Abstract

In this study, bioactive (total phenolic, antioxidant and antiradical activity) and rheological properties (steady and dynamic) of rose hip marmalade were investigated. Bioactive properties were determined in rose hip marmalade and extract. Extract had higher total phenolic content (38.5 mg GAE/g dry extract), antioxidant activity (124 mg AAE/g dry extract) and antiradical activity (49.98 %) than marmalade. Steady and dynamic rheological properties of the marmalade were determined at different temperature levels (5, 25 and 45 °C). Rose hip marmalade exhibited shear thinning behavior and Ostwald de Waele model best described flow behavior of the sample (R 2 ≥ 0.9880) at different temperature levels. Consistency index and apparent viscosity values (η 50 ) at shear rate 50 s−1 decreased with increase in temperature level. Viscoelastic properties were determined by oscillatory shear measurements and G' (storage modulus) values were found to be higher than G'' (loss modulus) values, indicating that the rose hip marmalade had a weak gel−like structure with solid–like behavior. G', G'', G * (complex modulus) and η* (complex viscosity) values decreased with increase in temperature level. Modified Cox-Merz rule was satisfactorily applied to correlate apparent and complex viscosity values of the rose hip marmalade at all temperatures studied.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In recent years, a strong relationship between diet and health has been reported. Therefore, vegetable and fruit based food products have been widely preferred by health-conscious people. Rose hip is one of the fruit types that have received a great attention due to its therapeutic properties and also used for food and pharmaceutical purposes as an ingredient in pro-biotic drinks, soups and yoghurts (Chrubasik et al. 2008; Larsen et al. 2003). Rose hip is consumed as marmalade, fruit juice, and tea bag. Rose hip fruits are rich in ascorbic acid (Gao et al. 2000; Olsson et al. 2004), carotenoids (Hornero-Mendez and Minguez-Mosquera 2000), phenolic compounds (Gao et al. 2000; Olsson et al. 2004), folates (Stralsjo et al. 2003) and fatty acids (Larsen et al. 2003). It was reported that rose hip had prophylactic and therapeutic properties against many ailments including inflammatory disorders arthritis (Kharazmi 2008; Rein et al. 2004), rheumatism and some infectious diseases such as influenza and gastrointestinal disorders (Orhan et al. 2007). In addition, rose hip can strengthen immune system against some infections especially the common cold (Ercisli 2007). Therefore, consumption of the rose hip based products is very important for human health.

One of the most widely consumed rose hip based products is rose hip marmalade that is widely consumed in breakfast in Turkey. Marmalade is prepared by boiling fruit pulp with sugar and acid until desired brix value is reached. Generally, shelf life of the marmalade is known to be approximately 2 years. In addition to its sensory characteristics, rheological properties of the marmalade are also among the most important factors determining consumer preference. In addition, from a general point of view, rheological characterization of food systems is useful in optimization of formula, observation of ingredient functionality and quality control (Dervisi et al. 2001; Kokini and Plutchok 1987). Rheological properties are remarkably affected by amount and type of sugar, concentration and type of gelling agent, fruit pulp content and process temperature (Basu and Shivhare 2010). In order to determine rheological properties, different types of tests, namely steady shear and dynamic shear measurements, are performed. Apparent viscosity which is determined by steady shear measurements is a function of shear rate data showing flow behavior of food systems. On the other hand, dynamic oscillatory measurements are performed to determine viscoelastic characteristics of food systems. Storage modulus (G'), loss modulus (G'') and complex modulus (G *) of food systems are determined by oscillatory measurements (Dolz et al. 2006). G' and G'' values represent the elastic or viscous structure of the sample, respectively. To the best of our knowledge, many studies have been conducted to investigate rheological properties of some fruit based products (jams and puree) (Igual et al. 2014; Basu et al. 2013; Falguera et al. 2010). The studies on rose hip fruits have solely focused on chemical composition and their functional properties (Demir et al. 2014; Andersson et al. 2011; Wenzig et al. 2008). However, no study has been reported so far in the literature on phenolic content and steady/dynamic rheological properties of the rose hip marmalade. Therefore, in the present study, bioactive, flow behavior (steady) and viscoelastic (dynamic rheological properties) properties of the rose hip marmalade were investigated.

Materials and methods

In this study, rose hip marmalade was prepared according to the traditional method reported by Özdemir et al. (1998). Rose hip fruits used in production of the marmalade was grown in Konya, Turkey. Process flow chart for the production of the marmalade is presented in Fig. 1. The ripened fruits were firstly dry cleaned in order to remove spoils and then washed. After cleaned, they were soaked into warm water in a ratio of 1:1.5 at 60 °C for 8 h. The fruit/water mixture was pressed to obtain pulp and then the pulp was filtered using sieve with 0.5 cm of pore dimater. Total soluble solid (TSS) content of the obtained pulp was determined as 10 °Brix. After cooking of the pulp until 50 °Brix, sucrose was added in a ratio of 1:1.5. Sucrose was thoroughly solved and the marmalade was hot filled, closed hermetically and cooled to 25 °C. Total soluble solid content of the end product was found to be 65 °Brix. Regarding chemical agents used in this study, Folin Ciocalteu reagent, sodium carbonate, sulphuric acid, sodium phosphate, ammonium molybdate (Merck) and DPPH (2,2-Diphenyl-1-picrylhydrazyl) were from obtained Sigma.

Determination of bioactive properties

Bioactive properties (total phenolic content, antioxidant and antiradical activity) were determined in two different types of sample that were prepared according to the following two methods.

-

1.

Extraction method: 1 g sample of rosehip marmalade was mixed with 10 mL 80 % ethanol solution. Extraction was carried out with shaker water-bath (Memmert WB 22, Germany) at 35 °C for 1 h. After that, dry extract was collected using the vacuum evaporator at 40 °C. The dry extract was diluted to 5000 ppm with addition of solvent (80 % ethanol) and the prepared dilution was mixed and filtered using syringe equipped with membrane filter (0.45 μm).

-

2.

Direct analyses method: 0.1 g of sample was taken and diluted to 10,000 ppm with addition of the ethanol solution (80 %). After this operation, the solvent was filtered using syringe equipped with membrane filter (0.45 μm).

Determination of total phenolic content

The total phenolic content analysis was performed according to the Folin-Ciocalteu colorimetric method (Singleton and Rossi 1965) with some modifications (Sagdic et al. 2013). The method measures necessary amount of the analyzed sample, in order to inhibit the oxidation of FCR (Folin–Ciocalteu reagent or Folin’s phenol reagent). FCR method is based on the principle of transformation of molybdenum electron from phenolic compounds and other reductive antioxidants. Absorbance of blue colored complex was measured by spectrophotometer at 760 nm (Ardag 2008). The results were calculated using gallic acid calibration curve and reported as mg GAE/g dry extract.

Determination of antioxidant activity

Antioxidant activity was determined according to the phosphomolibdenium complex method described by Prieto et al. (1999). The method is based on the formation of green colored phosphate/Mo (V) complex at a high temperature in acidic pH range by reducing Mo (VI) to Mo (V) in the existence of antioxidants, and on measurement of this color (Başak and Candan 2008). The results were calculated using ascorbic acid calibration curve and reported as mg AAE/g dry extract.

Determination of antiradical activity

Antiradical activity of the samples was determined using the DPPH (1,1-diphenyl-2-picrylhydrazyl) scavenging method as described by Brand-Williams et al. (1995) with some modifications. Five hundred μL of 5000 ppm sample and 3500 μL of DPPH (prepared with 100 % methanol) solvent were collected into test tubes. After 30 min of incubation, absorbance was read at 517 nm. The results were expressed as % inhibition.

Rheological measurements

Steady shear measurements

Steady shear rheological properties were determined using a controlled stress rheometer (Thermo-Haake, RheoStress 1, Germany) equipped with a parallel plate configuration (gap = 0.5 mm; diameter = 25 mm) at different temperature levels (5, 25 and 45 °C). The measurements were carried out within shear rate range of 1–100 s−1. Total 25 data points were recorded at 10 s intervals and time duration of the shearing was 250 s. The measurements were performed at five times at each temperature level. Three different models; namely, Ostwald de Waele (Eq. 1), Herschel Bulkley (Eq. 2) and Casson (Eq. 3) were used to describe flow behavior of the rose hip marmalade.

where σ is the shear stress (Pa), K is the consistency coefficient (Pa sn), \( \dot{\gamma} \) is the shear rate (s−1), n is the flow behavior index (dimensionless), σ 0 is the yield stress (Pa), σ 0C is the Casson yield stress (Pa0.5) and K c is the Casson constant (Pa s)0.5 (Rao 2005). The corresponding model parameters were calculated using RheoWin Data Manager (RheoWin Pro V. 4.0, HAAKE, Karlsruhe, Germany). Accuracy of the models were compared with respect to R 2 and RMSE values calculated using the following equations (Delgado et al. 2014):

where n and m is the observation number and number of constants in the corresponding model.

Dynamic shear measurements

The stress controlled rheometer (Thermo-Haake, RheoStress 1, Germany) was also used for determination of viscoelastic properties of the rose hip sample. In order to determine linear viscoelastic region (LVR), stress sweep test was performed within shear stress range of 0.1 and 10 Pa at 1 Hz. Frequency sweep test was performed at 0.3 Pa over a frequency (ω) range of 0.1–10 Hz at different temperature levels (5, 25 and 45 °C) to record storage (G') and loss modulus (G'') values.

Other parameters obtained from frequency sweep measurements were G * (complex modulus), η * (complex viscosity) and tan δ (loss tangent). The overall response of the sample versus to the sinusoidal strain were characterized by complex modulus (G*) (Gunasekaran and Ak 2000) and complex viscosity (η *).

Loss tangent, a dimensionless number which indicates if the material behaves as solid-like or liquid-like behavior, was calculated by dividing G′ to G′′ (Gunasekaran and Ak 2000).

Non-linear regression was applied to G′ and G′′ values versus ω data and then magnitudes of intercepts (K′, K′′ and K *) and slopes (n′, n′′ and n *) were computed using the following equations (Yoo and Rao 1996):

Applicability of Cox-Merz rule

Cox-Merz rule is applied to understand if the steady-state shear properties can be determined by oscillatory measurements and vice-verca (Augusto et al. 2012, 2013). To be clear, finding out that this rule would be valid enables us to determine the rheological properties of foods by either oscillatory or steady-state shear experiments. This is very useful because it is not always possible to sequentially conduct each kind of experiment (Gunasekaran and Ak, 2000). Especially for many polymeric systems, high shear stress conditions lead fracture in sample and secondary flows, which complicates measurement of steady viscosity. Therefore, in many cases, dynamic shear mesurements are more condifental. In addition, it is possible to have information on microstrcture of food materials that adhere to the rule, which reveals the significance of the application of Cox-Merz rule. Therefore, in this study, correlation between the dynamic shear (complex viscosity, η * and angular frequency, ω) and steady shear parameters (apparent viscosity, η and shear rate, γ˙) at different temperature levels was determined using the Cox-Merz rule (Eq. 9) (Rao and Tattiyakul 1999; Steffe 1996).

Statistical analysis

ANOVA test was used (SPSS Statistics 17.0, Armonk, NY, USA) to determine if the effect of temperature on the measured rheological parameters was significant (P <0.05).

Results and discussion

Bioactive properties

Table 1 reveals that total phenolic content (TPC) prepared by the direct method was recorded as 21.14 mg GAE/g dry extract, while that of the sample prepared by the extraction method was noted as 38.49 mg GAE/g dry extract. The phenolic content of rosehip over dry fruit weight was recorded as 96 mg GAE/g dry weight (Ercisli 2007). Yoo et al. (2008) extracted rosehip samples with 70 % methanol solution and determined the phenolic substance amount as 818.5 mg GAE/100 g. In addition, the phenolic compounds extracted with 50 % acetone and 80 % methanol were found to be 5.09 and 2.57 mg GAE/g botanicals, respectively. Barros et al. (2010) reported the total phenolic content of rose hip to be 143.17 mg GAE/g. From these results, it was possible to say that there were remarkable differences between the total phenolic content values of rosehip fruits in terms of total phenolic content. Different TPC results could be attributed to the differences between types of the fruit and extraction solvents used. Accordingly, Karaman et al. (2014) reported that TPC of persimmon fruit varied between 96.77 and 3872 mg GAE/100 g dry sample and they attributed these variations to the different solvent types used. Moreover, maturity level of the fruits may be another factor which can influence TPC of the sample. Accordingly, Costa et al. (2013) reported that immature fruits had higher phenolic content than mature ones and observed higher anti-oxidant activity in unripened fruits. On the other hand, many different phenolic compounds were determined in the previous studies. Gallic acid, protocatechuic acid, 4-hydroxy benzoic acid, catechin, vanillic acid, procyanidin-B2, syringic acid, epicatechin, epicatechin gallate, 2,5-dihidroxy benzoic acid, chlorogenic acid, caffeic acid, coumaric acid, ferrulic acid, sinapic acid and resveratrol were the common phenolic compounds found in the rose hips in variable quantity (Demir et al. 2014).

Antioxidant and antiradical activity values of the samples are also presented in Table 1. Antioxidant activity values were found to be 42.84 and 123.91 mg AAE/g dry extract while antiradical activity values were found to be 7.23 and 49.98 % for the samples prepared by direct and extraction methods, respectively. As can be seen, antioxidant and antiradical activity values of the samples prepared by extraction method were remarkadly higher than those of the samples prepared by direct method. These results could be attributed to the fact that the functional components could be passed from the solvent selectively in the extraction method. Although the direct method reflects more realistic results for bioactive properties of rose hip marmalade ready for consumption, different extraction methods should also be developed and tested to understand the possibility to increase yield of recovery of some natural components from plant materials such as colorants, flavor and antioxidant compounds. Regarding our study, antioxidant activity of the rose hip marmalade was thought to be resulted from vitamin C and phenolic compound content of the rose hip fruits. Accordingly, Chrubasik et al. (2008) reported that rose hips were rich in phenolic compunds and vitamin C. Therefore, daily consumption of rose hip maramalade is very beneficial for human health. In order to improve functional properties of the marmalade, it is necessary to determine processing condition (cooking temperature and time) to minimize damage of bioactive substances during production of the marmalade.

Rheological properties

Steady shear properties

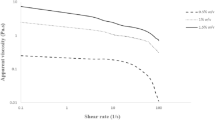

Figure 2 shows the effect of temperature on steady shear properties of the rose hip marmalade. The obtained data were fitted to three different models, namely, Ostwald de Waele, Herschel Bulkley and Casson models. Corresponding model parameters and their determination coefficient (R 2) values are summarized in Table 2. As can be seen from R 2 values, Herschel Bulkley and Ostwald de Waele models exhibited better performance than did the Casson model at all temperature levels. RMSE values were also calculated for only these two models since their R 2 values were found to be very close to each other. Except for the findings obtained at 5 °C, RMSE values of these models were also very close to each other. Based on these results, it can be said that Ostwald de Waele and Hershel Bulkley models can be used for description of flow behavior of the rose hip marmalade. Similar results were reported by Maceiras et al. (2007) who determined flow behavior of different purees and jams (raspberry, strawberry, prune, peach). Flow behavior of the mango (Basu and Shivhare 2010), banana and peach jams (Falguera et al. 2010), pear and peach purees (Holdsworth 1993), mango and papaya purees (Guerrero and Alzamora 1998) and banana puree (Ditchfield et al. 2004; Guerrero and Alzamora 1997) was best described by Herschel Bulkley. Ostwald de Waele model was found to be the best for description of flow behavior of blueberry puree (Nindo et al. 2007), guava puree (Rao 1999), raspberry, strawberry, prune and peach purees as well as jams prepared using these purees (Maceiras et al. 2007).

Consistency coefficient (K) and flow behavior index (n) values for the rose hip marmalade tested at different temperatures (5, 25 and 45 °C) are presented in Table 2. K values were found to be 29.4, 23.2 and 17.6 Pa sn at 5, 25 and 45 °C, respectively. Consistency and viscosity of the sample is strongly associated with the sucrose amount added to the product. High sugar concentration leads to decrease in viscosity of the sample by inhibiting molecular hydration of pectin (Mizrahi 1979). Therefore, sugar concentration to be added to the product should be taken into account to control rheological behaviour in terms of increasing resistance to flow or deformation. K values decreased with increase in temperature, which was similar to those reported for different foods in previous studies (Goksel et al. 2013; Toker et al. 2013; Yilmaz et al. 2011). Decrease in K value indicated that fluidity of the sample increased with increase in temperature, which is important for consumer acceptability since consistency of the marmalade product is one of the most important factors affecting consumer preference of the product. Therefore, relationship between storage condition or consumption temperature should be taken into consideration in order to reach desired consistency. The other parameter of the Ostwald de Waele model was the n value. Magnitude of n value was found as 0.227, 0.218 and 0.281 at 5, 25 and 45 °C, respectively (Table 2). As seen, n value of the sample tested at 45 °C was higher (P < 0.05) than those of the samples tested at 5 and 25 °C. The n values lower than unity indicated that rose hip marmalade showed shear thinning behavior, meaning that apparent viscosity decreased with increase in shear rate at all temperature levels. This result was thought to possibly result from the breakdown of the rose hip marmalade structure due to the shear applied during analysis (Yu et al. 2007). Moreover, weak physical bonds like electrostatic and hydrophobic forces might have been destroyed easily during shearing (Isanga and Zhang 2009), also contributing to the shear thinning behavior of the rose hip marmalade. Shear thinning behavior was also reported for blueberry puree (Nindo et al. 2007). Mizrahi (1979) reported that most fruit purees showed shear thinning behavior with zero yield stress. Given that viscosity or consistency is important characteristic for consumer acceptability, it is essential to determine application of the processes involving shear (as a consequence of mixing, stirring, pumping, pouring from bottle) to which the processed foods are subjected during production period. Selection of handling equipment and processing conditions should be made carefully to prevent structural breakdown of the sample resulting from flow transitions, heat application and high shear stresses applied (Nindo et al. 2005).

As mentioned above, Herschel Bulkley model was selected as the best model to describe flow behaviour of the rose hip marmalade sample. It was seen that K value also significantly decreased from 21.8 to 12.7 Pa as temperature increased from 5 to 45 °C. Yield stress was determined as 7.5, 6.5 and 6.4 Pa, respectively at 5, 25 and 45 °C. As understood from Table 2, yield stress decreased also with increasing temperature, which was in accordance with the findings reported by Nindo et al. (2007). The yield stress value of the material is strongly associated with shear rate range of the analysis, model type which described best the flow behaviour of the sample and shape and size of the particles (Steffe 1996; Mizrahi 1979). Knowledge acquisition about relation between temperature and yield stress is necessary to determine stress that must be overcome before starting of flow. This stress is very critical for obtaining desired product quality. For example, in the cases it would be too high, the structure is destroyed and therefore quality of the product is lost. In order to eliminate these problems, processing conditions and design, and formulation of the product should be selected carefully regarding rheological characteristics of the samples.

Another important parameter measured by steady shear measurements is η 50 , the apparent viscosity measured at shear rate 50 s−1 (the shear rate in the mouth) (Rao and Tattiyakul 1999). η 50 values measured at different temperature levels (5, 25 and 45 °C) are also shown in Table 2. As can be seen, η 50 values of the samples were determined to be 1.30, 1.07 and 0.93 Pa s at 5, 25 and 45 °C, respectively. As seen from the results, temperature significantly (P < 0.05) affected the η 50 values. Similar results were reported for different food products in previous studies (Arici et al. 2013; Goksel et al. 2013; Toker et al. 2013; Yilmaz et al. 2011; Yilmaz et al. 2014). The decrease in η 50 values due to increase in temperature levels might be due to increase in intermolecular distances resulting from thermal expansion leading to reduction of intermolecular forces (Arslan et al. 2005; Hassan and Hobani 1998; Holdsworth 1971), so decrease in viscosity of the rose hip marmalade. It is important to know appropriate temperature level if the relationship between temperature and viscosity should be understood. These results suggested that the load applied during pumping and shear stresses applied to the sample be reduced at the higher temperature levels (Nindo et al. 2007). Because the product is subjected to different shear rates, it is important for the industry to know how the viscosity of the sample would change depending on the temperature at specified shear rate. In this respect, it is essential to design proper equipments (Maceiras et al. 2007) and accomplish processing conditions (pumping level, temperature). This relationship between temperature and viscosity is also important for process optimization to obtain the product having desired quality, which would directly influence consumer acceptance for the product.

Dynamic shear properties

As known, foods are complex systems composed of both viscous and elastic parts. Therefore, determination of viscoelastic characteristics of the rose hip marmalade is important for suitable design and handling processes. Figure 3 presents storage modulus (G') and loss modulus (G'') values of the rose hip marmalade as a function of angular frequency (ω) at different temperature levels (5, 25 and 45 °C). G' and G'' increased with frequency and G' values were higher than G'' values at all temperature levels, indicating that rose hip marmalade had a weak gel−like structure (Ross-Murphy 1994). In other words, rose hip marmalade sample had solid−like character rather than viscous structure. The obtained data (G', G'' versus ω) were fitted to the Eqs. 6 and 7 and the corresponding parameters (Table 3) were calculated for each temperature level. R 2 values were calculated to range between 0.9839 and 0.9975, showing that the fitted models could successfully describe the relation between G' or G'' and ω. K' values were calculated to change between 244 and 525 Pa while K'' values varied between 70 and 121 Pa. K' and K'' values were significantly affected by temperature level, decreasing with increase in temperature. Magnitudes of K' value was higher than those of K'', proving the solid−like character of the rose hip marmalade at all temperature levels studied. n' and n'' are the parameters representing slope of ln (G') and ln (G'') versus ln (ω) data. For true gels, these slopes are considered as zero (Ross-Murphy 1994). The slopes calculated for rose hip marmalade (n' = 0.185–0.224, n'' = 0.333–0.395) were found as positive, further proving weak gel−like structure of the marmalade.

Another parameter obtained from frequency sweep test is complex modulus (G *) representing total resistance of the material to deformation (Steffe 1996). G * values increased with frequency (Fig. 3), but decreased with temperature, indicating that the resistance of rose hip marmalade to deformation decerased as the temperature level increased. This result suggested the rosehip marmalade be kept at low temperature levels during handling, storage, transportation or processing in order for the marmalade to show higher resistance to deformation.

Obtained η * (G */ω) versus ω data were fitted to the Eq. (8) and the corresponding parameters are summarized in Table 3. As can be seen from the R 2 values (0.9856–0.9945), Ostwald de Waele model successfully described the change in η* values as a function of ω at the temperature range studied in the present study. Temperature significantly (P < 0.05) affected K * values. Viscoelastic structure of the rose hip marmalade was also described by tan δ. Figure 3 shows that tan δ value was lower than unity at all temperature levels, indicating that rose hip marmalade sample had elastic behavior rather than viscous character. Loss tangent values were generally observed to increase with frequency and decreased with temperature, meaning that the rose hip marmalade sample showed more liquid character at higher temperatures.

Applicability of the Cox-Merz rule

Limitations and characteristics of each measurement (time, equipment, number of sample to be analyzed) may sometimes prevent simultaneous measurements of steady and dynamic properties (Augusto et al. 2013). Therefore, Cox-Merz rule was proposed to establish correlation between steady and dynamic shear viscosity (Gunasekaran and Ak 2000). In other words, it is possible to predict complex viscosity by using steady shear viscosity or vice versa. If the apparent viscosity is very close to complex viscosity as the shear rate is equal to frequency, empirical Cox-Merz rule can be performed (Cox and Merz 1958). However, application of the empirical Cox-Merz rule to food products is very difficult in some cases since some foods are very complex systems. Therefore, modified Cox-Merz rule was established by calculating shift factor (Rao and Cooley 1992). In our study, after oscillatory shear parameters [complex viscosity (η*) and angular frequency (ω)] and steady shear parameters [apparent viscosity (η) and shear rate (\( \dot{\gamma} \))] were sequentially plotted in a same graph, in our case, they produced lines parallel to each other, but not superimposed. In this case, in order to correct dynamic shear data, one of these parameters was multiplied by different shift factors until both lines aligned on a same line; namely, superimposed each other. Shift factors (α CM) were the dimensionless figures, and the most appropriate constant that made these lines superimposed were determined and used as the shift factors in this study. Figure 4 shows the applicability of Cox-Merz rule and the calculated shift factors for the rose hip marmalade at different temperature levels. It is seen from the figure that the modified Cox-Merz rule can be applied to the rose hip marmalade in order to correlate apparent viscosity values with complex viscosity values. Cox-Merz rule was also applied applied to tomato juice (Rao and Cooley 1992), tomato paste (Augusto et al. 2013), potato puree (Alvarez et al. 2011), rice starch/xanthan gum mixtures (Kim and Yoo 2006), O/W model system meat emulsions (Karaman et al. 2011), boza samples (Arici et al. 2013) and ice cream mix (Dogan et al. 2013).

Conclusions

In this study, bioactive properties of rose hip marmalade were determined in two different types of samples prepared by the extraction and direct analysis methods. The samples prepared by extraction methods had remarkably higher total phenolic content, antioxidant and antiradical activity than those prepared by direct analysis method. These results recommend that bioactive properties of rose hip marmalade could be enhanced by developing the suitable extraction methods. Rose hip marmalade showed shear thinning behavior. Ostwald de Waele model best described the flow behavior. Fluidity of the sample increased with increase in temperature, suggesting that storage and consumption temperature should be considered in order to achieve desired quality. Storage modulus (G') of the rose hip marmalade was found to be higher than the loss modulus (G''), indicating that rose hip marmalade showed elastic (solid) behavior rather than viscous (liquid) one. Dynamic rheological parameters (G', G'', G* and η*) decreased with increase in temperature. In order to correlate apparent and complex viscosity values, modified Cox-Mez rule was satisfactorily applied to the obtained data. These results revealed the importance of consumption and storage temperature values during handling or transportation in terms of quality of the rosehip marmalade.

References

Alvarez MD, Fernández C, Canet W (2011) Effect of cryoprotectant mixtures on rheological properties of fresh and frozen/thawed mashed potatoes. J Food Process Eng 34:224–250

Andersson SC, Rumpunen K, Johansson E, Olsson ME (2011) Carotenoid content and composition in rose hips (Rosa spp.) during ripening, determination of suitable maturity marker and implications for health promoting food products. Food Chem 128:689–696

Ardag A (2008) Antioksidan kapasite tayin yontemlerinin analitik acıdan karsılastırılması. Adnan Menderes Universitesi, Master Thesis, Aydın, 55 pages

Arici M, Ersoz NB, Toker OS, Yilmaz MT, Cankurt H, Durak MZ, Sagdic O (2013) Microbiological, steady and dynamic rheological characterization of boza samples: temperature sweep tests and applicability of Cox-Merz rule. Turk J Agric For 38:377–387

Arslan E, Yener ME, Esin A (2005) Rheological characterization of tahin/pekmez (sesame paste/concentrated grape juice) blends. J Food Eng 69:167–172

Augusto PED, Criostianini M, Ibarz A (2012) Effect of temperature on dynamic and steady-state shear rheological properties of siriguela (Spondias purpurea L.) pulp. J Food Eng 106:283–289

Augusto PED, Falguera V, Cristianini M, Ibarz A (2013) Viscoelastic properties of tomato juice: applicability of the Cox–Merz rule. Food Bioprocess Technol 6:839–843

Barros L, Carvalho AM, Morais JS, Ferreira ICFR (2010) Strawberry-tree, blackthorn and rose fruits: detailed characterization in nutrients and phytochemicals with antioxidant properties. Food Chem 120:247–254

Başak SŞ, Candan F (2008) Apium graveolens Linn. (Apiaceae) tohumu uçucu yağının kimyasal bileşimi ve in vitro antioksidan aktivitesi. İtü Fen Blimleri Dergisi 6:14–26

Basu S, Shivhare US (2010) Rheological, textural, micro-structural and sensory properties of mango jam. J Food Eng 100:357–365

Basu S, Sivhare US, Singh TV (2013) Effect of substitution of stevioside and sucralose on rheological, spectral, color and microstructural characteristics of mango jam. J Food Eng 114:465–476

Brand-Williams W, Cuvelier ME, Berset C (1995) Use of a free radical method to evaluate antioxidant activity. LWT Food Sci Technol 28:25–30

Chrubasik C, Roufogalis BD, Muller-Ladner U, Chrubasik S (2008) A systematic review on the Rosa canina effect and efficacy profiles. Phytother Res 22:725–733

Costa AGV, Garcia-Diaz DF, Jimenez P, Silva PI (2013) Bioactive compounds and health benefits of exotic tropical red-black berries. J Funct Foods 5:539–549

Cox W, Merz E (1958) Correlation of dynamic and steady flow viscosities. J Polym Sci 28:619–622

Delgado T, Pereira JA, Baptista P, Casal S, Ramalhosa E (2014) Shell’s influence on drying kinetics, color and volumetric shrinkage of Castanea sativa Mill. fruits. Food Res Int 55:426–435

Demir N, Yildiz O, Alpaslan M, Hayaloglu AA (2014) Evaluation of volatiles, phenolic compounds and antioxidant activities of rose hip (Rosa L.) fruits in Turkey. LWT Food Sci Technol 57:126–133

Dervisi P, Lamb J, Zabetakis I (2001) High pressure processing in jam manufacture: effect on textural and colour properties. Food Chem 73:85–91

Ditchfield C, Tadini CC, Singh R, Toledo RT (2004) Rheological properties of banana pureé at high temperatures. Int J Food Prop 7:571–584

Dogan M, Kayacier A, Toker OS, Yilmaz MT, Karaman S (2013) Steady, dynamic, creep, and recovery analysis of ice cream mixes added with different concentrations of xanthan gum. Food Bioprocess Technol 6:1420–1433

Dolz M, Hernandez MJ, Delegido J (2006) Oscillatory measurements for salad dressings stabilized with modified starch, xanthan gum and locust bean gum. J Appl Polym Sci 102:897–903

Ercisli S (2007) Chemical composition of fruits in some rose (Rosa spp.) species. Food Chem 104:1379–1384

Falguera V, Mengual A, Vicente M, Ibarz A (2010) Effect of calcium pidolate on the rheological chracteristics of jams and gelatins. Food Res Int 43:882–885

Gao X, Bjork L, Trajkovski V, Uggla M (2000) Evaluation of antioxidant activities of rosehip ethanol extracts in different test systems. J Sci Food Agric 80:2021–2027

Goksel M, Dogan M, Toker OS, Ozgen S, Sarioglu K, Oral RA (2013) The effect of starch concentration and temperature on grape molasses: Rheological and textural properties. Food Bioprocess Technol 6:259–271

Guerrero SN, Alzamora SM (1997) Effect of pH, temperature and glucose addition on flow behavior of fruit pureés: I. Banana pureé. J Food Eng 37:77–101

Guerrero SN, Alzamora SM (1998) Effect of pH, temperature and glucose addition on flow behavior of fruit pureés: II. Peach, papaya, and mango pureés. J Food Eng 33:239–256

Gunasekaran S, Ak MM (2000) Dynamic oscillatory shear testing of foods–selected applications. Trends Food Sci Technol 11:115–127

Hassan BH, Hobani AI (1998) Flow properties of roselle (Hibiscus sabdariffa L.) extract. J Food Eng 35:459–470

Holdsworth SD (1971) Applicability of rheological models to the interpretation of flow and processing behaviour of fluid food products. J Texture Stud 2:393–418

Holdsworth SD (1993) Rheological models used for the prediction of the flow properties of food products: a literature review. Trans Inst Chem Eng 71C:139–179

Hornero-Mendez D, Minguez-Mosquera MI (2000) Carotenoid pigments in Rosa mosqueta hips, an alternative carotenoid source for foods. J Agric Food Chem 48:825–828

Igual M, Contreras C, Martínez-Navarrete N (2014) Colour and rheological properties of non-conventional grapefruit jams: instrumental and sensory measurement. LWT Food Sci Technol 56:200–206

Isanga J, Zhang G (2009) Production and evaluation of some physicochemical parameters of peanut milk yoghurt. LWT Food Sci Technol 42:1132–1138

Karaman S, Yilmaz MT, Dogan M, Yetim H, Kayacier A (2011) Dynamic oscillatory shear properties of O/W model system meat emulsions: linear viscoelastic analysis for effect of temperature and oil concentration on protein network formation. J Food Eng 107:241–252

Karaman S, Toker OS, Cam M, Hayta M, Dogan M, Kayacier A (2014) Bioactive and physicochemical properties of persimmon as affected by drying methods. Dry Technol 32:258–267

Kharazmi A (2008) Laboratory and preclinical studies on the anti-inflammatory and anti-oxidant properties of rosehip powder—Identification and characterization of the active component GOPO®. Osteoarthr Cartil 16:S5–S7

Kim C, Yoo B (2006) Rheological properties of rice starch–xanthan gum mixtures. J Food Eng 72:120–128

Kokini JL, Plutchok GJ (1987) Viscoelastic properties of semisolid foods and their biopolymers components. Food Technol 41:89–95

Larsen E, Kharazmi A, Christensen LP, Christensen SB (2003) An anti-inflammatory galactolipid from rose hip (Rosa canina) that inhibits chemotaxis of human peripheral blood neutrophils in vitro. J Nat Prod 66:994–995

Maceiras R, Álvarez E, Cancela MA (2007) Rheological properties of fruit purees: Effect of cooking. J Food Eng 80:763–769

Mizrahi S (1979) A review of the physicochemical approach to the analysis of the structural viscosity of fluid fruit products. J Texture Stud 10:67–82

Nindo CI, Tang J, Powers JR, Singh P (2005) Viscosity of blueberry and raspberry juices for processing applications. J Food Eng 69:343–350

Nindo CI, Tang J, Powers JR, Takhar PS (2007) Rheological properties of blueberry puree for processing applications. LWT Food Sci Technol 40:292–299

Olsson ME, Gustavsson KE, Andersson S, Nilsson A, Duan RD (2004) Inhibition of cancer cell proliferation in vitro by fruit and berry extracts and correlations with antioxidant levels. J Agric Food Chem 52:7264–7271

Orhan DD, Hartevioglu A, Kupeli E, Yesilalada E (2007) In vivo anti-inflammatory and antinociceptive activity of the crude extract and fractions from Rosa canina L. fruits. J Ethnopharmacol 112:394–400

Özdemir F, Topuz A, Karkacier M (1998) Kusburnu pulpunun marmelata islenmesinde pisirme yöntemi ve formülasyonun marmelat kalitesine etkisi. J Eng Sci 4:577–580

Prieto P, Pineda M, Aguilar M (1999) Spectrophotometric quantitation of antioxidant capacity through the formation of a Phosphomolybdenum Complex: specific application to the determination of vitamin E. Anal Biochem 269:337–341

Rao MA (1999) Rheology of fluids and semi-solid foods. Aspen Publishers, Gaithersburg

Rao MA (2005) Rheological properties of fluid foods. In: Rao MA, Rizvi SSH, Datta AK (eds) Engineering properties of foods, 3rd edn. CRC Press, Boca Raton

Rao MA, Cooley HJ (1992) Rheological behaviour of tomato pastes in steady and dynamic shear. J Texture Stud 23:415–425

Rao MA, Tattiyakul J (1999) Granule size and rheological behavior of heated tapioca starch dispersions. Carbohydr Polym 38:123–132

Rein E, Kharazmi A, Winther K (2004) A herbal remedy, Hyben Vital (stand. powder of a subspecies of Rosa canina fruits), reduces pain and improves general wellbeing in patients with osteoarthritis-a double-blind, placebo-controlled, randomised trial. Phytomedicine 11:383–391

Ross-Murphy SB (1994) Rheological methods. In: Ross-Murphy SB (ed) Physical techniques for the study of food biopolymers. Blackie Academic Professional, New York, pp. 343–392

Sagdic O, Ekici L, Ozturk I, Tekinay T, Polat B, Tastemur B, Bayram O, Senturk B (2013) Cytotoxic and bioactive properties of different color tulip flowers and degradation kinetic of tulip flower anthocyanins. Food Chem Toxicol 58:432–439

Singleton VL, Rossi JR (1965) Colorimetry of total phenolics with Phosphomolybdic phosphothungstic acid. Am J Enol Vitic 16:144–158

Steffe JF (1996) Rheological methods in food process engineering. Freeman Press

Stralsjo L, Alklint C, Olsson ME, Sjoholm I (2003) Total folate content and retention in rosehips (Rosa ssp.) after drying. J Agric Food Chem 51:4291–4295

Toker OS, Karaman S, Yuksel F, Dogan M, Kayacier A, Yilmaz MT (2013) Temperature dependency of steady, dynamic and creep-recovery rheological properties of ice cream mix. Food Bioprocess Technol 6:2974–2985

Wenzig EM, Widowitz U, Kunert O, Chrubasik S, Bucar F, Knauder E, Bauer R (2008) Phytochemical composition and in vitro pharmacological activity of two rose hip (Rosa canina L.) preparations. Phytomedicine 15:826–835

Yilmaz MT, Karaman S, Cankurt H, Kayacier A, Sagdic O (2011) Steady and dynamic oscillatory shear rheological properties of ketchup-processed cheese mixtures: effect of temperature and concentration. J Food Eng 103:197–210

Yilmaz MT, Tatlisu NB, Toker OS, Karaman S, Dertli E, Sagdic O, Arici M (2014) Steady, dynamic and creep rheological analysis as a novel approach to detect honey adulteration by fructose and saccharose syrups: correlations with HPLC-RID results. Food Res Int 64:634–646

Yoo B, Rao MA (1996) A creep and dynamic rheological behavior of tomato concentrates: effect of concentration and finisher screen size. J Texture Stud 27:451–459

Yoo KM, Lee CH, Lee H, Moon B, Lee CY (2008) Relative antioxidant and cytoprotective activities of common herbs. Food Chem 106:929–936

Yu J, Ahmedna M, Goktepe I (2007) Peanut protein concentrates: production and functional properties as affected by processing. Food Chem 103:121–129

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sagdic, O., Toker, O.S., Polat, B. et al. Bioactive and rheological properties of rose hip marmalade. J Food Sci Technol 52, 6465–6474 (2015). https://doi.org/10.1007/s13197-015-1753-z

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-015-1753-z