Abstract

Ora-pro-nobis (OPN) is an unconventional food plant with high nutritional value, and its nutritional composition can be altered according to cultivation. Cereal bars are a popular nutrient-poor foods, and OPN could be incorporated to improve the nutritional quality. This study aimed to evaluate the physicochemical characteristics and sensory acceptability of cereal bars enriched with OPN flour (OpnF) from different forms of cultivation. OpnF was obtained by dehydrating and grinding OPN leaves collected in rural (ROpnF) and urban (UOpnF) municipalities. Two formulations of cereal bars, peanut flavor (Bpn) and mango flavor (Bmg), each with 10% OpnF, were prepared. The macronutrients and mineral composition, oxalate content, water activity, texture, color profile, and acceptability were evaluated. ROpnF had the highest protein, iron, and manganese content, whereas UOpnF had the highest ash and magnesium content. The oxalic acid/calcium ratio was 1.43 and did not imply calcium bioavailability. In addition to nutritional and protein values, Bpn and Bmg presented a good sensory acceptability index of > 77.5% with market potential. Bmg has the highest mineral content and is a source of iron, manganese, and magnesium. OpnF can be used in cereal bars and potentially improve nutritional attributes and used in other foods in a similar way.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Several species of tropical flora can be used as nutritional supplements and enhance cultural diversity. Unconventional food plants (UFP) range from native and unusual to exotic and wild plants. Due to their nutritional characteristics, these plants have been used as food options and a source of vitamins, minerals, fiber, and, in some cases, carbohydrates and proteins. One example is Pereskia aculeata Miller, Cactaceae family, popularly known as ora-pro-nóbis (OPN) (Da Silva et al. 2022).

OPN is a perennial plant native to tropical America, which adapts to different soil types and is not demanding in terms of fertilization (Oliveira et al. 2018). The growing interest of the industry and researchers in this UFP is due to its ease of use and low cost of production, in addition to its nutritional characteristics (Souza et al. 2009). Due to their high mucilage content, OPN sheets can be used in the food and pharmaceutical industries as an alternative for obtaining mucilage (Silva et al. 2019) or developing films for functional and/or edible packaging (Porto et al. 2021).

Pereskia aculeata leaves are used in folk medicine as emollients to treat skin wounds and inflammatory processes (Pinto et al. 2015), improve intestinal motility, reduce visceral fat and lipid profile, and increase high-density lipoprotein-cholesterol levels (Barbalho et al. 2016). It has protein content value, 85% digestibility, and high values of essential amino acids. The predominant amino acid in P. aculeata leaves is leucine, followed by phenylalanine and glutamate. The concentrations of essential and nonessential amino acids, except for methionine, are close to or higher than those recommended by the Food and Agricultural Organization for human diets (Santos et al. 2022). However, the leaves may have a different nutritional composition, depending on the soil in which the plant was grown, which may favor a greater or lesser supply of nutrients in the same species (Dimitrius et al. 2013; Queiroz et al. 2015) or present levels of antinutrients, such as calcium oxalate, ranging from 0.418 g% (Almeida et al. 2014) to 3.54 g% (Silva et al. 2013).

Its use as a food or an ingredient in food preparations can be considered an alternative to increasing the nutritional quality of foods and contributes to the lower consumption of animal proteins. The leaf of P. aculeata has been used in different preparations, such as bread (Alves et al. 2022), cakes (Rosa et al. 2020), and functional ice cream with high protein content (Santos et al. 2022). Incorporating dehydrated and ground OPN in foods for regular consumption is a healthy strategy to increase the intake of nutrients of plant origin (Sato et al. 2019).

In this context, cereal bars present attractive characteristics to the consumer for their nutritional composition associated with healthy products and for the convenience of consumption (Mello et al. 2012). However, the biggest challenge for obtaining a cereal bar with good acceptability is the combination of different ingredients with specific functionalities, such as vitamins, minerals, proteins, grains, fibers, thickening agents, sweeteners, and flavorings, while trying to achieve specific nutritional goals (Marchese and Novello 2017). Many protein bars are marketed with soy protein added (Freitas and Moretti 2006) or milk protein, such as whey, but the use of OPN would be an opportunity to introduce a less usual and high-value product of plant origin nutritional value; however, there is a need to verify the acceptability of consumption of this new product.

Therefore, this study aimed to evaluate the physicochemical characteristics and acceptability of cereal bars enriched with dehydrated and ground OPN leaves from rural and urban cultivation.

Methods

Preparation of P. aculeata leaves

Pereskia aculeata leaves were harvested in winter in rural areas (− 11.733071, − 39.304876; Riachão do Jacuípe, interior of Bahia, Brazil) and urban areas (− 12.8934913, − 38.3082858; Lauro de Freitas, metropolitan region of Salvador, Bahia, Brazil). OPN sheets were washed and immersed in sodium hypochlorite solution (250 ppm) for 15 min and subjected to dehydration in an oven with air circulation at 60 °C (Quimis, Brazil) for 24 h, according to the procedure adopted by Rodrigues et al. (2013). The obtained material was ground in a food processor (Phillips, Brazil) until a powder similar to flour was obtained. The powder of OPN leaves from rural (ROpnF) and urban (UOpnF) cultivation was subjected to physicochemical analysis before preparing the cereal bars; after mixing, they were coded as OpnF.

Preparation of cereal bars enriched with OpnF

Two formulations of cereal bars were prepared: peanut flavor (Arachis hypogea L.; Bpn) and mango flavor (Mangifera indica L. var. Tommy; Bmg) according to the formulation presented in Table 1. The ingredients were mixed and distributed manually in metal baking sheets until 1 cm thick, which was then submitted to baking (10 min at 150 °C), followed by manual cutting.

Analysis of centesimal and mineral composition

The centesimal composition of ROpnF, UOpnF, Bpn, and Bmg was determined according to the Association of Official Analytical Chemists (AOAC 2019) standards. Moisture, protein, lipid, and ash content were performed in triplicate. The total nitrogen content was determined by the Kjeldahl method with a conversion factor of 6.25 to obtain the total protein content. Carbohydrate was determined by difference.

The samples were dried in an oven (FANEM, Model 320-SE, São Paulo, Brazil), and the mass was measured on an analytical balance (CP2245 Sartorius®; Germany). About 0.2 g of each sample was digested in a microwave oven (MARS-6, CEM®; USA) according to Gomes-Junior et al. (2020) for mineralization. Concomitantly with the samples, four analytical blanks were processed. Optical emission spectrometry with inductively coupled plasma (iCAP PRO; Thermo Fisher, Waltham, MA, USA) was used for determination. The operational parameters and analytical wavelengths were as follows: cyclonic spray chamber and concentric nebulizer with a radiofrequency power of 1.15 kW; the flow of plasma, auxiliary, and nebulizer gas was 12.5, 0.5, and 0.5 L/min, respectively; and the wavelengths were Ca (I) 422.673, Fe (II) 238,204, K (I) 769,897, Mg (I) 285.213, Mn (II) 257,610, No. (I) 589,592, P (I) 177.434, and Zn (II) 202,548, with (I) as the atomic emission line and (II) as the ionic emission line. The multi-element solutions for the analytical curve were prepared from stock solutions containing 1000 mg/L of different elements at concentrations from 0.1 to 300.0 mg/L. The contents were expressed considering the samples on a wet basis as mg mineral/100 g sample (mg %).

Soluble oxalate content of UOpnF and ROpnF

The quantification of the oxalate content of ROpnF and UOpnF samples was performed in triplicate according to the procedure for separating the insoluble oxalate adopted by Rocha (2009). First, the aqueous extracts of the samples were obtained, followed by the precipitation step with saturated calcium chloride solution by cooling for 12 h. After the period, the samples were centrifuged to separate the soluble oxalate. The precipitate was filtered, solubilized in sulfuric acid, and titrated with potassium permanganate (KMnO4). Solution preparation, KMnO4 standardization, and sample titration were in accordance with the AOAC (2019). The result was expressed as g oxalate/100 g sample (g%).

Texture profile of Bpn and Bmg

Bpn and Bmg were submitted to instrumental texture analysis in a TA.XTExpress texturometer (Stable Micro Systems) under the following conditions: pre-test speed 1.0 mm/s, test speed 2.0 mm/s, post-test speed 10.0 mm/s, and penetration distance 7.0 mm/s. Each sample was analyzed separately in eight replicates as they presented a heterogeneous texture aspect. For this test, the samples were standardized at 7 × 2 cm in size and 1 cm in height.

Water activity and colorimetric profile of Bpn and Bmg

Bpn and Bmg were submitted in triplicate to analyze the water activity in a Decagon instrument model Aqualab Lite. For instrumental evaluation of the color of the cereal bars by the parameters L* (luminosity), a* (red-green component) b* (yellow-blue component), C* chroma [(a*2 + b*2)1/2], hab angle [tangent arc (b*/a*)], and color difference = DE* = {(DL*)2 + (Da*)2 + (Db*)2}1/2, the BYK colorimeter was used (Series 199968; Gardner, Germany (Pathare et al. 2013). Analyses were performed at six different points in the samples.

Sensory analysis and purchase intent

The prepared cereal bars were sensorially evaluated according to an acceptance test by a team composed of 51 volunteer judges, with different gender and age, using a hedonic scale from 1 to 9 points, with hedonic terms corresponding to “I liked it extremely” and “extremely disliked” in the upper and lower extremes, respectively, considering the attributes, including overall appearance, color, texture, aroma, and flavor. A product purchase intention test was also applied using a five-point scale of categories inserted in the same form, with terms corresponding to “certainly would buy” and “certainly not buy,” respectively, at the upper and lower ends of the scale. The judges signed an informed consent form, approved by the Ethics Committee and Research with Human Beings of the UFBA School of Nutrition (CAAE 20214219.4.0000.5023). The inclusion criteria for participants were ages between 18 and 60 years, regular consumers of cereal bars, individuals not allergic to the ingredients of cereal bars, and those free from health problems that could interfere with the sensory analysis.

The average data of the registered grades and the acceptability index [AI (%) = A × 100/B, where A is the average grade obtained for the product and B is the maximum grade given to the product] were evaluated (Damasceno 2016).

Statistical analysis

One-way analysis of variance and Tukey’s correction as post-test (for data with normal distribution), Kruskal–Wallis and Dunn’s correction as post-test (for data without normal distribution), and t-test paired samples were used to determine the statistical significance of the analyses of proximate composition, mineral and oxalate content, and physical and sensory analyses of the samples analyzed by GraphPad version 5 (GraphPad Software, Inc., San Diego, CA, USA).

Results and discussion

Centesimal, mineral, and oxalate content of ROpnF and UOpnF

Table 2 presents the centesimal composition data and mineral and oxalate content of UOpnF and ROpnF. The yield was 18% in relation to fresh leaves and met the maximum requirement of 15% moisture, as specified by Resolution 263/2005 (Brasil 2005) for the definition of flours and bran. The proximate contents obtained from the analyses of both samples showed similar proportions or within limits determined in other studies on P. aculeata, such as moisture content between 7.5% and 13.5%, ash from 18.8% to 32.5%, protein from 15.2% to 26.5%, and lipids from 4.4% to 11.9% (Vargas et al. 2017; Queiroz et al. 2015; Santos et al. 2021). However, differences in composition were observed between samples analyzed from different municipalities for moisture (p < 0.01), ash, and protein (p < 0.05).

The moisture content in the flours showed a difference of 2.3% between the average, with ROpnF presenting a lower content, despite the collection of P. aculeata leaves during the rainy season. The rural municipality is located in a semiarid area with low rainfall (Weather Spark 2019). Queiroz et al. (2015) justified the difference in moisture content in P. aculeata leaves due to the time of sun exposure suffered by the plantation, which is directly proportional to the dry mass of the sample.

The high ash content found in both flours was noteworthy. Conventional vegetables mostly have an ash content close to 10% in a dry sample (NEPA 2011), whereas the analyzed flours presented contents between 17.89 g% and 22.88 g%, respectively, for ROpnF and UOpnF, with a significant difference (p < 0.05, paired t-test; Table 1). Queiroz et al. (2015) also observed that P. aculeata plantations located in places with a predominance of shade from the sun have higher ash content in dry matter (32.5%) compared to more sunny places (18.8%). These data corroborated the contents identified in this study because the rural municipality has greater solar incidence than the urban one (Weather Spark 2019).

The lipid levels found in the analysis of ROpnF and UOpnF samples (4.51 g% and 4.39 g%) were similar (Table 1) and in line with the literature and the characteristics found in other vegetables, such as kale (Brassica oleracea Acephala; 4.1%; NEPA 2011), whereas Moringa (Moringa oleifera), another type of UFP, has an even higher content of 7.1% (Teixeira et al. 2014).

The flours showed high protein content, 23.45 g% and 20.4 g%, respectively, for ROpnF and UOpnF (p < 0.05, paired t-test; Table 1). Santos et al. (2021), Souza et al. (2016), and Vargas et al. (2017) identified similar levels of protein (23.8%, 21.9%, and 17.9%, respectively). P. aculeata is a UFP source of proteins, presenting levels of 100 g of dry sample close to the values found in other vegetable sources of protein, such as taioba (Xanthosoma sagittifolium Schott) (Araújo et al. 2019). The intake of 50 g of dried taioba leaves can provide 60% of the recommended daily intake of protein for adults and 86% for children (Araújo et al. 2019). 21.2 g%) and oilseeds, such as raw peanuts (27.2%; NEPA 2011), beans (Cajanus cajan L.; 22.06 g%), and mangalo beans (Phaseolus lunatus L.; 26.45 g% (Benevides et al. 2019). The protein content of the leaves can vary depending on the luminosity of the plantation, in which the greater the shading, the greater the protein content (Queiroz et al. 2015), which does not corroborate this study, because a higher content of proteins was identified in ROpnF. Another factor contributing to protein differences in plants is the nitrogen content available in the cultivated soil, which is directly proportional to the protein content of the leaf and, consequently, of its flour (Dimitrius et al. 2013).

The carbohydrate content showed a difference of 5.6% between the samples, comprising fiber and carbohydrate fractions together (Table 1). Ribeiro et al. (2019) determined the fiber fractions in OPN and identified insoluble fiber contents, on average, six times higher than the contents obtained in soluble fiber.

Regarding the content of the determined minerals, the flours showed a significant difference, except only for zinc. UOpnF showed higher calcium, potassium, magnesium, and phosphorus levels, whereas ROpnF showed higher iron, manganese, and sodium levels. Considering the averages of the content of each mineral in the flours and the requirements of nutritional attributes of foods specified in the IN75 of 2020 (Brasil 2020), the consumption of 25 g OpnF meets the designation as a flour source of iron and high in magnesium and manganese content.

As for oxalate levels (Table 2), there was no significant difference between the analyzed samples, and the results were not similar to those of Almeida et al. (2014) (41.79 mg%). Such differences can be justified by the place of cultivation and type of oxalate analyzed (soluble or total) and how the analysis procedure was performed. In this study, oxalate was determined based on the separation of insoluble oxalate, which interferes more with calcium bioavailability (Rocha 2009).

The biggest implication of consuming vegetables with high levels of oxalate is the decrease in calcium absorption (Higashijima et al. 2022). According to Guil et al. (1996), the oxalic acid/calcium ratio should be < 2.5. Considering the mean values of calcium (0.964 g%) and oxalates (1.38 g%) of the two flours in this study, this ratio was 1.43, suggesting that the content of this antinutrient will not affect the bioavailability of the calcium present in OpnF.

Physicochemical characterization of Bpn and Bmg

Table 3 presents the proximate composition, mineral content, water activity, texture profile, and color of Bpn and Bmg. Bmg and Bpn showed protein contents of 13.55 g% and 15.0 g%, respectively (Table 2). A serving of commercial cereal bars with 50 g will contain 6.8 and 7.5 g of protein, respectively, reaching 9.1% and 10% of the recommended daily value (%DV) of protein intake (Brasil 2020). In addition to OpnF present in 10% of the formulations of the cereal bars developed, oats (15% to 30%) and, for Bpn, also peanut butter (25%) are ingredients that increase the protein content of the products. The protein content of oats is 13.9 g% (NEPA 2011). Its characteristic amino acid profile of cereal is complemented with the amino acid profile of a peanut legume, which can reduce the limiting factor of amino acids. Additionally, OPN flour has already been described with a relevant concentration of essential amino acids (Santos et al. 2022); therefore, it´s probably that Bpn is complete in essential amino acids. Normative Instruction 75 of 2020 (Brasil 2020) specifies that food is a source of protein if it has a content of ≥ 10% of the %DV (75 g) per portion or unit and meets the amounts of essential amino acids established. Thus, Bpn (a portion of 50 g) resulted in a preparation with the potential to be considered a protein source. Adjustments in the formulation, such as a percentage increase in OpnF, could characterize this potential also in Bmg.

The significant difference (p < 0.05, paired t-test) in the lipid content between Bmg and Bpn samples is noteworthy (3.89 g% and 15.88 g%, respectively; Table 3) due to the lipids from commercial peanut butter (46.7 g% specified on the label). This ingredient option also resulted in the difference between the carbohydrate contents (66.3 and 56.8 g%) and moisture content of the cereal bars, with a significant difference (p < 0.05, paired t-test), with Bmg being wetter than Bpn. Mango jelly has a high carbohydrate content in its composition, in addition to the soluble fibers of the fruit, which contribute to greater moisture in the final product. The difference in the moisture content may reflect the acceptability of these products because the moisture content is within parameters that allow the maintenance of crispness (Baú et al. 2010).

Regarding the determined minerals, Bmg showed higher contents of all elements with a significant difference compared to Bpn. In addition to the fruit (mango), Bmg has a higher percentage of oats, raisins, and seed mix in its formulation, which may have contributed to the higher levels. Considering a portion of 50 g of cereal bar, Bmg has an attribute as a source of iron, and both cereal bars are a source of manganese and magnesium, according to the requirements of Brazil (2020).

The cereal bars prepared showed similar values of water activity (0.54 and 0.4 for Bpn and Bmg, respectively) and were below the range established for the growth of most microorganisms (0.90 and 0.99 (Vidal et al. 2022) and thus might have good microbiological stability, in addition to also influencing nutritional and sensory stability. Jelly, a colloidal system formed by incorporating water by pectin, especially due to hydrogen bonds, may favor a lower water activity value. However, it may present even higher humidity (Ahmed 2015).

Regarding the color parameters analyzed, there were no significant differences between the two formulations of cereal bars prepared (Table 3). The values found in L* and a* were very similar between the two formulations. Considering the parameter L*, the cereal bars presented low luminosity, characterizing a dark color. Although OpnF has a perceptible dark green color, the values of a* and b* indicated that the cereal bars have a greater tendency to be red and yellow, respectively, with higher intensities for Bmg (Table 2), which may be due to the addition of jelly of mango. The hab angle is a qualitative attribute of color and confirms the data of a* and b*; in this way, Bpn and Bmg present a shade closer to yellow (90° angle) (Pathare et al. 2013). However, Bpn and Bmg showed low saturation, as indicated by the C* parameter; therefore, the reddish and yellowish colors were barely visible. This may be related to the presence of OpnF in the formulations, which can decrease the brightness and intensity of the colors of the preparation.

Texture analysis results showed that there was a significant difference in hardness and cohesiveness (p < 0.05 and p < 0.01, respectively, paired t-test) between Bpn and Bmg (Table 3), and the groupings of the analyses are shown in Fig. 1. The cereal bar formulations analyzed in this work have a heterogeneous texture, especially for Bpn, as evidenced by hardness and chewiness (Fig. 1A and C). This heterogeneous characteristic is similar to other cereal bars with a high protein and vitamin content (Farinazzi-Machado et al. 2018) and quinoa grains (Da Silva et al. 2011) due to the mixture of different ingredients, which, in themselves, already have a variety of textures. The mango jelly may have contributed to a better uniform texture of Bmg. Bpn showed higher hardness and lower cohesiveness than Bmg (*p < 0.05 and **p < 0.01, paired t-test; Fig. 1).

Texture profile parameters of cereal bars enriched with OpnF. A Hardness (N). B Springiness (m). C Chewiness (N/m). D Cohesiveness. OpnF: ora-pro-nóbis (Pereskia aculeata) leaf flour. Bpn, cereal bar enriched with OpnF peanut flavor; Bmg, cereal bar enriched with mango-flavored OpnF. *p < 0.05 and**p < 0.01 (Paired t-test, GraphPad Prism v5)

Sensory analysis and purchase intention of Bpn and Bmg

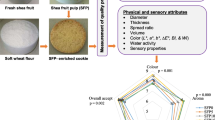

Figure 2 shows the sensory profile of Bpn and Bmg according to the average scores attributed by the judges to the attributes of color, flavor, texture, aroma, and overall acceptance. There was no difference in the average score of the attributes of the two different samples; however, there was a difference between the score of different attributes evaluated in the same sample.

Sensory profile of Bpn and Bmg. Average score of the judges for the attributes listed in the sensory analysis sheets. OpnF, ora-pro-nóbis (Pereskia aculeata) leaf flour; Bpn, cereal bar enriched with OpnF peanut flavor; Bmg, cereal bar enriched with mango-flavored OpnF. Different letters in the same column indicate a statistical difference, with *p < 0.05 in relation to the color attribute (Kruskal–Wallis and Dunn's test, GraphPad Prism v5)

Sensorial analysis results showed that there was a significant difference between flavor, general acceptance, and texture (p < 0.05) with the color attribute in Bpn and texture and aroma (p < 0.05) with the color attribute in Bmg (Kruskal–Wallis and Dunn’s test). The heterogeneity observed in the texture profile for Bpn and higher hardness (Fig. 1) did not influence a negative evaluation of this attribute. Although there was no difference between the grades of the two formulations of cereal bars, the average grade of the Bpn texture was still higher than that of Bmg (Fig. 2B). Both cereal bars presented low saturation (C*) associated with low luminosity (L*; Table 3), which can decrease the brightness and intensity of the colors of the samples. Consequently, the color was the attribute that least pleased the evaluators and showed the lowest score (Fig. 2B); however, the color can be modulated with the use of coatings on the cereal bars or other ingredients with greater luminosity.

The AI was 77.5% for Bmg and 83.4% for Bpn, which were > 70%; the cereal bars showed good acceptability (Bastos et al. 2014). In addition, in the purchase intent test, 86.3% and 78.4% of the judges recorded that they would “certainly buy/buy” Bpn and Bmg, respectively, which showed that, in addition to their good acceptability, the cereal bars also showed market potential.

Conclusion

OPN cultivated in different locations showed differences in nutrient contents. The leaves grown in the rural municipality had lower moisture and ash contents and higher protein content than those grown in the urban municipality. There was no difference in the oxalate content of the flours, and they did not seem to affect the bioavailability of calcium (an oxalic acid/calcium ratio of 1.43). OpnF presented high nutritional value, especially in relation to protein content, and ash is a source of iron and high magnesium and manganese content.

Cereal bars made with OpnF also have important nutritional value. They have potential as a protein source and a good sensory AI of > 77.5% with market potential. Bmg has the highest mineral content and is a source of iron, manganese, and magnesium. OpnF can be used as an ingredient in cereal bar preparations, of different flavors, or in other food preparations to improve the nutritional attributes of these products.

In addition to the macro and micronutrients present in the P. aculeata leaves, many phenolic compounds have already been identified, with caftaric acid being its main phenolic constituent (Garcia et al. 2019), in addition to carotenoids (α and β-carotene, lutein, zeaxanthin, and violaxanthin) (Agostini-Costa, et al. 2014). The presence of mucilage in the leaves characterizes this species as the potential for processing of natural emulsifiers and biomaterials for the pharmaceutical and food industries (Nogueira Silva et al. 2023). Some studies have evaluated the presence and technofunctional properties of phytonutrients from P. aculeata leaves after processing, such as cooking methods and obtaining flour. Vieira et al. (2020) observed beneficial anthropometric effects after the consumption of a dairy beverage developed with 5% of P. aculeata flour. Neves et al. (2021) evaluated how different methods of cooking P. acuelata leaves (frying, microwave, and steaming) could promote changes in the composition of phytochemicals. In general, the results demonstrated that some methods contributed to greater extraction of phenolics and carotenoids and better bioaccessibility. Considering that the process adopted to obtain the OpnF in the present study was at temperatures below cooking, while preparing the cereal bars was by baking at moderate temperatures, it is expected that there were no relevant losses of plant phytonutrients in the final product and that these processes are essential for sensory improvement and health safety of new products developed, such as cereal bars.

Data availability

Data sharing not applicable to this article as no datasets were generated or analysed during the current study.

Abbreviations

- OPN:

-

Ora-pro-nóbis

- UFP:

-

Unconventional food plants

- OpnF:

-

Powder of OPN leaves

- ROpnF:

-

OpnF from rural cultivation

- UOpnF:

-

OpnF from urban cultivation

- Bpn:

-

Cereal bars peanut flavor

- Bmg:

-

Cereal bars mango flavor

References

Agostini-Costa TS, Pêssoa GKA, Silva DB, Gomes IS, Silva JP (2014) Carotenoid composition of berries and leaves from a Cactaceae—Pereskia sp. J Funct Foods 11:178–184. https://doi.org/10.1016/j.jff.2014.09.015

Ahmed EM (2015) Hydrogel: Preparation, characterization, and applications: A review. J Adv Res 6:105–121. https://doi.org/10.1016/j.jare.2013.07.006

Almeida MEF, Junqueira AMB, Simão AA (2014) Caracterização química das hortaliças não-convencionais conhecidas como ora-pro-nobis: chemical characterization of the non-conventional vegetable known as ora-pro-nobis. Biosci J 30:431–439

Alves DT, Nascimento MHS, Eliane Maurício Furtado Martins EMF (2022) Pães enriquecidos com ora-pro-nóbis: elaboração e avaliação físico-química, microbiológica e sensorial/bread enriched with ora-pro-nobis: elaboration and physicochemical, microbiological and sensorial evaluation. Braz J Dev. https://doi.org/10.34117/bjdv7n2-061

AOAC (2019) Official methods of analysis. 21st ed. USA: AOAC International

Araújo SS, Araújo PS, Giunco AJ, Silva SM, Argandoña EJS (2019) Bromatology, food chemistry and antioxidant activity of Xanthosoma sagittifolium (L.) Schott. Emir J Food Agric 31:188–195. https://doi.org/10.9755/ejfa.2019.v31.i3.1924

Barbalho SM, Guiguer ÉL, Marinelli PS, do Santos Bueno PC, Pescinini-Salzedas LM, Dos Santos MC, Oshiiwa M, Mendes CG, de Menezes ML, Nicolau CG, Otoboni AM, de Alvares Goulart R (2016) Pereskia aculeata Miller flour: metabolic effects and composition. J Med Food 19(9):890–894. https://doi.org/10.1089/jmf.2016.0052

BastosPaulo GAEM, Chiaradia ACN (2014) Aceitabilidade de barra de cereais potencialmente probiótica. Braz J Food Technol 17(2):113–120. https://doi.org/10.1590/bjft.2014.012

Baú TR, Alves A, Cella SM, Laís A, Teixeira J (2010) Barra alimentícia com elevado valor proteíco: formulação, caracterização e avaliação sensorial. Revista Brasileira De Tecnologia Agroindustrial. https://doi.org/10.3895/S1981-36862010000100005

Benevides C, Costa A, Pinto D, Alves R, Nunes A, Oliveira M (2019) Germinação e desidratação de leguminosas: efeito na composição nutricional, compostos bioativos e atividade antioxidante de feijão andu e mangalô do Peru. Revista Virtual De Química 11(4):1249–1264. https://doi.org/10.21577/1984-6835.20190086

Brasil. Agência Nacional de Vigilância Sanitária. RDC nº 263, de 22 de setembro de 2005. https://bvsms.saude.gov.br/bvs/saudelegis/anvisa/2005/rdc0263_22_09_2005.html

Brasil. Agência Nacional De Vigilância Sanitária. (2020). RDC nº 429, de 8 de outubro de 2020. www.in.gov.br/en/web/dou/-/instrucao-normativa-in-n-75-de-8-de-outubro-de-2020-282071143

Da Silva MA, Damiani AP (2022) Uso de planta alimentícia não convencional (PANC) na gastronomia e suas propriedades nutricionais: ora-pro-nóbis (Pereskia aculeata Miller). Inova Saúde. https://doi.org/10.18616/inova.v12i2.5079

Da Silva FD, Pante CF, Prudêncio SH, Ribeiro AB (2011) Elaboração de uma barra de cereal de quinoa e suas propriedades sensoriais e nutricionais. Alimentos e Nutrição, Araraquara 22(1):63–69

Damasceno IAM (2016) Desenvolvimento de barra de cereal enriquecida com biomassa de arthospira platensis. Dissertation (Postgraduate degree in Food Science and Technology). Retrieved from: https://repositorio.uft.edu.br/handle/11612/291?mode=full

de Souza MRM, Pereira PRG, Magalhães IDPB, Sediyama MAN, Vidigal SM, Milagres CSF, Baracat-Pereira MC (2016) Teores de minerais, proteína e nitrato em folhas de ora-pro-nobis submetido a adubação nitrogenada. Pesquisa Agropecuária Tropical 46(1):43–50. https://doi.org/10.1590/1983-40632016v4637959

Dimitrius SPSF, Souza MRM, Hirano RT, Pereira PRG, Baracat-Pereira MC (2013) Concentração de proteína solúvel por Bradford revela diferenças no metabolismo de plantas de ora-pro-nobis em diferentes doses de nitrogênio. Revista Brasileira De Agropecuária Sustentável 3(1):40–44

dos Queiroz CRA, dos Moraes CMS, de Andrade RR, Pavani LC (2015) Crescimento inicial e composição química de Pereskia aculeata Miller cultivada em diferentes luminosidades. Revista Agrogeoambiental. https://doi.org/10.18406/2316-1817v7n42015695

dos Ribeiro PA, Melo CMT, de Andrade RR, dos Queiroz CRAA (2019) Quantificação do Teor de Fibra Alimentar em Folhas de Ora-Pro-Nóbis. Revista Inova Ciência Tecnologia/innov Sci Technol J 5(2):38–42

Farinazzi-Machado FMV, Giannini JA, Marinelli PS, Taniguchi ET, Souza NN, Silva AR (2018) Perfil fisico-químico, colorimétrico e sensorial de barras de cereais com polpa e amêndoas de macaúba (Acrocomia aculeata (Jacq.) Lodd.). Revista Unimar Ciências, São Paulo, 27 (1–2), pp 1–20. Retrieved from: http://ojs.unimar.br/index.php/ciencias/article/view/615/859

Freitas DGC, Moretti RH (2006) Caracterização e avaliação sensorial de barra de cereais funcional de alto teor protéico e vitamínico. Ciênc Tecnol Aliment 26(2):318–324. https://doi.org/10.1590/S0101-20612006000200014

Garcia JAA, Corrêa RCG, Barros L, Pereira C, Abreu RMV, Alves MJ, Calhelha RC, Bracht A, Peralta RM, Ferreira ICFR (2019) Phytochemical profile and biological activities of “ora-pro-nobis” leaves (Pereskia aculeata Miller), an underexploited superfood from the Brazilian atlantic forest. Food Chem 294:302–308. https://doi.org/10.1016/j.foodchem.2019.05.074

Gomes-Júnior EA, Bah HAF, de Rodrigues YJM, de Bandeira MJ, dos Santos NR, Menezes-Filho JA (2020) Lead in soil and vegetables in a glazed ceramic production area: a risk assessment. Environ Nanotechnol, Monit Manag 14:100392. https://doi.org/10.1016/j.enmm.2020.100392

Guil JL, Torija ME, Gimébez JJ, Rodriguez-Garcia IR, Giménez A (1996) Oxalic acid and calcium determination in wild edible plants. J Agricultural Food Chem 44(7):1821–1823. https://doi.org/10.1021/jf950472a

Higashijima NS, Lucca A, Rebizzi LRH, Rebizzi LMH (2022) Vista do Fatores antinutricionais na alimentação humana. Segurança Alimentar e Nutricional, Campinas 27:1–16. https://doi.org/10.20396/san.v27i0.8653587

Marchese NR, Novello Z (2017) Desenvolvimento e caracterização de barra de cereal salgada. Revista Brasileira De Tecnologia Agroindustrial. https://doi.org/10.3895/rbta.v11n1.3109

Mello AV, Cassimiro TAS, Pospischek VS, Villarim WLF, Pereira IRO, Abreu ES (2012) Avaliação da composição centesimal e da rotulagem de barras de cereais. e-Scientia 5(2):41–48

NEPA-Núcleo de Estudos e Pesquisa de Alimentos (2011) Tabela brasileira de composição de alimentos/NEPA-UNICAMP. 4. ed. Campinas: NEPAUNICAMP

Neves BV, Mesquita LMDS, Murador DC, do Cheberle AIP, Braga ARC, Mercadante AZ, de Rosso VV (2021) Improvement of bioactive compound levels, antioxidant activity, and bioaccessibility of carotenoids from Pereskia aculeata after different cooking techniques. ACS Food Sci Technol 1:1285–1293. https://doi.org/10.1021/acsfoodscitech.1c00162

Nogueira Silva NF, Silva SH, Baron D, Oliveira Neves IC, Casanova F (2023) Pereskia aculeata Miller as a novel food source: a review. Foods 12(11):2092. https://doi.org/10.3390/foods12112092

Oliveira NL, De Resende JV, Borges SV (2018) Desenvolvimento de Filmes Biopoliméricos a Base de Goma de Ora-Pro-Nóbis (Pereskia aculeata Miller). Universidade Federal de Lavras. http://repositorio.ufla.br/handle/1/29262

Pathare PB, Opara UL, Al-Said FAJ (2013) Colour measurement and analysis in fresh and processed foods: a review. Food Bioprocess Technol 6:36–60. https://doi.org/10.1007/s11947-012-0867-9

Pinto NDCC, Machado DC, da Silva JM, Conegundes JLM, Gualberto ACM, Gameiro J, Scio E (2015) Pereskia aculeata Miller leaves present in vivo topical anti-inflammatory activity in models of acute and chronic dermatitis. J Ethnopharmacol 173:330–337. https://doi.org/10.1016/j.jep.2015.07.032

Porto FGS, Campos ÂD, Carreño NLV, Garcia ITS (2021) Pereskia aculeata leaves: properties and potentialities for the development of new products. Nat Prod Res. https://doi.org/10.1080/14786419.2021.2010070

Rocha SRS (2009) Procedimentos e avaliação química de parâmetros de interesse nutricional de espinafre comercializado na Bahia. Dissertation (Postgraduate degree in Food Science and Technology). Retrieved from: https://repositorio.ufba.br/bitstream/ri/10014/1/Silvia%20Rocha.pdf

Rodrigues S, Marinelli PS, Otoboni AMMB, Tanaka AY, Oliveira AS (2013) Chemical and nutritional characterization of the ora-pro-nobis flour (Pereskia aculeata Mill.). FAEF Revistas científicas eletrônicas. 2013. Retrieved from: https://faef.revista.inf.br/imagens_arquivos/arquivos_destaque/9w5WLNyeuBN8Ro2_2015-1-26-16-10-54.pdf

Rosa L, dos Queiroz CRAA, Melo CMT (2020) Fresh leaves of ora-pro-nóbis in cakes prepared from commercial pre-mixture. Biosci J. https://doi.org/10.14393/bj-v36n2a2020-42319

Santos LS, dos Queiroz CRAA, Melo CMT (2021) Cactáceas do gênero Pereskia: composição nutricional e algumas aplicações. For Sci 9(2):e00702. https://doi.org/10.29069/forscience.2021v9n2.e702

Santos PPAD, Ferrari GDS, Rosa MDS, Almeida K, Araújo LDAD, Pereira MHC, Morato PN (2022) Desenvolvimento e caracterização de sorvete funcional de alto teor proteico com ora-pro-nóbis (Pereskia aculeata Miller) e inulina. Braz J Food Technol. https://doi.org/10.1590/1981-6723.12920

Sato R, Cilli LPDL, Oliveira BED, Maciel VBV, Venturini AC, Yoshida CMP (2019) Nutritional improvement of pasta with Pereskia aculeata Miller: a non-conventional edible vegetable. Food Sci Technol 39(suppl 1):28–34. https://doi.org/10.1590/fst.35617

Silva M, Rocha C, Silva T (2013) Caracterização química e antinutricional de farinhas de hortaliças não convencionais. Tecnologia e Ciência Agropecuária 7(3):51–57

Silva SH, Neves ICO, Oliveira NL, Oliveira ACF, Lago AMT, GiarolaResende TDMOJV (2019) Extraction processes and characterization of the mucilage obtained from green fruits of Pereskia aculeata Miller. Ind Crops Prod 140:111716. https://doi.org/10.1016/j.indcrop.2019.111716

Souza MRM, Correa EJA, Guimaraes G, Pereira PRG (2009) O potencial do ora-pro-nobis na diversificação da produção agrícola familiar. Revista Brasileira AgrAgroecologia 4(2):3550–3554. Retrieved from: https://revistas.aba-agroecologia.org.br/rbagroecologia/article/view/9145/6385

Teixeira EMB, Carvalho MRB, Neves VA, Silva MA, Arantes-Pereira L (2014) Chemical characteristics and fractionation of proteins from Moringa oleifera Lam. leaves. Food Chem 147:51–54. https://doi.org/10.1016/j.foodchem.2013.09.135

Vargas AG, Dalla R, Teixeira SD (2017) Influência da sazonalidade na composição centesimal da Pereskia aculeata Miller. Synergismus Scyentifica UTFPR 12(1):1–7

Vidal JMA, Rodrigues MDCP, Zapata JFF, Vieira JMM (2022) Concentrado protéico de resíduos da filetagem de tilápia-do-nilo (Oreochromis niloticus): caracterização físico-química e aceitação sensorial. Revista Ciência Agronômica 42(1):92–99

Vieira CR, Grancieri M, Martino HSD, César DE, Barra RRS (2020) A beverage containing ora-pro-nobis flour improves intestinal health, weight, and body composition: a double-blind randomized prospective study. Nutrition 78:110869. https://doi.org/10.1016/j.nut.2020.110869

Wheather Spark (2019) Condições meteorológicas. Retrieved from: https://pt.weatherspark.com

Funding

The authors acknowledge the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior—Brasil (CAPES)and the Federal University of Bahia (UFBA).

Author information

Authors and Affiliations

Contributions

Gabriela S. C. and Clara N. P. S. performed the literature search, formal and data analysis, and writing-original draft preparation. Erival A. G. J., Thaís L. S., Abdon L. O. T., Luis F. P. S., Leonardo F. M. performed the formal analysis and methodology. Giani A. L., Nelson B. C., Jose A. M. F. and Clícia M. J. B. performed the data curation and review writing. Laise C. P. performed the conceptualization, data curation, formal analysis and review.

Corresponding author

Ethics declarations

Conflict of interest

The authors report there are no competing interests to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

da Cruz, G.S., da Silva, C.N.P., Gomes-Junior, E.A. et al. Cereal bar enriched with ora-pro-nóbis (Pereskia aculeata Miller): physicochemical and sensory characterization. J Food Sci Technol 61, 1547–1556 (2024). https://doi.org/10.1007/s13197-024-05924-2

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-024-05924-2