Abstract

This study was undertaken to prepare novelly formulated cookies from elephant foot yam flour (EFYF) with refined wheat flour (RWF) and evaluate their proximate composition, quality characteristics, texture, pasting and organoleptic properties. The formulated cookies prepared from EFYF, substituting RWF up to 70% had sensory properties similar to that of refined flour cookies (control). EFYF and RWF blend revealed reduced water and oil absorption capacity with increased peak and final viscosities when compared with RWF. Reduced lightness, increased redness and hardness were observed for formulated cookies with increase in storage time. Irrespective of the decreasing trend in their texture, overall acceptance of the EFYF cookies by the consumers was increased. Sensory scores revealed the preference of consumers towards formulated cookies. Overall analysis disclosed that the cookies prepared from A. paeoniifolius flour proved acceptable not only in quality characteristics but also fulfil the demand of functional foods in preparation of cookies.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Amorphophallus paeoniifoilus known as elephant foot yam is a tropical tuber crop, commonly available throughout India. It is widely used in the Indian traditional system of medicine and it contains adequate source of starch, nutrients, minerals and proteins (Hurkadale et al. 2012). In general, the corms of A. paeoniifoilus are a delicacy in food and it is commonly used as vegetable in delicious cuisines. A. paeoniifoilus tuber contains blood purifier properties and traditionally used for the treatment of abdominal disorders, asthma, dyspnoea, splenomegaly, tumors and rheumatism (Hurkadale et al. 2012; Singh et al. 2015). The tuber can acts as functional food due to the presence of starch and resistant starch which confers numerous physiological health benefits in humans predominately on individuals with degenerative diseases like obesity, diabetes and hyperlipidemia (Reddy et al. 2014).

Consumption of A. paeoniifolius is not widely practiced, and further storage of fresh yam is a difficult process and deterioration is rapid (Afoakwa and Sefa-Dedeh 2001). Studies have proved that drying techniques combined with blanching process have significantly improved its feasibility and viability option in food formulations (Suriya et al. 2016). Discoloration phenomenon is the common defect observed in fresh tubers which is mainly associated with enzymatic browning. The browning reactions happen due to action of polyphenol-oxidase and peroxidase enzymes (Asemota et al. 1992). Blanching process prevents browning reaction through enzyme deactivation. Therefore, preservation of A. paeoniifolius would be a vital step in unraveling the nutraceutical potential of A. paeoniifolius.

Moreover, the dietary guidelines advocate the consumption of composite flour against the refined flours because of the ill effects on humans (Devi and Haripriya 2014). Bakery products are widely prepared using refined flour and also consumed by all individuals and in particular cookies are always the most opted products by all age groups (Zouari et al. 2016). Cookies are basically prepared with refined flour, sugar, salt and water as the main ingredient. Like biscuits, cookies are also advantageous foods to bring about composite flour incorporation from the view of health eminence. Universally refined flour is the key contributor to the organoleptic quality of finished product, which in turn rests on the gelling and pasting behavior of the flour (Jan et al. 2016). The physicochemical properties of the A. paeoniifolius flour (EFYF) have paved way with similar pasting and hydration behavior for its incorporation in cookies preparation (Reddy et al. 2014; Suriya et al. 2016).

There is no information on the preparation of A. paeoniifolius flour using hot air oven as a drying method involving blanching as a process and also incorporation of A. paeoniifolius flour in value added products. With this limited information the objective of the study was focused on the hydration and pasting properties of A. paeoniifolius flour; and also development and quality characteristics of cookies fortified with A. paeoniifolius flour.

Methodology

Materials

Refined wheat flour (RWF), A. paeoniifolius, sugar and butter were obtained from the local market of Puducherry, India. Refined wheat flour was sieved through 200 µm mesh sieve and stored in air tight containers at room temperature (25 ± 2 °C) for further analysis. All chemical and reagents used were of analytical grade.

Preparation of A. paeoniifolius flour

The flour was prepared using the modified procedure as described by Suriya et al. (2016). Briefly, the corms of yam were thoroughly washed with water, peeled and trimmed to remove defective parts; and then the corms were sliced with a slicer. Then yam slices were blanched with 0.1% sodium metabisulphite solution at 70 °C for 5 min. Blanched sample were cooled in tap water, drained and blotted dry with a paper towel. After that yam slices were dried in a hot-air oven (Technico, TLPPL-130, Chennai, India) for 12 h at 40 °C. Dried yam slices were ground in laboratory blender (Prestige Hand Blender PHB 5.0, Bangalore, India) and sieved through a 60 mesh screen to get yam flour. Samples were then stored in air tight plastic containers in a cool, dark and dry place at room temperature (25 ± 2 °C).

Proximate composition of flours

The proximate composition of RWF, EFYF and their flour blend (FB, 70:30 EFYF: RWF) were estimated using standard AOAC methods (2005). Moisture content was analyzed by hot air oven method, crude protein by Micro-Kjeldahl method, ash content by dry ashing method and crude fat by Soxhlet extraction method. The amount of carbohydrates was calculated by difference method and conversion factors.

Functional and hydration properties of flours

Water and oil absorption capacity

The water absorption capacity (WAC) and oil absorption capacity (OAC) of flour samples were analyzed according to the procedure of Suriya et al. (2016).

Swelling power

The swelling power (SP) of flour samples were analysed using the procedure described by Suriya et al. (2016).

Foaming capacity

The flour sample (2 g) was mixed with 50 mL distilled water at 30 °C in a 100 mL measuring cylinder. The suspension was shaken properly for 3 min to form foam. Volume of foam after 30 s was recorded.

Bulk density

The flour samples weighing 3 g were gradually placed in 10 mL graduated cylinder, respectively. The base of the graduated cylinder was tapped on the laboratory bench several times until there was no further attenuation of the level of sample. Weight of the sample per unit volume of sample (g/mL) corresponds the bulk density.

Pasting properties of flours

The pasting properties of flour samples were analysed using Rapid Visco Analyser (RVA starch master-2, Newport Scientific Pty. Ltd., Warriewood, Australia) according to the method of Reddy et al. (2016). The slurry was prepared by mixing 3.0 g of sample with 25 mL distilled water. Then, it was heated at 50 °C with continuous stirring for 10 s and held for 1 min. The temperature was elevated to 95 °C (heating rate 6 °C/min) for 7.3 min and held for 5 min and finally cooled at 50 °C (Cooling rate 6 °C/min).

Composition and development of cookies

Initially cookies were prepared with various percentage of EFYF (0, 10, 20, 30, 40, 50, 60, 70, 80, and 90) replacing RWF. Sensory evaluation of the prepared cookies was done and it was noted that until 70% incorporation of EFYF, cookies were accepted by consumers (results not presented). Therefore a flour blend (FB) of 70% EFYF and 30% RWF was used for the development of cookies. The recipe for preparation of yam cookies was optimized with flour blends along with the required other ingredients including: water (4.95 mL), RWF (14.85 g) and sugar (19.80 g) added together in a laboratory mixer and mixed for 20 min at slow speed. Further, sodium chloride (0.5 g), baking powder (1.0 g) was added and mixed for 2–3 min and then unsalted butter (24.75 g) was used as shortening agent. Later, whole mixture was agitated for 10–15 min until the mixture appeared creamy or fluffy incorporated with air. Sieved EFYF (34.65 g) was added portion by portion into the creamy mixture and mixed for 2 min. The dough was then sheeted to a thickness of 7 mm with the help of a cylindrical rolling pin and cut into circular shapes of 49 mm diameter. The cookies were baked at 200 °C for 20 min in a convention oven. The baked cookies were cooled at room temperature, packed in air tight LDPE pouches for further analysis. Cookies were made from RWF to serve as a control.

Quality characteristics of cookies

Physical analysis of cookies

The physical properties of control and yam cookies were analyzed for its weight using balance (ELB3000, Shimadzu, Japan) and cookie dimensions for the thickness (the distance between top and bottom surface of cookie) and width (distance across the cookie) were determined using Vernier caliper.

Spread ratio

The spread ratio of the baked cookies were determined from the ratio of width and thickness of cookies.

Proximate composition of cookies

The samples of baked cookies were estimated for their moisture, ash, protein (N*6.25) and fat content using standard AOAC (2005) methods. The content of carbohydrate was calculated by difference.

Colour analysis of cookies

The colour of baked cookies were read as L*, a* and b* using Hunter Lab Colorimeter (D-25, Hunter Associated Laboratory, USA). The Hunter lab colorimeter was calibrated by Hunter colour standard prior to the reading of cookies samples as described by Devi and Haripriya (2014).

Textural analysis of cookies

Hardness of baked cookies was measured in terms of breaking strength using Texture Analyzer (TA-HD plus, stable Micro systems, UK). Breaking strength of cookies was placed on the platform such that they are supported at two points and the blade was attached to the crosshead of the instrument. The analyzer was set to return to start cycle, at a speed of 1.5 mm/s and a distance of 15 mm. This experiment simulates the assessment of hardness by consumer holding the cookie in hands and breaking by bending. The peak force from the subsequent curve was measured as the breaking strength of the cookies.

Water activity of cookies

The water activity of the baked cookies were determined using an electronic dew point water activity meter (Aqualab Series 4TE, Decagon Devices, Inc., USA) at room temperature (25 ± 2 °C). Sufficient amount of sample was taken in sample holder and precaution was taken so that sample does not touch the sensor. Measurement of water activity was carried out until the value was concurrent.

Sensory evaluation

To assess the quality and acceptability of control and yam cookies, sensory evaluation was conducted by semi-trained panelists from the Food Science and Technology Division, Pondicherry University for appearance, color, aroma and texture of cookies. Sensory evaluation was carried out using 9-Point Hedonic Score System.

Statistical analysis

Analytical determination for the flours and cookies were carried out in triplicates and standard deviations were noted. The data was subjected to one way ANOVA to analyze the significant difference in all data. Duncan’s Multiple Range Test (DMRT) (p ≤ 0.05) was used to analyze the significant difference between the mean values of samples using IBM SPSS Statistics, version 20.0. Armonk, NY: IBM corporation.

Results and discussion

Proximate compositions of flours

Moisture, protein, fat, carbohydrate and ash contents of the RWF, EFYF and FB are depicted in Table 1. Moisture content of the flours ranged from 9.53 to 11.34%. Moisture content of flour could be influenced by processing conditions and surrounding atmospheric humidity (Reddy et al. 2015). As seen in Table 1, EFYF exhibited higher ash and carbohydrate content as compared to RWF and FB. The higher ash content of EFYF may be due to the presence of higher phosphorus and resistant starch content in their starches (Reddy et al. 2014; Singh et al. 2003). Similar results were also reported by Yousif and Safaa (2014) wherein chickpea and sweet lupine flours contained higher ash content than rice flour and corn flour. These observations were in agreement with the earlier reports (Cheng and Bhat 2016; Yadav et al. 2012) in which jering seed, bambara groundnut and chickpea flour had higher nutritional values compared to wheat flour. However, a significant difference was observed in ash, protein and carbohydrate content of RWF, EFYF and FB. The average content of protein in the flours ranged from 8.82 to 11.12%. Difference in chemical composition with respect to blending has also been noted by Ahmad et al. (2016) in wheat flour blended with carrot pomace powder. The variances in protein, fat, ash and carbohydrate contents of EFYF and RWF may also be accredited to genetic variation and botanical origin (Singh et al. 2003).

Functional and hydration properties of flours

Water absorption capacity and oil absorption capacity

In general, a functional characteristic of flour plays a major role in the accomplishment of ready to eat food products and high water absorption capacity may facilitate in the cohesiveness of the product (Shobha et al. 2014). It is vital to assess these intrinsic functional properties as they can maintain the behavior of food constituents in a complex food system, either during food processing, manufacturing or storage (Cheng and Bhat 2016). Table 1 presents the various functional characteristics of flours. The WAC of EFYF was observed to be significantly (p ≤ 0.05) higher than that of RWF and FB; the variance of WAC in flours may be due to the difference in particle size, shape and also the presence of different hydrophilic carbohydrates, lipids and proteins (Kaur et al. 2015; Singh et al. 2003). The OAC of EFYF was significantly higher than that of RWF and FB. Blend flour (70% EFYF and 30% RWF) has shown value of 1.87% OAC than RWF (1.86%). OAC of flour plays a significant role in improvement of shelf life and palatability especially in bakery product where fat absorption is desirable. OAC also reflects in flavor retention and enhanced mouth feel (Aremu et al. 2007). The variance in the existence of non-polar groups in flours and binding capacity with flour might be responsible for difference in OAC of flours; the content of protein with hydrophilic and hydrophobic groups plays a significant role in determining OAC of flours (Kaur et al. 2015).

Swelling power

The swelling power (SP) of the RWF, EFYF and FB are summarized in Table 1. SP is a denotation of the assimilation index of granules present in flours during heating. SP of RWF (5.28%) was significantly higher than that of EFYF (3.17%) and FB (4.57%); and SP can reveal the degree of the associative forces within the granule (Moorthy and Ramanujam 1986). Increased SP is referred to a movable structure that allows both water absorption and high soluble solids which may induce flaky nature which is a desirable property in cookies. The difference in SP of flour blends has also been stated by Ahmad et al. (2016) for wheat flour merged with carrot pomace powder and for wheat flour combined with sesame peels flour by Zouari et al. (2016).

Foaming capacity and bulk density

Foaming capacity (FC) and bulk density (BD) of RWF, EFYF and FB are summarized in Table 1. The FC is accredited to the existence of proteins, which form a continuous cohesive film around the air bubbles in the foam. The FC of RWF (33.38%) was found to be significantly higher than that of EFYF (7.21%) and FB (11.88%). The quantity and configuration of protein in flours play a significant role in the maintenance of FC. Good FC is observed in flexible protein whereas globular proteins are highly ordered in nature having low foam ability (Baljeet et al. 2010). The changes in the foaming capacity of flour blends are comparable with earlier studies stated by Ahmad et al. (2016) and Zouari et al. (2016). Bulk densities of RWF (0.52 g/mL), EFYF (0.55 g/mL) and FB (0.51 g/mL) showed no significant difference. In general, BD is affected by particle size and density of flours; and also plays a major role in analyzing the packaging requirement and material handling in the food industry (Cheng and Bhat 2016). Earlier, Chauhan et al. (2015) reported similar results for bulk density of flour blend especially wheat flour blended with amaranth flour.

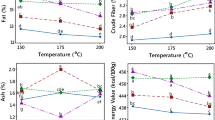

Pasting properties

Pasting properties are depended on the source, starch granule size, ratio of amylose to amylopectin, structure of amylopectin, interactions between molecules and testing conditions (Reddy et al. 2014; Singh et al. 2003). Amylopectin is predominantly responsible for granule swelling, whereas amylose and lipid control the swelling. In the presence of water, starch suspensions were subjected to thermal process, where the starch granules swell and thus the viscosity increased progressively. Pasting properties of RWF, EFYF and FB are given in Fig. 1 and Table S1. Significant variation was detected in pasting parameters of the flours and flour blends. Peak, breakdown and setback viscosities of RWF were significantly higher than that of EFYF, whereas hold viscosity of EFYF was significantly higher than that of RWF. Pasting temperature is the temperature at which irreversible swelling of the starch granules occur, leading to the formulation of a viscous paste in an aqueous solution. The pasting temperatures of RWF (66.65 °C), EFYF (86.54 °C) and FB (86.45 °C) had significant difference which indicates that the minimum temperature required to cook flours differed. The high pasting temperature specifies the occurrence of more starch that is extremely resistant to swelling and rupturing. Peak viscosities of RWF (2335 cP) and FB (2409 cP) were significantly higher when compared to EFYF (1917.50 cP) which indicates that both RWF and FB has higher water holding capacity than EFYF. Final viscosities of RWF (2566.5 cP), EFYF (2568 cP) and FB (2673.5 cP) had no significant difference indicating their similar retrogradation behaviour after cooling due to the recrystallization of leached amylose molecules. Breakdown viscosity indicates degree of disintegration of granules produced by the continuous shear and stress at raised temperatures (Ahmad et al. 2016). Breakdown viscosities of RWF (894 cP), EFYF (53 cP) and FB (628 cP) had significant difference, which could be due to difference in particle size of flours. Setback, a measure of retrogradation or re-ordering of starch molecules, was higher for RWF (1099 cP) than EFYF (704 cP) and FB (892 cP). This depicted that EFYF and FB starch retrograded less as compared to RWF starch. This can be illuminated on the basis that amylose molecules re-associate more readily than amylopectin (branched) molecules resulting in greater retrogradation (Shafi et al. 2016).

Quality evaluation of control and yam cookies

Physical analysis of cookies

Results on the physical properties of control and the yam cookies are shown in Table 2. The product parameters like weight, thickness, width and spread factor in case of cookies have direct relation to product uniformity, quality, and consumer acceptance (Chauhan et al. 2015). The weight, thickness, and width of control and EFYF cookies were not significantly different. In general cookies with higher spread ratios are considered as supremely desirable. The spreadability potential of the flour along with the action of leavening agent and influence of heat would be responsible for the changes in cookie dimensions when baked. Table 2 shows the improvement in diameter of cookies along with raise in thickness due to baking. The width of baked yam cookies was smaller than that of the control cookies.

The quality of cookies is widely determined by spread factor which is a relatively complex phenomenon influenced by a wide variety of factors (Pareyt et al. 2009). Earlier, Olapade and Adeyemo (2014) reported that the lowest spread ratio implies better rising ability of cookies. As shown in Table 2, the highest spread ratio was observed for control cookies (6.67) and lowest spread ratio for yam cookies (6.34). Similar results were reported in cookies made from wheat-water chestnut flour (Shafi et al. 2016). According to McWatters (1978), the composite flours may form aggregates with increased numbers of hydrophilic sites that compete for limited free water in cookies dough thereby increasing dough viscosity and limiting cookie spread. The major components in cookie formulation are flour, sugar and fat. Sugar mainly contributes to cookie spread. During baking, un-dissolved sugar gets dissolved which leads to the dough spreading on baking (Hoseney and Rogers 1994). Lai and Lin (2006) reported that during baking the melting of fat takes place which allows the water to migrate and make it available for the dissolution of sugar. The structural variation in flour helps absorb more water, but the water in the EFYF cookie formulation is already limited as a result the dough remained harder consequently less spread ratio is noted in case of yam cookies as compared to control cookies.

Chemical composition of cookies

Chemical composition of the product is very important as it describes about the percentage of nutrient content present in the food product. It extend its job to find out the qualitative and quantitative chemical changes taking place in product on storage and its effect on the overall quality and shelf life of the product. It also helps to find the appropriate packaging material for the product. From the results, it was detected that the chemical composition values for moisture, protein, fat, ash and carbohydrate were low in control cookies (Table 2). The proximate composition values augmented with addition of EFYF. The moisture content of the yam and control cookies are 3.53 and 3.43%, respectively. This trend can be acceptable as the moisture levels in freshly baked cookies are usually less than 5% (Cheng and Bhat 2016). Low moisture content can render the cookies to be more stable and is expected to enhance the shelf-life. In previous studies, Mustafa et al. (1986) described that an increase in moisture content of bakery products with increase in protein content. The protein content of the yam cookies (7.60%) was significantly higher compared to that of the control cookies (7.14%). These results are comparable with the previous studies including bambara groundnut and African yam bean flour based cookies (Idowu 2014) and in wheat-jering composite cookies (Cheng and Bhat 2016). The addition of EFYF at 70% level resulted in an increase in ash content up to 1.47%. The higher ash content of the supplemented cookies indicates that the cookies contain higher mineral content than the control cookies. With regard to the fat content of the cookies, yam cookies (18.70%) was significantly higher compared to that of control cookies (15.90%). The carbohydrate content of the yam cookies (73.47%) was significantly higher compared to that of control cookies (71.10%). These results were comparable and in agreement with the previous studies including biscuits and cookies (Cheng and Bhat 2016; Yadav et al. 2012).

Color properties of cookies

The color parameters with texture and taste, is a crucial parameter in influencing the acceptability of cookies. Substituting RWF with EFYF in the formulation significantly affected the surface color of the cookies (Table 3). Cookies containing EFYF displayed slightly lower lightness (L*) value but higher redness (a*) and yellowness (b*) values than the control cookies. This may be due to the augmentation in redness and yellowness of the cookies during the baking process. These observations are equivalent to that of the results stated earlier (Chauhan et al. 2015; Cheng and Bhat 2016). The yam cookies were darker in colour since there was reduction in lightness values and enhancement in both redness and yellowness values. Cookie color is promoted primarily during baking process from the Maillard reaction between protein and reducing sugars. Starch caramelization and dextrinization, which are accelerated by heating, affect the cookie color (Cheng and Bhat 2016). According to Chevallier et al. (2000), the whiteness of cookies was negatively correlated with the protein content. These browning reactions are affected by numerous factors including water activity, temperature, pH, sugars and type of amino compounds (Jan et al. 2016). During storage period, it is found that among control cookies lightness remains the same but redness (4.52–3.35) and yellowness (31.52–29.09) decreased significantly. Whereas in yam cookies lightness and redness was increased from 67.80 to 70.86 and 6.49 to 5.73; and yellowness (41.21–39.35) was decreased, respectively.

Texture properties of cookies

Eating quality of cookies is directly related to the texture property. Among the various textural parameters for cookies, hardness is considered as an important characteristic which is measured as the peak force required to snap the cookie (Cheng and Bhat 2016). Hardness of control cookies and yam cookies is shown in Table 4. Replacement of RWF with EFYF in cookie formulations resulted in a significant change in the textural quality of the cookies. Replacement of RWF with EFYF at 70% level shown higher hardness (1.71 kg) which is compared with control cookie (1.27 kg). These results are comparable with the previous studies (Yadav et al. 2012; Cheng and Bhat 2016) wherein incorporation of chickpea and jering flours caused in the increase in hardness of composite cookies. Earlier, De Simas et al. (2009) observed that hardness of cookies is increased by the replacement of wheat flour with king palm flour up to 30% level. Later, Shafi et al. (2016) reported that hardness of the cookies is increased by the replacement of wheat flour with water chestnut flour. Further, Hoseney and Rogers (1994) stated that hardness of the cookies is caused by the interaction of proteins and starch by hydrogen bonding. The increase in protein content could also be the promising reason of the harder texture detected due to its interaction during dough development (Cheng and Bhat 2016). Further, from the data it can be concluded that hardness of cookies decreased as the time progressed. In control and yam cookies, hardness decreased from 1.27 to 0.70 and 1.71 to 1.11 kg, respectively; which implies that the force required in snapping the cookies declined significantly for both cookies with time indicating that cookies have become softer over the storage period.

Water activity of cookies during storage

The loss or gain in moisture of the food component from one region to another occurs continuously until the thermodynamic equilibrium is reached with the surrounding food and its environment (Labuza and Hyman 1998). Water activity of cookies is an essential characteristic that governs shelf life of cookies and was significantly affected during storage period. Water activity of cookies made from blended flour (yam cookies) and wheat flour (control cookies) during storage period of 21 days is presented in Table 4. From the results, we observed that the water activity of cookies increased from 0.24 to 0.26 by replacement of RWF with EFYF. Further, it was found that during storage period water activity of control and yam cookies increased from 0.24 to 0.42 and 0.26 to 0.44, respectively. These results are comparable with the previous studies including okra-based cookies (Park et al. 2015) and in amaretti cookies (Secchi et al. 2011). During storage increase in water activity of cookies has been attributed to recrystallization of sugars (Shafi et al. 2016). In general, bakery products such as cookies and snacks with water activity greater than 0.8 are not microbiologically stable. As seen in Table 4, the yam cookie had higher water activity (0.26–0.44) compared to the control cookie (0.24–0.42) over the storage period. However, after 21 days storage period, water activity of yam and control cookies was unfavorable for growth of molds (0.80) bacteria (0.90) or yeast (0.85–0.88). Moisture migration between domains in food system can be avoided by adding an edible layer between domains in food system which can reduce moisture migration between domains resulting in change of water activity of the food ingredients (Labuza and Hyman 1998).

Sensory evaluation of cookies

Table 5 represents the sensory assessment of the control and yam cookies packed in LDPE packaging material which was observed for a period of 3 weeks. The sensory parameters such as appearance, color, flavor, texture, taste and overall acceptability were found to be acceptable by the panel members even on 3rd week of storage. Values of all the sensory parameters of both control and yam cookies were found to be decreased with increased storage period (0–21 days). Developed yam cookies were considered well accepted and the scores of all the parameters were greater than five which is considered minimum acceptable level of nine point hedonic scale. Overall, it was observed that at 70% of EFYF incorporation level, the yam cookies were ‘well accepted’ and not significantly different (p < 0.05) from the control cookies in terms of color, taste, texture and overall acceptability.

Conclusion

Amorphophallus paeoniifolius is a highly potential edible tropical tuber crop, which has a good source of starch as well as protein and also rich in other nutrients. There are no cookies available in the market so far which have been formulated by the incorporation of A. paeoniifolius flour. The sole possible way to mitigate the detrimental effects of gluten is to dilute the wheat flour proportion by suitable additives. With this view, the addition of A. paeoniifolius flour which could prove as a beneficial ingredient in the formulation of these cookies to be included. The physico-chemical characteristics of A. paeoniifolius flour are mostly similar to that of wheat flour and also yam is free from gluten. A. paeoniifolius have been least exploited for the development of cookies. This way a novel cookie has been developed with a blend of functional ingredient that will not only reduce the incidence of life style diseases but also fulfill the demand of functional foods to the greater extent at affordable cost.

References

Afoakwa EO, Sefa-Dedeh S (2001) Chemical composition and quality changes occurring in Dioscorea dumetorum pax tubers after harvest. Food Chem 75:85–91

Ahmad M, Wani TA, Wani SM, Masoodi FA, Gani A (2016) Incorporation of carrot pomace powder in wheat flour: effect on flour, dough and cookie characteristics. J Food Sci Technol 53(10):3715–3724

AOAC (2005) Official methods of analysis of AOAC International, 18th edn. AOAC International, Rockville

Aremu M, Olaofe O, Akintayo E (2007) Functional properties of some Nigerian varieties of legume seed flours and flour concentration effect on foaming and gelation properties. J Food Technol 5:109–113

Asemota HN, Wellington MA, Odutuga AA, Ahmad MH (1992) Effect of short-term storage on phenolic content, o-diphenolase and peroxidase activities of cut yam tubers (Dioscorea sp.). J Sci Food Agric 60(3):309–312

Baljeet S, Ritika B, Roshan L (2010) Studies on functional properties and incorporation of buckwheat flour for biscuit making. Int Food Res J 17(4):1067–1076

Chauhan A, Saxena D, Singh S (2015) Total dietary fibre and antioxidant activity of gluten free cookies made from raw and germinated amaranth (Amaranthus spp.) flour. LWT Food Sci Technol 63(2):939–945

Cheng YF, Bhat R (2016) Functional, physicochemical and sensory properties of novel cookies produced by utilizing underutilized jering (Pithecellobium jiringa Jack.) legume flour. Food Biosci 14:54–61

Chevallier S, Colonna P, Buléon A, Valle GD (2000) Physicochemical behaviors of sugars, lipids and gluten in short dough and biscuit. J Agric Food Chem 48:1322–1326

De Simas KN, Vieira LdN, Podestá R, Müller CMO, Vieira MA, Beber RC, Reis MS, Barreto PLM, Amante ER, Amboni RD (2009) Effect of king palm (Archontophoenix alexandrae) flour incorporation on physicochemical and textural characteristics of gluten-free cookies. Int J Food Sci Technol 44(3):531–538

Devi K, Haripriya S (2014) Pasting behaviors of starch and protein in soy flour-enriched composite flours on quality of biscuits. J Food Process Preserv 38(1):116–124

Hoseney R, Rogers D (1994) Mechanism of sugar functionality in cookies. Sci Cookie Crack Prod 1:203–225

Hurkadale PJ, Shelar PA, Palled SG, Mandavkar YD, Khedkar AS (2012) Hepatoprotective activity of Amorphophallus paeoniifolius tubers against paracetamol-induced liver damage in rats. Asian Pac J Trop Biomed 2(1):238–242

Idowu AO (2014) Development, nutrient composition and sensory properties of biscuits produced from composite flour of wheat and African yam bean. Br J Appl Sci Technol 4(3):1925–1933

Jan R, Saxena D, Singh S (2016) Physico-chemical, textural, sensory and antioxidant characteristics of gluten—free cookies made from raw and germinated Chenopodium (Chenopodium album) flour. LWT Food Sci Technol 71:281–287

Kaur M, Sandhu KS, Arora A, Sharma A (2015) Gluten free biscuits prepared from buckwheat flour by incorporation of various gums: physicochemical and sensory properties. LWT Food Sci Technol 62(1):628–632

Labuza T, Hyman C (1998) Moisture migration and control in multi-domain foods. Trends Food Sci Technol 9(2):47–55

Lai H, Lin T (2006) Bakery products: science and technology. Blackwell, Ames, pp 3–65

McWatters KH (1978) Cookie baking properties of defatted peanut, soybean and field pea flours in baking powder biscuits. Cereal Chem 55:853–863

Moorthy S, Ramanujam T (1986) Variation in properties of starch in cassava varieties in relation to age of the crop. Starch-Stärke 38(2):58–61

Mustafa AI, Al-Wessali MS, Al-Basha OM, Al-Amir RH (1986) Utilisation of cowpea flour and protein isolate in bakery products. Cereal Foods World 31:756–759

Olapade AA, Adeyemo MA (2014) Evaluation of cookies produced from blends of wheat, cassava and cowpea flours. Int J Food Stud 3(2):175–185

Pareyt B, Talhaoui F, Kerckhofs G, Brijs K, Goesaert H, Wevers M, Delcour JA (2009) The role of sugar and fat in sugar-snap cookies: structural and textural properties. J Food Eng 90(3):400–408

Park J, Choi I, Kim Y (2015) Cookies formulated from fresh okara using starch, soy flour and hydroxypropyl methylcellulose have high quality and nutritional value. LWT Food Sci Technol 63(1):660–666

Reddy CK, Haripriya S, Mohamed AN, Suriya M (2014) Preparation and characterization of resistant starch III from elephant foot yam (Amorphophallus paeonifolius) starch. Food Chem 155:38–44

Reddy CK, Haripriya S, Vidya P (2015) Morphology, physico-chemical and functional characteristics of starches from different banana cultivars. J Food Sci Technol 52(11):7289–7296

Reddy CK, Kimi L, Haripriya S (2016) Variety difference in molecular structure, physico-chemical and thermal properties of starches from pigmented rice. Int J Food Eng 12(6):557–565

Secchi N, Stara G, Anedda R, Campus M, Piga A, Roggio T, Catzeddu P (2011) Effectiveness of sweet ovine whey powder in increasing the shelf life of amaretti cookies. LWT Food Sci Technol 44(4):1073–1078

Shafi M, Baba WN, Masoodi FA, Bazaz R (2016) Wheat-water chestnut flour blends: effect of baking on antioxidant properties of cookies. J Food Sci Technol 53(12):4278–4288

Shobha D, Kumar HVD, Sreeramasetty TA, Gowda KTP, Puttaramanaik, Shivakumar GB (2014) Storage influence on the functional, sensory and keeping quality of quality protein maize flour. J Food Sci Technol 51(11):3154–3162

Singh J, Singh N, Sharma TR, Saxena SK (2003) Physicochemical, rheological and cookie making properties of corn and potato flours. Food Chem 83(3):387–393

Singh A, Gupta P, Shukla G, Wadhwa N (2015) Quality attributes and acceptability of bread made from wheat and Amorphophallus paeoniifolius flour. J Food Sci Technol 52(11):7472–7478

Suriya M, Baranwal G, Bashir M, Reddy CK, Haripriya S (2016) Influence of blanching and drying methods on molecular structure and functional properties of elephant foot yam (Amorphophallus paeoniifolius) flour. LWT Food Sci Technol 68:235–243

Yadav RB, Yadav BS, Dhull N (2012) Effect of incorporation of plantain and chickpea flours on the quality characteristics of biscuits. J Food Sci Technol 49(2):207–213

Yousif M, Safaa M (2014) Supplementation of gluten-free bread with some germinated legumes flour. J Am Sci 10(3):84–93

Zouari R, Besbes S, Ellouze-Chaabouni S, Ghribi-Aydi D (2016) Cookies from composite wheat–sesame peels flours: dough quality and effect of Bacillus subtilis SPB1 biosurfactant addition. Food Chem 194:758–769

Acknowledgements

This project is financially supported by the Department of Food Science and Technology, Pondicherry University, India.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Suriya, M., Rajput, R., Reddy, C.K. et al. Functional and physicochemical characteristics of cookies prepared from Amorphophallus paeoniifolius flour. J Food Sci Technol 54, 2156–2165 (2017). https://doi.org/10.1007/s13197-017-2656-y

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-017-2656-y