Abstract

Bromelain enzyme can be extracted from pineapple fruit including its waste parts. It is a valuable ingredient for various markets especially in the food and pharmaceutical areas. This enzyme can be extracted by membrane-based technology, but there is a lack of understanding of the properties of the crude pineapple extracts to link to functional membrane properties for efficient purification operation. This study focused on establishing characteristic properties of the crude pineapple waste mixture (CWM) extract, constituting of 57 % peel, 28 % crown and 15 % core, as a source of the enzyme and relevant to membr'ane processing. Rheological properties at different temperatures and pH levels were also determined in order to propose appropriate processing conditions for a practical and an efficient membrane operation. The CWM extract contained appreciable specific enzyme activity of 394.9 CDU/mg protein that would need to be purified at least 2–4 fold to achieve a required market standard. Existence of polysaccharides, particularly pectin, in the extract would be expected to cause fouling issues in membrane process, thus pre-treatment may be required to remove this compound from the mixture. The protein molecular weight of the CWM extract ranged between 11.7 and 26.9 kDa. The selection of membrane molecular weight cut-off (MWCO) should be above or below this range to isolate the enzyme. The evaluation on rheological properties of the CWM extract showed that it demonstrated lower viscosity at higher temperature and at neutral pH. Therefore, selection on temperature of 20–25 °C and pH 7 throughout the membrane purification operation has been recommended.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Pineapple (Ananas comosus) is one of the most popular fruits in the world and is the member of Bromeliaceae family. According to the FAO online database, the world’s production of pineapple in 2012 increased to 23.3 million tonnes from 21.5 million and 19.7 million tons in 2011 and 2010, respectively (FAOSTAT 2014). Such an increase in production of pineapple leads to simultaneous increase in waste generation due to selection and removal of fruit components unsuitable for human consumption during processing. While presenting an environmental burden, the pineapple waste has fortunately been identified as a potential source of valuable components such as bromelain enzyme.

Bromelain is a crude enzyme mixture obtained from pineapple plant with the major protease present in the mixture are known as stem bromelain (EC 3.4.22.32) and fruit bromelain (EC 3.4.22.33) (Bala et al. 2012). This enzyme is widely used in the pharmaceutical industry as a drug for treatment of inflammatory ailments, intestinal disorders, blood-coagulation-related diseases and improved absorption of antibiotics (Maurer 2001). Bromelain has also been successfully used in the food industry for meat tenderization, baking process, beer clarification and as a food supplement (Bala et al. 2012). The commercial production of this enzyme from the pineapple consists of several processes such as extraction, purification, drying and packing in the powder form. Among the related processes, the purification stage is the crucial process, which affects purity levels of the end product and the overall processing cost. Purification of bromelain from the pineapple can be performed using ion-exchange chromatography, reverse micellar system, gel filtration, ammonium sulphate fractionation, aqueous two-phase system, metal affinity membranes as well as membrane filtration process (Bala et al. 2012). Of these, membrane filtration is considered as one of the most practical approaches due to feasibility, ease to scale up, waste reduction during purification, and relatively lower cost than other techniques.

The application of membrane filtration process either with or without combination of other techniques for purification of bromelain from pineapple extracts has been reported to yield the enzyme with relatively high specific activity and purity. Doko et al. (1991) obtained bromelain powder with 2.8 fold purification by employing sequential batch membrane processing that involved microfiltration (MF) and ultrafiltration (UF) followed by ammonium sulphate extraction, ultracentrifugation and freeze drying. An increment of bromelain purity from 5.9 to 8.9-fold was reported by Hebbar et al. (2012), when integrating reverse miceller extraction with the ultrafiltration process. Additionally, Lopes et al. (2009) has achieved high bromelain purity and recovery from a pineapple pulp extract by combination of MF and UF processes. All these reports so far more focused on the effort of increasing the specific activity and purity of the enzyme without paying much attention to the conditions of the membrane processing itself. However, the design of a high efficiency membrane separation system would require a better understanding of the properties of the components in the crude pineapple extract.

Thus, a study on the membrane processing conditions would first involve the characterization of the incoming feed, which in this particular study is the crude pineapple extract. Each component of the extract would influence membrane-solute interactions differently in terms of solute shape and size, conformation, hydrophobic interactions and solute solubility (Cheryan 1986). The existence of complex sugars such as polysaccharides (Bartolomé et al. 1995) in the pineapple extract may also affect the efficiency of the membrane purification process since these polymers have a tendency to agglomerate with proteins under different conditions such as pH, temperature and shear stress. These interactions can lead to severe fouling and consequently substantial permeate flux decline. The fouling problem would affect the overall bromelain production line by increasing the maintenance and operating costs, due to the need for pre-treatment, high cross flow velocity, or frequent membrane cleaning.

In this study, the physicochemical and rheological properties of the crude extracts from commercial pineapple of the Smooth Cayenne variety are reported. Characterisation was carried out on a crude extract known as crude waste mixture (CWM) from the key waste components of the pineapple obtained after removal of the flesh at the processing plant. The CWM extract consisted of a specific ratio of non-edible crown, peel and core parts. The objectives of the present work were to establish chemical and physical properties of the CWM extract that relate to separation of the bromelain enzyme by membrane processing, and based on these the results to propose appropriate processing conditions for practical and efficient membrane operation.

Materials and methods

Materials

Commercial grade pineapples (Ananus comosus L.) of Smooth Cayenne cultivars were provided by a local supplier (Werribee, Victoria, Australia). The Smooth Cayenne cultivar was selected since it is commonly grown worldwide and is easily obtainable in Australia. Materials used in the study included casein, L-tyrosine, L-cysteine HCl, D-glucose, bromelain from pineapple stem, pectin from citrus fruit, phenol, ethylene diaminetetraacetic acid (EDTA), potassium bromide (KBr) and trichloroacetic acid (TCA), and were obtained from Sigma-Aldrich (St. Louis, Missouri, USA). Ethanol was purchased from Chem-Supply (Gillman, South Australia, Australia). Agilent Protein 250 kit which contains chips and reagents was purchased from Agilent Technologies (Santa Clara, California, USA). All chemicals used in the experiment were analytical grade.

Determination of fruit parts proportion and preparation of crude waste extract extracts

The whole fruits were washed, air dried and then manually peeled with a knife. The different parts (flesh, crown, skin and core) were separated, weighed and reported as a percentage of the proportion of a pineapple. A mixture of the crown, peel and core parts in a specific ratio was prepared and blended (8011ES, Waring, Torrington, Connecticut, USA) for 3 min with an equal weight of cold MiliQ water. The resulting blend was filtered through a cheese cloth and then centrifuged (Avanti J-26S XPI, Beckman Coulter, Pasadena, California, USA) at 10,000×g at 4 °C for 20 min (Ketnawa et al. 2012). The obtained supernatant, named crude waste mixture (CWM) extract, was used for further characterization of its physicochemical and rheological properties. Crude pineapple extracts from each individual pineapple parts were also been prepared by following the same procedure and used as references during the characterization study. The sample preparation was performed at a room temperature except during the centrifugation process.

Fourier transform infrared analysis

The FTIR was carried out on powders made from pineapple parts to identify the specific components of the pineapple waste, based on their functional groups. Pineapple powders were prepared from different pineapple parts by freeze drying (FD300, Dynavac Engineering, Bayswater, Victoria, Australia) and grinding (Waring, USA). The spectral analysis for all samples was carried out using a diffuse reflectance accessory (Valu-Line EasiDiff, Pike Technologies, Madison, Wisconsin, USA) in an FTIR instrument (IRAffinity – 1, Shimadzu, Kyoto, KYT, Japan) to detect characteristic chemical functional groups. All spectra recorded were an average of 20 scans in the absorbance mode with a 4 cm−1 resolution in the range of 600–4000 cm−1. All samples were mixed with ground potassium bromide and placed in the macro sampling cup accessory. The spectrum presented were smoothed (13–21 smoothing points) using an IR Solution software (Shimadzu).

Determination of pH and total solid

The pH measurement of all extracts was accomplished by using a pH meter (InoLab pH7110, WTW, Weilheim in Oberbayern, Bavaria, Germany). The total solid (TS) in the extracts was measured as reported previously (Ranganna 1986). Approximately 5 g of sample was evaporated on a boiling water bath and dried in an oven at 105 °C until constant weight was obtained. The total solids content was reported as a percentage of the dried weight over the initial weight of the sample.

Determination of total sugar

Total sugar in the crude pineapple extracts was determined according to the method of Dubois et al. (1956). A known quantity of aliquots of the extract was made up to 1 ml by adding distilled water and 1 ml of 5 % phenol was added and mixed thoroughly. Subsequently, 5 ml of a concentrated sulphuric acid (98 %) was added and the mixture allowed to stand for 10 min. The mixture was then placed in a water bath for 20 min at 20 °C. Yellow to orange colour developed was read at 480 nm using a spectrophotometer (Libra S12, Biocrom, Holliston, Massachusetts, USA) and concentration of glucose was calculated using a standard curve of D-glucose with a concentration range from 20 to 100 mg/L.

Determination of protein content

Total nitrogen content in the crude pineapple extracts was determined using a Total Organic Carbon (TOC) anaylzer with Total Nitrogen (TN) detector (TOC-V, Shimadzu, Kyoto, KYT, Japan). Sample preparation involved dilution to below 50 mg/L of nitrogen. Standard solution of 50 mg/L potassium nitrate (KNO3) was used to confirm the original calibration. The result was displayed as total nitrogen and conversion factor of 6.25 was used to calculate the protein content from the obtained value. This method is comparable to the Kjeldahl method for protein determination (Hausmann et al. 2013).

Determination of proteolytic activity and its specific activity

The proteolytic activity of the crude pineapple extracts was determined by the casein digestion unit (CDU) assay, using casein and L-tyrosine as substrate and standard, respectively (Murachi 1970). The extract was initially diluted to an appropriate concentration (5–16 dilution factors) with an enzyme diluent consisting of 0.03 M L-Cysteine HCL and 0.006 M EDTA. An aliquot of this diluted extract (1.0 ml) was then mixed with 5.0 ml of a casein substrate containing 0.6 % (w/v) of casein in a phosphate buffer at pH 7.0. The reaction was carried out at 37 °C for 10 min and was stopped by the addition of 5 ml of TCA (5 % (w/v). The reaction mixture was then centrifuged at 8000×g for 10 min (Beckman Coulter, USA). The absorbance of the supernatant was read at 275 nm using a spectrophotometer (Biocrom, USA). One unit of protease activity was defined as the amount of enzyme required to release a product equivalent to 1 μg of tyrosine in 1 min per ml of sample under the standard assay conditions and expressed as CDU/ml. The specific activity of the enzyme was calculated using Eq. 1 and expressed as CDU per mg of protein.

Determination of particle size distribution

Particle size of the samples was determined by using a particle size analyzer (Zetasizer 2000, Malvern Instruments, Malvern, Worcestershire, U.K.). The refractive index for all crude pineapple extracts (ranging from 1.337 to 1341) was pre-determined using a refractometer (Abbe no.302, Atago, Minato-ku, Tokyo, Japan) and a value of 1.33 was used for the water dispersant. Viscosity of the samples was following the water viscosity of 1.0031 cP. The measurement was carried out at 20 °C and at scattering angle of 173°. All samples were measured using square polystyrene cuvette (DTS0012).

Preparation of pectin powder derived from CWM extract

Preparation of pectin powder from the CWM extract was obtained following the method of Guo et al. (2012) with minor modifications. A volume (3 L) of the CWM extract was prepared from 6 fruits and the pH was adjusted to 1.5 using 0.5 M HCl. The mixture was then heated and kept at 80(±2) °C with continuous stirring for 1 h using a water bath oscillator. The hot mixture was then filtered through a Whatman no. 4 filter paper by vacuum filtration; and the filtrate was collected and cooled to a room temperature. The filtrate was mixed with an equal volumes of 95 % (v/v) ethanol and kept undisturbed overnight at 4 °C to precipitate pectin. The precipitated pectin was separated by centrifugation at 8000×g for 10 min (Beckman Coulter, USA) and then washed three times using 95 % ethanol to remove the monosaccharides and disaccharides. After purification, the wet pectin was dried at 40 °C in a drying oven until constant weight was observed, followed by grinding to powder. The pectin yield was calculated as follows.

Protein sizing

The proteins present in the CWM and other crude pineapple extracts were separated according to their molecular weight using a lab-on-a-chip technology (2100 Bioanalyzer, Agilent Technologies, California, US) with a Protein 250 LabChip kit. All chips were prepared according to the protocol provided by the manufacturer and a specific protein ladder was used as a standard. Initially, samples and ladder were labelled with a dye solution and incubated in ice for 30 min. They were then diluted with water in a ratio of 1:200, mixed with a denaturation buffer and heated up at 100 °C for 5 min to denature them. Subsequently, the samples and ladder were pipetted into chip wells. The chip was placed in the bioanalyzer and the assay was started within 5 min. Each sample was sequentially separated in the separation channel and detected by a laser-induced fluorescence detector (670–700 nm). All the process was controlled using Agilent 2100 Expert Software and the results of the analysis were presented as quantitative profiles and also as simulated gel-electrophoresis patterns.

Measurement of rheological properties

The rheological properties of the samples were established using a rheometer (MCR 301, Anton Paar, Graz, Austria) with a double gap cylinder geometry (DG.26.7/Q1, Anton Paar). The temperature was controlled by a Peltier system (Anton Paar GmbH). The data of the rheological measurements were analysed with a supporting Rheoplus rheometer software (Version 2.3, Anton Paar). The rheological behaviour of the pineapple extracts was determined with the increment of shear rate from 0 to 500 s−1 which is mostly applied in juice industry (Shamsudin et al. 2009). The temperature during all determinations was maintained at 20 ± 0.1 °C apart from the evaluation of rheological properties at different temperatures. Data from the experiments were fitted to existing rheological models including Newtonian, Bingham and Herschel-Bulkley. These models are presented as:

Where σ is the shear stress (Pa), \( \overset{\cdot }{\gamma } \) is the shear rate (s−1), η is the viscosity (Pa.s), η′ is the plastic viscosity, σ o is the yield stress (Pa), k is the consistency index (Pa1/2sn) and n is the flow behaviour index.

All samples examined for the rheological properties were adjusted to a total solid content of 2.8 % to eliminate concentration influence; and on the CWM extract under different temperature and pH conditions. Evaluation of the effects of the temperature on the rheological properties of the CWM extract was achieved by adjusting the temperature controller of the rheometer to 5, 10, 15, 20 or 25 °C. Effects of different pH level on the rheological properties of the CWM extract was assessed at 1, 4, 7 or 10. The pH of 30 ml CWM extract was adjusted with either 0.5 M HCl or 1.0 N NaOH and final volume of the samples was then made up to 35 ml with MilliQ water.

Statistical analysis

All tests were carried out in triplicate with at least one subsampling. The results were analysed by either one-way or two-way analysis of variance (ANOVA) using Statistical Analysis System (SAS) software (Version 9.2, SAS Institute, USA). Significant differences between mean were compared by t-test at 5 % level of significance.

Results and discussion

Proportion and FTIR spectra of pineapple parts

Table 1 shows the results of the different proportion of the pineapple parts. Non-edible parts of the commercial grade Smooth Cayenne pineapple consisting of a crown, peel and core, which are considered waste, represent almost half of the total fruit proportion. The waste percentage of the pineapple in our study was close to the waste percentage of 50 % (w/w) and 58 % (w/w) in Nang Lae and Phu Lae cultivars, respectively, reported by Ketnawa et al. (2012). The current progress in pineapple industry has led to a waste generation due to selection and removal of the components unsuitable for human consumption including the skins, peels, crowns, cores, pomace of the fruit, leaves and other non-edible parts. These parts are prone to microbial spoilage, which leads to an environmental issue, thus their utilization for production of certain by-products such as bromelain enzyme and dietary fibre appears a plausible approach that would generate additional profit for the industry and at least partially alleviate a problem of the waste disposal.

The peel constituted the largest portion of total waste (57 %, w/w) following by the crown and core (28 and 15 %, w/w, respectively). These proportions were used in the preparation of crude waste mixture (CWM) extract for subsequent characterization analyses. The CWM was prepared to represent a real form of raw materials obtained in the pineapple industry, which would normally be all mixed together without sorting process. Hence, the CWM extract was analyzed in order to provide a general understanding of this complex system and generate suggestions for utilization of all the waste in the pineapple industry for bromelain production.

FTIR has been used to assess the composition of the pineapple parts due to its non-invasive nature. FTIR spectra of pineapple powders and commercial bromelain are shown in Fig. 1. Bromelain can be characterised by the presence of peaks corresponding to C-N group (1149–1179 and 1255–1290 cm−1), amide I group (1600–1690 cm−1), C=O group (1640–1700 cm−1) and NH- group (3338–3380 cm−1) as reported by Soares et al. (2012) which were observed in our spectra as well. All the prepared pineapple powders showed similar spectrum as the commercial bromelain powder indicating the presence of bromelain in all the prepared samples tested.

Additionally, the spectra in Fig. 1 also show the existence of peaks characteristics of polysaccharide that are identified by an intense C-O stretching bands between 1000 and 1040 cm−1, COO- group (1400 cm−1) and C-H group (2800–3000 cm−1) (Gnanasambandam and Proctor 2000; Saha et al. 2007). This confirmed that the prepared sampled contained both bromelain and polysaccharides.

Physicochemical properties of crude pineapple extracts

Feed properties of the crude pineapple extracts would drive direction in terms of appropriate membranes configurations, membrane materials, pore sizes, operating parameters and cleaning methods for the bromelain purification. Various chemical properties of the crude pineapple extracts are presented in Table 2. In general, the extracts obtained from different parts of the pineapple varied in their composition. The overall properties of the CWM extract were clearly similar to the peel extract, which was likely related to its proportion, as more than a half of the mixture was made up of the peel.

The pH of CWM was 4.08, and was close to the average pH of individual crude pineapple extracts which had pH ranging from 3.49 to 4.25. The low pH in the pineapple is due to a high acidity caused by citric and malic acid content (Bartolomé et al. 1995).

Proteins and bromelain in particular, are present in the pineapple parts in different proportions in various concentrations and activities as shown in Table 2. Among the extracts, the flesh and crown parts showed the highest specific enzyme activity of 561 and 520 CDU/mg protein, respectively, while the core extract had the lowest specific enzyme activity (81 CDU/mg protein). Such a wide variation in specific enzyme activity among these extracts is likely influenced by different types of proteolytic enzymes present in the pineapple (Ketnawa et al. 2012). At least eight distinct proteolysis active compounds of similar molecular mass, including fruit bromelain, stem bromelain, ananain and comosain have been identified in the pineapple plant extract (Bhattacharyya 2008).

In our study, the CWM extract showed considerable specific enzyme activity of 395 CDU/mg protein, which demonstrated its potential for further utilization for bromelain extraction. Most of the commercial applications of bromelain do not require a high purity of the enzyme and therefore, the purification process can be designed depending on the destination of the bromelain (Costa et al. 2014). For food industry applications, the bromelain powder is commercially available in a specific enzyme activity ranging from 750 to 1600 CDU/mg protein (Biozym 2014) and even in a higher range for pharmaceutical and research applications. Thus, the CWM extract requires at least 2 to 4 fold purification for commercialization purpose, which may be achieved by using membrane filtration processes (Doko et al. 1991; Hebbar et al. 2012; Lopes et al. 2009).

However membrane filtration must also consider the effects of other components that may compromise performance, for example polysaccharides, which may interfere with membrane operation. Significant membrane fouling was reported in sugarcane juice clarification using UF due to interactions between polysaccharide and membrane (Saha et al. 2006). In the current study, the existence of polysaccharides and other carbohydrate components in the CWM and other crude pineapple extracts was established by determining the amount of total sugars and total solids (TS) in different pineapple parts (Table 2). As shown in Fig. 1, their presence was already observed by FTIR. The CWM extract contained considerable amounts of high molecular weight sugars. The mixture had 26 mg/ml of total sugar and 4 % (w/w) TS, most of which originated from the core portion. The core extract exhibited the highest amount of total sugar and total solid content 51 mg/ml and 6.14 %, respectively, compared to the other waste extracts, which was in agreement with a previous report (Ketnawa et al. (2012).

Membrane processes involve separation of principal components based on size exclusion. These particles would presumable composed of the proteins and polysaccharides present in the crude pineapple extracts. Particle size distributions observed in the crude pineapple extracts is shown in Fig. 2. Particle size distribution of the CWM extract varied between 3 and 1000 nm, with irregular peaks between 10 and 100 nm. In comparison, the flesh extract had a larger size distribution from 20 to 1500 nm followed by the core extract (20–1000 nm). This particle distribution in the flesh and core extracts is reflective of the presence of larger molecules such as polysaccharides which is in agreement with the total sugar and TS results in Table 2, which may also exist in the CWM extract. The presence of polysaccharides in the extract may result in formation of high molecular weight aggregates responsible for membrane fouling, which in turn may hinder the membrane performance.

Since the presence of high molecular weight polysaccharides in the extract was indicated by findings in Fig. 1 and Table 2, isolation of crude pectin from the CWM extract was performed for further characterization. The yield of crude pectin extracted from the CWM extract was fairly low at 0.06 % (w/v). The FTIR characterization of the CWM pectin is presented in Fig. 3 and was compared to commercial pectin derived from the citrus fruit. There are five characteristic peaks in this spectrum that can be used to identify pectin which includes R-O-R bond (1100 cm−1), C-C bond (1200 cm−1), COO- stretching (1650 cm−1), COO-R bond (1750 cm−1) and C-H bond (2800–3000 cm−1) (Monsoor et al. (2001). The presence of the typical peaks for pectin (Fig. 3) confirmed the presence of pectin in the CWM extract.

Various approaches such as feed pre-treatment, optimization of operating conditions and selection of different membrane materials can be chosen in order to reduce the fouling caused by polysaccharide component in the membrane process (Saha et al. 2006). The application of emerging ceramic membrane in the filtration process is believed to reduce the fouling caused by polysaccharides compared to conventional polymeric membranes (Finley 2005). Besides that, some studies have reported on success with using pectinase enzyme to hydrolyze both high and low esterified pectin in fruit juice that would reduce the juice viscosity and improve membrane filtration process including in the guava juice production (Akesowan and Choonhahirun 2013). If this option is chosen as a pre-treatment, selection of pectinase enzyme with higher molecular weight than the bromelain is important so that it can be separated from the extract during UF process and might be recycled back in the system.

Electrophoretic analysis of proteins present in the CWM and individual crude pineapple extracts was performed for determination of a molecular weight cut-off (MWCO) selection of the membrane filters in the bromelain purification process. The results in Fig. 4 show the protein patterns of all the crude pineapple extracts in comparison with a commercial stem bromelain as a reference (lane 6). In general, most of the proteins in all the crude pineapple extracts had different molecular weights (MW) of either 11.7, 19.6 and 26.9 kDa with the CWM extract was having all the bands (lane 5). Different parts of the pineapple contained different MW of the protein similarly to the report by Ketnawa et al. (2012) who found proteins with MW ranging of 18 to 39 kDa from crude extracts of different pineapple parts. The commercial stem bromelain showed MW of 27.1 kDa (lane 6) indicating the differences between the crude and the purified bromelain extract. Several authors characterized the crude and purified bromelain as having molecular weights ranging from 14.9 to 39.2 kDa (Chaurasiya and Hebbar 2013; Costa et al. 2014; Hebbar et al. 2012; Ketnawa et al. 2012; Soares et al. 2012). The variation in the molecular weight of the enzyme might be due to differences in the bromelain source e.g. peel, fruit, stem and core; and other parameters such as pineapple species, age, harvesting and size (Bresolin et al. 2013; Chaurasiya and Hebbar 2013).

The CWM extracts would be filtered by microfiltration (MF), where the permeate would then be fed to ultrafiltration (UF) to concentrate bromelain. This strategy is known as 2-stage membrane filtration and can be used for protein separation (Datta et al. 2009). The selection of MWCO should be above and below a specific protein size range. For bromelain purifcation, the 2-stage membrane filtration were performed at different size range of 0.1–8 μm and 5–10 kDa of the MF and UF, respectively (Doko et al. 1991; Hebbar et al. 2012; Lopes et al. 2009).

Based on the current result, the membrane process should have MWCO above 30 kDa to first pass the bromelain and filter remaining larger molecules. The permeate of the MF is then fed to a membrane with pore size below 10 kDa for protein capture and concentration in the retentate. Commercial membranes with pore sizes as small as 10 kDa are available from either polymeric or ceramic materials for this purpose. For instance, a range of pore sizes is offered by Pall Corporation for its Schumasiv ceramic membrane series which have high mechanical strength, good thermal resistance and high separation efficiency (Heidenreich 2011).

Rheological characteristics of crude pineapple extracts

Table 3 shows the fitted parameters of Newtonian, Bingham and Herschel-Bulkley rheological models for all the crude pineapple extracts at 20 °C with standardized total solid (TS) at 2.82 % (w/w). Viscosity of the feed is an important property affecting the flow behaviour in the membrane processing (Cheryan 1986). Thus, it is important to characterize the rheological properties of the CWM and other crude extracts since the feed viscosity in process stream effects mass transfer and pressure drop of the membrane filtration. The viscosity (η) values of the CWM extract and other crude extracts were similar (p > 0.05) at low values among each other and were maintained at satisfactory high R2 for Newtonian model. Thus, the result described the behaviour of the CWM and other pineapple extracts were comparable to Newtonian fluid. The Newtonian behaviour of the extracts may be attributed to the low molar mass of the extracts since the rheological behaviour of fluids depends on their molecular structures (Belibağli and Dalgic 2007). Low feed viscosity will directly influence better flux performance in membrane process especially for the UF and MF systems. The results were also similar (p > 0.05) in terms of yield stress (σ o ), plastic viscosity (η′), consistency index (k) and flow behaviour index (n) among all extracts. The best rheological model for describing the flow behaviour of the extracts was selected by comparing the value of coefficient of determination, R2. The experimental results showed the Herschel-Bulkley model fitted the best R2 value in the range of 0.9996–0.9999.

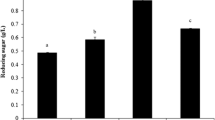

To further understand the rheological behaviour of the CWM extracts, evaluation of the rheological properties was performed at different temperatures and pH levels. Table 4 shows the parameters of the Newton, Bingham and Herschel–Bulkley models along with the correlation coefficient (R 2) for each flow model. The rheological models show that CWM extract had a significantly (p < 0.05) lower viscosity (η) at a higher temperature. Viscosity decline associated with a rise in temperature has been contributed to thermal expansion of the molecules, which increases the intermolecular distances and consequently a reduction in viscosity (Kumoro et al. 2009). Viscosity variations with temperature has been reported for pineapple juice extracted from Josapine variety and was described by the Arrhenius relationship especially at a higher concentration (Shamsudin et al. 2009). Available literature reports focused on investigating the effects of temperature on rheological properties of pineapple juice; however there are no reports on CWM extract. Nevertheless, these studies can be used as a base to analyse our findings.

In membrane processing, higher temperature would generally result in higher flux due to lower viscosity of the stream in pressure-controlled and mass transfer-controlled regions (Cheryan 1986). It also important to consider in the case of pineapple extracts, high temperature may lead to protein denaturation which would not only reduce the bromelain activity but also potentially cause fouling phenomena by particle-particle interactions. Although the optimum temperature for the highest bromelain activity appeared to be in the range between 50 and 70 °C (Ketnawa et al. 2012; Silvestre et al. 2012), a 17 % loss of the enzyme activity has been reported when it was exposed to 50 °C for 60 min (Jutamongkon and Charoenrein 2010). In contrast, the proteolytic activity of concentrated bromelain solutions remains relatively stable for at least 1 week at room temperature (Hale et al. 2005). The current study suggested in applying processing temperature of 20–25 °C in the membrane purification process in regards to the low feed viscosity for better flux performance, and to reduce the possibility of protein denaturation as well as the processing utility cost.

Solute-membrane and solute-solute interactions are also influenced by environmental pH. Table 4 indicates the CWM extract had significantly (p < 0.05) higher viscosity (η) at its natural pH (pH4) and pH 1 in comparison to that obtained at a more alkaline pH (7 and 10). Such rheological characteristics of the extract were attributed to its components responsible for the microstructure, related to the zeta potential of the extract. Stem and fruit bromelain are reported to have an isoelectric point (IEP) of pH 9.5 and 4.6, respectively (Chaurasiya and Hebbar 2013). In the current study, the pI of the CWM extract was determined at pH 2.37 indicating a mixture of bromelain with other components. At pH near to its pI, particles in the extract tend to agglomerate to each other due to neutral surface charge among them. Thus, changing the pH of the extracts away from its isoelectric point will lead to repulsion between the particles and hence, reducing the viscosity.

The feed pH is an important factor in protein separations through membrane process. Beside influencing the viscosity, the pH of the feed can also affect electrical charge on both the protein and the membrane due to the ionization or deionization of various acidic/basic groups on the protein and membrane surface (Burns and Zydney 1999). This can cause either attractive or repulsive response in the protein-membrane interaction based on their isoelectric point. The isoelectric point of a ceramic membrane coated with zirconium dioxide (ZrO2) is at pH 6.3–7.1 while for a polymeric membrane is in a range of pH 4–5 (Hofs et al. 2011). Better feed-membrane electrostatic interaction during the UF process is expected if the pH of the CWM extract is adjusted above its pI and below the membrane’s pI resulting in desired flux.

Lopes et al. (2009) reported the best pH condition for bromelain concentration using membrane process was at pH 7–7.5 with approximately 85–100 % enzyme activity recovery. The pH range between 6 and 7 was also reported to be the optimal values of the bromelain specific activity (Silvestre et al. 2012). Thus, altering the CWM extract to pH 7 might be a good alternative in order to optimize the membrane purification process and to obtain the best end product.

Conclusions

The CWM extract has been prepared from 57 % peel, 28 % crown and 15 % core according to the pineapple proportion. With a specific enzyme activity of 394.9 CDU/mg protein, the CWM extract should be purified at least 2–4 folds for commercialization purpose. Elimination of polysaccharide, in particular pectin, in the CWM extract by physical or chemical means was proposed prior to the membrane purification process to minimize the fouling issue. The membrane used in the purification process of the extract should have a molecular cut-off (MWCO) above 30 kDa or below 10 kDa for protein selectivity as permeate or as retentate, respectively. Based on the rheological properties evaluation, the current study suggests that the membrane-based bromelain purification process should be performed at temperature of 20–25 °C and at pH 7 of the extract.

References

Akesowan A, Choonhahirun A (2013) Effect of enzyme treament on guava juice production using response surface methodology. J Anim Plant Sci 23:114–120

Bala M, Ismail NA, Mel M, Jami MS, Salleh HM, Amid A (2012) Bromelain production current trends and perspective. Arch Des Sci 65:369–399

Bartolomé AP, Rupérez P, Fúster C (1995) Pineapple fruit: morphological characteristics, chemical composition and sensory analysis of Red Spanish and Smooth Cayenne cultivars. Food Chem 53:75–79

Belibağli KB, Dalgic AC (2007) Rheological properties of sour-cherry juice and concentrate. Int J Food Sci Technol 42:773–776

Bhattacharyya BK (2008) Bromelain: an overview. Nat Prod Rad 7:359–363

Biozym (2014) Data sheet - Bromelain. http://www.biozym.de/datasheets/bromelain.php. Accessed 9 Jul 2014

Bresolin IRAP, Bresolin ITL, Silveira E, Tambourgi EB, Mazzola PG (2013) Isolation and purification of bromelain from waste peel of pineapple for therapeutic application. Braz Arch Biol Technol 56:971–979

Burns DB, Zydney AL (1999) Effect of solution pH on protein transport through ultrafiltration membranes. Biotechnol Bioeng 64:27–37

Chaurasiya RS, Hebbar UH (2013) Extraction of bromelain from pineapple core and purification by RME and precipitation methods. Sep Purif Technol 111:90–97

Cheryan M (1986) Ultrafiltration handbook. Technomic Publishing Co. Inc., Pennsylvania

Costa HB, Fernandes PMB, Romão W, Ventura JA (2014) A new procedure based on column chromatography to purify bromelain by ion exchange plus gel filtration chromatographies. Ind Crop Prod 59:163–168

Datta D, Bhattacharjee S, Nath A, Das R, Bhattacharjee C, Datta S (2009) Separation of ovalbumin from chicken egg white using two-stage ultrafiltration technique. Sep Purif Technol 66:353–361

Doko MB, Bassani V, Casadebaig J, Cavailles L, Jacob M (1991) Preparation of proteolytic enzyme extracts from Ananas comosus L., Merr. fruit juice using semipermeable membrane, ammonium sulfate extraction, centrifugation and freeze-drying processes. Int J Pharm 76:199–206

Dubois M, Gilles KA, Hamilton JK, Rebers PA, Smith F (1956) Calorimetric method for determination of sugar and related substances. Anal Chem 28:350–356

FAOSTAT (2014) World’s production of pineapple. http://faostat.fao.org/site/567/DesktopDefault.aspx?PageID=567#ancor. Accessed 29 Sept 2014

Finley J (2005) Ceramic membranes: a robust filtration alternative. Filtr Sep 42:34–37

Gnanasambandam R, Proctor A (2000) Determination of pectin degree of esterification by diffuse reflectance Fourier transform infrared spectroscopy. Food Chem 68:327–332

Guo X, Han D, Xi H, Rao L, Liao X, Hu X, Wu J (2012) Extraction of pectin from navel orange peel assisted by ultra-high pressure, microwave or traditional heating: a comparison. Carbohydr Polym 88:441–448

Hale LP, Greer PK, Trinh CT, James CL (2005) Proteinase activity and stability of natural bromelain preparations. Int Immunopharmacol 5:783–793

Hausmann A, Sanciolo P, Vasiljevic T, Weeks M, Schroën K, Gray S, Duke M (2013) Fouling mechanisms of dairy streams during membrane distillation. J Membr Sci 441:102–111

Hebbar UH, Sumana B, Hemavathi AB, Raghavarao KSMS (2012) Separation and purification of bromelain by reverse micellar extraction coupled ultrafiltration and comparative studies with other methods. Food Bioprocess Technol 5:1010–1018

Heidenreich S (2011) Ceramic membranes: high filtration area packing densities improve membrane performance. Filtr Sep 48:25–27

Hofs B, Ogier J, Vries D, Beerendonk EF, Cornelissen ER (2011) Comparison of ceramic and polymeric membrane permeability and fouling using surface water. Sep Purif Technol 79:365–374

Jutamongkon R, Charoenrein S (2010) Effect of temperature on the stability of fruit bromelain from smooth cayenne pineapple. Kasetsart J (Nat Sci) 44:943–948

Ketnawa S, Chaiwut P, Rawdkuen S (2012) Pineapple wastes: a potential source for bromelain extraction. Food Bioprod Process 90:385–391

Kumoro AC, Retnowati DS, Budiyati CS (2009) Influence of temperature and solid concentration on the physical properties of Noni (Morinda citrifolia L.) juice. Food Bioprod Process 4:1482–1488

Lopes FLG, Júnior S, Baptista J, Souza RRD, Ehrhardt DD, Santana JCC, Tambourgi EB (2009) Concentration by membrane separation processes of a medicinal product obtained from pineapple pulp. Braz Arch Biol Technol 52:457–464

Maurer HR (2001) Bromelain: biochemistry, pharmacology and medical use. Cell Mol Life Sci 58:1234–1245

Monsoor MA, Kalapathy U, Proctor A (2001) Determination of polygalacturonic acid content in pectin extracts by diffuse reflectance Fourier transform infrared. Food Chem 74:233–238

Murachi T (1970) Bromelain enzymes. Methods Enzymol 19:273–284

Ranganna S (1986) Handbook of analysis and quality control for fruit and vegetable products. Tata McGraw-Hill Education, New Delhi

Saha NK, Balakrishnan M, Ulbricht M (2006) Polymeric membrane fouling in sugarcane juice ultrafiltration: role of juice polysaccharides. Desalination 189:59–70

Saha NK, Balakrishnan M, Ulbricht M (2007) Sugarcane juice ultrafiltration: FTIR and SEM analysis of polysaccharide fouling. J Membr Sci 306:287–297

Shamsudin R, Wan Daud WR, Takrif MS, Hassan O, Ilicali C (2009) Rheological properties of Josapine pineapple juice at different stages of maturity. Int J Food Sci Technol 44:757–762

Silvestre MPC, Carreira RL, Silva MR, Corgosinho FC, Monteiro MRP, Morais HA (2012) Effect of pH and temperature on the activity of enzymatic extracts from pineapple peel. Food Bioprocess Technol 5:1824–1831

Soares PAG, Vaz AFM, Correia MTS, Pessoa A Jr, Carneiro-da-Cunha MG (2012) Purification of bromelain from pineapple wastes by ethanol precipitation. Sep Purif Technol 98:389–395

Acknowledgments

The authors gratefully acknowledge the Ministry of Education Malaysia and Universiti Putra Malaysia (UPM) for providing the PhD scholarship for M.Z.M. Nor.

Author information

Authors and Affiliations

Corresponding author

Additional information

L. Ramchandran holds a PhD., Victoria University.

M. Duke holds a PhD., Victoria University.

T. Vasiljevic holds a PhD., Victoria University.

Rights and permissions

About this article

Cite this article

Nor, M.Z.M., Ramchandran, L., Duke, M. et al. Characteristic properties of crude pineapple waste extract for bromelain purification by membrane processing. J Food Sci Technol 52, 7103–7112 (2015). https://doi.org/10.1007/s13197-015-1812-5

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-015-1812-5