Abstract

The food product industry is increasingly looking for foods with nutritional properties that can provide health benefits. Additionally, a challenge for the food industry is the use of all raw materials. For these reasons, banana peel that is a raw material from Banana (Musa spp.) fruit emerges as potential for new food product development. Here, we developed powder blends using a lyophilization process for the preparation of flour to potential use in cookies, bread, and pasta products. Three formulations were designed; the main difference in the formulations was the use of banana peel concentration. Our results showed that blends produced with banana peel presented physical–chemical properties considered suitable for use in food industry. Moreover, the evaluated morphological parameters reveal the properties of the powders. The blends formulated with banana peel have more antioxidant properties, showing that the banana peel may be an attractive option to generate powders with high antioxidant properties.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Banana (Musa spp.) is widely consumed in the world, and the market for this food crop economically is one of the most significant in the world. Although economically rentable, the consumption of banana also generates more than 26 million tons of dry matter residue per year worldwide principally due to discarding its peels (Ahmad and Danish 2018; Coltro and Karaski 2019). Therefore, new economic strategies should be evaluated to reduce the discards and postharvest losses and increase the aggregate value of this food crop (Petsakos et al. 2019). In these terms, flour production with blends formulated with different groups of compounds and using residues for substitution in food products such as cookies, pasta, and bread represent a challenge for the food industry (Morone et al. 2019).

Despite the diversity of products made from banana, there are few studies in the literature related to product development with the complete substitution of wheat for banana biomass, particularly biomass processed by freeze drying. A few comparative studies with different proportions of peels and pulp substituting for wheat in products have been published (Khoozani et al. 2019a, b; Soto-Maldonado et al. 2018). Studies considering the development of innovative food products have suggested the use of blends derived from different food crops. The use of blends can offer versatility to improve the nutritional and sensory characteristics of the food products (Okpala and Egwu 2015; Tomasula et al. 2016). Additionally, blends can improve the physical–chemical properties of processed food (Pereira et al. 2019).

The use of blends from banana pulp and peels for cake production is an innovative development that can align with the use of the peels discarded for the improvement of quality in food production (Morone et al. 2019).The use of banana peels can increase the economic development for a value-add in this food chain. Additionally is known that banana peel have antioxidant properties, principally due de secondary metabolites such as phenolic compounds present in the peel (Vu et al. 2018; Kamel et al. 2017). Those antioxidant properties make the use of banana peel attractive, and with higher potential for development of new products (Ortiz et al. 2017). In this way, here we describe the development and evaluation of the physical–chemical characteristics of different lyophilized blends produced with banana pulp and banana peel. The analyses of the blends produced provided insights into their innovative use in cookie and dessert products.

Materials and methods

Plant material

Fresh banana (Musa acuminata Colla × Musa balbisiana Colla) fruit obtained at the local market was used in this study. Fruits were harvested at the stage of green maturity (color index 2 = entirely green) according to the commercial color scale of the peel as previously described (Aurore et al. 2009).

Pulp extraction and blend production

Fresh bananas were sanitized with chlorine-base 200 p.p.m. and cooked for 10 min. Then, they were separated into three formulations: the first composed only of the pulp (E1), the second used the whole banana (34% peel and 66% pulp) (E2), and the third composed of 50% peel and 50% pulp (E3). To finish the preparation of formulations, E1, E2, and E3 were dissolved in water (formulation/water, 1:0.5, w/v); subsequently, they were homogenized with an industrial blender. At room temperature, blends were prepared as shown in Table 1, distinguished as BLE1, BLE2, and BLE3 and then homogenized. After homogenization, the blends were frozen at − 18° C for 48 h. After this, the material was lyophilized at − 40 ± 3° C for 48 h. After the lyophilization process, the powder mixture was disintegrated for 3 min with an industrial blender and sieved through a 0.39 mm mesh.

Characterization of blends

Blends were characterized as previously described (Zenebon and Pascuet 2005) for water content, ash, total fiber, total starch content, total sugars, and reducing sugars. Nonreducing sugars were determined according to the method based on multiplying the difference between the percentages of total sugars and reducing sugars with the factor 0.95 (Zenebon and Pascuet 2005). The total protein content was quantified according to method 981.10 of the AOAC International and pH was quantified according to method 981.12 of the AOAC International (Lee et al. 2005). The lipid content was determined by extraction with cold solvent mixture according to a published method (Bligh and Dyer 1959). The water activity was determined by direct measurement in a Labswift water activity analyzer (Novasina, Switzerland) at 25° C. The morphology of the particles of the powder blends was evaluated by scanning electron microscopy (SEM) (TESCAN VEGA 3), operated at 5 kV and with magnifications ranging from 250 × to 1000 ×. No coating was required. Briefly, the samples were deposited in small amounts in metallic stubs with conventional double-sided adhesive tape. The samples were analyzed using the images acquired through LEO software, version 30.01.

Color determination

For color measurements, a MiniScan XE Plus colorimeter was used in the powder function. The values of \( {\text{L}}^{*} \), \( {\text{a}}^{ *} \), and \( {\text{b}}^{ *} \) were determined. The coordinate \( {\text{C}}^{*} \) is the chroma and was determined in accordance with Eq. 1. The coordinate \( {\text{H}}^{*} \) is the hue angle and was determined in accordance with Eq. 2 (Hutchings 2011).

Bulk density and tap density

Bulk density was determined by pouring 3 g powder blend into an empty 10 mL graduated cylinder. The volume was registered, and the ratio of mass to the occupied volume in cylinder gives the bulk density. Tap density was determined similarly, but the powder blends were tapped 100 times until the new volume was registered.

Carr index and Hausner ratio

The fluidity and compactibility of the powder blends were expressed in terms of the Carr index (CI) (Eq. 3) and the Hausner ratio (HR) (Eq. 4), respectively. The CI and HR were determined from the apparent density and compacted density of the mixtures, respectively.

Water solubility index and water absorption index

The water solubility index (WSI) and the water absorption index (WAI) were determined according to the methodology briefly described with modifications (Khoozani et al. 2019a). Briefly, 1 g each sample blend was added to a Falcon centrifuge tube and 35 mL distilled water was added. The mixture was homogenized on a microprocessor shaker (Vortex Q220M; Quimis, Brazil) at level 10 for 5 min. Then, the tube was incubated at room temperature for 1 h and the samples were centrifuged at 2190×g for 20 min. The tube was drained to a plate dish and the supernatant dried for 5 h at 105 °C until the weight was constant. The residue mass (soluble blend mass, g) compared to the total mass (total blend mass, g) was used to determine WSI. The WAI was calculated as the mass of precipitate in the Falcon tube compared to the total mass (total blend mass, g) used for analysis.

Oil-holding capacity (OHC)

Twenty-five milliliters commercial olive oil was added to 1 g dry sample, stirred and incubated at 40, 60 or 80 °C for 1 h. After centrifugation, the residue was weighed, and OHC was calculated as g oil per g of dry sample (Resende et al. 2019).

Total reactive antioxidant potential (TRAP) and total antioxidant reactivity (TAR)

Total reactive antioxidant potential (TRAP) is an in vitro nonenzymatic method that is based on the action of antioxidants on the fluorescence decay of luminol-enhanced chemiluminescence generated by the reaction of luminol (o-aminophthaloylhydrazide) with the peroxyl radicals produced by thermal decomposition of the free radical generator AAPH (Moresco et al. 2017). First, the AAPH solution (120 mM final concentration) was prepared by adding the AAPH reagent in 100 mM glycine buffer, pH 8.6 (20 mL final volume), followed by addition of luminol (4 μL, 0.001 mM final concentration) in the dark. The system was then allowed to stabilize for 2 h before the first reading. Different concentrations of blends were added, and the luminescence produced by the free radical reaction was quantified in a liquid scintillator counter (Wallac 1409, Perkin–Elmer, Boston, MA, USA) for 2 h. The system measured the chemoluminescence emitted by AAPH thermolysis alone. The data were transformed into the area under curve (AUC) using software (GraphPad software® San Diego, CA, USA; version 5.0) as previously described (Moresco et al. 2017). Total antioxidant reactivity (TAR) readings were obtained in the same experiment. These results were calculated as the ratio of light intensity in the absence of samples (I0)/light intensity after blend addition.

Statistical analysis

The experiments were set up in a completely randomized design with three replicates. The results were expressed as the mean and standard deviation. Comparison of means was performed by one-way analysis of variance (ANOVA) followed by Tukey’s test (p < 0.05). Statistical analysis was performed using the software ASSISTAT 7.7 beta (de Assis Santos and de Azevedo 2016).

Results

The physicochemical compositions of BLE1, BLE2, and BLE3 are presented in Table 2. The water content, pH, ash, total protein, total fiber, total carbohydrate and reducing carbohydrates did not differ significantly between the BLE1 and BLE2 samples. However, in terms of water activity, lipid, starch content, total carbohydrates, and nonreducing sugars, differences were observed between the BLE1 and BLE2 samples. BLE2, which is formulated with banana peel and pulp, had higher values for water activity, lipid, and starch content when compared to the BLE1 sample. Lower values were found in the BLE2 sample for nonreducing sugars and total carbohydrates compared to the BLE1 sample.

The BLE1 sample had differences in total carbohydrates, reducing carbohydrates and nonreducing carbohydrates compared to the BLE3 sample. Lower values of these parameters were observed in the BLE3 sample that was formulated with peel and pulp, while the BLE1 sample was formulated with only pulp. In terms of water content, water activity, lipids, total fiber and starch content, the BLE3 sample had higher values compared to the BLE1 sample. Analysis of the BLE2 sample compared to the BLE3 sample showed that the BLE2 sample had higher values for total carbohydrates and nonreducing carbohydrates.

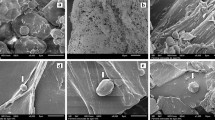

The photomicrographs (Fig. 1) obtained by scanning electron microscopy (SEM) for the blends formulated in our study reveal the morphological characterization of the powder produced from the banana pulp and peel. By comparing the blends, no significant differences were visually identifiable. All the samples had the same powder size variability, suggesting that the use of the banana peel in the BLE2 and BLE3 samples did not significantly interfere with the morphology of the blends.

Color is an important parameter, principally because of its influence on the visual attractiveness of a product (Dantas et al. 2018). Here, the blends produced from the banana pulp and banana peel had similar averages for the \( {\text{a}}^{ *} \), \( {\text{b}}^{ *} \), \( {\text{C}}^{ *} \), and \( {\text{H}}^{*} \) parameters (Table 3). However, the BLE3 sample had lower values for the \( {\text{L}}^{*} \) parameter than the BLE1 and BLE2 samples. Decreases in values for the \( {\text{L}}^{*} \) parameter in color are related to changes in the size of powder particulates. In terms of bulk density and tap density, we found that BLE3 had a higher value for bulk density and tap density compared to BLE1 and BLE2 samples (Table 4). The Carr index and Hausner ratio were not different between the blends.

The water solubility index (WSI) was evaluated in the blends here formulated and was not different between the blends (Table 2). However, for the water absorption index (WAI), BLE3 had higher values compared to the BLE1 and BLE2 samples (Table 2). The values for WAI in BLE2 were also higher compared to BLE1. In these terms, it is possible to suggest that the higher values for WAI in the BLE2 and BLE3 samples compared to BLE1 may be due to the presence of banana peels in the formulations of BLE2 and BLE3. Additionally, the oil-holding capacity (OHC) was evaluated. Interestingly, it was observed that BLE1 had higher values for OHC compared to the BLE2 and BLE3 samples (Table 2).

The total-radical trapping antioxidant potential (TRAP) and total antioxidant reactivity (TAR) were evaluated; BLE3 had a higher TRAP and TAR than the BLE1 and BLE2 samples. Our findings also showed that BLE2 had higher values for TRAP and TAR compared to BLE1 (Fig. 2). Taken together, these data reveal the antioxidant properties of the formulations of the blends developed in this study.

Analysis of total-radical trapping antioxidant potential (TRAP) and total antioxidant reactivity (TAR) from the blends formulated with banana pulp and banana peel. a TRAP of BLE1 sample; b TRAP of BLE2 sample; c TRAP of BLE3 sample; d TAR of BLE1 sample; e TAR of BLE2 sample; f TAR of BLE3 sample. Mean of three replicates (n = 3) and the values are expressed as the mean ± SEM

Discussion

The banana is a fruit that is widely used in different ways in food technology processing. The richness of biocompounds with certain chemical and physical properties has stimulated the development of new products using both banana pulp and banana peel (Vu et al. 2019). In these terms, our study evaluates the use of banana peel together with banana pulp in the production of a powder blend to be used in innovative cake and dessert products.

We found that powder blend samples produced through lyophilization that contain banana peel in the formulation chemically have higher water content and water activity. Others have shown that the presence of water in powdered products can influence different properties of the product (Calo et al. 2015). Different studies have related the effect of water activity in the flowability of powders (Juarez-Enriquez et al. 2017, 2019; Shenoy et al. 2015). The presence of water can alter the complex interactions between intermolecular forces of the particles. These alteration play directly in the powder flowability and influence the bulk and tap density (Althaus and Windhab 2012). Moreover, water activity represents a challenge for the food industry, principally during storage (Shenoy et al. 2015). The presence of water in powdered products can provide environmental conditions for microbial growth (Syamaladevi et al. 2016). The results for water activity in the blends formulated in our study are considered safe for powdered products principally because the values varied between 0.16 and 0.24 (Xu et al. 2019). Additionally, the variation in water activity between the blends suggests that the use of banana peels influenced this parameter in the powder produced.

Banana peels are an important source of soluble and insoluble fibers (Ferrante et al. 2019). Different authors have shown that the fiber present in both banana pulp and banana peels has a higher quality, which is associated with both water and oil holding capacities (Eshak 2016; Ferrante et al. 2019; Tibolla et al. 2019). In banana peel, studies have found high amounts of lignin, cellulose, and hemicelluloses (Eshak 2016). These compounds are insoluble fibers, and consequently, the presence of these compounds in the formulation modulated the water activity and oil-holding capacity. In terms of insoluble and soluble fibers, it is suggested that in cookies or dessert products, the crumb structure can be improved in a manner dependent on hydrocolloid composition (Mir et al. 2016). The blends formulated in our study with banana peel showed an increase in water retention, suggesting that fiber content in the powder affected this parameter. Some authors have suggested that the polarity present on surfaces of different fibers can interact with water structure and consequently alter the water retention (Díaz et al. 2017; Pelissari et al. 2017). Interestingly, oil-holding capacity decreases in formulated blends that contain banana peels. This result can be associated with the low level of treatment that banana peels received before being added to the formulation. It is known that soluble and insoluble fibers, when submitted to different treatments, alter the surface and consequently the physiochemical properties of the product. The hydrophilic group of the fibers, when exposed on the surface, can cooperate with the low oil-holding capacity (Yan et al. 2015). Here, the results suggest that the composition and structure of the fibers present in the banana peels were able to modulate the water retention and oil-holding capacity.

The microscopic structure of the lyophilized powders produced from blends was analyzed by SEM. The powders of all blends had an agglomerated structure. Additionally, the agglomerates had a gelatinous structure, which suggests that the starch present in the blends has low crystallinity. It is known that the type of starch also influences the crystallinity (Kiatponglarp et al. 2015). Starch type B, which is present in fruits, is less susceptible to enzymatic attacks. Starch type B has also been related to the agglomerate morphology of powders. Therefore, our results suggest that the structure of the blend powders here studied contain starch type B, principally due to the use of banana pulp in the formulations. Additionally is recognized that banana starch can present both starch type A and starch type B, which can collaborate to morphology structure of the powders (Zhang et al. 2005).

The color characteristic is an important feature for attractiveness in food products. The \( {\text{L}}^{*} \) parameter evaluates the black-white color scale. Our results reveal a significant decrease in the \( {\text{L}}^{*} \) parameter in the blends produced with a banana peel in the formulation. The low values for \( {\text{L}}^{*} \) observed in the blends produced with banana peel suggest that the dark color present in the peel contributes to color in the powder. Additionally, the morphology of the powder can modulate the \( {\text{L}}^{*} \) parameter (Dantas et al. 2018). However, the agglomeration observed in blend samples, according to the SEM results, reveals that in terms of powder, our blends have a similar morphology. Therefore, we believe that the presence of banana peel was the main factor influencing the \( {\text{L}}^{*} \) parameter. For the \( {\text{a}}^{ *} \) and \( {\text{b}}^{ *} \) parameters, no differences were observed in the powder blends. These results suggest that the powder blends BLE2 and BLE3 did not suffer alterations due to the presence of banana peel. In terms of product, this feature is relevant because it maintains the physical appearance. The chroma \( {\text{C}}^{ *} \) was determined using both the \( {\text{a}}^{ *} \) and \( {\text{b}}^{ *} \) parameters. Similar to the results for the \( {\text{a}}^{ *} \) and \( {\text{b}}^{ *} \) parameters, the chroma \( {\text{C}}^{ *} \) of the blend powders were not different.

Powder flowability and cohesiveness as evaluated by the Carr index (CI) and the Hausner ratio (HR) reveal that the blends did not differ in these parameters. In terms of CI, the powder values obtained have CI values considered fair for flowability. These results suggest the easy feasibility for industrial packaging of the powders produced (Assumpção et al. 2016; Jange and Ambrose 2019). Moreover, the banana peel composition did not alter this important property of the powders. The HS cohesiveness showed that blends did not differ in this parameter. Additionally, the HS also indicate that the powders presented a low level of cohesiveness. These results corroborate the data for CI values.

The total-radical trapping antioxidant potential (TRAP) is an assay commonly used to test the antioxidant activity of compounds or group of compounds present in different types of products. Here, we evaluated the levels of TRAP in the blends and observed that the BLE2 and BLE3 samples had significant higher levels of antioxidant compounds compared to BLE1. These results suggest that secondary metabolites present in the banana peels can collaborate to increase the antioxidant capacity of the powder blends formulated. Interestingly, for the total antioxidant reactivity (TAR), the BLE3 sample has an increased TAR. This result indicates that the BLE3 sample had more antioxidant compounds and, most importantly, those antioxidants were more reactive. In terms of antioxidants, it is known that banana has a higher number of secondary metabolites that can demonstrate antioxidant activity when submitted to determined redox conditions (Moresco et al. 2017). Our results reveal that the use of banana peel can improve the antioxidant properties of powders produced by lyophilization. Additionally is important to relate that banana peel is considered safe to health. In terms of challenges for the industry, today, most products have been explored commercially for their antioxidant properties principally because of the potential health benefits.

In conclusion, our data reveal that powder blends formulated with banana peel presented similar physicochemical characteristics to powder blend formulated alone with banana pulp. Additionally, our blends had properties that strongly support their use in the food industry, principally in the manufacturing of cookies and dessert products. These reinforce the importance for food industry investments in the development of innovative products, principally through effective methods to recycle or use residues, such as banana peel, in formulations. Economically, these attempts may result in gains for both agricultural practice and the food industry.

References

Ahmad T, Danish M (2018) Prospects of banana waste utilization in wastewater treatment: a review. J Environ Manage 206:330–348

Althaus T, Windhab E (2012) Characterization of wet powder flowability by shear cell measurements and compaction curves. Powder Technol 215:59–65

Assumpção CF, Nunes IL, Mendonça TA, Bortolin RC, Jablonski A, Flôres SH, de Oliveira Rios A (2016) Bioactive compounds and stability of organic and conventional vitislabrusca grape seed oils. J Am Oil Chem Soc 93(1):115–124

Aurore G, Parfait B, Fahrasmane L (2009) Bananas, raw materials for making processed food products. Trends Food Sci Technol 20(2):78–91

Bligh EG, Dyer WJ (1959) A rapid method of total lipid extraction and purification. Can J Biochem Physiol 37(8):911–917

Calo JR, Crandall PG, O’Bryan CA, Ricke SC (2015) Essential oils as antimicrobials in food systems—a review. Food Control 54:111–119

Coltro L, Karaski TU (2019) Environmental indicators of banana production in Brazil: Cavendish and Prata varieties. J Clean Prod 207:363–378

Dantas D, Pasquali MA, Cavalcanti-Mata M, Duarte ME, Lisboa HM (2018) Influence of spray drying conditions on the properties of avocado powder drink. Food Chem 266:284–291

de Assis Santos F, de Azevedo CAV (2016) The Assistat Software Version 7.7 and its use in the analysis of experimental data. Afr J Agric Res 11(39):3733–3740

Díaz M, Hernández M, Ibarra I, Guzmán A, Lara V, Lima E (2017) Cellulose with a high fractal dimension is easily hydrolysable under acid catalysis. Catalysts 7(5):162

Eshak NS (2016) Sensory evaluation and nutritional value of balady flat bread supplemented with banana peels as a natural source of dietary fiber. Ann Agric Sci 61(2):229–235

Ferrante A, Santulli C, Summerscales J (2019) Evaluation of tensile strength of fibers extracted from banana peels. J Nat Fibers. https://doi.org/10.1080/15440478.2019.1582000

Hutchings JB (2011) Food colour and appearance. Springer, Berlin

Jange CG, Ambrose RK (2019) Effect of surface compositional difference on powder flow properties. Powder Technol 344:363–372

Juarez-Enriquez E, Olivas G, Zamudio-Flores P, Ortega-Rivas E, Perez-Vega S, Sepulveda D (2017) Effect of water content on the flowability of hygroscopic powders. J Food Eng 205:12–17

Juarez-Enriquez E, Olivas G, Ortega-Rivas E, Zamudio-Flores P, Perez-Vega S, Sepulveda D (2019) Water activity, not moisture content, explains the influence of water on powder flowability. LWT 100:35–39

Kamel N, El-messieh S, Saleh N (2017) Chitosan/banana peel powder nanocomposites for wound dressing application: preparation and characterization. Mater Sci Eng, C 72:543–550

Khoozani AA, Bekhit AEDA, Birch J (2019a) Effects of different drying conditions on the starch content, thermal properties and some of the physicochemical parameters of whole green banana flour. Int J Biol Macromol 130:938–946

Khoozani AA, Birch J, Bekhit AEDA (2019b) Production, application and health effects of banana pulp and peel flour in the food industry. J Food Sci Technol 56(2):548–559

Kiatponglarp W, Tongta S, Rolland-Sabaté A, Buléon A (2015) Crystallization and chain reorganization of debranched rice starches in relation to resistant starch formation. Carbohyd Polym 122:108–114

Lee J, Durst R, Wrolstad R (2005) AOAC official method 2005.02: total monomeric anthocyanin pigment content of fruit juices, beverages, natural colorants, and wines by the pH differential method. Official Methods of Analysis of AOAC International, Chapter 37, pp 37–39

Mir SA, Shah MA, Naik HR, Zargar IA (2016) Influence of hydrocolloids on dough handling and technological properties of gluten-free breads. Trends Food Sci Technol 51:49–57

Moresco KS, Silveira AK, Schnorr CE, Zeidan-Chulia F, Bortolin RC, Bittencourt LDS, Mingori M, Heimfarth L, Rabelo TK, Morrone MDS, Carini JP, Gelain DP, Bassani VL, Moreira JCF (2017) Supplementation with achyrocline satureioides inflorescence extracts to pregnant and breastfeeding rats induces tissue-specific changes in enzymatic activity and lower neonatal survival. Biomedicines 5(3):53

Morone P, Koutinas A, Gathergood N, Arshadi M, Matharu A (2019) Food waste: challenges and opportunities for enhancing the emerging bio-economy. J Clean Prod 221:10–16

Okpala L, Egwu P (2015) Utilisation of broken rice and cocoyam flour blends in the production of biscuits. Niger Food J 33(1):8–11

Ortiz L, Dorta E, Lobo M, González-Mendoza L, Diaz C, González M (2017) Use of banana (Musa acuminata Colla AAA) peel extract as na antioxidant source in orange juices. Plant Foods Hum Nutr 72:60–66

Pelissari FM, Andrade-Mahecha MM, do Amaral Sobral PJ, Menegalli FC (2017) Nanocomposites based on banana starch reinforced with cellulose nanofibers isolated from banana peels. J Colloid Interface Sci 505:154–167

Pereira E, Ferreira MC, Sampaio KA, Grimaldi R, de Almeida Meirelles AJ, Maximo GJ (2019) Physical properties of Amazonian fats and oils and their blends. Food Chem 278:208–215

Petsakos A, Prager SD, Gonzalez CE, Gama AC, Sulser TB, Gbegbelegbe S, Kikulwe EM, Hareau G (2019) Understanding the consequences of changes in the production frontiers for roots, tubers and bananas. Glob Food Secur 20:180–188

Resende LM, Franca AS, Oliveira LS (2019) Buriti (Mauritia flexuosa L. f.) fruit by-products flours: Evaluation as source of dietary fibers and natural antioxidants. Food Chem 270:53–60

Shenoy P, Xanthakis E, Innings F, Jonsson C, Fitzpatrick J, Ahrné L (2015) Dry mixing of food powders: effect of water content and composition on mixture quality of binary mixtures. J Food Eng 149:229–236

Soto-Maldonado C, Concha-Olmos J, Cáceres-Escobar G, Meneses-Gómez P (2018) Sensory evaluation and glycaemic index of a food developed with flour from whole (pulp and peel) overripe banana (Musa cavendishii) discards. LWT 92:569–575

Syamaladevi RM, Tang J, Villa-Rojas R, Sablani S, Carter B, Campbell G (2016) Influence of water activity on thermal resistance of microorganisms in low-moisture foods: a review. Compr Rev Food Sci Food Saf 15(2):353–370

Tibolla H, Pelissari F, Martins JT, Lanzoni E, Vicente A, Menegalli F, Cunha R (2019) Banana starch nanocomposite with cellulose nanofibers isolated from banana peel by enzymatic treatment: in vitro cytotoxicity assessment. Carbohyd Polym 207:169–179

Tomasula P, Sousa A, Liou S-C, Li R, Bonnaillie L, Liu L (2016) Electrospinning of casein/pullulan blends for food-grade applications. J Dairy Sci 99(3):1837–1845

Vu HT, Scarlett CJ, Vuong QV (2018) Phenolic compounds within banana peel and hteir potential uses: a review. J Funct Foods 40:238–248

Vu HT, Scarlett CJ, Vuong QV (2019) Maximising recovery of phenolic compounds and antioxidant properties from banana peel using microwave assisted extraction and water. J Food Sci Technol 56(3):1360–1370

Xu J, Tang J, Jin Y, Song J, Yang R, Sablani SS, Zhu M-J (2019) High temperature water activity as a key factor influencing survival of Salmonella Enteritidis PT30 in thermal processing. Food Control 98:520–528

Yan X, Ye R, Chen Y (2015) Blasting extrusion processing: the increase of soluble dietary fiber content and extraction of soluble-fiber polysaccharides from wheat bran. Food Chem 180:106–115

Zenebon O, Pascuet NS (2005) Métodos físico-químicos para análise de alimentos. In: Métodos físico-químicos para análise de alimentos, 4ª edn

Zhang P, Whistler R, BeMiller J, Hamaker B (2005) Banana starch: production, physicochemical properties, and digestibility—a review. Carbohyd Polym 59:443–458

Funding

This work was supported by CAPES and the National Council for Scientific and Technological Development—CNPq (Grant number: 307060/2017-9—Ana Paula Trindade Rocha).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Martins, A.N.A., Pasquali, M.A.B., Schnorr, C.E. et al. Development and characterization of blends formulated with banana peel and banana pulp for the production of blends powders rich in antioxidant properties. J Food Sci Technol 56, 5289–5297 (2019). https://doi.org/10.1007/s13197-019-03999-w

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-019-03999-w