Abstract

The physicochemical properties and nanostructure of mixtures of egg albumen protein (EAP) and gelatin from under-utilised grass carp (Ctenopharyngodon idella) skins were studied. The gelatin with 1% EAP had an acceptable gel strength. The addition of 5% EAP significantly increased the melting and gelling temperatures of gelatin gels. Additionally, the colour turned white and the crystallinity was higher in gelatin gels with gradient concentrations of EAP (1, 3, and 5%). Gelatin with 5% EAP had the highest G′ values while gelatin with 1% EAP had the lowest G′ values. Atomic force microscopy showed the heterogeneous nanostructure of fish gelatin, and a simple coacervate with a homogeneous distribution was only observed with the addition of 1% EAP, indicating interaction between gelatin and EAP. These results showed that EAP effect fish gelatin’s physicochemical and nanostructure properties and has potential applications in foods and pharmaceuticals.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Gelatin is a denatured protein derived from collagen by thermo-hydrolysis and has a thermo-reversible transition between sol and gel (Cho et al. 2004). The gelatin industry primarily uses mammalian skins and bones (mainly bovine and porcine) as raw materials. However, the outbreak of bovine spongiform encephalopathy, transmissible spongiform encephalopathy, foot-and-mouth disease and avian influenza have caused some concerns among consumers (Badii and Howell 2006). In addition, extracted gelatin from pigs and cattle cannot be used as a component of some foods for religious reasons. Therefore, the search for other gelatin raw materials has been initiated. Gelatin from aquatic animals, especially from fish skins, could become a substitute for mammalian gelatins (Pranoto et al. 2007).

Recently, many papers have dealt with the extraction and characterisation of gelatins from various fish species, such as common carp (Duan et al. 2011), smooth hound (Bougatef et al. 2012), cobia (Silva et al. 2014), horse mackerel (Badii and Howell 2006), bighead carp (Tu et al. 2015; Sha et al. 2014), lizardfish (Wangtueai et al. 2010) and yellow-fin tuna (Cho et al. 2005). Grass carp (Ctenopharyngodon idellus) is a widely grown freshwater fish. Although eaten regularly in Asia, it has not been fully used in the United States, where it is considered an exotic species with ecological/environmental concerns. So grass carp is the most plentiful source for fish gelatin extraction.

For food applications, gel strength, viscosity, and melting point are usually the most important gelatin properties. To expand the application of fish gelatin in food, an understanding of how the properties of fish gelatin are affected by the addition of solutes, such as proteins, salts, sugars, glycerol, and enzymes is needed (Sarabia et al. 2000; Sow and Yang 2015). It has been proposed that electrolytes such as salts could affect gelatin by modification of the electrostatic forces and formation of salt bridges (Kaewruang et al. 2014), while non-electrolytes could affect gelatin gel properties due to the hydration effect or stabilisation of the hydrogen bond (Choi et al. 2004). However, the observed changes in the physical properties of fish gelatins due to addition of other proteins requires further research.

Egg albumen protein (EAP) is the major component of egg white and accounts for 9.7–10.6% of egg white. The superior quality of egg albumen protein in gelation, foaming and other application has contributed to its extensive utilization as a food ingredient (Mehdizadeh et al. 2015). Badii and Howell (2006) reported that North Sea horse mackerel gelatin could interacted with egg albumen protein, and the mixture had greater G′ values and compatibility. However, there was no available knowledge about abundant freshwater fish gelatin interacted with EPA. Thus, rheological properties of freshwater fish gelatin interacted with EPA were still unknown. Additionally, the physicochemical properties included texture, colour and gelling properties, and the secondary and nanostructures of fish gelatin interacted with EAP needed to be studied.

The objective of this study was to examine the effects of egg albumen protein on the physicochemical properties and nanostructure of gelatin from grass carp skins. These results will provide a starting point for a better understanding of the effects of other protein components on the properties of fish gelatin.

Materials and methods

Materials

The whole fresh grass carps with body weights of 1.5–2.0 kg and lengths of 38–45 cm were obtained from a local aquatic farm in autumn in Jinzhou, China in 2015. Fish skins were removed and washed with chilled tap water (5–8 °C). The skins were cut into 2 × 2 cm2 pieces using a scissor and lyophilized in a freeze dryer (FreeZone 2.5, Palo Alto, CA, USA). The EAP powder containing approximately 90.2% protein according to the manufacturer was purchased from Murray Goulburn Cooperative Co. Ltd (Melbourne, Australia). All solutions were prepared in distilled water and all chemicals and reagents used were of analytical grade.

Methods

Gelatin extraction

Gelatin was extracted from the lyophilized skins of grass carp according to the method of Duan et al. (2011), with some modifications. To extract gelatin, 10 g of dried fish skins were mixed with 0.1 M NaOH (1:30, w/v). The mixture was shaken well and slowly stirred at room temperature (27 °C) for 4 h. The alkaline solution was changed every 1 h for a total of four changes to remove pigments and non-collagen proteins. After the alkaline solution was drained, the residual material was washed with distilled water until a neutral pH value. Then the skin samples were treated with 0.1 M HCl (1:30, w/v) for 45 min at room temperature to remove minerals. After acid treatment, residual materials were washed with distilled water ten times and filtered through four layers of cheesecloth and squeezed dry by hand. Finally, the pretreated sample was mixed with distilled water at a ratio of 1:20 (w/v) at 50 °C for 4 h with continuous stirring using a magnetic stir bar. After extraction, the gelatin solution was filtered through four layers of cheesecloth to remove the skin residues and lyophilized using the freeze dryer. The dry matter was referred to as gelatin powder.

Sample preparation

EAP was dissolved in distilled water by stirring for 30 min at 27 °C. Gelatin powder was soaked in distilled water by stirring until completely dissolved for 30 min at 45 °C. Mixed solutions were prepared at 45 °C with a gelatin concentration of 6.67% (w/v) and gradient concentrations of EAP (0, 1, 3, and 5%, w/v). These samples were used for all analyses.

Gel strength and texture profile analysis (TPA)

After reaching room temperature, 16 mL of each solution was transferred into small plastic jars (35 mm diameter, 45 mm height, flat bottom) for measurements of both gel strength and TPA. The samples were matured in a refrigerator (4 °C) for 16–18 h prior to analysis. Gel strength of matured samples was measured using a TA-XT plus texture analyzer (Stable Micro Systems Ltd, Godalming, UK). The head penetration speed was 1 mm/s. The force required for the head (cylindrical plastic probe, 12.7 mm diameter, flat bottom) to penetrate 4 mm into the sample while in the jar was taken as the gel strength. For TPA, the gel samples removed from the jar were subject to two cycle compression to 30% of its original height with a flat cylindrical probe (50 mm diameter, flat bottom). The test settings were pre-test speed: 1 mm/s; test speed: 1 mm/s; target mode: strain; strain compression: 30%; time: 5 s; trigger force: 5 g. Hardness, cohesiveness, springiness and chewiness were calculated from the TPA curve according to the definitions of Yang et al. (2007).

Colour

The colour of gels was measured using a Minolta CR-400 colorimeter (Konica Minolta Sensing, Inc., Osaka, Japan). L*, a*, b*, and ∆E (∆E = [(∆a)2 + (∆b)2 + (∆L)2]1/2) values indicating lightness/brightness, redness/greenness, yellowness/blueness and the total difference in colour value, respectively, were obtained. The colorimeter was warmed for 10 min and calibrated with a white standard (L* = 93.25, a* = −5.21, b* = 7.68).

Rheological measurements

All rheological measurements were done using an AR-1000N rheometer (TA Instruments, Newcastle, DE, USA) with parallel plate geometry (25 mm diameter). Gelatin solutions (6.67%, w/v) were prepared as described. G′ (Pa), G″ (Pa), and tan δ (G″/G′) were recorded. The time sweep tests were done for 30 min at 5 °C at a frequency of 1 Hz and a stress of 200 Pa. The frequency sweep tests were done between 0.01 and 70 rad/s at 5 °C and a stress of 3 Pa. The stress sweep tests were done between 0.1 and 1000 Pa at 5 °C and a frequency of 1 Hz. The temperature sweep tests were done from 5 to 35 °C and from 35 to 5 °C at a scan rate of 1 °C/min, a frequency of 1 Hz and a stress of 3 Pa. Melting and gelling temperatures were calculated as the cross-over point of G′ and G″ where tan δ becomes 1 for the heating and cooling curves, respectively.

Fourier transform infrared (FTIR) spectroscopy

FTIR spectra of samples were recorded using a Scimitar 2000 Near FTIR Spectrometer (Orange, CA, USA). For spectra analysis, the samples were lyophilized, mixed with small amounts of potassium bromide. Spectra were acquired at a resolution of 4 cm−1 over a range of 4000–400 cm−1 (mid-IR region) at room temperature. Automatic signals were collected for 32 scans and were compared to a back-ground spectrum recorded from the clean empty cell at 25 °C. Analyses of the spectral data and plotting curves were done using the Origin 8.6 data collection software programme provided with the spectophotometer.

X-ray diffraction (XRD)

XRD measurements of dried samples were performed using a Rigaku Ultima IV X-ray diffraction instrument (Rigaku Corporation, Tokyo, Japan) using Cu Kα radiation with a scan speed of 2°/min ranging from 5° to 50°. The X-ray generator operating conditions were 40 kV voltages and 30 mA current at room temperature.

Atomic force microscopy (AFM)

Before AFM imaging, all samples were melted in a 60 °C water bath and stirred using a Vortex mixer (Fisher Scientific, Pittsburgh, PA, USA) according to the method of Wang et al. (2009). About 20 μL of each diluted solution (50 μg/mL) was pipetted rapidly onto a piece of freshly cleaved glass sheet that was placed onto a 15 mm diameter AFM specimen disc. A camera blower was used to facilitate the distribution of solution on the glass sheet, which was then kept in a desiccator for at least 24 h before imaging. Characterisation of samples’ nanostructure was carried out using an AFM (XE-70, Park Systems Corp., Suwon, Korea). Tapping mode AFM imaging was done in air using a NSC 11/no Al tip (Mikro-Masch, Wilsonville, OR, USA) with a resonance frequency of 330 kHz. The force constant of the cantilever B of the tip was 48 N/m and the scan rate was set at 1 Hz. The AFM images obtained were analyzed off-line with AFM software provided by the company.

Statistical analysis

All the experiments were repeated three times. The differences in the results among different groups were determined using ANOVA (P < 0.05) and Duncan’s multiple range test, using SAS software (version 9.2, Cary, NC, USA).

Results and discussion

Gel strength and TPA

Gel strength is usually considered as the most important quality characteristic in the gelatin industry and must be reasonably high (Zhou and Regenstein 2004). TPA is useful for gel texture analysis because the textural parameters well correlated with sensory evaluation of textural parameters and it provides more information than traditional gel strength measurements (Lau et al. 2000).

Table 1 shows the effects of EAP addition on gel strength and TPA of fish gelatin. The addition of 5% EAP into gelatin gels resulted in a reduction of gel strength which was lower than the gelatin gel without EAP and that with 3% EAP. Fish gelatin with 5% EAP had significant higher (P < 0.05) cohesiveness, which may be due to the high content of viscous components. The springiness and resilience parameters of gelatin with 3% EAP were lower than that of other samples, suggesting that 3% EAP changes the texture of gelatin gel in such a way that prevents resilience and its coefficient of restitution. However, the hardness and gumminess parameters were not significantly different (P ≥ 0.05) among the four gelatin gels. This behavior of gels may be attributed to the destruction of weak bonds while the strong bonds remained unaffected by mechanical deformation.

Determination of colour parameters

The appearance of gelatin gels is of major importance to consumers, both from the point of view of acceptability and preference. The colour of the gelatin gels from grass carp skins with various EAP percentages is shown in Table 2; L* values of gelatin gels containing EAP were significantly higher (P < 0.05) than those without EAP. This might have been due to the colour of the EAP powder, which was close to a milky-white. The a* values were more related to the colour perceived by the human eye (Cai et al. 2014). Values of a* showed significant differences (P < 0.05) between different compositions. Nevertheless, no difference (P ≥ 0.05) in the b* values were found between gelatin gel without and with 1% EAP. Addition of 3 and 5% EAP to gelatin had a significant difference (P < 0.05) in the b* values. The ΔE values of gelatin gels containing EAP were significantly lower (P < 0.05) than those without EAP.

Rheological properties

The melting and gelling temperatures of the samples are given in Table 1. Melting and gelling temperatures of pure gelatin from fish skins were 24.3 and 20.0 °C, respectively, which were similar to the results with gelatin from silver carp skin (Boran et al. 2010). There were no significant differences (P > 0.05) in the melting temperature between gelatin with 1% EAP (23.8 °C) and pure gelatin, but the gelling temperature (19.2 °C) for gelatin with 1% EAP was significantly lower (P < 0.05) than pure gelatin. Similar results were reported by Badii and Howell (2006) who found that at a low concentration of EAP the gelling temperature of the mixed gels decreased, and then increased as the concentration of EAP was changed. The highest melting temperature measured was 25.7 °C for the gelatin with 5% EAP and was significantly higher (P < 0.05) than the value of 23.8 °C. Moreover, the gelatin with 3% EAP was not significantly (P ≥ 0.05) different from the pure gelatin in melting temperature. Fish gelatin is the product of aquatic animal, and their special living environment results in the unique characteristics of fish gelatin. The melting temperature of fish gelatin was lower than gelatin from terrestrial animal (Karim and Bhat 2009), and EPA derived from terrestrial animal, thus the melting temperature of the samples increased with increasing gradient concentrations of EPA.

The rheological measurements (time sweep, frequency sweep and stress sweep) are being used as tools to determine the quality of gels and provide information on molecular arrangements in gels. The time sweep tests indicated that all samples showed a time-dependent response to the applied stress, with the elastic modulus increasing with time (Fig. 1a). The increase in G′ values were steep after 200 s suggesting the network formation with time. Under a stress of 200 Pa, the gelatin and gelatin-EAP showed a change, or reorganisation, in the structures therein. Gelatin with 5% EAP had a higher G′ value during the test while gelatin with 1% EAP gave the lowest G′, which was in good agreement with the other rheological tests. The frequency sweep tests showed a slight dependence of G′ on frequency (Fig. 1b). A similar result has been reported in gelatin gels from cod skin (Gilsenan and Ross-Murphy 2000). The G′ values of gelatin with 5% EAP were higher than that of gelatin with 3 and 1% EAP, and were concentration dependent, which showed an increase in the strength and stability of gelatin structure, resulting in resistance to unfolding probably due to hydrophobic interactions. The stress sweep tests were also done to determine the G′ of gelatin and the results are shown in Fig. 1c. The stress sweep tests seemed to give the best discrimination of the samples in terms of their elastic response, giving a similar order to that of the time and frequency sweep tests. From three sweep modes, the changing trends of G′ values were gelatin > + 5%EAP > + 3%EAP > + 1%EAP, indicating that pure gelatin formed a stronger gel compared to EAP addition. The addition of EAP to gelatin solution might change gelatin gel structures and molecular arrangements of two protein molecules to form a new gel network (Sarbon et al. 2015). The G′ values of mixed gels increased with the concentration of EAP, which was consistent with the result reported by Badii and Howell (2006), indicating the usefulness of combining the two proteins.

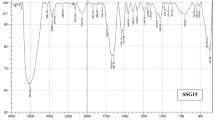

FTIR spectroscopy

FTIR data are shown in Fig. 2, and give more information about the interactions between the pure fish gelatin and EAP. Generally, all samples had a similar spectrum. The amide A bands of fish gelatin, +1% EAP, +3% EAP, and +5% EAP were found at wave numbers of 3328, 3321, 3321, and 3320 cm−1, respectively. According to Dolye et al. (1975), the amide A band is related to a free N–H stretching vibration that commonly occurs in the range of 3400–3440 cm−1. However, when the NH group of samples is part of a hydrogen bond, the position will be shifted to a lower wave number. These displacements were related to the possible extra interactions that arise between the EAP and the gelatin structure. The amide B bands of samples were observed at wave number of 2928 cm−1, corresponding to the asymmetric stretching vibration of CH2· and NH3 + (Dolye et al. 1975).

The amide I bands of all samples with the characteristic strong absorbance at 1655 cm−1 were primarily related to a C=O stretching vibration coupled to contributions from the CN stretch, CCN deformation and in-plane NH bending modes (Bandekar 1992). The translation in the amide I region depends on the hydrogen bonding and is probably the most useful for infrared spectroscopic analysis of the secondary structure of proteins (Kittiphattanabawon et al. 2010). The translation peak at amide I (1635 cm−1) was characteristic of the coil structure of gelatin (Nagarajan et al. 2012). Kittiphattanabawon et al. (2010) reported that a higher extraction temperature of gelatin increased the amount of low molecular weight components, in which the reactive group (C=O) could be more exposed, and the amide I band of gelatin can shift to a higher wave number (1655 cm−1). Additionally, the samples exhibited the amide II band at the wave number of 1541 cm−1, which is in agreement with a previous study in which gelatin extracted from seabass skin exhibited the amide II bands at a wave numbers of 1540–1543 cm−1 (Sinthusamran et al. 2014). The amide II band resulted from the out-of-phase combination of a CN stretching, and in-plane NH deformation, modes of the peptide group (Bandekar 1992). It was noted that the amide II band of samples showed similar spectra. Furthermore, the amide III bands of all the gelatin samples were observed at a wave number of 1240 cm−1, which indicated disorder in the gelatin molecules and was more likely to have been associated with the loss of its triple helix state (Friess and Lee 1996). Thus, a high helical content and hydrogen bonding in +3% EAP gels might explain its higher gel strength compared to others.

XRD

XRD can be used to analyse the helical structure of the gelatin and gelatin-EAP mixtures. The X-ray spectra of gelatin with various EAP percentages are shown in Fig. 3. There were two diffraction peaks in each X-ray spectra. The first diffraction peak was sharp while the second diffraction peak was wide. The result was similar to that of fish gelatin reported by Zhang et al. (2011). The first peak of gelatin, +1% EAP, +3% EAP, and +5% EAP located at 2θ = 8.02°, 8.00°, 8.36° and 8.16°, and the second broad peak located at 2θ = 19.60°, 20.02°, 20.21° and 20.12°. The first diffraction peak showed that these mixtures had ordered structures or ordered structure snippets (Cameron et al. 2007). The second peak shifted to larger scattering angles due to the formation of hydrogen bonds between gelatin and EAP.

From the Bragg equation d (Å) = λ/2sinθ (λ = 1.54 Å), the minimum values (d) of the repeat spacings were calculated. The d values of gelatin, +1% EAP, +3% EAP, and +5% EAP of the two peaks were 11.01 and 4.52 Å, 11.04 and 4.43 Å, 10.56 and 4.39 Å, 10.82 and 4.41 Å, which were related to the diameter of the tri-helix molecule and the single left-hand helix chain. The sample with 3% EAP had the smallest d value, which indicated that protein crystallisation had the shortest spacing after cross-linking of 3% EAP and gelatin. It is evident that the intensity of the peak first increased, then decreased with increasing EAP content, indicating first the gain, and then the loss, of crystallinity. The decrease in the crystal peak intensity might have been due to the intermolecular interactions between the hydroxyl groups in EAP and the NH2 side-chain groups in gelatin, which limits molecular movement and thus prevents crystallisation. These findings are supported by the work of Peña et al. (2010).

AFM

To understand more of the underlying mechanism behind the changes in material properties caused by EAP addition, nanostructural analysis of the gelatin was undertaken using AFM. Figure 4 shows the two- and three-dimensional AFM images of samples. They showed a certain roughness on their surface although multi-particle images gave a relatively smoother surface. Most of the samples showed the expected spherical structure with different diameters. Figure 4a–c confirmed that there was no aggregation or adhesion among the gelatin nanoparticles. As the EAP concentration increased, the nanoparticle cores became larger as indicated by an increase in diameter. Figure 4d–f showed that gelatin nanoparticles had a simple coacervate and homogeneous distribution. This could be attributed to the changes in surface properties caused by adding a low concentration of EAP (1%). The photographs of +1% EAP showed that no hair cracks or heterogeneity appeared on the nanoparticle surface, presenting a morphological evidence for homogeneous nanoparticles which were suitable for drug delivery. Figure 4g–i showed that gelatin nanoparticles had a further coacervation and heterogeneous distribution. This could be attributed to the changes in surface properties with the 3% EAP treatment, i.e., more hydrophilicity, a higher surface energy and a greater surface roughness. In addition, Fig. 4j–l showed a cluster structure of gelatin with 5% EAP, which is similar to other results (Wang et al. 2009). The aggregation occurred in +5% EAP gels, which might lead to low solubility of gels (Badii and Howell 2006). Lin et al. (2002) proposed that the aggregation of gelatin molecules occurred mainly by a multimeric association process in which multimers aggregated to form cluster structures that then associated further.

AFM images of gelatin from the skin of grass carp with various egg albumen protein (EAP) percentages. a Two-dimensional image of gelatin; b enlarged two-dimensional image of (a); c corresponding three-dimensional image of (b); d Two-dimensional image of gelatin with 1% EAP; e enlarged two-dimensional image of (d); f corresponding three-dimensional image of (e); g Two-dimensional image of gelatin with 3% EAP; h enlarged two-dimensional image of (g); i corresponding three-dimensional image of (h); j Two-dimensional image of gelatin with 5% EAP; k enlarged two-dimensional image of (j); l corresponding three-dimensional image of (k)

Conclusion

This study provides an insight into the effects of the addition of EAP on the gel behaviour of gelatin. Mixed gels of gelatin and EAP had different qualities. The addition of small amounts of EAP (1%) resulted in an acceptable gel strength value and G′ values that were smaller than expected. Gelatin with 5% EAP had higher G′ values than others, indicating synergistic interactions between the two proteins. The addition of 5% EAP significantly increased the melting and gelling temperatures of gelatin gels. In addition, gradient concentrations of EAP (1, 3, and 5%) can improve the colour of gelatin gels and lead to development of a crystalline structure and a higher degree of crystallinity. The overall changes in secondary structure with EAP addition led to poor textural properties of the fish gelatin gels. AFM showed that a heterogeneous nanostructure was present in fish gelatin gels. The addition of 3 and 5% EAP favoured formation of large aggregates, which may have been unfavourable for the formation of a rigid gel network. Interestingly, simple coacervation and a homogeneous distribution was only observed upon the addition of 1% EAP to gelatin. This study confirmed that gelatin from grass carp skins can be used in combination with other food proteins, such as EAP, to change the gelation properties and textures of the gels, which may have interesting applications in foods and pharmaceuticals.

References

Badii F, Howell NK (2006) Fish gelatin: structure, gelling properties and interaction with egg albumen proteins. Food Hydrocoll 20(5):630–640

Bandekar J (1992) Amide modes and protein conformation. BBA Protein Struct Mol 1120(2):123–143

Boran G, Mulvaney SH, Regenstein JM (2010) Rheological properties of gelatin from silver carp skin compared to commercially available gelatins from different sources. J Food Sci 75(8):E565–E571

Bougatef A, Balti R, Sila A, Nasri R, Graiaa G, Nasri M (2012) Recovery and physicochemical properties of smooth hound (Mustelus mustelus) skin gelatin. LWT Food Sci Technol 48(2):248–254

Cai LY, Wu XS, Dong ZJ, LinXP Yi SM, Li JR (2014) Physicochemical responses and quality changes of red sea bream (Pagrosomus major) to gum arabic coating enriched with ergothioneine treatment during refrigerated storage. Food Chem 160:82–89

Cameron GJ, Cairns DE, Wess TJ (2007) The variability in type I collagen helical pitch is reflected in the D periodic fibrillar structure. J Mol Biol 372(4):1097–1107

Cho SM, Kwak KS, Park DC, Gu YS, Ji CI, Jang DH, Lee YB, Kim SB (2004) Processing optimization and functional properties of gelatin from shark (Isurus oxyrinchus) cartilage. Food Hydrocoll 18(4):573–579

Cho SM, Gu YS, Kim SB (2005) Extracting optimization and physical properties of yellowfin tuna (Thunnus albacares) skin gelatin compared to mammalian gelatins. Food Hydrocoll 19(2):221–229

Choi YH, Lim ST, Yoo B (2004) Measurement of dynamic rheology during ageing of gelatine-sugar composites. Int J Food Sci Technol 39(9):935–945

Dolye BB, Bendit EG, Blout ER (1975) Infrared spectroscopy of collagen and collagen-like polypeptides. Biopolymers 14(5):937–957

Duan R, Zhang J, Xing F, Konno K, Xu B (2011) Study on the properties of gelatins from skin of carp (Cyprinus carpio) caught in winter and summer season. Food Hydrocoll 25(3):368–373

Friess W, Lee G (1996) Basic thermoanalytical studies of insoluble collagen matrices. Biomaterials 17(23):2289–2294

Gilsenan PM, Ross-Murphy SB (2000) Viscoelasticity of thermoreversible gelatin gels from mammalian and piscine collagen. J Rheol 44:871–882

Kaewruang P, Benjakul S, Prodpran T, Encarnacion AB, Nalinanon S (2014) Impact of divalent salts and bovine gelatin on gel properties of phosphorylated gelatin from the skin of unicorn leatherjacket. LWT Food Sci Technol 55(2):477–482

Karim AA, Bhat R (2009) Fish gelatin: properties, challenges, and prospects as an alternative to mammalian gelatins. Food Hydrocoll 23(3):563–576

Kittiphattanabawon P, Benjakul S, Visessanguan W, Shahidi F (2010) Comparative study on characteristics of gelatin from the skins of brownbanded bamboo shark and blacktip shark as affected by extraction conditions. Food Hydrocoll 24(2–3):164–171

Lau MH, Tang J, Paulson AT (2000) Texture profile and turbidity of gellan/gelatin mixed gels. Food Res Int 33(8):665–671

Lin W, Yan L, Mu C, Li W, Zhang M (2002) Effect of pH on gelatin self-association investigated by laser light scattering and atomic force microscopy. Polym Int 51(3):233–238

Mehdizadeh SA, Minaei S, Torshizi MAK, Mohajerani E (2015) Effect of UV irradiation, sample thickness and storage temperature on storability, bacterial activity and functional properties of liquid egg. J Food Sci Technol 52(7):4414–4422

Nagarajan M, Benjakul S, Prodpran T, Songtipya P, Kishimura H (2012) Characteristics and functional properties of gelatin from splendid squid (Loligo formosana) skin as affected by extraction temperatures. Food Hydrocoll 29(2):389–397

Peña C, Caba K, Eceiza A, Ruseckaite R, Mondragon I (2010) Enhancing water repellence and mechanical properties of gelatin films by tannin addition. Bioresour Technol 101(17):6836–6842

Pranoto Y, Lee CM, Park HJ (2007) Characterizations of fish gelatin films added with gellan and κ-carrageenan. LWT Food Sci Technol 40(5):766–774

Sarabia AI, Guillén MC, Montero P (2000) The effect of added salts on the viscoelastic properties of fish skin gelatin. Food Chem 70(1):71–76

Sarbon NM, Badii F, Howell AK (2015) The effect of chicken skin gelatin and whey protein interactions on rheological and thermal properties. Food Hydrocoll 45:83–92

Sha XM, Tu ZC, Liu W, Wang H, Shi Y, Huang T, Man ZZ (2014) Effect of ammonium sulfate fractional precipitation on gel strength and characteristics of gelatin from bighead carp (Hypophthalmichthys nobilis) scale. Food Hydrocoll 36:173–180

Silva RSG, Bandeira SF, Pinto LAA (2014) Characteristics and chemical composition of skins gelatin from cobia (Rachycentron canadum). LWT Food Sci Technol 57(2):580–585

Sinthusamran S, Benjakul S, Kishimura H (2014) Characteristics and gel properties of gelatin from skin of seabass (Lates calcarifer) as influenced by extraction conditions. Food Chem 152(1):276–284

Sow LC, Yang H (2015) Effects of salt and sugar addition on the physicochemical properties and nanostructure of fish gelatin. Food Hydrocoll 45:72–82

Tu ZC, Huang T, Wang H, Sha XM, Shi Y, Huang XQ, Man ZZ, Li DJ (2015) Physico-chemical properties of gelatin from bighead carp (Hypophthalmichthys nobilis) scales by ultrasound-assisted extraction. J Food Sci Technol 52(4):2166–2174

Wang Y, Zhang Y, Du W, Wu C, Zhao J (2009) Intelligent core-shell nanoparticles and hollow spheres based on gelatin and PAA via template polymerization. J Colloid Interface Sci 334(2):153–160

Wangtueai S, Noomhorm A, Regenstein JM (2010) Effect of microbial transglutaminase on gel properties and film characteristics of gelatin from lizardfish (Saurida spp.) scales. J Food Sci 75(9):C731–C739

Yang H, Wang Y, Jiang M, Oh J, Herring J, Zhou P (2007) 2-step optimization of the extraction and subsequent physical properties of channel catfish (Ictalurus punctatus) skin gelatin. J Food Sci 72(4):C188–C195

Zhang FX, Xu SY, Wang Z (2011) Pre-treatment optimization and properties of gelatin from freshwater fish scales. Food Bioprod Process 89:185–193

Zhou P, Regenstein JM (2004) Optimization of extraction conditions for pollock skin gelatin. J Food Sci 69(5):C393–C398

Acknowledgements

This study was supported by the National Natural Science Foundation of China (31401478), the National Postdoctoral Science Foundation of China (2015M570760), the China Scholarship Council (201508210023), the Postdoctoral Special Funding of Chongqing City (Xm2015021), the Research Project from the Science and Technology Department of Liaoning Province of China (No. 2015103020).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Cai, L., Feng, J., Peng, X. et al. Effect of egg albumen protein addition on physicochemical properties and nanostructure of gelatin from fish skin. J Food Sci Technol 53, 4224–4233 (2016). https://doi.org/10.1007/s13197-016-2416-4

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-016-2416-4