Abstract

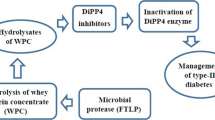

Enzymatic hydrolysis of whey protein concentrate was used to prepare hydrolysates with appropriate peptide profiles for use in the development of dietary supplements. Effects of the type of enzyme (pancreatin and proteases from Bacillus licheniformis, Aspergillus oryzae and Aspergillus sojae) and enzyme:substrate ratio (0.5:100, 1:100, 2:100, 3:100, 4:100 and 8:100) were evaluated. Twenty-four hydrolysates were prepared, and their peptide profiles were characterized by chain length using size exclusion liquid chromatography fractionation, followed by a rapid Correct Fraction Area method for quantifying the peptide and amino acid contents. The use of a protease from Bacillus licheniformis (E:S 8:100) and a pancreatin (E:S 2:100, 3:100, 4:100 and 8:100) yielded preparations of hydrolysates with the highest sums of di- and tripeptide and free amino acid contents (9.99 and 11.28 % for the protease from Bacillus licheniformis and pancreatin, respectively) as well as the lowest amount of large peptides (44.61 and 44.13 %, respectively).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Whey is defined as a byproduct of cheese-making or casein production in the dairy industry. It constitutes approximately 85–90 % of the milk volume and retains approximately 55 % of the milk ingredients (Sinha et al. 2007). However, due to its high organic substance content, especially the prevalence of lactose (approximately 75 % of the total whey solids), which is responsible for its high biological and chemical oxygen demands, it is considered one of the most polluting food by/co-product streams (Moreno-Indias et al. 2009). In spite of this, whey is considered a valuable product because of its soluble proteins and its high levels of essential amino acids, B vitamins, lactose and salts (Barbosa et al. 2010).

Although whey is a source of ingredients with significant biological value, its use in natura is limited because of its perishable components and the excessive dilution of its components. However, certain membrane separation technologies can be used to partially concentrate the whey, giving rise to whey protein concentrate (WPC), which consists of 35–80 % proteins (Brans et al. 2004).

The nutritional value of whey proteins should be stressed due to their great biological value and amino acid composition. Whey proteins contain a significant amount of some essential (tryptophan, lysine, threonine, methionine and isoleucine) and sulfur-containing amino acids (cysteine and methionine) (Sinha et al. 2007), the amount of which is higher than the amino acid requirements established by the World Health Organization for infants, children and adolescents (WHO 2002). In addition, it is known that many of these amino acids have specific biological properties, i.e., they participate in biochemical pathways and are precursors of active metabolites (Korhonen and Pihlanto 2006).

With the purpose of increasing the use of WPC proteins, enzymatic hydrolysis can be used to produce protein hydrolysates with different free amino acid and peptide profiles, depending on the enzyme specificities. These protein hydrolysates may have several applications in special foods, such as those designed to provide nutritional support to individuals with particular physiological and nutritional needs not covered by conventional diets (Pacheco et al. 2002). Protein hydrolysates have been used as main ingredients of geriatric products, high-energy supplements, hypoallergenic formulas, as well as parenteral and enteral solutions. Additionally, these hydrolysates are used in formulas designed for premature newborns and children with acute or chronic diarrhea, food intolerances, or inborn errors of metabolism, such as phenylketonuria and cystic fibrosis (Silvestre et al. 2011).

Aiming at using a protein hydrolysate for dietetic purpose, a characterization regarding the size distribution of peptides is needed, because the length of the peptide chain influences the rate of absorption. Regarding this subject, several chromatographic techniques have been described in the literature, but they have shown some drawbacks, such as interactions between the solute and the stationary phase and inefficiency in separating small peptides (Silvestre et al. 2011). For these reasons, our group (Silvestre et al. 1994a, b) has developed a method based on the fractionation of peptides by size exclusion high performance liquid chromatography which allowed separating and quantifying peptides with molecular masses smaller than 1,000 Da, and this technique was employed in the current work.

To the authors knowledge, the current work is the in which a quantity of enzyme up to 8 % was used to prepare whey protein enzymatic hydrolysates, employing several protease preparations either purified (microbial enzymes) or in crude form (pancreatin).

With the aim of using enzymatic protein hydrolysates from WPC in dietary supplements for different clinical applications, the goal of the present study was to optimize WPC hydrolysis by evaluating the effect of the enzyme type and the enzyme:substrate ratio to obtain appropriate peptide profiles from a nutritional point of view.

Material and methods

Materials

WPC (Kerrylac 750) in powder form was kindly furnished by Kerry of Brazil Ltda. (Três Corações, MG, Brazil). Pancreatin (Corolase PP® from porcine pancreas, activity = 5.97 U mL−1) and proteases from Aspergillus sojae (Corolase LAP®, activity = 0.63 U mL−1), Bacillus licheniformis (Alcalase®, activity = 6.22 U mL−1) and Aspergillus oryzae (Flavourzyme®, activity = 0.69 U mL−1) were kindly furnished by AB Enzymes (Barueri, SP, Brazil). In this study, one unit protease (U mL−1) activity was defined as the activity that liberates1 μg of tyrosine per minute (μg Tyr × mL−1 min−1) under described conditions (Dias et al. 2008).

Formic acid was purchased from Merck (Whitehouse Station, NJ, USA). Polyvinylidene fluoride membranes (0.22 μm for samples and 0.45 μm for solvents) and the tangential flow filtration system of 10 kDa porosity were purchased from Millipore (São Paulo, SP, Brazil). All solvents used in this study were analytical grade.

The HPLC system used for fractionating protein hydrolysates consisted of one isocratic pump and a UV-Vis detector (1200 Series, Agilent, Santa Clara, CA, USA) coupled to a computer with ChemStation software for LC Systems (Agilent, Santa Clara, CA, USA). A poly(2-hydroxyethylaspartamide)-silica (PHEA) column (250 × 9.4 mm, 5 μm and 200 Å pore size) was used for HPLC. The water for HPLC was purified by passage through a MilliQ water purification system (Millipore, Billerica, MA, USA).

Methods

Determination of chemical composition of whey protein concentrate

Chemical composition of the WPC was determined according to the Association of Official Analytical Chemists (Horwitz and Latimer 2007), and all analysis were performed in triplicate. Moisture content was determined using an evaporation method that employed a forced draft oven (Quimis Q-314M242, serial 020, Diadema, SP, Brazil) at 105 °C until a constant weight was observed. The total ash was determined by incineration with a muffle furnace at 550 °C (MDS, Fornitec, São Paulo, SP, Brazil). Total lipid content was determined using a Soxhlet extraction method with ethylic ether (Quimis Q-308G26, serial 018, Diadema, SP, Brazil). Protein content was determined using the micro-Kjeldahl method (digestion apparatus model MA4025 and distillation system model MA036 from Marconi, Piracicaba, SP, Brazil), using a nitrogen to protein conversion factor of 6.38. Lactose content was quantified by the determination of reducing sugars.

Preparation of hydrolysates from whey protein concentrate

Twenty-four hydrolysates from WPC were prepared with (A) Protease from Bacillus licheniformis, pH 8, 60 °C (H1–H6), (B) Protease from Aspergillus oryzae, pH 7, 50 °C (H7–H12.), (C) Protease from Aspergillus sojae, pH 7, 50 °C (H13–H18) and (D) Pancreatin, pH 7, 50 °C (H19–H24). The E:S ratios were 0.5, 1, 2, 3, 4 and 8:100 for all enzymes.

WPC solutions (10 %, w/v) were prepared in distilled water, which corresponded to 3.42 % protein (w/v), and the pH was adjusted to 7.0 or 8.0 with a 3 mol L−1 NaOH solution. Then, the WPC solutions were heated in an oil-bath with continuous stirring (stirrer 752A model from Fisatom, São Paulo, SP, Brazil), and the enzymes were added in such a concentration to attain the desired enzyme:substrate ratios. The total reaction time was 5 h for all samples, and the hydrolytic reaction was stopped by heating at 75 °C for 15 s, followed by immediately cooling on ice bath until the temperature of 25 °C. The hydrolysates were freeze-dried (Freeze Dry System/FreeZone 4.5, model 77500, LABCONCO, Kansas City, MO, USA) and stored in the freezer (−4 °C) until analysis.

Characterization of peptide profiles from WPC hydrolysates

Characterization of peptide profiles was performed in two stages, which included the fractionation of peptides according to size and their subsequent quantification. The fractionation of WPC hydrolysates was carried out by size exclusion (SE) HPLC on a PHEA column, according to the method previously developed by our group (Silvestre et al. 1994a), using 0.05 mol L−1 formic acid (pH 2.5) as the mobile phase, with isocratic conditions at a flow rate of 0.5 mL min−1 for 35 min. The samples were dissolved in the mobile phase (0.1 % wt/vol) and filtered through a membrane of 0.22 μm, and 50 μL of these solutions were injected onto the column. The mobile phase was filtered through a membrane of 0.45 μm and degassed by sonication in an ultrasound bath (USC1400 model, UNIQUE, Santo Amaro, SP, Brazil) for 30 min before use.

The rapid method of Correct Fraction Area (CFA) that was previously developed by our group (Silvestre et al. 1994b) was used for quantifying the peptides and free amino acids in the SE-HPLC fractions of the WPC hydrolysates. Briefly, five whey standard hydrolysates (two using trypsin and three using pancreatin) were prepared and then fractionated into four fractions by SE-HPLC, as described above. The four fractions were collected (Fraction Collector, CF-1 model, Spectrum Chrom, Houston, TX, USA) and submitted to amino acid analysis following solvent removal (Centrivap, 78100-00D model, LABCONCO, Kansas City, MO, USA). The calculation of CFA was performed using specific formulas after detection at three wavelengths (230, 280 and 300 nm) to remove the contribution of aromatic amino acids. A standard curve was drawn to correlate CFA with the amino acid contents of the fractions.

Evaluation of the effects of enzyme type and enzyme:substrate ratio

Effects of enzyme type and enzyme:substrate (E:S) ratio on the peptide profiles of enzymatic hydrolysates from WPC was evaluated in this study. Four enzymes, three of microbial origin (proteases from Bacillus licheniformis, Aspergillus oryzae and Aspergillus sojae) and pancreatin, all with E:S ratios of 0.5:100, 1.0:100, 2.0:100, 3.0:100, 4.0:100 and 8.0:100, were used to prepare the protein hydrolysates.

Statistical analysis

All experiments and measurements were performed in triplicate. A completely randomized factorial design (four enzymes × six E:S ratios) was adopted to investigate the presence of significant effects among the various treatments (p < 0.05). The results were analyzed with Statistica software. An analysis of variance was performed to evaluate the peptide and free amino acid contents of chromatographic fractions at each condition, and the Duncan test was applied to establish differences among the means (Pimentel-Gomes 2000).

Results and discussion

Chemical composition of WPC

The determination of the chemical composition of WPC is relevant because this concentrate is the raw material that is used to prepare protein hydrolysates. As seen in Table 1, among the measured ingredients, the protein and lactose contents were closest to those reported by other authors or found in our previous studies (Silva et al. 2009; Silvestre et al. 2011). For the other components, the moisture, lipid and ash contents were close to those found in only one prior study from our group (column F for moisture and lipid components and column E for ash) (Silva et al. 2009; Silvestre et al. 2011). In addition, the moisture results were in accordance with the WPC furnisher (>5 g%).

The variations observed in the results shown in Table 1 are most likely due to factors such as the breed of cows, feeding (nutritional and physical form of the diet), handling, intervals between milking and infections of the mammary glands that may influence the milk composition (Brito et al. 2010) and consequently the whey composition.

Another factor to be considered is that there are two whey types, sweet and acid whey, whose compositions depend on the method of cheese manufacturing. Although they have similar protein levels, the former has a higher lactose content, while the second has a higher amount of ash. The use of the different types of whey and of the different methods regarding its concentration and processing may also interfere in the WPC composition (Whetstine et al. 2005).

Chromatographic patterns of protein hydrolysates

The SE-HPLC technique used here proved to be efficient for fractionating the WPC hydrolysates, especially peptides of molecular masses lower than 1,000 Da. Thus, as shown in Fig. 1, the hydrolysates were resolved in four fractions: F1, from 13.0 to 17.0 min (large peptides, with more than 7 amino acids residues); F2, from 17.0 to 20.5 min (medium peptides, with 4 to 7 amino acids residues); F3, from 20.5 to 21.5 min (di- and tripeptides) and F4, from 21.5 to 32.0 min (free amino acids). This result confirms those of previous studies from our group that used the same technique for fractionating enzymatic hydrolysates obtained from whey (Biasutti et al. 2008; Silva et al. 2009, 2010).

Chromatographic pattern of whey protein concentrate hydrolysates. a, b, c and d chromatograms of hydrolysates obtained with proteases from Bacillus licheniformis (H6), Aspergillus oryzae (H12), Aspergillus sojae (H18) and pancreatin (H24), respectively. F1: large peptides (>7 amino acid residues); F2: medium peptides (4 to 7 amino acid residues); F3: di- and tripeptides; F4: free amino acids

As shown in Fig. 1, a significant variation existed between the peptide profiles of WPC hydrolysates obtained using pancreatin and the proteases from Bacillus licheniformis, Aspergillus oryzae or Aspergillus sojae, which could be associated with the differences in enzyme specificities.

Several authors have also reported this variation of the distribution of peptides by chain length due to enzyme. Wróblewska et al. (2004) employed a papain and a protease from Bacillus licheniformis in the hydrolysis of WPC (50 ° C, pH 8.0, 120 min). Although no quantitative data were shown, these authors stated that, using HPLC-MS, the best peptide profile was obtained by the action of the protease from Bacillus licheniformis, because it produced the least peak area for the non-hydrolyzed protein (>12,600 Da), and the greatest number of peaks corresponding to peptides with molecular weight less than 1,040 Da.

The peptide profile of WPC hydrolysates, evaluated by high performance capillary electrophoresis, was also different when comparing the action of pancreatin (Sigma, St Louis, MO, USA) and proteases from Bacillus sp. (Protamex™, Novo Nordisk, Bagsvaerd, Denmark) and Bacillus licheniformis (Alcalase 0,6L, Novo Nordisk, Bagsvaerd, Denmark) (Pacheco and Sgarbieri 2005). Although the authors did not show the molecular mass distributions of the peptides, they stated that the chromatographic pattern of the hydrolysates from the first two enzymes were very similar, considering the similarities of the retention times of the peaks in the electrophoretograms, which were different from those observed for the protease from Bacillus licheniformis. According to these authors, these differences could be explained by the different specificities of the enzymes.

Kim et al. (2007) used the reversed phase liquid chromatography with a Zorbax 300SB column to evaluate the peptide profile of WPC hydrolysates obtained by the action of a trypsin, a papain, and two proteases, one from Bacillus licheniformis and the other from Aspergillus oryzae. The authors inferred that the most extensive hydrolysis was observed with the protease from Bacillus licheniformis, considering the greatest number of peaks corresponding to short-chain peptides.

Peptide and amino acid contents

As shown in Table 2, there was a significant variation in the peptide and free amino acid contents among the different WPC hydrolysates. To choose the most appropriate hydrolysates for the development of nutritional supplements for clinical use, previous studies were considered. According to Frenhani and Burini (1999), during the metabolism of proteins, the first stage of hydrolysis leads to the formation of oligopeptides that contain 2 to 6 amino acid residues and free amino acids. Then, these peptides are broken to di- and tripeptides, and the proteins are finally absorbed in the form of di- and tripeptides and free amino acids. Also, according to these same authors, the di- and tripeptides are absorbed more efficiently than the free amino acids, which, in turn, have greater absorption than the tetra- and higher peptides. For equivalent quantities of di- and tripeptides and mixtures of amino acids, the di- and tripeptides exhibited absorption rates approximately 10 times faster. A study by González-Tello et al. (1994) also reported the advantage of di- and tripeptides over free amino acids with regard to the rate of absorption.

In this context, the criteria for choosing the most advantageous hydrolysates in the present work were associated with the presence of high amounts of di- and tripeptides (fraction F3) and of free amino acids (F4), as well as a low content of large peptides (fraction F1).

Thus, it can be inferred that, from a nutritional standpoint, five hydrolysates (H6, H21, H22, H23 and H24) showed similar peptide profiles. The advantage of H6, with regard to its higher content of di- and tripeptides, can be compensated by the superiority of the other hydrolysates that had similar (H22) or lower (H23 and H24) large peptides content and/or higher amounts of free amino acids (H21, H22, H23 and H24). Additionally, among the five best hydrolysates, four were prepared with pancreatin (H21, H22, H23 and H24), and only one was prepared with the protease from Bacillus licheniformis (H6).

Comparing the results obtained for the large peptides (F1) to the sum of the di-and tripeptides and free amino acids (F3 + F4) in H6 (F1 = 44.61; F3 + F4 = 9.99) and the average of the four hydrolysates above (F1 = 44.13; F3 + F4 = 11.28), a slight superiority, from a nutritional standpoint, was observed when using pancreatin, which yielded a higher value of the sum of di- and tripeptides and free amino acids.

One report was found in the literature on the quantification of peptides from WPC following their fractionation according to their size. Spellman et al. (2005) reported the effect of the action of two enzymatic preparations of Bacillus licheniformis (Alcalase 2.4L and Prolyve 1000) and a subtilisin on the peptide profile of WPC hydrolysates, measured by high performance liquid chromatography gel permeation chromatography using a column TKS G2000 SW. These authors concluded that the action of one of the proteases from Bacillus licheniformis (Alcalase 2.4L) was the most advantageous because it produced the highest content of peptides with mass less than 1 kDa (81 %) when compared with the other protease from Bacillus licheniformis (Prolyve 1000) and the subtilisin, that were 62.6 and 63.2 % respectively. They also found that the hydrolysate of the protease from Bacillus licheniformis (Alcalase 2.4L) contained only 3.2 % of peptides having more than 5 kDa, while for the other protease from Bacillus licheniformis (Prolyve 1000) and subtilisin these values were 13.8 % and 13.1 %, respectively. According to these authors, these results could be justified by the fact that the Alcalase 2.4 L showed the greatest proteolytic activity (23.0 U mg−1 of enzyme), followed by Prolyve 1000 (18.9 U mg−1 of enzyme) and subtilisin (15.2 mg, 1 U of enzyme).

The peptide profiles of the WPC hydrolysates were previously evaluated in three studies from our group. In the first one, the action of subtilisin (protease from Bacillus subtilis, Protemax N200, Prozyn, São Paulo, Brazil) under different conditions led to a better peptide profile than the best results of the present study (H6, H21, H22, H23 and H24), with regard to the higher amounts of di- and tripeptides (13.34 %) and free amino acids (45.56 %) as well as the smaller large peptide content (12.28 %) (Silvestre et al. 2011).

In this study (Silvestre et al. 2011), several WPC hydrolysates were prepared using the same pancreatin as the present study. It was noted that most of the hydrolysates exhibited appropriate peptide profiles from a nutritional standpoint, with low amounts of large peptides (12.80 %, on average) and high amounts of di- and tripeptides (12.11 % on average) and free amino acids (49.06 % on average) (Silvestre et al. 2011). A comparison with hydrolysate H6 led to the conclusion that these peptide profiles were more nutritionally advantageous. These results were also better than all those obtained from the pancreatic hydrolysates in the current work (H19 to H24), which most likely occurred due to differences in the catalytic activity of the enzyme, which was not reported in the study by Silvestre et al. (2011), and the use of different lots and hydrolytic conditions of WPC.

In the second study, different enzymes and reaction conditions from those used in the current work were used to hydrolyze WPC. The best peptide profile was obtained from the action of a protease from Aspergillus oryzae (E:S 1:100, pH 7, 50 °C, 5 h), which was better than that of H6 in terms of the amounts of di- and tripeptides (16.14 %) and free amino acids (18.43 %), in addition to the lower large peptide content (18.76 %) (Silva et al. 2009). This result was also better than those obtained for all of the hydrolysates prepared with the identical enzyme in the current study (H7 to H12). However, a considerable difference was found between the enzymatic activity (512.43 U mL−1) reported by Silva et al. (2009) and the activity in this study (0.69 U mL−1), which could explain the differences of the results.

In the third study, the use of papain (E:S 2:100, pH 7, 55 °C, 5 h) for hydrolyzing WPC produced a better peptide profile than pancreatin (E:S 0.5:100, 1.0:100, 2.0:100 and 3.0:100; pH 7, 50 °C, 5 h), and the peptide profile from papain was also better than the one obtained in the current work for H6 because it showed higher amounts of di- and tripeptides (15.29 %) and free amino acids (47.83 %) as well as lower amounts of large peptides (25.73 %) (Silva et al. 2010). However, the results from Silva et al. (2010) were only reached after having submitted the hydrolysates to ultrafiltration/diafiltration with a 10 kDa cut-off membrane, which probably reduced the amount of non-hydrolyzed substrate and large peptides, increasing proportionally the oligopeptide content.

Effects of enzyme type and enzyme:substrate ratio on peptide profile

The effect of enzyme type and E:S ratio was evaluated based on two factors. The first involved the production of an appropriate peptide profile from a nutritional point of view, and the second involved a reduction of costs for scaling up the process (e.g., use of a smaller E:S ratio), as we intend to use the best hydrolysates obtained in the current study for the development of nutritional supplements with several clinical applications.

The results from this evaluation are shown in figure form to make their interpretation and discussion easier. Also, instead of showing the values of F3 and F4 separately, the sum of these two fractions was chosen because it represented the form in which proteins are more efficiently absorbed by the body, due to the existence of specific transport systems for these products during protein digestion (Bröer 2008; Gilbert et al. 2008).

Effect of enzyme type

To evaluate the influence of enzyme type on the peptide profiles of WPC hydrolysates, the samples were divided into six groups, each corresponding to a different value of E:S (0.5:100 to 8.0:100), as shown in Fig. 2. It was apparent that there was an advantage to using pancreatin over the other enzymes because among the six groups, the lowest amounts of large peptides (F1) and the highest of di- and tripeptides and free amino acid contents (F3 + F4) were obtained from using this enzyme in three (E:S = 2.0:100, 3.0:100 and 4.0:100) and five groups (E:S = 1.0:100, 2.0:100, 3.0:100, 4.0:100 and 8.0:100), respectively. Along the same reasoning, in descending order of the nutritional quality of the peptide profiles were the action of proteases from Bacillus licheniformis, Aspergillus oryzae and Aspergillus sojae.

Effect of enzyme type on the peptide profile of whey protein concentrate hydrolysates. Within each group, corresponding to a value of enzyme:substrate ratio, the bars represent the hydrolysates obtained by the action of proteases from (left to right) Bacillus licheniformis, Aspergillus oryzae, Aspergillus sojae and pancreatin. F1: large peptides (>7 amino acid residues); F3 + F4: di- and tripeptides (2 and 3 amino acid residues) + free amino acids. Each value represents the mean of triplicate measurements. Different letters represent significantly different (p < 0.05) values for the same E:S ratio of different enzymes

According to the specificities of the enzymes used in the current work, the results obtained for pancreatin were expected because this is an enzymatic mixture containing both endopeptidases (trypsin and chymotrypsin) and exopeptidases (carboxypeptidases A and B), which lead to the cleavage of protein molecules at specific points, yielding the release of smaller peptides.

However, from a comparison between the action of the protease from Aspergillus oryzae, which also constitutes a mixed function enzyme (Rao et al. 1998), with those of the pancreatin and the protease from Bacillus licheniformis, it is clear that the former led to a more unfavorable peptide profile. This may at least be partly attributed to its lower enzyme activity (0.69 U mL−1 for the protease from Aspergillus oryzae vs. 5.97 U mL−1 for pancreatin and 6.22 U mL−1 for the protease from Bacillus licheniformis).

The peptide profile obtained by the action of the protease from Bacillus licheniformis was second best in this evaluation, probably because this is an endopeptidase of broad specificity (Doucet et al. 2003). Also, it had an enzymatic activity slightly higher than pancreatin (6.22 U mL−1 for the protease from Bacillus licheniformis and 5.97 U mL−1 for pancreatin).

The poorest performing enzyme was the protease from Aspergillus sojae. It could partly be justified by the fact that this protease is an exopeptidase of the group of leucil-aminopeptidases (EC 3.4.11.1), which are able to release N-terminal amino acids, preferably leucine (NC-IUBMB 2010). Moreover, this enzyme showed the lowest activity (0.63 U mL−1) among all enzymes employed in the current study.

A few reports (Pacheco and Sgarbieri 2005; Silva et al. 2009, 2010) were found in the literature that have addressed the effect of enzyme type on the peptide profiles of WPC hydrolysates. However, two studies have been conducted by our research group, in addition to another study from a separate group. In the first case, seven enzymes were used to hydrolyze WPC, from which three corresponded to those that were employed in the current work (pancreatin and proteases from Aspergillus oryzae and Aspergillus sojae), but hydrolysis was performed under different conditions than those used here (Silva et al. 2009). Unlike the results of the current study, the peptide profiles obtained from the protease from Aspergillus oryzae were better than pancreatin from a nutritional standpoint, which could be explained by the higher activity reported in this paper for the protease from Aspergillus oryzae (512.43 U mL−1 vs. 34.71 U mL−1 for pancreatin). Likewise, in the current work, the protease from Aspergillus sojae produced the most unfavorable peptide profile among the three enzymes used and held the last place in this evaluation.

More recently, our group has reported the action of the same pancreatin used in the current study. This enzyme was compared with papain (endopeptidase), and it showed that the former yielded hydrolysates with better peptide profiles in terms of the number of fractions, which were similar to the results reported here. However, the action of papain was considered nutritionally more advantageous because it yielded one of the highest amounts of di- and tripeptides (15.29 %) and one of the smallest of large peptides (25.73 %) (Silva et al. 2010).

Regarding the results of other authors, Pacheco and Sgarbieri (2005) reported the effect of the actions of three enzymes (a different pancreatin from that used in the current study and two proteases, one from Bacillus sp. and the other from Bacillus licheniformis) on the free amino acid content of WPC, evaluated by ion exchange chromatography with derivatization by ninhydrin. As in the present work, the pancreatin was the most beneficial enzyme due to its release of larger amounts of free amino acids, which was followed by the protease from Bacillus sp. and then from Bacillus licheniformis.

Effect of enzyme:substrate ratio

The effects of the E:S ratio (0.5:100; 1.0:100; 2.0:100; 3.0:100; 4.0:100 and 8.0:100) on the peptide profiles of WPC hydrolysates are shown in Fig. 3, where the samples were divided into four groups, each one corresponding to a different enzyme employed in this study.

Effect of enzyme:substrate ratio on the peptide profile of whey protein concentrate hydrolysates. F1: large peptides (>7 amino acid residues); F3 + F4: di- and tripeptides (2 and 3 amino acid residues) + free amino acids. Each value represents the mean of triplicate measurements. Different letters represent significantly different (p < 0.05) values for the same enzyme at different enzyme:substrate ratios

As also shown in Fig. 3, the advantageous use of a lower E:S ratio was observed in some cases for three of the enzymes (Aspergillus oryzae, Aspergillus sojae and pancreatin), while the same did not occur for the protease from Bacillus licheniformis. Concerning the action of Aspergillus oryzae, this beneficial effect was noticed when comparing the E:S of 3.0:100 with that of 2.0:100 and observing a reduction in the amounts of large peptides (F1) and an increase of di- and tripeptides as well as free amino acid contents (F3 + F4).

For the protease from Aspergillus sojae, a reduction of the amounts of large peptides (F1) was observed with lower E:S ratios in only two situations: from 3.0:100 to 2.0:100 and from 2.0:100 to 1.0:100. For pancreatin, lowering the E:S ratio increased the amounts of F3 + F4 fractions in just one case, when passing from an E:S of 4.0:100 to 3.0:100.

The beneficial effect of using a lower E:S ratio on the peptide profiles of WPC hydrolysates had already been demonstrated in two previous studies from our group. Using the same pancreatin of the current work but in different hydrolytic conditions, it was possible to obtain lower amounts of the large peptide and higher amounts of free amino acids when the E:S ratio decreased from 4.0:100 to 2.0:100 (Silva et al. 2010).

The action of a subtilisin in E:S ratios of 1.0:100, 2.0:100 and 4.0:100 also previously demonstrated, in some cases, the advantageous use of a lower E:S ratio as it was decreased from 4.0:100 to 2.0:100 and from 2.0:100 to 1.0:100. It led to a reduction of the amount of large peptides and an increase in free amino acid content (Silvestre et al. 2011).

Conclusions

The action of pancreatin (E:S of 2.0:100, 3.0:100, 4.0:100 and 8.0:100) and of a protease from Bacillus licheniformis (E:S of 8.0:100) proved to be more advantageous than the other enzymes used in the current study , leading to a more appropriate peptide profile for nutritional purposes. Therefore, some of the WPC hydrolysates obtained here could be used to prepare dietary supplements for various clinical applications.

References

Afonso WO, Biasutti EAR, Geraldi LM, Silva VDM, Capobiango M, Silvestre MPC (2009) Use of enzymatic hydrolysis using subtilisin for increasing the nutritional value of whey. Nutrire 34:97–114

Barbosa AS, Florentino ER, Florêncio IM, Araújo AS (2010) Utilização do soro como substrato para produção de aguardente: estudo cinético da produção de etanol. Rev Verde Agroecol Desenvolv Sustent 5:7–25

Biasutti EAR, Afonso WO, Lopes Junior CO, Coelho JV, Silva VDM, Silvestre MPC (2008) Ação da pancreatina na obtenção de hidrolisados proteicos de soro de leite com elevado teor de oligopeptídeos. Braz J Pharm Sci 44:51–60

Brans G, Schroën CGPH, Van der Sman RGM, Boom RM (2004) Membrane fractionantion of milk: state of the art and challenges. J Membr Sci 243:263–272

Brito MA, Brito JR, Arcuri E, Lange C, Silva M, Souza G (2010) Composição do leite. In: Agência de Informação Embrapa. Available at: www.agencia.cnptia.embrapa.br/Agencia8/AG01/arvore/AG01_128_21720039243.html (acessed 10 Nov 2011)

Bröer S (2008) Amino acid transport across mammalian intestinal and renal epithelia. Physiol Rev 88:249–286

Dias DR, Vilela DM, Silvestre MPC, Schwan RF (2008) Alkaline protease from Bacillus sp. isolated from coffee bean grown on cheese whey. World J Microbiol Biotechnol 24:2027–2034

Doucet D, Otter DE, Gauthier SF, Foegeding EA (2003) Enzyme-induced gelation of extensively hydrolyzed whey proteins by Alcalase: peptide identification and determination of enzyme specificity. J Agric Food Chem 51:6300–6308

Frenhani PB, Burini RC (1999) Mecanismos de absorção de aminoácidos e oligopeptídeos: controle e implicações na dietoterapia humana. Arq Gastroenterol 36:227–237

Gilbert ER, Wong EA, Webb KE Jr (2008) Peptide absorption and utilization: implications for animal nutrition and health. J Anim Sci 86:1493–1501

González-Tello P, Camacho F, Jurado E, Páez MP, Guadix EM (1994) Enzymatic hydrolysis of whey proteins. II. Molecular-weight range. Biotechnol Bioeng 44:529–532

Horwitz W, Latimer GW Jr (2007) Official methods of analysis of AOAC International, 18th edn. AOAC International, Gaithersburg

Kim SB, Seo IS, Khan MA, Ki KS, Lee WS, Lee HJ, Shin HS, Kim HS (2007) Enzymatic hydrolysis of heated whey: iron-binding ability of peptides and antigenic protein fractions. J Dairy Sci 90:4033–4042

Korhonen H, Pihlanto A (2006) Bioactive peptides: production and functionality. Int Dairy J 16:945–960

Moreno-Indias I, Castro N, Morales-Delanuez A, Sánchez-Macías D, Assunção P, Capote J, Argüello A (2009) Farm and factory production of goat cheese whey results in distinct chemical composition. J Dairy Sci 92:4792–4796

Mortenson MA, Vickers ZM, Reineccius GA (2008) Flavor of whey protein concentrates and isolates. Int Dairy J 18:649–657

NC-IUBMB - Nomenclature Committee of the International Union of Biochemistry and Molecular Biology (2010) Enzyme nomenclature: recommendations of the Nomenclature Committee of the International Union of Biochemistry and Molecular Biology on the nomenclature and classification of enzymes by the reactions they catalyses. School of Biological and Chemical Sciences, Queen Mary University, Londres. Available at: http://www.chem.qmul.ac.uk/iubmb/enzyme (acessed: 12 Oct 2011)

Pacheco MTB, Sgarbieri VC (2005) Effect of different hydrolysates of whey protein on hepatic glutathione content in mice. J Med Food 8:337–342

Pacheco MTB, Amaya-Farfan J, Sgarbieri VC (2002) Partial characterization of a whey protein concentrate and its enzyme hydrolysates. J Food Biochem 26:327–338

Pimentel-Gomes F (2000) Curso de estatística experimental, 14th edn. Livraria Nobel S/A, Piracicaba, 468p

Rao MB, Tanksale AM, Ghatge MS, Deshpande VV (1998) Molecular and biotechnological aspects of microbial proteases. Microbiol Mol Biol Rev 62:597–635

Sammel LM, Claus JR (2003) Whey protein concentrates effects on pink color development in a cooked ground turkey breast model system. Meat Sci 65:1293–1299

Silva MC, Silva VDM, Lana AMQ, Silvestre MPC (2009) Grau de hidrólise e perfil peptídico de hidrolisados enzimáticos do concentrado protéico de soro de leite. Alim Nutr 20:395–402

Silva MR, Rodrigues DF, Lana FC, Silva VDM, Morais HA, Silvestre MPC (2010) Perfil peptídico de hidrolisados enzimáticos do concentrado proteico do soro de leite, obtidos pela ação da pancreatina e da papaína. Nutrire 35:97–114

Silvestre MPC, Hamon M, Yvon M (1994a) Analyses of protein hydrolysates. 1. Use of poly (2-hydroxyethyl-aspartamide)-silica column in size-exclusion chromatography for the fractionation of casein hydrolysates. J Agric Food Chem 42:2778–2782

Silvestre MPC, Hamon M, Yvon M (1994b) Analyses of protein hydrolysates. 2. Characterization of casein hydrolysates by a rapid peptide quantification method. J Agric Food Chem 42:2783–2789

Silvestre MPC, Afonso WO, Lopes Junior CO, Silva VDM, Morais HA, Souza MWS, Silva MR (2011) Use of subtilisin and pancreatin for hydrolysing whey protein concentrate. Am J Food Technol 6:647–660

Sinha R, Radha C, Prakash J, Kaul P (2007) Whey protein hydrolysate: functional properties, nutritional quality and utilization in beverage formulation. Food Chem 101:1484–1491

Spellman D, Kenny P, O’Cuinn G, Fitzgerald R (2005) Aggregation properties of whey protein hydrolysates generated with Bacillus licheniformis proteinase activities. J Agric Food Chem 53:1258–1265

Whetstine AEC, Croissant AE, Drake MA (2005) Characterization of dried whey protein concentrate and isolate flavor. J Dairy Sci 88:3826–3839

WHO – World Health Organization (2002) Protein and amino acid requirements in human nutrition. Geneva, WHO, 2002. Available at: www.who.int/nutrition/publications/nutrecomm/en/index.html (acessed: 12 Oct 2011)

Wróblewska B, Karamać M, Amaraowicz R, Szymkiewicz A, Troszyńska A, Kubicka W (2004) Immunoreactive properties of peptide fractions of cow whey milk proteins after enzymatic hydrolysis. Int J Food Sci Technol 39:839–850

Acknowledgments

The authors thank CNPq, CAPES and FAPEMIG for their financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Morais, H.A., Silvestre, M.P.C., Silva, M.R. et al. Enzymatic hydrolysis of whey protein concentrate: effect of enzyme type and enzyme:substrate ratio on peptide profile. J Food Sci Technol 52, 201–210 (2015). https://doi.org/10.1007/s13197-013-1005-z

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-013-1005-z