Abstract

Liophilized açaí pulp (LAP), which is considered a power food, could enrich broken rice grains flours (BRG), which is an abundant by-product in many countries. The extrusion could change the physico-chemical properties of this mixture, which later could be applied in the development of instant food products, as an appeal regarding the appearance, nutritional value and the presence of bioactive compounds. This study examined the effect of LAP incorporation (0, 5, 10, 15, and 20%) on the physical, chemical, and functional properties of BRG pregelatinized flours at mild extrusion conditions. Extrusion significantly changed the solubility and absorption of water, the thermal and pasting properties of pregelatinized flours. DSC analysis did not show gelatinization peaks after extrusion, indicating a total gelatinization of the starch. Extrusion also affected the color and chemical composition, and to a greater extent, the anthocyanin content, the phenolic compounds and the antioxidant capacity, despite the mild process conditions. The mixture with 10% LAP resulted in a product with a reddish color, rich in fiber and presented lower loss of anthocyanin (27.16%), therefore, the most suitable to be used as an ingredient in the preparation of ready-to-eat foods with higher functional value.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Broken rice is a by-product of the rice industry produced during normal grain polishing. This residue is rich in starch, and its reuse in the industry is of quite interest, since it can be employed as an ingredient in various food products.

Increased use of broken rice grains (BRG) would depend on the development or application of adequate technologies to produce meal or flour with acceptable functional properties. Among the various ingredient choices, mixed flours and pregelatinized mixtures have become quite timely and cost-effective. Once incorporated into other foods, they turn them into instant or semi-ready foods with specific functional properties, in addition to maintaining their high nutritional value (Saleh and Meullenet 2013).

The physical, chemical, and functional characteristics of coarse cereals or staple grain flours can be physically modified through a range of treatments such as fine grinding, dry and wet thermal treatments. The flours obtained may differ in their water absorption capacity, thickening power, emulsifying properties, pasting properties and chemical reactivity with enzymes (Gómez and Martínez 2016; Sun et al. 2018).

Flour pregelatinization can be done through thermoplastic extrusion, a processing technique that employs high temperature and short time, and gives products that are differentiated by their chemical, structural and sensory characteristics. In addition, a flour or mixture obtained by extrusion show greater solubility and viscosity in cold water and can be used as instant, fast and practical food ingredient, also in combination with fruit flours, since traditional extruded foods are considered energetic (Cruz et al. 2015; Jozinović et al. 2016), with limited nutritional quality due to their low amounts of other nutrients and bioactive compounds.

Pregelatinized rice extrudates are poor in fiber, phenolic compounds, antioxidants and proteins, although they are good sources of energy. Thus, there is a need to incorporate new sources of these nutrients, which can enrich the extruded flours. Several studies have been successful with the use of extruded rice flour combined with other raw material for nutrients incorporation in food products. Phillipp et al. (2017) elaborated rice flour extrudates enriched with pea protein in order to add the missing amino acids in the cereals, and obtained extrudates with high protein content. Kumar et al. (2018) fortified extrudates based on corn and rice flour with quitozana and obtained fiber-rich products. Bassinello et al. (2011) obtained cookies rich in protein and fiber by adding by-products from the rice and beans industry.

Açaí is a fruit from Amazon, and its pulp is considered to be a source of fiber, lipid, bioactive compounds, minerals, and protein (Rufino et al. 2011), and may be a potential ingredient in the incorporation of nutrients into pregelatinized flours. However, there are concerns about preserving the nutrients present in açaí pulp that can be lost during extrusion, such as phenolic compounds, antioxidants and anthocyanins. Therefore, this work aimed to study the effect of incorporation of five levels (0, 5, 10, 15, and 20%) of LAP at mild extrusion conditions on the physical, chemical, and functional properties of BRG pregelatinized flours.

Materials and methods

Materials

BRG and LAP were used as raw materials in the formulation of the flour blends. BRG were kindly provided by Cristal Alimentos, a national rice processing company located in Aparecida de Goiânia (Goiás, Brazil). Frozen açaí pulp was procured from a local market in Maioba (Maranhão, Brazil). All chemical were purchased from Sigma-Aldrich Company Ltd. (St Louis, MO, USA).

Preparation of raw materials

The thick structure of BRG resembles that of corn grits, a material traditionally used in the manufacturing of extruded products, and it was used as received. Açaí pulp, after thawing at 5 °C for 12 h, was placed on the stainless steel trays of the lyophilizer (LIOTOP, L101, São Carlos, Brazil), and frozen in an ultrafreezer (ColdLab, CL347-80, Piracicaba, Brazil) to − 40 °C. Then, the trays containing the frozen açaí pulp were transferred to the lyophilizer, and the vacuum was activated so that some of the free water of the pulp could be sublimated. The process took approximately 72 h at 138 mmHg, and the condenser temperature was at − 51 °C. LAP was further ground in an industrial blender (Vitalex, LQI-02, Catanduva, Brazil) to pass all through a 0.842 mm (20 mesh) sieve to improve homogeneity, and packed in low density polyethylene bags, metallized with aluminum, in order to avoid the passage of light, and stored at − 18 °C. LAP was then incorporated into BRG at levels of 0, 5, 10, 15, and 20% and mixed thoroughly to get homogenous blends for extrusion.

Pregelatinization

Prior to extrusion, distilled water was added to the experimental mixtures by means of a pipette to achieve a final moisture of 12.5%. In order to obtain the pregelatinized flours, the materials were processed in a single-screw extruder (Imbramaq, PQ 30, Ribeirão Preto, Brazil), with three barrel constant heating zones (41, 61 and 84 °C), helical grooved extrusion sleeve, and 4 mm matrix diameter. After extrusion, the extrudates were dried at 100 °C in a forced air circulation oven for 20 min, and after cooling to room temperature, milled in a cyclone-type knife mill (TECNAL, TE-65I/2, Piracicaba, Brazil). The ground material was sieved (0.250 mm) and packed into low density polyethylene bags, sealed and stored in desiccators until the analyses were carried out.

Characterization analyses

The characterization analyses were carried out for both raw (before extrusion) and pregelatinized (after extrusion) materials.

Proximate composition

The moisture content was quantified by drying the samples overnight at 105 °C in an oven with air circulation to constant weight; ash by weighing the samples after incineration at 550 °C in a muffle furnace; nitrogen content by the micro-Kjeldahl method, with results multiplied by the factor 6.25 to estimate the crude protein content; and lipid by extraction with petroleum ether P.A. in a Soxhlet apparatus. To obtain the total dietary fiber, a defatted sample from the Soxhlet extraction was used, followed by an enzyme-gravimetric method. The carbohydrate content was calculated as the difference between 100 and the sum of the percentages of moisture, protein, lipid, fiber, and ash. The energy value (kcal) was estimated by multiplying the weight (g) of carbohydrates and protein by 4 and the weight (g) of lipid by 9. All analyses were performed on according to AOAC (2016).

Scanning electron microscopy (SEM)

After vacuum dehydration, a thin and homogeneous layer of each type of sample was placed on a double-sided adhesive carbon tape mounted on an aluminum stub, any unattached particles were removed, and this was sputter coated with approximately 10 nm gold (Kurt J. Lesker Co., model 108, Clairton, USA). The samples were observed in a scanning electron microscope (Jeol, JSM-6610, São Paulo, Brazil) at a voltage of 5 kV. The surface micrographs were taken in magnifications 1500× and 5000×.

Color parameters

Color parameters were determined using a colorimeter (Bankinh Meter Minolta, BC-10, Ramsey, USA). The color values were measured as Chroma (C*; color saturation) (Eq. 1) and Hue angle (H*) (Eq. 2), which were calculated from a * (− (green) to + (red)) and b * (− (blue) to + (yellow)) parameter readings. Samples were placed in clear Petri dishes for measurement.

Water solubility index (WSI), water absorption index (WAI) and oil absorption index (OAI)

The WAI and WSI were determined according to Anderson et al. (1970) who adapted the method described by Kite et al. (1957). WAI was calculated from Eq. 3, which represents the relation between the precipitate mass (PRE; g) and the sample mass (PA; g) (d.b.). WSI is the mass ratio of the dry residue from the supernatant (evaporation residue) (PRE; g) and the sample mass (PA; g) (d.b.) (Eq. 4). The OAI or fat absorption capacity was determined by using the procedure of Lin et al. (1974) with slight modifications by Boye et al. (2010). The oil was replaced by soybean oil to determine the OAI. After centrifugation, the liquid supernatant from each sample was discarded by allowing the tubes to be slightly inverted for 1 min. The OAI was obtained by the mass ratio of the centrifuged residue (weight of fat absorbed by sample) (CR; g) and the sample mass (PA; g) (d.b.) (Eq. 5).

Thermal properties

Chemical and structural changes, including starch gelatinization and starch–lipids complex formation, of the samples were determined with a differential scanning calorimeter (DSC) (TA Instruments, Q20, New Castle, UK). The analyses were adapted from the methodology described by Mayachiew et al. (2015). Samples of 2 mg (d.b.) were weighed into aluminum pans, suitable for DSC equipment. Distilled water (6 μL) was added and the samples were sealed in a specific press. Samples were held for 12 h at room temperature to standardize the water distribution and then heated from 35 to 100 °C at a rate of 10 °C/min in order to determine the onset temperature (Ton), peak temperature (Tpeak), final temperature (Tf), and transition enthalpy (ΔH), which are indicators of starch–lipid complex melting and starch gelatinization. These parameters were determined with the aid of the software TA Universal Analysis (TA Instruments, New Castle, UK).

Pasting properties

Pasting properties were determined using a Rapid Visco Analyzer (RVA) (Perten, RVA 4500, Huddinge, Sweden) by recording the viscosity profiles of suspensions. Samples of 3.5 g (d.b.) were directly weighed into an RVA canister, followed by the addition of distilled water (25 mL). The “Flour” programming was used according to methodology 162 proposed by the International Association for Cereal Science and Technology (ICC 1996) for raw mixtures for which the evaluated characteristics were pasting viscosity (PV), final viscosity (FV), breakdown (BV), and setback (RT), expressed in the unit of the apparatus, rapid visco units (RVU). For the pregelatinized flours, the “Extrusion 2” programming was used, where the evaluated characteristics were cold peak viscosity (IV), hot peak viscosity (PV), final viscosity (FV), breakdown (BV), and setback (RT), expressed in rapid visco units (RVU).

Bioactive compounds

The analyses were carried out for both raw materials (before extrusion) and pregelatinized product.

Antioxidant and phenolic compounds extracts

In order to perform the analyses, extracts of each sample were prepared following the procedures proposed by Larrauri et al. (1997). Briefly, 40 mL of methanol (50%) was added to 1.5 g of dry sample. The solution remained at room temperature in the dark for 1 h and then centrifuged (15,000 rpm/15 min); the supernatant was filtered, and to the remaining solute in the centrifuge tube was added another 40 mL of acetone (70%), and the previous steps were repeated. After filtration, this supernatant was added to the methanolic extract (previously prepared), and the volume was made up to 100 mL with distilled water.

DPPH radical scavenging capacity

The DPPH (2,2-difenil-1-picril hidrazil) free radical-scavenging capacity was estimated using the method of Blois (1958), later modified by Brand-Williams et al. (1995). An aliquot of 3.9 mL of the solution of ·DPPH (60 μM) in methanol was added to 0.1 mL of the extract. The extracts were allowed to react with DPPH radical solution for 1 h in the dark (time required to reach the steady state). The absorbance of the reaction mixture was measured at 515 nm. A calibration curve was prepared (0–60 μM DPPH 60 μM) using methanol as the solvent. The results are expressed as the radical scavenging capacity of the samples (%).

Total phenolic compounds (TPC)

The phenolic content was determined according to the Folin–Ciocalteu method (Waterhouse 2002). The results are expressed as mg of gallic acid equivalent (GAE) per 100 g of dry sample.

Monomeric anthocyanins

The content of total monomeric anthocyanins was determined by the differential pH method using two buffer systems: potassium chloride–hydrochloric acid pH 1.0 (0.025 M) and sodium acetate pH 4.5 (0.4 M) at wavelengths 510 and 700 nm (Wrolstad et al. 2005). The results are expressed as mg of cyanidin 3-glucoside per 100 g of dry sample.

Design of experiments and statistical analysis

A completely randomized design was applied in the experiments, where five treatments (BRG:LAP; 100:0, 95:5, 90:10, 85:15, and 80:20) with four original replicates were carried out. All the analyses were performed at least in triplicate. Regression was used to estimate the model parameters based on the data. Data obtained on the physical, chemical, and functional properties, including thermal and pasting properties analyses were studied using one-way analysis of variance (Anova), and are expressed as mean ± standard deviation. Tukey’s multiple range test was conducted to assess significant differences between means (p < 0.05). All statistical analyses were conducted using the Statistica software (STATISTICA 2007).

Results and discussion

Chemical composition

By comparing the chemical composition of the two products under study (raw mix and extruded blends), it could be stated that only the ash content was not modified by extrusion (Table 1), which was favored by the gradual addition of LAP (Table 1). Moisture, protein, lipid, total dietary fiber, carbohydrate, energetic value, total phenolic compounds, antioxidant capacity, and anthocyanins contents showed significant changes (p < 0.05) with the incorporation of LAP before and after extrusion. All regression models were significant, and approximately 88–99% of the responses were explained by them (Tables 1, 2).

There was a significant decrease (p < 0.01) in the moisture content with the incorporation of LAP, and further decrease after extrusion (Table 1). The moisture loss after the extrusion was expected (average of 59.24%) due to the vaporization of water at the matrix outlet, with consequent expansion promoted by the temperature and pressure gradient. This moisture loss from extrusion can vary depending on the temperature of the last heating zone and the geometry of the matrix (Limberger et al. 2009).

On increasing the substitution level of BRG by LAP there was no significant difference in protein content between the raw and extruded flours. However, extrusion significantly (p < 0.05) differentiated the flours with 0% and 15% LAP, with an increase in protein content after extrusion (Tables 1, 2). The substitution of BRG by LAP in the raw flour increased the lipid content, but there was a decrease of this component in the mixture by extrusion (Tables 1, 2). The literature reports that this phenomenon may be due to interactions of the mixture components during extrusion, such as lipid and protein forming complexes, which makes it difficult to detect them by traditional analytical methods (Makkar et al. 2008). The method used to determine lipid, based on solvent extraction, is not able to undo these complexes, underestimating components after extrusion (Dors et al. 2006).

The gradual replacement of BRG by LAP in the raw flour significantly increased (p < 0.05) total dietary fiber in both raw and extruded mixtures (Tables 1, 2). Extrusion affected this component by significantly decreasing it in all cases. Honců et al. (2016) evaluated the effects of extrusion on the content and properties of food fiber components in various barley cultivars, and also observed a decrease in total dietary fiber content after the thermoplastic extrusion process, which may be due to solubilization of the fibers. Sobota et al. (2010) also reported a decrease in total dietary fiber in extruded corn and wheat mixed flours. Stojceska et al. (2010) stated that this change by extrusion is due to structural modifications in food materials, disrupting the structure and interfering with determination of dietary fiber in extruded vegetables. Concerning the content of fibers, all flour blends in this study were rich in fiber, which is an important nutrient in human nutrition due to its benefits related to coronary diseases prevention, hypertension, obesity, diabetes, and colon cancer (Burkitt 1973).

The carbohydrate content decreased significantly (p < 0.05) with the substitution of BRG by LAP in the raw and extruded flours (Tables 1, 2). However, there was a significant (p < 0.05) increase in carbohydrates content in the pregelatinized flours compared to the raw flour. This trend could be due to the fact that the other components analyzed were lost on extrusion, resulting in a higher carbohydrate concentration. The replacement of BRG by LAP significantly increased the total energy value (Tables 1, 2), which was reduced by extrusion; this may be due to the fact that the components responsible for it (lipid and protein) showed a substantial decrease from extrusion.

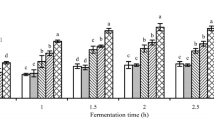

The Anova showed that the model for total phenolic compounds was significant (p < 0.05) with the substitution of BRG for LAP in both raw and extruded flours. The coefficient of determination (R2) varied from 98 to 99% for TPC and antioxidants before and after extrusion (Table 2), indicating a good fit of the models to the data. The Anova was significant for anthocyanins, but there was no significant regression in any statistical model. The substitution of BRG by LAP increased TPC content in the mixture (Table 1). However, after the mixture went through extrusion these concentrations dropped significantly (p < 0.05). The antioxidant activity and anthocyanins content, also declined with processing (Tables 1, 2). The decrease in these components can be explained by the fact that they are extremely sensitive to high temperatures, which damage their structure compromising their functionality. Roy et al. (2007) reported that this decrease is expected when temperatures above 50 °C are used, causing negative effects on TPC content and antioxidant activity.

White et al. (2010) studied the changes in bioactive compounds in cranberry bagasse mixed with corn starch in different proportions (30:70, 40:60, and 50:50) after extrusion, and reported that the temperature of the extrusion jacket and the bagasse levels were the factors that most affected the amount of total anthocyanins and antioxidant activity. The same authors also stated that there were lower losses of anthocyanins with high fractions of corn starch, suggesting that the starch served as a barrier preserving the anthocyanins, but the mechanism has not yet been clarified. The same behavior could be observed in the present study, as 10% replacement of BRG by LAP resulted in a lower loss (27.16%), while 15 and 20% replacements resulted in greater anthocyanin losses from extrusion (58.71 and 48.24%, respectively).

WSI, WAI, and OAI

The models for WSI and WAI were significant, both before and after extrusion (p < 0.01). However, it was not possible to obtain a significant model (p > 0.05) to represent OAI data prior to extrusion, only after the process. The WAI results for the crude mixtures showed difference (p < 0.05) only for 20% LAP before extrusion (Tables 2, 3). After extrusion, there was a significant difference only between 0 and 5% LAP; there was no significant difference for the remaining treatments. However, extrusion increased the WAI in all cases (p < 0.05) (Tables 2, 3). This trend is rather common for pregelatinizing starch that increased the water absorption potential (Tacer-Caba et al. 2014). This increase may be explained by the possible loss of crystallinity of the starch by gelatinization during extrusion, with the release of hydroxyls available to form hydrogen bonds with water (Clerici and El-Dash 2008).

In addition, the extrusion process can alter the conformation of the proteins present in the flours allowing the availability of sites for interaction with water molecules (Fernandes et al. 2003). An elevated WAI indicates larger starch fragments (Van Den Einde et al. 2003), which, on the other hand, was not observed by Singh et al. (2016), WHO studied the effect of beetroot powder (BRP) (5, 10 and 15%) incorporation at different extrusion temperatures (125, 150 and 175 °C) on the properties of corn grits extrudates. These authors reported that there was a reduction in the WAI with BRP incorporation which could be attributed to the fact that there was a reduction in the starch content. Moreover, higher amounts of BRP had high amounts of sugar which increased the pasting temperature, limiting the starch gelatinization and leading to the interaction between starch and sucrose. A high WAI, as observed in this study, is a very important property for application in meat products, bread, and cakes, as they help to maintain their moisture, avoiding dryness during storage (Carvalho et al. 2012).

Concerning the WSI, there was also a significant increase of this parameter by extrusion (Tables 2, 3). The temperature used in the extrusion may have degraded the starch present in the BRG flour, turning it into smaller molecules that are more water soluble (dextrins) (Singh et al. 2016).

Flours with high WAI and WSI, such as the pregelatinized ones obtained in the present study, are interesting for the fast and practical food processing industry, due to their pasting formation at room temperature, being ideal for use as ingredients in instant noodles and dessert, bread, among others (Vernaza and Chang 2012).

Regarding the WSI, there was no significant difference (p > 0.05) between the treatments before extrusion. After extrusion, there was a significant difference only in the treatment with 20% LAP with an increase of 45.87% in the WAI (Table 3). This increase may be due to the fact that after extrusion the treatment with 20% LAP had a large amount of lipid (Table 1) with apolar sites in their structure that can trap oil (Zheng et al. 2008).

Color parameters

The addition of LAP and the thermoplastic extrusion process were noteworthy to C* and H* parameters behavior. The incorporation of LAP notably darkened both raw and pregelatinized flours, with a significant difference (p < 0.05) between the treatments (Tables 2, 4). This is probably due to the browning reactions (Singh et al. 2016). Similar findings were observed by Singh et al. (2016), who studied the incorporation of BRP into corn grits extrudates. The color intensity (C*) and the hue (H*) of the raw flours slightly increased with the substitution of BRG by LAP, while there was a reduction in the pregelatinized flours with gradual increase of LAP incorporation. After extrusion, all treatments presented higher values of C* and H* when compared to the raw flours (Tables 2, 4).

BRG alone had the H* parameter indicating yellow, but this reduced with added LAP, indicating red. The pregelatinized flours had significantly reduced (p < 0.05) C* in all cases, with lower color intensities. The H* of the raw flours was significantly increased (p < 0.05) by extrusion, possibly indicating partial degradation of anthocyanins, responsible for the red color of the mixture, presenting orange–brown hue.

Thermal and pasting properties

Thermal properties of raw mixtures (Table 5; Supplementary Fig. 1) indicate that the addition of LAP did not influence Ton, Tpeak and Tf (p > 0.05). However, there was a significant difference among the ∆Hgel of the flours with 0%, 5%, and 20% that could be explained by the interference of the non-starchy components in the mixtures. The extruded flours did not show an endothermic gelatinization peak and ΔHgel, suggesting that all the starch present in the raw samples was gelatinized with loss of their molecular order after the extrusion process (Cooke and Gidley 1992). The same happened with mixed pregelatinized soybean meal, starch, and cassava flours studied by Trombini and Leonel (2010).

Table 5 indicates the changes in the pasting viscosity behavior of the raw and pregelatinized flours. The viscosity curves showed a typical behavior of flours during heating, allowing the evaluation of the characteristics of the pulp formed, due to the structural modifications of the starch molecules, despite other components present in the raw and extruded mixtures. The initial cold viscosities of the raw flours, indicating the ability of the flours to absorb water at room temperature, and to form paste, gel or viscous liquid, were lower than those of the extruded flours (Table 5) at all levels of LAP incorporation, reflecting the extension of the molecules rupture during extrusion in regards to the increase of moisture absorption and starch gelatinization.

The starch in the raw flours was largely in crystalline form and could not absorb water easily, unlike the extruded flours that were pregelatinized, resulting in the structural modification of the starch facilitating the connection of their molecules with water (Lobo and Silva 2003).

Regarding the warm pasting viscosity, only 0% BRG had a higher peak before extrusion. The other cases had higher PV after extrusion. However, there was gradual reduction of PV with LAP incorporation, which could be attributed to the higher content of sugar limiting the starch gelatinization (Singh et al. 2016).

The extrusion significantly decreased (p < 0.05) (Table 5) initial and pasting viscosities by substitution level, indicating that the LAP substitution reduced the intermolecular forces responsible by this property; this could be related to the protein in the LAP. According to El-Saied et al. (1979) and Batista et al. (2008), protein content of a raw material is negatively correlated with the maximum viscosity, since it acts as a physical barrier to the swelling of the starch granules, that are easily coupled in the protein matrix. As it can be seen on Table 5, there was a decrease in the maximum pasting viscosity with the LAP added in the raw and extruded flours.

The breaking viscosity, which configures the resistance to shear strength and temperatures, decreased with increased LAP incorporation (Table 5), probably due to the leaching of less amylose in the presence of high levels of fibers in the LAP that may have restricted granular swelling and disintegration (Singh et al. 2015). There was a significant increase in BV after the extrusion process.

Menegassi et al. (2007) observed the same difference in the breaking viscosity after the extrusion of Arracacia xanthorrhiza. According to the same authors, high breaking viscosity after extrusion indicates that the process was not aggressive enough to degrade the polymers, to partially disrupt molecular structures and to reduce their recrystallization capacity.

The final viscosity reflected the pasting behavior after cooling. The final viscosity of the raw blends decreased with increasing LAP addition, the possible reason may be the same as for BV. The final viscosity reflected the pasting behavior after cooling. The final viscosities of the crude blends were significantly higher when compared to the extruded blends, except for 20% LAP treatment, which did not differ. The high final viscosity of the raw flours indicates the presence of intact starch granules, with low resistance to high temperatures. The opposite occurred with the extruded flours, indicating that most of the starch present in the raw flours had been degraded, resulting in lower final viscosity. Regarding the retrogradation, pasting property that reflects the replacement of amylose molecules that were leached from the swollen starch granules during the cooling, the substitution of BRG by LAP promoted the lowering of this property of the raw flours, while it increased in the extruded flours (Table 5). This could be explained by the presence of other components, in addition to the starch in the mixtures, such as lipids and proteins, since these tend to cover the starch, retarding hydration and decreasing the rate of viscosity development (Oliveira Filho and Mancim 2009; Li et al. 2019).

SEM

The flours presented compact and irregular surfaces where it was possible to distinguish starch granules in the formulations with 5%, 10%, 15% and 20% LAP replacement levels (Fig. 1a–d, respectively), which are indicated by the arrows. This is consistent with the results obtained in the viscoamylograms (Supplementary Fig. 2) of the respective cases, which showed peaks indicating possible non-gelatinized starch after extrusion of BRG (Fig. 1e). The LAP flour presented spongy surfaces with holes formed by the water sublimation during the lyophilization process (Fig. 1f). Sun et al. (2018) evaluated the extruded buckwheat flour microstructure and observed very different microstructures compared to the raw flour, with relatively uniform microstructure with starch granules. After the treatment, no intact starch granules could be found, and more amorphous flakes were observed. This might be due to pregelatinization, resulting in a homogenous network of crosslinked protein and starch (Ma et al. 2011). In this work, in spite of the amorphous structure of the samples, some granules could be identified as stated before (Fig. 1).

Conclusion

Extrusion significantly changed the solubility and absorption of water, the thermal and pasting properties of LAP and BRG mixed flours. DSC analysis did not show gelatinization peaks after extrusion, indicating a total gelatinization of the starch, consequently, produced different types of ingredients to application in instant foods. Extrusion also affected the color and chemical composition, and to a greater extent, the anthocyanin content, the phenolic compounds and the antioxidant capacity, despite the mild process conditions. The 10% LAP mixture resulted in a product with reddish color, rich in fiber, which presented lower loss of anthocyanin (27.16%), therefore, the most suitable to be used as an ingredient in the preparation of ready-to-eat foods with higher functional value.

References

Anderson RA, Conway HF, Peplinski AJ (1970) Gelatinization of corn grits by roll cooking, extrusion cooking and steaming. Starch. https://doi.org/10.1002/star.19700220408

AOAC (Association of Official Analytical Chemists) (2016) Official methods of analysis of the Association of Official Analytical Chemists International, 20th edn. AOAC, Gaithersburg

Bassinello PZ, Freitas DGC, Ascheri JLR, Takeiti CY, Carvalho RN, Koakuzu SN, Carvalo AV (2011) Characterization of cookies formulated with rice and black bean extruded flours. Procedia Food Sci. https://doi.org/10.1016/j.profoo.2011.09.243

Batista WP, Silva CEM, Liberato CM (2008) Chemical and past properties of wheat and maize starches phosphorilads Williams Pereira. Food Sci Techno. https://doi.org/10.1590/s0101-20612010005000006

Blois MS (1958) Antioxidant determinations by the use of a stable free radical. Nature. https://doi.org/10.1038/1811199a0

Boye JI, Aksay S, Roufik S, Ribéreau S, Mondor M, Farnworth E, Rajamohamed SH (2010) Comparison of the functional properties of pea, chickpea and lentil protein concentrates processed using ultrafiltration and isoelectric precipitation techniques. Food Res Int. https://doi.org/10.1016/j.foodres.2009.07.021

Brand-Williams W, Cuvelier ME, Berset C (1995) Use of a free radical method to evaluate antioxidant activity. LWT Food Sci Technol. https://doi.org/10.1016/s0023-6438(95)80008-5

Burkitt D (1973) Some diseases characteristic of modern Western civilization. Br Med J 1(5848):274–278

Carvalho AV, Rios AO, Bassinello PZ, Ferreira TF (2012) Effect of thermoplastic extrusion parameters on the technological properties of pre-cooked flours prepared with rice and beans. J Food Sci Technol. https://doi.org/10.1590/s1981-67232012005000029

Clerici MTPS, El-Dash AA (2008) Technological properties of pre-gelatinized rice flour obtained by thermoplastic extrusion. Sci Agrotechnol. https://doi.org/10.1590/s1413-70542008000500028

Cooke D, Gidley MJ (1992) Loss of crystalline and molecular order during starch gelatinization. Carbohydr Res 227:103–112. https://doi.org/10.1016/0008-6215(92),85063-6

Cruz CR, Kamarudin MS, Saad CR, Ramezani-Fard E (2015) Effects of extruder die temperature on the physical properties of extruded fish pellets containing taro and broken rice starch. Anim Feed Sci Technol. https://doi.org/10.1016/j.anifeedsci.2014.11.010

de Oliveira Filho HJ, Mancim AC (2009) Additives and ingredients and their reflexes on the viscoamilografics properties of corn starch. Braz J Food Technol VII BMCFB:78–84

Dors GC, Castiglioni GL, Augusto-Ruiz W (2006) Using rice flour for preparing dessert. Vetor 16:63–67

El-Saied HM, El-Attar W, Ahmed EA, Roushdi M (1979) Gelatinization, pasting characteristics and cooking behaviour of Egyptian rice varieties in relation to amylose and protein contents. Starch. https://doi.org/10.1002/star.19790310808

Fernandes MS, Wang SH, Ascheri JRL, Oliveira MF, Costa SAJ (2003) Effect of extrusion temperature in water absorption, solubility and dispersibility of pre-cooked corn-soybean (70:30) flours. Braz J Food Technol. https://doi.org/10.1590/s0101-20612003000200023

Gómez M, Martínez MM (2016) Changing flour functionality through physical treatments for the production of gluten-free baking goods. J Cereal Sci. https://doi.org/10.1016/j.jcs.2015.07.009

Honců I, Sluková M, Vaculová K, Sedláčková I, Wiege B, Fehling E (2016) The effects of extrusion on the content and properties of dietary fibre components in various barley cultivars. J Cereal Sci. https://doi.org/10.1016/j.jcs.2016.01.012

ICC (International Coffee Council) (1996) Rapid pasting method using the Newport Rapid Visco Analyser (Standar Method 162). ICC, Vienna

Jozinović A, Šubarić D, Ačkar Đ, Babić J, Miličević B (2016) Influence of spelt flour addition on properties of extruded products based on corn grits. J Food Eng. https://doi.org/10.1016/j.jfoodeng.2015.04.012

Kite FE, Schoch TJ, Leach HW (1957) Granule swelling and paste viscosity of thick-boiling starches. Bak Dig 31:42–44

Kumar R, Xavier M, Lekshmi M, Balange A, Gudipati V (2018) Fortification of extruded snacks with chitosan: effects on techno functional and sensory quality. Carbohydr Polym. https://doi.org/10.1016/j.carbpol.2018.04.050

Larrauri JA, Rupérez P, Saura-Calixto F (1997) Effect of drying temperature on the stability of polyphenols and antioxidant activity of red grape pomace peels. J Agric Food Chem. https://doi.org/10.1021/jf960282f

Li L, Yuan TZ, Setia R, Raja RB, Zhang B, Ai Y (2019) Characteristics of pea, lentil and faba bean starches isolated from air-classified flours in comparison with commercial starches. Food Chem. https://doi.org/10.1016/j.foodchem.2018.10.064

Limberger VM, Comarela CG, Patias LD, Brum FB, Emanuelli T, da Silva LP (2009) Extruded snack broken rice production to the food industry usage. Ciênc Rural 39:2590–2594

Lin MJY, Humbert ES, Sosulski FW (1974) Certain functional properties of sunflower meal products. J Food Sci. https://doi.org/10.1111/j.1365-2621.1974.tb02896.x

Lobo AR, de Silva GML (2003) Resistant starch and its physicochemical properties. Rev Nutr. https://doi.org/10.1590/s1415-52732003000200009

Ma Z, Boye JI, Simpson BK, Prasher SO, Monpetit D, Malcolmson L (2011) Thermal processing effects on the functional properties and microstructure of lentil, chickpea, and pea flours. Food Res Int. https://doi.org/10.1016/j.foodres.2010.12.017

Makkar HP, Francis G, Becker K (2008) Protein concentrate from Jatropha curcas screw-pressed seed cake and toxic and antinutritional factors in protein concentrate. J Sci Food Agric. https://doi.org/10.1002/jsfa.3248

Mayachiew P, Charunuch C, Devahastin S (2015) Physicochemical and thermal properties of extruded instant functional rice porridge powder as affected by the addition of soybean or mung bean. J Food Sci. https://doi.org/10.1111/1750-3841.13118

Menegassi B, Leonel M, Mischan MM, de Pinho SZ (2007) Effect of extrusion parameters on color and pasting properties of peruvian carrot flour (Arracacia xanthorrhiza). Sci Agrotechnol 31:1780–1792

Phillipp C, Buckow R, Silcock P, Oey I (2017) Instrumental and sensory properties of pea protein-fortified extruded rice snacks. Food Res Int. https://doi.org/10.1016/j.foodres.2017.09.048

Roy MK, Takenaka M, Isobe S, Tsushida T (2007) Antioxidant potential, anti-proliferative activities, and phenolic content in water-soluble fractions of some commonly consumed vegetables: effects of thermal treatment. Food Chem. https://doi.org/10.1016/j.foodchem.2006.08.002

Rufino M do SM, Pérez-Jiménez J, Arranz S, Alves RE, de Brito ES, Oliveira MSP, Saura-Calixto F (2011) Açaí (Euterpe oleracea) ‘BRS Pará’: a tropical fruit source of antioxidant dietary fiber and high antioxidant capacity oil. Food Res Int. https://doi.org/10.1016/j.foodres.2010.09.011

Saleh M, Meullenet J-F (2013) Broken rice kernels and the kinetics of rice hydration and texture during cooking. J Sci Food Agric. https://doi.org/10.1002/jsfa.5948

Singh N, Kaur N, Katyal M, Kaur A, Shevkani K (2015) Characteristics of starch separated from coarse and fine flour fractions obtained from hard, medium-hard, and soft Indian wheat cultivars. Starch. https://doi.org/10.1002/star.201600012

Singh JP, Kaur A, Shevkani K, Singh N, Singh B (2016) Physicochemical characterisation of corn extrudates prepared with varying levels of beetroot (Beta vulgaris) at different extrusion temperatures. J Food Sci Technol. https://doi.org/10.1111/ijfs.13051

Sobota A, Sykut-Domanska E, Rzedzicki Z (2010) Effect of extrusion-cooking process on the chemical composition of corn-wheat extrudates, with particular emphasis on dietary fibre fractions. Pol J Food Nut Sci 60:251–259

STATISTICA (2007) Data analysis software system. version 8.0, StatSoft Inc., Tulsa

Stojceska V, Ainsworth P, Plunkett A, İbanoğlu Ş (2010) The advantage of using extrusion processing for increasing dietary fibre level in gluten-free products. Food Chem. https://doi.org/10.1016/j.foodchem.2009.12.024

Sun X, Li W, Hu Y, Zhou X, Ji M, Yu D et al (2018) Comparison of pregelatinization methods on physicochemical, functional and structural properties of tartary buckwheat flour and noodle quality. J Cereal Sci. https://doi.org/10.1016/j.jcs.2018.01.016

Tacer-Caba Z, Nilufer-Erdil D, Boyacioglu MH, Ng PKW (2014) Evaluating the effects of amylose and Concord grape extract powder substitution on physicochemical properties of wheat flour extrudates produced at different temperatures. Food Chem. https://doi.org/10.1016/j.foodchem.2014.02.064

Trombini FRM, Leonel M (2010) Paste and thermal properties of instant mixtures of soybean flour, cassava starch and fibrous residue. Rev Energia Agric. https://doi.org/10.17224/energagric.2010v25n4p50-71

Van Den Einde RM, Van Der Goot AJ, Boom RM (2003) Understanding molecular weight reduction of starch during heating–shearing processes. J Food Sci. https://doi.org/10.1111/j.1365-2621.2003.tb07036.x

Vernaza MG, Chang YK (2012) Evaluation of guar gum and salt addition on the water absorption and on the quality of instant noodles. Aliment Nutr 23:435–442

Waterhouse AL (2002) Wine phenolics. Ann N Y Acad Sci 957:21–36

White BL, Howard LR, Prior RL (2010) Polyphenolic composition and antioxidant capacity of extruded cranberry pomace. J Agric Food Chem. https://doi.org/10.1021/jf902838b

Wrolstad RE, Durst RW, Lee J (2005) Tracking color and pigment changes in anthocyanin products. Trends Food Sci Technol. https://doi.org/10.1016/j.tifs.2005.03.019

Zheng H-G, Yang X-Q, Tang C-H, Li L, Ahmad I (2008) Preparation of soluble soybean protein aggregates (SSPA) from insoluble soybean protein concentrates (SPC) and its functional properties. Food Res Int. https://doi.org/10.1016/j.foodres.2007.10.013

Acknowledgements

The authors are grateful for the support from the Federal University of Goiás, FAPEG (Fundação de Amparo à Pesquisa do Estado de Goiás), CAPES (Coordenação de Aperfeiçoamento de Pessoal de Nível Superior), and CNPq (Conselho Nacional de Desenvolvimento Científico e Tecnológico).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

13197_2019_3606_MOESM1_ESM.pdf

Thermograms of of the raw (a) and pregelatinized (b) flours with different levels of replacement of broken rice grains (BRG) by lyophilized açaí pulp (LAP) (PDF 62 kb)

13197_2019_3606_MOESM2_ESM.pdf

Viscoamilograph profile of the raw and pregelatinized flours with different levels of replacement of broken rice grains (BRG) by lyophilized açaí pulp (LAP). 10% raw (a1); 10% pregelatinized (a2); 15% raw (b1); 15% pregelatinized (b2); 20% raw (c1); 20% pregelatinized (c2) (PDF 148 kb)

Rights and permissions

About this article

Cite this article

Ribeiro Oliveira, A., Chaves Ribeiro, A.E., Resende Oliveira, É. et al. Broken rice grains pregelatinized flours incorporated with lyophilized açaí pulp and the effect of extrusion on their physicochemical properties. J Food Sci Technol 56, 1337–1348 (2019). https://doi.org/10.1007/s13197-019-03606-y

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-019-03606-y