % (w/v), 1:20 solid–liquid ratio, at a temperature of 100 °C for one hour. The hydrolysate obtained was filtered through a paper filter for solid mass separation (cellulose pulp). The resulting cellulose pulp underwent acid hydrolysis with H2SO4 2 % (v/v), 1:8 solid–liquid ratio, at a temperature of 155 °C for 10 min. The cellulosic hydrolysate obtained was filtered through a paper filter for solid mass separation. The hemicellulosic and cellulosic hydrolysates were concentrated at 70 °C under vacuum to obtain a fourfold increase in sugar content. Afterwards, both hydrolysates were submitted to detoxification procedure in order to reduce the concentration of toxic compounds. The hemicellulosic hydrolysate (59.10 g L−1 xylose, 5.17 g L−1 glucose; 9.40 g L−1 arabinose, 4.22 g L−1 acetic acid, 0.087 g L−1 furfural, 0.063 g L−1 hydroxymethylfurfural, and 7.17 g L−1 total phenolic compounds) was detoxified by adjusting initial pH to 8.0 with CaO (commercial grade), followed by the addition of 15.0 % (v/v) Acquapol WW® biopolymer (Acquaquimica), for 15 min under agitation (200 rpm, 25 °C). The precipitate formed as a result of this treatment was removed by centrifugation (2,000 g; 20 min) (Chaud et al. 2012). The cellulosic hydrolysate (70.0 g L−1 glucose, 0.032 g L−1 furfural, 0.468 g L−1 hydroxymethylfurfural, and 18.15 g L−1 total phenolic compounds) was treated by adjusting pH initially to 7.0 with CaO (commercial grade), and then to 2.5 with H3PO4, followed by the addition of 1.0 % (w/v) activated charcoal (refined powder), for 30 min under agitation (200 rpm, 60 °C). The precipitate formed as a result of this treatment was removed by vacuum filtration (Marton et al. 2006). Both hydrolysates were autoclaved at 110 °C, under 0.5 atm, in order to be used as fermentation medium.

Medium and fermentation conditions

For fermentation medium preparation, concentrated and treated sugarcane bagasse hemicellulosic hydrolysate (50.0 g L−1 xylose, 4.0 g L−1 glucose; 7.5 g L−1 arabinose, 3.7 g L−1 acetic acid, 0.0036 g L−1 furfural, 0.0013 g L−1 hydroxymethylfurfural, and 1.5 g L−1 total phenolic compounds) and cellulosic hydrolysate (69.2 g L−1 glucose, 0.0019 g L−1 furfural, 0.0542 g L−1 hydroxymethylfurfural, and 2.65 g L−1 total phenolic compounds) were supplemented with 2.0 g L−1 (NH4)2SO4, 5.0 g L−1 peptone, 3.0 g L−1 yeast extract and 0.1 g L−1 CaCl2·2H2O. Control experiments with semi-defined media simulating the concentrations of xylose and glucose in the hydrolysates were also performed. The media (50 mL) were placed in 125 mL Erlenmeyer flasks and fermented at 200 rpm at 30 ºC for 96 h with initial pH adjusted to 5.5. Experiments were carried out in duplicate.

Analytical methods

Xylose, glucose, arabinose, xylitol, ethanol, glycerol and acetic acid concentrations were determined by HPLC (Waters, Milford, MA) with a refraction index detector on a Bio-Rad Aminex HPX-87H at 45 ºC, with 0.01 N H2SO4 as the eluent at 0.6 mL min−1 flow rate. Stock solutions of 10 g L−1 of xylose, arabinose, glucose, xylitol, glycerol, acetic acid and ethanol were prepared separately in deionized water. From the stock solutions, suitably diluted mixed standard solutions were prepared to contain 0.5, 1.0, 2.0, 4.0, 6.0, 8.0 and 10 g L−1 of xylose and 0.5, 1.0, 2.0, 3.0, 4.0 and 5 g L−1 of arabinose, glucose, xylitol, glycerol, acetic acid and ethanol.

Furfural and hydroxymethylfurfural concentrations were determined with a Hewlett-Packard RP 18 column at 25 °C with acetonitrile: water (1:8) and 1 % acetic acid as the eluent, and a 0.8 mL min−1 flow rate in a visible ultraviolet-light detector (SPD-10A UV–VIS). Stock solutions of 100 mg L−1 of furfural and 5-hidroxymetilfurfural were prepared separately in deionized water. From the stock solutions, suitably diluted mixed standard solutions were prepared to contain 5, 10, 20, 30, 40, 50, 60, 70, 90 and 100 mg L−1 of furfural and 5-hidroxymetilfurfural.

The total phenolic compound concentration was estimated by ultraviolet spectroscopy at 280 nm (Gouveia et al. 2009).

Cell growth was monitored by measuring the absorbance at 600 nm (Beckman-DU 640B spectrophotometer). Cell concentration was calculated based on the relationship between the optical density and cell dry weight through a calibration curve. Yeast cells were stained with methylene blue (1 %) and observed with a digital binocular light microscope (LABO) equipped with digital camera (× 100 objective) for morphology analysis.

Results

Sugar consumption and cell growth

The K. marxianus fermentative performance in sugarcane bagasse hemicellulosic and cellulosic hydrolysates can be observed in Fig. 1. Glucose and xylose co-fermentation was verified in the hemicellulosic hydrolysate, with full depletion of the glucose and assimilation of 47.37 % of xylose, whereas arabinose was not assimilated. Growing yeast in the cellulosic hydrolysate led to a partial glucose consumption (52.62 %), which resulted in a slower growth when compared with the one observed in the hemicellulosic hydrolysate (Fig. 1). The use of simulated hydrolysates favored the consumption of xylose and glucose at 44 % and 90 %, respectively, in comparison with the hemicellulosic and cellulosic hydrolysates. This higher sugar consumption favored cell growth, which was much higher when glucose was used, and the final cell concentration (12.25 g L−1) was 195 % greater than the one found in the cellulosic hydrolysate (4.15 g L−1) and 62.2 % greater than the one found in the hemicellulosic hydrolysate (7.55 g L−1) (Fig. 1).

Ethanol and xylitol formation

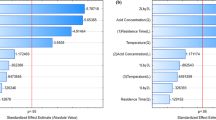

In relation to the main metabolites produced (Fig. 2), it was verified that K. marxianus grown in the medium containing glucose produced only ethanol, while in medium containing xylose, xylitol was produced as the main product and ethanol as a by-product (Fig. 2).

Ethanol (black square) and xylitol (black circle) formation by K. marxianus during fermentation in: (A) cellulosic hydrolysate (straight line) and simulated hydrolysate containing glucose (dashed line) and (B) hemicellulosic hydrolysate (straight line) and simulated hydrolysate containing xylose and glucose (dashed line)

Figure 2 also shows that ethanol production during yeast cultivation in the cellulosic hydrolysate started only after 72 h, which coincides with the maximum cell growth. A different behavior was observed in the semi-defined medium that simulated this hydrolysate, in which the maximum ethanol production occurred at the first 12 h and decreased from this time on.

The maximum values of yield (YP/S) and productivity (QP) during yeast cultivation in the hydrolysates and in the semi-defined media are found in Fig. 3. They confirm ethanol as the main product derived from glucose metabolism by the yeast and its prevalence during the culture in the semi-defined medium containing the same glucose concentration of the cellulosic hydrolysate (YP/S = 0.33 g g−1 and QP = 0.86 g L−1 h−1), which corresponded to increases of 1.5 and tenfold for YP/S and QP, respectively, in relation to cultivation in the cellulosic hydrolysate (YP/S = 0.22 g g−1 and QP = 0.08 g L−1 h−1). Fig. 3 also shows xylitol as the main metabolite from yeast growth in hemicellulosic hydrolysate (9.35 g L−1), and ethanol as a by-product (1.31 g L−1). In addition, it was observed that the bioconversion of xylose into xylitol by K. marxianus in hemicellulosic hydrolysate was favored. The xylitol yield was 53.8 % greater in comparison with the semi-defined medium with glucose and xylose concentrations similar to those found in the hydrolysate.

Figure 4A shows the yeast capacity to assimilate acetic acid at the first 12 h of fermentation, with a consequent increase in pH values (Fig. 4B). However from this moment on, acetic acid concentration increased, which points to the fact that it was produced by the cells, resulting in pH reduction (Fig. 4B).

It was also noted that the toxic compounds such as furfural, hydroxymethylfurfural, and phenolic compounds, found in the hydrolysates as residual concentrations even after the detoxification procedure, were assimilated by K. marxianus at different rates due to the type of hydrolysate employed. Total assimilation of furfural and hydroxymethylfurfural was observed in the hemicellulosic hydrolysate, although phenolic consumption did not occur. On the other hand, when grown in cellulosic hydrolysate, 100 % assimilation of hydroxymethylfurfural and 12.45 % of phenolic compounds were observed at the end of fermentation, although furfural assimilation did not occur.

Discussion

The results presented in this paper allowed us to confirm the capacity of K. marxianus to co-ferment glucose and xylose, while the arabinose current in the hemicellulosic hydrolysate was not assimilated. Reports on the repression of xylose assimilation due to the presence of glucose are common for different yeasts (Lee et al. 2002; Silva et al. 2007). Specifically for K. marxianus UFV3, Santos et al. (2013) reported such catabolic repression, as xylose consumption began only after glucose exhaustion. This behavior differs from what has been observed in the present study, in which glucose and xylose consumption occurred simultaneously. On the other hand, arabinose is not usually assimilated by most microorganisms, and according to Mussatto et al. (2012), Kluyveromyces fragilis was not able to assimilate this pentose in experiments using coffee industry wastes hydrolysate. A 100 % consumption of glucose by K. marxianus NRRL Y-6860 was verified in the rice straw cellulosic hydrolysate obtained by enzymatic hydrolysis (Castro 2011). Another important aspect is that sugar consumption in the hydrolysates was lower than in hydrolysate-simulating media. The difficulty to assimilate these sugars in hydrolysates is possibly related to the concentration of the remaining toxic residues even after the detoxification procedures, since the residual phenolic concentrations were 1.50 g L−1 in the hemicellulosic hydrolysate and 2.65 g L−1 in the cellulosic hydrolysate.

Sugar assimilation difficulties also affected K. marxianus cell growth, mainly during cellulosic hydrolysate fermentations, in which a lag phase in glucose assimilation and in cell growth was observed (Fig. 1). It was also verified that, regardless of the carbon source (glucose or xylose), cell growth in hydrolysate-simulating media was greater than in hydrolysate-formulated media. These differences in yeast growth might be a consequence of two factors: 1) K. marxianus preference for glucose, since the consumption of this sugar and cell growth were greater in media that simulates cellulosic hydrolysate; 2) the effect caused by the presence of phenolic compounds on cell metabolism is due to a higher concentration of the compounds (2.65 g L−1) in the cellulosic hydrolysate than in the hemicellulosic hydrolysate (1.50 g L−1). The different physiological responses of the yeast when grown in hemicellulosic and cellulosic hydrolysates as well as in the semi-defined media can also be noticed in the cell morphology (data not shown). Robust cells presenting gemmule could be viewed during cultivation in the hemicellulosic hydrolysate and in its corresponding semi-defined medium in the first 12 h. With respect to the cellulosic hydrolysate, robustness and cell division were evident only in the simulated hydrolysate. In general terms, it can be considered that the yeast was able to adapt to the different media, with consequent growth and generation of ethanol and xylitol products, as previously shown in Fig. 2.

The ability of K. marxianus to drive its metabolism to xylitol production when grown in a medium containing xylose must be related to the type of co-factor required by the xylose reductase (XR) and xylitol dehydrogenase (XDH) enzymes (Zhang et al. 2011; Lulu et al. 2013). In pentose assimilating yeasts like Candida guilliermondii and K. marxianus, once inside the cell, xylose is reduced to xylitol in a reaction catalyzed by NADPH or NADH-linked xylose reductase. Xylitol is oxidized to xylulose by NADP+ or NAD+-linked xylitol dehydrogenase. Xylulose is phosphorylated into xylulose-5-phosphate, which can be converted into pyruvate through the connection of the phosphopentoses and the glycolytic pathway (Hahn-Hägerdal et al. 1994). The type of co-factor dependence of XR may affect the proportion between the amounts of xylitol and xylulose produced. The intense xylulose formation is a necessary condition for ethanol production and for blocking the formation of xylulose due to XR dependence on NADPH, which leads to the production of xylitol as the main product of xylose fermentation (Sene et al. 2001; Yablochkova et al. 2003).

The values of fermentative parameters obtained during the cellulosic hydrolysate fermentation (Fig. 3) were similar to those found by Moreno et al. (2012) in experiments with K. marxianus CECT 10875 grown in rice straw cellulosic hydrolysate obtained by enzymatic hydrolysis (YP/S ranging from 0.30–0.38 g g−1), and lower than those reported by Castro (2011), when K. marxianus was grown in enzymatic rice straw cellulosic hydrolysate (YP/S = 0.44 g g−1 and QP = 2.89 g L−1 h−1).

With regard to the values of fermentative parameters referring to xylitol production either in the hemicellulosic hydrolysate or in semi-defined medium containing xylose and glucose, the results obtained in this study were higher than the ones reported by Wilkins et al. (2008), who obtained YP/S = 0.30 g g−1 and QP = 0.04 g L−1 h−1 xylitol, when K. marxianus IMB 4 was grown in a medium containing 20 g L−1 glucose and 20 g L−1 xylose. Meanwhile, the values obtained in this study were lower than the xylitol yield (0.75 g g−1) and productivity (0.48 g L−1 h−1) obtained by Candida guilliermondii, a good and broadly studied xylitol producer, grown in sugarcane bagasse hemicellulosic hydrolysate (Chaud et al. 2012).

Another important issue to be highlighted is the fact that xylitol production was higher in hemicellulosic hydrolysate than the one obtained in the simulated hydrolysate medium with the same concentration of xylose and glucose in this hydrolysate, indicating the presence of a compound in the hydrolysate that might have favored the bioconversion of xylose into xylitol by K. marxianus, such as acetic acid, for example. According to Felipe et al. (1995), xylitol production by C. guilliermondii in a semi-defined medium was favored at a low concentration of this acid (1.0 g L−1). According to these authors, the acid in low concentration would go straight to the Krebs cycle via acetyl-CoA. Diaz et al. (2009) also reported a facilitated fermentation by Pichia stipitis in the presence of acetic acid under concentrations considered to be non-inhibiting for cell growth (smaller than 3.0 g L−1) in the hydrolysate from olive tree cuttings. The hydrolysate employed as fermentation medium in this study contained 3.7 g L−1 acetic acid, a concentration that is within the range considered not to be inhibitory to yeasts such as C. guilliermondii (Felipe et al. 1995; Lima et al. 2004); this could have favored the metabolism for xylitol production. Besides, during fermentation of hemicellulosic hydrolysate, a decrease in pH due to acetic acid formation was observed, but pH values remained higher than the pKa (4.75). Such behavior was favorable, since according to Lawford and Rousseau (1998), the acetic acid toxicity is related to the ability of undissociated (protonated) weak acid to act as a membrane protonophore, causing acidification of the cytoplasm.

The capacity of K. marxianus to assimilate the acetic acid present in the hemicellulosic hydrolysate is in accordance with these reports, in addition to its ability to form acetic acid along the fermentations (Fig. 4A). Wilkins et al. (2008) also reported the formation of about 2 g L−1 of acetic acid when K. marxianus IMB 4 was grown in a medium containing a glucose-xylose mixture under concentrations of 20 g L−1 of each sugar. The consumption of acetic acid was also noticed even before carbon source exhaustion during K. marxianus ATCC 26548 culture in a medium containing glucose (Fonseca et al. 2007).

In relation to the phenolic compounds, theye inhibit microbial growth as a result of changes in the plasmatic membrane, and the minimum inhibitory concentration verified for different bacteria and yeasts is around 1.5 g L−1 in media containing xylose as carbon source (Zaldivaar et al. 1999; Mills et al. 2009)—this is a concentration equal or smaller than the one found in the evaluated hydrolysates in this study. According to Mills et al. (2009), different microorganisms have already been described as presenting tolerance models for the phenolic compounds, mainly related to their conversion into carboxylic acids or alcohols due to the reduced toxicity of the functional groups, which could justify the consumption of these compounds by K. marxianus during the cellulosic hydrolysate fermentations.

Conclusions

The results reported in this paper improve our knowledge about K. marxianus physiology. This yeast showed an ability to ferment C5 and C6 sugars in sugarcane bagasse hemicellulosic and cellulosic hydrolysates in the presence of toxic compounds such as phenols and acetic acid. The metabolism of these sugars resulted in ethanol and xylitol production, depending on the hydrolysate employed. It was also observed that the use of cellulosic hydrolysate resulted in a long lag-phase for glucose assimilation when compared to simulate -hydrolysate medium. The behavior observed for sugar metabolism in hemicelullosic and cellulosic hydrolysates in comparison to their simulated media is related not only to the difference in the composition of carbohydrates, but also to the presence of toxic compounds liberated from the hydrolysis process. Indeed, the phenols concentration in cellulosic hydrolysates was 77 % higher than in the hemicellulosic hydrolysates. Probably this fact could contribute to the inhibition of glucose consumption and consequently low ethanol production. In the hemicellulosic hydrolysate, the toxics compounds did not inhibit sugar metabolism. On the contrary, the presence of any other compound in this medium likely favored the xylose to xylitol bioconversion. Thus, the total removal of toxic compounds from the hydrolysate is not necessary to obtain bioproducts from lignocellulosic hydrolysates.

References

Alvira P, Tomás-Pejó E, Ballesteros M, Negro MJ (2010) Pretreatment technologies for an efficient bioethanol production process based on enzymatic hydrolysis: a review. Bioresour Technol 101:4851–4861. doi:10.1016/j.biortech.2009.11.093

Banat IM, Nigam P, Singh D, Marchant R, McHale AP (1998) Review: Ethanol production at elevated temperatures and alcohol concentrations: Part I - Yeasts in general. World J Microbiol Biotechnol 14:809–821. doi:10.1023/A:1008802704374

Canilha L, Carvalho W, Felipe MGA, Silva JB A e, Giulietti M (2010) Ethanol production from sugarcane bagasse hydrolysate using Pichia stipitis. Appl Biochem Biotechnol 161:84–92. doi:10.1007/s12010-009-8792-8

Canilha L, Chandel AC, Milessi TSS, Antunes FAF, Freitas WLC, Felipe MGA, Silva SS (2012) An overview about composition, pretreatmentmethods, detoxification of hydrolysates, enzymatic saccharification, and ethanol fermentation. J Biomed Biotechnol 2012(989572):15. doi:10.1155/2012/989572

Castro RCA (2011) Seleção de uma linhagem termotolerante de Kluyveromyces marxianus produtora de etanol e sua aplicação no processo de sacarificação e fermentação simultânea da celulignina de palha de arroz. Escola de Engenharia de Lorena, Universidade de São Paulo, Dissertation

Chaud LCS, Silva DDV, Felipe MGA (2012) Evaluation of fermentative performance of Candida guilliermondii in sugarcane bagasse hemicellulosic hydrolysate detoxified with activated charcoal or vegetal polymer. Microbes Appl 8:617–623. doi:10.1142/9789814405041_0126

Diaz MJ, Ruiz E, Romero I, Cara C, Moya M, Castro E (2009) Inhibition of Pichia stipitis fermentation of hydrolysates from olive tree cuttings. World J Microbiol Biotechnol 25:891–899. doi:10.1007/s11274-009-9966-9

Felipe MGA, Vieira DC, Vitolo M, Silva SS, Roberto IC, Mancilha IM (1995) Effect of acetic acid on xylose fermentation to xylitol by Candida guilliermondii. J Basic Microbiol 35:171–177. doi:10.1002/jobm.3620350309

Fengel D and Wegener G (1984) Wood chemistry, ultraestruture, reactions. Walter de Gruyter, Berlin and New York, pp 613. doi: 0.1002/pol.1985.130231112

Fonseca GG, Gombertz AK, Heinzle E, Wittmann C (2007) Physiology of the yeast Kluyveromyces marxianus during batch and chemostat cultures with glucose as the sole carbon source. FEMS Yeast Res 7:422–435. doi:10.1111/j.1567-1364.2006.00192.x

Fonseca GG, Heinzle E, Wittmann C, Gombert AK (2008) The yeast Kluyveromyces marxianus and its biotechnological potential. Appl Microbiol Biotechnol 79:339–354. doi:10.1007/s00253-008-1458-6

Gabardo S, Rech R, Ayub MAS (2012) Performance of different immobilized-cell systems to efficiently produce ethanol from whey: fluidized batch, packed-bed and fluidized continuous bioreactors. J Chem Technol Biotechnol 87:1194–1201. doi:10.1002/jctb.3749

Gírio FM, Fonseca C, Carvalheiro F, Duarte LC, Marques S, Bogel-Łukasik R (2010) Hemicelluloses for fuel ethanol: a review. Biores Technol 101:4775–4800. doi:10.1016/j.biortech.2010.01.088

Gouveia ER, Nascimento RT, Souto-Maior AM (2009) Validação de metodologia para a caracterização química de bagaço de cana-de-açúcar. Quim Nova 32(6):1500–1503

Hahn-Hägerdal B, Jeppsson H, Skoog K, Prior BA (1994) Biochemistry and physiology of xylose fermentation by yeasts. Enz Microb Technol 16:933–943. doi:10.1016/0141-0229(94)90002-7

Kang HW, Kim Y, Kim SW, Choi GW (2012) Cellulosic ethanol production on temperature-shift simultaneous saccharification and fermentation using the thermostable yeast Kluyveromyces marxianus CHY1612. Bioprocess Biosyst Eng 35:115–122. doi:10.1007/s00449-011-0621-0

Lane MM, Morrissey JP (2010) Kluyveromyces marxianus: a yeast emerging from its sister’s shadow. Fungal Biol Rev 24:17–26. doi:10.1016/j.fbr.2010.01.001

Lark N, Xia Y, Qin C-G, Gong CS, Tsao GT (1997) Production of ethanol from recycled paper sludge using cellulose and yeast, Kluyveromyces marxianus. Biomass Bioenergy 12(2):135–147. doi:10.1016/S0961-9534(96)00069-4

Lawford HG and Rousseau JD (1998) Improving fermentation performance of recombinant Zymomonas in acetic acid-containing media. Appl. Biochem. Biotechnol 70–72:161–172. doi: ISSN: 0273–2289

Lee WJ, Kim MD, Ryu YW, Bisson LF, Seo JH (2002) Kinetic studies on glucose and xylose transport in Saccharomyces cerevisiae. Appl Microbiol Biotechnol 60(1–2):186–191. doi:10.1007/s00253-002-1085-6

Lenihan P, Orozco O, O’Neill O, Ahmad MNM, Rooney DW, Walker GM (2010) Dilute acid hydrolysis of lignocellulosic biomass. Chem Eng J 156:395–403. doi:10.1016/j.cej.2009.10.061

Lima LH, Felipe MGA, Vitolo M, Torres FA (2004) Effect of acetic acid present in bagasse hydrolysate on the activities of xylose reductase and xylitol dehydrogenase in Candida guilliermondii. Appl Microbiol Biotechnol 65(6):734–738. doi:10.1007/s00253-004-1612-8

Lulu L, Ling Z, Dongmei W, Xiaoian G, Hisanori T, Hidehiko K, Jiong H (2013) Identification of a Xylitol Dehydrogenase Gene from Kluyveromyces marxianus NBRC1777. Mol Biotechnol 53:159–169. doi:10.1007/s12033-012-9508-9

Marton JM, Felipe MGA, Silva JB A e, Pessoa Junior A (2006) Evaluation of the activated charcoals and adsorption conditions used in the treatment of sugarcane bagasse hydrolysate for xylitol production. Braz J Chem Eng 23(1):9–21. doi:10.1590/S0104-66322006000100002

Matsuzaki CC, Nakagawa A, Koyanagi T, Tanaka K, Minami H, Tamaki H, Katayama T, Yamamoto K, Kumagai H (2012) Kluyveromyces marxianus-based plataform for direct ethanol fermentation and recovery from cellulosic materials under air-ventilated conditions. J Biosci Bioeng 113(5):604–607. doi:10.1016/j.jbiosc.2011.12.007

Mills TY, Sandoval NR, Gill RT (2009) Cellulosic hydrolysate toxicity and tolerance mechanisms in Escherichia coli. Ind Crops Prod 2(26):24–33. doi:10.1186/1754-6834-2-26

Moreno AD, IbarraD FJL, Ballesteros M (2012) Different laccase detoxification strategies for ethanol production from lignocellulosic biomass by the thermotolerant yeast Kluyveromyces marxianus CECT 10875. Bioresour Technol 106:101–109. doi:10.1016/j.biortech.2011.11.108

Mussatto SI, Machado EMS, Carneiro LM, Teixeira JA (2012) Sugars metabolism and ethanol production by different yeast strains from coffee industry wastes hydrolysates. Appl Energy 92:763–768. doi:10.1016/j.apenergy.2011.08.020

Nigam JN (2001) Ethanol production from wheat straw hemicelluloses hydrolysate by Pichia stipitis. J Biotechnol 87:17–27. doi:10.1016/S0168-1656(00)00385-0

Palmqvist E, Hahn-Hägerdal B (2000) Fermentation of lignocellulosic hydrolysates. I: inhibition and detoxification. Bioresour Technol 74:17–24. doi:10.1016/S0960-8524(99)00160-1

Pessoa Júnior A, Mancilha IM, Sato S (1997) Acid hydrolysis of hemicellulose from surgarcane bagasse. Braz J Chem Eng 14(03):291–297. doi:10.1590/S0104-66321997000300013

Rocha GJM, Gonçalves AR, Oliveira BR, Olivares EG, Rossell CEV (2012) Steam explosion pretreatment reproduction and alkaline delignification reactions performed on a pilot scale with sugarcane bagasse for bioethanol production. Ind Corp Prod 35:274–279. doi:10.1016/j.indcrop.2011.07.010

Rodrigues RCLB, Rocha GJM, Rodrigues JRD, Filho HJI, Felipe MGA, Pessoa A Jr (2010) Scale-up of diluted sulfuric acid hydrolysis for producing sugarcane bagasse hemicellulosic hydrolysate (SBHH). Bioresour Technol 101:1247–1253. doi:10.1016/j.biortech.2009.09.034

Santos VC, Bragança CRS, Passos FJV, Passos FML (2013) Kinetics of growth and ethanol formation from a mix of glucose/xylose substrate by Kluyveromyces marxianus UFV-3. Anton Leeuw 103:153–161. doi:10.1007/s10482-012-9794-z

Sene L, Converti A, Zilli M, Felipe MGA, Silva SS (2001) Metabolic study of the adaptation of the yeast Candida guilliermondii to sugarcane bagasse hydrolysate. Appl Microbiol Biotechnol 57:738–743. doi:10.1007/s002530100816

Silva DDV, Felipe MGA, Mancilha IM, Luchese RH, Silva SS (2004) Inhibitory effect of acetic acid on bioconversion of xylose in xylitol by Candida guilliermondii in sugarcane bagasse hydrolysate. Braz J Microbiol 35:248–254. doi:10.1590/S1517-83822004000200014

Silva DDV, Mancilha IM, Silva SS, Felipe MGA (2007) Improvement of biotechnological xylitol production by glucose during cultive of Candida guilliermondii in sugarcane bagasse hydrolysate. Braz Arch Biol Technol 50(2):207–215. doi:10.1590/S1516-89132007000200005

UNICA União da Agroindústria Canavieira de São Paulo. http://www.portalunica.com.br [accessed 02 June 2012].

Wilkins MR, Mueller M, Eichling S, Banat IM (2008) Fermentation of xylose by the thermotolerant yeast strains Kluyveromyces marxianus IMB2, IMB4, and IMB5 under anaerobic conditions. Process Biochem 43:346–350. doi:10.1016/j.procbio.2007.12.011

Yablochkova EN, Bolotnikova OI, Mikhailova NP, Nemova NN, Ginak AI (2003) The activity of xylose reductase and xylitol dehydrogenase in yeasts. Microbiology 72(4):414–417. doi:10.1023/A:1025032404238

Zaldivaar J, Martinez A, Ingram LO (1999) Effect of selected aldehydes on the growth and fermentation of ethanologenic Escherichia coli. Biotechnol Bioeng 65(5):24–33. doi:10.1002/(SICI)1097-0290(19991005)65:1<24::AID-BIT4>3.0.CO;2-2

Zhang M, Shukla P, Ayyachamy M, Permaul K, Singh S (2010) Improved bioethanol production through simultaneous saccharification and fermentation of lignocellulosic agricultural wastes by Kluyveromyces marxianus 6556. World J Microbiol Biotechnol 26:1041–1046. doi:10.1007/s11274-009-0267-0

Zhang B, Zhang L, Wang D, Gao X, Hong J (2011) IdentiWcation of a xylose reductase gene in the xylose metabolic pathway of Kluyveromyces marxianus NBRC1777. J Ind Microbiol Biotechnol 38:2001–2010. doi:10.1007/s10295-011-0990-z

Zhang B, Lulu L, Zhang J, Gao X, Wang D, Hong J (2013) Improving ethanol and xylitol fermentation at elevated temperature through substitution of xylose reductase in Kluyveromyces marxianus. J Ind Microbiol Biotechnol 40:305–316. doi:10.1007/s10295-013-1230-5

Acknowledgments

The authors are grateful to CAPES, CNPq and FAPESP for the financial support and to Acquaquimica for having donated the vegetal polymer.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

da Silva, D.D.V., de Arruda, P.V., Vicente, F.M.C.F. et al. Evaluation of fermentative potential of Kluyveromyces marxianus ATCC 36907 in cellulosic and hemicellulosic sugarcane bagasse hydrolysates on xylitol and ethanol production. Ann Microbiol 65, 687–694 (2015). https://doi.org/10.1007/s13213-014-0907-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13213-014-0907-y