Abstract

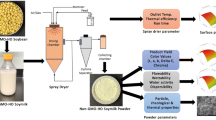

The aim of this study was to find the optimum extrusion process conditions for texturized soybean meal as a meat analogue for food formulations using genetic algorithm. The defatted soybean meal was replaced with whole soybean meal at 10% and extruded in the temperature range of 150–200 °C, screw speed of 270–300 rpm and 20–25% feed moisture content based on the Box–Behnken design. The barrel temperature effect was markedly greater than those of the feed moisture content and screw speed on the product functional properties and appearance. Higher temperatures led to a higher rehydration capacity, water and oil absorption capacity, however, it had a negative effect on the product brightness. It was found that the extrusion at lower moisture content improved soy protein functionality. Genetic algorithm technique was applied to find the best process conditions. The optimized process conditions were found to be the temperature of 198.8 °C, screw speed of 291 rpm and feed moisture content of 20.2%. Overall, the whole soybean treatment was applicable to overcome the oil separation issue during extrusion and the process was optimized to produce texturized soy protein with the maximum attainable functionality.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Extrusion is a continuous, high-capacity, energy-efficient cooking process at high temperatures and short times, which transforms food materials into a plastic-like paste that forms shaped products with a special texture after expansion (Singh et al. 2012; Tovar-Jiménez et al. 2015; Singh et al. 2016). In addition, extrusion causes the destruction of heat-labile compounds like trypsin inhibitors, hemagglutinins, gossypol, lipoxigenases, peroxidases and lipoxidases (Yu 2011). It also results in more digestibility of proteins (Camire 1991; Yu et al. 2013).

Texturized soy protein (TSP) is a mechanically extruded product based on defatted soybean meal with a meat-like texture after rehydration (Lusas 1996). In this process, defatted soybean meal with the moisture range of approximately 20–25% is passed through an extrusion cooker to create a fibrous structure due to disulfide bonding and pressure. Due to the physical and chemical changes in soy proteins during extrusion, the final product has functionalities which make it suitable to be used in food formulations as a meat substitute, owing to its water and oil binding capability.

Successful preparation of TSP products requires the control of the extrusion variables including screw speed, feed moisture content, barrel temperature, extruder properties and feed chemical and physical composition (Guerrero et al. 2012). By studying the effects of barrel temperature (135–165), screw speed (110–190 rpm) and feed moisture content (21–27% wet basis), Rueda et al. (2004) concluded that continuous increases in barrel temperature and screw speed increased the expansion, water absorption index, water hydration capacity and hardness of TSP based on defatted soy flour.

The usual raw material to prepare TSP is defatted soybean meal with a protein dispersibility index of 60–70%. Solvent extraction is the main process to produce defatted soybean meal, combined with heating to evaporate residual hexane; hence, full-fat soy flour (or whole soybean) has a lower protein content, but at higher protein dispersibility indices and no residual solvent (Camire 1991). The main problem of full-fat soy flour (or whole soybean) extrusion cooking is the high fat content which causes shear reduction, oil separation (Crowe and Johnson 2001) and a lower oxidative stability (Bookwalter et al. 1971).

While the extrusion cooking of defatted soybean meal/flour at moderate moisture contents has been studied (Chen et al. 2012; Garg and Singh 2010; Hager 1984; Jao et al. 1978; Prudencio-Ferreira and Areas 1993), to the best of our knowledge, there is no published data on TSP production optimization based on defatted soybean meal. In this research, to take advantage of the whole soybean, we partially replaced the defatted soybean meal by the alkaline pretreated whole soybean and the main objectives were to evaluate the effects of the processing parameters on the quality of the extrudate and to determine the optimized conditions to produce a healthier TSP with better functional properties using genetic algorithm.

Materials and methods

Materials

Defatted soybean meal (containing 52% protein, 1.5% fat and 3% fiber, with particle passing through 2.38 mm mesh sieve, based on company information) was purchased from Soypak Co. (Behshahr, Iran). Soybean seeds were provided by Toos Soya Co. (Mashhad, Iran). Commercial sodium hydroxide was supplied from Kimiapars Co. (Tehran, Iran) and sunflower oil was obtained from Ladan edible oil Co. (Tehran, Iran).

Feed preparation

Based on the method previously described by Nelson and Leigh (1983), the raw whole soybeans were soaked in an equal weight of 0.5 N NaOH solution for 4.5 h at room temperature. The excess alkaline solution was drained off and the seeds were rinsed and ground for 3 min. As explained before, to take advantage of the whole soybean, defatted soybean, as the base material to produce TSP, was replaced with the treated whole soybean meal at 10%. Our preliminary experiments showed that higher levels of whole soybean meal led to the extrusion process disruption and oil-off from the extruder die which requires further research to be overcome. 400 g of the ground soybean seed and 1800 g of the defatted soybean were blended and the moisture level was adjusted to the desired final moisture as one of the process variables, by adding a predetermined amount of water. Mixing was done at the blender medium speed for 5 min. The samples were then packaged in polythene bags and allowed to equilibrate overnight at 5 °C before extrusion. The material was brought to room temperature prior to extrusion.

Extrusion

A semi-industrial co-rotating twin-screw extruder (DS32-II, Jinan Saixin Food Machinery, Shandong, P. R. China) was used for extrusion. The barrel was comprised of three independent temperature-controlled zones. The first zone (after the feeding section) temperature was controlled at 70 °C. The temperature of the second zone (mixing section) was set on 110 °C and the temperature of the third zone (metering section) was adjusted to the required levels as one of the process independent variables. The diameter of the screw was 30 mm. The diameter of the hole in the die was 5 mm with a die length of 27 mm. The extruder was fed automatically at a constant feeding rate of 50 kg per hour during the experiments. The extruded samples were cut using a mechanical cutter at a constant speed. After the stable conditions were established, the extrudate was collected and dried in an air-convection oven at 60 °C until reaching a moisture content of about 5% (wet basis, measured at 105 °C). The dried samples were stored in air tight plastic containers at room temperature and used for further analyses.

Rehydration ratio

Twenty grams of the extrudate sample were weighed (M1) and mixed with 100 ml of distilled water at 5 °C for 1 h. After that, the water was drained off and the rehydrated sample was weighed (M2). The rehydration ratio (RR) (%) was calculated using Eq. 1.

TSP flour functionality

The dried extrudate samples were ground with a kitchen grinder and passed through a 50 mesh sieve. The functional properties of the extrudate flour, including water absorption capacity (WAC) and oil absorption capacity (OAC) were analyzed as follows:

Water absorption capacity

WAC was determined according to the AACC method 56-20 (AACC 2000) with minor modifications. A 1.5 g (M1) flour sample was dispersed in 30 ml of deionized water, agitated vigorously and then completely dispersed using a high speed shaker for 10 min. The samples were centrifuged (1000g, 15 min at 20 °C) and the supernatant was decanted. The weight of the swelled sample was determined (M2) and WAC (%) was calculated using Eq. 1.

Oil absorption capacity

OAC was determined according to (Lin et al. 1974). 0.3 g (M1) of the flour was completely mixed with 3 ml of sunflower oil and then centrifuged (2060g, 30 min at 25 °C). Subsequently, the supernatant decanted and the residue were weighted (M2). OAC (%) was calculated using Eq. 1.

Color properties

Image processing was used for the extrudate flour color evaluation. The flour was poured into a plate, surface leveled and then the images were captured under the fallowing conditions. The plate was positioned in a dark wooden chamber and illuminated by eight fluorescent lights, 20 and 45 cm above the sample at an angle of 45º with the plate to give a uniform light intensity over the sample. A digital camera (Sony, Model W210, Japan) was located vertically at a distance of 20 cm from the sample and the images were captured with a lens aperture of 2.8 and an ISO speed of 1/125 s (no zoom, no flash). Image processing was done using ImageJ software (National Institutes Health, Bethesda, MD, USA) version 1.46r. A region of interest was cropped from the center of the image, its color space was converted from RGB chromatic space into \( L^{*} a^{*} b^{*} \) space using the color space converter plug-in. Finally, the mean gray value was measured.

Experimental design and data analysis

Response surface methodology was used to investigate the main effects of the process variables on RR, WAC, OAC and \( L^{*} \) value of the extruded samples. A Box–Behnken design was used where the barrel temperature (150–200 °C), screw speed (270–300 rpm), and feed moisture content (20–25% wet basis) were the independent process variables. The minimum and maximum values of the process parameters were determined based on preliminary experiments. A total of 20 experiments were performed in duplicate, and the responses average values were calculated. Nonlinear regression was applied to evaluate each response against the process variables at the cubic degree of nonlinearity. Moreover, the backward elimination algorithm was applied to remove the insignificant terms. The experiments design and data analysis were done using Design-Expert statistical package software version 8.07 (Stat ease Inc., Minneapolis, USA).

Genetic algorithm optimization

Genetic algorithm (GA) is based on the rule of nature’s best selection and Darwin’s theory of species evolution. GA advantages over usual numerical optimization methods are (1) the less susceptibility of this technique to be stuck in local minima. (2). A lower degree of knowledge is needed about the process being optimized and (3) this method is able to find the optimum process parameters when there is a large search space of available solutions. GA is a widely used algorithm to find the best solution for both constrained and unconstrained optimization problems. Because of its high capability and easy setups for different types of optimization problems, GA has been used frequently for food processes optimization (Koc et al. 2007; Mohebbi et al. 2011; Shankar and Bandyopadhyay 2004; Shankar et al. 2010). It repeatedly modifies a population of individual solutions. At each step, the algorithm selects individuals using a special method from the population to be the parents and uses them to produce a part of the next generation. Over successive generations, the population evolves toward the best available solution. GA uses three main operators at each step to create the next generation from the current population: (1) Selection operator: selects the individuals, called parents, which contribute to the population in the next generation. (2) Crossover operator: combines two parents to form offspring for the next generation. (3) Mutation operator: makes small random changes in the individuals, which provide genetic diversity and prevents the genetic algorithm from falling into local minimums (Fathi et al. 2010). For the current optimization problem, the chromosomes containing three genes of binary numbers (representing barrel temperature, screw speed and feed moisture content as the operation variables) were defined and the initial population of chromosomes was set to 60. The uniform selection function (with 1% probability) was applied and the single point crossover function with a 0.8 fraction ratio was used to create the next generation population. The adaptive feasible function was used as the mutation operation. GA uses a function to evaluate the fitness of every chromosome of a population. The fitness function was defined based on the goals of optimization, including the maximum RR, WAC, OAC and brightness (as presented by \( L^{*} \) value). After finding the best correlations with the highest coefficient of determinations (R2) and the lowest coefficient of variations (CV) between each response and the process variables, the quality factor, as the fitness function, was defined using Eq. 2:

The chromosomes with higher quality factor values have more chance to transfer their genes to the next generation. The number of generations was 100 and the genes of the best chromosome of the final population were presented as the problem solution or the optimized process conditions. GA optimization was done using MATLAB R2013a.

Results and discussion

For each run of the experimental design, the extruded samples were analyzed and the results are summarized in Table S1. After applying the cubic polynomial regression and backward elimination algorithm on the model, analysis of variance (ANOVA) was performed. Probability was below 0.001 for all the F-values of the regression models and the lack of fit values were not significant (Table S2) which showed the models were statistically reliable. The coefficients of variation and coefficients of determination of all the fitted models are given in Table S2 and were in acceptable range.

Rehydration ratio

Regression analysis showed that temperature and feed moisture content were two significant parameters on the TSP rehydration quality (Table S2) which is a measure of the product porosity and the number of polar sites that interact with water molecules. The linear interaction between temperature and moisture content and the quadratic term of temperature and its interaction with screw speed were also significant for the final product rehydration quality. The interactive effect of barrel temperature and moisture content on rehydration ratio is illustrated in Fig. 1 which shows that increasing the temperature resulted in a TSP with a higher rehydration ratio and its effect was enhanced when the feed moisture was lower (20%). Higher temperatures and lower water content led to higher barrel pressure and more melted plasticized material (Guerrero et al. 2012). This made the TSP more porous on the die exit (Thymi et al. 2005). Screw speed was less effective at low temperatures, but at high temperatures, higher screw speeds caused higher rehydration ratios (Fig. 2), which may be because of higher barrel pressure and more texturization as explained before. The regression model for RR is presented in Eq. 3. In this equation and the following ones, the codes A, B and C represent barrel temperature, screw speed and feed moisture content, respectively.

Water absorption capacity

WAC is a property of food protein molecular composition, conformation state, hydrophilic intensity and the presence of carbohydrates (Edward Doe and Barbara Cybulska 2006). When proteins unfold at high temperature and pressure such as extrusion conditions, most of these lose their natural state and the hydrophilic groups may appeared at the surface of the molecule; therefore more water molecules were absorbed that led to increase in water absorption capacity of TSP will increase (Osen et al. 2014; Sorgentini et al. 1991). According to the regression model for WAC presented in Eq. 4, temperature had a significant effect on WAC as its linear and quadratic terms as well as its interaction with moisture content and screw speed appeared in the model. Figure 3 shows that when the moisture content was low (20%), an increase in temperature had minor effect on WAC; nevertheless, at a higher feed moisture content (25%) the pressure of extrusion on the molten soy flour changed and the microstructure of TSP was effectively different as with an increase in temperature, WAC decreased, but above 175 °C, WAC started to increase. The maximum WAC was attainable at the lowest moisture content and the highest process temperature. This result is in contrast with that of Yu et al. (2012) who observed the maximum water solubility index at the highest temperature and moisture for the extruded corn four-soy protein isolate blend at 20–35% moisture which may have arisen from the different chemical compositions of corn flour and soy. Similar to our result, the increase in WAC due to the increase of extrusion temperature was observed for the extruded corn–lentil blend (Lazou and Krokida 2010). It seems that lower moisture contents led to a higher denaturation degree of soy protein, because lower moisture contents increased the viscosity as well as the friction between the material, screw shaft and extruder barrel. As a result, the required force to push the mass through the barrel and die was increased. These led to more severe conditions on soy protein and increased the degree of denaturation (Chen et al. 2010; Guerrero et al. 2012). The difference between WAC and RR behavior against the process variables arises from the different physical properties of the sample and the test methods performed.

Oil absorption capacity

OAC is an important functional property for TSP because of its abundant usage in meat products to reduce the production cost along with its oil in water emulsion stabilization capacity. OAC depends on protein surface hydrophobic groups. Native proteins exhibited lower oil binding capacity than their denatured state, due to their structural folding (Osen et al. 2014). Feed moisture content influence on OAC was not significant, while the linear and quadratic effects of barrel temperature and screw speed were significant. According to the regression model (Eq. 5), no interaction term was included.

It can be seen in Fig. 3, the minimum OAC has been predicted for mid temperatures near 175 °C which is similar to the minimum WAC near this temperature. Wang and Johnson (2001) stated that functional properties like OAC were attributed to the changes in protein hydrophobicity accompanied by protein denaturation. A similar result has been also reported on the OAC increase of soy protein isolate due to hydrothermal processing (Wang and Johnson 2001) and in another study, higher extrusion temperatures led to an increased OAC of extruded navy and Pinto bean (Gujska and Khan 1990) (Fig. 4).

Brightness (\( L^{*} \))

Brightness is an effective factor to satisfy consumers to use a product as darker products will have lower acceptability. The color properties of TSP were evaluated using an accurate image processing technique and among the three component of \( a^{*} \), \( b^{*} \) and \( L^{*} \), given that \( L^{*} \) underwent more considerable changes in the extrusion process and also \( a^{*} \) and \( b^{*} \) values did not yield any significant models, only \( L^{*} \) was selected as the main color variable of the samples. The regression equation (Eq. 6) showed that only temperature was the significant factor controlling the final brightness value of the TSP powder in linear and quadratic terms, and screw speed or the residence time of the material in the extruder and the selected moisture range had no significant influence on the color properties. Figure 5 shows that the maximum brightness would be expected for the TSP processed at mid temperatures, which confirms the results achieved for WAC and OAC. Higher temperatures led to more decomposition of polysaccharides during extrusion and also enhanced protein amino groups and the polysaccharides carbonyl groups in Maillard reaction. Yu et al. (2012) and Joshi et al. (2012) reported similar results for corn blends with soy protein isolate and spirulina, respectively. It should be noticed that at lower temperatures (150 °C), \( L^{*} \) value is lower than those of the samples processed at 175C that can be attributed to less decomposition of darker materials.

Genetic algorithm optimization

Process optimization first requires finding the overall optimization function and then, searching in the solutions space to find the optimized conditions which result in the defined fitness function value. In this study, GA was used to find the best process conditions. For each generation, the mean and best fitness values of the population are graphically presented in Fig. 6. The mean fitness value of the population decreased during the algorithm progress which shows the evolution of the solutions population towards the optimum conditions. The best chromosome of the final population was selected as the best solution and its genes values were found to be barrel temperature at 198.8 °C, screw speed at 291 rpm and 20.2% of feed moisture content. Applying these process conditions will lead to produce TSP with the highest RR, WAC, OAC and brightness in the ranges studied in this project. If we put this process conditions in the regression equation of each response, the results are: RR = 331.6%, WAC = 366.4%, OAC = 200.8% and \( L^{*} \) = 86 which are near the maximum values measured for different treatments. The optimum process conditions calculated by GA, were not exactly the same as the performed treatments, but can be compared with the results of the experimental conditions provided in Table S1.

Conclusion

The objective of this study was firstly to replace defatted soy with whole soybean and to overcome the problems of extruding oily feed material, which was successfully fulfilled for 10% replacement level. The second goal was to model the effects of the most important extrusion process factors. It was concluded that barrel temperature had a profound effect on the TSP functionality since lower feed moisture content led to a better functionality and screw speed changed water absorption capability to a lower extent. The TSP color, in terms of brightness, was only affected by barrel temperature. The main aim of this study was to use GA evolutionary search method to find the optimum extrusion process conditions. Based on the regression models, GA-optimized process conditions resulted in the maximum functionality properties i.e. maximum water and oil binding along with maximum brightness. One of the important aspects of TSP products with nearly high fat content is shelf life stability which is a function of lipid oxidation rate over the storage period that should be included in optimization goals. This can be taken into consideration for further research.

References

AACC (2000) Approved methods of the American Association of Cereal Chemists. Method 56-20: hydration capacity of pregelatinized cereal products. American Association of Cereal Chemists, St Paul

Bookwalter GN, Mustakas GC, Kwolek WF, McGhee JE, Albrecht WJ (1971) Full-fat soy flour extrusion cooked: properties and food uses. J Food Sci 36:5–9. doi:10.1111/j.1365-2621.1971.tb02019.x

Camire M (1991) Protein functionality modification by extrusion cooking. J Am Oil Chem Soc 68:200–205. doi:10.1007/bf02657770

Chen W, Wang W-P, Zhang H-S, Huang Q (2012) Optimization of ultrasonic-assisted extraction of water-soluble polysaccharides from Boletus edulis mycelia using response surface methodology. Carbohydrate Polymers 87:614–619. doi:10.1016/j.carbpol.2011.08.029

Chen FL, Wei YM, Zhang B, Ojokoh AO (2010) System parameters and product properties response of soybean protein extruded at wide moisture range. J Food Eng 96:208–213. doi:10.1016/j.jfoodeng.2009.07.014

Crowe T, Johnson L (2001) Twin-screw extrusion texturization of extruded-expelled soybean flour. J Am Oil Chem Soc 78:781–786. doi:10.1007/s11746-001-0342-8

Edward Doe P, Barbara Cybulska E (2006) Water and food quality. In: Sikorski ZE (eds) Chemical and functional properties of food components, 3rd edn. Chemical and Functional Properties of Food Components. CRC Press, pp 29–60. doi:10.1201/9781420009613.ch3

Fathi M, Mohebbi M, Razavi SMA (2010) Genetic algorithm optimization of drying conditions of kiwifruit. In: 17th international drying symposium (IDS), Magdeburg, pp 1437–1440

Garg S, Singh D (2010) Optimization of extrusion conditions for defatted soy-rice blend extrudates. J Food Sci Technol 47:606–612. doi:10.1007/s13197-010-0117-y

Guerrero P, Beatty E, Kerry JP, de la Caba K (2012) Extrusion of soy protein with gelatin and sugars at low moisture content. J Food Eng 110:53–59. doi:10.1016/j.jfoodeng.2011.12.009

Gujska E, Khan K (1990) Effect of temperature on properties of extrudates from high starch fractions of navy, pinto and garbanzo beans. J Food Sci 55:466–469. doi:10.1111/j.1365-2621.1990.tb06788.x

Hager DF (1984) Effects of extrusion upon soy concentrate solubility. J Agric Food Chem 32:293–296. doi:10.1021/jf00122a029

Jao YC, Chen AH, Lewandowski D, Irwin WE (1978) Engineering analysis of soy dough rheology in extrusion. J Food Process Eng 2:97–112. doi:10.1111/j.1745-4530.1978.tb00197.x

Joshi SMR, Bera MB, Panesar PS (2012) Extrusion cooking of maize/spirulina mixture: factors affecting expanded product characteristics and sensory quality. J Food Process Preserv 38:655–664. doi:10.1111/jfpp.12015

Koc AB, Heinemann PH, Ziegler GR (2007) Optimization of whole milk powder processing variables with neural networks and genetic algorithms. Food Bioprod Process 85:336–343. doi:10.1205/fbp07074

Lazou A, Krokida M (2010) Functional properties of corn and corn–lentil extrudates. Food Res Int 43:609–616. doi:10.1016/j.foodres.2009.09.017

Lin MJY, Humbert ES, Sosulski FW (1974) certain functional properties of sunflower meal products. J Food Sci 39:368–370. doi:10.1111/j.1365-2621.1974.tb02896.x

Lusas E (1996) Modern texturized soy proteins: preparation and uses. Food Technol 50:132–135

Mohebbi M, Shahidi F, Fathi M, Ehtiati A, Noshad M (2011) Prediction of moisture content in pre-osmosed and ultrasounded dried banana using genetic algorithm and neural network. Food Bioprod Process 89:362–366. doi:10.1016/j.fbp.2010.08.001

Nelson AI, Leigh JS (1983) Extrusion texturization of full-fat soybean and product thereof. U.S. Patent No. 4,369,195. 18 Jan

Osen R, Toelstede S, Wild F, Eisner P, Schweiggert-Weisz U (2014) High moisture extrusion cooking of pea protein isolates: raw material characteristics, extruder responses, and texture properties. J Food Eng 127:67–74. doi:10.1016/j.jfoodeng.2013.11.023

Prudencio-Ferreira SH, Areas JG (1993) Protein–protein interactions in the extrusion of soya at various temperatures and moisture contents. J Food Sci 58:378–381. doi:10.1111/j.1365-2621.1993.tb04279.x

Rueda J, Kil-Chang Y, Martínez-Bustos F (2004) Functional characteristics of texturized defatted soy flour. Agrociencia 38:63–73

Shankar TJ, Bandyopadhyay S (2004) Featuring tissue engineering optimization of extrusion process variables using a genetic algorithm. Food Bioprod Process 82:143–150. doi:10.1205/0960308041614855

Shankar TJ, Sokhansanj S, Bandyopadhyay S, Bawa AS (2010) A case study on optimization of biomass flow during single-screw extrusion cooking using genetic algorithm (GA) and response surface method (RSM). Food Bioprocess Technol 3:498–510. doi:10.1007/s11947-008-0172-9

Singh RKR, Majumdar R, Venkateshwarlu G (2012) Optimum extrusion-cooking conditions for improving physical properties of fish-cereal based snacks by response surface methodology. J Food Sci Technol 51:1827–1836. doi:10.1007/s13197-012-0725-9

Singh JP, Kaur A, Shevkani K, Singh N, Singh B (2016) Physicochemical characterisation of corn extrudates prepared with varying levels of beetroot (Beta vulgaris) at different extrusion temperatures. Int J Food Sci Technol 51:911–919. doi:10.1111/ijfs.13051

Sorgentini DA, Wagner JR, Arrese EL, Anon MC (1991) Water imbibing capacity of soy protein isolates: influence of protein denaturation. J Agric Food Chem 39:1386–1391. doi:10.1021/jf00008a006

Thymi S, Krokida MK, Pappa A, Maroulis ZB (2005) Structural properties of extruded corn starch. J Food Eng 68:519–526. doi:10.1016/j.jfoodeng.2004.07.002

Tovar-Jiménez X et al (2015) Third generation snacks manufactured from orange by-products: physicochemical and nutritional characterization. J Food Sci Technol 52:6607–6614. doi:10.1007/s13197-015-1726-2

Wang C, Johnson LA (2001) Functional properties of hydrothermally cooked soy protein products. J Am Oil Chem Soc 78:189–195. doi:10.1007/s11746-001-0242-y

Yu L (2011) Extrusion processing of protein rich food formulations. McGill University Libraries, Montreal

Yu L, Ramaswamy H, Boye J (2012) Twin-screw extrusion of corn flour and soy protein isolate (spi) blends: a response surface analysis. Food Bioprocess Technol 5:485–497. doi:10.1007/s11947-009-0294-8

Yu L, Ramaswamy HS, Boye J (2013) Protein rich extruded products prepared from soy protein isolate–corn flour blends. LWT Food Sci Technol 50:279–289. doi:10.1016/j.lwt.2012.05.012

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Mazaheri Tehrani, M., Ehtiati, A. & Sharifi Azghandi, S. Application of genetic algorithm to optimize extrusion condition for soy-based meat analogue texturization. J Food Sci Technol 54, 1119–1125 (2017). https://doi.org/10.1007/s13197-017-2524-9

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-017-2524-9