Abstract

Physico-chemical, hydration, cooking, textural and pasting properties of thirteen adzuki bean (Vigna angularis) accessions were studied. Protein and ash content ranged from 18.82 to 24.52% and 2.02 to 7.03%, respectively. Bulk density and seed weight of the adzuki seed ranged from 0.76 to 1.00 g/mL and 74.87 to 148.20 g/1000 seeds, respectively. Hydration capacity, swelling capacity and cooking time ranged from 0.05 to 0.12 g/seed, 0.04 to 0.15 mL/seed and 48.67 to 74.33 min, respectively. Different accessions showed significant variations in their physicochemical, cooking, hydration and texture properties. Swelling capacity showed significantly positive correlation with L* value. Hardness of soaked grain varied ranged between 68.67 and 120.25 N and had significant positive correlation with gumminess and chewiness. The springiness and chewiness of cooked seeds showed highly significant positive correlation. Peak viscosity, breakdown viscosity, final viscosity, setback viscosity and pasting temperature of adzuki bean flour ranged from 1979 to 2373 cP, 45 to 183 cP, 2954 to 4004 cP, 931 to 1666 cP and 75.02 to 78.27 °C, respectively. Peak viscosity and breakdown viscosity were negatively correlated to amylose content while setback viscosity showed positive correlation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Legumes belong to the family Leguminosae and are widely grown throughout the world (Singh et al. 2004). The terms “legumes” and “pulses” are interchangeable, these are major sources of dietary proteins in the developing countries and source of nutrition for billions of people around the world (Singh 2017). In addition to their protein contributions, pulses are also rich in other nutrients such as starch, dietary fiber, phytochemicals, non-digestible carbohydrates, vitamins and minerals (Tiwari and Singh 2012; Singh 2017). Pulses contain about 60% carbohydrate including starch, reducing and non-reducing sugars, oligosaccharides of the raffinose family, etc. (Shimelis and Rakshit 2005). Research efforts are often being made to identify, cultivate and evaluate unexploited sources as a source of dietary protein for world consumption. The studies on desired functional properties of pulses are important for competent consumption and consumer acquiescence of their seed flours Eke and Akobundu (1993). Earlier, grain, flour, starch and protein characteristics of rice bean, kidney bean, field pea, lentils and horse gram have been reported (Kaur et al. 2013, Shevkani et al. 2015, Ghumman et al. 2016, Parmar et al. 2017).

Adzuki bean (Vigna angularis) is one such under-explored bean which needs to be explored for its possible food use. Adzuki bean are small red beans that have an inherently sweet, nutty taste. “Adzuki” is Japanese word which means small due to its small shape it got name adzuki beans (Small beans). In China, this bean is a popular food legume with the name Hongdou and chidou while in Korea it is known as pat. It is widely grown in the northeast and northern parts of China. As being the origin place of adzuki bean, China has the largest number of accessions in the world (Ning et al. 2009). Adzuki beans are a rich source of carbohydrates (57–62%), protein (17–21%), potassium and fiber (12–13%), as well as B-vitamins such as thiamin, niacin, and riboflavin and minerals such as Fe (4.6 mg), Mg (119.6 mg), K (1223 mg), and Zn (4.0 mg), Folic acid (278 mg) (Tjahjadi and Breene 1988).

Pulses require longer cooking time, therefore, soaked overnight before cooking. The grains get hydrated, swelled and softened during soaking that reduces the cooking time. The soaking also brings about uniform expansion of the seed coat and cotyledon. The extent of hydration and swelling of grains during soaking vary amongst different pulses and both were related to cooking quality (Kaur et al. 2009; Singh et al. 2004). The seed weight and hydration capacity of pulses has been associated with cooking time (Singh et al. 2004). Cooking quality attributes such as cooking time, textural parameters are used to evaluate the quality of pulses (Singh et al. 2004; Kaur et al. 2005). Physical properties of grains such as size/weight, volume, hull (coat) and cotyledon characteristics varied amongst the pulses and reported to affect their cooking quality (Kaur et al. 2009; SefaDedah and Stanley 1979; Singh et al. 2004). Pulse grain coats were reported to be rich in water insoluble fibers and polyphenols while cotyledons had higher soluble fibers, oligosaccharides and resistant starch (Singh 2017). Earlier, the variability in physical, hydration, textural and cooking quality of black gram and kidney bean cultivars have been reported (Kaur et al. 2009; Singh et al. 2004). The knowledge of hydration and textural properties of pulse grains is desired and assist in selecting the accessions that are suitable for canning. Parmar et al. (2016) reported that varieties of pulses that had higher hydration capacity and lower hardness and splitting tendency during processing are more suitable for canning. At present, limited information is available on the variability in physical, cooking, textural and pasting properties among different adzuki bean accessions. The objective of the present study was to investigate the diversity in quality traits of seed and flour of adzuki bean germplasm.

Materials and methods

Adzuki bean seeds from 13 different accessions namely, EC340255, EC57459, EC340271-A, IC SMLAB-1, EC8707, EC340271-B, IC341952, HPAV9, IC241041 SMLAB4, EC15257, IC469173 HPAB30, EC000254 and EC340284 were procured from National Bureau of Plant Genetic Resources (NBPGR) regional station, Shimla, India.

Physical properties of adzuki bean seeds

L*, a* and b*values were determined using Hunter colorimeter Model D-25 optical sensor (Hunter Associates). Grain weight (g) was calculated by randomly selecting and counting 100 grain followed by weighing. Seed volume was determined using the method as described by William et al. (1983). Fifty seeds were transferred to a 50 mL measuring cylinder and 25 mL distilled water was added. The difference in the volume was noted down and divided by 50 to calculate the volume per seed. For bulk density determination, adzuki seeds were gently added to 100 mL graduated cylinder and gently tapped on a laboratory bench, several times, until there was no further diminution of the sample level after filling to the 100 mL mark. It was calculated as weight of sample per unit volume of sample (g/mL). All the measurements were taken in triplicate.

Hydration and swelling properties

Hydration capacity, hydration index, swelling capacity and swelling index of the adzuki seeds were determined as described by William et al. (1983). All the measurements were in triplicate.

Textural analysis of soaked and cooked grains

Texture profile analysis (TPA) of the beans from different accessions was performed on a single grain using a TA/XT texture analyzer (Stable Microsystems, Crawley, UK). The method adopted was as described earlier by Singh et al. (2010). The seed was subjected to 75% compression with a probe (P/75) at a speed of 1 mm/s. The textural parameters of hardness (maximum height of the force peak on the 1st compression cycle), springiness (ratio of the time elapsing between the end of 1st compression and the start of 2nd compression), cohesiveness (ratio of the positive force areas under the 1st and 2nd compressions), gumminess (hardness × cohesiveness) and chewiness (gumminess × springiness) were determined. The mean values of ten repeated measurements were reported.

Cooking time

Cooking time was determined using the method given by Singh et al. (2010). The cooking time (minutes) determination was done in triplicate.

Chemical properties of adzuki bean flour

The grains were ground to flour in a milling machine with sieve No. 72 (BIS), which was packed in airtight containers for further analysis. Moisture, ash, fat and protein contents were determined using the standard methods of analysis (AOAC 1990). The starch was extracted from adzuki beans adopting the method given by Kaur and Sandhu (2010). Amylose content of starch was determined as described earlier (William et al. 1970).

Pasting properties of adzuki bean flours

Pasting properties of adzuki bean flours were evaluated using Rapid Visco Analyzer (RVA4, Newport Scientific Pvt. Ltd., Warriewood, Australia). Viscosity profile was recorded using flour suspensions (3.5 g flour + 24.5 g distilled water). The temperature–time conditions included a heating step from 50 to 95 °C at 6 °C/min (after an equilibration time of 1 min at 50 °C), a holding phase at 95 °C for 5 min, a cooling step from 95 to 50 °C at 6 °C/min and a holding phase at 50 °C for 2 min. All the measurements were done in triplicate.

Statistical analysis

Pearson correlation (r) and principal component analysis (PCA) were carried out using XLSTAT 2015.1 software for determining the relationship between different parameters. The PCA results were graphically represented by the projection of the first two principal components.

Results and discussion

Physical properties

The physical properties of different adzuki bean accessions are given in Table 1. Seed weight of adzuki bean accessions ranged from 74.87 to 148.20 g/100 seeds. EC8707 had the lowest while EC340271-B showed the highest seed weight. The variation in seed weight may be due to the genetic variation in the size of seeds of different accessions. Kaur et al. (2009) reported the weight of 100 seeds of kidney bean cultivars in the range between 10.16 and 51.68 g. Singh et al. (2010) reported the weight of 100 seeds of field pea cultivars in the range between 4.26 and 29.3 g. Bulk density of adzuki bean accessions ranged between 0.76 and 1.00 g/mL. The highest bulk density was observed for EC340271-A, whereas most of the accessions had bulk density of 0.76 g/mL. Seed volume of different adzuki bean accessions ranged between 50 and 100 mL/1000 seeds.

The colour of most of the beans was deep red. L* value ranged from 38.72 (EC15257) to 42.74 (EC340271-B). The a* and b* values ranged from 0.18 to 11.22 and 0.68 to 4.07, respectively. The highest values were recorded for EC000254 and the lowest for EC340271-A. Higher a* values indicated the presence of greater redness in the accessions. Similar variations in colour parameters were observed for field pea cultivars by Singh et al. (2010). The variation in colour of beans has been attributed to variation in concentration of flavonoids (Feenstra 1960).

Hydration and swelling properties

The hydration capacity per seed of Adzuki bean accessions ranged between 0.05 and 0.12 g and hydration index between 0.43 and 0.95. EC000254 showed the lowest, while EC340255 showed the highest index. The hydration capacity per seed of 0.03–0.62 g and hydration index of 0.16–1.97 for kidney bean seeds was reported earlier (Kaur et al. 2009). These differences may be attributed to difference in size, seed coat thickness and water absorption characteristics of seeds (SefaDedah and Stanley 1979). It has been studied by Yousif and Deeth (2003) that the hydration rate was related to the size of adzuki beans. A reduction of 10% in size within a population of regular-sized adzuki beans may cause a significant reduction in the water imbibition rate, resulting in a higher incidence of hard beans, i.e. beans with the ‘hard shell’ defect or impermeable bean coat. Swelling capacity and swelling index ranged from 0.04 to 0.15 mL/seed and 0.50 to 1.88, respectively (Table 1). EC340271-B showed the highest whereas IC469173 had the lowest values for both parameters. The swelling capacity of field pea accessions ranging between 0.02 and 0.76 mL/seed was reported in study by Singh et al. (2010). Swelling capacity/seed and swelling index for different chickpea cultivars ranged between 0.11–0.23 and 103.1–136.5, respectively (Kaur et al. 2005), which were comparatively higher than observed in adzuki beans. Low hydration capacity, swelling capacity and swelling index of adzuki beans indicated that the seed had higher hardness and impermeability of the seed coat (Seena and Sridhar 2005). Water absorbing capacity of the seeds depends on the cell wall structure, composition of seed and compactness of the cells in the seed (Kaur et al. 2005). Swelling capacity was positively correlated with L* value (r = 0.782, p < 0.01) of seeds. This indicated that the lighter accessions swelled more during hydration than darker accessions. Swelling index was positively correlated to swelling capacity (r = 0.786, p < 0.01).

Cooking time

Cooking time is a heritable characteristic that differs widely among genotypes (Kaur et al. 2005). Cooking time for different bean accessions varied significantly, ranging from 49 min (EC8707) to 74 min (ICSMLAB-1) (Table 2). Cooking time between 45 and 81 min for different field pea accessions was reported by Singh et al. (2010). Amongst the field pea accessions studied, 40% of the accessions required cooking time between 55 and 60 min. The longer cooking time required for ICSMLAB-1 could be attributed to its higher density as the cotyledon with higher density had slower water uptake resulting in longer cooking time (Seena and Sridhar 2005). Cooking time may vary due to the rate at which cell separation occurs, due to loosening of the intercellular matrix of the middle lamella upon cooking (Ghribi et al. 2015). Size also governed the distance to which the water must penetrate in order to reach the innermost part of the seed (SefaDedah and Stanley 1979).

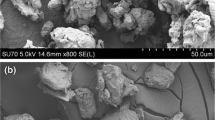

Textural properties of soaked and cooked adzuki bean seeds

The change in textural parameters during soaking reflects the hydration properties of the grains (Singh et al. 2009). The rate and degree of softening of soaked and cooked seeds from different bean accessions varied significantly. The hardness of soaked beans ranged from 68.67 N (EC340255) to 120.25 N (EC340271-A) while of cooked beans ranged from 10.70 N (EC340271-A) to 29.35 N (IC341952) indicating the increase in tenderness of the seeds with cooking (Table 2). Hardness and gumminess was positively correlated with L* value (r = 0.681, 0.673, p ≤ 0.05). It was observed that the variety with high cooking time have higher hardness values for soaked grains. The grey-black accessions (EC340271-A and EC340271-B) which had highest L* values had the highest hardness value after soaking. The results revealed that accessions with greater seed weight required longer cooking time and consequently had higher hardness, as compared to those with lower seed weight, which may be due to compact granular structure. SefaDedah and Stanley (1979) reported that seed coats of accessions possessing good hydration properties facilitate rapid softening of the seed during soaking. The constituent like fibre, lignin, cellulose and hemicelluloses are the factors responsible for the hardness of the grains (Singh et al. 1992). Soaked seed cohesiveness ranged between 0.21 to 0.26, ICSMLAB-1 showed the highest and EC340255 showed the lowest cohesiveness. The cohesiveness of cooked seeds ranged from 0.17 (EC340271-B) to 0.24 (EC340271-A). Chewiness of soaked and cooked seed ranged from 5.21 to 9.85 N and 0.73 to 1.75 N, respectively. Gumminess of soaked and cooked adzuki bean seeds ranged from 14.30 to 28.56 and 2.60 to 6.68, respectively. Cohesiveness of cooked seeds were significantly correlated with gumminess, springiness and chewiness of the seeds (r = 0.977, 1.00, 0.999, respectively, p < 0.01). Both the chewiness and gumminess of cooked and soaked seeds were significantly interrelated. Chewiness and gumminess were observed to be dependent upon hydration. During cooking, seed undergoes important physiochemical changes involving gelatinization and swelling of the starch and other physical and chemical changes, which results in a palatable texture (Stanley and Aguilera 1985).

Chemical properties

The seed flour was also analyzed for moisture, protein, ash and amylose content and the results are depicted in Table 3. Moisture content of adzuki bean accessions ranged between 8 and 9%. The protein content of the adzuki bean accessions ranged from 18.82 to 24.52%. IC241041 had the highest protein content (24.5%) and the lowest ash content (2.02%). EC340284 had the highest ash content i.e. 7.03%. Amylose content of starches separated from different adzuki bean accessions ranged between 9.96 and 23.99%. Study revealed that EC340271-A had the highest amylose content while ICSMLAB-1 had the lowest amylose content. Amylose content was negatively correlated with a* and b* values (r = 0.704, 0.803, respectively, p ≤ 0.05) and positively correlated with L*. This indicated that lighter grain varieties had higher amylose content compared to darker varieties, thus EC340271-A and EC340271-B had amylose content of 23.99% and 22.38% respectively, which is higher than all other varieties.

Pasting properties

Pasting properties of flour from different adzuki bean accessions varied significantly (Table 4). Peak viscosity and trough viscosity of different adzuki bean accessions ranged between 1979 and 2373 cP and 1880 and 2308 cP, respectively. Peak and trough viscosity showed strong negative correlation (r = − 0.847, − 0.778, respectively, p < 0.01) with hydration capacity of adzuki bean seeds. The differences in pasting properties may be attributed to the difference in amylose content, swelling and hydration properties of starch. During heating, the starch granules swell followed by dissolution of amylose leading to rise in paste viscosity to the maximum termed as peak viscosity (Singh et al. 2006). The extended heating and shearing led to decrease in viscosity termed as breakdown viscosity. Peak viscosity and breakdown viscosity was negatively correlated with amylose content (r = − 0.568 and − 0.562, respectively, p < 0.05). These correlations indicated restricted swelling and disintegration of granules occurred in the presence of higher amylose. Similar observations were earlier made (Singh et al. 2006, 2007). The results reflected that amylose content was mainly responsible for the variations in pasting properties, though the contribution of other components to the pasting properties of bean flours such as protein, fiber etc. cannot be ruled out. Henshaw et al. (1996) reported that flour contains other substances such as protein, lipid, and minerals that may interact with starch to varying degrees and influence the paste characteristics of flour. The behavior of viscosity during cooking (from 50 to 90 °C) reflects the capacity of starch to absorb water and swell (Sandhu et al. 2007). Breakdown viscosity, final viscosity and setback viscosity of different adzuki bean accessions ranged from 45 to 183 cP, 2954 to 4004 cP and 931 to 1696 cP, respectively. Among various accessions studied, EC15257 showed the highest peak, trough and final viscosity, whereas breakdown and setback viscosity were the highest for EC8707 and EC340271-B, respectively. The lowest breakdown viscosity of ICSMLAB-1 indicated its high thermal stability. EC8707 showed the lowest final viscosity, while EC000254 had the lowest setback viscosity. Setback viscosity was positively correlated to amylose content (r = 0.575, p < 0.05). The lower setback indicates lower tendency towards retrogradation (Sandhu et al. 2007). Pasting temperature of adzuki bean accessions ranged from 75.02 to 78.27 °C. EC-340255 showed the lowest, whereas EC8707 had the highest pasting temperature. The high pasting temperature of flour indicates the presence of starch that is highly resistance to swelling and rupturing (Kaur and Sandhu 2010). Pasting temperature provides an indication of minimum temperature to cook as well as temperature at which the viscosity begins to increase during the heating process which is important in production of soups, gravies etc. A gradual increase in the viscosity may be due to removal of water from the exuded amylose by the granules on swelling (Ghaisi et al. 1982). An increase in viscosity during cooling of the heated pastes might be due to the alignment of amylose chains (Flores-Farias et al. 2000).

Principal component analysis

Principal component analysis (PCA) of raw seeds, soaked seeds, cooked seeds and flours properties were carried out separately to study the relationship between various properties. Analysis of raw seeds properties separately revealed that PC1 accounted for 36.9% of variability with a*, b* values and bulk density being the major components, whilst PC2 is responsible for 22.0% variance with L* value being the main component. The cumulative variance of factor 1 and 2 was 58.9%. PCA revealed that a*, b*values were closely located and L* closely located with seed weight.

PCA analysis of raw, soaked cooked seeds and flour properties revealed that PC1, PC2 and PC3 accounted for 60.7% of cumulative variance. Loading plot for PC1 and PC2 accounting for 26.3 and 21.4%, respectively variance is shown in Fig. 1. PC1 mainly constituted protein content, a*, b*, cooked seed texture traits (cohesiveness, gumminess, springiness and chewiness), flour paste traits (breakdown viscosity and setback viscosity). PC2 constituted of L*, hydration capacity, seed volume and flour paste viscosity (peak, trough and final) while PC3 was mainly contributed by amylose content. Final viscosity, setback viscosity and amylose content are located on same side indicating their positive relationship and negative with breakdown viscosity. Cooked seed textural properties were located on the opposite side of amylose indicating negative relationship of cooked seeds textural properties with amylose content. Cooking time and seed volume had negative relationship with each other.

Conclusion

The results showed that a significant diversity was present in physical, soaking, cooking and pasting properties in the thirteen adzuki bean accessions studied. IC241041 had the highest protein content, which can be used as good dietary protein source. EC340271-A bean line had highest amylose content (23%) and high swelling power, suggesting its potential use in curries and soups to give a good consistency and mouth feel. Most of the varieties had cooking time around 60 min, indicating that pressure cooking of the beans would be faster and economical method for cooking. Results also revealed that EC8707 which had the lowest weight as well as high protein content will be cooked at the fastest rate. These adzuki bean accessions may be further exploited genetically to improve their cooking and pasting characteristics.

References

AOAC (1990) Official methods of analysis, 15th edn. Association of official Analytical chemists, Washington

Eke OS, Akobundu NT (1993) Functional properties of African yam bean (Sphenostylis stenocarpa) seed flour as affected by processing. Food Chem 48:337–340

Feenstra WJL (1960) Biochemical aspects of seed coat colour inheritance in Phaseolus vulgaris L. Med Landbouwhogeschool Wegeningen 60:1–53

Flores-Farias R, Martinez-Bustos F, Salians-Moreno Y, Chang YK, Hernaadez JS, Rios E (2000) Physicochemical and rheological characteristics of commercial nixtamalised Mexican corn flours for tortillas. J Sci Food and Agric 80:657–664

Ghaisi K, Varriano-Martson E, Hoseney RC (1982) Gelatinization of wheat starch-II starch-surfactant interaction. Cereal Chem 59:6–88

Ghribi AM, Maklouf I, Blecker C, Attia H, Besbes S (2015) Nutritional and compositional study of desi and kabuli chickpea (Cicer arietinum L.) flours from Tunisian cultivars. Adv Food Technol Nutri Sci 1:38–47

Ghumman A, Kaur A, Singh N (2016) Impact of germination on flour, protein and starch characteristics of lentil (Lens culinari) and horsegram (Macrotyloma uniflorum L.) lines. LWT Food Sci Technol 65:137–144. https://doi.org/10.1016/j.lwt.2015.07.075

Henshaw FO, McWatters KH, Oguntunde AO, Phillips RD (1996) Pasting properties of Cowpea flour: effects of soaking and decortication method. J Agric Food Chem 44:1864–1870

Kaur A, Kaur P, Singh N, Virdi AS, Singh P, Rana JC (2013) Grains, starch and protein characteristics of rice bean (Vigna umbellata) grown in Indian Himalaya regions. Food Res Int 54(1):102–110. https://doi.org/10.1016/j.foodres.2013.05.019

Kaur M, Sandhu KS (2010) Functional, thermal and pasting characteristics of flours from different lentil (Lens culinaris) cultivars. J Food Sci Technol 47:273–278

Kaur M, Singh N, Sodhi NS (2005) Physicochemical, cooking, textural and roasting characteristics of chickpea (Cicer arietinum L.) cultivars. J Food Eng 69:511–517

Kaur S, Singh N, Sodhi NS, Rana JC (2009) Genotypic diversity in physicochemical, hydrating, pasting and textural properties of kidney bean varieties. Food Chem 117:282–289

Ning Xu, Xz Cheng, Wang Li-Xia, Wang Su-Hua, Liu Chang-You, Sun Lei, Mei Li (2009) Screening SSR marker for Adsuki bean and its application in diversity evaluation in chinese Adzuki bean germplasm resources. Acta Agron Sin 35:219–227

Parmar N, Singh N, Kaur A, Virdi AS, Thakur S (2016) Effect of canning on colour, protein and phenolic profile of grains from kidney bean, field pea and chickpea. Food Res Int 89:526–532

Parmar N, Singh N, Kaur A, Thakur S (2017) Comparison of color, anti-nutritional factors, minerals, phenolic profile and protein digestibility between hard-to-cook and easy-to-cook grains from different kidney bean (Phaseolus vulgaris) accessions. J Food Sci Technol 54:1023–1034

Sandhu KS, Singh N, Malhi NS (2007) Some properties of corn grains and their flours I: physicochemical, functional and chapatti making properties of flours. Food Chem 101:938–946

Seena S, Sridhar KR (2005) Physicochemical, functional and cooking properties of under explored legumes, Canavalia of the southwest coast of India. Food Res Int 38:803–814

SefaDedah S, Stanley DW (1979) Textural implications of the microstructure of legumes. Food Technol 33:77–83

Shevkani K, Singh N, Kaur A, Rana JC (2015) Structural and functional characterization of kidney bean and field pea protein isolates: a comparative study. Food Hydrocolloids 43:679–689. https://doi.org/10.1016/j.foodhyd.2014.07.024

Shimelis AE, Rakshit SK (2005) Proximate composition and physico-chemical properties of improved haricot bean (Phaseolus vulgaris L.) varieties grown in Ethiopia. LWT- J Food Sci. Technol 38:331–338

Singh N (2017) Pulses: an overview. J Food Sci Technol 54:853–857

Singh N, Sekhon KS, Bajwa U, Goyal S (1992) Cooking and parching characteristics of Chickpea (Cicer arietinum L.). J Food Sci Technol 29:347–350

Singh N, Kaur M, Sandhu KS, Sodhi NS (2004) Physicochemical, cooking and textural characteristics of some Indian black gram varieties (Phaselous mungo L.). J Sci Food Agric 84:977–982

Singh N, Inouchi N, Nishinari K (2006) Structural, thermal and viscoelastic characteristics of starches separated from normal, sugary and waxy maize. Food Hydrocolloids 20:923–935

Singh N, Nakaura Y, Inouchi N, Nishinari K (2007) Fine structure, thermal and viscoelastic properties of starches separated from Indica rice cultivars. Starch-Starke 59:10–20

Singh N, Kaur S, Rana JC (2009) Diversity in seeds and flours in Kidney bean germplasm. Food Chem 117:282–289

Singh N, Kaur N, Rana JC, Sharma SK (2010) Diversity in seed and flour properties in field pea (Pisum sativum) germplasm. Food Chem 122:518–525

Stanley DW, Aguilera JM (1985) A review of textural defect in cooked reconstructed legumes—the influence of structure and composition. J Food Biochem 9:233–277

Tiwari BK, Singh N (2012) Pulse chemistry and technology. Royal Society of Chemistry, Cambridge, pp 1–348

Tjahjadi C, Breene WM (1988) Isolation and characterisation of adzuki bean (Vigna angularis cultivar Takara) proteins. J Food Sci 53:1438–1443

William PC, Kuzina FD, Hlynka I (1970) A rapid colorimetric procedure for estimating the amylose content of starches and flours. Cereal Chem 47:411–420

William PC, Nakul H, Singh KB (1983) Relationship between cooking time and some physical characteristics in chick pea (Cicer arietinum L.). J Sci Food Agric 34:492–496

Yousif AM, Deeth HC (2003) Effect of storage time and conditions on the cotyledon cell wall of the adzuki bean (Vigna angularis). Food Chem 81:169–174

Acknowledgement

NS acknowledged the financial support of Department of Science and Technology, Ministry of Science and Technology, Govt. of India. We also thank Dr. Jai Chand Rana, National Bureau of Plant Genetic Resources (NBPGR) regional station, Shimla, India for providing adzuki bean accessions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yadav, U., Singh, N., Kaur, A. et al. Physico-chemical, hydration, cooking, textural and pasting properties of different adzuki bean (Vigna angularis) accessions. J Food Sci Technol 55, 802–810 (2018). https://doi.org/10.1007/s13197-017-2994-9

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-017-2994-9