Abstract

In previous work, our research group isolated and bred a γ-aminobutyric acid (GABA)-producing microorganism, Lactobacillus brevis CGMCC 1306, from fresh unpasteurized milk and found that the strain possessed high glutamate decarboxylase (GAD) activity. However, the cells of the strain grew poorly during submerged fermentation, with the highest dry cell weight only 2.78 g/L. To enhance the efficiency of GABA biosynthesis and achieve GAD production in high cell-density fermentations, the gad gene from L. brevis CGMCC 1306 was cloned using degenerate PCR. Nucleotide sequencing analysis showed that the cloned gene comprised 1407 bp and encoded a 468-amino acid protein. The gad gene with a hexa-His tag was inserted into pET-28a(+) and expressed in Escherichia coli BL21. Sodium dodecyl sulfate-polyacrylamide gel electrophoresis (SDS-PAGE) analysis revealed that the recombinant protein product had a molecular weight of approximately 53 kDa, which corresponded to the predicted size of the deduced protein (53.47 kDa). High-performance liquid chromatography analysis showed that the purified recombinant protein was capable of catalyzing α-decarboxylation of L-sodium glutamate into GABA, which confirmed that the protein was derived from a gad gene. GAD activity was the highest at pH 4.8 and 48°C. Using Lineweaver–Burk plots, the K m and V max of the recombinant enzyme were 10.26 mM and 8.86 U/mg, respectively. Its activity was not dependent on the addition of pyridoxal 5'-phosphate. These results strongly suggest that cloning of the gad gene is not only of interest to researchers in terms of affecting GAD production by protein engineering strategies, but that it may increase GAD production by high cell-density fermentation and enhance the efficiency of GABA biosynthesis.

Similar content being viewed by others

Introduction

Glutamate decarboxylase (GAD, EC 4.1.1.15) is a unique pyridoxal enzyme that can catalyze α-decarboxylation of L-glutamate or its salts to produce γ-aminobutyric acid (GABA). Many neurological disorders, such as Huntington's chorea and Parkinson's disease, are associated with alterations of the GAD level because its substrate (L-glutamate) acts as an excitant of human neurons and its product (GABA) acts as an inhibitor (Battaglioli et al. 2003). Moreover, autoantibodies to GAD, which are a symptom of type I diabetes, are detectable before clinical onset and define the subgroup of patients with latent autoimmune diabetes in adults (Bingley 2010).

GABA is a four-carbon non-protein amino acid found in living cells of various organisms that acts as a major cerebral neurotransmitter in the central nervous system of animals (Krnjevic 1974). As the product of the reaction catalyzed by GAD, GABA has several physiological functions, such as the induction of hypotensive effects and diuretic effects. It can also be used therapeutically in the treatment of epilepsy, as a strong secretagogue of insulin, as an inhibitor of cancer cell proliferation and as a tranquilizer (Adeghate and Ponery 2002; Cohen et al. 2002). Therefore, GABA is important for human health and has been used extensively in pharmaceuticals and functional foods, such as soy product, kimchi, rice germ cheese and GABA tea (Tsai et al. 2006; Zhang et al. 2006; Seok et al. 2008; Wang et al. 2011a), leading to an increasing commercial demand for its mass production.

Among the various methods used to produce GABA, the biosynthetic approach appears to be promising due to the simple reaction procedure, high catalytic efficiency, mild reaction conditions and environmental compatibility (Huang et al. 2007; Huang et al. 2008; Yang et al. 2008). Because lactic acid bacteria (LAB) possess special physiological activities and are generally regarded as safe, the use of LAB as cell factories for GABA production has fascinating potential and opens up a vast range of prospects for making use of GABA (Li and Cao 2010). To date, various LABs, such as Lactobacillus brevis (Kim et al. 2007; Park and Oh 2007; Hiraga et al. 2008), L. delbrueckii (Siragusa et al. 2007), L. plantarum (Park and Oh 2004), L. paracasei (Komatsuzaki et al. 2005; Siragusa et al. 2007) and Lactococcus lactis (Siragusa et al. 2007), have been used to produce large amounts of GABA, and the corresponding genes encoding GAD from various LABs have been cloned and expressed.

In a previous study, we isolated a GABA-producing strain (hjxj-01) from fresh, unpasteurized milk samples and identified the isolate as L. brevis. The strain was treated with UV and 60Co gamma irradiation, and a mutant strain (hjxj-08119) for alleviating GABA inhibition was isolated using the gradient plate method with different GABA concentrations (Xia et al. 2006). This strain was stored in the China General Microbiological Culture Collection Center (CGMCC; accession number 1306). After optimization of GABA liquid fermentation conditions, a maximum GABA yield of 76.36 g/L was achieved at 108 h of fermentation, and the productivity of GABA was 707 mg/L/h in a 3.7-L stirred fermentor (Huang et al. 2008). However, cells of L. brevis CGMCC 1306 have a poor growth rate, and the highest dry cell weight obtained has been only 2.78 g/L. We speculated that the high production of GABA was related to the GAD present in this microorganism. To enhance the efficiency of GABA biosynthesis and achieve GAD production at high cell densities, the gad gene from L. brevis CGMCC 1306 was cloned, expressed and characterized.

To date, there is no information available on the gad gene of L. brevis CGMCC 1306. In the study reported here, degenerate primers were designed based on the analysis of existing Lactobacillus gad genes, and the gad gene from L. brevis CGMCC 1306 was amplified by PCR, cloned and sequenced. The cloned gene was efficiently expressed in Escherichia coli and the recombinant enzyme purified, following which the biochemical properties of the recombinant enzyme produced in E. coli were determined.

Materials and methods

Chemicals and reagents

γ-Aminobutyric acid was purchased from Acros Organics (Geel, Belgium). Dansyl chloride (Dns-Cl) was obtained from Sigma-Aldrich (St. Louis, MO); 5′-pyridoxal phosphate (5′-PLP), isopropyl-β-D-thiogalactopyranoside (IPTG), kanamycin (Kan) and phenylmethanesulfonyl fluoride (PMSF) were provided by Sangon Inc (Shanghai, China); L-sodium glutamate (L-MSG) was purchased from Sinopharm Chemical Reagent Co., Ltd (Shanghai, China). Unless specified, all other chemicals were of analytical grade or higher quality.

Plasmids, bacterial strains and culture medium

Escherichia coli BL21 and plasmid pET 28a(+) were obtained from Novagen (Madison, WI). The plasmid pMD19-T simple vector was from Takara Bio Inc (Shiga, Japan). The UNIQ-10 Column Plasmid Mini-preps kit and EZ Spin Column DNAgel Extraction kit were from Bio Basic Inc. (Markham, ON, Canada). The pMD19-T Simple vector and pET 28α(+) vector were used for the cloning and expression of the GAD gene, respectively. L. brevis CGMCC 1306 was cultured at 30°C in GYP medium [(g/L) glucose, 10; yeast extract, 10; peptone, 5; sodium acetate, 2; MgSO4·7H2O, 20; MnSO4·4H2O, 1; FeSO4·7H2O, 1; NaCl, 1; pH 6.8] without agitation. E. coli JM109 and BL21 were used as the cloning and expression host cells, respectively. All E. coli strains were cultivated in Luria-Bertani (LB; 1.0% tryptone, 0.5% yeast extract, 1.0% NaCl) medium at 37°C. Kan was added, when necessary, at a final concentration of 30 μg/mL.

PCR amplification of 16S rDNA and sequence analysis

To clone the 16S rDNA fragment of L. brevis CGMCC 1306 strain, PCR amplification was performed using the universal primers 5′-AGAGTTTGATCMTGGCTCAG-3′ (forward) and 5′-GGCTACCTTGTTACGA CTT-3′ (reverse) (Sakamoto et al. 2003). The PCR cycling program for 16S rDNA amplification was 95°C for 5 min, 25 cycles of 95°C for 30 s, 58°C for 30 s and 72°C for 2 min, with a final extension at 72°C for 10 min. A 5-μL volume of PCR product was electrophoresed in a 0.75% agarose gel and stained with ethidium bromide for detection. The amplified DNA was ligated into the pMD19-T Simple Vector using T4 ligase, and the ligated product was transformed into E. coli JM109 cells using a standard protocol (Sambrook and Russell 2001). Positive transformants were selected on LB ampicillin plates, and several of these were confirmed by colony PCR. The final validated positive clone of pMD19-T-16S rDNA was sent to Shanghai Sangon Co., Ltd. (http://www.sangon.com) for sequence determination. Sequence similarity analysis was performed in the GenBank database using the BLAST program (http://blast.ncbi.nlm.nih.gov/Blast.cgi).

Cloning of L. brevis CGMCC 1306 GAD and sequence analysis

Genomic DNA from L. brevis CGMCC 1306 was purified and used as the template for the PCR analysis. As the nucleotide sequence of GAD in L. brevis CGMCC 1306 was unknown, three sets of primers were designed based on the codon bias of all publicly available Lactobacillus GAD genes (Table 1). Using degenerate primers to amplify the unknown GAD gene, we adjusted and optimized the PCR reaction conditions until a target DNA fragment was obtained. PCR products were purified, ligated into pMD19-T Simple Vector with T4 ligase and then transformed into E. coli JM109. The final validated positive clone of pMD19-T-GAD was sent to Shanghai Sangon Co., Ltd. for sequence determination.

Construction of pET-28a (+)-GAD, expression of GAD in E. coli and preparation of crude enzyme extracts

The gad gene and expression vector pET28α (+) were digested with EcoRI and BamHI and purified with DNAgel Extraction Kit (Bio Basic). The purified products were ligated using T4 DNA ligase to form the expression vector pET-28a-GAD. The recombinant expression vector was transformed into E. coli BL21 competent cells. Colonies were selected on LB-Kan plates, and positive clones were identified by colony PCR as well as restriction digestion of purified plasmid DNA with EcoRI and BamHI. E. coli BL21 cells carrying pET-28a(+)-GAD were inoculated into LB medium containing Kan (30 μg/mL). At an optical density of 0.7 (600 nm) at 37°C, GAD expression was induced with 1 mM IPTG. After an additional incubation of 8 h at 37°C, cells were collected for protein analysis by sodium dodecyl sulfate-polyacrylamide gel electrophoresis (SDS-PAGE; Bio-Rad, Hercules, CA). Protein molecular weight markers for SDS-PAGE were obtained from Takara Bio Inc (Shiga, Japan). A negative control was prepared using the same method but with cells not subjected to IPTG induction.

Purification of the GAD-(His)6 fusion protein

After the expression of 6-His-tagged GAD had been determined, cells were harvested by centrifugation (12,000 rpm, 4°C, 10 min), washed twice with sodium phosphate buffer (50 mM, pH 8.0) and then were resuspended in disruption buffer (50 mM phosphate, 1 mM PMSF, 300 mM NaCl, 10 mM imidazole, pH 8.0). After ultrasonic treatment of the cells at 4°C in an ice bath (Sonifier JY92; Xinzhi Biotechnology Institute, Shanghai, China; output level 300 W, duty time 3 s, interval time 6 s, 90 times), the lysed debris was removed by centrifugation (12,000 rpm, 4°C, 30 min), and soluble GAD (crude enzyme) was obtained from the supernatant.

The ÄKTA Explorer 100 chromatography system was purchased from GE Healthcare (Uppsala, Sweden), and affinity chromatography was carried out with Ni2+-nitrilotriacetate (Ni-NTA) agarose (Qiagen, Hilden, Germany) according to the manufacturer’s purification protocol. The supernatant was first loaded onto an affinity column pre-equilibrated with disruption buffer. The contaminant proteins were removed with washing buffer (50 mM phosphate, 1 mM PMSF, 300 mM NaCl, 20 mM imidazole, pH 8.0), and then GAD protein was eluted with elution buffer (50 mM phosphate, 1 mM PMSF, 300 mM NaCl, 250 mM imidazole, pH 8.0). The protein concentration was determined according to the modified Bradford method with bovine serum albumin (BSA) as a standard (Bradford 1976). Discontinuous gel electrophoresis was performed using vertical 12% SDS-PAGE slab gels for separation and 5% stacking gels with Laemmli’s Tris–glycine electrolyte buffer system at pH 8.3 (Laemmli 1970). The molecular weight of the sample was determined by SDS-PAGE using protein markers with molecular weights of 95, 72, 55, 43, 34 and 26 kDa as the reference. SDS-PAGE staining was carried out with Coomassie Blue. The activity of recombinant GAD was confirmed by analysis of the reaction products with high performance liquid chromatography (HPLC).

Characterization of recombinant GAD

The effect of pH on GAD activity was determined in a volume of 0.2 μL of substrate solution (0.1 M Na2HPO4-citric acid buffer, pH range 2.2–7.0, 10 mM L-MSG, 0.01 mM PLP) and 10 μL of purified GAD solution, with incubation at 37°C for 10 min. The relative activities of the purified recombinant enzyme were then estimated. Temperature effects on GAD activity were evaluated at different temperatures (10–70°C) in a volume of 0.2 mL of substrate solution (0.1 M Na2HPO4-citric acid buffer, pH 4.4, 10 mM L-MSG, 0.01 mM PLP) and 10 μL of purified GAD solution after a 10 min, and relative activities of GAD were evaluated. Three parallel assays were performed under each experimental condition.

The effect of PLP concentration on GAD activity was determined in a volume of 0.2 mL of substrate solution (0.1 M Na2HPO4-citric acid buffer, pH 4.4, 10 mM L-MSG) and 10 μL of purified GAD solution, ranging in PLP concentration from 1 to 100 μM, with a 10-min incubation, and the relative activities of GAD were evaluated.

The effect of substrate L-MSG concentration on GAD activity was determined in a volume of 0.2 mL of substrate solution (0.1 M Na2HPO4-citric acid buffer, pH 4.8, 0.01 mM PLP) and 10 μL of purified GAD solution, ranging in L-MSG concentration from 0 to 100 μM, with incubation at 48°C for 10 min. The Michaelis constant (K m ) and maximum velocity (V max ) values were calculated using Lineweaver–Burk plots.

Analysis of GABA and GAD activity

Glutamate decarboxylase activity was measured by combining the purified enzyme solution and L-MSG, incubating the mixture, terminating the reaction by boiling and determining the GABA produced (Ueno et al. 1997). One unit of enzyme activity (U) was defined as the amount of enzyme that produced 1 μmol GABA/min.

The concentration of GABA in the supernatant was determined by HPLC using an Agilent 1100 series HPLC system (Agilent Tech, Santa Clara, CA) equipped with a Hypersil ODS C18 reverse-phase column (diameter 5 μm, length 250 mm, internal diameter 4.6 mm) using a gradient elution procedure (Chen et al. 1997). A 100-μL sample was mixed with 900 μL sodium bicarbonate solution (0.2 M, pH 9.8), followed by derivatization through the addition of 100 μL of the above mixture into an aliquot (100 μL) of Dns-cl (8 g/L) and incubation at 30°C for 1 h. After derivatization, the sample was diluted and subjected to HPLC analysis.

Results and discussion

16S rDNA identification of L. brevis CGMCC 1306

The GABA high-yielding strain was a non-spore-forming Gram-positive, facultative anaerobic, short rod-shaped bacterium without flagella (Xia et al. 2006). The strain is able to grow in the presence of NaCl at concentrations ranging from 0 to 5% (Xia et al. 2006), and can utilize glucose, fructose, maltose and ribose, but not mannose or arabinose (Huang 2007). On the basis of morphological and biochemical characteristics, the isolate was considered to be a strain of L. brevis (Krieg et al. 1984) and deposited in CGMCC (accession no. 1306). A 1527-bp fragment of 16S rDNA was amplified from the genomic DNA, and the validated positive clone of pMD19-T-16S rDNA was used for sequence determination. The 16S rDNA nucleotide sequence of L. brevis CGMCC 1306 was submitted to GenBank under accession no. HQ726794. Sequence analysis with other 16S rDNA sequences in GenBank revealed that the 16S rDNA of the strain showed 99% similarity with L. brevis NRIC 0138, L. brevis ATCC 14687 and L. brevis TCCC 13001.

Cloning of gad gene from L. brevis CGMCC 1306

To clone the gad gene from L. brevis CGMCC 1306, we used amino acid sequences from all publicly available Lactobacillus GADs from NCBI (National Center for Biotechnology) to analyze conserved sequences at both ends of the coding regions. As shown in Table 1, BH2, WCFS1, 100–23, ATCC 367 and ATCC 14917 have conserved N-terminal amino acid sequences [MA(M/G)LYGK] and scarcely differ in the third base position of the triplet code, while the N-terminal sequences of OPK-3 (MENTRMK) and IFO 12005 (MNKNDQE) are poorly matched. C-terminal amino acid residues (KKYGFTH) of these GADs also have high homologies, and their corresponding nucleotide sequences have a good similarity, except for IFO 12005. Based on the bioinformatic analysis of the N– and C-terminal sequences, the following oligonucleotides were designed as the forward primers: 5′-cgggatccatggcWatgttRtaYggWaaa-3′ (F1; BH2, WCFS1, 100–23, ATCC 367, ATCC 14917), 5′-ggggatccatgaaYaaRaaYgaYcaRgaRc-3′ (F2; IFO 12005) and 5′-ggggatccatggaaaacacacgcatgaaac-3′ 5(F3; OPK-3). The reverse primer (R1) was 5′-gggaattcttagtgHgtgaaYccgtattt-3′. For degenerate primer design, the nucleotide base abbreviations were used: W, a or t; Y, c or t; R, a or g; H, a, t or c. The underlined portions in the primer sequences represent the recognition sites for the restriction enzymes BamHI and EcoRI. These restriction sites are also present in pET-28a(+).

Because the genetic code is degenerate and one amino acid corresponds to one or more triplet codons, preferential codon usage and partial mixed bases were considered for degenerate primer design (Preston 2003; Linhart and Shamir 2005). PCR for cloning the gad gene from L. brevis CGMCC 1306 was carried out with degenerate oligonucleotide primers as described above. The amplified product appeared at the expected molecular mass of approximately 1.4 kb on agarose gels using the F1 and R1 primers, but no target fragment appeared using the F2, F3 and R1 primers. To increase both specificity and yield of the PCR product, higher annealing temperatures are useful in reducing nonspecific priming, which can significantly affect reactions containing degenerate primers. The optimized amplification profile for degenerate PCR was: 94°C for 5 min, 32 cycles of 94°C for 1.5 min, 57°C for 1 min and 72°C for 2 min, with a final extension at 72°C for 8 min.

Combining the results from the bioinformatics analysis with those from the PCR analysis with degenerate oligonucleotide primers, we successfully cloned the full-length gad gene from L. brevis CGMCC 1306. General methods used to obtain the full-length sequence of a target gene require either enzyme purification and partial sequencing, followed by PCR to obtain the open reading frame (ORF), or cloning from a genomic library (or cDNA library for eukaryotic genes) and screening for the gene cloned using a hybridization probe. These methods are laborious and time-consuming. Here, our simpler method for cloning the gad gene required searching the sequences of potentially related genes from the Lactobacillus species bioinformation database, analyzing the N– and C-terminal conserved sequences, designing the degenerate oligonucleotide primers and performing PCR with these degenerate oligonucleotide primers.

Sequence analysis

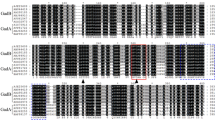

The nucleotide sequence of the gad gene was determined and submitted to the GenBank nucleotide sequence database under the accession number GU987102.1. Sequence analysis showed that the fragment contained a complete ORF of 1,407 nucleotides that encoded a protein of 468 amino acids with a calculated molecular weight of 53.47 kDa and a pI of 5.51. The deduced amino acid sequence was multiply aligned with other GAD sequences obtained from GenBank. As shown in Fig. 1, the amino acid sequence deduced from the L. brevis CGMCC 1306 GAD ORF showed 98.5, 83, 68 and 48% identity with the L. brevis BH2 (ABU55419), L. plantarum WCFS1(NP_786643), Listeria monocytogenes (ZP_05231499) and Streptococcus thermophilus (ADQ62455) GAD sequences, respectively.

Alignment of the deduced amino acid sequence of glutamate decarboxylase (GAD) isolated from Lactobacillus brevis CGMCC 1306 with its homologues. Asterisks denote residue positions that are identical in all sequences, colon and dot mark conservative replacement and non-conservative replacement, respectively. L. brevis CGMCC 1306 GAD accession number: ADG02973 (468 amino acids); L. brevis BH2: ABU55419 (468 amino acids); Lactococcus lactis subsp. cremoris MG1363: AAC46188 (466 amino acids); Listeria monocytogenes FSL N3-165: ZP_05231499 (464 amino acids); L. brevis IFO 12005: BAF99137 (480 amino acids); L. plantarum WCFS1: NP_786643 (469 amino acids); Streptococcus thermophilus ND03: ADQ62455 (459 amino acids); Escherichia coli: ABQ85058 (466 amino acids). The deduced amino acid sequence was analyzed using the Clustal X program (ver. 2.0.12)

Among the reported GAD enzymes in L. brevis (Kim et al. 2007; Hiraga et al. 2008), alignment with other GAD sequences revealed that they contained highly conserved catalytic domains that belong to the PLP-dependent decarboxylase superfamily (Murzin 1996). The GAD domain of L. brevis CGMCC 1306 also possesses a conserved lysine residue (Lys279) that is known to be essential to the binding of PLP as well as to the active site residues (Thr215 and Asp246) that promote decarboxylation (Kim et al. 2007). In addition, the motif [HVDAA(S/F)GG], which is highly conserved in PLP-dependent decarboxylases, was detected in the L. brevis CGMCC 1306 GAD sequence (Kim et al. 2007; Kawalleck et al. 1993).

Expression and purification of the recombinant GAD

The recombinant plasmid [pET-28a(+)-GAD] was transformed into E. coli BL21. Expression of the gad gene was driven by the T7 promoter and induced by addition of IPTG. Protein expression was monitored by SDS-PAGE, and analysis of Coomassie-stained protein revealed the presence of an additional protein in the crude cell extract obtained after sonication treatment, which was not observed in the crude cell extract obtained from cells that did not bear the pET-28a(+)-GAD plasmid (Fig. 2). This additional protein had an approximate molecular weight of 53 kDa, which agreed well with the predicted size of the GAD protein (53.47 kDa) (Fig. 2).

Sodium dodecyl sulfate-polyacrylamide gel electrophoresis (SDS-PAGE) analysis of the expression and purification of recombinant GAD in E. coli BL21. The figure shows a 12% SDS-PAGE gel stained with Coomassie Blue. Lanes: M low-weight protein marker, 1 cell extracts of E. coli BL21 without pET-28a(+)-GAD plasmid, 2 and 3 cell extracts of E. coli BL21 transformed with pET-28a(+)-GAD and induced with 1 mM IPTG at 37°C for 4 h and 8 h,respectively, 4 recombinant GAD purified by Ni-NTA agarose column

Recombinant GAD was expressed as a His-tagged fusion protein to facilitate purification. After centrifugation and sonication, the cell lysate was loaded onto a nickel-charged NTA-agarose column. A single protein was eluted with an elution buffer containing 250 mmol/L imidazole. As shown in Fig. 2, a clear single band was observed with a molecular weight of about 53 kDa. About 13 mg of recombinant GAD protein was purified from wet cells derived from a 1-L fermentation. To further confirm the presence of GAD in E. coli, the activity of the purified enzyme was analyzed by HPLC, revealing that there was a noticeable peak at a retention time of 17.49 min in the reaction products, which coincided with the peak of the GABA standard (Fig. 3).

High-performance liquid chromatography (HPLC) analysis of reaction products of purified recombinant GAD with L-sodium glutamate (L-MSG) as the substrate. Absorption traces of the column eluates are shown. Absorption of the derivatized γ-aminobutyric acid (GABA) was measured at 254 nm. a HPLC chromatogram of GABA standard sample, b HPLC chromatogram of the L-MSG substrate solution, c HPLC chromatogram of the reaction products

Characteristics of the recombinant GAD

Purified recombinant GAD activity was measured using a 0.1 M citric acid/sodium phosphate buffer system which allowed the pH to be varied from 2.2 to 7.0. Previous reports cite the optimum pH of bacterial GAD to be in the range of 4.0–5.0 (Ueno 2000; Lin et al. 2009). Figure 4a shows the pH optimum of the L. brevis recombinant GAD; optimal activity was observed at pH 4.8, which is similar to that of purified GAD from other microorganisms. The activity of the recombinant GAD was highest at 48°C (Fig. 4b).

Effect of temperature and pH on GAD activity and stability. a pH activity curve; activity was determined at 37°C in 0.1 M citric acid/sodium phosphate buffer containing 10 mM L-MSG that ranged in pH from 2.2 to 7.0. b Temperature activity curve; GAD activity was determined at temperatures ranging from 10 to 70°C in 0.1 M citric acid/sodium phosphate buffer, pH 4.4, containing 10 mM L-MSG

As reported, GAD is a PLP-dependent decarboxylase, and the coenzyme PLP is required by GAD for its activity (Murzin 1996; Ueno 2000). Some portion of GAD is present as apoenzyme (apoGAD) without PLP in some strains of E. coli (Wang et al. 2011b), Lactobacillus paracasei (Komatsuzaki et al. 2005) and mammals (Martin and Rimvall 1993). Inactive apoGAD regains its activity with the addition of PLP forming an intact GAD-PLP complex (holoGAD). Figure 5 shows the effect of adding additional amounts of PLP on the activity of purified recombinant GAD. In our study, additional PLP had little effect on recombinant GAD activity, suggesting that the recombinant GAD of L. brevis CGMCC 1306 is very strongly bound to the PLP coenzyme when expressed in E. coli and that it exists mostly as holoGAD. The steady-state kinetics of GAD were measured for different substrate concentrations of L-MSG at 48°C and pH 4.8, and the K m and V max values were calculated by fitting the data into the Michaelis–Menten equation. As shown in Fig. 6, the purified recombinant enzyme had a V max value of 8.86 U/mg and a K m value of 10.26 mM.

In conclusion, the results of this study should pave the way for using protein engineering strategies, such as directed evolution or site-directed saturation mutagenesis, to strength GAD activity, pH or thermal stability, increasing GAD production by high cell-density fermentation and enhancing the efficiency of GABA biosynthesis.

References

Adeghate E, Ponery AS (2002) GABA in the endocrine pancreas: cellular localization and function in normal and diabetic rats. Tissue Cell 34(1):1–6

Battaglioli G, Liu H, Martin DL (2003) Kinetic differences between the isoforms of glutamate decarboxylase: implications for the regulation of GABA synthesis. J Neurochem 86(4):879–887

Bingley PJ (2010) Clinical applications of diabetes antibody testing. J Clin Endocrinol Metab 95(1):25–33

Bradford MM (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72(1–2):248–254

Chen X, Li D, Lv JX (1997) Determination of γ-aminobutyric acid and glutamic acid in human cerebrospinal fluid by high performance liquid chromatography (in Chinese). Chin J Chromatogr 15(3):237–239

Cohen I, Navarro V, Clemenceau S, Baulac M, Miles R (2002) On the origin of interictal activity in human temporal lobe epilepsy in vitro. Science 298(5597):1418–1421

Hiraga K, Ueno YH, Oda KH (2008) Glutamate decarboxylase from Lactobacillus brevis: activation by ammonium sulfate. Biosci Biotechnol Biochem 72(5):1299–1306

Huang J (2007) Process study on the preparation of γ-aminobutyric acid by Lactobacillus brevis. PhD thesis. Zhejiang University, Xihu, Hangzhou, China

Huang J, Mei LH, Xia J (2007) Application of artificial neural network coupling particle swarm optimization algorithm to biocatalytic production of GABA. Biotechnol Bioeng 96(5):924–931

Huang J, Mei LH, Sheng Q, Xu J, Wu H (2008) Optimization of γ-aminobutyric acid liquid fermentation conditions and fed-batch fermentation (in Chinese). J Chem Eng Chin Univ 22(4):618–624

Kawalleck P, Keller H, Hahlbrock K, Scheel D, Somssich IE (1993) A pathogen-responsive gene of parsley encodes tyrosine decarboxylase. J Biol Chem 268(3):2189–2194

Kim SH, Shin BH, Kim YH, Nam SW, Jeon SJ (2007) Cloning and expression of a full-length glutamate decarboxylase gene from Lactobacillus brevis BH2. Biotechnol Bioprocess Eng 12(6):707–712

Komatsuzaki N, Shima J, Kawamoto S, Momose H, Kimura T (2005) Production of gamma-aminobutyric acid (GABA) by Lactobacillus paracasei isolated from traditional fermented foods. Food Microbiol 22(6):497–504

Krieg NR, Holt JG, Murray RGE (1984) Bergey’s manual of systematic bacteriology, Vol. 1 and 2. Williams and Wilkins, Baltimore

Krnjevic K (1974) Chemical nature of synaptic transmission in vertebrates. Physiol Rev 54(2):418–540

Laemmli UK (1970) Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature 277(5259):680–683

Li HX, Cao YS (2010) Lactic acid bacterial cell factories for gamma-aminobutyric acid. Amino Acids 39(5):1107–1116

Lin Q, Yang SY, Lu FX, Lu ZX, Bie XM, Jiao Y, Zou XK (2009) Cloning and expression of glutamate decarboxylase gene from Streptococcus thermophilus Y2. J Gen Appl Microbiol 55(4):305–310

Linhart C, Shamir R (2005) The degenerate primer design problem: theory and applications. J Comput Biol 12(4):431–456

Martin DL, Rimvall K (1993) Regulation of gamma-aminobutyric acid synthesis in the brain. J Neurochem 60(2):395–407

Murzin AG (1996) Structural classification of proteins: new superfamilies. Curr Opin Struct Biol 6(3):386–394

Park KB, Oh SH (2004) Cloning and expression of a full-length glutamate decarboxylase gene from Lactobacillus plantarum. J Food Sci Nutr 9:324–329

Park KB, Oh SH (2007) Cloning, sequencing and expression of a novel glutamate decarboxylase gene from a newly isolated lactic acid bacterium, Lactobacillus brevis OPK-3. Bioresour Technol 98(2):312–319

Preston GM (2003) Cloning gene family members using PCR with degenerate oligonucleotide primers. Methods Mol Biol 226:485–498

Sakamoto M, Takeuchi Y, Umeda M, Ishikawa I, Benno Y (2003) Application of terminal RFLP analysis to characterize oral bacterial flora in saliva of healthy subjects and patients with periodontitis. J Med Microbiol 52(1):79–89

Sambrook J, Russell DW (2001) Molecular cloning: a laboratory manual, 3rd edn. Cold Spring Harbor Laboratory Press, Cold Spring Harbor, NY

Seok JH, Park KB, Kim YH, Bae MO, Lee MK, Oh SH (2008) Production and characterization of Kimchi with enhanced levels of gamma-aminobutyric acid. Food Sci Biotechnol 17(5):940–946

Siragusa S, Angelis MD, Cagno RD, Rizzello CG, Coda R, Gobbetti M (2007) Synthesis of γ-aminobutyric acid by lactic acid bacteria isolated from a variety of Italian cheeses. Appl Environ Microbiol 73(22):7283–7290

Tsai JS, Lin YS, Pan BS, Chen TJ (2006) Antihypertensive peptides and gamma-aminobutyric acid from prozyme 6 facilitated lactic acid bacteria fermentation of soymilk. Process Biochem 41(6):1282–1288

Ueno H (2000) Enzymatic and structural aspects on glutamate decarboxylase. J Mol Catal B Enzym 10(1–3):67–79

Ueno Y, Hayakawa K, Takahashi S, Oda K (1997) Purification and characterization of glutamate decarboxylase from Lactobacillus brevis IFO 12005. Biosci Biotechnol Biochem 61(7):1168–1171

Wang HF, Chuang SM, Hsiao CC, Cherng SH (2011a) A synergistic effect of GABA tea and copper(II) on DNA breakage in human peripheral lymphocytes. Food Chem Toxicol 49(4):955–962

Wang Q, Xin YQ, Zhang F, Feng ZY, Fu J, Luo L, Yin ZM (2011b) Enhanced c-aminobutyric acid-forming activity of recombinant glutamate decarboxylase (gadA) from Escherichia coli. World J Microbiol Biotechnol 27(3):693–700

Xia J, Mei LH, Huang J, Sheng Q, Xu J, Wu H (2006) Screening and mutagenesis of Lactobacillus brevis for biosynthesis of γ-aminobutyric acid (in Chinese). J Nucl Agric Sci 20(5):379–382

Yang SY, Lin Q, Lu ZX, Lü FX, Bie XM, Zou XK, Sun LJ (2008) Characterization of a novel glutamate decarboxylase from Streptococcus salivarius ssp. thermophilus Y2. J Chem Technol Biotechnol 83(6):855–861

Zhang H, Yao HY, Chen F (2006) Accumulation of gamma-aminobutyric acid in rice germ using protease. Biosci Biotechnol Biochem 70(5):1160–1165

Acknowledgments

This work was supported by the grants from the National Natural Science Foundation of China (NO. 20876143 and 30970638), and the National Basic Research Program of China (2007CB714305).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fan, E., Huang, J., Hu, S. et al. Cloning, sequencing and expression of a glutamate decarboxylase gene from the GABA-producing strain Lactobacillus brevis CGMCC 1306. Ann Microbiol 62, 689–698 (2012). https://doi.org/10.1007/s13213-011-0307-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13213-011-0307-5