Abstract

The low cost raw material, apple variety Idared, was turned into value-added product, apple chips. The apple chips were produced in a two-step process consisting of osmotic treatment and conventional drying. Osmotic treatment was carried out in 40 % glucose solution at room temperature, followed by convective drying at 105 °C, till reaching water activity of 0.3. Mechanical properties of the apple chips measured by compression and penetration tests were correlated with the sorption properties. The low browning index, 25.5 and high whitening index, 63.7, proved the good retention of the color of the apple chips. The instrumental characteristics of the apple chips were correlated with the sensory characteristics of the product. The new product was accepted by the 95 % of the panelists. The stored apple chips under modified atmosphere showed no significant changes in the quality parameters over 6 month period.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Consumers are currently focused on healthy foods that are safer, convenient and easy to preserve and use. These requirements increased the demand of fresh or minimally-processed food devoid of synthetic chemical preservatives (Señorans et al. 2003). Among the convenient ready to eat products are the fruit and vegetable-based snacks. Most of the fruit and vegetable-based snacks available in the market are processed by frying in cooking oil (Maity et al. 2012). Desired crispness in apple slices was reached by vacuum frying in vegetable oil at high temperatures, but the process was accompanied with high oil uptake and extensive non-enzymatic browning (Shyu et al. 2005). Nowadays, consumers’ health concerns have forced the snack foods industry to produce low-fat foods while keeping their traditional flavor and texture characteristics. For this reason, research aimed at reducing the fat content in fried foods or snacks has gained importance, either by modifying process conditions, by changing the frying medium, or by the use of pretreatments such as blanching, immersion in sugar solutions, or edible coatings (Bravo et al. 2011). In respect to the packaging, the modified atmosphere packaging has lately become widely used technique for food preservation, which minimally affects the product characteristics and provides better consumer perception as a natural and additive-free technique (Rocculi et al. 2004).

Applying osmotic pre-treatment on sweet potatoes, Taiwo and Baik (2007) reported that the changes occurring in the cell membranes in the pre-treatment step, played the key role in the further processing of the potatoes. The most positive benefits of the combined effect of the osmotic dehydration and conventional drying in the production of the crispy products are considered to be the color and flavor retention, as well as the texture shift of the fruit flesh (Pisalkar et al. 2011; Chavan et al. 2010).

In reference to fruits and vegetables, the characteristics that impart distinctive quality may be described by four different attributes: color and appearance; flavor (taste and aroma); texture and nutritional value. The consumers, first, evaluate visual appearance and color, followed by the taste, aroma, and texture (Barrett et al. 2010).

Products that are perceived as healthy foods and are a desirable ingredient for fruit-based snacks are apples. They are the fourth most important tree fruit crop worldwide after all citrus, grapes and bananas (Guine et al. 2011). The development of new apple products, such as apple chips is interesting for their promotion as ready to eat snacks according to the current tendencies. The aim of our research was the production of dried, fat-free, healthy and appreciated apple product from low cost, easy available and abundant apple variety, Idared. Osmotic dehydration was used as pre-treatment to the conventional drying to develop apple chips with crispy texture. The change of the elastic viscoplastic texture of the fresh apples to rigid, fragile and brittle in the apple chips were evaluated by instrumental and sensory methods. All the changes of the physical properties, such as mechanical and sorption properties, density, porosity and color, occurring in the apple tissue during storage were also investigated. The overall acceptance of the new value added product was evaluated by means of sensory analysis.

Materials and methods

Raw material and sample preparation

The apple variety Idared was selected for this investigation. Fruits were purchased from the local market. Apples were studied at commercial maturity. In the lab, they were examined within maximum duration of 1 week storage in a cold chamber at 4 °C, to minimize development of chilling injury.

The apples were washed and manually cut with a specially designed sharp stainless steel blade into very thin sheets of approximately 2 mm. Then the chips were cut out of these sheets, by using cork borer, in form of discs with 18 mm diameter. The apple discs were cut from the parenchyma region.

Apple chips production

The apple chips production was multi-step process consisting of osmotic treatment, conventional drying and packaging of the apple chips:

Osmotic pre-treatment

The apple discs were subjected to osmotic dehydration in 40 % aqueous glucose solution, which corresponds to a water activity of 0.927. The osmotic treatment was carried out at mild temperature of 25 °C (Farris et al. 2008). Apple discs were placed in 200 mL glass jars. The material to solution ratio was 1:20 (w/w), in order to avoid dilution of the osmotic solution during the dehydration process (Castro-Giraldez et al. 2011). Samples were kept submerged by means of light plastic cover. The dewatering process was performed for 150 min, and three samples were collected at the 15th, 30th, 60th, 90th, 120th and 150th min, respectively, for the analysis of moisture and solute contents in the apple discs. After the osmotic treatment, the samples were quickly blotted with tissue paper to remove the excess of osmotic solution from their surface and weighed. Separate samples were used for texture analysis. All the experiments were repeated three times and the average values were taken for calculations.

Convective drying

Convective drying was carried out in conventional cabinet dryer where the apple discs were placed in one layer on a tray and dried at 105 °C for 120 min. These operating conditions were slightly modified from those suggested by Farris et al. 2008. Occasionally, the samples were flipped over during drying to avoid sticking of the slices to the tray and to allow equal dehydration from all sides. Samples were collected at the 5th, 10th, 15th, 20th, 30th, 60th, 90th and 120th min, to analyze the water activity drop and the mechanical changes in the apple discs.

Packaging

After the drying, the chips were cooled down to room temperature for 20 min and packaged in multi-layered packaging bags. The packaging material was metalized polypropylene (as suggested by potato chips producers) and the chips were packaged under the nitrogen atmosphere to avoid moisture absorption, discoloration and spoilage (Salvador et al. 2009). Small bags with dimensions of 8 × 8 cm were used for packaging of 1.5 g apple chips. The bags were flushed with nitrogen gas for one minute before being heat-sealed.

Storage stability

The storage stability of the apple chips produced with the combined drying techniques (osmotic pre-treatment for 90 min and conventional drying at 105 °C for 60 min) and packaged according to the above described procedure was also investigated. The chips were stored in a dry place at 25 ± 2 °C and the stability was evaluated over storage time of 6 months.

Measurement of water activity

Water activity of the samples and osmotic solution was measured with Testo-650 water activity system, Germany. Approximately 3 ± 0.01 g of the sample were put in a special cuvette and the cuvette was placed in the aw-chamber. The water activity was measured and displayed on the aw-meter screen. The experiments were repeated 6 times.

Measurement of moisture loss and solute uptake

Moisture content was measured gravimetrically by drying the samples at 105 °C. The moisture loss and solute uptake of the samples during the osmotic process was calculated using the Eqs. (1) and (2):

where M o is the mass of the sample, \( {M_{{{w_o}}}} \) is the mass of the water in the sample at time t o , M w is the mass of the water in the sample at time t, M s is the mass of the solid content of the sample at t and \( {M_{{{s_o}}}} \) is the mass of the solid content of the sample at t o .

Density and porosity

The bulk volume of fresh apples was measured using the liquid displacement technique (Mandala et al. 2005). Measurements were made as quickly as possible (less than 30 s) to avoid water uptake by samples. The bulk density, ρ b , (g/cm3) was expressed as the ratio of the sample to its bulk volume, while the solid density, ρ s , was determined by dividing the mass of the grinded sample by its solid volume. The test was repeated 3 times. The porosity, Φ, was calculated as:

The density of the apple chips was determined using the toluene method as described by Xie and Zhao (2004). Known quantity of apple chips broken down into small pieces were weighed to 0.001 g accuracy and immediately placed in 10 mL graduated cylinder. The cylinder with the apple chips was accurately filled with toluene from 10 mL pipette. The remaining toluene in a pipette was equal to a volume of known amount of apple chips sample. The density was expressed in g/cm3 and represented an average value of 3 measurements.

Texture analysis

Texture measurements were conducted by means of a texture analyzer (TA-XT2i of Stable Micro Systems, Godalming, England). To determine the texture of the fresh apples and apple chips two types of mechanical tests were applied. For the puncture test apple discs were placed on the platform and the 2 mm probe was used to puncture them in the center. The probe moved with cross-head speed of 1 mm/s, trigger force 1 g and travel distance of the probe 5 mm, penetrating trough the whole height of the tissue. The pre- and post-test speed was set at 10 mm/s. A force-time curve was recorded by the instrument and the stress (MPa) was calculated as a ratio between the maximum force at fraction, F, and the cross-sectional area, A.

The compression test was conducted using a 5 mm cylindrical probe. The probe descended at speed of 10 mm/s and compressed the sample at a speed of 1 mm/s up to a distance making 50 % deformation. When the compression stroke was completed, the probe abruptly reversed its direction and started the upward move at 10 mm/s. Then a second down and up cycle was run on the same sample. A force-time curve was recorded by the instrument and five textural attributes including hardness, cohesiveness, springiness, brittleness and chewiness were calculated.

Sorption properties

The sorption isotherm of the apple chips was determined using a static gravimetric method at the storage temperature of 25 ± 2 °C. Chips samples (0.350 ± 0.010 g) were placed in weighing bottles and stored in air-sealed glass jars until maintaining equilibrium relative humidity with saturated salt solutions. The experiment was carried out until the difference between two consecutive measurements was less than 0.001 g. The total time for the pulling out, weighing and putting back the samples in the jars was about 30 s, which minimized the degree of atmospheric moisture sorption during weighing. The equilibrium moisture content was determined by drying in an oven at 105 °C until constant weight. The percentage difference in equilibrium moisture content between triplicate samples was usually bellow 5 %, and the average of the three values was taken.

The relation between the equilibrium moisture content and the water activity of the apple chips was predicted using four isotherm models presented in Table 1. The model’s constants, X m , C and K, were obtained by non-linear fitting using the software package Scientist™, from MicroMath®. These parameters proved to be very useful in the physicochemical description of the final product. The goodness of the fit of each model was evaluated by calculating the mean relative percentage deviation modulus, E (%) (Cepeda et al. 1999), the standard error, S, and the correlation coefficient, r, (Bellagha et al. 2008) which are defined as follows:

where X exp is the experimental value of equilibrium moisture content, X cal is the calculated equilibrium moisture content from the tested method, N unknown is the number of unknowns of the particular model and N exp.data is the number of experimental points.

Measurement of color

To measure the color of fresh apples as well as the color of the apple samples during the osmotic dehydration and at the end of the drying process, Dr. Lange spectro-color colorimeter was used. The instrument was calibrated against the black and white tile before use. After collecting the three parameters that is L* (lightness), a* (greenness) and b* (yellowness) they were fitted in several equations to calculate some specific color changes. The experiments were replicated five times.

The total color difference, ΔE, the chrome, C, and hue angle, h°, were calculated using the Eqs. 8, 9 and 10, respectively:

Browning index, BI, represents the purity of brown color in the apple flesh due to enzyme activity, which can cause deleterious changes in the appearance and organoleptic properties of the food and therefore is considered as an important parameter associated with the browning of the samples (Jalaee et al. 2011). The whitening index on the other hand, WI, corresponds to lesser browning and product discoloration and it is an indicator of enzymatic discoloration (Pathare et al. 2012a).

Sensory analysis

A simultaneous sensory evaluation was also conducted to compare analytical texture and color measurements to the respective organoleptic results. The sensory analysis was carried out with two groups of panelists. One panel group of 15 assessors with experience in the descriptive evaluation of crispy products was used to evaluate the apple chips. Each panel member was asked to describe the apple chips with few attributes. Testing was carried out in a sensory laboratory. The intensity of all sensory impressions was evaluated using a scale from 1 to 7 (1=low intensity, non-satisfactory and 7=high intensity, very satisfactory). The perception that a person consuming food products receives, depends on the stimuli received during biting and chewing of the food. During chewing the consumer receives stimuli connected both with the mechanical strength and the rheological properties of the eaten product. Therefore, before scoring the product, the panelists were asked to describe the apple chips. To evaluate hardness the instruction was to bite the whole chip with the incisors until fracture and to score the material resistance. To score crispness the instruction was to evaluate altogether the amount and quality of the sound produced, deformability and brittleness during mastication. The samples were served in random order, each in a separate packaging of 1.5 g. Another panel was used as consumer representative. This group consisted of 53 persons with age from 13 to 67, of which 33 were women and 20 were men. Both panel groups participated in the evaluation of the overall acceptability of the product by using 9-point Hedonic scale. All assessors participating in this test declared themselves as consumers of fresh apples and potato chips and other crispy products and were therefore suitable as panelists.

Statistical analysis

Descriptive statistics and one-way analysis of variance (ANOVA) was performed on the instrumental (n = 5 for color and n = 6 for texture measurements) and sensory parameters (n = 15 panelists) to evaluate significant differences among the samples at 95 % confidence interval according to Tukey’s test using Minitab 15 statistical software.

Results and discussion

Among all varieties of apples Idared is the cheapest, most abundant and available variety throughout the year, and therefore it is suitable for industrial processing and development of value-added products. All the apples used in this study were selected at the same ripening degree with 88.7 ± 3.9 % moisture content. The bulk density of the fresh apples was 0.920 ± 0.083 g/cm3, while the porosity of the apples, or volume fraction filled with gas, was 0.150 ± 0.004 cm3/cm3, which made the fruit suitable for osmotic treatment. Barrera et al. (2009) when working with apples from the variety of Granny Smith, found out that fresh apples with porosity of 0.2 ± 0.04 cm3/cm3 were highly susceptible to osmo-impregnating processes.

Production of apple chips

Osmotic pre-treatment

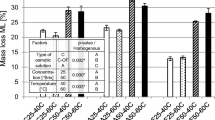

The osmotic pre-treatment was studied in terms of moisture loss, solute uptake and texture changes (Fig. 1). The moisture loss rate changed with the time of immersion. During the initial phase of osmosis (first 30 min), the water removal rate was controlled by the high concentration gradient and the rate attained its maximum value of 0.975 gwater/gdry mass .h. The intensive water removal was accompanied with leaching out of the low-molecular weight solutes dissolved in the intra- and extracellular fluid. After this initial period, the system was approaching to equilibrium state where the process rate was controlled by the internal mass transfers, which led to progressive decrease in the water removal rate. Between the 30 and 60 min of the treatment the water removal rate dropped more than 10 times and it was 0.074 gwater/gdry mass .h. After one hour it reached a plateau where no further water removal was noticed. The solid uptake within the tissue started only after 90 min of treatment when the system reached equilibrium. The final concentration of the solute uptake at the end of the treatment never exceeded 5 % or 0.05 g glucose/ g dry sample mass. Similar results were reported by Khin et al. (2007), when working with Fuji apples. As the osmotic treatment progressed, it was noticed that the loss of water in the beginning of the osmosis led to softening of the apple discs. After 90 min, the solute uptake started, and the consequent increase in the solid fraction slightly regained the hardness of the apple samples.

Convective drying

The apple chips, both osmotically treated and not treated, were dried until reaching stable water activity of the product of 0.3 (Fig. 2). The initial moisture content of the treated and not treated samples was 5.17 ± 0.231 g/g and 6.04 ± 0.316 g/g, while the final moisture content was 0.11 ± 0.001 g/g and 0.20 ± 0.016 g/g for treated and not treated samples, respectively. The total processing time for the osmotically treated apples was 4.5 h. From the results of water loss (Fig. 1) and rapid drop of the water activity and moisture content after osmotic treatment (Fig. 2) it was noticed that the whole process (osmotic drying step + convective drying step) can be shortened and therefore optimized for industrial purposes. The critical dewatering period without uptake of any solids from the osmotic solution was 30 min, and the time necessary for required drop in the water activity and moisture content was also 30 min, meaning that the total processing time can be reduced to 1 h which would result in lower energy costs. The pretreated apple discs manifested more pronounced drop of the water activity when compared to the non-treated apples due to the partial water removal during the osmotic step. The apple chips produced with the combined technique reached the water activity of 0.3, suitable for long storage and stability of the product, in just 30 min. The apples dried without any pre-treatment reached the necessary water activity in 105 min, which was 3.5 times slower than the pretreated apples.

The apple chips produced by the combined drying methods had bulk density of 1.737 ± 0.056 g/cm3. The porosity of the apple chips was 0.015 ± 0.002 cm3/cm3, which was ten times lower than the porosity of the fresh apples. Porosity of the osmotically treated material can be related to the degree of water loss and solute uptake, to the immersion time during osmosis, to the fruit’s moisture content or to the microstructure changes of the tissue during drying (Mandala et al. 2005). Usually the changes in fruit porosity result in changes of its texture, especially its firmness. The changes in the mechanical properties during convective drying are given in Fig. 3. The osmotic dewatering of the apples prior the drying (Fig. 1) affected the mechanical properties of the apple tissue in a different way than just convective drying to the same final water content. Hardness of the pre-treated apple discs increased linearly during convective drying, while the non-treated samples exhibited loss of the initial hardness. The resistance of the material to penetration, corresponding to higher breaking force and shorter distance, increased noticeably in the first 30 min for the osmotically treated apples, reaching values of 10 N and 0.2 mm, respectively. These changes are strongly related to the moisture content and water activity of the apples. The lower moisture content and water activity values can explain the stiffness and brittleness, characteristic for crispy texture, of the apple chips produced by the combined drying techniques. The non-treated apples showed different behavior. The loss of hardness from 5.6 to 1.7 N in the first 30 min was accompanied with bigger brittleness or longer distance, 1.05 mm, necessary to penetrate trough the apple tissue. The higher moisture content and water activity values of these samples confirmed the more elastic and viscous texture of the not treated dried apples.

Characterization of apple chips

Texture analysis

The typical force-displacement curves (mean values) for the penetration and compression tests from the texture profile analysis are presented in Fig. 4. The curves from the penetration test presented the differences in the mechanical pattern of each sample. The fresh apple sample showed low penetration force and flatter peak (a), the work needed to penetrate trough the flesh was 0.02 MPa. The dried apple without any pre-treatment, even though, needed higher breaking force and stress of 0.7 MPa, was still far from the desired crispy structure because the elongated and wide peak (b) without any remarkable jaggedness is more typical for the elastic–plastic behavior of the tissue. The behavior of the pretreated apple chips is represented with a very sharp curve (c) where the stress was 1.07 MPa. The initial quick, steep and linear tract was reached after just 0.05 mm deformation. Afterwards two more spiky peaks followed, these ruptures are typical for the crispy products. The similar behavior was reported for apple rings osmotically treated in maltose solution and dried at 90 °C by Farris et al. (2008).

The area under the first and second peak in the texture profile analysis from the compression test (Fig. 4b) enabled calculation of several texture parameters that are presented in Fig. 5. As mentioned previously, the steepness of the slope at the beginning of each curve is defined as crispness (Pathare et al. 2012b) and it was 15.8 N/mm, 3.6 N/mm and 126.9 N/mm for fresh, non-treated and osmotically treated dried apples, respectively. The hardness of the samples was defined by the peak force during the first compression cycle and it is related with structural integrity in the tissue and the change in the cell membrane structure due to different drying treatments. The two-step apple chips production by the combination of osmotic pre-treatment and the convective drying led to increased water loss (Fig. 1) resulting in reduced plasticizing effect of the water and changes in the rheological properties of the apple tissue which promote the crispy structure. The crispy structure of the pretreated apple chips was accompanied with most pronounced brittleness of just 0.11 mm. The breaking distance of the fresh and dried apples without pretreatment was 0.37 and 0.40 mm, meaning that the stiffness of the apple chips was one third of the stiffness of the fresh and not treated dried apples, respectively. Similar results for substantial change in the mechanical properties of the apple tissue due to osmotic treatment were reported by Lewicki and Lukaszuk (2000). They proved that osmotic treatment with 61.5 % sucrose solution at 30 °C for 3 h and subsequent convective drying resulted in samples with half of the stiffness of the samples dried solely by convective drying. The cohesiveness of the non-treated dried apples suggested that the strength of the internal bonds inside this sample, which keeps the sample cohesive and elastic, was higher than the cohesiveness of the other samples.

a Instrumental texture profile for fresh apples, non-treated dried apples and the apple chips and b Sensory attributes of apple chips obtained with descriptive sensory analysis. Bars with different letter for the instrumental texture attribute are significantly different (p < 0.05). Vertical bars represent the standard deviation of n = 6 for instrumental measurements and n = 15 panelists for sensory analysis

Sorption properties

The quality of the crispy products during storage primarily depends on their sorption properties. The knowledge of the sorption isotherm is an important tool in food dehydration as a good indicator for predicting the shelf-life of the dried fruit. The sorption isotherms of the apple chips fitted according to the different mathematical models are plotted in Fig. 6, while the calculated constants and the goodness of the fit are listed in Table 2. The isotherms have the sigmoidal shape, typical for many foods. The water activity of the food product gives the amount of water available for chemical and biochemical reactions and microbial development. From the results it was proved that the experimental values could be fitted in all models. It is usually considered that a good fit is reached when E values < 10 % and r values > 0.9. Since in all cases E values were between 3.9 and 5.8 % and r values above 0.99, the correlation criteria for the apple chips are very satisfactory. Yet, the GAB model presented the best fit.

The C constant was found to be 26.44 and similar values in the literature were reported by Timmerman et al. (2001) and Goula et al. (2008). Other authors reported similar values of X m for GAB model fitting, such as 0.062–0.138 g water/g dry mass for Chilean papaya (Vega-Galvez et al. 2008); 0.041–0.050 g water/g dry mass for pineapple (Kiranoudis et al. 1993) and between 0.067 and 0.220 g water/g dry mass for grapes, apricots, apples and potatoes (Kaymak-Ertekin and Gedik 2004).

Surface color change

Changes in the surface color of apple samples in different stages of processing are given in Table 3. The color of fresh apples was used as a positive control. The negative controls represent intensive browning non desirable for the product. Therefore, the color of samples left at room temperature without any treatment for the same extent of time as the osmotic pre-treatment (150 min) and the color of non-treated dried apples, that showed intensive browning, were used as negative controls. The results proved that there were no statistically significant changes at the confidence level of p > 0.05 in all color parameters among the fresh, osmotically treated samples and the chips produced with the combined dehydration techniques. The osmotic pre-treatment reduced the product water activity and enzyme activity resulting in better retention of food product color, which was proven by the lower browning index values of 16.25 for the osmotically treated samples. Increased browning index for non-treated apples, 39.12, corresponds to the lower whitening index, 55.20, and hue values, 77.67, characteristic for the darker samples. Besides the enzymatic browning, the convective drying can cause an even higher degree of non-enzymatic browning of the sample. The appearance of brown spots and the development of burned taste are related to the chemical composition. Due to the leaching out of the soluble solids during the osmotic pre-treatment prior to drying (Fig. 1) the non-enzymatic browning reaction, also known as the Maillard reaction, was minimized and enabled production of better looking chips. Leeratanarak et al. (2006) reported similar results for potato chips undergoing different drying techniques.

Sensory analysis

The resulting descriptive analysis gives a multi-dimensional sensory “image” of the product. The sensory attributes chosen by the panelists to describe the apple chips were: crispy, sweet, hard, tender, fresh, sticky, dry, sour and apple taste and the results from this descriptive analysis are depicted in Fig. 5b. Most of the panelist described the apple chips with more than one attribute, but mostly as crispy and sweet with the sourish apple taste, proving that the apple chips preserved part of the fresh-like characteristics of the apple.

When asked to compare and grade the apple chips with the fresh apple in terms of color, aroma, texture, flavor, taste and crispness (Fig. 7), panelists ranged the apple chips very close to the fresh apple. There was no significant difference between the scores in some of the attributes. As expected, the attribute that showed significant difference at p < 0.05 level was the crispness. The crispness of the apple chips was significantly higher than the crispness of the fresh apple, proving again the crispy structure of the produced apple chips.

The total sensory quality is a complex concept, which consists of several attributes perceived through the senses, such as appearance, odor, flavor and texture. Their quality, intensity and mutual relations are very important for product identification and acceptance by the consumers, especially when a newly developed product is being assessed. Since 85 % of the panelists confirmed themselves as potato chips consumers, there was a possibility for them to stick to the image kept in their mind about the appearance of the chips. The overall acceptance of the product, or the liking of the apple chips, was evaluated by 9-point Hedonic scale. The results revealed that the consumers expressed different liking of the apple chips. The part of the panel group that did not like the product was less than 5 %. One should always remember that consumer liking of the product is not constant and may fluctuate together with the development of new habits and new products (Jaworska and Hoffmann 2008). Therefore, at the end the consumers were asked if they would consume, or even substitute the potato chips, with this healthy, fat-free apple chips. More than 95 % of them said that they would consume the apple chips if offered on the market, 40 % would replace the potato chips with the apple chips, while 55 % would continue consuming both chips.

Storage stability

Moisture sorption isotherm exhibited the relation between the moisture content of the apple chips and the water activity at the storage temperature. The relationship between the water activity, the equilibrium moisture content and the texture properties is presented in Fig. 8. It can be seen that till water activity of 0.5 the sample contains water in the range of the monolayer moisture content, 0.158 g water/g dry mass and it is still acceptable for use, due to preserved texture and crispness above the satisfactory level. After absorbing more water there is a significant loss of the hardness, around 70 %, and the crispness, which satisfactory score is above 4.5 or above 60 % of the maximum value (Kappel et al. 1995; Imm et al. 2011). Hough et al. (2001) reported that the critical a w value of other dry and crisp products was also about 0.5.

Apart from testing the stability of the product from the point of the processing conditions, the packaging technique as a preservation mean was also investigated. Hence, the produced apple chips were packaged with gas-flushing technique using nitrogen gas. The results of the evaluated sensory parameters during 6 months storage are given in Table 4. The modified atmosphere packaging inhibited the development of flesh browning or any other changes in apple chips during storage, because there were no statistically significant changes among the chips samples.

Conclusions

The low cost apple variety Idared was converted to highly value-added ready to eat product, apple chips, by combination of osmotic pre-treatment with conventional drying. The crispy texture of the apple chips produced with combined drying techniques was characterized by its mechanical and sorption properties. The reduced water activity level of the final product and the packaging conditions under atmosphere of nitrogen extended the shelf-life of the product. The apple chips preserved the good color and all mechanical properties during storage. These dried apples having common characteristics of crispy products were evaluated by the consumers as very healthy and satisfying for consumption. Moreover, no solute uptake rendered the chips suitable for consumption even for diabetics.

References

Barrera C, Betoret N, Corell P, Fito P (2009) Effect of osmotic dehydration on the stabilization of calcium-fortified apple slices (var. Granny Smith): influence of operating variables on process kinetics and compositional changes. J Food Eng 92:416–424

Barrett DM, Beaulieu JC, Shewfelt R (2010) Color, flavor, texture, and nutritional quality of fresh-cut fruits and vegetables: desirable levels, instrumental and sensory measurement, and the effects of processing. Crit Rev Food Sci 50:369–389

Bellagha S, Sahli A, Ben Zid M, Farhat A (2008) Desorption isotherms of fresh and osmotically dehydrated apples (Golden Delicious). Rev Ener Renouv SMSTS’08 Alger 45-52

Bouquet R, Chirife J, Iglesias HA (1978) Equations for fitting water sorption isotherms for food. Part 2. Evaluation of various two-parameter models. J Food Technol 13:319–323

Bravo J, Sanjuán N, Clemente G, Mulet A (2011) Pressure effect on deep fat frying of apple chips. Dry Technol 29:472–477

Castro-Giraldez M, Fito PJ, Fito P (2011) Nonlinear thermodynamic approach to analyze long time osmotic dehydration of parenchymatic apple tissue. J Food Eng 102:34–42

Cepeda E, Ortiz de Latierro R, San Jose MJ, Olazar M (1999) Water sorption isotherms of roasted coffee and coffee roasted with sugar. Int J Food Sci Technol 34:287–290

Chavan UD, Prabhukhanolkar AE, Pawar VD (2010) Preparation of osmotic dehydrated ripe banana slices. J Food Sci Technol 47(4):380–386

Farris S, Gobbi S, Torreggiani D, Piergiovanni L (2008) Assessment of two different rapid compression tests for the evaluation of texture differences in osmo-air-dried apple rings. J Food Eng 88:484–491

Goula AM, Karapantsios TD, Achilias DS, Adamopoulos KG (2008) Water sorption isotherms and glass transition temperature of spray dried tomato pulp. J Food Eng 85:73–83

Guine RFP, Andrade S, Correia AC, Jordão AM, Lopes AD, Ferreira D (2011) Evaluation of textural properties in apples of regional varieties. Int J Food Prop 14:331–338

Hough G, Ruera MDP, Chirife J, Moro O (2001) Sensory texture of commercial biscuits as a function of water activity. J Texture Stud 32:57–74

Imm BY, Lee JH, Lee SH (2011) Sensory quality index (SQI) for commercial food products. Food Qual Prefer 22:748–752

Jalaee F, Fazeli A, Fatemian H, Tavakolipour H (2011) Mass transfer coefficient and the characteristics of coated apples in osmotic dehydrating. Food Bioprod Process 89:367–374

Jaworska D, Hoffmann M (2008) Relative importance of texture properties in the sensory quality and acceptance of commercial crispy products. J Sci Food Agric 88:1804–1812

Kappel F, Fisher-Fleming R, Hogue EJ (1995) Ideal pear sensory attributes and fruit characteristics. Hortic Sci 30:988–993

Kaymak-Ertekin F, Gedik A (2004) Sorption isotherms and isosteric heat of sorption for grapes, apricots, apples and potatoes. LWT – Food Sci Technol 37:429–438

Khin MM, Zhou W, Yeo SY (2007) Mass transfer in the osmotic dehydration of coated apple cubes by using maltodextrin as the coating material and their textural properties. J Food Eng 81:514–522

Kiranoudis CT, Maroulis ZB, Tsami E, Marinos-Kouris D (1993) Equilibrium moisture content and heat of desorption of some vegetables. J Food Eng 20:55–74

Leeratanarak N, Devahastin S, Chiewchan N (2006) Drying kinetics and quality of potato chips undergoing different drying techniques. J Food Eng 77:635–643

Lewicki PP, Lukaszuk A (2000) Effect of osmotic dewatering on rheological properties of apple subjected to convective drying. J Food Eng 45:119–126

Maity T, Shah A, Raju PS, Bawa AS (2012) Development of ready-to-fry frozen vegetable snack and its quality evaluation. J Food Sci Technol 49(1):42–49

Mandala IG, Anaggnostaras EF, Oikonomou CK (2005) Influence of osmotic dehydration conditions on apple air-drying kinetics and their quality characteristics. J Food Eng 69:307–316

Oswin CR (1946) The kinetics of package life-III: the isotherm. J Soc Chem Ind 65:419–421

Pathare PB, Opara UL, Al-Said FA (2012a) Colour measurement and analysis in fresh and processed foods: a review. Food Bioprocess Technol. doi:10.1007/s11947-012-0867-9

Pathare PB, Baş N, Fitzpatrick JJ, Cronin K, Byrne EP (2012b) Production of granola breakfast cereal by fluidized bed granulation. Food Bioprod Process 90:549–554

Pisalkar PS, Jain NK, Jain SK (2011) Osmo-air drying of aloe vera gel cubes. J Food Sci Technol 48(2):183–189

Rocculi P, Romani S, Dalla Rosa M (2004) Evaluation of physic-chemical parameters of minimally processed apples packed in non-conventional modified atmosphere. Food Res Int 37:329–335

Salvador A, Varela P, Sanz T, Fiszman SM (2009) Understanding potato chips crispy texture by simultaneous fracture and acoustic measurements, and sensory analysis. LWT – Food Sci Technol 42:763–767

Señorans FJ, Ibáñez E, Cifuentes A (2003) New trends in food processing. Crit Rev Food Sci 43:507–526

Shyu SL, Hau LB, Hwang LS (2005) Effects of processing conditions on the quality of vacuum-fried carrot chips. J Sci Food Agric 85:1903–1908

Smith SE (1947) Sorption of water vapor by proteins and the high polymers. J Am Chem Soc 69:646–651

Taiwo KA, Baik OD (2007) Effects of pre-treatments on the shrinkage and textural properties of fried sweet potatoes. LWT – Food Sci Technol 40:661–668

Timmerman EO, Chirife J, Iglesias HA (2001) Water sorption isotherms of foods and foodstuffs: BET and GAB parameters. J Food Eng 48:19–31

Van den Berg C, Bruin S (1981) Water activity and its estimation in food systems: theoretical aspects. In: Rockland LB, Stewart GF (eds) Water activity: influences on food quality. Academic, New York, pp 1–61

Vega-Galvez A, Palacios M, Lemus-Mondaca R (2008) Moisture sorption isotherms and isosteric heat determination in Chilean papaya (Vasconcellea pubescens). Quim Nova 31:1417–1421

Xie J, Zhao Y (2004) Physical and physicochemical characteristics of three U.S. strawberry cultivars grown in the pacific northwest. J Food Qual 27:181–194

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Velickova, E., Winkelhausen, E. & Kuzmanova, S. Physical and sensory properties of ready to eat apple chips produced by osmo-convective drying. J Food Sci Technol 51, 3691–3701 (2014). https://doi.org/10.1007/s13197-013-0950-x

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-013-0950-x