Abstract

The lack of updated knowledge about the physical properties of milk powders aimed us to evaluate selected physical properties (water activity, particle size, density, flowability, solubility and colour) of eleven skim and whole milk powders produced in Europe. These physical properties are crucial both for the management of milk powder during the final steps of the drying process, and for their use as food ingredients. In general, except for the values of water activity, the physical properties of skim and whole milk powders are very different. Particle sizes of the spray-dried skim milk powders, measured as volume and surface mean diameter were significantly lower than that of the whole milk powders, while the roller dried sample showed the largest particle size. For all the samples the size distribution was quite narrow, with a span value less than 2. The loose density of skim milk powders was significantly higher than whole milk powders (541.36 vs 449.75 kg/m3). Flowability, measured by Hausner ratio and Carr’s index indicators, ranged from passable to poor when evaluated according to pharmaceutical criteria. The insolubility index of the spray-dried skim and whole milk powders, measured as weight of the sediment (from 0.5 to 34.8 mg), allowed a good discrimination of the samples. Colour analysis underlined the relevant contribution of fat content and particle size, resulted in higher lightness (L*) for skim milk powder than whole milk powder, which, on the other hand, showed higher yellowness (b*) and lower greenness (−a*). In conclusion a detailed knowledge of functional properties of milk powders may allow the dairy to tailor the products to the user and help the food processor to perform a targeted choice according to the intended use.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Milk is an extremely perishable product and yet it could be preserved for later consumption by removing water by means of drying methods (i.e. spray drying and roller drying), in order to prevent the growth of microorganisms and inhibit enzymatic reactions. Moreover, milk powders are frequently used for convenience in transportation, handling, processing, and product formulations but they are highly susceptible to various changes such as moisture uptake, softening, browning, compaction, collapse or caking (Al Mahdi et al. 2006).

The basic quality indicators of milk powders are both their chemical composition and their physical properties (particle size, density, flowability, solubility, water activity, etc.). The variability of the milk powders properties comes from the raw material, the different drying methods and the numerous chemical reactions that could happen during storage because of the temperature, relative humidity and time. Milk powder manufacturers use worldwide many resources to ensure products with good sensory quality and longer shelf life. In spite of the raw milk standardization, the carefully defined technological parameters and the rigorous quality assurance procedures adopted in the production plants, some unacceptable variations may remain between different batches of milk powder (Nielsen et al. 1997). The measurement of these parameters by means of well-defined test methods is important because they intrinsically affect the powder behaviour.

The particle size distribution (PSD) of a milk powder determinates its appearance, the reconstitution properties, the surface reactivity, and the flow characteristics. The PSD is influenced by the original milk characteristics, the processing conditions, and the equipment used during and after the drying process (Schuck and Ouest 2011). It is generally assumed that powders with particle sizes larger than 200 micron are free flowing, while fine powders are subject to cohesion and their flowability is more difficult because of the higher resistance to flow (Kim et al. 2005). In the dairy industry, flowability affects air transportation, bag, bin or silos filling and emptying, dosage of specific quantities or the selection of optimal parameters for mixing and conditioning the powders (Ilari 2002). Properties such as loose and tapped bulk density and their ratios (e.g. Hausner Ratio and Carr’s index) have been used as qualitative descriptors of the food powders flowability (Juliano et al. 2006). The classification of the powder’s flowability according to European Pharmacopeia is showed in Table 1. For powders with difficulty to flow the tapped density is much lower than the loose density of consolidated material (Guerin et al. 1999). On the other hand, the relatively low density of milk powders is undesirable as it leads to higher costs of packaging, storage, and transportation (Schuck and Ouest 2011).

The rehydration properties affect the reconstitution of the milk powder with water. Reduced powder solubility is mainly the consequence of milk protein denaturation and/or aggregation (Thomas et al. 2004) and can cause processing difficulties. The solubility of spray-dried skimmed milk powder (SMP), whole milk powder (WMP), and partially skimmed milk powder (PSMP) is usually more than 99%, while for roller-dried milk powder it is generally lower (about 85%) (Tamime 2009).

The colour of powdered milk products may be influenced by the technological parameters (e.g. temperature) used during production in turn responsible for the formation of Maillard reactions (non-enzymatic browning reactions) compounds, which commonly occurs in thermally processed milk between proteins and reducing sugars. PSD can influence colour, too, because the backscattering of light in the visible range depends on the ratio between particle size and incident wavelength (Walstra 2003).

There has been an increasing interest in the research on milk derivatives (i.e. milk protein concentrate powders, whey proteins and caseins powders) (Crowley et al. 2015; Kelly et al. 2015) and/or powder mixtures (Murphy et al. 2015) that have determined a large innovation in drying technology (Patel et al. 2009; Schuck et al. 2008). Nevertheless, there is a general lack of updated literature data on the physical properties of pure milk powders. A detailed knowledge of the functional properties of milk powders may allow the dairy to tailor the products to the user, and at the same time, it may help the food producer to perform a targeted industrial choice according to the intended use of milk powders as food or dairy ingredient (Damin et al. 2009; Kenny et al. 2000). Thus, the objective of this work was to measure selected physical properties (particle size, density, flowability, solubility and colour) of skim and whole (full fat) milk powders produced nowadays in Europe to enforce and update literature data on this topic.

Materials and methods

Samples, collection and composition

Seven skim (SMP1-7) and four whole milk (WMP1-4) powder samples were supplied as a courtesy by an Italian trader (HLSTrading, Merate, Lecco, Italy) collecting them from six European manufacturers located in Germany, Ireland (SMP4), and Poland (SMP2). All samples were spray dried, except for sample WMP2 that was dried with a roller system. 0.5–1 kg of powder were collected from 25 kg plastic lined multiply craft paper sacks within the first 2 months of shelf-life and immediately packed into plastic coated aluminium bags under vacuum. After opening, milk powders were divided into several lots and each lot was stored in dark cases without headspace at room temperature before analysis. Analyses were performed within 1 month from the delivery of the sample. The trader kindly supplied the chemical composition (fat, protein, lactose, ash and moisture) of milk powders (Table 2).

Water activity

The water activity (a w) of the milk powders was measured at 25 °C using an AquaLab Water Activity Meter Series 3TE with internal temperature control (Decagon Devices, Inc., Pullman, WA, USA). 1.5 ± 0.5 g of milk powder were sampled according to the sample dish capacity. The analyses were performed in triplicate.

Particle size distribution

Particle size distribution of the dried products was measured by laser light scattering using a Malvern Mastersizer 2000 granulometer equipped with a Hydro 2000MU sampler for liquids (Southborough, MA, USA). For the measurements the dried powders samples were dispersed in ethanol and the particle size distribution was calculated using a model based on the Fraunhofer theory (using ethanol refractive index: 1.36), because the refractive index of the powders was unknown. The dispersant liquid was put into a 600 mL beaker and the samples were added until the instrument measured the 15% of obscuration. The mean values of the particle size measured in micron were expressed as D[4, 3] (volume weighted mean) and D[3, 2] (surface weighted mean) values. Size dispersion was evaluated directly by the software of the instrument, using the span index (SI), according to the formula

where D10, D50, D90 represent the size of the sample lying below 10, 50 and 90% of the entire distribution, respectively (Ilari and Mekkaoui 2005; Iezzi et al. 2012).

The analyses were performed in triplicate.

Density and flowability (loose and tapped bulk density; Hausner ratio; Carr’s index)

Density of milk powders was measured both as loose (or poured) and tapped bulk density. Loose density was measured weighing a 100 mL calibrated cylinder filled with dried milk carefully levelled, without compacting, till an established level, and expressed with the following expression: loose density = powder weight (kg) / powder volume (m3). The tapped density was measured on the cylinder containing the dried milk that was gently tapped on a table top for at least 10 min, and in any case until negligible difference in volume between succeeding measurements was observed. The new volume obtained after tapping was read on the graduated cylinder and the density is expressed by the following expression: Tapped density = powder weight (Kg)/volume of tapped powder (m3). Flowability and cohesiveness can be expressed in terms of Carr’s index (CI), also called compressibility index, and Hausner ratio (HR), respectively, using the following expressions (Reddy et al. 2014): CI = 100 × (Tapped density − Loose density)/Tapped density; HR = Tapped density/Loose density. The analyses were performed in triplicate.

Insolubility index

The insolubility index of the dried products was analysed according to IDF Standard 129A (1988), modified as follows: 10 g of dried skim milk or 13 g of dried whole milk were mixed with 100 mL of water at 25 or 50 °C, for spray- or roller-dried milk respectively. After 5 min of mixing at high speed, the suspension rested for a period of 5–15 min, after which it was stirred with a spatula. A volume of 50 mL was filled into a graduated 50 mL centrifuge tube with conically graduated bottom. After centrifugation for 5 min at 5070 g, the sediment-free liquid was siphoned off and the tube was filled up again with water. The tube was then centrifuged for 5 min at the same speed, after which the level of sediment on the graduated bottom was read. Moreover, the sediment was dried into an air oven at 70 °C overnight and in any case until it reached a constant weight. The insolubility index is expressed both as volume of wet residue (mL), according to IDF method, and as weight of the sediment after drying (mg). The analyses were performed in triplicate.

Colour

Colour determination was carried out using a Minolta Colorimeter (CM 2600d, Minolta Co., Osaka, Japan) equipped with a standard illuminant D65. The assessments were carried out at room temperature (25 °C). CIELAB colour space was used, determining the parameters L* (lightness or whiteness, black = 0, white = 100), a* (redness >0, greenness <0), b* (yellowness >0, blue <0) for each sample. The analyses were performed in triplicate.

Statistical analysis

Mean and standard deviation of data were calculated with SPSS (version 23.0, SPSS Inc., Chicago, IL) statistical software. SPSS was used to perform one-way analysis of variance (ANOVA) followed by Tukey’s test (p < 0.05). A t test (p < 0.05) was carried out to compare the differences between SMP and WMP samples.

Principal component analysis (PCA) was carried out on data by means of Matlab release 2014b (The MathWorks Inc., Natick, MA, USA) equipped with PLS Toolbox 8.0 (Eigenvector Research Inc. Manson WA, USA). Factor analysis such as PCA is a statistical procedure that uses an orthogonal transformation to convert a set of observations of possibly correlated variables into a set of values of linearly uncorrelated variables called principal components. This method maximizes the information presented using limited factor numbers and allows to detect structure in the relationships between variables. PCA was used as descriptive statistical technique by plotting the selected projection of original variables and the projections of all cases (samples) on a plane described by principal components.

Results and discussion

Composition and water activity

Generally, dairy powders show a very large diversity of physicochemical properties, despite a comparable gross chemical composition, excluding the fat content (Ilari and Mekkaoui 2005; Tamime 2009). European legislation defined skimmed dried milk as the dehydrated milk with a total fat less than 1.5% and whole dried milk the product with a fat content from 26 to 42% (OJEC 2002), while the protein content should have a minimum value of 34%, expressed on free fat dry matter. The compositional requirements can be obtained by standardization of the raw material and/or the dried product by the addition of milk permeate and retentato of ultrafiltration (OJEC 2007); this explains the relative low variability of the gross chemical composition. The chemical composition of the samples analyzed in this study is reported in Table 2 and reflects the legal limits required from the European legislation.

Water activity (a w) highly influences the quality of the dried milk products. As milk powder is commonly stored for long time, it is critical, in order to minimize nutritional damages, to keep the system at correct temperature and a w conditions, below the lactose glass transition, in order to prevent the crystallization of amorphous lactose and control the water migration (Pugliese et al. 2016; Kim et al. 2009). The irreversible conversion of the amorphous lactose to the crystalline form may lead to lumping and caking of the powder and deterioration of its reconstitution properties (Mistry and Pulgar 1996).

The water activity values of the analysed powders ranged from 0.237 to 0.303 and from 0.249 to 0.329, for the skim and whole milk powders, respectively (Table 3). The studies of Szulc et al. (2016) and Thomsen et al. (2005) are consistent with our findings reporting respectively, for whole milk powders, water activity values of 0.360 and 0.230. On the other hand, other authors found a wide range of water activity in skim milk powders with values ranging from 0.100 to 0.380 (Hogan et al. 2010; Morgan et al. 2005).

Particle size distribution of dried milk products

The shape and the size of the particles are function of the drying system and the grinding operations (Tamime 2009; Schuck and Ouest 2011). The particles of spray-dried powder are spherical with diameters in the range of 10–250 micron and depends mostly on the nozzle properties (Schuck and Ouest 2011). Powders produced by roller drying, on the other hand, have a compact structure, irregular shape with no occluded air and the final particle dimensions depends mostly by the grinding operations.

The volume weighted mean (D[4, 3]) and the surface weighted mean (D[3, 2]) diameters of the spray-dried milk particles ranged from 72.60 to 135.66, and from 25.86 to 85.19 micron, respectively (Table 4). The roller-dried powder reported the highest particle size diameters among all the analysed samples. SMP2 and SMP6 as well as WMP2 showed an increased span with respect to other samples indicating a higher inhomogeneity of the powders. The size of WM powder particles was significantly (p < 0.05) higher than that of SM powders. The average of the median particle size (D50) for skim and whole milk powder was 83.87 and 128.76 micron (Table 4), respectively. Smaller dimensions were found by Fitzpatrick et al. (2004) in which skim and whole milk had a D50 of 53 and 99 micron, respectively. On the contrary, Szulc et al. (2016) reported the opposite trend for skim and whole milk powders: 91.2 micron for the skim and 55.5 micron for the whole milk powders. Ilari and Mekkaoui (2005) found a D50 of 66 micron for skim milk powder. Gaiani et al. (2011) reported approximately 75 micron for D50 in whole milk. The median particle size of the skim milk powders obtained with different pressure and temperature by Nikolova et al. (2014) ranged between 51 and 123 micron.

Kwak et al. (2009) analysed the particle size of a spray dried infant formula using ethanol as a dispersant and reported a volume weighted mean diameter (D[4, 3]) of 197.6, a surface weighted mean diameter (D[3, 2]) of 120.1, and a median of 174.3 micron. These results were so much higher than the spray-dried samples studied in the present study and were probably due to the aggregation of powder particle of the infant formula. Murphy et al. (2015) reported a D[4, 3] of 155.4 micron for a manufactured infant milk formula containing non-hydrolysed proteins. The size and the distribution of the droplets of spray-dried products is well known to be strongly dependent on the type of nozzle used to nebulize the milk (Tamime 2009).

The particles of the roller-dried powder (WMP2) were the largest (p < 0.05) with a volume weighted mean and a median diameter value of 215.26 and 168.14 micron, respectively. Fitzpatrick et al. (2005) reported that roller-dried powder tends to have larger mean particle size of around 150 micron and low vacuole volume, while spray-dried powder has smaller particle size of about 70 micron and a high vacuole volume.

Size distribution and inter-particles relationships originated during the drying operation influenced the powder flowability. In general, powders with good flow properties are those with a narrower distribution (Sharma et al. 2012). The amplitude of size distribution is usually measured with the span value. Span values of the particles size of the analysed milk powders resulted from 1.65 to 2.33 (Table 4). These findings confirmed the research of Ilari and Mekkaoui (2005) who reported a span of 1.93 for skim milk powder. However, Nikolova et al. (2014) reported a lower span values ranging from 1.11 to 1.39. Roller-dried milk particles had the largest median diameter and the largest D90 value, but the span value was not the highest.

Density and flowability

The loose density of the studied milk powders was in the range of 407–666 kg/m3. Except for the skim sample SMP5 (407 kg/m3), the loose density of skim milk powders resulted significantly higher (p < 0.05) than that of whole milk powder, with an average of 541.36 and 449.75 kg/m3 (Table 5), respectively. The loose density measurement of the dried milk necessarily takes into account the contribution of the air included in the particles, created by the moisture evaporation during the drying process, and of the interstitial air between particles, influenced by the shape and size of the particles themselves. To reduce the influence of the interstitial air on the measurement, the loose density is juxtaposed with the tapped density. For all the samples, the tapped density followed the same trend of the loose density (R2 = 0.99), suggesting that the shape of the particles was quite homogeneous, as expected for spray dried samples. Tapping increased the density values about 1.4 times up to an average of 736.91 and 625.62 kg/m3 for the skim and whole milk powder, respectively. Loose density values measured in this work were in the range of data reported in literature, while tapped density values were higher, as shown in Table 5 (Ilari 2002; Szulc et al. 2016; Fitzpatrick et al. 2005; Mistry and Pulgar 1996).

It is possible to calculate other two critical quality attributes by using loose and tapped density values: (1) the Hausner ratio, that is an indicator of the cohesion of the milk powder particles, inversely related with the size of the particles (Ilari and Mekkaoui 2005); (2) the compressibility index (sometimes referred as Carr’s index) that measures the ability to reduce the volume of a powder by tapping. A milk powder with a compressibility index higher than 28% is classified as cohesive (Ilari and Mekkaoui 2005) or, in other words, with lower flowability. In general, powders with good flow properties are those with large agglomerates and few fines (Sharma et al. 2012), as a larger size is related with lower cohesion because of less friction and poor Van der Walls forces (Ilari and Mekkaoui 2005).

The values of flowability, evaluated on the basis of these indexes, ranged in this paper from passable to poor (Table 5), according to the classification of the European Pharmacopeia (Powder flow, European Pharmacopoeia) (Table 1) and the values suggested by Lebrun et al. (2012). The presence of fat does not seem to influence the values of Hausner ratio and Carr’s index of the skim and whole milk powders analysed, that resulted in similar values (Table 5). The values found in the present paper were in the range of previous literature: Ilari and Mekkaoui (2005) reported values of Hausner ratio between 1.26 and 1.59 for skim and whole milk powders, respectively. Focusing on the SMP and WMP groups separately, with the few exception of samples SMP4, SMP7 and WMP2, the lowest values of Hausner ratio and Carr’s index fitted with the large particle size of the analysed samples (Tables 4, 5).

Insolubility index (ISi)

The insolubility index (ISi) is an indirect method to measure the solubility. Since the solubility index is inversely related to solubility, it seems more direct and more rational to use the term “insolubility index” to describe what is determined by a solubilisation method. The ISi values of SM powders were equal or less than 0.1 mL (Table 6). ISi of WM powders varied from 0.1 to 0.8 mL, with the highest value measured for the roller dried sample WMP2. WM powders show ISi values higher than SM powders, probably because of the lower water dispersion of fats in water. The ISi values found in this study were often lower than the value of 0.45 mL reported in non-fat dried milk by Mistry and Pulgar (1996). Augustin et al. (2014) found an insolubility index lower than 0.5 mL for several full cream milk powders. For a more accurate description of the solubility properties, the sediment was dried and weighted. SM powder dried residue ranged from 0.8 to 8.0 mg, while WMP dried residue ranged from 3.9 to 113.5 mg, the latter related to the sample obtained with roller technology (WMP2) (Table 6). The expression of the insolubility index using the weight of the sediment has been found to be a better method in this study to compare different categories of milk powders and is in agreement with the classical differentiation from high to extra low heat milk powders, based on the whey nitrogen protein index (Bylund 1995).

During spray-drying the main factor controlling the insolubility index is the particle temperature when their moisture content is between 10 and 30%. ISi may increase with the particle diameter and the air temperature (Straatsma et al. 1999). The mechanism proposed to explain milk powder insolubility involves the unfolding of the β-lactoglobulin and its aggregation with casein, and also the fouling of heating equipment associate to the drying conditions (Thomas et al. 2004). The present results for the roller-dried WMP sample confirmed the finding of Tamime (2009), who affirmed that the roller-dried milk powder has the lowest solubility (about 85%). Several process parameters may be controlled to improve the solubility of the milk powder. Preheat treatment of the milk improves the stability of the final reconstituted product. The drying procedure parameters need to be adjusted so that the last phase of drying, when the concentration of total solids is high, is as short as possible. Direct contact between milk and hot metal surfaces of roller dryers causes high degree of denaturation, which affects the solubility. Ions (i.e., ion balance), including pH or added salts, have a great influence on the protein stability and the powder solubility (Schuck and Ouest 2011).

Colour

Colour properties of milk powders are reported in Table 7. L* values of skim milk were slightly higher than that of whole milk powders. As expected because of their fat content, WMP resulted yellower (significant higher positive values of b*) (p < 0.05), and less green (p < 0.05) (values of a* less negative) than SMP. The values found in this study (Table 7) were in agreement with the findings of Bosset et al. (1979) and with the trend shown by Kneifel et al. (1992) who reported L* values from 93 to 94.9, a* values from −1.7 to −2.6 and b* values from 11.3 to 18.3 on skim milk powders. On the other hand, Koc et al. (2003) found different colour properties of WM powders with L* value around 79, a* from 0.0 to −1.7, and b* from 6.9 to 8.9. Nanua et al. (2000) found results similar to the present study for the L* value (95.96), but quite different values of a* and b* (3.05 and 9.56, respectively) denoting a whole milk powder less green and yellow.

The differences of colour may be due to the interactions of many variables. The modification of the particles size, the concentration of the particles and pigments, due to the moisture removal during evaporation and drying; the formation of brownish pigments by Maillard reactions during the heat treatment (Walstra et al. 2006) could all have contributed.

Factor analysis and principal component analysis (PCA)

Figure 1 shows the principal component (PC) analysis projection of the variables and cases on the principal factors plan. The two principal components (PC1 and PC2) well described relations among variables in the model, explaining 73.18% of the total variance (49.92% the first and 23.26% the second component). The graph shows a separation between SMP and WMP samples along the PC1, principally due to the parameters of density, insolubility, particles diameter and colour. On the other hand, PC2 discriminate the samples SMP2, SMP4 and WMP2 from the other milk powders, clearly as consequence of the a w and span values, which didn’t show projections on PC1. D[4, 3] and D[3, 2] had very close projections on PC1 denoting the high correlation along these components whereas they were discriminant along PC2.

The loose and tapped densities, being highly correlated, behave as a single variable. The different physical properties of milk powders included in the first component can be attributed to the fat content of the milk, which is decisive for such properties as density and colour components (a* and b*) for WMP. The milk powder obtained with the roller drying method confirmed its particular behaviour, underlined by the loadings that mostly characterize that sample, as the D[4, 3], the D[3, 2] and the insolubility index.

Conclusion

The scope of this research was to complement and to extend the literature information on physical properties of milk powders produced in the last few years. Most of the results obtained in this research are in agreement with the pre-existing literature. Activity water, particle size, density, flowability and, to a lesser extent, colour were similar to those reported in the past. Quite different from literature values were the results of the insolubility index, that highlighted a higher solubility of the powders analysed in the present research in comparison to the previous published data. Furthermore, the expression of the insolubility index, using the weight of the sediment, improved the ability to discriminate among different samples, which resulted to have optimal properties (insolubility index <0.1 mL), as with to discriminate clearly among different samples as also measured with the reference method.

Physical properties of milk powders were found to be largely influenced by the drying method, varied process conditions, composition and make thus governing the intended use.

References

Al Mahdi R, Nasirpour A, Banon S, Scher J, Desobry S (2006) Morphological and mechanical properties of dried skimmed milk and wheat flour mixtures during storage. Powder Technol 163:145–151

Augustin MA, Puvanenthiran A, Clarke PT, Sanguansri P (2014) Energy use for alternative full-cream milk powder manufacturing processes. J Food Eng 124:191–196

Bosset JO, Martin B, Blanc B (1979) La mesure de la couleur du lait et des produits laitiers par photométrie de réflexion (méthode tristimulus). Trav Chim Aliment Hyg 70:203–227

Bylund G (1995) Dairy processing handbook. Tetra Pack Publisher, Lund

Crowley SV, Desautel B, Gazi I, Kelly AL, Huppertz T, O’Mahony JA (2015) Rehydration characteristics of milk protein concentrate powders. Int Dairy J 149:105–113

Damin MR, Alcântara MR, Nunes AP, Oliveira MN (2009) Effects of milk supplementation with skim milk powder, whey protein concentrate and sodium caseinate on acidification kinetics, rheological properties and structure of nonfat stirred yogurt. LWT-Food Sci Technol 42:1744–1750

Fitzpatrick J, Iqbal T, Delaney C, Twomey T, Keogh M (2004) Effect of powder properties and storage conditions on the flowability of milk powders with different fat contents. J Food Eng 64:435–444

Fitzpatrick JF, Arry KB, Elaney CD, Eogh KK (2005) Assessment of the flowability of spray-dried milk. Lait 85:269–277

Flow Powder (2011) European pharmacopoeia, 7.1st edn. Council of Europe, Strasbourg

Gaiani C, Boyanova P, Hussain R, Murrieta Pazos I, Karam MC, Burgain J, Scher J (2011) Morphological descriptors and colour as a tool to better understand rehydration properties of dairy powders. Int Dairy J 21:462–469

Guerin E, Tchoreloff P, Leclerc B, Tanguy D, Deleuil M, Couarraze G (1999) Rheological characterization of pharmaceutical powders using tap testing, shear cell and mercury porosimeter. Int J Pharm 189:91–103

Hogan SA, Famelart NM, O’Callaghan DJ, Schuck P (2010) A novel technique for determining glass–rubber transition in dairy powders. J Food Eng 99:76–82

IDF Standard 129A (1988) Dried milk and dried milk product. Determination of insolubility index. IDF, Brussels

Iezzi R, Locci F, Ghiglietti R, Belingheri C, Francolino S, Mucchetti G (2012) Parmigiano Reggiano and Grana Padano cheese curd grains size and distribution by image analysis. LWT-Food Sci Technol 47:380–385

Ilari JL (2002) Flow properties of industrial dairy powders. Lait 82:383–399

Ilari JL, Mekkaoui L (2005) Physical properties of constitutive size classes of spray-dried skim milk powder and their mixtures. Lait 85:279–294

Juliano P, Muhunthan B, Barbosa-Cánovas GV (2006) Flow and shear descriptors of preconsolidated food powders. J Food Eng 72:157–166

Kelly GM, O’Mahony JA, Kelly AL, Huppertz T, Kennedy D, O’Callaghan DJ (2015) Influence of protein concentration on surface composition and physico-chemical properties of spray-dried milk protein concentrate powders. Int Dairy J 51:34–40

Kenny S, Wehrle K, Stanton C, Arendt EK (2000) Incorporation of dairy ingredients into wheat bread: effects on dough rheology and bread quality. Eur Food Res Technol 210:391–396

Kim EHJ, Chen XD, Pearce D (2005) Melting characteristics of fat present on the surface of industrial spray-dried dairy powders. Colloids Surf B Biointerfaces 42:1–8

Kim EHJ, Chen XD, Pearce D (2009) Surface composition of industrial spray-dried milk powders. 3. Changes in the surface composition during long-term storage. J Food Eng 94:182–191

Kneifel W, Ulberth F, Schaffer E (1992) Tristimulus colour reflectance measurement of milk and dairy products. Lait 72:383–391

Koc A, Heinemann P, Ziegler G (2003) A process for increasing the free fat content of spray-dried whole milk powder. Food Eng Phys Prop 68:210–216

Kwak BM, Lee JE, Ahn JH, Jeon TH (2009) Laser diffraction particle sizing by wet dispersion method for spray-dried infant formula. J Food Eng 92:324–330

Lebrun P, Krier F, Mantanus J, Grohganz H, Yang M, Rozet E, Boulanger B, Evrard B, Rantanen J, Hubert P (2012) Design space approach in the optimization of the spray-drying process. Eur J Pharm Biopharm 80:226–234

Mistry VV, Pulgar JB (1996) Physical and storage properties of high milk protein powder. Int Dairy J 6:195–203

Morgan F, Nouzille Appolonia C, Baechler R, Vuataz R, Raemy A (2005) Lactose crystallisation and early Maillard reaction in skim milk powder and whey protein concentrates. Lait 85:315–323

Murphy EG, Roos YH, Hogan SA, Maher PG, Flynn CG, Fenelon MA (2015) Physical stability of infant milk formula made with selectively hydrolysed whey proteins. Int Dairy J 40:39–46

Nanua JN, McGregor JU, Godbert JS (2000) Influence of high-oryzanol rice bran oil on the oxidative stability of whole milk powder. J Dairy Sci 83:2426–2431

Nielsen BR, Stapelfeldt H, Skibsted LH (1997) Differentiation between 15 whole milk powders in relation to oxidative stability during accelerated storage: analysis of variance and canonical variable analysis. Int Dairy J 7:589–599

Nikolova Y, Petit J, Sanders C, Gianfrancesco A, Desbenoit N, Frache G, Francius G, Scher J, Gaiani C (2014) Is it possible to modulate the structure of skim milk particle through drying process and parameters? J Food Eng 142:179–189

OJEC (2002) Council Directive 2001/114/EC of 20 December 2001 relating to certain partly or wholly dehydrated preserved milk for human consumption. Official Journal of European Community 17.1.2002 L15/19

OJEC (2007) Council Directive 2007/61/EC of 26 September 2007 amending Directive 2001/114/EC relating to certain partly or wholly dehydrated preserved milk for human consumption. Official Journal of European Community 4.10.2007 L258/27

Patel RP, Patel MP, Suthar AM (2009) Spray drying technology: an overview. Indian J Sci Technol 2:44–47

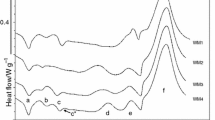

Pugliese A, Paciulli M, Chiavaro E, Mucchetti G (2016) Characterization of commercial dried milk and some of its derivatives by differential scanning calorimetry. J Therm Anal Calorim. doi:10.1007/s10973-016-5243-y (In Press)

Reddy RS, Ramachandra CT, Hiregoudar S, Nidoni U, Ram J, Kammar M (2014) Influence of processing conditions on functional and reconstitution properties of milk powder made from Osmanabadi goat milk by spray drying. Small Rumin Res 119:130–137

Schuck P, Ouest A (2011) Milk powder: physical and functional properties of milk powders. In: Fuquay JW, Fox PF, McSweeney PLH (eds) Encyclopedia of dairy sciences. Academic Press, San Diego, pp 117–124

Schuck P, Dolivet A, Méjean S, Jeantet R (2008) Relative humidity of outlet air: the key parameter to optimize moisture content and water activity of dairy powders. Dairy Sci Technol 88:45–52

Sharma A, Jana AH, Chavan RS (2012) Functionality of milk powders and milk-based powders for end use applications—a review. Compr Rev Food Sci Food Saf 11:518–528

Straatsma J, Van Houwelingen G, Steenbergen E, De Jong P (1999) Spray drying of food products: 2. Prediction of insolubility index. J Food Eng 42:73–77

Szulc K, Nazarko J, Ostrowska-Ligęza E, Lenart A (2016) Effect of fat replacement on flow and thermal properties of dairy powders. LWT-Food Sci Technol 68:653–658

Tamime AY (2009) Dried milk products. Dairy powders and concentrated milk products. Blackwell Pub. Ltd., Oxford, pp 231–245

Thomas MEC, Scher J, Desobry-Banon S, Desobry S (2004) Milk powders ageing: effect on physical and functional properties. Crit Rev Food Sci Nutr 44:297–322

Thomsen MK, Jespersen L, Sjøstrøm K, Risbo J, Skibsted LH (2005) Water activity-temperature state diagram of amorphous lactose. J Agric Food Chem 53:9182–9185

Walstra P (2003) Physical chemistry of foods. Marcell Dekker Inc, New York

Walstra P, Wouters JTM, Geurts TJ (2006) Dairy science and technology. CRC Press, Boca Raton

Acknowledgements

The study has been carried out with financial support from the European Commission’s, 7th Framework Programme (FP7), Project SUSMILK (Re-design of the dairy industry for sustainable milk processing), and no. 613589. The authors gratefully acknowledged Miss Angelica Alberti for performing part of the experiments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pugliese, A., Cabassi, G., Chiavaro, E. et al. Physical characterization of whole and skim dried milk powders. J Food Sci Technol 54, 3433–3442 (2017). https://doi.org/10.1007/s13197-017-2795-1

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-017-2795-1