Abstract

In this work, citric acid (CA) modified starch/gelatin composite films were prepared by mixing modified starch and gelatin in different proportions (1:0, 1:1, 1:4, 4:1 and 0:1). Blending of chemically modified starch with food grade CA and gelatin as second polymers were studied as a new and novel approach for fabrication of eco-friendly composite films with excellent packaging properties. Taking considerations of improvement in functional properties of the films, a series of starch films were derived using CA–starch and gelatin using solution casting approach. Influence of CA (0.5%, 1%, 3%, 5% and 7% w/w of total starch) on functional properties (moisture content, solubility, swelling index, moisture migration rate, moisture absorption, opacity and mechanical properties) were studied. FTIR and SEM analysis were utilized to characterize the interaction between the starch chains and surface morphology of films. Findings revealed that functional properties (aqueous solubility, swelling index, and moisture barrier properties) significantly (p < 0.05) improved as CA content increased. Composite films with CA–starch/gelatin of the ratio (4:1) revealed excellent functional properties. FTIR spectra illustrated strong interaction between the starch chains in the starch films. SEM analysis showed that gelatin exhibited good compatibility in the composite films. Therefore obtained composite films possessed a homogenious, dense and compact networks. In conclusion, CA and gelatin made better starch film properties and broadened the potential applications in the food packaging.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Last two decades, the population and urbanization in the developing countries have been increased. Therefore consumption of petroleum-based synthetic packaging materials has been exponentially enhanced for different applications. Besides due to the reduction of the petroleum resources and impact of social awareness on food quality and safety, it has become necessary to search alternative natural and renewable resources. Therefore, there is an urgent demand to develop environment friendly and biodegradable polymers from renewable resources such as agricultural waste, marine waste, and food industry waste. In addition, these polymers can be used as edible films or coatings which may improve shelf life and quality of fruits and vegetables by controlling the respiration rate and metabolism. So, these polymers have been believed as sustainable options for many synthetic polymers (Caz 2017). Starch is a low-cost polysaccharides polymer that is originated from renewable resources and it has abundant resources in nature (Singh et al. 2009). Due to the film forming nature of starch, it is used to make biodegradable polymers that have capabilities to replace petroleum-based packaging materials in future (Fai et al. 2016). Along with many advantages, hydrophilicity, brittle nature and low mechanical strength limited the use of that film in the food packaging and in many other areas. To deal with these problems, there are many options to eradicate these hindrances. Generally, various methods such as chemical and physical methods are recommended to reduce these hindrances. In physical modification, there is a blending of many polysaccharides, proteins, resins, fillers and nanoparticles etc. with starch to enhance the properties of the film. However, obtained films develop some drawbacks such as hydrophilicity, poor water barrier property, and water solubility compared to synthetic polymers, which indicates the demand for inventing new techniques for creating a hydrophobic film or cross-linked structure that might enhance the functional properties of the starch film (Oleyaei et al. 2016). In order to overcome these problems, chemical modifications in the structure of polysaccharides and proteins (starch, cellulose, gelatin and soy etc.) are done to enhance the cross-linking in the matrix by using many cross-linking agents such as boric acid and oxidized sucrose etc. that help to enhance the properties of polysaccharides films (Xu et al. 2015). CA cross-linked starch film showed good tensile and barrier properties and also enhanced water solubility but showed low extensibility of the film. Film properties can be improved by interaction between the carboxyl groups of citric acid and the hydroxyl groups on the starch. Moreover, few cross-linking agents are not used in food packaging due to its toxicity which results in environmental pollution. Among all cross-linking agents, citric acid (CA) is the appropriate crosslinker because of its non-toxicity, cheap and capabilities to improve the film functional properties (Menzela et al. 2013). Protein plays a vital role in the food industries and widely consumed for different applications. Gelatin is the renewable source, obtained from collagen by catalytic hydrolysis. Gelatin is different from other polymers as a fully digestible protein, containing nearly all the essential amino acids, except tryptophan (Otoni et al. 2017). Recently, gelatin is increasingly gaining popularity due to their high nutritional values and film forming properties (Acosta et al. 2015). In the current work, mixing and laminating of modified potato starch and gelatin was presented to develop the composite films using casting method which is a current trend to form new biocomposites materials. They showed the better film forming properties than the single polymers film (Inge 2007; Wang et al. 2014). Main purpose of the current work was to evaluate the statistically significant influence of citric acid and gelatin on the functional properties of starch film such as thickness, moisture content, swelling index, solubility, opacity, mechanical and moisture barrier properties.

Materials

Food grade potato starch, citric acid, lithium chloride, potassium acetate, magnesium chloride ammonium nitrate, magnesium nitrate, sodium chloride and potassium chloride and gelatin were purchased from Loba chemical (Mumbai, India). Sorbitol was obtained from HiMedia (Mumbai, India). All chemicals were of analytical grade.

Preparation of gelatin solution

Biopolymers with plasticizers were utilized to develop the films by following the procedures reported by Tao et al. (2018). The gelatin solution was prepared by mixing gelatin (8 g) and sorbitol (25% w/w total gelatin) in 100 mL distilled water for 10 min at room temperature, and then the solution was heated in water bath at 60 ± 1 °C for 20 min with constant mechanical stirring (Perfit, India) until the clear solution was obtained. Thereafter the solution was cooled at room temperature till 40 ± 1 °C.

Preparation of CA–starch solution

Cross-linked potato starch with citric acid was prepared by following procedures reported by Kim et al. (2017). The starch solution was prepared by blending starch (3 g) and sorbitol as a plasticizer (25% w/w of starch) in 100 mL of distilled water for 5 min at room temperature. Then, starch solution was heated in water bath at 90 ± 1 °C for 10 min with constant stirring. Subsequently, citric acid was added into starch solution with different concentrations (0.5%, 1%, 3%, 5% and 7% w/w of total starch) and then the solution was kept at that temperature for 30 min. Thereafter, the solution was allowed to cool at room temperature till 40 ± 1 °C was achieved. Then, About 10 mL of each prepared homogeneous solutions were poured evenly onto the petri dishes and then allowed to dry at 25 ± 1 °C for 24 h, followed by peeling of the films from the dishes and stored in airtight polythene bags for further analysis.

CA modified starch/gelatin film preparation

The composite film of CA–starch/gelatin was made following casting method. A series of composite films were made by mixing of prepared CA–starch and gelatin solutions in different ratios (1:0, 1:1, 1:4, 4:1, 0:1) (Al-Hassan and Norziah 2012). Then solutions were homogenized using high shear homogenizer. Prepared solutions were degassed by vacuum oven (NSW, India). About 10 mL of each prepared homogeneous solutions were poured evenly into the petri dishes, and then allowed to dry at 25 ± 1 °C for 24 h, followed by peeling of the films from the dishes and stored in airtight polythene bags for further analysis.

Properties of CA–starch/composite films

Film thickness

CA–potato starch and CA–starch/gelatin films thickness was measured using a digital micrometer with an accuracy of ± 0.001 mm (Mitutoyo, Japan). The thickness of each film was evaluated at six different positions and then average of thickness was taken for analysis.

Moisture content (MC)

The moisture content of the films was measured in terms of weight loss. Briefly, specimens with dimension (2 × 2 cm2) were cut from each film and then weighed. Then, all specimens were dried in a hot air oven at 105 ± 1 °C for 24 h and again weighed. Moisture content was calculated using Eq. (1):

where Ww is the mass of the pre-dried specimen and wd is the mass of the dried specimen.

Swelling index

Predefined method with small modification was adopted to determine the swelling index of the films (Cao et al. 2007). Specimens with dimension (2 cm × 2 cm) were cut from the films, and then dried in hot air oven at 105 ± 1 °C for 24 h and weighed. Dried specimens were immersed in distilled water for 2 min and then removed from the distilled water. An excess amount of water was removed from the swelled specimens and weighed. The quantity of water absorbed by the specimen was evaluated as per standard Eq. (2)

where m1, m2 are the weight of swelled specimens after removal of excess water and weight of dried specimens respectively, each measurement was done in triplicate.

Optical property

Film opacity was measured using the Hunter Lab colorimeter (Color Flex EZ, Hunter Lab, USA). The measurements were made after calibration of the equipment with a white and a black background. L*, a* and b* values of the films from CIE LAB color space were determined using a D65 illuminant and 10° standard observers. The opacity of the film was determined according to the following Eq. (3)

where Op is opacity of the film (%); Opw is the opacity of the film against a white background; Opb is the opacity of the film against a black background.

Solubility

Water solubility of the film was measured according to the standard method described by Podshivalov et al. (2017) with some modifications. Briefly, four specimens with dimension (2 × 2 cm2) were cut from the each film. Initial weights with an accuracy of ± 0.0001 of all dried specimens are appraised by drying them at 105 ± 1 °C for 24 h in a hot air oven. After taking dried weights of all specimens, they were immersed in a beaker containing 15 mL double distilled water. Thereafter, all samples were removed and then dried at 105 ± 1 °C for 24 h in a hot air oven. Dried samples weight was evaluated and then used to calculate the solubility. Film solubility (S%) was evaluated by Eq. (4)

where W0 is the weight of the dried specimen before water immersion and W1 is the dry weight of the insoluble specimen after immersion.

Water vapor barrier property (WVP)

Water vapor barrier test was performed by using predefined method with minor changes (Colivet and Carvalho 2017). Specimens with proper size were cut from the CA–starch and composite films and then fixed on the mouth of modified glass beaker with capacity of 50 mL using vacuum grease. The modified glass beaker filled with dried calcium chloride (0 ± 1% RH). Thereafter, specimens loaded beakers were kept in a desiccator containing distilled water (RH of 100 ± 1%). Subsequently, desiccators were put in an incubator (Innova-4230, New Brunswick, NJ, USA) at 25 ± 1 °C temperature. The gain in weight of the beakers was recorded at a fixed interval of time until the constant weight of the beakers was attained. Water vapor barrier through the specimen was calculated by using Eq. (5)

WVTR is water vapor transmission rate, L is the thickness of specimens and the (pa − pb) is the difference in pressure outside and inside of the sample beakers. All measurements were performed in triplicates.

Mechanical property

Tensile strength and elongation-at-break (E%) of the films were measured with the help of Texture Analyzer (TA.XT Plus, Stable Microsystems) with a load cell of 5 kg and a crosshead speed of 0.5 mm/s. Tensile strength (TS) and elongation at break (E%) of the films were calculated according to a standard method (Farhan and Mohd 2017). Films specimens (1.5 cm wide × 7 cm long) were cut to the film. All specimens were put in a desiccator for conditioning at 58 ± 1% RH at 25 ± 1 °C for 72 h. Conditioned specimens were mounted between the grips with an initial grips distance of 50 mm. Tensile strength and elongation were determined by applying following Eqs. (6) and (7)

where F is the maximum force at break point, A is the cross-sectional area of specimen (Thickness, Width), X1 is the initial gaps in grips and X is the length of the specimen at break point. Three replicates were used to analyze for each formulation of the film.

Moisture absorption

Moisture intake (MI) was evaluated according to standard procedure (Farhan and Mohd 2017). Specimens with dimension 2 × 2 cm2 were cut from the film. Prior to evaluation the moisture absorption capacity, all specimens were dried in hot air oven at 105 ± 1 °C for 24 h and weighed. Subsequently, dried specimens were transferred into three desiccators containing saturated solution such as sodium chloride, copper sulfate and potassium sulfate for maintaining different relative humidity and then all desiccators were kept at 25 ± 1 °C in an incubator. The gain in weight of all the specimens was recorded until the constant weight achieved. Calculation of water intake was evaluated according to Eq. (8):

where W0 is the dry weight of the specimen and Wf is the equilibrated weight of specimen. All the results were evaluated in triplicate.

Biodegradability of film

Specimens with a dimension of 1 cm × 1 cm were sliced from the films. Then, specimens were buried below 2 cm in steel trays containing bio-compost fertilizer. Then all samples holders were placed in an incubator with humidity (RH of 75%) at 25 ± 1 °C. To check the degradation rate in terms of weight loss of specimens were recorded after removing the specimens from the medium at different intervals, dried them at 50 ± 1 °C for 24 h and weighed.

Characterization of films

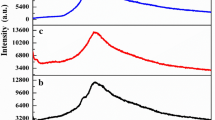

Fourier transform infrared spectroscopy (FTIR)

FTIR technique was used to identify the interaction among the starch, plasticizer and citric acid. IR Spectra of both crossed and the control were taken using FT-IR (Shimadzu-8400, Japan) in the range 400–4000 cm−1 with a resolution of 4 cm−1 by the accumulation of 32 scans. Before taking spectra of specimens, they were conditioned at RH 53 ± 1% for 24 h.

Scanning electron microscopy (SEM)

Scanning electron microscopy (ZEOL, Germany) was used to explore the microstructure of CA–starch and CA–starch/gelatin composite films. All prepared specimens were placed in a desiccator for conditioning at 25 ± 1 °C at RH of 53 ± 1%. Scanning electron microscopy was made for prepared specimens as per standard procedure.

Statistics

The measurements of thickness, opacity, swelling index, moisture content, moisture absorption, water vapor permeability and mechanical properties etc. were evaluated in triplicate. Results were reported as mean ± SD and analyzed using the Graph Pad 6.0 software. Analysis of variance was evaluated by ANOVA procedure (p < 0.05).

Result and discussion

CA–starch film

Thickness

Film thickness is the most important parameter in food packaging that affects the mechanical properties and moisture permeability of the films. Figure 1a illustrates the influence of citric acid on the thickness of the film. It is evident that incorporation of citric acid in the starch film did not significantly (p > 0.05) enhance the film thickness. Regression analysis showed the significant relationship between citric acid (R2 < 0.9) and thickness. The influence of citric acid on the thickness of the films was explained in terms of orientation/rearrangement of starch chains in the starch matrix. Citric acid entered in the starch matrix chains, which was characterized by slight rearrangement of starch chains in the matrix, leading to increased thickness of the films (Azeredo and Waldron 2016).

Moisture content (MC)

Moisture holding capacity of the film can be represented in terms of moisture content. Regression analysis utilized to show the relationship among the CA and MC, and found considerable impact of citric acid on the outcomes of moisture content (R2 > 0.9). Incorporation of CA (0.5%, 1%, 3% and 5% w/w of total starch) to the starch film significantly (p < 0.01) decreased the moisture content as shown in Fig. 1a. Similarly, Sharma et al. (2017) also suggested that sesame protein based films modified with citric acid showed lower moisture content than that of the unmodified starch film. Results indicated that cross linking among the functional group of citric acid (–COOH) and starch (–OH) formed strong interaction in the starch chains resulted to decrease the availability of free hydroxyl groups in the starch matrix. We suppose that this might decrease the water holding capacity, leading to decreased moisture content. Further addition of the CA content (more than 5% w/w of total starch) in the film was able to enhance the free volume space and mobility in between the polymer chains due to its plasticization effect, enhanced the MC of the film (Wang et al. 2014).

Swelling index (SI)

Swelling index values of starch with modified starch films were demonstrated in Fig. 1b. From the regression analysis, it was found that swelling index was strongly (R2 > 0.9) influenced by the addition of citric acid in the films. Addition of citric acid up to 5% w/w of total starch level was significantly (p < 0.01) reduced the SI of the film. Reduction in SI might be linked with dense, homogeneous, compact structure and non availability of hydroxyl groups in the starch matrix. Cross linking in the starch matrix decreased the availability of –HO groups for interactions with water molecules and also reduced free space. Consequently, the compactness and hydrophobic nature of films improved, resulting in a decrease in the swelling index of the starch film. As citric acid concentration further increased from 5 to 7% (CA w/w of total starch), SI increased due to its plasticizing nature (Kapelko-Żeberska et al. 2016).

Opacity (OP)

The opacity is most important functional property of the film which shows a strong impact on the food properties as well as on appearance. Transparency of the films significantly (p < 0.01) improved as CA increased from 0.5 to 5% in the starch films as shown in Fig. 1b. In contrast, opacity of the potato starch films decreased. Reduction in the opacity of the films may be linked to compactness and crystallinity of starch molecules. Citric acid developed strong interaction in terms of cross linking in the starch films. It made the starch matrix more compact and less crystalline. Therefore opacity of the films decreased. Further addition of citric acid (more than 5%) enhanced the free volume space in the matrix, leading to diminish the opacity of the film (Seligra et al. 2016).

Solubility (S)

Solubility is an essential functional parameter of the films due to its food packaging applications. Films should illustrate minimum solubility in the water to maintain the food integrity. From findings, it was found that outcomes of solubility were strongly (R2 > 0.9) affected with CA content in the films. As, citric acid amount increased from 0.5 to 5% w/w in the starch film, significant differences in the solubility (p < 0.01) of the modified starch and native starch films were recorded as illustrated in Fig. 1c. As expected, aqueous solubility decreased with addition of CA up to 5% (w/w of total starch) level in the starch film. The outcomes are also consistent with previous studies (Ma et al. 2018), who reported that solubility of the edible films containing soybean residue decreased with addition of citric acid. This dramatic influence of citric acid on the solubility of the starch film might be happened due to cross linking and hydrogen bonding among the functional groups of citric acid and starch chains. Consequently, hydrophobic, homogeneous and compact structures of starch matrix achieved which block the water molecules to penetrate into the matrix, leading to a diminish aqueous solubility (Sun et al. 2017).

Water vapor permeability (WVP)

Many food products lose their important properties due to migration of water vapor through packing materials from surrounding atmosphere. Therefore, WVP become an important parameter for determination of possible films applications. From the regression analysis, it was noticed that CA showed strong positive (R2 > 0.9) impact on the moisture permeability of the films. Incorporation of citric acid in varying amount (0.5%, 1%, 3% and 5% w/w of total starch) significantly (p < 0.01) reduced the WVP of potato starch film as shown in Fig. 1c. Improvement in the WVP of the starch films may be related to cross linking in the starch matrix which can improve the hydrophilic nature as well as compactness of starch films. Besides, this made tortuous path in the matrix. Consequently, water vapor needed to move more distance to cross the films, leading to decrease in the moisture permeability (Tan and Thomas 2017). The findings are consistent with previously reported work (Azeredo et al. 2016). Addition of citric acid more than 5% (w/w of total starch) reduced the moisture barrier of the films due to its plasticizing effects.

Mechanical property

Native potato starch films illustrated lower tensile strength (TS) than that of the modified potato starch films, which was changed with incorporation of citric acid (0.5 to 5% w/w total starch) as presented in Fig. 1d. The significant differences (R2 > 0.9) in the tensile strength were achieved among the modified and unmodified starch films. Similar work reported on the Chinese yam starch by (Wang et al. 2017a). These authors illustrated that mechanical property of the starch film improved by the addition of citric acid. Citric acid could create strong interactions by generating cross linking between starch chains, thus increasing the tensile strength. Besides these interactions reduced the mobility among the chains, leading to reduce the elongation at break point (E%). When citric acid in the films incorporated more than 5% CA in the films caused a notable decrease in the film strength. In contrast extensibility of the films enhanced due to the introduction of mobility in the CA–starch film due to its plasticization nature (Wang et al. 2014).

Composite film

The outcomes were studied using regression analysis. From the findings, it was revealed that gelatin content significantly (p < 0.05) affected the functional properties of the composite films and had a positive relation between them (R2 > 0.9).

Thickness

CA–starch/gelatin composite films exhibited higher thickness than that of the CA–starch films (control). Thickness of the starch film enhanced, when gelatin was added in different proportions (1:1, 1:4 and 4:1) in the film as shown in Fig. 2a. The film with ratio (4:1) demonstrated lower thickness compared to other films with ratios 1:1 and 1:4. Increment in the thickness of the starch films might be due to the orientation of starch molecules, and also compatibility of polymers in the composite film (Acosta et al. 2015).

Moisture content (MC)

MC content of CA–starch/gelatin film was illustrated in Fig. 2a. Addition of gelatin in different ratios (1:1, 1:4 and 4:1) in the films caused a significant (p < 0.05) increase in MC of the films. The composite films with ratio 1:4 attained a minimum MC compared to others films with ratios (1:1 and 4:1). Enhancement in the MC of starch films with addition of gelatin associated with hydrophilic nature of gelatin, and it may change nature of starch film from hydrophobic to hydrophilic (Wang et al. 2017b), consequently, MC decreased. It was also observed that the composite film exhibited lower MC compared to the gelatin film.

Swelling index (SI)

Figure 2b shows swelling index of composite films with varying ratios (1:1, 1:4 and 4:1) of the modified starch and gelatin. Composite films showed increasing swelling index with increasing gelatin content. SI of the gelatin film significantly (p < 0.05) decreased from 141 ± 0.81% to 46.28 ± 0.48% (control). The films with ratio 4:1 recorded a minimum SI compared to others films. Moreover, the reduction in SI is also linked with the results of FTIR, WVP and mechanical properties of the composite films. This showed that interactions among the CA–starch and gelatin were taken place in the composite films. Therefore, the hydrophilicity of the composite film was improved, leading to decreased SI of the films (Fakhoury et al. 2012).

Opacity (OP)

Variation in the color and transparency when gelatin and modified starch were added in different proportions in the composite films as represented in Fig. 2b. The composite film was slightly brighter than the CA–starch film. The opacity of the CA–starch film was significantly (p < 0.05) increased as gelatin was added. Improvement in the opacity of the starch film with gelatin content in the composite film could be connected to excellent orientation/distribution of starch molecules in the composite films which created haziness in the composite film. So, light was not able to penetrate into the composite film, and thus opacity was increased (Surendra Babu et al. 2015).

Solubility (S)

High solubility indicates that gelatin loaded composite films have more affinity for water. Composite films showed increasing aqueous solubility with elevating gelatin content. The CA–starch and gelatin were blended in different proportions (1:1, 1:4 and 4:1). The solubility of the composite film was considerably (p < 0.05) improved as displayed in Fig. 2c. Composite films showed inferior solubility than that of the modified potato starch films. Gelatin is more hydrophilic than control film. Consequently, the addition of gelatin enhanced hydrophilicity of modified starch films. Therefore, water molecules were easily able to access the surface resulted in an increased solubility. The solubility of the composite films improved as CA–starch content increased which indicated excellent orientation and arrangement of starch molecules in the CA–starch/gelatin composite films. So, penetration of water molecules into the composite film became difficult eventually resulted in a decrease in the solubility (Xu et al. 2015).

Water vapor permeability (WVP)

Water vapor permeability of composite films was measured and outcomes were demonstrated in Fig. 2c. WVP of the composite films decreased with elevating amount of CA–starch content. Meanwhile, the composite films with ratio (4:1) showed a lower WVP than that of the gelatin films. But it showed inferior WVP values as compared to the CA–starch films. As per expectation, WVP values of the CA–starch films significantly (p < 0.05) decreased with addition of gelatin. This may be linked to hydrophilic mass content in the form of gelatin in the composite films (Fakhouria et al. 2015). In another word, hydrophilic nature and spiral structure of gelatin led to make the composite film more hydrophilic, leading to enhanced water vapor permeability of the CA–starch films (Fakhoury et al. 2012).

Mechanical property

Prepared solution of CA–starch and gelatin were utilized in the different proportions (1:1, 1:4 and 4:1) to prepare the composite films, and to evaluate the effect gelatin on the functional properties of the film especially on strength and elongation as shown in Fig. 2d. When comparing film strength of the CA–starch with CA–starch/gelatin film, there was no confusion that film strength was significantly (p < 0.05) improved with the incorporation of gelatin in the CA–starch film (control). Improvement in the tensile strength of films with addition of gelatin content may be attributed to low free space in CA–starch/gelatin composite films, due to strong cohesive interaction between the polar groups of starch and gelatin chains in the composite film, Therefore tensile strength of the composite film improved. The composite film with (4:1) CA–starch/gelatin concentration exhibited higher film strength compared to the other composite films (1:1 and 1:4). This showed that excess part of gelatin disturbed the arrangement of components in composite films. Therefore, compactness of the film decreased, resulting in a decrease in the film strength (Wang et al. 2017b).

Moisture absorption (MA)

The ability of the film to absorb moisture from surrounding represents in terms of MA. Addition of increasing content of CA up to 5% w/w of total starch level considerably (p < 0.05) decreased the moisture absorption capacity of the starch films as illustrated in Fig. 3a. Reduction in the moisture absorption indicates that availability of free –OH groups in the starch matrix is reduced during the film forming process, due to cross linking in the starch matrix. MA of the starch films containing more than 5% w/w citric acid was higher than other starch films (0.5%, 1%, 3% and 5%), due to plasticization effect of unreacted citric acid in the starch films (Yin et al. 2005). MA is directly proportional to gelatin concentration in the composite film. Gelatin shows hydrophilic nature. As expected, the addition of gelatin in different proportions (1:1, 1:4 and 4:1) in the starch films, MA capacity of the composite films significantly (p < 0.05) enhanced. Enhancement in MA might be related to free space and hydrophilicity. Gelatin in the films slightly disturbed the hydrophilicity and free space, causing an increased MA of the composite films (Mali et al. 2005).

Biodegradation of the starch/gelatin composite film

Biodegradability of CA–starch and CA–starch/gelatin films were evaluated using soil buried technique with some modifications. No major changes were noticed on the surface of specimens except small weight loss in the first week of examination. From the findings, it was observed that weight loss and pores numbers in the specimens were not significantly (p > 0.05) enhanced after the 3rd week of the test as illustrated in Fig. 3b. Enhancement in the degradation rate of the samples was associated with elevated swelling index of specimens, resulting in enhancement of microorganisms attack on specimen’s surface. Consequently, weight loss of the specimens was significantly enhanced. The specimen with 5% w/w of citric acid was demonstrated a minimum degradation compared to other specimens with citric acid content (0.5%, 1%, 3% and 7%). Addition of CA content more than 5% w/w of total starch level in the film caused a gradually enhanced weight loss. Enhancement in the degradation of specimens might be linked with unreacted citric acid in the CA–starch film. Unreacted citric acid molecules illustrated plasticization effect in the films, causing an increased hydrophilic nature of the films (Seligra et al. 2016). As expected, incorporation of gelatin in the CA–starch films significantly (p < 0.05) enhanced the moisture absorption capacity due to its hydrophilic nature, resulting in increased swelling index. Therefore degradation of specimens enhanced. Our observations agree with previous results (Kuniak and Marchessault 1972).

FTIR analysis

Molecular interaction between the film components were identified by FTIR, and exhibited in the spectral range of 500–4000 cm−1 as shown in Fig. 4a, b. Broad characteristic bands located in the range of 3262–3295 cm−1, which represented the stretching of –OH groups. Similar observation was reported by Byun and Yoon (2013) and Sharma et al. (2017). Besides, this characteristic band indicated interactions among the starch chains in terms of hydrogen bonding. The peak at 1657.85 cm−1 showed the hydration of starch (Xu et al. 2015). Main important new peak was located at 1741.28 cm−1, developed by a carbonyl stretch assigned to ester groups was noticed for all the modified starch films. Ester group’s visibility in the modified starch films was due to ester bonds which were developed by the esterification reaction that come during the film forming process (Reddy and Yang 2010). The characteristic peaks in the range of 1000–1400 cm−1 represented the stretching in the glycosidic bond of starch due to the reaction (Garavand et al. 2017). The findings are consistent with previously published work (Singh et al. 2009). Authors were noticed that peak around 1000 cm−1 was recognized as plasticizing effect of water.

SEM analysis

All modified films were seemed to be uniform, homogeneous, non-porous, dense in structure and have slight rough surface due to the cross linking in the starch matrix and illustrated good moisture barrier, and film strength as shown in Fig. 5a–d. Similarly, Sharma et al. (2017) observed that sesame protein films become rough and compact structure with addition of citric acid. When gelatin was added in the modified potato starch film, the films became smoother, compact and also little bit shiny compared to cross linked starch films. Morphology of the composite films noticed here were in accordance with previously published work (Mirele et al. 2018) who utilized cassava starch and recycled gelatin to develop composite films. Authors observed that starch and gelatin were completely mixed and formed a homogeneous and compact structure. Besides, it was also noticed that gelatin and CA modified starch film exhibited good compatibility.

Conclusion

The main aim of this work was to fabricate eco-friendly composite films using CA–starch and gelatin in different proportions by solution casting technique. The results revealed that functional properties of CA–starch films significantly (p < 0.05) improved with the addition of citric acid up to 5% level in the starch films. FTIR data indicated that citric acid in the starch decrease the presence of free hydroxyl groups in the starch matrix via cross linking. Modified starch films were stiffer and more transparent compared to starch films, with a decrease in elongation. Presence of gelatin in the modified starch films caused a remarkable improvement in the mechanical property (p < 0.05) even at low concentration of gelatin. SEM data also suggested that gelatin and citric acid in the films caused improvement in the compactness, porosity, and homogeneity of the starch film. However, high gelatin content led to enhance solubility, swelling index, moisture content, water vapor migration rate, and moisture absorption. Findings suggested that functional properties of composite films were considerably (p < 0.05) enhanced compared to gelatin films. The results assured that packaging properties of the starch films were improved by simultaneous use of citric acid and gelatin. It can be predicted that this approach will be utilized to fabricate eco-friendly composite films for food packaging and coating in future.

References

Acosta S, Jiménez A, Cháfer M, González-Martínez C, Chiralt A (2015) Physical properties and stability of starch–gelatin based films as affected by the addition of esters of fatty acids. Food Hydrocoll 49:135–143. https://doi.org/10.1016/j.foodhyd.2015.03.015

Al-Hassan AA, Norziah MH (2012) Starch–gelatin edible films: water vapor permeability and mechanical properties as affected by plasticizers. Food Hydrocoll 26:108–117. https://doi.org/10.1016/j.foodhyd.2011.04.015

Azeredo HMC, Waldron KW (2016) Crosslinking in polysaccharide and protein films and coatings for food contact—a review. Trends Food Sci Technol 52:109–122

Azeredo HMC, Morrugares-Carmona R, Wellner N, Cross K, Bajka B, Waldron KW (2016) Development of pectin films with pomegranate juice and citric acid. Food Chem 198:101–106. https://doi.org/10.1016/j.foodchem.2015.10.117

Byun H, Yoon S (2013) Crosslinked potato starch-based blend films using ascorbic acid as a plasticizer. J Agric Food Chem 62:1755–1762. https://doi.org/10.1021/jf4024855

Cao N, Fu Y, He J (2007) Mechanical properties of gelatin films cross-linked, respectively, by ferulic acid and tannin acid. Food Hydrocoll 21:575–584. https://doi.org/10.1016/j.foodhyd.2006.07.001

Caz P (2017) Polysaccharide-based films and coatings for food packaging: a review. Food Hydrocoll 68:136–148

Colivet J, Carvalho RA (2017) Hydrophilicity and physicochemical properties of chemically modified cassava starch films. Ind Crops Prod 95:599–607

Fai AEC, de Souza MRA, de Barros ST, Bruno NV, Ferreira MSL, de Andrade Gonçalves ECB (2016) Development and evaluation of biodegradable films and coatings obtained from fruit and vegetable residues applied to fresh-cut carrot (Daucus carota L.). Postharvest Biol Technol 112:194–204. https://doi.org/10.1016/j.postharvbio.2015.09.021

Fakhouria FM, Martellia SM, Caonc T, Velascod JI, Mei LHI (2015) Edible films and coatings based on starch/gelatin: film properties and effect of coatings on quality of refrigerated Red Crimson grapes. Postharvest Biol Technol 109:57–64. https://doi.org/10.1016/j.postharvbio.2015.05.015

Fakhoury FM, Martelli SM, Bertan LC, Yamashita F, Mei LHI, Queiroz FPC (2012) Edible films made from blends of manioc starch and gelatin—influence of different types of plasticizer and different levels of macromolecules on their properties. LWT Food Sci Technol 49:149–154. https://doi.org/10.1016/j.lwt.2012.04.017

Farhan A, Mohd N (2017) Characterization of edible packaging films based on semi-refined kappa-carrageenan plasticized with glycerol and sorbitol. Food Hydrocoll 64:48–58

Garavand F, Rouhi M, Hadi S, Cacciotti I (2017) Improving the integrity of natural biopolymer films used in food packaging by crosslinking approach: a review. Int J Biol Macromol 104:687–707

Inge UMRI (2007) Antimicrobial paper based on a soy protein isolate or modified starch coating including carvacrol and cinnamaldehyde. J Agric Food Chem 55:2155–2162

Kapelko-Żeberska M, Zięba T, Pietrzak W, Gryszkin A (2016) Effect of citric acid esterification conditions on the properties of the obtained resistant starch. Int J Food Sci Technol 51:1647–1654. https://doi.org/10.1111/ijfs.13136

Kim JY, Lee Y, Chang YH (2017) Structure and digestibility properties of resistant rice starch cross-linked with citric acid. Int J Food Prop 2:2166–2177. https://doi.org/10.1080/10942912.2017.1368551

Kuniak L, Marchessault RH (1972) Study of the crosslinking reaction between epichlorohydrin and starch. Starch-Stärke 24:110–116. https://doi.org/10.1002/star.19720240404

Ma W, Rokayya S, Xu L, Sui X, Jiang L, Li Y (2018) Physical–chemical properties of edible film made from soybean residue and citric acid. J Chem. https://doi.org/10.1155/2018/4026831

Mali S, Sakanaka LS, Yamashita F, Grossmann MVE (2005) Water sorption and mechanical properties of cassava starch films and their relation to plasticizing effect. Carbohydr Polym 60:283–289. https://doi.org/10.1016/j.carbpol.2005.01.003

Menzela C, Olssonb E, Plivelicc TS, Anderssona R, Johanssonb C, Kuktaited R, Järnströmb L, Koch K (2013) Molecular structure of citric acid cross-linked starch films. Carbohydr Polym 96:270–276. https://doi.org/10.1016/j.carbpol.2013.03.044

Mirele N, Fakhouri FM, Fialho RLL, de Magalhaes Christine, Cabral Albuquerque E (2018) Starch–recycled gelatin composite films produced by extrusion: physical and mechanical properties. J Appl Polym Sci 46254:1–9. https://doi.org/10.1002/app.46254

Oleyaei SA, Almasi H, Ghanbarzadeh B, Moayedi AA (2016) Synergistic reinforcing effect of TiO2 and montmorillonite on potato starch nanocomposite films: thermal, mechanical and barrier properties. Carbohydr Polym 152:253–262. https://doi.org/10.1016/j.carbpol.2016.07.040

Otoni CG, Avena-Bustillos RJ, Azeredo HMC, Lorevice MV, Moura MR, Mattoso LHC, Tara H, McHugh TH (2017) Recent advances on edible films based on fruits and vegetables—a review. Compr Rev Food Sci F 16:1151–1169. https://doi.org/10.1111/1541-4337.12281

Podshivalov A, Zakharova M, Glazacheva E, Uspenskaya M (2017) Gelatin/potato starch edible biocomposite films: correlation between morphology and physical properties. Carbohydr Polym 157:1162–1172

Reddy N, Yang Y (2010) Citric acid cross-linking of starch films. Food Chem 118:702–711. https://doi.org/10.1016/j.foodchem.2009.05.050

Seligra PG, Medina Jaramillo C, Fama L, Goyanes S (2016) Biodegradable and non-retrogradable eco-films based on starch–glycerol with citric acid as crosslinking agent. Carbohydr Polym 138:66–74. https://doi.org/10.1016/j.carbpol.2015.11.041

Sharma L, Sharma HK, Saini CS (2017) Edible films developed from carboxylic acid cross-linked sesame protein isolate: barrier, mechanical, thermal, crystalline and morphological properties. J Food Sci Technol 55:532–539. https://doi.org/10.1007/s13197-017-2962-4

Singh N, Belton PS, Georget DMR (2009) The effects of iodine on kidney bean starch: films and pasting properties. Int J Biol Macromol 45:116–119. https://doi.org/10.1016/j.ijbiomac.2009.04.006

Sun S, Liu P, Ji N, Hou H, Dong H (2017) Effects of various cross-linking agents on the physicochemical properties of starch/PHA composite films produced by extrusion blowing. Food Hydrocoll 77:964–975

Surendra Babu A, Parimalavalli R, Rudra SG (2015) Effect of citric acid concentration and hydrolysis time on physicochemical properties of sweet potato starches. Int J Biol Macromol 80:557–565. https://doi.org/10.1016/j.ijbiomac.2015.07.020

Tan B, Thomas NL (2017) Tortuosity model to predict the combined effects of crystallinity and nano-sized clay mineral on the water vapour barrier properties of polylactic acid. Appl Clay Sci 141:46–54. https://doi.org/10.1016/j.clay.2017.02.014

Tao F, Shi C, Cui Y (2018) Preparation and physicochemistry properties of smart edible films based on gelatin–starch nanoparticles. J Sci Food Agric 98:5470–5478. https://doi.org/10.1002/jsfa.9091

Wang S, Ren J, Li W, Suna R, Liua S (2014) Properties of polyvinyl alcohol/xylan composite films with citric acid. Carbohydr Polym 103:94–99. https://doi.org/10.1016/j.carbpol.2013.12.030

Wang L, Liu X, Wang J (2017a) Structural properties of chemically modified Chinese yam starches and their films. Int J Food Prop 20:1239–1250. https://doi.org/10.1080/10942912.2016.1209775

Wang W, Wang K, Xiao J, Liua Y, Zhaoa Y, Liu A (2017b) Performance of high amylose starch-composited gelatin films influenced by gelatinization and concentration. Int J Biol Macromol 94:258–265. https://doi.org/10.1016/j.ijbiomac.2016.10.014

Xu H, Canisag H, Mu B, Yang Y (2015) Robust and flexible films from 100% starch cross-linked by biobased disaccharide derivative. ACS Sustain Chem Eng 3:2631–2639. https://doi.org/10.1021/acssuschemeng.5b00353

Yin Y, Li J, Liu Y, Li Z (2005) Starch crosslinked with poly (vinyl alcohol) by boric acid. Appl Polym Sci 96:1394–1397. https://doi.org/10.1002/app.21569

Acknowledgements

R. Kumar is thankful to UGC, New Delhi for RGN fellowship. Authors are thankful to DST PURSE II and TEQIP-II for financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kumar, R., Ghoshal, G. & Goyal, M. Synthesis and functional properties of gelatin/CA–starch composite film: excellent food packaging material. J Food Sci Technol 56, 1954–1965 (2019). https://doi.org/10.1007/s13197-019-03662-4

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-019-03662-4