Abstract

This research aimed to extend the postharvest shelf life of Royal Gala apple during cold storage and maintain its market value in simulated retail conditions. Apples were treated with hypobaric pressure (50 kPa for 4 h) followed by 1-MCP (0.5 µL L−1, 0.7 µL L−1, and 1.0 µL L−1) treatment for 24 h individually and in combinations, stored at (1 ± 1 °C, 85 ± 3% RH) for 120 d and analyzed for different quality parameters (Peel color, firmness, weight loss, TSS, acidity, ethylene production rate, and respiration rate) at each 30 d interval, followed by a 20 d simulated retail condition at 20 ± 3 °C with 4 d interval. Results indicated that all 1-MCP concentrations were more effective in retaining quality compared to individual hypobaric treatment. However, a synergistic effect was observed by combining 1-MCP with hypobaric treatment. Among the combined treatments, 1.0 µL L−11-MCP + 50 kPa more effectively and significantly retained quality during cold storage. Furthermore, the apples were more juicy, tasty, and attractive in color than others in simulated conditions. Addition of hypobaric treatment to 1-MCP might reduce endogenous ethylene in fruit by outward diffusion and blocking further ethylene synthesis by the action of 1-MCP. However, in-depth study is required for further understanding the phenomena.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Royal gala is an important apple cultivar of Pakistan and is highly preferred due to its unique physical and excellent nutritional qualities (Ullah et al. 2021). Apple is a climacteric fruit and usually harvested at optimum maturity. At ambient temperature the storage life of apple is limited to 2–3 weeks (Wu et al. 2021). Like other climacteric fruit, postharvest increase in ethylene limits apple shelf life by promoting ripeining and senecsence. During ripening, softening of cell wall leads to increase in sugars concentration and decrease in organic acids, which adversely affects postharvest quality of apple fruit (Wei et al. 2010). Postharvest fungal attack and poor postharvest management in developing countries are the major factors in limiting fruit shelf life (Khalil et al. 2019). Around 30–40% losses occur during the postharvest supply chain of fresh produce (Bordoh et al. 2020). In addition, due to low quality, fruit do not satisfy consumer requirement in retail (Shukla and Jharkharia 2013). To control ethylene production, which is the major contributor of postharvest decay of the fruit, different strategies like chemical methods, biological products, Physical treatments, heat, including hot air and hot water treatments, microwave, radiofrequency, UV-C light and gaseous treatments have all been tested (Zhang et al. 2018).

Among gaseous treatments, 1-Methylcyclopropene (1-MCP) has been tested globally for ethylene inhibition in most of the climacteric fruits like apple. 1-MCP encounter ethylene receptors and block ethylene dependent response, resulting in decreased respiration rate leading to increase in the storage life of fruit, However, to increase the ethylene inhibition efficiency of 1-MCP, it should be combined with other postharvest techniques like cold storage, control atmosphere, low oxygen storage systems (Radenkovs and Juhnevica-Radenkova 2018). Moreover, the response of a recently emerging strategy hypobaric treatment (pressure below 101 kPa) has not been elucidated in combination with 1-MCP (Huan et al. 2021). Hypobaric treatment (25 kPa for 30 min) demonstrated promising results in retention of TSS, firmness, weight loss and total phenolics. Similarly, hypobaric treatment was also effective against fungal decay in strawberries, sweet cherries and table grapes. Furthermore, it has been observed that timing and length of application manipulate the efficacy of hypobaric treatment (Hashmi et al. 2016). Moreover, treatment for 6 h mitigates the effectiveness of hypobaric treatment against fungal decay in strawberries as compared to 4 h. Currently, studies on the efficacy of hypobaric treatment as a hurdle technique as well as on apple storage and shelf life is limited. Therefore, the objectives of this research were to (1) determine the effectiveness of hypobaric treatment in improving storage life of apple (2) find the integrated effect of 1-MCP and hypobaric treatments on the storage life of apple fruit (3) investigate the effect of 1-MCP and hypobaric treatment on sensory attributes of apple fruit in simulated retail conditions.

Materials and methods

Fruit source

Royal gala apple at optimum maturity with TSS (10.80–11.00), peel color (80–82) h° and firmness (75–80) N, were picked from orchard in Swat, Khyber Pakhtunkhwa, Pakistan and shifted to the postharvest lab Department of Food Science and Technology, The University of Agriculture Peshawar-Pakistan. Where, bruised, immature and diseased fruit were discarded, and only uniform sized sound fruit without any defects were selected.

Treatments

Total 792 apple fruit (360 for cold storage and 432 for simulated retail study) were selected for experiment. Treatments consists of hypobaric treatment (50 kPa-4 h), three concentrations (0.5, 0.7, 1.0 µL L−1) of 1-MCP, and combination of hypobaric and 1-MCP treatments such as (0.5 µL L−11-MCP + 50 kPa), (0.7 µL L−11-MCP + 50 kPa) and (1.0 µL L−11-MCP + 50 kPa) while untreated fruits were used as control. These fruits were packed in polystyrene clamshells stored at 1 ± 1 °C RH (85 ± 3) % for 120d and analyzed for different physical and chemical properties at 30 d interval. After the completion of this period, the selected fruit were transferred to simulated conditions at 20 ± 3 for 20d and organoleptically evaluated at a gap of 4 days. All analysis was made in triplicates and the entire experiment was repeated however, data of the first experiment were presented due to similarity in results.

Hypobaric treatment

Fruit were subjected to hypobaric treatment (50 kPa-4 h) and the hypobaric pressure was generated according reported method of (Hashmi et al. 2016). Pressure was generated in an automatic chamber with a fixed vacuum pump. apple clamshells were placed in the chamber for 4 h and pressure was set to 50 kPa in display with accuracies of 10 at room temperature 20 °C while fruit kept for the same time at the same ambient temperature at pressure of 101 kPa were treated as control.

1-MCP treatment

The 1-MCP treatment was carried out following method of (Breitel et al. 2016) with slight modifications. Gently 0.82 g of 1-MCP powder (0.14% active ingredient) was added to the 1,000 mL of volumetric flask. Additionally, 50 ml of distilled water was injected into the closed flask and shaken to release the 1-MCP gas to make stock solution of 1-MCP. Apple were placed in tin containers which were sealed airtight to prevent gas leakage. Gas with a concentration of 8, 11.2, and 16 mL from stock solution was injected to six containers 16 L each which give a concentration of 0.5, 0.7, and 1.0 ppm 1-MCP respectively, to the apples. Treatment was given to the fruit for 24 h at 20 °C.

Fruit quality assessment

Weight loss

Initially, all fruits were weighed at ambient temperature using 0.001 g accuracy balance (Adam USA). These fruits were re-weighed at each interval and final weight was subtracted from initial. The data was calculated in percentage according to (Hashmi et al. 2016).

Firmness

Firmness of the fruit were determined through Penetrometer (Lutron FR-5120 Enterprises, Taiwan) using 11 mm hard fruit probe. The fruit were peeled on both sides 1 mm deep through a stainless-steel fruit peeler. The probe was inserted from both peeled sites and data was recorded in Newton (N) following method of (Hashmi et al. 2016).

Total soluble solids

Total soluble solids were examined by Digital refractometer (Atago, Japan) using standard method of Kulcu (2018).

Titratable acidity

Titratable acidity was determined by taking 10 ml sample from 100 ml ten-time diluted apple juice. The samples were titrated against 0.1 N NaOH solution and values were noted at appearance of light pink color using well examined method of Kulcu (2018).

Peel color

Fruit color was determined in L*a*b*c*h* mode, using a colorimeter PCE-CSM 2 (PCE.

Instruments, Meschede, Germany). Firstly, the equipment was calibrated with white and black tiles. Apple color was recorded in h* by placing the aperture of colorimeter on apple in middle from two sides. The final readings were recorded in h* with difference noted in initial data of first day and final in apple peel color as mentioned by Kulcu (2018).

Ethylene production

Ethylene production was determined by gas analyzer F-900 (Felix Instruments, USA). Three apple fruits were placed in a wide air-tight jar (1 L), and air sample was taken from the jar with in first few seconds using 10 cc syringe. Similarly, another sample was taken after one hour and ethylene production rate (C2H4 kg−1 h−1) was calculated using the formula used by Lerud et al. (2019).

Respiration rate

The method of Hashmi et al. (2016) with slight modification was followed for determination of respiration rate. Respiration rate was determined from rate of CO2 production from the same fruits used for ethylene production. CO2 production was measured by gas analyzer (F-900(Felix Instruments, USA)).

Sensory evaluation (overall acceptability)

The sensory evaluation was performed in simulated retail chain after 120d of cold store by 10–12 trained sensory panel of age (15–60) years. Panelists were given white sheets to rate apple sensory parameters (color, mouthfeel, crispiness, taste, aroma) according to a 1–9 points hedonic scale where, 1 stand for extremely dislike and 9 for extremely like according to method of Escribano et al. (2016).

Statistical analysis

The obtained data were statistically analyzed by two factorial completely randomized design (CRD) using statistix 8.1 software. Similarly, LSD test was carried out to determine the mean difference at 5% significance level.

Results and discussion

Ethylene production rate

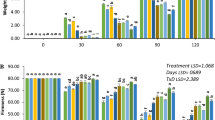

Ethylene production in 1-MCP treated fruit was low as compared to control and 50 kPa treated fruit during storage (Fig. 1a). Hypobaric treatment combined with 1-MCP (1.0 µL L−1) effectively delayed ethylene production than individual application of each 1-MCP and 50 kPa treatment. 1-MCP treated fruit observed a significant (P < 0.05) decrease in ethylene production from 30 d till end of storage. Likewise, Mattheis et al. (2005) observed a similar trend in ethylene production of 1-MCP treated Gala apple. Previously, hypobaric treatment reduced ethylene production in loquat and Chinese berries (Chen et al. 2013). As previously speculated that low pressure removes endogenous ethylene from fruit through outward diffusion (Hashmi et al. 2016; Huan et al. 2021). This might explain the production of less ethylene in hypobaric treated apple in this study. Furthermore, 1-MCP application was found more effective after hypobaric treatment, because less internal ethylene (Hashmi et al. 2016) in hypobaric treated fruit might have promoted 1-MCP to bind more strictly with free receptors and reduced ethylene synthesis effectively as observed in this study (Fig. 1a).

Integrated effect of hypobaric treatment (50 kPa) and 1-MCP (0.5 and 1.0 µL L−1) on the a ethylene production rate (µmol kg−1 h−1) and b CO2 production rate (mmol kg−1 h−1) of Royal gala apple during cold storage (0 ± 1 °C). Each data point represents the mean value of three replicates. Vertical bars represent standard error. Letters on bars showed significant (P < 0.05) difference among treatments

3.2 Respiration rate

As the storage time progressed increase in respiration rate was recorded in control and 50 kPa treated samples. CO2 production in 1-MCP treated fruits were very low as compared to control and 50 kPa treated fruit. However, 50 kPa treatment were better in control of respiration rate than untreated fruits (Fig. 1b). The combine application of 1-MCP especially (1.0 µL L−1) and 50 kPa were more effective in controlling respiration rate and significantly (P < 0.05) maintained it throughout storage duration (Fig. 1b). Respiration continues in fruit even after harvesting therefore, ripening proceeds and results in senescence of the fruit (Tano et al. 2005). In our study 1-MCP reduced ethylene production which ultimately decrease respiration rate, as previously reported that Ethylene, being a ripening hormone in fruits involved in gene expression that control metabolic pathways of reactions such as respiration (Pech et al. 2012). Similarly, Mattheis et al. (2005) observed the same trend in CO2 production in 1-MCP treated Gala apple and reported that lower ethylene production in Royal gala apple directly decreased respiration rate. The best results here in augmented 1-MCP (1.0 µL L−1) and 50 kPa treated fruit might be linked with lower ethylene production by 1-MCP and removal of auto catalytic ethylene during hypobaric treatment (Hashmi et al. 2016). So, in their integration 1-MCP might more effectively controlled respiration by strictly binding with free receptors in hypobaric treated apple.

Weight loss (%)

Increase in weight loss was observed in all treated and untreated samples during cold storage (Fig. 2a). Importantly, 50 kPa has slight but significant effect (P < 0.05) on weight loss of apple as compared to control. While all three concentrations of 1-MCP retained maximum reduction in weight loss as compared to 50 kPa and untreated fruits. Similarly, among different concentrations 1-MCP (1.0 µL L−1) was found more effective in control of weight loss during storage (Fig. 2a).

Integrated effect of hypobaric treatment (50 kPa) and 1-MCP (0.5 and 1.0 µL L−1) on the a weight loss (%) and b firmness (N) of apples during cold storage (0 ± 1 °C). Each data point represents the mean value of three replicates. Vertical bars represent standard error. Letters on bars showed significant (P < 0.05) difference among treatments

Post harvest increase in respiration leads to increase in transpiration resulting in water loss from the fruit (Kabir et al. 2020). Similarly, Neuwald et al. (2009) reported only 2.6% weight loss in 1-MCP treated apple during 5 month storage. In addition, Błaszczyk and Gasparski (2019) observed that 1-MCP effectively controlled weight loss in apple for 6 months in cold storage. Like our study, Hashmi et al. (2016) also observed no weight loss in strawberries during hypobaric treatment. The benificial effect of low presuure treatment in controlling weight loss in apple might be linked with less transpiration from apple fruit due to low respiration.The combined treatment increased the firmness and reduce all degradative reactions which could lead to production of simpler compounds and high water content providing a chance for more evaporation and weight loss (Kabir et al. 2020).

Firmness (N)

Firmness plays a vital role in the eating quality of apple (Hashmi et al. 2016). Firmness of all treated samples and control decreased with storage. Hypobaric treatment (50 kPa for 4 h) had a slight effect on keeping the fruit firm as compared to all three concentrations of 1-MCP. Similarly, 50 kPa integrated with 1-MCP (1.0 µL L−1) maintain the highest firmness (P < 0.05) in apples during storage (Fig. 2b).

Previous research reported a little or no impact of hypobaric treatment on firmness of peach fruit (Song et al. 2016). In fact, hypobaric treatment induces hermetic stress in delicate fruits such as strawberries (Hashmi et al. 2016). However, the same stress is not likely to produce in the hard-peeled apple fruit. Błaszczyk and Gasparski (2019) observed high firmness in 1-MCP treated apples. The higher firmness of (50 kPa + 1-MCP 1.0 µL L−1) treated apples might the result of reducing degradation of complex carbohydrates because of low catabolic break down.

Total soluble solids (°Bx)

All 1-MCP treated fruits and 50 kPa + 1-MCP 1.0 µL L−1 maintained TSS as compared to control and 50 kPa treated fruits (Fig. 3a). Our results supported with the findings of Bai et al. (2005) who found that 1-MCP treated significantly maintained TSS in Royal Gala apple as compared to other cultivars. In addition, hypobaric treatment was also tested positive on TSS of other fruits (Huan et al. 2021). During ripening and senescence, complex polysaccharides and starches are converted to simple sugars results in increasing total soluble solids content (Huan et al. 2021). However, the combined treatment delayed factors leading to senescence (Fig. 1a, b) and hence the TSS was maintained.

Integrated effect of hypobaric treatment (50 kPa) and 1-MCP (0.5 and 1.0 µL L−1) on the a TSS (°Bx) and b acidity (%) of apples during cold storage (0 ± 1 °C). Each data point represents the mean value of three replicates. Vertical bars represent standard error. Letters on bars showed significant (P < 0.05) difference among treatments

Titratable acidity TA (%)

One of good indicator about fruit metabolism is titratable acidity during storage. Due to increase in respiration rate in storage period, organic acids are used in TCA cycle for cellular energy production resulting in decrease in titratable acidity (Both et al. 2018). 1-MCP treated fruit retained maximum TA as compared to control and 50 kPa treated fruits. Interestingly, 50 kPa treated fruits are also observed slightly better in retaining TA as compared to untreated samples. However, the integration of 1-MCP (1.0 µL L−1) + 50 kPa retained highest acidity in storage period (Fig. 3b). Our results are in line with the results of Błaszczyk and Gasparski (2019) who observed significant retention of TA in 1-MCP treated Gala apple. Similarly, 1-MCP is better in controlling reduction of acids at low temperature (Both et al. 2018). However, Hypobaric pressure-maintained acidity only in asparagus, cherries, peaches, pears, tomato, Chinese bayberries, and louqat (Chen et al. 2013). Furthermore, it has been reported that hypobaric treatment control increases in pH which ultimately maintained acidity of blue berry (Li et al. 2019). The utilization of organic acids for cellular energy production might be reduced in 50 kPa treated apples due to low respiration and further declined by 1-MCP leading to maximum TA retention in apple.

Hue angle of apple peel (h°)

Color plays a crucial role in consumer’s sensory perception in fruit selection. In this study, all concentrations of 1-MCP significantly controlled color degradation as compared to control and 50 kPa treated fruit. However increase in concentration of 1-MCP (1.0 µL L−1) retained maximum color of apple (Fig. 4). Considering hypobaric treatment, 50 kPa retained color but the effect was slightly significant as compared to untreated fruits (Fig. 4). Our study are supported by findings of Lee et al. (2016) with greater color retention in 1-MCP treated apple. The change in color from green to yellow is due to degradation of Chlorophyll and carotenoids synthesis which were inhibited by the application of 1-MCP (Zhao et al. 2020). The property of 1-MCP to retain color of the fruit is directly linked with lower ethylene production in 1-MCP treated fruit as previous research suggested that ethylene is involved in different genes expression that control fruit color (Pech et al. 2012). While hypobaric treatment control changes in color for 15 days in Chinese bay berries (Chen et al. 2013). In this study (1.0 µL L−1 1-MCP and 50 kPa) controlled color changes might be the result of little degradation of chlorophyll and less development of carotenoids and anthocyanins in peel tissues due to suppressed ethylene synthesis.

Effect of hypobaric treatment (50 kPa) and 1-MCP (0.5 and 1.0 µL L−1) on the peel color (h°) of apples during cold storage (0 ± 1 °C). Each data point represents the mean value of three replicates. Vertical bars represent standard error. Letters on bars showed significant (P < 0.05) difference among treatments

Sensory evaluation (overall acceptability)

Besides nutritional profile, consumer acceptability to purchase a particular fruit mainly focus on organoleptic properties like color/appearance taste, texture, aroma, and flavor (Caracciolo et al. 2020). In this study, 1-MCP treated fruits gained poor acceptance in first two intervals while control and 50 kPa treated fruits were preferred in simulated retail condition (Fig. 5). But later on, control and 50 kPa treated fruits loss quality attributes such as decrease in firmness, loss of crispiness and production of fermented flavor and were therefore discarded. The 1-MCP (1.0 µL L−1) treated fruit alone and in integration with 50 kPa (1.0 µL L−1 1-MCP + 50 kPa) were accepted slowly by the judges with the passage of time in simulated retail chain (Fig. 5). Similarly, at last interval 1.0 µL L−1 1-MCP + 50 kPa treated fruit treated achieved maximum score because these fruits were juicier along with good taste, color, and aroma.

Integrated effect of hypobaric treatment (50 kPa) and 1-MCP (0.5 and 1.0 µL L−1) on overall acceptability of apples in simulated retail condition (20 ± 3 °C). Each data point represents the mean value of three replicates. Vertical bars represent standard error. Letters on bars showed significant (P < 0.05) difference among treatments

The lower acceptability of 1.0 µL L−1 1-MCP + 50 treated fruits in initial intervals might be due to the green color along with hard texture and slight taste. Our results are supported by the findings of Marin et al. (2009) they argued that 1-MCP treated fruits suppressed aroma of the fruit but later, consumers accepted 1-MCP treated fruits. However, (Marin et al. 2009) emphasized that 1-MCP treatment caused to lower aroma volatiles production, concluding that there was no advantage for overall taste indices in 1-MCP treated Gala fruit compared to the control fruit. Interestingly, fruit treated with low concentration (0.6 µL L−1) of 1-MCP were more accepted by the consumers because these fruits retained more aroma as compared to higher concentrations. Moreover, 1-MCP treated fruits were very juicy and retained excellent color in additional storage (Juhnevica et al. 2013).

Conclusion

Comparing all treatments, 1.0 µL L−1 1-MCP + 50 kPa treatment was found best treatment in maintaining different quality attributes in cold storage as well as in simulated retain chain of 20 days. Furthermore, ripening process was still noticed on the 1.0 µL L−1 1-MCP + 50 kPa treated fruits after 20 days at ambient storage. Similarly, the other concentrations of 1-MCP were also found significant alone and in combination with hypobaric treatment. But as compared to 50 kPa, 1-MCP treatment irrespective of concentrations was found more effective in maintaining quality attributes of apple fruits while, 50 kPa treated fruits ripe quickly after control therefore it is concluded from this study that hypobaric alone is quite poor to maintain enough quality attributes of apple fruit during long term cold storage therefore it should be combined with 1-MCP to give more pronounced results. We further concluded that our treatment 1.0 µL L−1 + 50 kPa increased shelf life of apples by decreasing ripening of apples therefore it may provide an opportunity to the farmers, stake holders or those who involved in apples business to sell their apple with good quality in long distinct markets to get enough economic gain from their fruits.

References

Bai J, Baldwin EA, Goodner KL, Mattheis JP, Brecht JK (2005) Response of four apple cultivars to 1-methylcyclopropene treatment and controlled atmosphere storage. HortScience 40(5):1534–1538. https://doi.org/10.21273/HORTSCI.40.5.1534

Błaszczyk J, Gasparski K (2019) Influence of 1-methylcyclopropene (1-MCP) on the quality and storability of ‘Red Jonaprince’ apples stored in different conditions. Acta Scientiarum Polonorum Hortorum Cultus 18(6):7–15. https://doi.org/10.24326/asphc.2019.6.1

Bordoh PK, Ali A, Dickinson M, Siddiqui Y, Romanazzi G (2020) A review on the management of postharvest anthracnose in dragon fruits caused by Colletotrichum spp. Crop Prot 130:105067. https://doi.org/10.1016/j.cropro.2019.105067

Both V, Brackmann A, Thewes FR, Weber A, Schultz EE, Ludwig V (2018) The influence of temperature and 1-MCP on quality attributes of ‘Galaxy’ apples stored in controlled atmosphere and dynamic controlled atmosphere. Food Packag Shelf Life 16:168–177. https://doi.org/10.1016/j.fpsl.2018.03.010

Breitel DA, Chappell-Maor L, Meir S, Panizel I, Puig CP, Hao Y, Aharoni A (2016) Auxin response factor 2 intersects hormonal signals in the regulation of tomato fruit ripening. PLoS Genet 12(3):e1005903. https://doi.org/10.1371/journal.pgen.1005903

Caracciolo F, El-Nakhel C, Raimondo M, Kyriacou MC, Cembalo L, De Pascale S, Rouphael Y (2020) Sensory attributes and consumer acceptability of 12 microgreens species. Agronomy 10(7):1043. https://doi.org/10.3390/agronomy10071043

Chen H, Yang H, Gao H, Long J, Tao F, Fang X, Jiang Y (2013) Effect of hypobaric storage on quality, antioxidant enzyme and antioxidant capability of the Chinese bayberry fruits. Chem Cent J 7(1):1–7. https://doi.org/10.1186/1752-153X-7-4

Escribano S, Lopez A, Sivertsen H, Biasi WV, Macnish AJ, Mitcham EJ (2016) Impact of 1-methylcyclopropene treatment on the sensory quality of ‘Bartlett’ pear fruit. Postharvest Biol Technol 111:305–313. https://doi.org/10.1021/jf051339d

Hashmi MS, East AR, Palmer JS, Heyes JA (2016) Hypobaric treatments of strawberries: a step towards commercial application. Sci Hortic 198:407–413. https://doi.org/10.1016/j.scienta.2015.12.017

Huan C, Li H, Jiang Z, Shen S, Zheng X (2021) Effect of hypobaric treatment on off-flavour development and energy metabolism in ‘Bruno’ kiwifruit. LWT 136:110349. https://doi.org/10.1016/j.lwt.2020.110349

Juhnevica K, Skudra L, Skrivele M, Radenkovs V, Seglina D, Stepanovs A (2013) Effect of 1-methylcyclopropene treatment on sensory characteristics of apple fruit. Environ Exp Biol 11:99–105

Kabir M, Nur S, Ali M, Lee WH, Cho SI, Chung SO (2020) Physicochemical quality changes in tomatoes during delayed cooling and storage in a controlled chamber. Agriculture 10(6):196. https://doi.org/10.3390/agriculture10060196

Khalil AJ, Barhoom AM, Musleh MM, Abu-Naser SS (2019) Apple trees knowledge based system. http://dspace.alazhar.edu.ps/xmlui/handle/123456789/482. Accessed 19 Feb 2022

Kulcu R (2018) Determination of the effects of different packaging methods and materials on storage time of dried apple. Matter Int J Sci Technol 4(2):238–255. https://doi.org/10.20319/mijst.2018.42.238255

Lee J, Mattheis JP, Rudell DR (2016) Storage temperature and 1-methylcyclopropene treatment affect storage disorders and physiological attributes of ‘Royal Gala’ apples. HortScience 51(1):84–93. https://doi.org/10.21273/HORTSCI.51.1.84

Lerud RM, Beseau D, Hale CM, Noll C, Rananavare SB (2019) Optimizing the performance of a commercial electrochemical ethylene sensor via controlled ethylene generation in situ. Sens Actuators B Chem 281:535–541. https://doi.org/10.3390/ijms22031297

Li H, James A, He X, Zhang M, Cai Q, Wang Y (2019) Effect of hypobaric treatment on the quality and reactive oxygen species metabolism of blueberry fruit at storage. CyTA J Food 17(1):937–948. https://doi.org/10.1080/19476337.2019.1674925

Marin AB, Colonna AE, Kudo K, Kupferman EM, Mattheis JP (2009) Measuring consumer response to ‘Gala’ apples treated with 1-methylcyclopropene (1-MCP). Postharvest Biol Technol 51(1):73–79. https://doi.org/10.1016/j.postharvbio.2008.06.008

Mattheis JP, Fan X, Argenta LC (2005) Interactive responses of Gala apple fruit volatile production to controlled atmosphere storage and chemical inhibition of ethylene action. J Agric Food Chem 53(11):4510–4516. https://doi.org/10.1021/jf050121o

Neuwald DA, Streif J, McCormick R (2009) A case study: potential energy savings using 1-MCP with ‘Gala’ apples in commercial CA storage. In: VI international postharvest symposium, 877:323–326

Pech JC, Purgatto E, Bouzayen M, Latché A (2012) Ethylene and fruit ripening. Annu Plant Rev 44:275–304. https://doi.org/10.1002/9781118223086.ch11

Radenkovs V, Juhnevica-Radenkova K (2018) Comparison of three storage techniques for post-harvest quality preservation of six commercially available cultivars of apple. Int J Fruit Sci 18(3):268–286. https://doi.org/10.1080/15538362.2017.1422451

Shukla M, Jharkharia S (2013) Agri-fresh produce supply chain management: a state-of-the-art literature review. Int J Oper Prod Manag 33(2):144–158. https://doi.org/10.1108/01443571311295608

Song L, Wang J, Shafi M, Liu Y, Wang J, Wu J, Wu A (2016) Hypobaric treatment effects on chilling injury, mitochondrial dysfunction, and the ascorbate–glutathione (AsA-GSH) cycle in postharvest peach fruit. J Agric Food Chem 64(22):4665–4674. https://doi.org/10.1021/acs.jafc.6b00623

Tano K, Kamenan A, Arul J (2005) Respiration and transpiration characteristics of selected fresh fruits and vegetables. Agron Afr 17(2):103–115. https://doi.org/10.4314/aga.v17i2.1662

Ullah S, Shah OU, Said F, Umer S, Khan A, Sultan H, Faisal S (2021) Proximate composition and biological activities of different cultivars of apples (Malus Domestica) grown at Swat, Pakistan. Ann Rom Soc Cell Biol 25(6):20074–20085

Wei J, Ma F, Shi S, Qi X, Zhu X, Yuan J (2010) Changes and postharvest regulation of activity and gene expression of enzymes related to cell wall degradation in ripening apple fruit. Postharvest Biol Technol 56(2):147–154. https://doi.org/10.1016/j.postharvbio.2009.12.003

Wu B, Shen F, Chen CJ, Liu L, Wang X, Zheng WY, Zhang XZ (2021) Natural variations in a pectin acetylesterase gene, MdPAE10, contribute to prolonged apple fruit shelf life. Plant Genome 14(1):e20084. https://doi.org/10.1002/tpg2.20084

Zhang H, Mahunu GK, Castoria R, Yang Q, Apaliya MT (2018) Recent developments in the enhancement of some postharvest biocontrol agents with unconventional chemicals compounds. Trends Food Sci Technol 78:180–187. https://doi.org/10.1016/j.tifs.2018.06.002

Zhao J, Xie X, Wang S, Zhu H, Dun W, Zhang L, Fang C (2020) 1-Methylcyclopropene affects ethylene synthesis and chlorophyll degradation during cold storage of ‘Comice’ pears. Sci Hortic 260:108865. https://doi.org/10.1016/j.scienta.2019.108865

Acknowledgements

This work was carried out as a requirement of M.Sc. (Hons) degree of the first author. Thanks to the Higher Education Commission, Pakistan for funding this project under National Research Program for Universities (NRPU).

Funding

This research was carried out in The University of Agriculture, Peshawar-Pakistan, under National Research Program for Universities (NRPU 6301) with financial support from The Higher Education Commission Pakistan.

Author information

Authors and Affiliations

Contributions

The research was designed by MSH, carried out by WUR, data analysis was done by SS and YD, and the paper was formatted by AA and WA.

Corresponding author

Ethics declarations

Conflict of interest

There are no conflict of interests among authors of this manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rahman, W.U., Hashmi, M.S., Durrani, Y. et al. Hypobaric treatment augments the efficacy of 1-MCP in apple fruit. J Food Sci Technol 59, 4221–4229 (2022). https://doi.org/10.1007/s13197-022-05481-6

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-022-05481-6