Abstract

Ultrafiltration is one of the types of clarification process that was undertaken in this study together with examining and comparing the storage period of clarified juice by other methods (enzymatically treated, centrifugation, microfiltration). Centrifugation, ultrafiltration and microfiltration of jamun juice was carried out using a laboratory scale refrigerated centrifuge and filtration system. The juices obtained from various processes were evaluated on the basis of their physiochemical and microbial aspects over a period of 8 weeks. Enzyme treated and centrifuged juices were found to be degraded within 15–30 days while other juices had lesser changes in their properties. However microfiltered juice contained some yeasts and molds which increased with time. Ultrafiltration with 50 kDa pore size and 20 psi pressure was found to be the best method for clarification of jamun juice having a prolong shelf life with optimum qualities.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Fruit juice is one of the non-alcoholic drink which attracts people from age group of 8 to 80 for its health benefit and nutritional properties. Every year, India produces 9 million tons of fruit, among which total market for fruit juice is 230 million litre, with a growing trend of 12% per annum (Gahlawat et al. 2014). The Indian fruit juice market is divided into two category i.e. organised (packaged fruit juice) and unorganised one (fresh juice). The organised packaged juices are not having the original nutritional benefit of the fruit as it is passed through pasteurization process. Due to the heat treatment denaturation of protein, polyphenols, antioxidant and loss of vitamins takes place. Therefore, clarification can be one of the major unit operations in the juice industry which can be used to retain the nutritional quality of juice before its packaging. Clarification is the process of separating dense cloudy or hazy solution from the raw juice to obtain a slightly translucent juice.

Jamun is one of the seasonal minor fruit with a distinct flavour and colour (Ghosh et al. 2017). The fruit, juice as well as the seed is having several medicinal values (Sehwag and Das 2015). The raw juice is full of suspended particles and macromolecules (pectin, tannin, fibre). To clarify the juice several pre-treatments have been done. Specific enzyme is added to the juice that breaks pectin into soluble form, thereby freeing the suspended particles which settle down and leaves the juice clear (Sin et al. 2006; Pinelo et al. 2010; Sagu et al. 2014a). In specific pectinase, tannase, cellulose had been used to clarify jamun juice for further treatment. The clarification through enzyme treatment process depends upon type of enzyme used, time, concentration and temperature (Ghosh et al. 2016a, b).

Non-enzymatic clarification can be sub-divided into five types (clarification through adding chemical agents, heating, centrifugation, microfiltration and ultrafiltration). Gelatine, chitosan, bentonite, silica are used often to clarify juice by breaking the cell wall structure in case of chemical agents treatment (Yang et al. 2015). But the main disadvantage of the process is that it takes a longer period of time for the completion of the whole process and risk of contamination. In case of heat treatment colloidal materials usually gets coagulated due to protein denaturation and finally a cooked flavour is produced in the juice. Centrifugation is generally used to separate the large particles present in the raw juice by centrifugal action. The process depends on the speed and time of the operation. Membrane filtration is one of the effective process proves its benefit. Microfiltration as well as ultrafiltration process has been used for clarifying the juice through a decade. Several studies have been investigated to compare the better clarifying treatment within centrifugation and microfiltration (Chhaya et al. 2013; Sagu et al. 2014b). Sagu et al. (2014b) studied comparison of banana juice clarification through centrifugation and microfiltration and concluded that microfiltration method is more suitable for further clarification in terms of viscosity, pectin and clarity. But in another study Chhaya et al. (2013) reported that in terms of quality parameter centrifugation gives better result than microfiltration for stevia extract clarification.

In the beverage industry instead of sterilization, microfiltration followed by ultrafiltration gives a better quality product without changing the characteristics flavour, aroma, colour of the original juice. Ultrafiltration is known as the most suitable clarifying process separating valuable compounds from the juices. The processes eliminates the use of enzymes, chemicals, and heat, thereby decreasing the chances of contamination and process failure. It is mainly used for removal of suspended solids which is responsible for haze formation and turbidity factors. If ultrafiltered juice can be packaged properly then shelf life of the juice will be same as commercially available product with a better quality. So this process is known as cold sterilization.

During storage of the fruit juice, degradation occurs due to microbial growth, physicochemical changes and colour changes. Storage study is needed for enumerating the shelf life of the product (Cortés et al. 2008). For further industrial application the meaningful clarification process will be which possess a longer shelf life. Several treatments (ultra-sonication, pasteurization, sterilization, microfiltration, ultrafiltration, changes in temperature) has been applied to fruit juice for enhancing the shelf life and storage study of those juices has been also reported (Mondal et al. 2016; Cruz-Cansino et al. 2015; Ain et al. 2014; Vegara et al. 2013; Rai et al. 2008; Campos et al. 2002).

The primary aim of the study was to clarify the jamun juice by ultrafiltration. The next aim was to determine the storage period of clarified jamun juice by different methods (enzymatically treated, centrifugation, microfiltration) and comparison between them with ultrafiltration process. The outcome will not only helpful for the storage study and shelf life prediction but also for any further treatment after clarification of the juice.

Materials and methods

Raw material

Fresh and ripe jamun (variety: Ram jamun) procured from local market of Rourkela, Odisha (India) was utilized as the raw material. As jamun is highly perishable, it was defrosted at − 20 °C. Prior to the deep freezing process, it was cleaned with CaCl2 solution.

Preparation of jamun juice

Jamun fruits were kept outside the deep freezer and thawed for 4 h until it reached the room temperature. For the preparation of jamun juice, the required jamun pulp was obtained by deseeding the fruits manually and storing the pulp in a clean container. The pulp was grinded in a mixer (Bajaj Mixer, India) for 5 min at its high speed. The grinded pulp was treated with Pectinase (Aspergillus aculeatus) Enzyme (Pectinex Ultra SPL; activity 3800 units/ml, Sigma-Aldrich, India) with a concentration of 0.05% (w/w) for 80 min at 44 °C (Ghosh et al. 2016b; Shahnawaz and Sheikh 2011).

Centrifugation

Centrifugation of jamun juice was performed in a laboratory scale refrigerated centrifuge (2-16KL, Sigma, Germany). The operation was done on batch mode method with 50 ml capacity tubes at 25 °C. Based on the previous scientific results (Rai et al. 2006) and preliminary trials, the rotational speed (rpm) and time (min) of centrifugation were maintained at 7000 turns and 40 min, respectively.

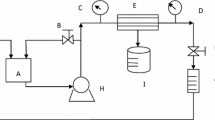

Microfiltration and ultrafiltration

Microfiltration (MF) and ultrafiltration (UF) of jamun juice were carried out using a laboratory scale filtration system attached with hollow fibre membrane (Explorer 12, Polysulfone material, Effective area 0.005 m2, inner diameter 0.013 m with a height of 0.312 m) which was supplied by CleanSep, Mumbai, India. Schematic diagram of membrane filtration system was given in Fig. 1. A certain amount of juice was used for each trial under batch concentration mode where permeate was collected separately with the recirculation of retentate. The process was done until recovery was more than 80%. The peristaltic pump supplied the feed to the micro filter membrane. Inlet (P1) and outlet (P2) pressure of the membrane was visible through attached pressure gauge. The Trans membrane pressure [TMP = (P1 + P2)/2] was calculated on the basis of the average of both the pressure. After passing through membrane, filtrate was obtained on one side and retentate on the other. The retenate was recirculated to the feed tank. Pressure valve was used to maintain the back pressure throughout the time of experiment. The amount of filtrate was collected in a measuring cylinder. Time to collect each 10 ml of juice was noted down and the permeate flux (J) was calculated. Filtrate as well as retentate was collected for physicochemical analysis.

The juice was passed through Microfiltration with 0.45 µm pore size membrane and a pressure of 20 psi. Temperature was constant throughout the experiment. Transmembrane pressure and membrane pore size was varied through a certain range. The operating parameter for ultrafiltration was membrane pore size (100, 50 and 10 kDa) and Trans membrane pressure (TMP) was 10, 15 and 20 psi respectively.

Physicochemical analysis of juice

Enzymatically treated, centrifuged jamun juice, filtrate collected from microfiltration and ultrafiltration unit were analysed for different physicochemical analysis. Various parameters such as pH, TSS, turbidity, colour difference, protein content, polyphenol content, clarity and microbiological analysis had been experimented and analysed.

pH, TSS and turbidity

The pH (hydrogen ion concentration) was estimated with the help of a Elico pH meter. Abbe-type digital Refractometer was used for total soluble sugar (TSS) and results were expressed in degree Brix (°B). Turbidity [Nephelometric Turbidity Units (NTU)] was measured by Digital Turbidity-meter (Model 335, Deluxe Company, India) (Sin et al. 2006).

Colour analysis

In order to get the accurate color and quantify the variation of color pigments in different samples, Hunter colorimeter (Colorflex EZ, USA) was used. The instrument was standardized during each sample measurement with a black and a white tile and the color values were represented in form of brightness/darkness (L*), redness/greenness (a*) and yellowness/blueness (b*). Change in color (ΔE) with respect to raw juice was also evaluated using the following equation (Fernández-vázquez et al. 2011)

Protein and phenol content

Spectrophotometric method was used for both protein and polyphenol concentration. Protein concentration was determined with Bovine serum albumin (BSA) as standard, according to the dye binding method and phenol concentration was measured at 650 nm by Folin–Ciocalteu method with Gallic acid standard (Ghosh et al. 2016a).

Juice clarity

Clarity of the juices were evaluated by transmittance (%T) at 660 nm utilizing the UV–VIS spectrophotometer (Model: AU 2701, Systronics India Ltd) as described by Ghosh et al. (2016a).

Browning index

Browning index was estimated by UV–VIS Double Beam Spectrophotometer (Systronics India Limited, India). The absorbance of sample was measured at 430 nm and 520 nm wavelength and ratio of the results were expressed as browning index value (Vegara et al. 2013).

Antioxidants activity (DPPH)

Antioxidant activity of the juice sample was determined as the free radical scavenging activity against DPPH (2,2-diphenyl-1-picrylhydrazyl) by the method described by Bermúdez-Soto and Tomás-Barberán (2004). The result was expressed as percentage reduction in the DPPH· radicals.

where X absorbance of sample and Y absorbance of the blank sample.

Microbiological analysis

The juice sample was taken from the filtration unit to the laminar flow chamber directly through a sterilized pipe without any contact with the outside environment.

In order to determine bacterial count and yeast and molds count the method described by Cruz-Cansino et al. (2015) was used. For total aerobic plate count (TAPC), the samples were incubated 30 °C for 48 h and for yeasts and molds, it was incubated at 25 °C for 72 h. Finally, the colonies were enumerated manually and results were expressed as the logarithm of colony forming units (cfu) per mL of juice.

Storage study

The main objective behind the study was to see the effect of storage on various physiochemical properties of clarified jamun juice so as to produce a long shelf-life product retaining all its qualities. The clarified juices were stored under refrigeration temperature (4 °C) for 8 weeks without any additive or preservative. All the experiments were conducted in controlled environment without any kind of contamination. Samples were collected in sterilized bottles. Before any microbiological analysis, the laminar flow chamber was cleaned with ethanol and UV lamp was switched on with door closed.

Sensory evaluation

Sensory evaluation of various clarified jamun juices was done by a panel of 20 judges and the scoring was done on 9-point Hedonic scale (Ranganna 2005). Various attributes such as physical appearance, texture, aroma, flavour, color, and overall acceptability were tested on day 0 and day 60. The analyses were done in a room equipped with proper light and mean scores were calculated for each juice. The samples were served in identical glasses with an exact amount (50 ml) with proper coding.

Statistical analysis

All results obtained were expressed as mean ± SD of three independent evaluations and were subjected to statistical analysis using SPSS Statistics 20 (SPSS, Inc., Chicago). The means were compared by using Turkeys test and ANOVA. Significance level was settled as p < 0.05 for all the differences.

Results and discussions

Optimization of operating conditions for ultrafiltration

Throughout the ultra-filtration process, temperature (30 °C) and flow rate (10 L/h) of the jamun juice was constant. Changes of permeate flux with time at three different membrane pore was mentioned in Fig. 2. With the increase in pressure permeate flux decreases and with increase in the pore size permeate flux increases but at highest membrane pore size (100 kDa) flux declined observed. In case of membrane pore size of 50 kDa, permeate flux was highest. There is a significant difference (p < 0.01) observed in the permeate flux with change in pressure and pore size. At this pore size uniformity of flux has been observed at 10 psi. In every case at highest pressure level sudden change of decrease in permeate flux observed due to deposition of the macromolecule in the membrane (Sagu et al. 2014a; Cassano et al. 2010). Steady state flow rate was observed after 20 min in case of 10 psi pressure. These trends can be explained due to the solid particle deposition at the beginning in the membrane module. The rapid declination of the flux after a certain time was due to the pore blocking of membranes and fouling. But according to the processing time 50 kDa pore size takes less time with a higher permeate flux (105 l/h2 m to 61 l/h2 m) rather than the other two. So according to the operating conditions the best result was obtained at 50 kDa pore size membrane module.

The physicochemical, nutritional properties were analysed for all the juices (filtrate) as well as retentate obtained from each treatment (Table 1). From the table it can be observed that pH of the filtrate as well as retentate varies within the range of 3.5–3.7. Significant differences observed with the change in the pore size of the membrane but no change observed when pressure changes. Optimum pH was recorded at 50 kDa pore size membrane with 15 psi pressure as the microfiltered juice was having pH of 3.61. In case of TSS and turbidity significant differences (p < 0.05) observed for changes both membrane pore size and pressure. Maximum TSS and minimum turbidity is necessary for the clarified juice. 50 kDa pore size membrane with a pressure of 20 psi gives the maximum TSS of 16.06°B with a minimum turbidity of 0.03NTU. Opposite results have been enlisted for the retentate section as sugars and fibrous material (macromolecule particles) has its own tendency of deposition due to the membrane barrier. For colour values dark pigments were present in the retentate and the light particle passes through. There is no significant change with change of membrane pore size but with the change in pressure colour changes occurs. Original purple colour of the juice turns to pink colour after clarification process. Lightness (L value) and blueness (b* value) decreased which is responsible for the new colour. In case of nutritional parameters (protein and polyphenols) significant changes observed with change in membrane size and pressure. The lower the pore size and pressure the accumulation of protein and polyphenol in filtrate was low. The highest amount of retention was enlisted in 100 kDa pore size with 20 psi pressure. Finally overall clarity of the juice was not having a significant difference with the applied pressure. The maximum the clarity the acceptance of the juice was more to the customer. The result shows that maximum clarity was obtained by 50 kDa pore size membrane with 20 psi pressure. From the above discussion it can be concluded that ultrafiltered juice pass through 50 kDa membrane pore size and with a pressure of 20 psi gives the best result.

Storage study

The clarified juices obtained by different methods were evaluated for various physical and microbial parameters and the variation of these parameters with storage period is listed in Table 2.

Changes in pH and TSS

pH is an important parameter for storage of juice as high variation in its values can lead to deterioration of the quality of juice. pH of various juices were found to be in range of 3.446–3.760. Significant changes observed (p < 0.05) with different method 0 of clarification but with the changes in storage period pH changed very slightly. In case of micro filter (MF) treated jamun juice with increase in storage time initially the pH increases and then it decreases. Campos et al. (2002) also found similar variation for pH of microfiltered cashew apple juice.

Different clarification treatments led to a decrease in the initial TSS value of the juice with maximum decrease for ultrafiltration, followed by microfiltration and centrifugation. Overall there is a decreasing trend observed with the increase in the storage period. But the rate of change in TSS value is less in ultrafiltered juice rather than the other ones which make ultra-filter (UF) treated juice more stable for a longer period. Storage study of Arenga pinnata juice also resulted in decreasing trend of TSS value with storage period (Ain et al. 2014).

Changes in browning index and clarity

It is an indicator of the browning of various sugars present in the juice sample (Buera et al. 1986). Browning can also possible due to the oxidation phenomena. All the juices were found to have low values initially with lowest value for enzyme treated juice and highest value for ultrafiltered juice. The values were found to increase with storage time for all types of juice. Therefore, with increase in storage time, browning reaction progresses and the browning index of juice increases. At day 0, the values differed greatly with the process but at day 60, the values did not differed much. The rate of browning indicated less stability of all types of juice. The values were found to be significantly different (p < 0.05) along the storage period for all types of juice. Various treatment gave juices with significantly dissimilar values (p < 0.05) at each day. Browning index of MF-clarified pineapple stored at 4 °C was also found to increase with increase in storage period (Laorko et al. 2013).

Initially clarity of enzyme treated juice was found to be lowest (77.933 ± 0.058%) and that of ultrafiltered juice was found to be highest (96.600 ± 0.001%). The juices clarified by microfiltration and ultrafiltration were found to be almost clear (clarity > 90%) in appearance initially. Clarity of all the juices was found to decrease greatly with storage time which can be attributed to various biochemical reactions occurring in them. At day 60, clarity values were found to be low for centrifuged juice (0.983%) and enzyme treated juice (4.000%); microfiltered juice had moderate clarity (29.113%) where ultrafiltered juice possess maximum clarity (50.660%) indicating that the latter juices are quite stable in comparison to the former juices. Storage study of ultrafiltered mosambi juice also exhibited decreasing trend of clarity with storage (Rai et al. 2008).

Microbiological study

TPC

Total plate count was done in order to check the spoilage of juice by various kinds of bacteria present in it. The initial microbial load of enzyme treated and centrifuged juice were found to be 35 × 103 and 21 × 102 log CFU/ml respectively and the final load (at day 30) were 75 × 104 and 53 × 104 log CFU/ml respectively. The microfiltered and ultrafiltered juice were found to have negligible bacterial count from initial day to the final day of storage. As per the rate of bacterial growth, it can be noted that centrifuged juice acts as a better substrate than enzyme treated juice for growth of bacteria.

Yeast and mold count

During ultrafiltration process, the yeast and mold cannot pass through the membrane, so their count was nil for ultrafiltered juice (till day 60). However, enzyme treated juice was found to have highest count at all the times followed by centrifuged juice. The juices were considered spoiled when the values were of the order of 106 log CFU/ml. So evaluation was not done for enzyme treated juice and centrifuged juice after day 15 and 30 respectively. The count was very less for microfiltered juice and it increased from 3 log CFU/ml at day 1 to 29 log CFU/ml at day 60. The values increased with increase in storage period for all the juices. Salomão et al. (2014) also found yeast and mold count of untreated apple juice to be of the order of 105 log CFU/ml and the value decreased with enzymatic treatment and ultrafiltration.

Changes in various chemical parameters

Protein

Initially, the protein content of enzyme treated juice was highest followed by microfiltered, ultrafiltered and centrifuged juice and the result is justified by the fact that during the clarification process, some of the macromolecules are retained in the filter pores (Fig. 3a). The degradation was fastest in enzyme treated juice (decreasing to < 10% of the original value in 60 days) indicating its fast degradation. The centrifuged juice also showed decreasing trend for protein content and was found to have minimum values at all the times (44.61–9.16 mg/g). This indicates that either most of the proteins were removed or were being denatured during centrifugation process. Initially, the microfiltered and ultrafiltered juice exhibited an increasing and then decreasing trend of protein content with storage period. All the values were found to be statistically different (p < 0.05) both along storage period as well as with different processes. Mondal et al. (2016) found that the initial protein content of ultrafiltered, microfiltered and enzyme treated bottle gourd juice were in increasing order and the protein content of ultrafiltered juice increased with the storage period.

Polyphenols

Jamun juice obtained by different processes gave varying trends of polyphenols with storage time (Fig. 3b). Generally phenolic compounds are reactive in nature and are easily converted into procyanadins by the action of phenol oxidases. Initially enzyme treated juice was found to have highest polyphenolic content (302 mg GAE/g of juice) followed by microfiltered, ultrafiltered and centrifuged juice. The polyphenolic content of microfiltered and ultrafiltered juice showed a decreasing trend initially and then became almost constant after 30 days of storage. This trend was similar to that of MF-clarified pineapple stored at 4 °C (Laorko et al. 2013). For centrifuged juice, the value increased initially upto 30 days and then decreased. Cruz-Cansino et al. (2015) also found increasing trend of total phenolic compounds in purple cactus pear juice during storage. At each day, the values were found to be statistically different except at day 30 when all the juices except the enzyme treated juice had similar values (p < 0.05). Singh et al. (2015) had also observed initial polphenol content of jamun pulp 421.2 μg GAE/g.

DPPH

For all type of juices the amount of antioxidants decreased as the storage time increased (Fig. 3c). The rate of degradation of antioxidants was found to be highest in enzyme treated juice and least in microfiltered juice. Similar results have been found for variation of antioxidant capacity of MF-clarified pineapple stored at different temperatures (Laorko et al. 2013) with storage time. Singh et al. (2016a) concluded that freeze dried jamun polyphenol extract was rich in antioxidant activities which can be useful for natural preservative. At day 15 and 60, various juices were found to have statistically different values (p < 0.05) whereas at other days, there were similarities in some of the values.

Changes in colour parameters

Color is a very important parameter for storage study of juice as it is the first attribute that judges its acceptability by the consumer. Color attributes of various types of clarified jamun juices are depicted in Fig. 4. For better acceptability, color deviation from the fresh juice should be minimal. At day 0, centrifuged juice was found to have minimum L* value indicating that it was of darkest color among all the juices (Fig. 4a). The values were found to increase with storage time for all the juices except for enzyme treated juice for which the value decreased initially and then started increasing. The increasing lightness of juice can be due to precipitation of some of the coloured suspended particles in the juice and the same is reflected in decreasing TSS values of the juice. Storage study of purple cactus pear juice also resulted in an increasing L* value of control juice with increase in storage period (Cruz-Cansino et al. 2015). Similar type of result was obtained by Singh et al. (2016b).

All the samples were found to have positive a* value throughout the storage life implying that they were red in color (Fig. 4b). At day 0, enzyme treated juice had maximum redness followed by ultrafiltered juice while other juices had similar values (p < 0.05). Centrifuged juice was found to have an increasing trend in a* value throughout the study while for other juices the value increased initially and then decreased. For microfiltered juice, the value did not increased significantly (p < 0.05) from 0 to 30 days while after that it increased rapidly. There was an overall increase in a* value for all the juices and similar results have been found by Cruz-Cansino et al. (2015).

All the juices were found to have positive b* value (Fig. 4c) at all days of storage except enzyme treated juice at day 0 for which the value was negative. Clarification of juice reduced its blue components greatly resulting in positive b* values. All the juices (except ultrafiltered one) were had an overall decrease trend. Various processes gave juices with significant values at day 0, 30 and 60 (p < 0.05). However Laorko et al. (2013) also found an overall increase in b* values during storage of clarified pineapple juice at 4 °C.

Change in color can be attributed to various physico-chemical reactions, enzymatic and non-enzymatic browning, microbial deterioration and several other factors. The variation was highest in case of enzyme treated and centrifuged juice (Fig. 4d) and is justified by the deterioration by microbes which were present in these juices. However, the variation was least in ultrafiltered juice in which microbial load was negligible and the change in color is a result of physico-chemical reactions only. Cruz-Cansino et al. (2015) also found similar trend for storage of pasteurised purple cactus pear juice.

Changes in sensory properties

From initial sensory evaluation of various clarified jamun juices, it was clear that centrifuged juice was of worst quality among all juices. Initially, the overall acceptability was higher for enzyme treated juice as its fresh in quality but the purchase intention was better for ultrafiltered juice because of its appearance and texture. At day 60, it was found that the values for various sensory properties were very less for enzyme treated juice whereas ultrafiltered juice maintains its quality (Table 3). However ultrafiltered juice still possessed the highest scores and can be considered best among all the juices.

Conclusion

Ultrafiltration was used for juice clarification process and comparison of storage study has been observed. Optimization of the process parameters and physicochemical properties for ultrafiltration method had been analysed. 50 kDa membrane pore size with a pressure of 20 psi gives the best result for clarification. Storage study of various clarified jamun juices was done to find the variation in their properties with storage period. The enzyme treated juice and centrifuged juice degraded within a month period due to the presence of microbial loads. Ultrafiltered juice has least change in colour (∆E value) and had maximum clarity even at day 60 of experimentation. The stability of the juice was due to proper filtration and no microbial growth. The rate of degradation of various nutritional parameters (protein, polyphenols and antioxidants) was found to be quite less in microfiltered and ultrafiltered juice and their total aerobic plate count were found to be zero. However, microfiltered juice was found to have small amount of yeasts and moulds which can degrade its quality. Therefore it can be concluded that the ultrafiltration can be considered as the best method for clarification jamun juice having a prolong shelf life with optimum qualities. So further research could be done on packaging and storage of the ultrafiltered jamun juice with the help of different type of packaging material and environment. Value addition of the concentrated jamun juice can also be aimed for further study.

References

Ain MF, Yusof YA, Chin NL, Dom ZM (2014) Storage study of Arenga pinnata juice. Agric Agric Sci Procedia 2:218–223

Bermúdez-Soto MJ, Tomás-Barberán FA (2004) Evaluation of commercial red fruit juice concentrates as ingredients for antioxidant functional juices. Eur Food Res Technol 219(2):133–141

Buera MD, Lozano RD, Petriella C (1986) Definition of colour in the non enzymatic browning process. Die Farbe 32(33):318–322

Campos DC, Santos AS, Wolkoff DB, Matta VM, Cabral LM, Couri S (2002) Cashew apple juice stabilization by microfiltration. Desalination 148(1–3):61–65

Cassano A, Conidi C, Drioli E (2010) Physico-chemical parameters of cactus pear (Opuntia ficus-indica) juice clarified by microfiltration and ultrafiltration processes. Desalination 250(3):1101–1104

Chhaya R, Majumdar GC, De S (2013) Primary clarification of Stevia extract: a comparison between centrifugation and microfiltration. Sep Sci Technol 48(1):113–121

Cortés C, Esteve MJ, Frígola A (2008) Color of orange juice treated by high intensity pulsed electric fields during refrigerated storage and comparison with pasteurized juice. Food Control 19(2):151–158

Cruz-Cansino N, Ramírez-Moreno E, León-Rivera JE, Delgado-Olivares L, Alanís-García E, Ariza-Ortega JA, de Jesús Manríquez-Torres J, Jaramillo-Bustos DP (2015) Shelf life, physicochemical, microbiological and antioxidant properties of purple cactus pear (Opuntia ficus indica) juice after thermoultrasound treatment. Ultrason Sonochem 27:277–286

Fernández-vázquez RO, Stinco CM, Meléndez-martínez AJ, Heredia FJ, Vicario IM (2011) Visual and instrumental evaluation of orange juice color: a consumers’ preference study. J Sens Stud 26(6):436–444

Gahlawat V, Rambir A, Garg A (2014) Consumer behaviour for fruit juices market in India. Int Res J Commer Arts Sci 5(2):232–237

Ghosh P, Pradhan RC, Mishra S (2016a) Low-temperature extraction of jamun juice (Indian Black Berry) and optimization of enzymatic clarification using Box–Behnken design. J Food Process Eng 40(2):e12414

Ghosh P, Pradhan RC, Mishra S (2016b) Optimization of process parameters for enhanced production of jamun juice using Pectinase (Aspergillus aculeatus) enzyme and its characterization. 3 Biotech 6(2):241

Ghosh P, Pradhan RC, Mishra S, Patel AS, Kar A (2017) Physicochemical and nutritional characterization of jamun (Syzygium cuminii). Curr Res Nutr Food Sci J 5(1):25–35

Laorko A, Tongchitpakdee S, Youravong W (2013) Storage quality of pineapple juice non-thermally pasteurized and clarified by microfiltration. J Food Eng 116(2):554–561

Mondal M, Biswas PP, De S (2016) Clarification and storage study of bottle gourd (Lagenaria siceraria) juice by hollow fiber ultrafiltration. Food Bioprod Process 100:1–5

Pinelo M, Zeuner B, Meyer AS (2010) Juice clarification by protease and pectinase treatments indicates new roles of pectin and protein in cherry juice turbidity. Food Bioprod Process 88(2–3):259–265

Rai P, Rai C, Majumdar GC, DasGupta S, De S (2006) Resistance in series model for ultrafiltration of mosambi (Citrus sinensis (L.) Osbeck) juice in a stirred continuous mode. J Membr Sci 283(1–2):116–122

Rai P, Rai C, Majumdar GC, Dasgupta S, De S (2008) Storage study of ultrafiltered mosambi (Citrus sinensis (L.) Osbeck) juice. J food Process Preserv 32(6):923–934

Ranganna S (2005) Handbook of analysis and quality control for fruit and vegetable products. Tata McGraw-Hill Education, New Delhi

Sagu ST, Karmakar S, Nso EJ, De S (2014a) Primary clarification of banana juice extract by centrifugation and microfiltration. Sep Sci Technol 49(8):1156–1169

Sagu ST, Nso EJ, Karmakar S, De S (2014b) Optimisation of low temperature extraction of banana juice using commercial pectinase. Food Chem 151:182–190

Salomão BD, Muller C, Amparo HC, Aragão GM (2014) Survey of molds, yeast and Alicyclobacillus spp. from a concentrated apple juice productive process. Bra J Microbiol 45(1):49–58

Sehwag S, Das M (2015) Nutritive, therapeutic and processing aspects of jamun, Syzygium cuminii (L.) Skeels: an overview. Indian J Nat Prod Resour 5(4):295–307

Shahnawaz M, Sheikh SA (2011) Physicochemical characteristics of jamun fruit. J Hortic For 3(10):301–306

Sin HN, Yusof S, Hamid NS, Rahman RA (2006) Optimization of enzymatic clarification of sapodilla juice using response surface methodology. J Food Eng 73(4):313–319

Singh JP, Kaur A, Shevkani K, Singh N (2015) Influence of jambolan (Syzygium cumini) and xanthan gum incorporation on the physicochemical, antioxidant and sensory properties of gluten-free eggless rice muffins. Int J Food Sci Technol 50(5):1190–1197

Singh JP, Kaur A, Singh N, Nim L, Shevkani K, Kaur H, Arora DS (2016a) In vitro antioxidant and antimicrobial properties of jambolan (Syzygium cumini) fruit polyphenols. LWT Food Sci Technol 65:1025–1030

Singh JP, Kaur A, Shevkani K, Singh N (2016b) Composition, bioactive compounds and antioxidant activity of common Indian fruits and vegetables. J Food Sci Technol 53(11):4056–4066

Vegara S, Martí N, Mena P, Saura D, Valero M (2013) Effect of pasteurization process and storage on color and shelf-life of pomegranate juices. LWT Food Sci Technol 54(2):592–596

Yang H, Xue L, Fan D, Sun T, Deng J (2015) Effects of enzymolysis, ultrafiltration and diatomaceous earth filtration on clarification of red dates (Ziziphus jujuba Mill.) juice. Asia Life Sci 24(1):427–434

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

It is hereby declared that all of the authors have read and approved the manuscript and there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ghosh, P., Garg, S., Mohanty, I. et al. Comparison and storage study of ultra-filtered clarified jamun (Syzygium cumini) juice. J Food Sci Technol 56, 1877–1889 (2019). https://doi.org/10.1007/s13197-019-03648-2

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-019-03648-2