Abstract

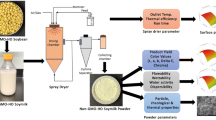

The effects of feed moisture, screw speed, and barrel temperature on physical properties of extruded corn flour and soy protein isolate (SPI) blends were investigated in a co-rotating twin-screw extruder using a response surface methodology. Corn flour and SPI were mixed with a ratio of 4:1. The screw speed was set at five levels between 60 and 140 rpm, barrel temperature between 140 °C and 180 °C, and feed moisture between 18% and 38%. All physical properties of the extruded material evaluated—included expansion ratio, bulk density, breaking strength, water solubility index, rehydration ratio, and color—were significantly (p < 0.05) affected by the three process variables. Feed moisture was the most significant variable with quadratic effects on most of the physical properties. Response surface regression models were established to correlate the physical properties of the extruded product to the process variables. Understanding the effect of these variables on the product physical properties was deemed useful for the development of protein-rich extruded products.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Extrusion technology has been commercially stable in food industry for a long time (Harper 1978; Rossen and Miller 1973). Starch-based food materials, like corn, rice, and semolina, are ideal candidates for extrusion processing (Chinnaswamy and Hanna 1988). As a high temperature short time process, extrusion involves simultaneous thermal and pressure treatment along with mechanical shearing, which can result in several changes in the extrudate such as gelatinization of starch, denaturation of protein, and even complete cooking thereby resulting in a final product that may be ready to eat. Extrusion processing of corn and oatmeal has been very well studied (Gomez and Aguilera 1983, 1984; Bhattacharya and Hanna 1987) and well commercialized especially in the category of breakfast cereals. Extruded corn products are rich in carbohydrates and fibers but are relatively low in protein content, and hence there is an increasing interest in enhancing the protein component of these products (Muhungu et al. 1999; Konstance et al. 1998).

Soybean is a low cost, superior protein source available in the world. Besides protein fortification, soy-based supplementary foods also provide many other nutritional benefits. Soy-containing foods have been shown to reduce risks of breast cancer and other cancers and to protect against cardiovascular disease and osteoporosis (Messina and Messina 1991; Caragay 1992; Potter 1995). Soy protein is an edible component of the soybean. It is produced from raw whole soybeans by a multi-step process that removes the lipid and indigestible components to concentrate the protein and increase its availability. Depending on the particular steps used during processing, soy protein ingredients may take the form of isolated soy protein, soy protein concentrate, or soy flour. Each ingredient may be further processed into texturized soy protein or texturized vegetable protein used in the manufacture of meat and poultry analogs by thermoplastic extrusion or steam texturization to impart structure and shape. In addition to protein, these soy protein ingredients contain other naturally occurring soy constituents, such as isoflavones, fiber, and saponins. The different processing steps used ultimately define the extent of retention of naturally occurring components in the final product. Soy protein is also consumed as a component of traditional fermented and non-fermented soy foods, such as tofu, tempeh, and miso, as well as whole soybeans, soynuts, soymilk, soy yogurt, and soy cheese. These products contain variable amounts of soy protein and other naturally occurring soy constituents depending on the specific technologies used in these products. Soy protein ingredients and soy protein-containing foods may partially replace or be used in addition to animal or other vegetable protein sources in the human diet.

The extrusion process of corn and soy flour blends has been investigated in some studies. Konstance et al. (2002) studied drying properties and storage stabilities of a high-energy extruded food consisting of blends of full fat soy grits, cornmeal, soy concentrate, and soybean oil. Sun and Muthukumarappan (2002) studied single-screw extruder effects of soy flour content, feed moisture, screw speed, and barrel temperature on some physical properties of the extrudates. Park et al. (1993) studied the effects of feed moisture, corn starch levels, and process temperature on selected physical properties of soy flour–corn starch–raw beef extrudates using a single-screw extruder.

With the rapid development of soybean processing industry, soy protein isolates (SPI) have been widely used in food industry. Compared with soy flour, SPI can provide highly concentrated protein, high in lysine, with bland flavor and reduced flatulence factors and reduced sugars, and are hypothesized to lead to improved overall product quality (Konstance et al. 1998). Some studies have explored the use of soybean in the form of SPI. Camire and King (1991) incorporated soy fiber to SPI and corn flour blends to enhance nutritional values of the extrudate. Ghorpade et al. (1997) studied the pore structure of the extrudate from corn starch and SPI blends. Konstance et al. (1998) developed a nutritious “instant” extruded product using corn meal, soy flakes, soy protein concentrate, and soy oil. Faller et al. (1999) conducted consumer testing for the extruded SPI and corn flour blends. Faller et al. (2000) added sugar to SPI and corn flour blends and studied its effects on the characteristic soy flavor and sensory characteristics of the extrudate. Seker (2005) evaluated the expansion ratio (ER) of the extrudate using SPI and different corn starch blends. More recently, Brnčić et al. (2009) studied the influence of various whey protein concentrate addition and some extrusion process parameters on physicochemical properties of directly expanded corn flour extrudates manufactured in twin-screw co-rotating extruder and found the lowest water solubility indeed and highest water absorption index were associated with the highest protein addition. Arhaliass et al. (2009) evaluated the expansion mechanism in the extrusion cooking process during maize and wheat flours processing in a twin-screw extruder. They found that the maximum expansion is obtained with maize flour and that the difference in composition between maize and wheat flours had an impact on the expansion mechanism.

Response surface methodology (RSM) is a statistical method used to describe the relationship between process variables and product quality characteristics (Giovanni 1983). RSM has been effectively used in several extrusion studies to relate the product characteristics to extrusion variables (Chen et al. 1991; Park et al. 1993; Nwabueze 2008; Altan et al. 2008; Pansawat et al. 2008; Sibel and Fahrettin 2008; Aylin et al. 2008; Altan et al. 2009).

Extrusion processing of SPI incorporated with corn flour blends has not been studied in detail exploring the relationships between process parameters and physical properties of the extrudate. Such a study is essential for product development and process control considering the popularity of the application of corn and SPI in food extrusion.

The objectives of the present work were therefore to investigate (a) the influence of extrusion process variables on physical properties of extruded corn flour and SPI blends using a twin-screw extrusion process by using RSM and (b) establish regression models to predict the physical properties of the extruded material as a function of the process variables. This study forms the basis of our extrusion research program on soy protein-enriched extruded products.

Materials and Methods

Materials

Corn flour from Brar Natural Flour Mills (Winnipeg, MB, Canada) was purchased locally (composition: 1.7% of lipids, 76.7% of starch, and 10% of protein). SPI was received from American Health & Nutrition (Ann Arbor, MI, USA), which contained 90% protein. The moisture contents of the flours were measured before mixing. The flours were mixed using a Hobart mixer (Hobart Food Equipment Group, North York, ON, Canada) to give corn flour:SPI ratio of 4:1 (wet basis). Appropriate amount of water was added to adjust the mixture to the required moisture content as per the experimental design. The blends were sealed in polyethylene bags and equilibrated for 24 h at 4 °C before extrusion.

Extrusion Process

Extrusion was performed in a co-rotating twin-screw extruder (DS32-II, Jinan Saixin Food Machinery, Shandong, People's Republic of China), consisting of three independent zones of controlled temperature in the barrel. The diameter of the screw was 30 mm. The length to diameter ratio of the extruder barrel was 20:1. The diameter of the hole in the die was 5 mm with a die length of 27 mm. The screw speed and the temperature of the third barrel section (metering section) were adjusted to the required levels. The extruder was fed manually through a conical hopper, keeping the flights of the screw fully filled and avoiding accumulation of the material in the hopper.

After stable conditions were established, extrudates were collected and cool dried under mild air flow conditions at room temperature overnight and then finish dried to moisture content of 9–10% (wet basis) by an air convection oven at 45 °C and a wind flow at 0.1 m/s. Dried samples were stored in air tight plastic containers at room temperature and used for analysis.

Experimental Design

Extrusion is a complex process involving many variables. Among them, barrel temperature, screw speed, and feed moisture are the most important factors. A central composite rotatable design (CCRD; Draper 1982) was used to incorporate these three independent variables. This design required 20 experimental runs with eight (23) factorial points (three level for each variables), six star corner points (two for each variable) and six center points. Overall, this yields five levels for each variable and permits a better assessment of their quadratic effects. The CCRD-coded levels and experiment ranges of the three independent variables are shown in Table 1; these were selected based on preliminary tests.

In order to develop the RSM models, coded values are used which are obtained from the real values of independent variables screw speed (S; rpm), barrel temperature (T; °C), and feed moisture (M; %) as shown below:

Physical Properties

Several physical parameters were selected from those that have been used to describe the properties of the extruded products.

Expansion Ratio (ER)

This was defined as the ratio of the diameter of the extrudate to the diameter of the die (Jyothi et al. 2009). In order to determine the ER, 20 randomly selected segments of each sample were measured using caliper, and the average value was used.

Bulk Density (BD)

Bulk density (BD) was measured using displacement method (Seker 2005). Extrudates were cut into strands about 25 mm long, and around 15 g strands were weighed (M ext, g) and put in a 100-ml cylinder, then yellow millet particles were added to fill up the cylinder. The extrudates were taken out, and the volume of the yellow millet particles was measured (V ym, ml). BD was calculated as below:

Breaking Stress (BS)

Breaking stress (BS) was measured using a single cycle compression test in a Lloyd texture machine with a 500-N load cell (Lloyd model LRX, Lloyd Instruments Ltd., Fareham, Han, UK). A three-point breaking test (Zasypkin and Lee 1998) was used to measure the maximum force required to break the extrudate samples. The extruded product was cut to obtain 35-mm-long strands, which were placed at right angle on two rounded stands (bridge) 30 mm apart. The rounded crosshead exerting force in the middle of the bridge was moving down at 5 mm/min until breaking. BS (N/mm2) was determined as the breaking force per unit cross section area. Eight measurements were made on each product, and the average value was used.

Water Solubility Index (WSI)

Water solubility index (WSI) was determined using the method of Anderson et al. (1969).

Rehydration Ratio (RR)

Rehydration ratio (RR) was measured at 30 °C. The extrudate was cut to obtain 35-mm-long strands, and around 20 g strands were weighed (M 1) and placed in 500 ml of water at 30 °C for 15 min. The water was drained, and the rehydrated samples were weighed (M 2). RR was defined as:

Color

Color measurements were made in a Minolta colorimeter (Minolta Colorimeter Model CM-500d) using an aperture of 1.2 cm diameter. The exposed area was sufficiently great relative to the illuminated area to avoid any light-trapping effect. The instrument was calibrated with a standard white tile (L = 77.58, a = −0.27, b = −26.63). The color was reported in terms of L, a, and b values. Eight measurements on each sample were taken, and the average value was used.

Data Analysis

Results were analyzed using Design-Expert 6.0 (Stat-Ease Inc.), and the second-order polynomial model was established to predict the dependent variable (Y):

where c 0, c i , c ii , and c ij are coefficients of intercept, linear, quadratic, and interactive effects, respectively, and X i and X j are independent variables. The mapping of the fitted response was generated using Design-Expert 6.0 (Stat-Ease Inc.). The response surface was plotted as a function of two variables while keeping the remaining variable at the center point value.

Results and Discussion

The data on mean values of all physical properties of extruded products along with their standard deviations are summarized in Table 2. Analysis of variance is summarized in Tables 3 and 4. Models for all parameters were significant, and all parameters were significantly (p < 0.05) affected by screw speed, barrel temperature, and feed moisture, and their quadratic effects.

Various physical properties have been studied in different extruded products. Jyothi et al. (2009) studied the physical properties, including BD, true density, porosity, and ER; water absorption index; WSI; and oil absorption index in the single extruder to process tuber starch. Rocha-Guzman et al. (2008) studied water absorption index, water absorption capacity, oil absorption capacity, and emulsifying capacity in the extrusion process of normal bean cultivars flour. Őzer et al. (2004) studied the physical properties (BD, expansion, and porosity) of a nutritionally balanced extruded snack food by the RSM method. The influence of process variables on physical properties have been shown to be generally significant in all these studies.

Expansion Ratio (ER)

The fitted model for ER is shown in Eq. 7 (all independent variables in coded values) indicating quadratic effects with all three variables.

Figure 1 shows the response surface plot of ER vs two independent variables with the third taken at the midpoint (coded 0) level. Figure 1a is ER vs temperature and screw speed in which the feed moisture was controlled at 28% (coded value 0), Fig. 1b is ER vs feed moisture and screw speed with the barrel temperature set to 160 °C, and Fig. 1c is ER vs feed moisture and temperature with the screw speed set at 100 rpm.

Feed moisture was the most significant factor affecting the ER. The effect of feed moisture on extrusion process has been observed to be complex. In this study, a quadratic effect of feed moisture on ER was found, and the maximum ER was obtained when feed moisture was around 28%. Park et al. (1993) studied the extrusion of soy flour–corn starch–raw beef blends in a single-screw extruder and reported similar results with 23% feed moisture predicted for having optimum ER. Sun and Muthukumarappan (2002) extruded corn flour and soy flour blends in a single-screw extruder and also reported that ER increased with increasing feed moisture from 15% to 18% and then decreased with further increasing to 21%. With blends of full fat soy grits, corn meal, soy concentrate, and soybean oil extruded in a twin-screw extruder, Konstance et al. (2002) did not find significant change of ER when feed moisture was changed from 11% to 13% and then to 19%. Hagenimana et al. (2006) found that ER decreased with increasing feed moisture from 16% to 19% and 22% when rice flour was extruded in a twin-screw extruder. Zasypkin and Lee (1998) reported that ER of extruded wheat flour or soy flour alone increased with lowering of the feed moisture from 18% to 17% and 16%, while for extruded blends, ER remained the same or was lower. It has been observed that suitable feed moisture depends on not only the extrusion condition, such as barrel temperature and screw speed, but also the feed composition, which can affect the water binding capacity (Park et al. 1993). SPI has a high water holding capacity, which appeared to be the main cause of high optimum feed moisture in this study.

Quadratic effects of screw speed and barrel temperature on ER were also found in this study, although to a slightly lower extent as compared with feed moisture. On one hand, increasing screw speed and barrel temperature will introduce more energy to the material in the barrel, which would enhance the moisture evaporation at the die exit and hence increase ER. On the other hand, increasing screw speed will reduce the residence time of the material (Gogoi and Yam 1994), which could reduce the energy received by the material in the barrel, and therefore could result in lower ER. Sun and Muthukumarappan (2002) reported similar results when screw speed increased from 180 to 200 rpm and 220 rpm. However, Seker (2005) and Hagenimana et al. (2006) found that increasing screw speed steadily enhanced ER. Park et al. (1993) and Hagenimana et al. (2006) also reported the quadratic effect of barrel temperature on ER. Sun and Muthukumarappan (2002) stated that when temperature increased from 155 °C to 185 °C, ER steadily decreased.

When the extrusion process is carried out at temperatures above 100 °C, moisture is superheated inside the extrusion barrel due to internal high temperature and high-pressure conditions (Park et al. 1993; Heldman and Hartel 1997). As the product exits the die nozzle, moisture flash evaporates suddenly due to the pressure drop. As a result, the extruded product is expanded, and the characteristic texture of the extrudate is formed with a porous structure. Sufficient amount of moisture for the vaporization is necessary for the expansion of the product. However, too high a feed moisture reduces the shear strength and the energy input to the material, therefore, decreases the moisture evaporation at the die exit and results in lower product expansion.

ER is an important quality parameter in products like breakfast cereals and ready-to-eat snack foods. In products intended for further cooking, this may not be important; in fact, large ER, which promotes increased porosity, may result in softer texture in cooked products. Hence, choosing the optimal level depends on the intended product.

Bulk Density (BD)

The fitted regression model for BD is shown in Eq. 8 (all independent variables in coded values) demonstrating quadratic effects only with the feed moisture.

Figure 2 shows the response surface plot of BD vs two independent variables at a time with the third taken at the midpoint level. Feed moisture was again the most significant factor for BD among the three; however, the influence was not as pronounced as with ER, as the feed moisture surface plot concaved at mid-moisture content somewhat similarly with both temperature and screw speed indicating a lower BD. Park et al. (1993) reported similar results. However, Sun and Muthukumarappan (2002) found that with increasing the feed moisture, BD increased steadily. Hagenimana et al. (2006) reported that BD increased with an increase in feed moisture at low barrel temperature, whereas the opposite effect occurred at high temperature.

BD relationship with temperature and screw speed was somewhat flat showing minimal interactions, with both barrel temperature and screw speed contributing to a lower BD. Seker (2005) and Hagenimana et al. (2006) reported similar results. High screw speed and barrel temperature could result in larger extent of starch gelatinization. Case et al. (1992) indicated that with starch gelatinization increasing, the volume of the extrudate increases and the BD decreases, but Sun and Muthukumarappan (2002) found BD increased significantly with increasing screw speed, and no explanation was provided.

Both ER and BD represent the extent of puffing of the extrudate. Therefore, it might be expected that these two properties would be negatively correlated, with higher ER contributing to lower BD, but Park et al. (1993) reported that this is not always the case. The reason could be that ER only considers the expansion in the radial direction, perpendicular to extrudate flow, whereas BD considers the expansion in all directions (Falcone and Phillips 1988). In this study, a significant inverse relationship (r = −0.71) was found between ER and BD. Park et al. (1993) and Falcone and Phillips (1988) also showed a similar result.

Breaking Stress (BS)

The mean values of BS values under different extrusion conditions are listed in Table 2. Analysis of variance (Tables 3 and 4) showed that BS was significantly (p < 0.05) affected by screw speed, barrel temperature, feed moisture, and the quadratic effect of feed moisture. The fitted regression equation for BS is shown in Eq. 8 (all independent variables in coded values).

Figure 3 shows the response surface plot of BS vs two independent variables at a time with the third taken at the midpoint level. Like the situations in ER and BD, feed moisture had a quadratic effect on BS. The combined effect of feed moisture and temperature or screw speed was much more severe on the BS than the combination of temperature and screw speed. The latter combination showed a relatively small but perceptible effect demonstrating a steady decrease in the BS as the temperature and screw speed increased. This combination produced a crispier product that was easier to break. The feed moisture relationship with BS was somewhat consistent at different temperature and screw speeds. The BS increased with an increase in moisture content but decreased with an increase in temperature and screw speed, but the curves were somewhat convex upwards suggesting some interactions. One would expect that BS would decrease with an increase in feed moisture. This would be the case normally under low temperature extrusion conditions. Under the conditions tested, high moisture promotes more explosive behavior at the exit die resulting in an increase in the ER. Higher ER results in a larger diameter sample which offers a greater resistance to breaking resulting in an increase in BS, which is consistent with the experimental results. Sun and Muthukumarappan (2002) found that the shear force per unit weight of extrudate decreased with the increase of the feed moisture and decrease of barrel temperature, and it increased with increasing screw speed to a certain point and then decreased with the further increase of screw speed.

Water Solubility Index (WSI)

The WSI values under different extrusion conditions (Table 2) and the analysis of variance results (Tables 3 and 4) showed that WSI was significantly (p < 0.05) affected by the individual and quadratic effects of screw speed, barrel temperature, feed moisture, as well as the interaction effect of barrel temperature and feed moisture. The fitted regression model for WSI is shown in Eq. 9 (all independent variables in coded values).

Figure 4 shows the response surface plot of BS vs two independent variables at a time with the third taken at the midpoint level. Again, the feed moisture was the most dominant factor. Higher screw speed and higher barrel temperatures resulted in increase in the WSI. The surface plot showed a slight convex surface with levels of temperature and screw speed at the higher end yielding the maximum WSI. Hagenimana et al. (2006) also reported that with barrel temperature and screw speed increased, WSI increased steadily; however, Seker (2005) reported that screw speed was not significant for WSI.

With the feed moisture, the surface response plot relationship with WSI was a bit different when temperature and screw speeds were considered co-variables. In both situations, WSI increased with moisture content, with the higher end feed moisture resulting in a greater quadratic influence on the WSI. The surface plots were concave upwards. The WSI is contributed by the nature of the major components in the feed mix—the carbohydrates and proteins and their status whether they are in their native state or in the gelatinized/denatured state. At lower feed moisture levels, it is possible that there was not enough water for the starch gelatinization and protein denaturation to be completed. This could be the reason for gradual increase in WSI with an increase in moisture content. When feed moisture is higher than a certain critical level, higher feed moisture levels contribute to a greater starch gelatinization and denaturation of protein resulting in an increased WSI. Hagenimana et al. (2006), however, reported that with extruded rice flour when feed moisture increased from 16% to 22%, WSI decreased. The opposite results could be due to the inclusion of higher amounts SPI in the present study. The combination perhaps helped to increase the WSI.

Rehydration Ratio (RR)

Extruded products are frequently rehydrated prior to consumption like in a breakfast cereal or used as an ingredient in cooking preparations. The RR is an important parameter for such consideration as it will define the ability of how much liquid the product can be absorb.

The RR values was significantly (p < 0.05) affected by screw speed, barrel temperature, feed moisture, and also the interaction effects of barrel temperature and feed moisture (Tables 2 and 3). However, there were only linear effects with all variables and no quadratic effects. The fitted regression equation for RR is shown in Eq. 10 (all independent variables in coded values).

Figure 5 shows the response surface plot of RR vs two independent variables at a time with the third taken at the midpoint level. The effects of the process variables on RR were the straight forward. RR increased with feed moisture, barrel temperature, and screw speed. Each of these also contributed to higher ER and lower BD. Higher ER means higher porosity of the sample and hence greater ease for rehydration. All these conditions are indicative of higher and more rapid expulsion of moisture due to the larger pressure difference and higher temperature at the die. Park et al. (1993) and Sun and Muthukumarappan (2002) also found higher barrel temperature to result in increased water absorption. Sun and Muthukumarappan (2002) and Seker (2005), however, did not find any significant effect of screw speed on water absorption of the extrudate. In this study, although significant, screw speed was the least important factor for RR.

Correlation analysis showed that RR was positively related to ER and WSI (r > 0.71). The expanded structure of the extrudate could be one of the main forces of the water absorption. RR was found negatively related to BD (r = −0.56). Park et al. (1993) also reported water absorption was reversely related with BD (r = −0.66).

Color

The color coordinates of L*, a*, and b* under different extrusion conditions were evaluated (Table 2). Analysis of variance results (Tables 3 and 4) showed that L* was significantly (p < 0.05) affected by barrel temperature, feed moisture, and the quadratic effect of feed moisture. The b value was significantly (p < 0.05) affected by feed moisture and its quadratic effect, while a value was significantly (p < 0.05) affected by only barrel temperature. Only L values were used in the regression analysis, because of the low R 2 of the regression for a and b values. L value regression equation is shown in Eq. 11 (all independent variables in coded values).

Figure 6 shows the response surface plot of L values vs two independent variables at a time with the third taken at the midpoint level. L value increased with barrel temperature. Sun and Muthukumarappan (2002) found insignificant effect of barrel temperature on L value. Park et al. (1993) reported significant interaction effects between feed moisture and barrel temperature. Feed moisture—screw speed and feed moisture—barrel temperature effects were similar. Low feed moisture was associated with higher L value (lighter color), and increasing moisture content had a quadratic effect on L irrespective of screw speed and temperature. Sun and Muthukumarappan (2002) reported that the increase of feed moisture increased L value.

Conclusions

RSM revealed the significant effects of all three important extrusion parameters (screw speed, feed moisture, and barrel temperature) on the physical properties of twin-screw extruded SPI and corn flour blends. Within the experimental range, feed moisture was the most important factor for the physical properties of the extrudate.

The effects of feed moisture on most of the properties of the extrudate were found to be quadratic; the effects were linear with some interaction only with for RR. Screw speed also had quadratic effects on ER and WSI, while higher screw speeds always resulted in high RR and low BS and BD. Interactive effects of barrel temperature and feed moisture were found on WSI and RR. The effect of barrel temperature on ER was quadratic. High barrel temperature resulted in high L value and low BS and BD.

Some differences were found between the results of the present study and published results, which could be due to the different configurations of the extruder, the experiment range and, more importantly, feed compositions, especially the combination of corn starch and SPI. Some physical properties could be expected and interrelated, but this was not always the case, revealing more studies required to fully understand the complicated extrusion process. Clearly some of the differences in the extrusion behavior was caused by the inclusion of SPI (25% level in the feed mix). Hence, if protein dense products are desired, such studies should be extended to higher protein levels to assess their influence on the physical and sensory properties of the extruded product.

References

Altan, A., McCarthy, K. L., & Maskan, M. (2008). Extrusion cooking of barley flour and process parameter optimization by using response surface methodology. Journal of the Science of Food and Agriculture, 88(9), 1648–1659. (12).

Altan, A., McCarthy, K. L., & Maskan, M. (2009). Effect of extrusion cooking on functional properties and in vitro starch digestibility of barley-based extrudates from fruit and vegetable by-products. Journal of Food Science, 74(2), E77–E86.

Anderson, R. A., Conway, H. F., Pfeifer, V. F., & Griffin, L. E. J. (1969). Gelatinization of corn grits by roll-and extrusion cooking. Cereal Science Today, 14(4–7), 11–12.

Arhaliass, A., Legrand, J., Vauchel, P., Fodil-Pacha, F., Lamer, T., & Bouvier, J.-M. (2009). The effect of wheat and maize flours properties on the expansion mechanism during extrusion. Food and Bioprocess Technology, doi:10.1007/s11947-007-0038-6.

Aylin, A., McCarthy, K. L., & Medeni, M. (2008). Evaluation of snack foods from barley–tomato pomace blends by extrusion processing. Journal of Food Engineering, 84(2), 231–242.

Bhattacharya, M., & Hanna, M. A. (1987). Texture properties of extrusion-cooked corn starch. Lebensmittel-Wissenschaft + Technologie, 20(4), 195–201.

Brnčić, M., Tomislav Bosiljkov, T., Ukrainczyk, M., Tripalo, B., Brnčić, S. R., Karlović, S., et al. (2009). Influence of whey protein addition and feed moisture content on chosen physicochemical properties of directly expanded corn extrudates. Food and Bioprocess Technology, doi:10.1007/s11947-009-0273-0.

Camire, M. E., & King, C. C. (1991). Protein and fiber supplementation effects on extruded cornmeal snack quality. Journal of Food Science, 56(3), 760–763. 768.

Caragay, A. B. (1992). Cancer-preventive foods and ingredients. Food Technology, 46(4), 65–68.

Case, S. E., Hamann, D. D., & Schwartz, S. J. (1992). Effect of starch gelatinization on physical properties of extruded wheat and corn based products. Cereal Chemistry, 69, 401–409.

Chen, J., Serafin, F. L., Pandya, R. N., & Daun, H. (1991). Effects of extrusion conditions on sensory properties of corn meal extrudates. Journal of Food Science, 56(1), 84–89.

Chinnaswamy, R., & Hanna, M. A. (1988). Optimum extrusion-cooking conditions for maximum expansion of corn starch. Journal of Food Science, 53(3), 834–836. 840.

Draper, N. R. (1982). Center points in second order response surface designs. Technometrics, 24, 127–133.

Falcone, R. G., & Phillips, R. D. (1988). Effects of feed composition, feed moisture, and barrel temperature on the physical and rheological properties of snack-like products prepared from cowpea and sorghum flours by extrusion. Journal of Food Science, 53, 1464–1469.

Faller, J. Y., Klein, B. P., & Faller, J. F. (1999). Acceptability of extruded corn snacks as affected by inclusion of soy protein. Journal of Food Science, 64(1), 185–188.

Faller, J. F., Faller, J. Y., & Klein, B. P. (2000). Physical and sensory characteristics of extruded corn/soy breakfast cereals. Journal of Food Quality, 23(1), 87–102.

Ghorpade, V. M., Bhatnagar, S., & Hanna, M. A. (1997). Structure characteristics of corn protein isolate or wheat gluten. Plant Foods for Human Nutrition, 51, 109–123.

Giovanni, M. (1983). Response surface methodology and product optimization. Food Technology, 37, 41–45. 83.

Gogoi, B. K., & Yam, K. L. (1994). Relationships between residence time and process variables in a corotating twin-screw extruder. Journal of Food Engineering, 21, 177–196.

Gomez, M. H., & Aguilera, J. M. (1983). Changes in the starch fraction during extrusion-cooking of corn. Journal of Food Science, 48(2), 378–381.

Gomez, M. H., & Aguilera, J. M. (1984). A physicochemical model for extrusion of corn starch. Journal of Food Science, 49(1), 40–43. 63.

Hagenimana, A., Ding, X., & Fang, T. (2006). Evaluation of rice flour modified by extrusion cooking. Journal of Cereal Science, 43, 38–46.

Harper, J. M. (1978). Extrusion processing of food. Food Technology, 32(7), 67–72.

Heldman, D. R., & Hartel, R. W. (1997). Principles of food processing. New York: Chapman & Hall.

Jyothi, A. N., Sheriff, J. T., & Sanjeev, M. S. (2009). Physical and functional properties of arrowroot starch extrudates. Journal of Food Science, 74(2), E97–E104. (1).

Konstance, R. P., Onwulata, C. I., Smith, P. W., Lu, D., Tunick, M. H., Strange, E. D., et al. (1998). Nutrient-based corn and soy products by twin-screw extrusion. Journal of Food Science, 63(5), 1–5.

Konstance, R. P., Strange, E. D., & Onwulata, C. I. (2002). Processing properties of extruded corn-soy blends. Journal of Food Science, 67, 347–350.

Messina, M., & Messina, V. (1991). Increasing use of soyfoods and their potential role in cancer prevention. Journal of the American Dietetic Association, 91, 836–840.

Muhungu, S. M., Diaz-Mercado, S., Li, J., Schwenk, M., Singletary, K., & Faller, J. (1999). Stability of isoflavones during extrusion processing of corn/soy mixture. Journal of Agriculture and Food Chemistry, 47(1), 279–284.

Nwabueze T. U., Iwe M. O. & Akobundu E. N. T. (2008). Physical characteristics and acceptability of extruded African breadfruit-based snacks. Journal of Food Quality, 31(2):142–155

Őzer, E., İbanoğlu, Ş., Ainsworth, P., & Yağmur, C. (2004). Expansion characteristics of a nutritious extruded snack food using response surface methodology. European Food Research and Technology, 218(5), 474–479. (6).

Pansawat, N., Jangchud, K., Jangchud, A., Wuttijumnong, P., Saalia, F. K., Eitenmiller, R. R., et al. (2008). Effects of extrusion conditions on secondary extrusion variables and physical properties of fish, rice-based snacks. Food Science and Technology, 41(4), 632–641.

Park, J., Rhee, K. S., Kim, B. K., & Rhee, K. C. (1993). Single-screw extrusion of defatted soy flour, corn starch and raw beef blends. Journal of Food Science, 58(1), 9–20.

Potter, S. (1995). Overview of proposed mechanisms for the hypocholesterolemic effect of soy. Journal of Nutrition, 125, 606S–611S.

Rocha-Guzman, N. E., Gallegos-Infante, J. A., Gonzalez-Laredo, R. F., Bello-Perez, A., Delgado-Licon, E., & Ochoa-Martinez, A. (2008). Physical properties of extruded products from three mexican common beans (Phaseolus vulgaris L.) cultivars. Plant Foods for Human Nutrition (Dordrecht, Netherlands), 63(3), 99.

Rossen, J. L., & Miller, R. C. (1973). Food extrusion. Food Technology, 27(8), 46–53.

Seker, M. (2005). Selected properties of native or modified maize starch/soy protein mixtures extruded at varying screw speed. Journal of the Science of Food and Agriculture, 85, 1161–1165.

Sibel, Y., & Fahrettin, G. (2008). Response surface methodology for evaluation of physical and functional properties of extruded snack foods developed from food-by-products. Journal of Food Engineering, 86(1), 122–132.

Sun, Y., & Muthukumarappan, K. (2002). Changes in functionality of soy-based extrudates during single-screw extrusion processing. International Journal of Food Properties, 5(2), 379–389.

Zasypkin, D. V., & Lee, T Ch. (1998). Extrusion of soybean and wheat flour as affected by moisture content. Journal of Food Science, 63(6), 1058–1061.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yu, L., Ramaswamy, H.S. & Boye, J. Twin-screw Extrusion of Corn Flour and Soy Protein Isolate (SPI) Blends: A Response Surface Analysis. Food Bioprocess Technol 5, 485–497 (2012). https://doi.org/10.1007/s11947-009-0294-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-009-0294-8