Abstract

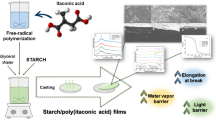

Starch-based composite films have been proposed as food packaging. In this context, the study of non-conventional starch sources (sagu, Canna edulis Kerr) has worldwide special attention, because these materials can impart different properties as carbohydrate polymers. A thorough study of the matrices used (sagu starch and flour) was carried out. In the same way, thermoplastic starch (TPS)/PCL blend and thermoplastic flour (TFS)/PCL blend were obtained by melt mixing followed by compression moulding containing glycerol as plasticizer. In this study, chemical composition of the matrices and their properties were related with the properties of the developed films. Moisture content, water solubility, X-ray diffraction, thermogravimetric analysis and mechanical and microstructural properties were evaluated in the films. Taking into account the results, the sagu flour has great potential as starchy source for food packaging applications. However, concretely the flour had lower compatibility with the PCL compared to the starch/PCL blend.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Starch-based films have been proposed as food packaging [1–4]. This, because are ecological materials, which reduce in part the problem caused by synthetic plastics from the petroleum industry [5]. Nevertheless, these materials have some drawbacks, between one of these, it can be mentioned its high sensitivity to water, this due to its hydrophilic character. For this reason, in recent years it has proposed several alternatives to improve their properties. Among one of the alternatives that has brought a growing interest, it found the development of starch-based films blended with some biopolyesters of family of the polyhydroxyalkanoates (PHAs).

In this context, poly(ε-caprolactone) (PCL) is an aliphatic polyester of hydrophobic nature obtained by chemical synthesis from crude oil or from renewable resources such as polysaccharides. Likewise, PCL is a thermoplastic, biodegradable, biocompatible and semicrystalline polymer that has a very low glass transition temperature (approx. −60 °C), as well as has a low melting point (58–60 °C) and low viscosity [6–9]. Additionally, PCL is a synthetic material fully biodegradable, which is easily processable and can be used with conventional melt processing equipment [6, 10–12]. In fact, this material is already used in food packaging and biomedical field [13, 14].

Among the advantages of using PLC, it can be mentioned: (1) PCL is a hydrophobic material with respect to other biopolymers such as proteins and, therefore, they do not suffer plasticization and swelling [15], (2) PCL has great stretch ability and low water vapor permeability [16] and (3) PCL-based films have good water resistance.

Nevertheless, biopolyesters and polysaccharides are thermodynamically immiscible, i.e. lack of polymeric compatibility, due to their difference in polarity. Hence, starch-PCL blends obtained by simple blending are not adequate due to low affinity between both polymers, which leads to phase separation between polymers, thus limiting the adhesion between the polymeric interfaces, resulting in poor film properties [9, 17, 18].

Despite this disadvantage, the barrier properties and the retrogradation phenomena in starch-based films could be overcome. In addition, there are no potential toxic compounds present in the film formulation, which is crucial for food packaging applications [19]. Likewise, biodegradability of starch-PCL blends has been reported by Sawada [20] and Yang and Wu [21]. These authors found a reduction in PCL degradation time when it is blended with starch.

Based on previous studies, and in spite of polymeric incompatibility, PCL-starch blends could offer properties of interest for the development of biodegradable packaging materials for foodstuffs, where some drawbacks of starch films could be solved such as its hydrophilic nature and its poor water resistance.

On the other hand, the properties of PCL-starch blends have been analyzed by several authors for different applications. Averous et al. [16], have found a phase separation between polymers due to its incompatibility, although the thermal transitions of each polymer suffered minor changes in the characteristic temperatures. The hydrophobicity of blends increased considerably compared with TPS. Rosa et al. [22], also analyzed the properties of PCL blends with different ratios of gelatinized and non-gelatinized corn starch. They observed that melt flow index increased when ratio of PCL increased in the blend, while PCL reduced water sorption capacity of materials. A decrease in crystallinity of PCL in the blends was also observed.

Likewise, non-conventional starches have had great interest worldwide, since it is well known that the properties of starches are influenced by its botanical source. In particular, Venezuela has a large amount of starchy sources, due to vegetal diversity that provides the Amazon. In this sense, canna rhizome is called “sagu” in Venezuela and in other South American countries is called arrowroot [23–25]. In South American countries there is confusion in the use of the name “sagu” (Canna edulis Kerr) [25–27], since is confused with the zulu rhizome (Maranta sp.). For this reason, in Fig. 1 can be seen the appearance of the sagu rhizome. The sagu rhizome is cultivated by peasants in small plantations or “conucos”. This crop is used for fresh consumption or for starch extraction at small scale. According to Pérez et al. [27], the sagu starch is frequently used by vegetarians, due to its supposedly easier digestion compared to other starches. Even, probably the sagu starch has also different functional properties in food formulations.

Moreover, the study of starch/PCL blend-based films has had great interest. However, the study of the flour/PCL compatibility has not been evaluated in order to obtain cheaper biodegradable materials. It is worth remembering that the flour yield as a starchy source is much higher to starch yield, which reduces the costs and improves the competitiveness with the synthetic materials made from petroleum. In addition, recent studies have demonstrated the potential of the flours with higher starch content as a renewable resource for food packaging production [28].

The aim of this study was to characterize the biomatrices used for forming films and evaluate the flour/PCL blend compatibility compared to the starch/PCL blend. Likewise, provide information about films made from a non-conventional starchy source.

Experimental

Materials

Native starch from sagu (Canna edulis Kerr) was obtained from harvested crops in the Estado Monagas, Venezuela, near the riverbanks of the Orinoco River. The starch extraction from the sagu rhizomes was carried out using the methodology described by Pérez et al. [29], obtaining a yield of approximately 2 %. The sagu flour was obtained by the method described by Pacheco [30], but with some modifications, e.g. the sagu rhizome was not immersed in a solution of citric acid (1 %) before dehydration the rhizome slices, obtaining a yield of approximately 20 %. Both the sagu starch and flour were used as matrices for forming films. Poly(ε-caprolactone) (PCL) was supplied by Aldrich Chemistry, having a molar weight of 42,500 g/mol. Glycerol from Aurum, Argentina, was employed as plasticizer in forming films.

Characterization of the Starch and the Flour

The chemical composition of the starch and the flour was determined. Moisture content, ash, fat, crude protein (N × 6.25) (obtained by the micro-Kjeldahl method), were determined using the gravimetric method [31]. Determination of crude fiber was performed by the method proposed by Van Soest and Wine [32]. The total amylose content was determined by differential scanning calorimetry (DSC) method described by Pérez et al. [33, 34]. Starch purity was calculated by subtracting the percent of the ash, crude protein and fatty materials, from 100 % of sample. Total carbohydrate content of the flour was calculated by subtracting the percentages of water content, ash, crude protein and fatty materials from one hundred percent of sample.

Color parameters of the starch and flour were obtained by a Colorimeter Macbeth model Color-eye 2445 using CIE-L*a*b* scale. Water activity (a w ) in the starch and the flour was determined using a psychrometric a w meter Aqualab Cx-2 (Decagon Devices, Pullman, USA) previously calibrated with water at 25 °C.

The morphology of granules of the starch and the flour was observed by optical microscopy [34, 35].

The infrared (IR) spectra of the starch and the flour was recorded in a Nicolet 8700 Fourier transform infrared spectrometer, with diamond crystal at an incident angle of 45°. The spectra were obtained by recording 40 scans performed with a resolution of 4 cm−1 between 600 and 4000 cm−1.

The rheological characteristics of the starch and the flour were determined through the interpretation of data obtained from a Brabender® Rapid-Visco-Analyser (RVA), (Micro Visco-Amylo-Graph model, Duisbur’s, Germany), executed under the Viscograph program (Version 2.4.9). A suspension of 7 % starch solids (14 % moisture on a dry basis) was prepared. This suspension was heated from 30 to 90 °C at a constant rate of 6 °C/min and then cooled from 90 to 50 °C at same rate to obtain the following data: onset of gelatinization (A), maximum viscosity (B), stability “breakdown” (breakdown = maximum viscosity—viscosity at the end of the heating period at 90 °C, BD), settling “setback” (setback = viscosity at the start of cooling period at 50 °C—maximum viscosity, EB) and consistency (consistency = viscosity at the start of cooling period at 50 °C—viscosity at the end of heating period at 90 °C, ED).

The heat flow curves of the matrices used were determined using a differential scanning calorimeter (Perkin Elmer, Pyris 1). A sample weight of approximately 10 mg was packed and sealed in a high pressure aluminum pan. The reference was an empty aluminum pan. The heating of samples was performed in the range of 20–120 °C at a constant heating rate of 10 °C/min. The gelatinization temperature (Tgelatinization) was obtained from middle temperature of relaxation range of heat flow curves and the gelatinization enthalpy (ΔHg) was estimated as the difference in enthalpy. This test was performed in 2 samples of each matrix.

Thermogravimetric test (TGA) of the starch and the flour were carried out with a TA Model TGA Q500. Samples were heated at a constant rate of 10 °C/min from room temperature to 500 °C, under nitrogen atmosphere. From thermogravimetric curves (DTG) were determined the characteristic decomposition temperatures of each biomatrix.

Film Formation

Biodegradable films were developed with the same ratio plasticizer:matrix used by Gutiérrez et al. [1, 2], i.e. a ratio of 1:1.4 (w/w) (glycerol:matrix). In the case of films made from blends with PCL, the same were obtained by replacing 60 % of the matrix by PCL, and maintaining the same glycerol content (Table 1). This, based on the best formula obtained in previous studies done by Mollega [36] and Maliger and Halley [37]. In each case the compounds were pre-mixed in a beaker. Then the blend was introduced in a Brabender type mixer at 130 °C and 60 rpm for 30 min. The paste were put onto steel sheets and preheated for 5 min at 130 °C. Films were obtained by compressing at 130 °C for 15 min at 100 bars; thereafter a cooling cycle was applied until obtaining a temperature of 30 °C. The resulting thermoplastic starch (TPS) and thermoplastic flour (TPF) films: native sagu starch (TPS-S), native sagu starch/PCL blend (TPS-S/PCL), native sagu flour (TPF-S) and native sagu flour/PCL blend (TPF-S/PCL). Before characterization, the films were conditioned at ~57 % relative humidity (RH) for a week at 25 °C.

Characterization of the Films

Moisture Content

The moisture content of the different films was determined using standard methods of analysis of the International Association of Official Analytical Chemistry [38]. Samples (~0.5 g) were dried in an oven at 100 °C for 24 h until constant weight was reached. The reported results represent the average of three samples in each case. Results were expressed as % of moisture.

Water Solubility

Water solubility was expressed as percentage of the film dry matter solubilized after 24 h of immersion in distilled water. This protocol is based on the method described by Romero-Bastida et al. [39] using the few modifications proposed by Hu et al. [40]. Pre-weighted (Wi) dry films were immersed in 50 mL distilled water at 25 ± 1 °C for 24 h in order to determine the mass of solubilized film. After, water content was removed to dry the samples in an oven for 24 h at 100 °C to determine the final weight (Wf) of the dry matter. All tests were carried out in triplicate and water solubility was calculated using the following equation:

X-Ray Diffraction (XRD)

Film crystallinity was evaluated by measuring the XRD from a PAN analytical X’Pert PRO diffractometer (Netherlands) equipped with a monochromatic CuKa radiation source (λ = 1.5406 Å) operating at 40 kV and 40 mA, at a scanning rate of 2° per min. Scattered radiation was detected in an angular range of 3°–33° (2θ). The thicknesses of the samples on the slides were ~1 mm. From the scattering spectrum, the percent crystallinity of films was determined according to Hermans and Weidinger [41], as the ratio of the integrated crystalline intensity to the total intensity. Crystalline fraction was estimated by the area above the smooth curve drawn on the basis of the main peaks (main d-spacing).

Thermogravimetric Analysis (TGA)

Thermogravimetric tests were carried out with a TA Model TGA Q500. Samples were heated at a constant rate of 10 °C/min and a nitrogen flow of 30 mL/min from room temperature up to 500 °C. The weight loss of materials was recalculated on dry basis and the different degradation phases were noted. Analyses were performed in triplicate to ensure repeatability.

Scanning Electron Microscopy (SEM)

SEM micrographs of the crio-fractured surface of samples were taken with a JEOL JSM-6460 LV instrument. For this, film pieces were mounted on bronze stubs. Thereafter, samples were sputter-coated (Sputter coater SPI Module, Santa Clara, CA, USA) with a thin layer of gold for 35 s.

Uniaxial Tensile Tests

An INSTRON 4467 machine was used to measure the mechanical properties of films development and following the ISO 527-2 norm [42]. Film strips (10 per formulation) were mounted in the tensile grips (A/TG model) and stretched at a rate of 0.01 mm/s until it broke. The relative humidity from the environment was maintained at nearly 57 % during tests, besides; essays were performed at 25 °C.

The force-distance curves obtained in tests were transformed into stress–strain curves, which allowed obtaining the following parameters: Young’s modulus (E), maximum stress (σ m ), strain at break (ε b ) and toughness (T).

Statistical Analysis

Analysis of variance (ANOVA) test was used to analyze the data, using Statgraphics Plus 5.1. software (ManugisticsCorp., Rockville, MD). The results of statistical analysis were shown as mean values ± SD. Differences between the mean values of the measured properties were compared using multiple-range Tukey’s test. A significance level of 0.05 was used.

Results and Discussion

Characterization of the Starch and Flour Used for Forming Films

Starch isolated from the sagu rhizome had a dry basis yield of 2 %, less than that reported in the specialized literature for other commercial starch sources, e.g. starch extracted from banana (28.5 %) or cassava (30 %) [35, 43]. In contrast, the yield for obtaining the sagu flour was 10 times higher. In this context, Gallardo and Bowler [44] reported that starch content in different vegetable materials depends on multiple factors such as season of the year, soil characteristics, botanical source, among others.

The chemical composition of the sagu flour and the starch are presented in Table 2. As can be observed, moisture values obtained for both biomatrices were within the range reported for a lifespan stable for both biomatrices [45]. However, no statistically significant differences (p ≥ 0.05) were observed in moisture content between the starch and the flour. Similar results were reported by Gutiérrez et al. [35], Sívoli et al. [46] and Pérez et al. [47], for starches of different starchy sources.

The contents of ash, protein, lipids, and crude fiber of sagu starch are comparable to those reported for conventional starches such as banana and cassava [48, 49]. The lower values of ash, protein, lipids, and crude fiber in the starch as compared to the flour show that these components are extensively extracted during starch preparation. Similar results were reported by Pelissari et al. [43].

The starch purity was very high, corroborating the efficiency of purification process. Similar results were reported by Gutiérrez et al. [35], for cassava and cush–cush yam starches.

The total amylose content in the flour was ~63 % lower compared to the starch. This, possibly due to increasing other constituents of the flour (ash, protein, lipids, and crude fiber).

Table 3 shows the values of water activity (a w ) of the biomatrices used. A direct relationship between the moisture content and the a w was found, confirming that the biomatrices used are not susceptible to growth of molds and yeasts. Similar results were reported by Gutiérrez et al. [50].

Color parameters were determined (Table 3), indicating highest L* values for the starch. Therefore, it can be said that flour was darker than the starch. The lower a* and b* values were obtained for the starch compared to the flour. This may be due to leaching the pigments during starch extraction. The lowest color difference (ΔE) was determined in the starch. Again, this result may be related to pigments loss during starch extraction, which increased the whiteness index (WI) and decreased the yellow index (Yl). Based on the ΔE values, the sagu starch can be recommended for use in products requiring a uniform color (e.g., candies, ice creams, juices).

Optical micrographs (Fig. 2) of the sagu flour and the starch showed small rounded granules of starch. The granular size was about 25 µm. Pérez et al. [27] reported higher granule size values for the sagu starch. Particles of fibrous material in microstructure of the flour can be seen in Fig. 2b. Additionally, the starch granules revealed no apparent damage, suggesting adequacy of technique of preparation of the flour and the starch.

In Fig. 3 are showed the FTIR spectra of the sagu flour and the starch. Both biomatrices presented a band at 3300 cm−1 corresponding to symmetric and asymmetric stretching of O–H bonds. The second band, at 2933–2943 cm−1, would be the result of the stretching of C–H bonds. The bands from 2363 to 2673 cm−1 would be associated with the tension of C=O group. The amide I band was found between 1632 and 1736 cm−1; this is amide group of proteins and reflects C=O stretching. Another major band relating to proteins is amide III band, located between 1200 and 1350 cm−1 [51]. This band arises from the stretching of the C–N bond and the inflexion of the N–H bond of the amide group. All these bands were present in both materials studied, although, with a greater intensity in the plantain flour due to its greater protein content. Similar results were reported by Pelissari et al. [43], for the banana starch and flour. The region located from 400 to 1200 cm−1 originates mainly from carbohydrate vibrations. In this area, the presence of the band at 1155 cm−1 represents the C–O stretching of carbohydrates. The bands observed at 1080 cm−1 in spectra of the sagu starch was attributed to stretching of COH bond of the starch molecules, while the bands from 987 to 1015 cm−1 is characteristic of partially crystalline materials [52]. A peak that clearly differentiates the two matrices is located at 1736 cm−1, which was associated to best hydrogen bonding interactions in the starch [53].

The rheological properties of the starch and the flour from the sagu rhizome are summarized in Table 4. According to Pelissari et al. [43], Rasper, [54]; Hoseney, [55] and Zhou et al. [56], the pasting properties are influenced by granular size, amylose/amylopectin ratio, starch molecular characteristics, volume fraction of suspended solids, affinity between hydroxyl groups of the molecules, molecular weight of amylose leached from the starch granules and the conditions of the thermal process used to induce gelatinization. The gelatinization temperature was higher in the sagu flour than in the starch. This probably due to higher ash, protein and lipid contents present in the flour compared to the starch. Besides, the sagu starch had an increase noticeable in maximum viscosity, breakdown and setback compared to the flour.

According to Harper and Tribelhorn [57], those starchy matrices which have high maximum viscosity values have weak cohesive forces, high swelling and high leaching of amylose into the surrounding medium. This fits well because the sagu starch had higher amylose content compared to the flour. Likewise, the flour was most resistant to mechanical fragmentation than isolated starch. This behavior was confirmed by breakdown values which represent the granule fragmentation (Fig. 4). The sagu starch retrogradation was higher than the sagu flour (setback values in Table 4). The significant differences in the pasting properties of the sagu flour and starch (p ≤ 0.05) suggest that the presence of other components in the flour may be influencing this characteristic, such as a reaction between amylose and lipids, or between protein and starch gel. Similar results have been reported for banana flour and starch [58], as well as for rice [59].

In the same way, greater consistency of paste was obtained in the flour compared to the starch. Finally, such raw materials made from sagu rhizomes have a potential in applications as thickeners in products requiring sterilization such as sauces and baby foods [60].

The DSC heating curves for the sagu flour and starch are shown in Fig. 5. DSC thermograms show a falls in heat flow, which was attributed to the gelatinization process. The sagu flour had a significantly higher gelatinization temperature (Tgelatinization) than the starch (p ≤ 0.05). These results were consistent with those obtained by RVA. Similar behavior was also reported by Moorthy et al. [61], for gelatinization of cassava flour and starch, indicating that highest fiber content in the flour, could contribute to greater Tgelatinization from the same plant species. Other authors have suggested that since lipids, also present in greater amounts in flours, it can be formed stable complexes with the amylase; their presence may contribute to increasing Tgelatinization values in the flours [62]. Another factor that may increase gelatinization temperature is the presence of proteins in suspension, which may provide a protective effect and prevent the entrance of water to the starch granules, such as, was indicated by Pelissari et al. [43] and Zaidul et al. [63]. The combined presence of these other components in highest proportions in the sagu flour may thus explain the differences in the thermal properties between the flour and the starch.

The gelatinization enthalpy (ΔHg) was slightly higher for the flour compared to the starch. According to Pelissari et al. [43], the ΔHg represents the amount of energy required to break molecular interactions inside the starch granules during gelatinization. So, the plantain flour due to constituents such as lipids, proteins and ashes possibly allow increasing energy required to achieve the flour gelatinization. Famá et al. [64] indicated that possibly the presence of fiber constituted a major barrier for gelatinization occurrence.

Figure 6 shows the TGA and DTGA curves for the biomatrices used. TGA curve of the sagu starch showed a higher weight loss compared to the flour (Fig. 6a). This is probably because the flour contains highest ash content, which decreased weight loss. Likewise, a sharper weight loss was observed in the sagu starch compared to the flour, this probably due to highest starch purity. Additionally, a lowest decomposition temperature was observed in the flour. The latter would be related to a potential plasticizing effect of proteins and lipids, which allow a greater molecular mobility of starch, thus reducing the starch–starch interactions, consequently resulting a lowest decomposition temperature.

Characterization of the Films

Figure 7 shows the appearance of the different films studied, which were easy to handle during all performed tests. Additionally, films made from flour (TPF-S and TPF-S/PCL) were darker than the starch-based films (TPS-S and TPS-S/PCL). It is worth emphasizing that possibly the darker coloration of the flour films is a result of the Maillard reactions, which are possible between the components of flour matrix under processing conditions. On the contrary, these reactions are not possible in the starch-based films. The flour films could be more appropriate when the protection against incident light is necessary, especially for packaging foodstuffs that are sensitive to degradation reactions catalyzed by light [28]. In contrast, the more transparent films (TPS-S and TPS-S/PCL, Fig. 8) could be particularly useful for foods that are benefited by be seen through its packaging to attract to consumers [65].

Moisture Content

Table 5 shows the moisture content of the different films studied. Films with PCL (TPS-S/PCL and TPF-S/PCL) had higher moisture contents than the films without PCL (TPS-S and TPF-S). According to Bikiaris et al. [66], an increase in moisture content in the starch/PCL systems occurs due to incompatibility between the matrices. Therefore, the low compatibility between the matrices evaluated (sagu starch and flour) and the PCL, allowed that the free plasticizer (glycerol), could absorb water from the enviroment. Similarly, the significant increase (p ≤ 0.05) in moisture content of the TPF-S/PCL film was possibly due to a weaker interaction between the flour-PCL compared to the TPS-S/PCL film.

On the other hand, the sagu flour-based film (TPF-S) had a significant decrease (p ≤ 0.05) in the moisture content compared to the sagu starch-based film (TPS-S). As is well known a better starchy matrix-glycerol interaction allows obtaining less sensitive films to moisture absorption [67]. Based on this, it can be established that the sagu flour has better interaction with the glycerol compared to the starch-glycerol interaction. Additionally, the lower tendency to retrogradation of the sagu flour compared to the starch, allows to say that the film made from flour (TPF-S) was more stable than the starch-based film (TPS-S), since a less tendency to retrogradation of starchy matrix, and prevents phase separation between the starch and the glycerol, thus leading to obtaining films with lower moisture content. Following to García-Tejeda et al. [68], native and oxidized banana starch-based films, modify their properties during storage due to tendency to starch retrogradation. For this reason, we can say that this fits well with the established in the results obtained.

Water Solubility

Table 5 shows the water solubility values of the different systems studied at 25 °C. Both films with addition of PCL (TPS-S/PCL and TPF-S/PCL), increased its solubility compared to the samples elaborated without PCL. This trend possibly was due to incompatibility of matrices, thus allowing that the free plasticizer (glycerol) can be solubilized in water. Specifically, a highest solubility was presented in the TPF-S/PCL film, which suggests a greater incompatibility between the flour and the PCL.

In the same way, Romero-Bastida et al. [39] indicated that solubility of the films provides an indication of integrity of materials in an aqueous medium, so that higher values of solubility indicate a lower water resistance. Therefore, a lowest water resistance was observed for the films plus PCL (TPS-S/PCL and TPF-S/PCL).

On the other hand, water solubility of the sagu starch film (TPS-S; 50.0 %) was higher (p ≤ 0.05) than that of the sagu flour film (TPF-S; 44.0 %). According to Pelissari et al. [28], better amylose–amylose, amylopectin–amylopectin and amylose-amylopectin interactions take place during drying of starch films, which reduces the amount of hydrophilic groups available for interaction with water. For this reason, a higher flour-glycerol interaction is presumed compared to the starch–glycerol interaction. Likewise, various authors have compared solubility of the flour and starch films made from other starchy sources such as achira, amaranth, and quinoa. Following to Tapia-Blácido [69], Araujo-Farro [70] and Andrade-Mahecha [71], have observed that this property is linked to type of raw material used for formation of polymeric matrix, type of interactions that occur in the matrix, use of plasticizers and process conditions, among other factors.

X-Ray Diffraction (XRD)

Figure 9 shows the X-ray diffraction patterns of the developed films. The diffraction curves of the TPS-S and TPF-S films show a behavior typical of a semicrystalline material mainly composed of an amorphous phase with a small crystalline fraction. Taking into account to Gutiérrez et al. [2], Angellier et al. [72] and Kristo and Biliaderis, [73], this would be consistent with the results obtained for the TPS-S and TPF-S films.

Concerning to the films with PCL showed the characteristic peaks of the crystallinity of polymer at 2θ = 21°, 22° and 24° [74]. Similar results were reported by Ortega-Toro et al. [75], for starch-based films with different ratios of starch-PCL. It is important to note that the addition of PCL increased the crystallinity of these systems (TPS-S/PCL and TPF-S/PCL) (Table 5). Likewise, it can be observed in Table 5 that the crystallinity of the TPF-S/PCL film was larger than the crystallinity of the TPS-S/PCL film. Therefore, it can be said that a highest crystallinity of the TPF-S/PCL film occurred due to low flour-PCL compatibility compared to the starch-PCL compatibility. This is based on the fact that minor interactions between the biopolymers, allows starch retrogradation and crystallization of the PCL, i.e. higher crystallinity in these systems could indicate a greatest possibility of crystallizing the materials as a result of a reduced interaction between the biopolymers.

Another relevant issue is a slight increase in crystallinity of the starch-based film (TPS-S) compared to the flour-based films (TPF-S) (Table 5). According to the literature, crystallinity of starch films is mainly associated with the amylose contained within the branches of the amylopectin [76]. This fits well with the results obtained, since a highest amylose content was determined for the sagu starch. Besides, a slight increase in crystallinity of the starch-based film (TPS-S) compared to the film made from flour (TPF-S) could also be related to the lesser tendency to starch retrogradation compared to the flour. Following to García-Tejeda et al. [68] and Bertuzzi et al. [77], starch retrogradation during storage reduces the mobility of polymeric chains.

Thermogravimetric Analysis (TGA)

Thermogravimetric analysis (TGA) was performed in order to analyze the thermal stability of the films evaluated (Fig. 10a). According to Pelissari et al. [28], Gutiérrez et al. [67], Marques et al. [78] and Ayala et al. [79], thermal decomposition of the glycerol-starch films occurs in three main stages. The first stage corresponds to water evaporation, which occurs about at 100 °C, the second stage is associated to decomposition of the glycerol-rich phase which also contains starch, and occurs between ~180 and 260 °C, and lastly, the third stage occurs from the 330 °C, due to thermal degradation that undergoes the partially decomposed starch [67, 80–82].

As can be seen from Fig. 10, the first stage of thermal degradation is not observed, since weight loss of materials was recalculated on dry basis in order to avoid distortions as a result of the different moisture values of the films. In the second stage of thermal degradation was observed the lower thermal resistance of the film made from flour (TPF-S) compared to the film made from starch (TPS-S). This can be clearly observed through DTGA curves of these materials (Fig. 10b). This effect is widely known and is attributed to the plasticizing effect, which may be related to the highest protein content in the flour, which leads to increasing the molecular mobility of polymeric chains, i.e. higher hydrogen-bonding interactions between the starch chains and the hydroxyl groups of the glycerol [28, 83–85].

On the other hand, a double weight loss between 270 and 410 °C in films made from PCL blends (TPS-S/PCL and TPF-S/PCL) was observed. Clearly, it can be observed through DTGA curves (Fig. 10b). This confirms the phase separation that occurs in the films made from PCL blends, this due to immiscibility of the polymeric matrices used and the PCL. This could also explain the increase in moisture content in the films made from PCL blends (TPS-S/PCL and TPF-S/PCL), since being the free glycerol, the same can absorb moisture from the environment, thus increasing moisture content. This behavior has been previously reported in the literature by Liu et al. [81], Sanyang et al. [82], Shi et al. [86] and Liu et al. [87]. Additionally, temperature required for onset of degradation of the PCL-rich phase of the TPF-S/PCL film occurred at 343 °C, whereas the onset of decomposition of the TPS-S/PCL film occurred at 350 °C, which gives evidence of the higher compatibility of the TPS-S/PCL film compared to the TPF-S/PCL film. It is also worth noting that the addition of PCL in the blends decreased the decomposition temperature of the starch-rich phase. Possibly, this is due to the repulsive forces between starch matrices and PCL. Additionally, this behavior was most pronounced in the TPF-S/PCL film. In this sense, the proteins contained in sagu flour could contribute to separation of the mixtures with PCL.

Likewise, blends containing PCL showed the final decomposition temperature corresponding to the starch matrices plus PCL (~430 °C). Previously, other authors have reported similar the thermal degradation behavior for blends based on PCL containing different thermoplastic starches [73, 88, 89]. In the same way, it can be clearly observed that final decomposition temperature of the PCL-rich phase was not influenced by interaction with the starchy matrices.

Finally, in the third stage were observed stable curves of thermal degradation up to 500 °C [90–92]. Besides, a further decomposition phase at around 475 °C was detected in the sagu starch-based films (TPS-S and TPS-S/PCL) compared to the flour-based films (TPF-S and TPF-S/PCL). In accordance to Ruiz [90], this stage is mainly related to thermal decomposition of the starch. Likewise, blends containing PCL had higher weight loss compared to the films without PCL (TPS-S and TPF-S).

Scanning Electron Microscopy (SEM)

Figure 11 shows the SEM images of the cryo-fracture surfaces of the different films. The heterogeneity of the films based on starchy matrix/PCL blends was observed (TPS-S/PCL and TPF-S/PCL, Fig. 11b, d, respectively). These films evidenced the lack of miscibility of both polymers. Similar structures were reported by Ortega-Toro et al. [75]. Likewise, blends exhibited poor interfacial adhesion, due to the difference of polarity of polymers [93, 94].

Following to Pelissari et al. [28] a more compact structure leads to lower water adsorption as it makes less likely the interactions between the starch-glycerol and the water, leading to a decrease in the polar glycerol-starch character of the films [68]. The moisture content results obtained for the systems analysed (Table 5) are agreed with the structures observed by SEM, since more open structures were obtained for the films made from PCL blends (TPS-S/PCL and TPF-S/PCL, Fig. 11b, d, respectively), and precisely these films were those with highest moisture content. Likewise, a more compact structure was observed for the film made from flour (TPF-S, Fig. 11c) compared to the starch-based film (TPS-S, Fig. 11a), which also fits well with the results obtained for moisture content of these films.

In addition, small particles in the TPS-S and TPF-S samples were observed (Fig. 11a, c, respectively). These were more developed on the starch-based film (TPS-S, Fig. 11a) possibly due to starch recrystallization, i.e. the phenomenon of starch retrogradation. The presence of these particles in the TPS-S and TPF-S samples (Fig. 11a, c, respectively) was consistent with the X-ray diffraction results, i.e. a slight increase in crystallinity was observed for the starch-based film (TPS-S) compared to the film made from flour (TPF-S).

Uniaxial Tensile Tests

The stress–strain curves of each films developed are shown in Fig. 12. A small elastic linear zone followed by a non-linear zone until breaking point, regardless of the matrix used was observed. The films made from PCL blends (TPS-S/PCL and TPF-S/PCL), provokes an increase in the stiffness, which is reflected in higher Young’s modulus values compared to the films made without PCL (TPS-S and TPF-S). According to Ninago et al. [74], this behavior is attributed to reduced mobility of the polymer chains (PCL), which leads to obtaining more rigid films (Table 6).

In general, the results of mechanical tests showed that Young’s modulus of samples ranged from 0.051 to 0.27 MPa. Whereby, the films obtained are less rigid compared to the films made by Gutiérrez et al. [1] from cassava and cush–cush yam starches.

On the other hand, the sagu flour-based film (TPF-S) had a significant increase in strain at break compared to the sagu starch-based film (TPS-S), i.e. the flour film was more flexible. This can be verified in typical curves of the mechanical properties (Fig. 12). These results confirm that protein and lipids present in the flour films could provoke a plasticizing effect. Shellhammer and Krochta [95] and Batista et al. [96] have reported that lipid-protein interactions improve film flexibility. Similar behaviors have been detected by other authors in studies on mechanical characteristics of the flour and starch films elaborated from the same botanical source, e.g. Pelissari et al. [28] determined this behavior in films made from plantain starch and flour. Nevertheless, the strain at break of the films significantly decreased (p ≤ 0.05) when PCL was incorporated. No significant differences were observed for the films made from PCL blends (TPS-S/PCL and TPF-S/PCL). Similar results were obtained to those reported by Corradini et al. [94] for PCL-zein starch blends, and by Ishiaku et al. [97], for PCL-sago starch blends. In both cases, incompatibility of polymers was observed. Besides, spontaneous release of both phases was observed in the films made from PCL blends (Fig. 9b, d), which caused a loss in cohesion of the blend matrix and lack of stretch ability of the blend films (TPS-S/PCL and TPF-S/PCL) [94, 97].

Likewise, different authors have related the elasticity of starch films with their structure, indicating that higher elasticity values are associated with materials with a more compact structure [1, 98]. This is consistent with our results, since films with a more compact morphology (Fig. 11a, c) were also more elastic.

In addition, a stronger glycerol-matrix interaction limits the possible interaction between the water and the glycerol or the starch, thus decreasing moisture levels in the analyzed films (Table 5).

Regarding to maximum stress, films made from PCL blends (TPS-S/PCL and TPF-S/PCL) had the greater values. Although a statistically significant decrease (p ≤ 0.05) in maximum stress in was observed the films based on the flour/PCL blend (TPF-S/PCL) compared to the film made from the starch/PCL blend (TPS-S/PCL). This behavior is probably related with a lowest compatibility of the flour with the PCL. Additionally, the sagu starch film (TPS-S) has the lower tensile strength values compared to the sagu flour film (TPF-S). This indicates that the flour film was more resistant and rigid than the starch film. Probably this occurs due to lowest amylose content in the sagu flour. According to Gutiérrez et al. [2] “waxy” starch-based films had the higher tensile strength values.

Finally, a highest toughness value was obtained for the film based on sagu flour (TPF-S). According to Gutiérrez et al. [50], this could be very useful, since these films could absorb more energy without being transmitted to foods, this could minimize damage caused by the blows in foods during transport and storage. Similar toughness values were obtained by Gutiérrez et al. [50] for films made from plantain flour.

Conclusions

In this work, two non-conventional starchy matrices, namely sagu starch and flour were characterized in detail to be used in manufacture of films with application in the food industry. Marked differences between the matrices were obtained and the same determined the properties of the developed films. In the same way, it was determined that the sagu flour is a potential material for obtaining films with better mechanical properties than the sagu starch-based film. Nonetheless, a greater compatibility was obtained for the starch-PCL blend.

References

Gutiérrez TJ, Tapia MS, Pérez E, Famá L (2015) Food Hydrocoll 45:211

Gutiérrez TJ, Tapia MS, Pérez E, Famá L (2015) Starch Stärke 67:90

Santacruz S, Rivadeneira C, Castro M (2015) Food Hydrocoll 49:89

Fakhouri FM, Martelli SM, Caon T, Velasco JI, Mei LHI (2015) Postharvest Biol Technol 109:57

Arena U, Mastellone ML, Perugini F (2003) Int J Life Cycle Assess 8(2):92

Flieger M, Kantorová M, Prell A, Rezanka T, Votruba J (2003) Folia Microbiol 48(1):27

Cao X, Chang PR, Huneault MA (2008) Carbohydr Polym 71(1):119

Fabra MJ, Lopez-Rubio A, Lagaron JM (2013) Food Hydrocoll 32(1):106

Ortega-Toro R, Morey I, Talens P, Chiralt A (2015) Carbohydr Polym 127:282

Ludueña LN, Alvarez VA, Vazquez A (2007) Mater Sci Eng A 460:121

Ludueña LN, Vazquez A, Alvarez VA (2008) J Appl Polym Sci 109(5):3148

Guarás MP, Alvarez VA, Ludueña LN (2015) J Polym Res 22(9):1

Modi S, Koelling K, Vodovotz Y (2009) Thermal and rheological properties of PHB synthesized with various hydroxyvalerate content for potential use in food packaging. In: Annual technical conference e ANTEC, conference proceedings 3, pp 1636–1640

Erdal E, Kavaz D, Şam M, Demirbilek M, Demirbilek ME, Sağlam N, Denkbaş EB (2012) J Biomed Nanotechnol 8(5):800

Miguel O, Fernandez-Berridi MJ, Iruin JJ (1997) J Appl Polym Sci 64:1849

Averous L, Moro L, Dole P, Fringant C (2000) Polymer 41(11):4157

Avella M, Errico ME, Laurienzo P, Martuscelli E, Raimo M, Rimedio R (2000) Polymer 41:3875

Kweon DK, Kawasaki N, Nakayama A, Aiba S (2003) J Appl Polym Sci 92(3):1716

Duquesne E, Rutot D, Degee P, Dubois P (2001) Macromol Symp 175(1):33

Sawada H (1994) In: Doi Y, Fukuda K (eds) Biodegradable plastics and polymers. Elsevier Science, Amsterdam, p 298

Yang S-R, Wu CH (1999) Macromol Symp 1999(144):101

Rosa DS, Guedes CGF, Pedroso AG, Calil MR (2004) Mater Sci Eng C 24(5):663

Erdman MD, Erdman BA (1984) Econ Bot 38(3):332

Erdman MD (1986) Cereal Chem 63:277

Montaldo A (1972). Canna edulis. In: Cultivos de Raíces y Tubérculos Tropicales, Instituto Interamericano de Ciencias Agrícolas (IICA) de la O.E.A., Lima, Perú, Textos y Materiales de Enzeñanza. No. 21

Chaparro R, Cortés H (1978) Canna edulis Kerr. Cultivo. Industrialización. Utilidad Forrajera. In: Temas de Orientación Agropecuaria, (Edit.) Ruíz, R., Bogotá, Colombia, vol 131

Pérez E, Lares M, González Z (1997) J Agr Food Chem 45(7):2546

Pelissari FM, Andrade-Mahecha MM, do Amaral Sobral PJ, Menegalli FC (2013) Food Hydrocoll 30(2):681

Pérez E, Bahnassay Y, Breene W (1993) Starch Stärke 45(6):211

Pacheco E (2001) Acta Cient Venez 52(4):278

AACC (2003) Approved methods of the American association of cereal chemists. Methods no. 44-15A, 30-10, 08-01, 46-13, 02-52 and 02-31. American Association of Cereal Chemists, St. Paul

Van Soest PU, Wine RH (1967) J Assoc Off Anal Chem 50(1):50

Pérez E, Gilbert O, Rolland-Sabaté A, Jiménez Y, Sánchez T, Giraldo A, Pontoire B, Guilois S, Lahon M-C, Reynes M, Dufour D (2010) J Agric Food Chem 59(1):263

Pérez E, Rolland-Sabaté A, Dufour D, Guzmán R, Tapia M, Raymundez M, Ricci J, Guilois S, Pontoire B, Reynes M, Gilbert O (2013) Carbohydr Polym 98:650

Gutiérrez TJ, Pérez E, Guzmán R, Tapia MS, Famá L (2014) J Polym Biopolym Phys Chem 2(1):1

Mollega IP (2008) Caracterización y biodegradación de mezclas de policaprolactona y poliácido láctico con almidón de yuca. Tesis de Maestría. Universidad Simón Bolívar, Caracas, Venezuela. http://159.90.80.55/tesis/000144538.pdf

Maliger R, Halley PJ (2014) Chapter 11. Reactive extrusion for thermoplastic starch-polymer blends. In: Halley PJ, Avérous LR (eds) Starch polymers: from genetic engineering to green applications. Elsevier, Amsterdam, pp 291–317

AOAC (1990) Official methods of analysis, 13th edn. Association of Official Analytical Chemists, Washington, DC

Romero-Bastida CA, Bello-Péreza LA, García MA, Martino MN, Solorza-Feriaa J, Zaritzkyb NE (2005) Carbohydr Polym 60:235

Hu G, Chen J, Gao J (2009) Carbohydr Polym 76:291

Hermans PH, Weidinger A (1961) Makromol Chem 44:24

ISO 527-2 (1996) Plastics–determination of tension properties—part, 2

Pelissari FM, Andrade-Mahecha MM, Sobral PJDA, Menegalli FC (2012) Starch Stärke 64(5):382

Gallardo T, Bowler P (1987) Morphology and composition of starch. In: Galliard T (ed) Starch: properties and potential, critical reports on applied chemistry, vol 13. Society of Chemical Industry by John Wiley and Sons, vol 6, pp 115–149

Jay JM (1996) Modern food microbiology, 5th edn. Chapman and Hall, New York

Sívoli L, Pérez E, Rodríguez P, De Abrisqueta A, Raymúndez MB (2005) Acta Microscópica 14 (1 y 2):5

Pérez E, Segovia X, Tapia MA, Schroeder M (2012) J Cell Plast 48(6):545

Eggleston G, Swennen R, Akoni S (1992) Starch Stärke 44(4):121

Pérez-Sira E (1997) Starch Stärke 49(2):45

Gutiérrez TJ, Guzmán R, Medina M, Famá L (2016) Int J Biol Macromol 82:395

Singh BR (2000) Infrared analysis of peptides and proteins-principles and applications. American Chemical Society, Washington

Vicentini NM, Dupuy N, Leitzelman M, Cereda MP, Sobral PJA (2005) Spectrosc Lett 38(6):749

Kapusniak J, Siemion P (2007) J Food Eng 78(1):323

Rasper V (1982) Theoretical aspects of amilographology. In: Shuey WC, Tipples KH (eds) The amylograph handbook, chapter 1. AACC, Sto Paul

Hoseney RC (1986) Principles of cereal science and technology. American Association of Cereal Chemists Inc, St. Paul

Zhou M, Robards K, Glennie-Holmes M, Helliwell S (1998) Cereal Chem 75(3):273

Harper JM, Tribelhorn RE (1992) In: Kokini JL, Ho CT, Karwe MV (eds) Food extrusion science and technology. Marcel Dekker Inc., New York, pp 653–667

da Mota RV, Lajolo FM, Cordenunsi BR, Ciacco C (2000) Starch Stärke 52(2–3):63

Yu S, Ma Y, Menager L, Sun DW (2012) Food Bioprocess Technol 5(2):626

de la Torre-Gutiérrez L, Chel-Guerrero LA, Betancur-Ancona D (2008) Food Chem 106(3):1138

Moorthy SN, Rickard J, Blanshard JM (1996) In: Dufour D, O’Brien GM, Best R (eds) Cassava flour and starch: progress in research and development. Cali, CIAT, pp 150–155

Osman EM (1967) In: Whistler RL, Paschall EF (eds) Starch chemistry and technology. Academic Press, New York, pp 163–215

Zaidul ISM, Absar N, Kim SJ, Suzuki T, Karim AA, Yamauchi H, Noda T (2008) J Food Eng 86(1):68

Famá L, Bittante AMB, Sobral PJ, Goyanes S, Gerschenson LN (2010) Mater Sci Eng C 30(6):853

Gontard N, Guilbert S, Cuq JL (1992) J Food Sci 57(1):190

Bikiaris D, Prinos J, Koutsopoulos K, Vouroutzis N, Pavlidou E, Frangis N, Panayiotou C (1998) Polym Degrad Stab 59(1):287

Gutiérrez TJ, Suniaga J, Monsalve A, García NL (2016) Food Hydrocoll 54:234

García-Tejeda YV, López-González C, Pérez-Orozco JP, Rendón-Villalobos R, Jiménez-Pérez A, Flores-Huicochea E, Solorza-Feria J, Bastida CA (2013) LWT Food Sci Technol 54:447

Tapia-Blácido DR (2006) Films based on derivates of amaranth for use in foods. PhD thesis, Unicamp, Brazil

Araujo-Farro PC (2008) Development and optimization of biodegradables films made of products derivated from “royal” variety quinoa (Chenopodium quinoa Willdenow) seeds. PhD thesis, Unicamp, Brazil

Andrade-Mahecha MM (2009) Development and characterization of films based on Canna indica L. flour. Master thesis, Unicamp, Brazil

Angellier H, Molina-Boisseau S, Dole P, Dufresne A (2006) Biomacromolecules 7:531

Kristo E, Biliaderis CG (2007) Carbohydr Polym 68:146

Ninago MD, López OV, Lencina MS, García MA, Andreucetti NA, Ciolino AE, Villar MA (2015) Carbohydr Polym 134:205

Ortega-Toro R, Contreras J, Talens P, Chiralt A (2015) Food Packag Shelf Life 5:10

Zobel HF (1992) Starch granule structure in: developments in carbohydrate chemistry. H.F. Zobel and R.J. Alexandes, Edicion A.A.C.C

Bertuzzi MA, Castro EF, Armada M, Gottifredi JG (2007) J Food Eng 80(3):972

Marques PT, Lima AMF, Bianco G, Laurindo JB, Borsali R, Le Meins JF, Soldi V (2006) Polym Degrad Stab 91(4):726

Ayala G, Agudelo A, Vargas R (2012) Dyna 79(171):138

Wilhelm HM, Sierakowski MR, Souza GP, Wypych F (2003) Carbohydr Polym 52(2):101

Liu H, Xie F, Yu L, Chen L, Li L (2009) Prog Polym Sci 34(12):1348

Sanyang ML, Sapuan SM, Jawaid M, Ishak MR, Sahari J (2015) Polymer 7(6):1106

Cyras VP, Tolosa Zenklusen MC, Vazquez A (2006) J Appl Polym Sci 101(6):4313

Mathew S, Abraham TE (2008) Food Hydrocoll 22(5):826

Gutiérrez TJ, Morales NJ, Tapia MS, Pérez E, Famá L (2015) Proc Mater Sci 8:304

Shi R, Zhang Z, Liu Q, Han Y, Zhang L, Chen D, Tian W (2007) Carbohydr Polym 69(4):748

Liu X, Yu L, Liu H, Chen L, Li L (2008) Polym Degrad Stab 93(1):260

Hubackova J, Dvorackova M, Svoboda P, Mokrejs P, Kupec J, Pozarova I, Alexy P, Bugaj P, Machovsky M, Koutny M (2013) Polym Test 32(6):1011

Cai J, Xiong Z, Zhou M, Tan J, Zeng F, Lin S, Xiong H (2014) Carbohydr Polym 102:746

Ruiz G (2006) Ingeniería y Ciencia 2(4):5

Patel P, Hull TR, McCabe RW, Flath D, Grasmeder J, Percy M (2010) Polym Degrad Stab 95(5):709

Gutiérrez TJ, Morales NJ, Pérez E, Tapia MS, Famá L (2015) Food Packag Shelf Life 3:1

Rosa DDS, Rodrigues TC, Graças Fassina Guedes CD, Calil MR (2003) J Appl Polym Sci 89(13):3539

Corradini E, Mattoso LC, Guedes CGF, Rosa DS (2004) Polym Adv Technol 15(6):340

Shellhammer TH, Krochta JM (1997) Edible coatings and film barriers. In: Gunstone FD, Padley FB (eds) Lipid technologies and applications. Marcel Dekker, New York, pp 453–479

Batista JA, Tanada-Palmu PS, Grosso CRF (2005) Ciencia e Tecnol Alime 25:781

Ishiaku US, Pang KW, Lee WS, Ishak ZM (2002) Eur Polym J 38(2):393

Saavedra N, Algecira N (2010) Evaluación de películas comestibles de almidón de yuca y proteína aislada de soya en la conservación de fresas. NOVA-Publicación científica en ciencias biomédicas. ISSN:1794-2470, 8(14):171–182

Acknowledgments

The authors would like to thank the Consejo Nacional de Investigaciones Científicas y Técnicas (CONICET) (Postdoctoral fellowship internal PDTS-Resolution 2417), Universidad Nacional de Mar del Plata (UNMdP), for the financial support and to Dr. Mirian Carmona-Rodríguez.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Gutiérrez, T.J., Alvarez, V.A. Films Made by Blending Poly(ε-Caprolactone) with Starch and Flour from Sagu Rhizome Grown at the Venezuelan Amazons. J Polym Environ 25, 701–716 (2017). https://doi.org/10.1007/s10924-016-0861-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-016-0861-9