Abstract

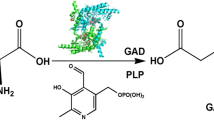

Human gut-originated lactic acid bacteria were cultivated, and high γ-aminobutyric acid (GABA)-producing Lactococcus garvieae MJF010 was identified. To date, despite the importance of GABA, no studies have investigated GABA-producing Lactococcus species, except for Lc. lactis. A recombinant glutamate decarboxylase of the strain MJF010 (rLgGad) was successfully expressed in Escherichia coli BL21(DE3) with a size of 53.9 kDa. rLgGad could produce GABA, which was verified using the silylation-derivative fragment ions of GABA. The purified rLgGad showed the highest GABA-producing activity at 35 °C and pH 5. rLgGad showed a melting temperature of 43.84 °C. At 30 °C, more than 80% of the activity was maintained even after 7 h; however, it rapidly decreased at 50 °C. The kinetic parameters, Km, Vmax, and kcat, of rLgGad were 2.94 mM, 0.023 mM/min, and 12.3 min− 1, respectively. The metal reagents of CaCl2, MgCl2, and ZnCl2 significantly had positive effects on rLgGad activity. However, most coenzymes including pyridoxal 5′-phosphate showed no significant effects on enzyme activity. In conclusion, this is the first report of Gad from Lc. garvieae species and provides important enzymatic information related to GABA biosynthesis in the Lactococcus genus.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

γ-Aminobutyric acid (GABA) is a four-carbon non-protein amino acid widely distributed in nature and a primary suppressive neurotransmitter in the central nervous system of mammals (Sarasa et al. 2020). GABA is distributed throughout the human body and exerts therapeutic effects on disorders of the nervous system, including Alzheimer’s, Parkinson’s, and Huntington’s diseases (Diez-Gutiérrez et al. 2020; Lee et al. 2005; Solas et al. 2015). It also plays a role in the regulation of cardiovascular conditions, such as blood pressure and heart rate, and reduction of anxiety and pain (Sarasa et al. 2020). In particular, the anti-hypertensive and anti-depressant functions of GABA were verified by oral administration of GABA-enriched foods in humans (Diana et al. 2014; Wu and Shah 2017). GABA is responsible for the regulation of motor activity and sleep-awake cycle. In addition, GABA is involved in the maintenance of memory formation, cognition, and high seizure threshold. GABA also has the metabolic functions including the provision of energy to the brain and the resistance to oxygen deficiency (Kalueff and Nutt 2007; Auteri et al. 2015; Yunes et al. 2016).

Because of the physiological effects of GABA, scientific interest and commercial demands for GABA have been increasing. In the pharmaceutical and food industries, it is applied as a bioactive component that positively affects physiological activity; therefore, the demand for GABA is immense. However, the current demand of GABA cannot be sufficiently satisfied by the amounts naturally present in plants and animals (Choi et al. 2006; Youn et al. 2011). In addition, the chemical synthesis of GABA is not suitable to be used in foods due to the use of harmful reagents and the corrosive reactants. However, the bioconversion method for GABA production is, not only, efficient and economic, but also, safer and eco-friendly (Diez-Gutiérrez et al. 2020). Bioconversion of GABA has a high transformation rate and convenient control over an enzyme reaction; hence, researchers are now using microbial and enzymatic methods to produce GABA.

Glutamate decarboxylase (Gad, EC. 4.1.1.15), a pyridoxal 5’-phosphate-dependent enzyme, is a primary enzyme for GABA production. GABA is produced through the irreversible α-decarboxylation of L-glutamic acid in a reaction catalyzed by Gad (Lyu et al. 2021). Gad is an intracellular enzyme that induces an acid stress response (Villegas et al. 2016).

Numerous studies have reported GABA-producing microorganisms and their Gad activity. To date, studies have focused on lactic acid bacteria (LAB) as GABA-producing microorganisms, and many strains of GABA-producing LAB derived from food sources have been reported. In particular, Levilactobacillus brevis is the most studied species. In addition, various Lactobacillus genera and a few other genera (Streptococcus sp., Pseudomonas sp., and Enterococcus sp.) have been studied (Sarasa et al. 2020).

Despite their minor contribution to the population of human gut microbiota, LAB have attracted considerable attention due to their positive effects on human health. Various species of LAB provide health-promoting benefits, such as anti-obesity, anti-inflammatory, anti-cancer, and anti-allergic activities, urogenital health care (Kerry et al. 2018), and GABA-producing ability. However, the ability of human-originated bacteria to produce GABA remains poorly studied. Moreover, only a few gut-originated strains have been shown to produce GABA. It has been recently reported that the strains of Bacteroides species isolated from human gut can produce GABA, of which biosynthesis is regulated by pH (Otaru et al. 2021). In addition, Yunes et al. (2016) reported the GABA-producing ability and the presence of the gad gene of human-originated Lactiplantibacillus plantarum, Levi. brevis, Bifidobacterium adolescentis, B. angulatum, B. dentium, and other gut-originated bacterial species, which can be considered as delivery vehicles for GABA to specific regions of the gut.

In this study, human gut-originated LAB were cultivated, and GABA-producing Lactococcus garvieae MJF010 was isolated. The Gad of strain MJF010 was successfully produced in Escherichia coli, and its enzymatic properties were investigated. This is the first study on the Gad of Lc. garvieae species, providing an important enzymatic information on GABA biosynthesis in the Lactococcus genus.

Materials and methods

Reagents and bacterial strains

Monosodium glutamate (MSG) and γ-aminobutyric acid (GABA) were purchased from Sigma-Aldrich (St. Louis, MO, USA). The media used in this study, De Man, Rogosa and Sharpe (MRS) broth and MRS agar, and Luria-Bertani (LB), were obtained from MBcell (Seoul, Korea). All other chemicals used in this study were of analytical grade. Lactococcus garvieae MJF010 isolated in this study was deposited in the Korea Culture Center of Microorganisms (KCCM; Seoul, Korea) under the collection number KCCM12722P. E. coli DH5α (Takara, Shiga, Japan) and E. coli BL21(DE3) (Stratagene, La Jolla, CA, USA) were used as hosts for construction and expression, respectively. The plasmid pET28a (Merck, Darmstadt, Germany) vector was used to express the gad gene from Lc. garvieae MJF010.

Isolation and identification of GABA-producing LAB from human fecal microbiota

The human fecal sample was collected from a 45-year-old healthy Korean male adult (height and weight were 174 cm and 80 kg, respectively) with no history of gastrointestinal diseases and who had not taken any antibiotics in the last six months. The care and use of human derivatives were approved by the Institutional Review Board of Incheon National University (IRB 7007971-202006-001 A) and compliant with all relevant ethical guidelines. The fecal samples were serially diluted ten folds with 10 mL of 0.85% NaCl solution, followed by homogenization. To isolate LAB from human feces, 100 µL of each prepared diluted feces sample was spread and incubated on MRS agar at 37 °C for 48 h. Fifty colonies were randomly picked and grown individually in MRS broth for 24 h at 37 °C under anaerobic conditions. All processes including the dilution of fecal samples and incubation step were performed in anaerobic chamber (Coy Laboratory Products, Grass Lake, MI, USA) filled with 85% N2, 10% CO2, and 5% H2 gas.

To identify the isolated LAB strains, genomic DNA was extracted using the HiYield Genomic DNA Mini Kit (RBC, Taiwan). The full-length 16 S rRNA gene was amplified using recombinant EF-Taq DNA polymerase (Solgent, Daejeon, Korea) with universal primers (27 F and 1492R). The polymerase chain reaction (PCR) conditions were as follows: 95 °C for 5 min; 30 cycles of 30 s at 95 °C, 30 s at 55 °C, and 1.5 min at 72 °C; and 5 min at 72 °C. The amplified fragments were sequenced and identified using the EzBioCloud database ver. 2021.04.13 (https://www.ezbiocloud.net/). Phylogenetic tree of Lc. garvieae MJF010 was constructed using MEGA7 software (Kumar et al. 2016). Multiple alignment of the 16 S rDNA gene (mean length 1443 nt) was performed using EBI-Clustal Omega (Madeira et al. 2019). The Kimura 2-parameter model was applied with bootstrap replications of 1,000 datasets. The 16 S rRNA gene sequence of Lc. garvieae MJF010 was deposited in the NCBI GenBank database (https://www.ncbi.nlm.nih.gov/genbank/) under accession number MH057260.

To select the GABA-producing LAB strain, each strain isolated from human feces was individually grown in 10 mL of MRS broth containing 1% (w/v) MSG at 37 °C for 48 h in anaerobic chamber as mentioned above. The supernatant of each culture was harvested by centrifugation at 4000×g for 20 min and analyzed using thin layer chromatography (TLC).

Cloning and expression of glutamate decarboxylase from Lc. garvieae MJF010

The glutamate decarboxylase gene (gad) of Lc. garvieae MJF010 (hereafter referred to as lggad) was amplified using a primer set, which was designed based on Gad sequence of Lactococcus species accessed from NCBI (protein ID: WP_019292826.1), including restriction enzyme sites (forward: 5′-CGC CAT ATG TTA TAT GGA AAA GAA AAT C-3′ and reverse: 5′- CGC GGA TCC TTA ATG TGT AAA TCC−3′, NdeI and BamHI underlined). The amplification of lggad was conducted using recombinant EF-Taq DNA polymerase (Solgent) under the following conditions: 95 °C for 5 min; 30 cycles of 30 s at 95 °C, 45 s at 58 °C, and 1.5 min at 72 °C; and 5 min at 72 °C. The 1.4 kb amplified lggad was ligated into the pET28a vector using T4 ligase (Enzynomics, Daejeon, Korea). The ligation mixture was transformed into E. coli DH5α for the propagation of the construct, followed by transformation into E. coli BL21(DE3) for expression. The gene sequence of lggad was deposited in the NCBI GenBank database under accession number MH071407.

The growth of E. coli BL21(DE3) harboring pET28a-lggad and the purification of the recombinant Gad from Lc. garvieae MJF010 (rLgGad) was performed according to the previous report (Lim et al. 2018). Briefly, the recombinant E. coli BL21(DE3) harboring pET28a-lggad was cultivated in 250 mL of LB medium including kanamycin (50 mg/mL) at 37 °C. The expression of rLgGad with C-terminal His6 tag was induced at an optical density (600 nm) of 0.6 by adding 0.5 mmol/L isopropyl β-D-1-thiogalactopyranoside (IPTG) and incubated at 18 °C for 18 h. After centrifuging the harvested cell broth at 7000×g for 10 min at 4 °C, the cell pellets were resuspended in lysis buffer (20 mmol/L Tris-HCl, 300 mmol/L NaCl, 5 mmol/L β-mercaptoethanol, 0.1% triton X-100, 5% glycerol, and 10 mmol/L imidazole, pH 8.5). The lysed cells were disrupted by sonifier (Sonics & Materials, Inc., Newtown, CT, USA), followed by being harvested using centrifugation at 10,000×g for 30 min at 4 °C to remove cell debris. The supernatant was loaded onto a Ni-NTA polypropylene column (Bio-Rad Laboratories, Inc., Hercules, CA, USA) filled with Ni-NTA agarose (QIAGEN, Hilden, Germany) and washed with 20 mmol/L imidazole in lysis buffer. The targeted rLgGad protein was finally eluted with 250 mmol/L imidazole in lysis buffer. The final purified protein was analyzed by 10% (w/v) sodium dodecyl sulfate-polyacrylamide gel electrophoresis (SDS-PAGE). Protein concentration was determined using a bicinchoninic acid protein assay kit (Thermo Fisher Scientific; Waltham, MA, USA), with bovine serum albumin as the standard.

Analysis of rLgGad activity and its GABA production

The activity of rLgGad was measured by the production of GABA. To produce GABA, 25 µL of rLgGad was mixed with 0.2 mL of buffer consisting of 70 mM Na2HPO4-citric acid (pH 5.0), 10 mM MSG, and 0.01 mM pyridoxal 5′-phosphate (PLP). The reaction mixture was incubated at 35 °C for 1 h and then boiled for 5 min to stop the reaction. The supernatant containing GABA was harvested by centrifugation at 10,000×g for 20 min at 10 °C.

The amount of GABA in the supernatant was analyzed by a spectrophotometric GABA assay using GABase enzyme (5 units/mL; Sigma-Aldrich, St. Louis, MO, USA) as described previously (Zhang and Bown 1997). The assay mixture contained 234 µL of 100 mM K4P2O7 buffer (pH 8.6), 42 µL of 10 mM NADP+, 12 µL of the supernatant of the reaction mixture, and 5 µL of GABase. The initial absorbance was measured at 340 nm using a Multiskan FC plate reader (Thermo Fisher), and 6 µL of 100 mM α-ketoglutarate was added and incubated at room temperature for 1 h. The final absorbance was measured at the same wavelength, and the GABA concentration was calculated based on the difference in these absorbances and the GABA standard curve. One unit of rLgGad activity was defined as the amount of enzyme that produced 1 µmol of GABA per min under the assay conditions.

Qualitative analysis of GABA produced by rLgGad

GABA production was verified by TLC and gas chromatography-mass spectrometry (GC-MS). For TLC analysis, one µL of culture supernatant was loaded onto a TLC silica gel plate (Merck). The samples were developed with a mixed solvent consisting of n-butanol, acetic acid, and water (4:1:1, v/v/v). After development, the plate was dried completely at 115℃ for 5 min and visualized using 0.2% (w/v) ninhydrin solution and dried again.

For GC-MS analysis, the supernatant was filtered using a 0.2 μm syringe filter and then freeze-dried. Samples (10 mg) were extracted with 1 mL of a solvent mixture consisting of methanol, chloroform, and water (2.5:1:1, v/v/v), and subjected to two-stage derivatization (oximation with trimethylsilyl etherification). The separation of GABA and MSG from the derivative (1 µL) was performed with a DB-5 capillary column (0.25 mm I.D.×30 m, 1.0 μm film thickness; J&W Scientific, Folsom, CA, USA) by using the GCMS-QP2010 Ultra system equipped with an AOC20i auto-sampler (Shimadzu, Kyoto, Japan). The carrier gas was helium with a flow rate of 1 mL/min and split ratio of 1:10. The temperatures of the injector, ion source, and interface were 280 °C, 200 °C, and 280 °C, respectively. The temperature program was operated as follows: 100 °C for 4 min, followed by an increase of 10 °C/min to 320 °C, and holding for 11 min at 320 °C. The standard spectra were recorded in scan mode within a scanned mass range of 45–600 m/z, and selected ion monitoring (SIM) mode was used for identification (m/z 304 for GABA).

Biochemical characterization of rLgGad

The biochemical characterization of rLgGad, including the effects of temperature, pH, metal reagents (CaCl2, CuCl2, KCl, MgCl2, NaCl, ZnCl2, (NH4)2SO4, MgSO4, MnSO4, Na2SO4, AgNO3, and KI), PLP, and other coenzymes was performed under the enzyme reaction conditions as mentioned above, except for changes in the parameter to be measured. The temperature was changed from 20 to 50 °C, and the pH was adjusted from 2 to 8 by controlling the ratio of the buffer components (Na2HPO4 and citric acid).

Two millimolar of each metal reagent was added to the reaction mixture to study their effects on rLgGad. The effect of PLP on rLgGad was measured at different PLP concentrations (0–1 mM). The effect of coenzymes was also measured by adding 0.5 mM each of pyridoxal HCl, pyridoxine HCl, and pyridoxine, respectively, at 35 °C and pH 5.

The thermostability was determined by measuring the residual activities after standing at 30–50 °C for 0–7 h. In addition, the fluorescence data to calculate melting temperature were measured using differential scanning fluorimetry (Niesen et al. 2007). The sample mixture containing 10 µL of the enzyme solution (0.01 mg/mL) and 10 µL of SYPRO orange (10×; Invitrogen, Waltham, MA, USA) was incubated at a temperature gradient ranging from 25 to 95 °C in 1 °C increment by using a StepOnePlus Real-Time PCR System (Applied Biosystems, Foster City, CA, USA). Melting temperature was calculated using GraphPad Prism 5.0 software (GraphPad, San Diego, CA, USA) with a Boltzmann Sigmoidal curve. Non-linear fitting of truncated fluorescence data were applied to the following equation (Huynh and Partch 2015).

Y = fluorescence emission in arbitrary units; X = temperature; Bottom = baseline fluorescence at low temperature; Top = maximal fluorescence at top of the truncated dataset; Slope = describes the steepness of the curve, with larger values denoting shallower curves; and Tm = melting temperature of the protein.

The kinetic parameters (Km and Vmax) were determined under optimum conditions (35 °C and pH 5) with changes in the MSG concentrations (5–20 mM). The data were analyzed using a Lineweaver-Burk plot to calculate the kinetic parameters.

Statistical analysis

In the biochemical characterization of rLgGad, data are expressed as the mean ± standard error of mean of three independent measurements. Tukey’s multiple-comparison test analyzed significant differences from control. All statistical analyses were performed using GraphPad Prism 5.0 (GraphPad, San Diego, CA, USA).

Results

Isolation of GABA-producing Lactococcus garvieaeMJF010 from human fecal microbiota

Fifty LAB were isolated from the feces of a healthy Korean male adult and identified using 16 S rRNA genes. Each species was closest to the following bacteria: E. coli, Streptococcus agalatiae, Lactococcus garvieae, Lactobacillus salivarius, Weissella cibaria, and Leuconostoc lactis, and was organized into 23 strains. To select the GABA-producing strain, each strain was cultivated in MRS broth containing MSG and screened by TLC analysis. Consequently, one bacterium, strain MJF010, was observed to produce the darkest and largest spot on the TLC plate, indicating that a significant amount of a compound expected to be GABA was produced from MSG (data not shown). The 16 S rRNA sequence of strain MJF010 showed 99.93%, 99.86%, 99.64%, 98.91%, and 93.64% similarity to Lc. garvieae subsp. garvieae FDAARGOS 929T, Lc. petauri 159,469T, Lc. garvieae subsp. bovis BSN307T, Lc. formosensis 516T, and Lc. lactis subsp. lactis JCM 5805T, respectively. The strain MJF010 had the closest sequence identity with that of Lc. garvieae subsp. garvieae FDAARGOS_929T in the phylogenetic tree (Fig. 1). However, it should be noted that the strain MJF010 might correspond to one of the already described strains, because its 16 S rRNA sequence similarity to Lc. garvieae subsp. garvieae FDAARGOS_929T showed more than 98.5%, and its phylogenetic analysis was evaluated at the species level, not the strain level. Nevertheless, the GABA-producing strain MJF010 in this study could be designated as Lc. garvieae MJF010. In the future, the ortho average nucleotide identity and in silico DNA-DNA hybridization analyses based on the whole genome of the strain MJF010 will conducted to identify the novelty of the strain MJF010 at the strain level.

Phylogenetic tree of Lc. garvieae MJF010. The tree was constructed using MEGA X software using the 16 S rRNA genes (mean length of 1443 nt) of a closely related Lactococcus species from EzBioCloud database ver. 2021.04.13 (https://www.ezbiocloud.net/). The neighbor-joining statistical method was applied with bootstrap replications of 1,000 datasets using kimura 2-parameter model. The bar represents 0.01 substitutions per site. The accession number for 16 S rRNA genes of each strain is in parentheses

Sequence analysis of glutamate decarboxylase (Gad) from Lc. garvieae MJF010

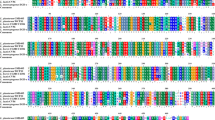

The full-length coding sequence of Gad from Lc. garvieae MJF010 was composed of 1,401 bp with 35% G + C content, which could be translated into 466 amino acids. The mature protein of LgGad showed a predicted molecular weight (MW) of 53.9 kDa and a theoretical isoelectric point of 5.37. In the BlastP analysis, LgGad contained a highly conserved catalytic domain of PLP-dependent Gad, and was identical to Gad from Lactococcus species. Among the 24 species, including eight subspecies of Lactococcus, only Lc. petauri (98.28% similarity), Lc. lactis (90.77 − 92.70%), Lc. cremoris (91.85%) were observed to have Gad. Therefore, it was considered that this type of Gad is observed in four out of 24 Lactococcus species. In general, Gad can be divided into two isoforms, GadA and GadB (Yunes et al. 2016). LgGad was aligned with other GadA and GadB (Fig. 2) and was identified as belonging to GadB. The LgGad contains a motif [H(V/I)DAASGG], which is highly conserved in PLP-dependent decarboxylases, and a PLP-binding domain (Murzin 1996). In LgGad, the catalytic amino acid residues (Thr215, Asp246, and Lys279) were confirmed. The active site residues (Thr215 and Asp246) are known to promote decarboxylation, and the highly conserved lysine residue (Lys279) is indispensable for PLP binding (Kim et al. 2007; Li et al. 2013).

Amino acid sequence alignment of Gad from Lc. garvieae MJF010. The multiple alignment with other GadA and GadB was performed by Clustal Omega (http://www.ebi.ac.uk/Tools/msa/clustalo/). The motif [H(V/I)DAASGG] and the PLP binding domain are in the solid and dotted line boxes, respectively. Arrows represent the catalytic amino acid residues (Thr215, Asp246, and Lys279). The Gad sequences used for comparison were from Lc. garvieae MJF010 (AYV62236.1) and Levi. brevis [strain OPK-3 (AAZ95185.1); ATCC 367 (ABJ64910.1); CGMCC 1306 (ADG02973.1); 877G (AFU61547.1); NCL912 (AFP81722.1); BH2 (AIC75915.1); ATCC 367 (ABJ63253.1); IFO 12,005 (BAF99137.2)]

Production and verification of GABA by rLgGad

Recombinant LgGad (rLgGad) was overexpressed in E. coli and purified successfully. The purified rLgGad carrying C-terminal His6 tag showed a clear single band of approximately 53 kDa, which was identical to the theoretical MW of 53.9 kDa (Fig. 3). Then, biosynthesis of GABA was carried out by rLgGad using MSG as the sole substrate.

GABA was identified using thin-layer chromatography (Fig. 4a). It was confirmed that rLgGad produced a compound from MSG, which was presumed to be GABA. The MW was determined using gas chromatography-mass spectrometry, as shown in Fig. 4b and c. The sialylation-derivative of GABA appeared 319 MW and had an important fragment ion at m/z 304 [M–CH3]− (Iwase et al. 1979). The prominent peak at m/z 174 of GABA was assigned to the fragment (CH2 = N+(TMS)2) of the N,N,O-trimethylsilyl derivative of GABA (Cattabeni et al. 1976). Thus, the MW of the compound produced from MSG by rLgGad (spot in lane 4) was identical to that of GABA.

Enzymatic characterization of of rLgGad

The enzymatic reaction conditions of rLgGad carrying C-terminal His6 tag such as reaction temperature and pH and thermal stability, were evaluated. rLgGad showed GABA-producing activity over a wide range of temperatures (Fig. 5a). It showed the highest activity at 35 °C, but showed at least 40% activity at 20–50 °C. As the strain MJF010 is a human gut-originated bacterium, it can be considered to exhibit optimal activity under mesophilic conditions. In contrast, GABA-producing activity was observed in a very narrow pH range (Fig. 5b). The optimum activity of rLgGad was shown at pH 5, and no activity was shown in the acidic pH range (pH 2–4) and the pH range from 6 to 8. The alkaline pH range (pH 9–10) also resulted in no activity of rLgGad (data not shown). The optimal reaction pH for other Gads, found in various LAB reported previously, was approximately near 4 to 5, which is mostly acidic condition (Table 1). Therefore, it could be anticipated that most LAB-derived Gads optimally convert glutamate to GABA under acidic conditions. According to previous reports, in bacteria, the Gad, together with Glu/GABA antiporter, forms the glutamate-dependent acid resistance systems; the Gad catalyzes the decarboxylation of glutamate by consuming protons to maintain the intracellular pH in the acidic environment (Wu et al. 2017). The rLgGad showed a melting temperature of 43.84 °C, which was slightly above the optimum temperature (35 °C) (Fig. 5c). The rLgGad retained 60% of its initial activity after 7 h at 40 °C, whereas the enzyme activity remarkably decreased to 1.5% at 50 °C after 5 h (Fig. 5d). The activity gradually decreased as time elapsed and decreased to 60% after 7 h of exposure at 40 °C. At 50 °C, approximately 80% of the activity was diminished after 1 h, and almost all the activity was lost after 3 h. But more than 80% of the activity was maintained even after 7 h of exposure at 30 °C. The kinetic parameters, Km, Vmax, and kcat, were estimated using a Lineweaver-Burk plot (data not shown) and calculated as 2.94 mM, 0.023 mM/min, and 12.3 min− 1, respectively.

Enzymatic characteristics of rLgGad at different a reaction temperatures, b pH, c melting temperature, and d thermal stability of rLgGad (wherein, triangle, square, and circle symbols represent 50 °C, 40 °C, and 30 °C, respectively). The residual enzyme activity was expressed as the relative percentage rLgGad activity

Effects of chemical reagents and coenzymes on rLgGad activity

The chemical reagents and coenzymes affecting the activity of rLgGad were evaluated under optimum conditions (35 °C and pH 5) (Fig. 6). Statistically significant positive effects on the GABA-producing activity of rLgGad were observed in three chemical reagents [CaCl2 (120%), MgCl2 (119%), and ZnCl2 (119%)] (p < 0.05) (Fig. 6a). In contrast, AgNO3 completely inhibited the activity of rLgGad (p < 0.001). The effect of exogenous PLP concentrations on rLgGad was investigated under optimum conditions (Fig. 6b). It was seen that the GABA-producing activity of rLgGad was not dependent on exogenous PLP, suggesting that rLgGad is mostly expressed as a Gad-PLP complex in E. coli. It was also investigated if the Gad-PLP complex could be affected by other coenzymes including pyridoxal HCl, pyridoxine HCl, and pyridoxine (Fig. 6c). Most of the tested coenzymes showed no significant increase in catalytic activity; pyridoxal HCl exhibited a very slight positive effect on activity (107%).

Discussion

GABA is a major inhibitory neurotransmitter in the mammalian central nervous system. GABA is widely distributed in bacteria, plants, and vertebrates. LAB are the main GABA-producers among bacteria (Sarasa et al. 2020). GABA-producing LAB derived from food sources have been reported in many strains, such as Companilactobacillus farciminis, Com. futsaii, Lacticaseibacillus paracasei, Lacti. plantarum, L. helveticus, Lactococcus lactis, Latilactobacillus sakei, Lentilactobacillus bunchneri, Len. Curieae, Len. otakiensis, Levilactobacillus zymae, and Limosilactobacillus fermentum have been studied. In addition, Streptococcus thermophilus, Pseudomonas, Saccharomyces cerevisiae, Enterococcus raffinosus, E. avium, E. faecium, Asepergillus oryzae, Candida utilis, and C. fermani have been reported (Sarasa et al. 2020). However, GABA-producing LAB from the human body remain poorly studied. In fact, only a few gut-originated strains have been shown to produce GABA. Recently, Otaru et al. (2021) investigated the GABA production by human gut-derived Bacteroides in culture and metabolic assays combined with genomics and phylogenetics, resulting in a high prevalence of the Gad-system among Bacteroides genomes harboring all genes of the Gad-system. Yunes et al. (2016) screened the collection of 135 human-derived Lactobacillus and Bifidobacterium strains for their ability to produce GABA from its precursor, monosodium glutamate. In their study, only 58 human gut-originated Lactobacillus (Lacti. plantarum and Levi. brevis), and Bifidobacterium (B. adolecentis, B. angulatum, and B. dentium) are able to produce GABA (Yunes et al. 2016). Lacti. plantarum and Levi. brevis is the most widely found species capable of producing GABA (Sarasa et al. 2020). The gastrointestinal (GI) tract of mammalian hosts is inhabited by numerous and diverse gut microbiota. The human gut is a complex ecosystem and a good habitat for commensal microbiota, which is more than 1,000 species with a population of up to 1014 (Sender et al. 2016). The human gut microbiota is mainly composed of Firmicutes and Bacteroidetes, accounting for more than 90% of the entire phylogenetic classification, and significant numbers of Actinobacteria and Proteobacteria (Eckburg et al. 2005; El Kaoutari et al. 2013). The numbers of human gut-commensal LABs were less than 1% of the total bacterial population of the human gut (Heeney et al. 2018). However, from a probiotic perspective, research on human gut-commensal LAB producing GABA is of great importance. An extensive literature confirmed GABA as a mediator within the enteric nervous system controlling GI function, and therefore the presence of GABA in the human gut is imperative (Auteri et al. 2015). Probiotic strains derived from the human gut are inherently hypothesized to have great advantages in adaptability in the host gut. Therefore, human gut-commensal probiotic strains can be considered as delivery vehicles for GABA to specific regions of the gut (Ghatge et al. 2012).

As a beneficial symbiotic gut microbiota, LAB have been extensively studied for their functional elucidation. In this study, we screened and isolated GABA-producing LAB from the human fecal microbiota. A high GABA-producing Lactococcus species was isolated and identified as belonging to Lactococcus garvieae. To date, few studies have described GABA-producing Lactococcus species (for example, Lc. lactis), and Gads. Several GABA-producing L. lactis strains isolated from cheese, kimchi, frozen peas, yam pickle, and dairy have been reported (Lyu et al. 2021).

So far, various Gads from various LABs have been characterized as recombinant enzyme and natural forms (Table 1). In fact, the direct recovery of microbial Gads in natural form is time-consuming and needs the expensive tasks with further processes using protein precipitation and purification. However, the production of heterologous proteins using an expression host (e.g. E. coli) has the advantages of efficient and mass production (Hannig and Makrides 1998). In this study, the lggad gene encoding a Gads from human gut-originated Lc. garvieae MJF010 was cloned and overexpressed in E. coli. Thereafter, the resulting rLgGad protein carrying C-terminal His6 tag was purified Ni-NTA chromatography before enzymatic characterization. The purified rLgGad finally showed that the optimal temperature and pH for its activity was 35 °C and pH 5, respectively. The reported Gads-derived LAB including rLgGad showed optimal activity at 30–45 °C and under acidic conditions (pH range 4–5). The main function of Gad is to encounter acidic stress by consuming the hydrogen ions in the cytoplasm in the presence of L-glutamate, of which is called the glutamate-dependent acid-resistance system (Cotter and Hill 2003; Gong et al. 2019). Therefore, the expression of Gad requires LAB to survive under acidic pH, following that the increased Gad activity is critical to survive in acidic condition (Sarasa et al. 2020; Yogeswara et al. 2020). Consequently, most LAB-derived Gads exhibit optimal activity at pH 4–5, whereas they significantly lose the activity at near-neutral pH. The activity of rLgGad was significantly increased by adding metal reagents, in particular CaCl2, whereas AgNO3 completely inhibited its activity. These results were consistent with the previously-reported LAB-derived Gads with reporting that Ca2+ enhanced the GABA conversion activity, but Ag+ inhibited it. The other ions such as K+, Mg2+, Zn2+ NH4+ Co2+ Fe3+, Na+ were inconsistent, either as activators or inhibitors. The Km value of rLgGad characterized in this study was determined to be 2.94 mM, which was lower than those of corresponding Gads from most LABs except for Levi. brevis IFO 12,005 (Higara et al. 2008) and Lactobacillus zymae GU240 (Park et al. 2014), indicating that rLgGad has higher affinity for MSG compared to other previously reported Gads.

Gad has been known to be a PLP-dependent enzyme and apoGad can be converted to an active Gad-PLP complex in the presence of free PLP (Yogeswara et al. 2020). Therefore, the addition of PLP could enhance GABA biosynthesis by acting as a cofactor for the Gad enzyme. Several studies have reported that the supplement with PLP in the bacterial culture could increase the Gad biosynthesis in Lacti. Paracasei and E. coli (Su et al. 2015), and the GABA production in Bacillus subtilis, Lacti. Plantarum, and Streptococcus salivarius (Cui et al. 2020). Since PLP is required by a number of key enzymes, cells probably synthesize PLP at a sufficient rate when the Gad is expressed at relatively acceptable levels (Li et al. 2010; Yang et al. 2008). However, under most of the overexpression conditions described in previous reports, the PLP concentration generated in the normal growth of the cells was not sufficient for Gad overexpression (Su et al. 2015). Whereas, it has been reported that E. coli can biosynthesize PLP by de novo and salvage pathways (Ghatge et al. 2012). Therefore, it could be suggested that the rLgGad produced in recombinant E. coli was expressed as a Gad-PLP complex. The further rationale for this suggestion is that the GABA-producing activity of rLgGad in this study was not affected by exogenous PLP, despite that Gad is a PLP-dependent enzyme. Similar results have also been previously reported for Gads from Levi. brevis (Fan et al. 2012; Li et al. 2013). Perhaps, the expression condition applied in these studies produced adequate amount of PLP to form Gad-PLP complex with host-generated PLP. In addition, it should be noted that the addition of another coenzymes (pyridoxal HCl, pyridoxine HCl, and pyridoxine) did not affect the activity of rLgGad expressed in Gad-PLP complex.

In this study, as the first strain of GABA-producing Lc. garvieae species, the gad gene of Lc. garvieae MJF010 was first expressed in E. coli. In addition, the enzymatic properties of recombinant Gad were determined. Various methods are used to produce GABA, among which biosynthetic approaches, mainly microbial and enzymatic methods, are considered more effective. In this regard, the ability to synthesize GABA is an important criterion in the selection of microbial strains. The results of this study provide information on the Gad of the Lactococcus genus. Thus, the results of this study will contribute to the ongoing discovery of Gads.

References

Auteri M, Zizzo MG, Serio R (2015) GABA and GABA receptors in the gastrointestinal tract: from motility to inflammation. Pharmacol Res 93:11–21

Cattabeni F, Galli C, Eros T (1976) A simple and highly sensitive mass fragmentographic procedure for γ-aminobutyric acid determinations. Anal Biochem 72:1–7

Choi SI, Lee JW, Park SM, Lee MY, Ji GE, Park MS, Heo TR (2006) Improvement of γ-aminobutyric acid (GABA) production using cell entrapment of Lactobacillus brevis GABA 057. J Microbiol Biotechnol 16:562–568

Cotter PD, Hill C (2003) Surviving the acid test: Response of Gram-positive bacteria to low pH. Microbiol Mol Biol Rev 67:429–453

Cui Y, Miao K, Niyaphorn S, Qu X (2020) Production of gamma-aminobutyric acid from lactic acid bacteria: A systematic review. Int J Mol Sci 21:995

Diana M, Quílez J, Rafecas M (2014) Gamma-aminobutyric acid as a bioactive compound in foods: a review. J Funct Foods 10:407–420

Diez-Gutiérrez L, San Vicente L, Barron LJR, del Carmen Villaran M, Chávarri M (2020) Gamma-aminobutyric acid and probiotics: Multiple health benefits and their future in the global functional food and nutraceuticals market. J Funct Foods 64:103669

Eckburg PB, Bik EM, Bernstein CN, Purdom E, Dethlefsen L, Sargent M, Gill SR, Nelson KE, Relman DA (2005) Diversity of the human intestinal microbial flora. Science 308:1635–1638

El Kaoutari A, Armougom F, Gordon JI, Raoult D, Henrissat B (2013) The abundance and variety of carbohydrate-active enzymes in the human gut microbiota. Nat Rev Microbiol 11:497–504

Fan E, Huang J, Hu S, Mei L, Yu K (2012) Cloning, sequencing and expression of a glutamate decarboxylase gene from the GABA-producing strain Lactobacillus brevis CGMCC 1306. Ann Microbiol 62:689–698

Ghatge MS, Contestabile R, di Salvo ML, Desai JV, Gandhi AK, Camara CM et al (2012) Pyridoxal 5′-phosphate is a slow tight binding inhibitor of E. coli pyridoxal kinase. PLoS ONE 7:e41680

Gong L, Ren C, Xu Y (2019) Deciphering the crucial roles of transcriptional regulator GadR on γ-aminobutyric acid production and acid resistance in Lactobacillus brevis. Microb Cell Factories 18:1–12

Hannig G, Makrides SC (1998) Strategies for optimizing heterologous protein expression in Escherichia coli. Trends Biotechnol 16:54–60

Heeney DD, Gareau MG, Marco ML (2018) Intestinal Lactobacillus in health and disease, a driver or just along for the ride? Curr Opin Biotechnol 49:140–147

Hiraga K, Ueno Y, Oda K (2008) Glutamate decarboxylase from Lactobacillus brevis: activation by ammonium sulfate. Biosci Biotechnol Biochem 72:1299–1306

Iwase H, Takeuchi Y, Murai A (1979) Gas chromatography-mass spectrometry of trimethylsilyl derivatives of amino acids. Chem Pharm Bull 27:1307–1315

Kalueff AV, Nutt DJ (2007) Role of GABA in anxiety and depression. Depress Anxiety 24:495–517

Kerry RG, Patra JK, Gouda S, Park Y, Shin HS, Das G (2018) Benefaction of probiotics for human health: A review. J Food Drug Anal 26:927–939

Kim SH, Shin BH, Kim YH, Nam SW, Jeon SJ (2007) Cloning and expression of a full-length glutamate decarboxylase gene from Lactobacillus brevis BH2. Biotechnol Bioprocess Eng 12:707–712

Komatsuzaki N, Nakamura T, Kimura T, Shima J (2008) Characterization of glutamate decarboxylase from a high γ-aminobutyric acid (GABA)-producer, Lactobacillus paracasei. Biosci Biotechnol Biochem 72:278–285

Kumar S, Stecher G, Tamura K (2016) MEGA7: molecular evolutionary genetics analysis version 7.0 for bigger datasets. Mol Biol Evol 33:1870–1874

Lee B, Lee H, Nam YR, Oh JH, Cho YH, Chang JW (2005) Enhanced expression of glutamate decarboxylase 65 improves symptoms of rat parkinsonian models. Gene Ther 12:1215–1222

Lee SJ, Lee HS, Lee DW (2015) Production of γ-aminobutyric acid using immobilized glutamate decarboxylase from Lactobacillus plantarum. Microbiol Biotechnol Lett 43:300–305

Lee KW, Shim JM, Yao Z, Kim JA, Kim HJ, Kim JH (2017) Characterization of a glutamate decarboxylase (GAD) from Enterococcus avium M5 isolated from Jeotgal, a Korean fermented seafood. J Microbiol Biotechnol 27:1216–1222

Li H, Qiu T, Huang G, Cao Y (2010) Production of gamma-aminobutyric acid by Lactobacillus brevis NCL912 using fed-batch fermentation. Microb Cell Factories 9:1–7

Li H, Li W, Liu X, Cao Y (2013) gadA gene locus in Lactobacillus brevis NCL912 and its expression during fed-batch fermentation. FEMS Microbiol Lett 349:108–116

Lim HS, Seo DH, Cha IT, Lee H, Nam YD, Seo MJ (2018) Expression and characterization of glutamate decarboxylase from Lactobacillus brevis HYE1 isolated from kimchi. World J Microbiol Biotechnol 34:1–10

Lin Q, Li D, Qin H (2017) Molecular cloning, expression, and immobilization of glutamate decarboxylase from Lactobacillus fermentum YS2. Electron J Biotechnol 27:8–13

Lyu CJ, Fei JY, Yan JP, Xu QC, Mei JQ, Yue HY et al (2020) Improvement of γ-aminobutyrate biosynthesis by genetically engineered Lactococcus lactis. Biochem Eng J 157:107525

Lyu C, Yao L, Zhu Q, Mei J, Cao Y, Hu S, Zhao W, Huang J, Mei L, Yao S (2021) Reconstruction of the glutamate decarboxylase system in Lactococcus lactis for biosynthesis of food-grade γ-aminobutyric acid. Appl Microbiol Biotechnol 105:4127–4140

Madeira F, Lee J, Buso N, Gur T, Madhusoodanan N, Basutkar P, Tivey A, Potter SC, Finn RD, Lopez R (2019) The EMBL-EBI search and sequence analysis tools APIs in 2019. Nucleic Acids Res 47:W636–W641

Murzin AG (1996) Structural classification of proteins: new superfamilies. Curr Opin Struct Biol 6:386–394

Niesen FH, Berglund H, Vedadi M (2007) The use of differential scanning fluorimetry to detect ligand interactions that promote protein stability. Nat Protoc 2:2212–2221

Otaru N, Ye K, Mujezinovic D, Berchtold L, Constancias F, Cornejo FA, Krzystek A, de Wouters T, Braegger C, Lacroix C, Pugin B (2021) GABA production by human intestinal Bacteroides spp.: Prevalence, regulation, and role in acid stress tolerance. Front Microbiol 12:656895

Park JY, Jeong SJ, Kim JH (2014) Characterization of a glutamate decarboxylase (GAD) gene from Lactobacillus zymae. Biotechnol Lett 36:1791–1799

Sa HD, Park JY, Jeong SJ, Lee KW, Kim JH (2015) Characterization of glutamate decarboxylase (GAD) from Lactobacillus sakei A156 isolated from Jeot-gal. J Microbiol Biotechnol 25:696–703

Sarasa SB, Mahendran R, Muthusamy G, Thankappan B, Selta DRF, Angayarkanni J (2020) A brief review on the non-protein amino acid, gamma-amino butyric acid (GABA): its production and role in microbes. Curr Microbiol 77:534–544

Sender R, Fuchs S, Milo R (2016) Revised estimates for the number of human and bacteria cells in the body. PLoS Biol 14:e1002533

Seo MJ, Nam YD, Lee SY, Park SL, Yi SH, Lim SI (2013) Expression and characterization of a glutamate decarboxylase from Lactobacillus brevis 877G producing γ-aminobutyric acid. Biosci Biotechnol Biochem 77:853–856

Shin SM, Kim H, Joo Y, Lee SJ, Lee YJ, Lee SJ, Lee DW (2014) Characterization of glutamate decarboxylase from Lactobacillus plantarum and its C-terminal function for the pH dependence of activity. J Agric Food Chem 62:12186–12193

Solas M, Puerta E, Ramirez J M (2015) Treatment options in alzheimer s disease: the GABA story. Curr Pharm Des 21:4960–4971

Su L, Huang Y, Wu J (2015) Enhanced production of recombinant Escherichia coli glutamate decarboxylase through optimization of induction strategy and addition of pyridoxine. Bioresour Technol 198:63–69

Villegas JM, Brown L, de Giori GS, Hebert EM (2016) Optimization of batch culture conditions for GABA production by Lactobacillus brevis CRL 1942, isolated from quinoa sourdough. LWT 67:22–26

Wu Q, Shah NP (2017) High γ-aminobutyric acid production from lactic acid bacteria: emphasis on Lactobacillus brevis as a functional dairy starter. Crit Rev Food Sci Nutr 57:3661–3672

Wu Q, Tun HM, Law YS, Khafipour E, Shah NP (2017) Common distribution of gad operon in Lactobacillus brevis and its GadA contributes to efficient GABA synthesis toward cytosolic near-neutral pH. Front Microbiol 8:206

Yang SY, Lü FX, Lu ZX, Bie XM, Jiao Y, Sun LJ, Yu B (2008) Production of γ-aminobutyric acid by Streptococcus salivarius subsp. thermophilus Y2 under submerged fermentation. Amino Acids 34:473–478

Youn YS, Park JK, Jang HD, Rhee YW (2011) Sequential hydration with anaerobic and heat treatment increases GABA (γ-aminobutyric acid) content in wheat. Food Chem 129:1631–1635

Yu JJ, Oh SH (2011) γ-Aminobutyric Acid Production and Glutamate Decarboxylase Activity of Lactobacillus sakei OPK2-59 Isolated from Kimchi. Korean J Microbiol 47:316–322

Yunes RA, Poluektova EU, Dyachkova MS, Klimina KM, Kovtun AS, Averina OV, Orlova VS, Danilenko VN (2016) GABA production and structure of gadB/gadC genes in Lactobacillus and Bifidobacterium strains from human microbiota. Anaerobe 42:197–204

Zhang G, Bown AW (1997) The rapid determination of γ-aminobutyric acid. Phytochemistry 44:1007–1009

Huynh K, Partch CL (2015) Analysis of protein stability and ligand interactions by thermal shift assay.Curr Protoc Protein Sci79:28.9.1–28.9.14.

Yogeswara IBA, Maneerat S, Haltrich D (2020) Glutamate decarboxylase from lactic acid bacteria-A key enzyme in GABA synthesis. Microorganisms 8:1923

Acknowledgements

We thank Prof. Jae Kwang Kim (Division of Life Science, Incheon National University) for help in the GC-MS analysis for the GABA production.

Funding

This work was supported by the Incheon National University Research Grant in 2019.

Author information

Authors and Affiliations

Contributions

All authors analyzed the experimental data and discussed the results. HJL and E-SC performed the experiments. HJL, D-HJ, and M-JS contributed to the writing of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Ethical approval

All applicable international, national, and/or institutional guidelines for the care and use of human derivatives were followed. The study of human derivatives was approved by the Institutional Review Board of Incheon National University University (IRB 7007971-202006-001 A).

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lim, H.J., Jung, DH., Cho, ES. et al. Expression, purification, and characterization of glutamate decarboxylase from human gut-originated Lactococcus garvieae MJF010. World J Microbiol Biotechnol 38, 69 (2022). https://doi.org/10.1007/s11274-022-03256-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11274-022-03256-x